BBK DV318SI Service manual

DV318SI

Service manual

Catalog

Chapter One About Maintenance

1.1 Safety precautions

1.1.1 Power supply

1.1.2 Precautions for antistatic

1.1.3 Precautions for laser head

1.1.4 About placement position

1.2 Maintenance method

1.2.1 Visualized method

1.2.2 Electric resistance method

1.2.3 Voltage method

1.2.4 Current method

1.2.5 Cutting method

1.2.6 Element substitution method

1.2.7 Comparison method

1.3 Required device for maintenance

1

1

1

1

1

2

2

2

2

2

2

2

3

3

3

Chapter Two Functions and Operation Instructions

2.1 Features

2.2 Control Button Locations and Explanations

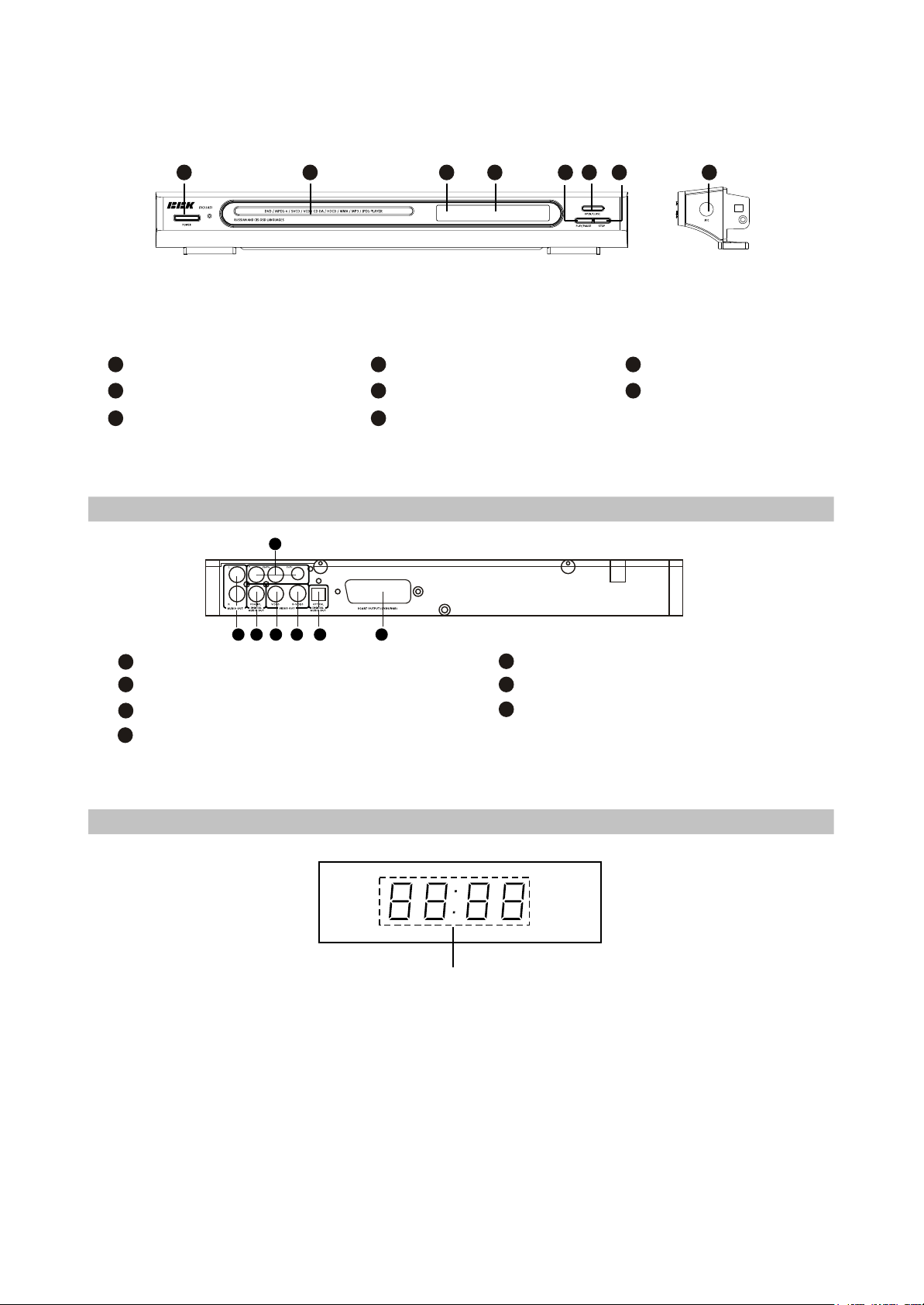

2.2.1 Front Panel Illustration

2.2.2 Rear Panel Illustration

2.2.3 Display Window Illustration

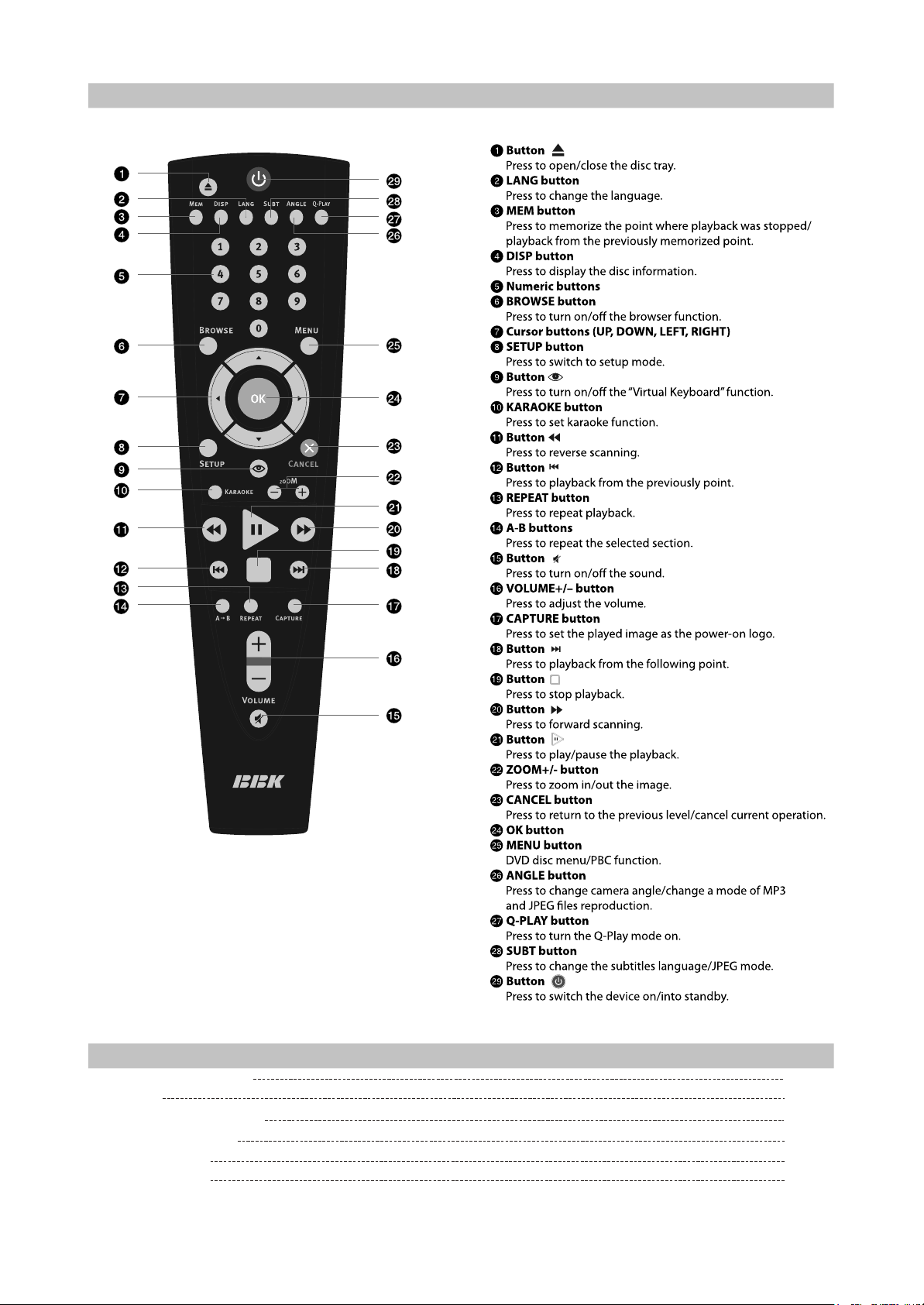

2.2.4 Remote Control Illustration

2.3 Accessories

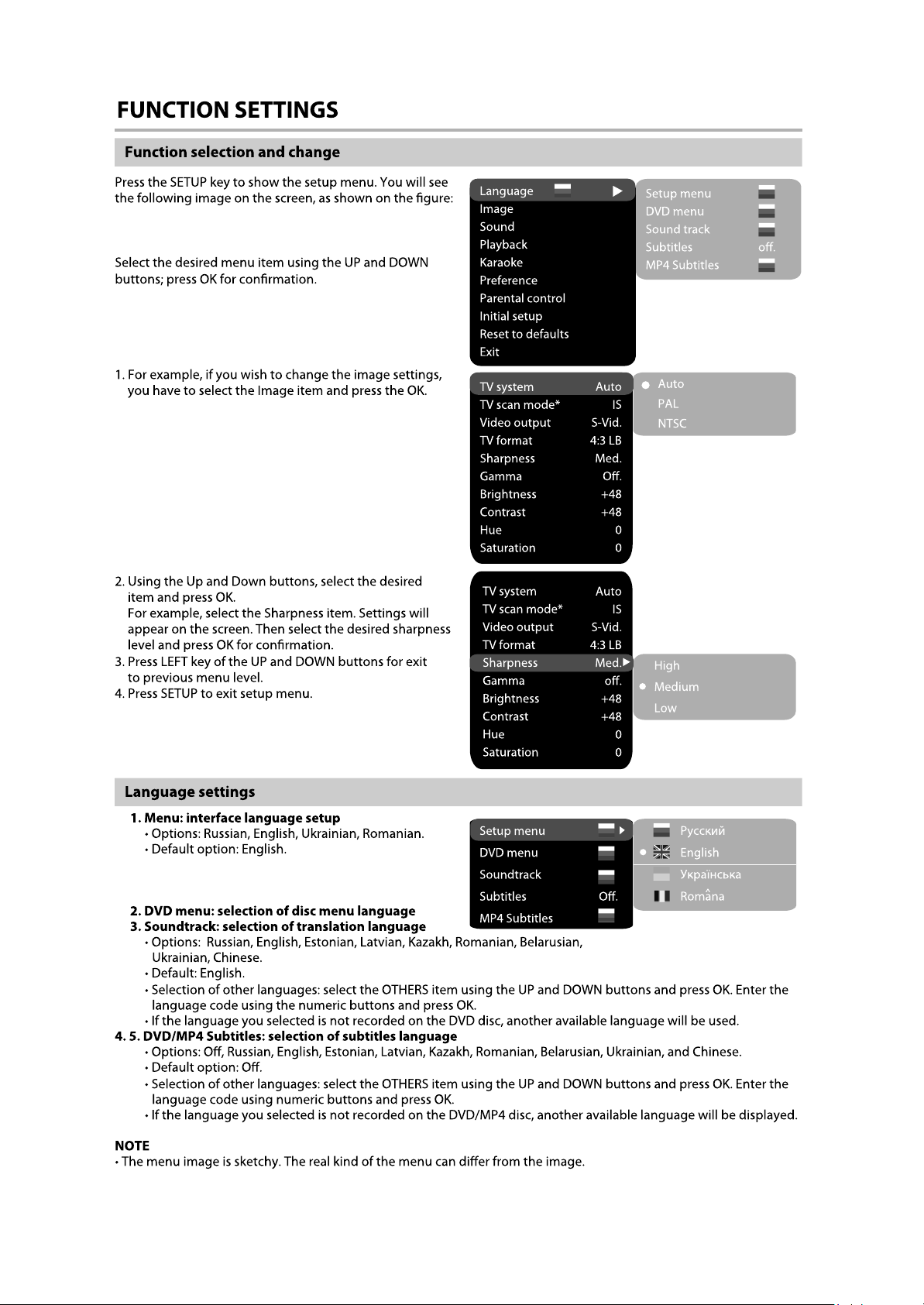

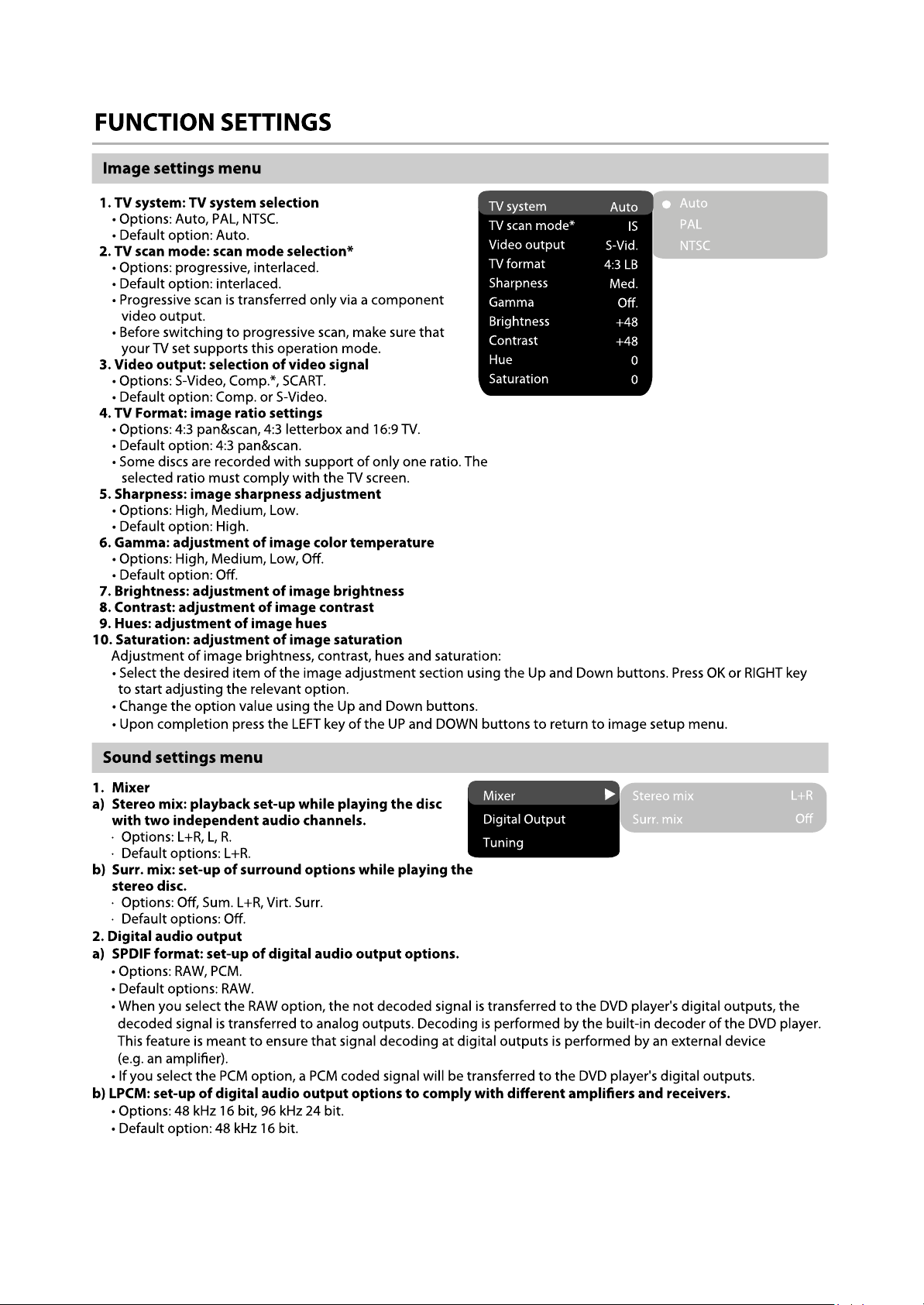

2.4 FUNCTION SETUP

2.4.1 Function Setup

2.4.2 Language

2.4.3 Image

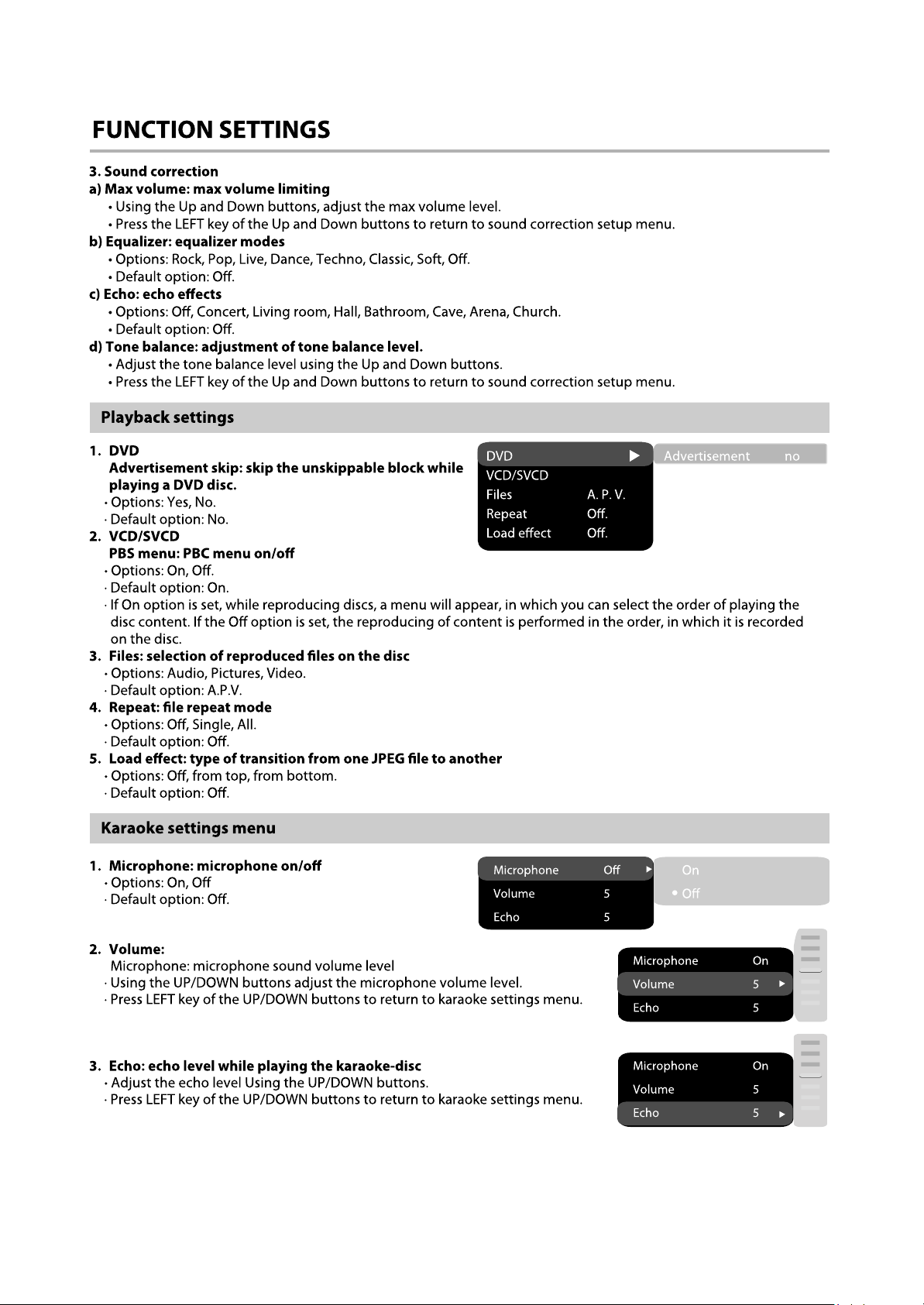

2.4.4 Sound

2.4.5 Playback

4

4

4

4

5

5

5

6

7

7

7

7

8

8

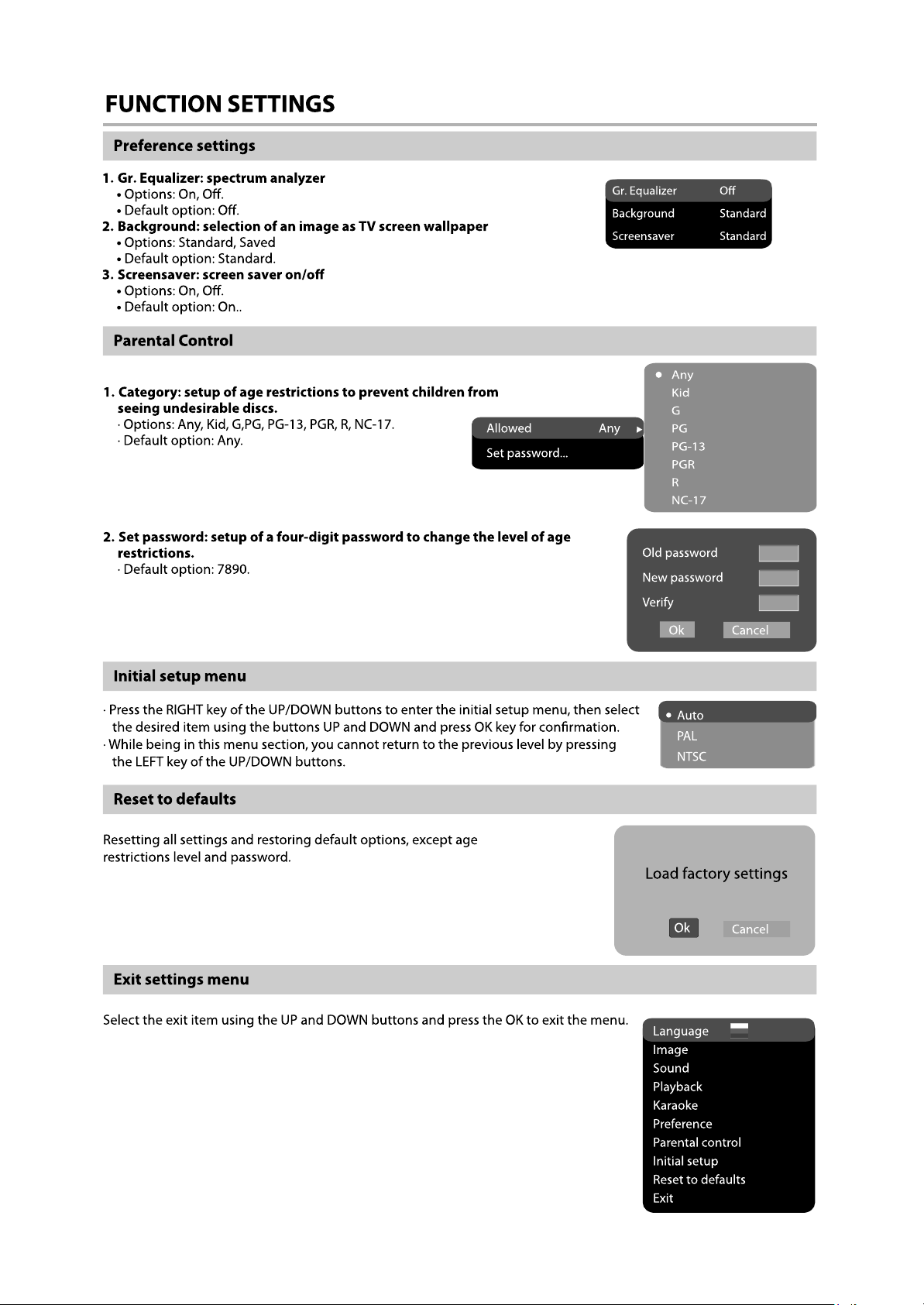

2.4.6 Preference

2.4.7

Parental control

9

9

2.4.8

2.4.9

2.4.10

2.5

Chapter

Section

3.1.1

Section Two

3.2.1

3.2.3

Initial setup

Rest to defaults

Exit

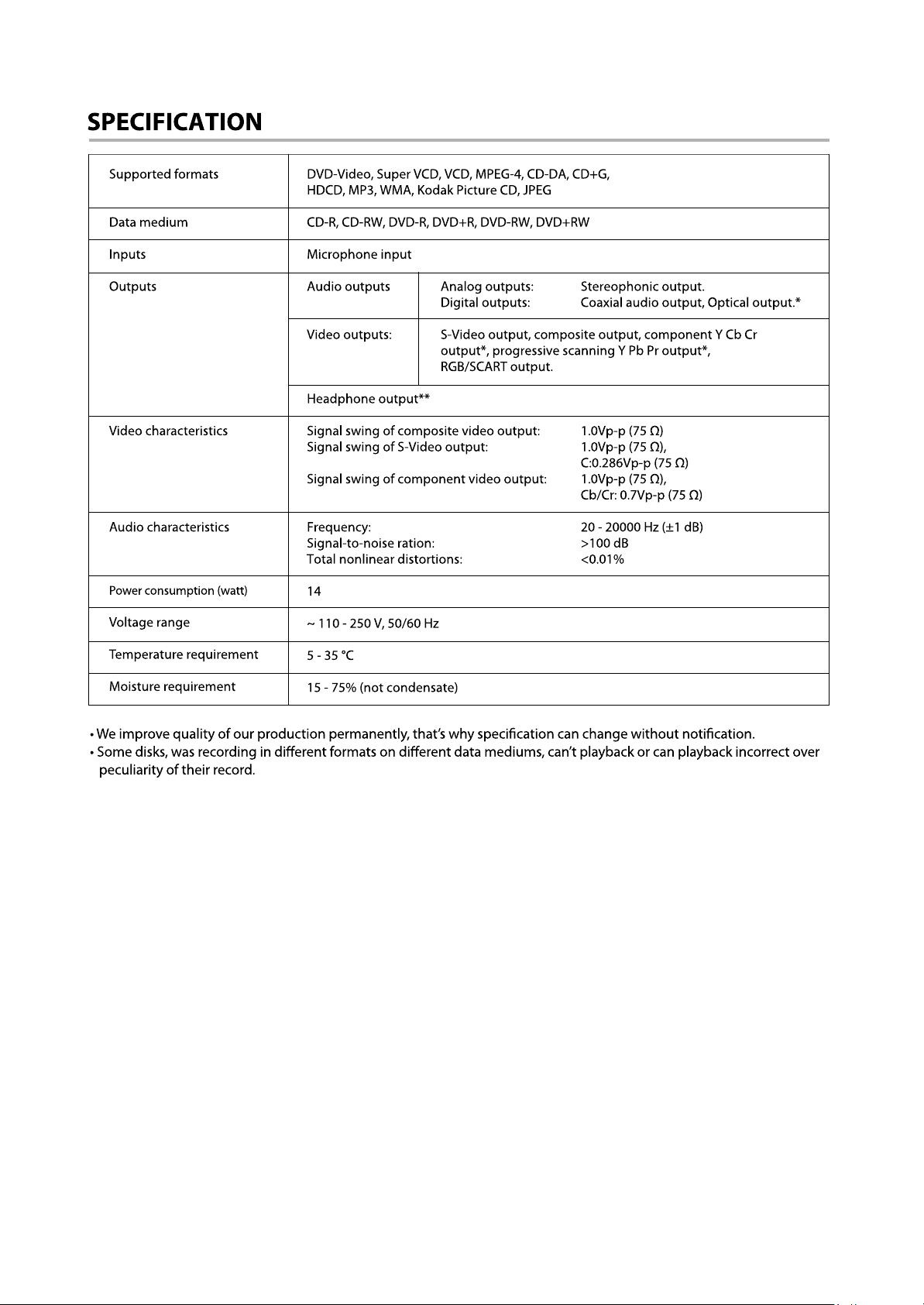

Specifications

One Principle of the Player

Block diagram of the player

3.1.2

PCB board block diagram of the player

3.1.3

How to use IC

Unit Circuit Principle

Introduction to laser head

3.2.2

Servo circuit

Open/close drive circuit

3.2.4

Laser power control circuit

Three Principle and Servicing

9

9

9

9

11

11

11

12

13

14

14

16

18

18

3.2.5

3.2.6

3.2.7

3.2.8

3.2.9

3.2.10

3.2.1

3.2.12

3.2.13

3.2.14

3.2.15

Section

Section

Three Servicing Cases

3.3.1

3.3.2

Four

CD/DVD conversion circuit

Main axis control circuit

Decode circuit

Reset circuit

Video circuit

Audio circuit

1 Mute circuit

Decode circuit voltage regulating

Panel control circuit

MIC circuit

Power circuit

Servicing cases

Troubleshooting flow chart

Waveform

diagram

19

20

21

22

23

24

25

26

27

27

27

29

29

35

47

Section

3.5.1

3.5.2

Five Function Introduction to IC

function introduction to MT1389 DE-EE

function introduction to 4558

53

53

61

3.5.3 function introduction to AT24C02

62

3.5.4

Section

Section Two

function introduction to TDA1308

3.5.5

function introduction to TNY275PN

3.5.6

function introduction to AM5888S

3.5.7

function introduction to AP6928

3.5.8

Function introduction to SDRAM

3.5.9

Function introduction to FLASH

3.5.10

3.5.1

1 Function introduction to EL817

Chapter

Chapter

One PCB board

Function introduction to TL431

Four Disassembly and Assembly Process

Cinque PCB board & Circuit diagram

circuit diagram

63

64

65

67

68

69

70

71

72

73

73

80

7.1.1

7.2.1

7.2.2

7.3.1

7.3.2

Chapter

DV123SI

PCB composition figure of the player

Panel control circuit

MIC circuit

PCB board

circuit diagram

six BOM List

Service Manual

87

94

94

95

95

96

10

0

Chapter One About Maintenance

1.1 Safety precautions

1.1.1 Power supply

When maintenance personnel are repairing DVD players, he should pay special attention to the

power board with 220V AC and 330V DC which will cause hurt and damage to persons!

1.1.2 Precautions for antistatic

Movement and friction will both bring static electricity which causes serious damages to integrated

IC. Though static charge is little, when a limited quantity of electric charge is added to large-

scaleintegrated IC, as the capacitance is very small in the meantime, now the integrated IC is very much

easy to be struck through by static electricity or the performance will decrease. Thus static electricity

prevention is of extraordinary importance. The following are several measures to prevent static

electricity:

1. Use a piece of electric conduction metal with the length of about 2 metres to insert into the earth,

and Fetch the lead wire from the top of the surplus metal and connect to the required static electricity

device. The length and depth of the metal embedded under the earth should be determined according to

the wettability of the local soil. For humid places, it may be shorter, and longer and deeper for dry places.

If possible, it can be distributed and layed in terms of “#” shape.

2. On operating table-board, the antistatic table cushion should be covered and grounded.

3. All devices and equipments should be placed on the antistatic table cushion and grounded.

4. Maintenance personnel should wear antistatic wrist ring which should be grounded.

5. Places around the operating position should also be covered with electric conduction cushion or

Painted with antistatic paint.

1.1.3 Precautions for laser head

1. Do not stare at laser head directly, for laser emission will occur when laser head is working, which

will Hurt your eyes!

2. Do not use wiping water or alcohol to clean laser head, and you may use cotton swab.

- 1 -

1.1.4 About placement position

1. Never place DVD player in positions with high temperature and humidity.

2. Avoid placing near high magnetic fields, such as loudspeaker or magnet.

3. Positions for placement should be stable and secure.

1.2 Maintenance method

1.2.1 Visualized method

Directly view whether abnormalities of collision, lack of element, joint welding, shedding welding,

rosin joint, copper foil turning up, lead wire disconnection and elements burning up among pins of

elements appear. Check power supply of the machine and then use hands to touch the casing of part of

elements and check whether they are hot to judge the trouble spot. You should pay more attention when

using this method to check in high voltage parts.

1.2.2 Electric resistance method

Set the multimeter in resistance position and test whether the numerical value of resistance of each

point in the circuit has difference from the normal value to judge the trouble spot. But in the circuit the

tested numerical value of resistance is not accurate, and the tested numerical value of integrated IC's

pins can only be used for reference, so the elements should be broken down for test.

1.2.3 Voltage method

Voltage method is relatively convenient, quick and accurate. Set the multimeter in voltage position

and test power supply voltage of the player and voltage of a certain point to judge the trouble spot

according to the tested voltage variation.

1.2.4 Current method

Set the multimeter in current position and test current of the player of a certain point to judge the

trouble spot. But when testing in current method, the multimeter should be series connected in the

circuit, which makes this method too trivial and troublesome, so it is less frequently used in reality.

1.2.5 Cutting method

Cutting method should be combined with electric resistance method and voltage method to use.

This method is mainly used in phenomena of short circuit and current leakage of the circuit. When

cutting the input terminal voltage of a certain level, if voltage of the player rises again, it means that the

trouble lies in this level.

- 2 -

1.2.6 Element substitution method

When some elements cannot be judged good or bad, substitution method may de adopted directly.

1.2.7 Comparison method

A same good PC board is usually used to test the correct voltage and waveform. Compared these

data with those tested through fault PC board, the cause of troubles may be found.

Through the above maintenance method, theoretical knowledge and maintenance experience, all

difficulties and troubles will be readily solved.

1.3 Required device for maintenance

Digital oscillograph ( 100MHE)

TV set

SMD rework station

Multimeter

Soldering iron

Pointed-month pincers

Cutting nippers

Forceps

Electric screw driver

Terminals connecting cord

Headphone

Microphone

- 3 -

Functions and Operation Instructions

2.1 Features

Compatible Disc Types:

Digital video playback:DVD-Video, Super VCD, VCD Compatibility.

Digital audio playback:CD-DA and HDCD compatibility

Fully compatible with compressed audio files such as Mp3and WMA.

Digital graphic albums playback:kodak picture CD, JPEG compatibility.

Audio:

Coaxial output for Dolby Digital/DTS/LPCM digital audio.

Mixed audio output for amplifier or TV connection.

Digital multi-channel decoders, providing Dolby Digital/DTS audio stream playing.

MIC input for karaoke function.

Video:

108 MHZ/12 bit video Digital/Analog converter.

Composite, S-Video and RGB/SCART outputs for various types of connections.

Capable of playing NTSC/PAL discs.

Multiple dubbings, angles, subtitles support.

Sharpness, gamma, brightness, contrast, hue, saturation adjustment.

Others:

Compatible disc types:CD-R/CD-RW, DVD-R/DVD-RW, DVD+R/DVD+RW

Russia, CIS and Baltic States adaptation interface and filenames, ID3-tags and CD-Text support

simplifies device operation.

"Memory” function enables to save the last point after stop playback.

"Q-play” function provides direct playback and allows to skip commercial that is not possible to

rewind.

"Captrue” function allows to save any picture as background.

"Virtual Keyboard” function provides more convenient DVD playback control.

"Browser” function provides easy access to playback control.

Automatic Screenaver function.

Parental control function to protect children from watching inappropriate discs.

Super wide range of operating power supplies(~110-250V, 50/60Hz), automatic short circuit

protection.

Chapter Two

2.2 Control Button Locations and Explanations

2.2.1 Front Panel Illustration

- 4 -

1 2 34 5 6 78

2.2.4 Remote Control Illustration

DV318SI

1

POWER switch

2

Disc

tray

3

OPEN/CLOSE

button

2.2.2 Rear Panel Illustration

7

1 3 56

42

1

Digital Audio Coaxial Out jack

2

3

4

Audio Out jacks

2CH

S-Video

Video Out jack

4

Display window*

5

PLAY/

PAUSE button

6

STOP

button

5

SCART Out jack

6

Video

7

Y/Cb/Cr

7

MIC jack

8

sensor button

IR

9

2.2.3 Display Window Illustration

Playback time

- 5 -

2.2.4 Remote Control Illustration

2.3 Accessories

AUDIO/VIDEO CORD

REMOT

AAA

WARRANTY

USER

KARAOKE

E

SIIZE BATTERIES

CARD

MANUAL

DISC

- 6 -

1PC

1PC

2PC

1PC

1PC

1PC

S

S

S

S

S

S

- 7 -

- 8 -

- 9 -

- 10 -

- 11 -

Chapter Principle and Servicing

Section One Principle of the Player

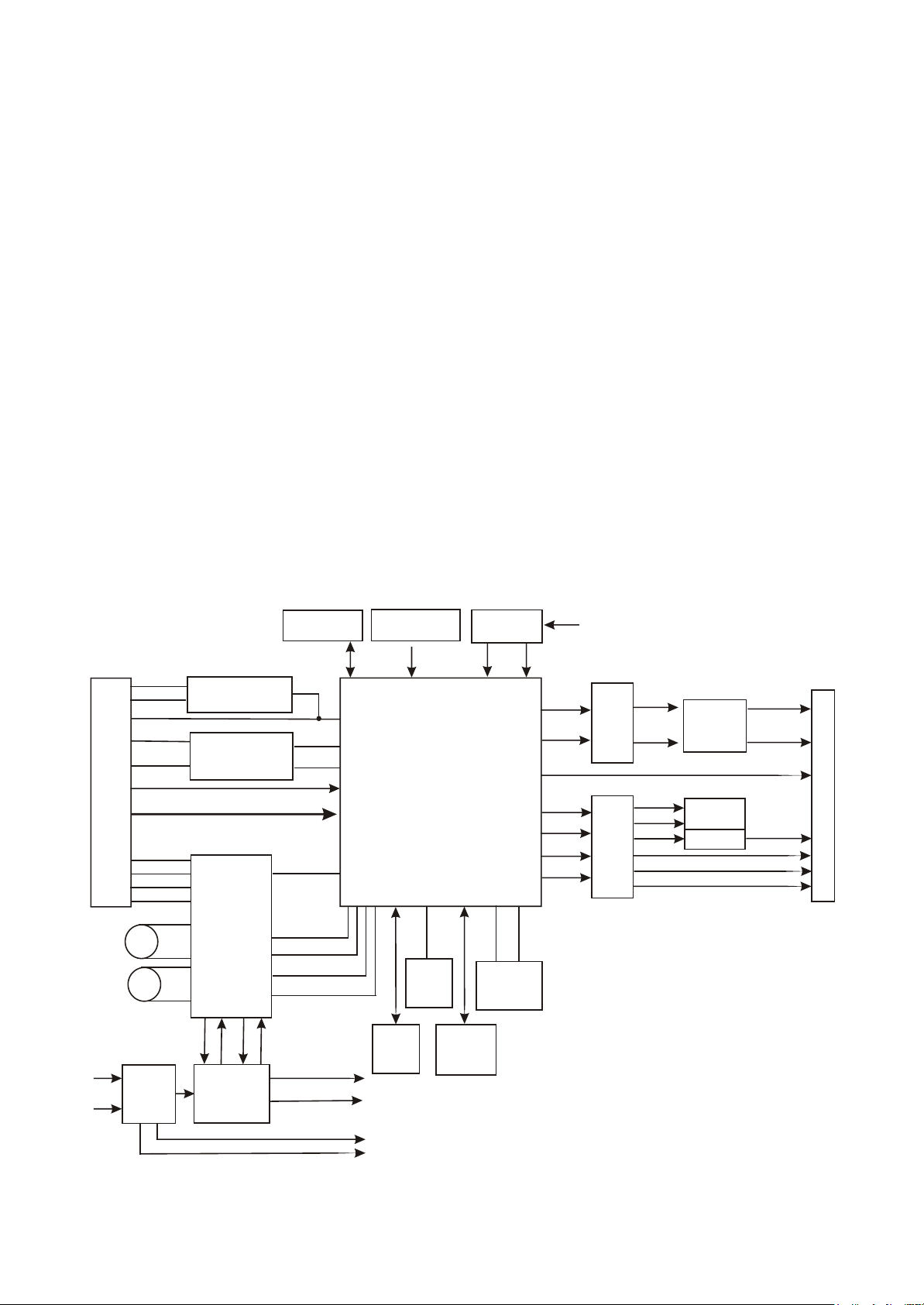

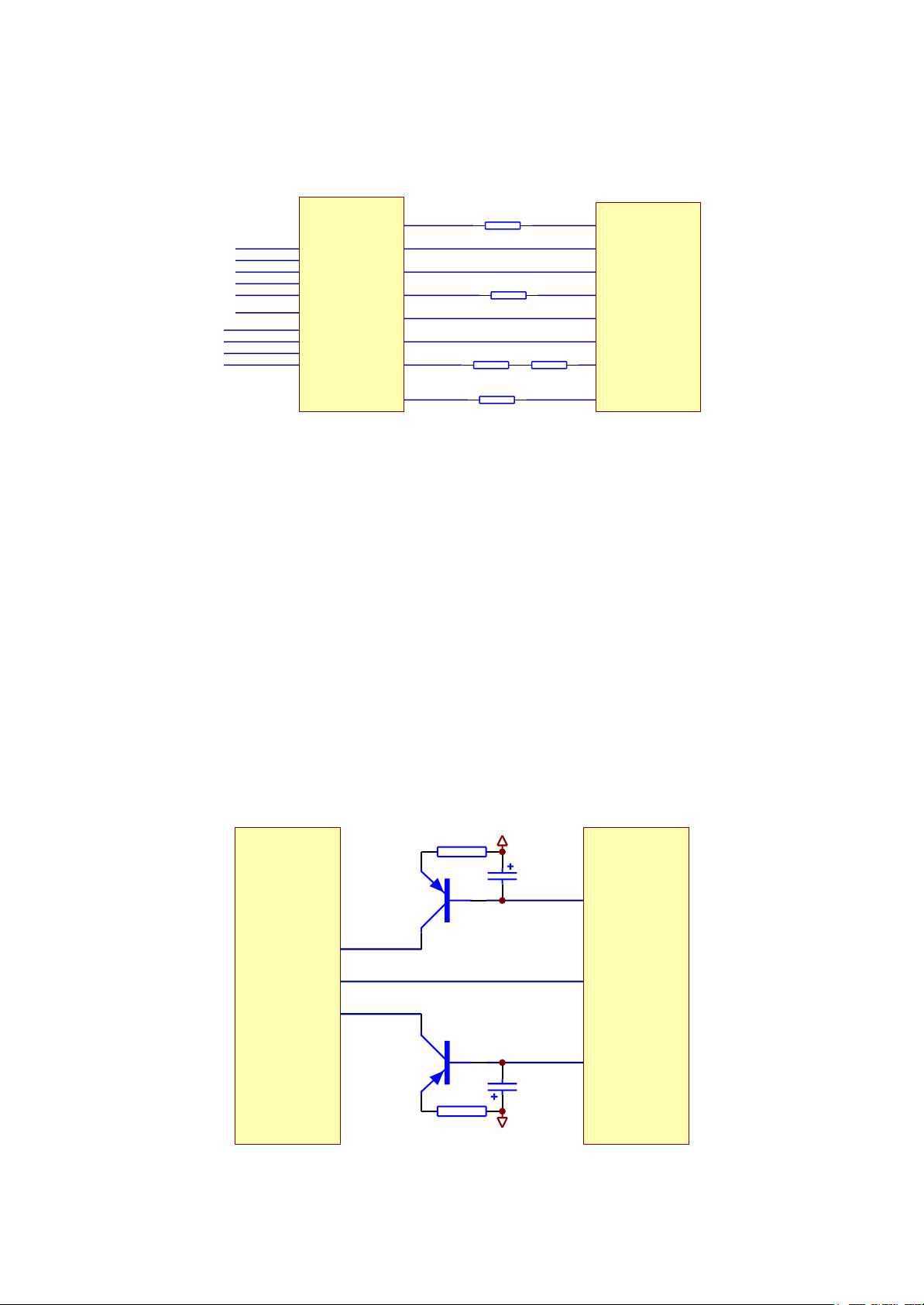

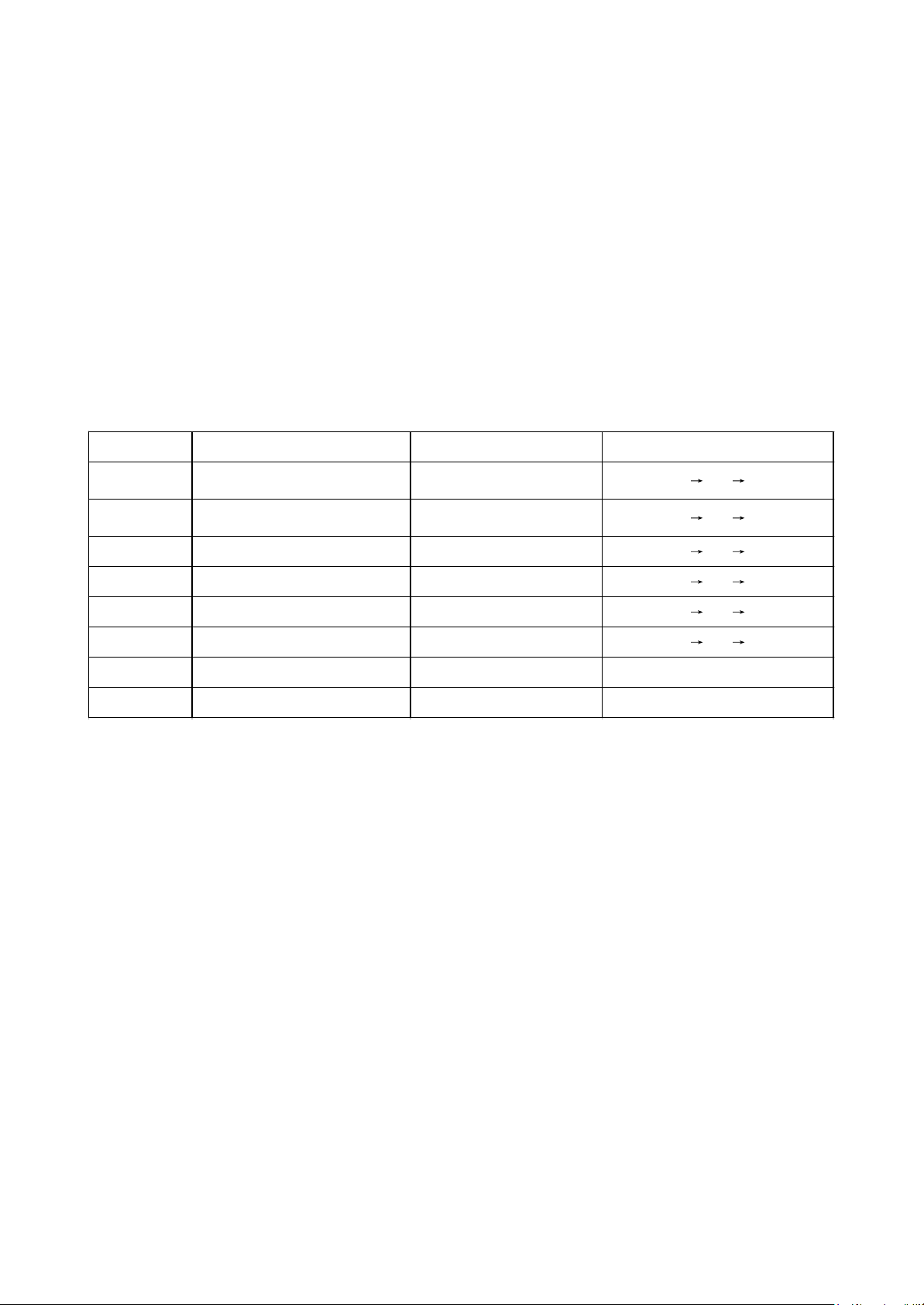

3.1.1 Block diagram of the player

DV317SI is composed by decode circuit, servo circuit, audio circuit, video circuit, MIC circuit and

power

circuit, the block diagram of the player is shown as in the following figure 3.1.1.1:

Feed

electri

machin

Mai

axi

s

electri

machin

ACIN

P

PICK-U

c

n

c

VR-DVD

VD-C

LD-DV

LD-CD

TK

TK

FC

FC

SL

M

M

e

M

e

Power

boar

d

D

CD/DVD switch

D

Laser power

contro

DVD:A/B/C/D/RFO

CD:A/B/C/D/E/FRF

-

+

+

-

Am5888

+

U2

-

SL

SP

+

SP

TRB

TRB1

REGO

Voltage

regulat in

circui

t

l

1

g

2

REGO2

SDRAM

U8

Ld02

Ld0

MDI

O

VIP4

FOSO

O

FMS

O

DMS

TRS

O

64M

1

V1

8

Dv33

+12V

IOA

FLASH16M

U9

MT1389 D

U3

URES

Reset

Panel

SD

T

SC

EEPRO

U11

24C0

MIC board

XI

2

XO

A

L

27M clock

M

CVB

Y/

CB/

CR/

MIC1

AL

AR

G

B

R

S

Audio

amplify in

filteri n

g

U13

ering

lt

ng

i

h

c

t

ideo fi

a

V

c

L

g

R

SY

SC

CVB

U

B/

R/

V

G/

Y

S

Audio

outpu

t

termina

S-video

Termina l

Vid eo out put

L#

R#

l

SPDIF

VIEDO

PB#

PR

Y#

l

a

n

i

rm

e

t

t

u

#

ART outp

#

SC

-12

V

Figure 3.1.1.1 Block diagram of the player

- 11 -

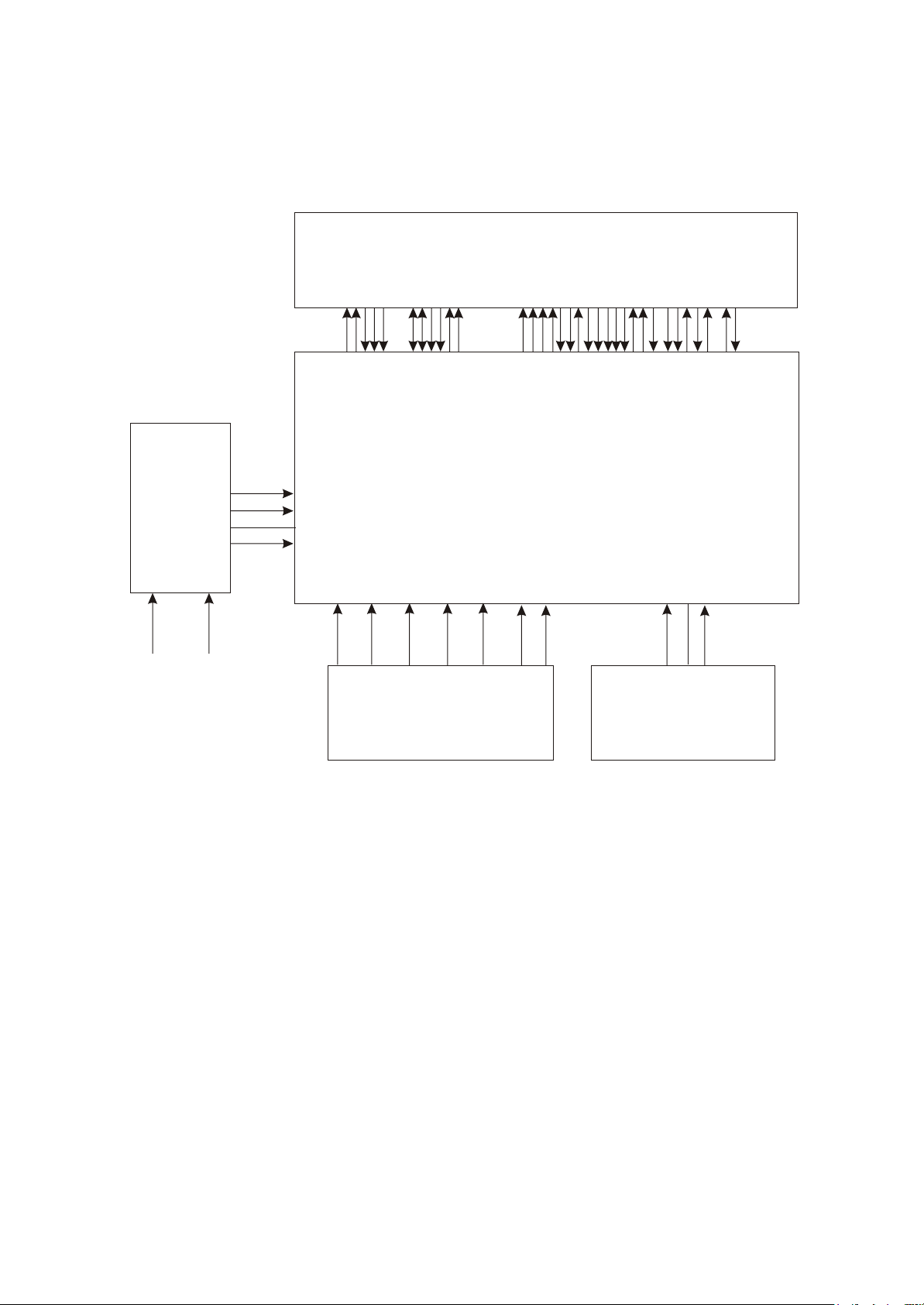

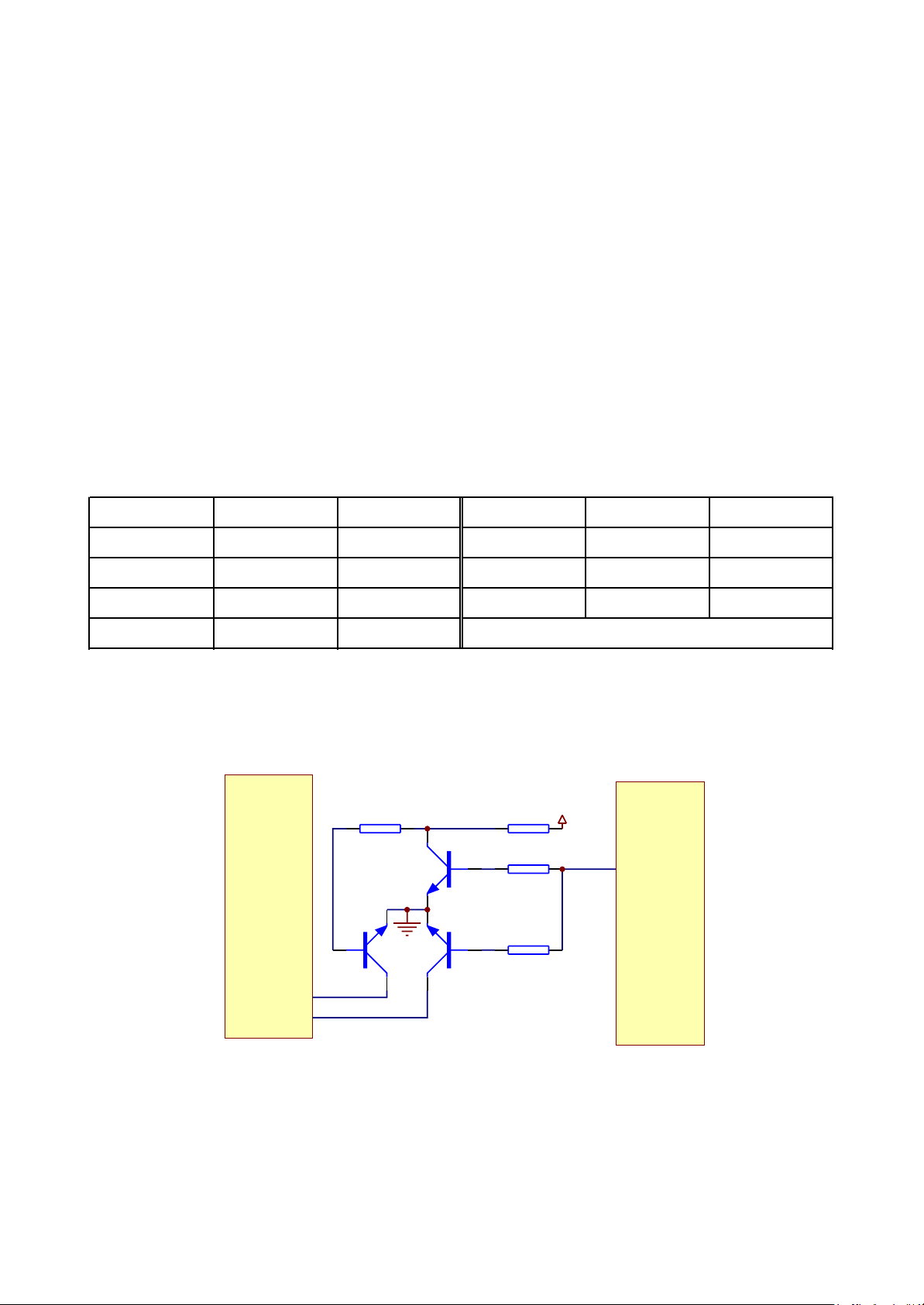

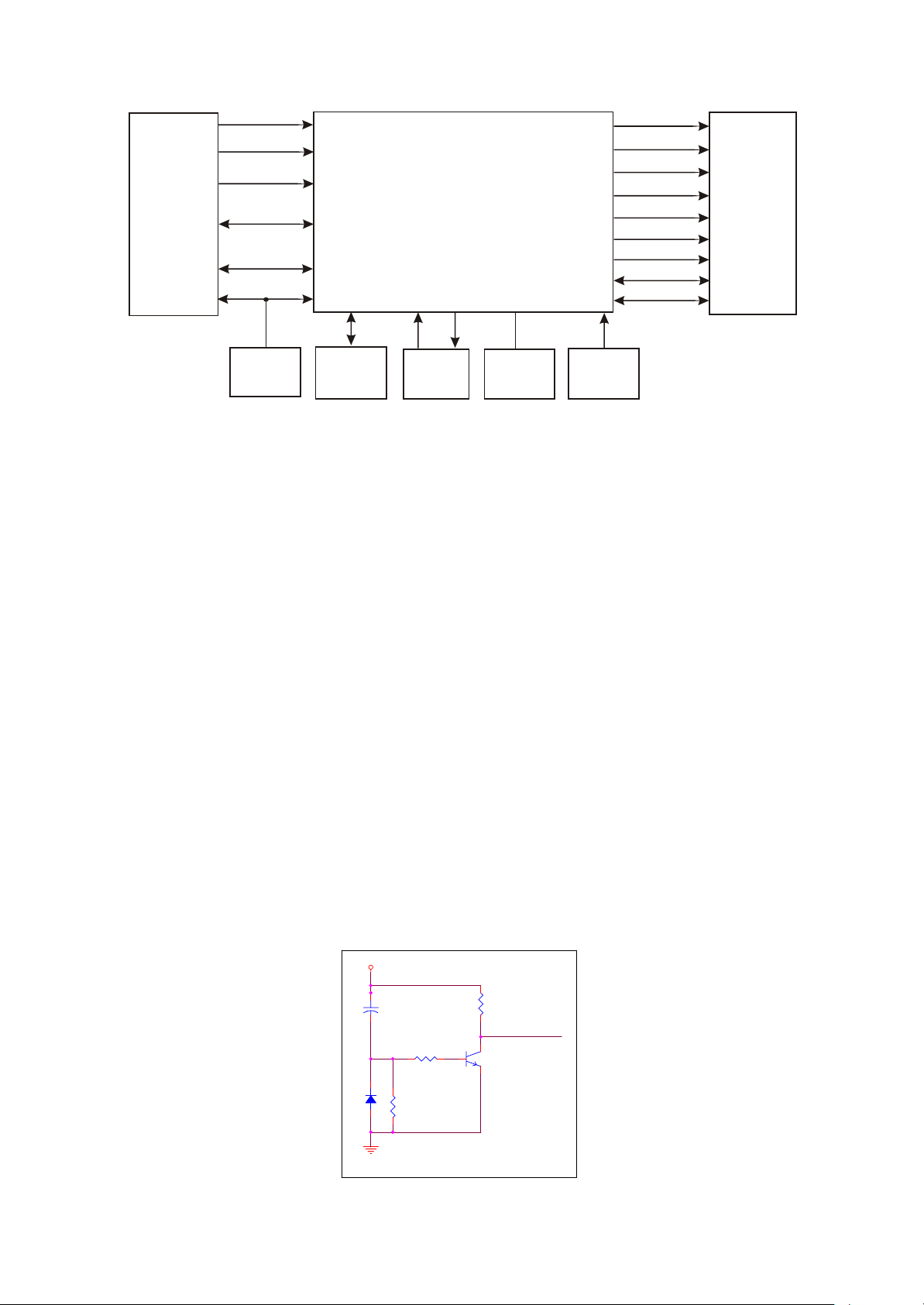

3.1.2 PCB board block diagram of the player

PCB board block diagram of the player is show as in the following figure 3.1.2.1:

Laser

ABF

0

2

GND

V

head

C

C

E

AV

R-CDVR-DV

V

Loader frame Small bracket

N

D

AD-

OUT

I

R

R

LO

LOAD+T

T

GN

#

+

-

MIT

P

P

I

SL+

L

GND

S

S

SL-

O

TK-CD

F

IOA

R

FC-

FC+TK+

D

D

D

-L

L

D

ND-LD

CD-

MDIHFM

DV

G

Power board

CN602

CON1. CON2

AC220V

+

D

GND

LOAD-

LOA

TROUT#

L

P-

P+

ND

S

S

SL+

RIN

T

S

G

LIMIT#

-

#

J4 J2

CN

60

2

+12V

-12V

GND

VCC

CN6

Decode board

MTK1389DE-EE

-

+

C

D

K

TK

FC-

IOA

T

FC+

0

F

A

B

2

ND

V

RFO

VCC

G

A

HA1

CN3

5

6

7

IRH/L IO

GND

Main panel

3

4

2 1

DAT A

STBCLK

VCC

MIC board

I

E

D

D

D

L

C

-

-

M

D

C

VR

VR-DVD

CN4

MIC1 GND MIC2

D

D

L

-

HFM

D

V

D

GND-L

DV318/319/115SI

Figure 3.1.2.1 PCB board block diagram of the player

This machine is mainly composed of decode board, power board, MIC board, main panel buildup

Decode

Power

MIC board:

amplified

Main

Remark:

PCB

composition figure, the connecting lines in PCB composition figure are the main control line, signal

line

and power cord connected through flat cable, but all connected flat cable are not included.

board: includes decode, servo, audio, video output circuit.

board: provides working voltage for each circuit, output voltage has +12V, -12 and +5V.

with single-way microphone input, MIC signals input to decode board after being

.

panel: this panel is simple and mainly composed of remote control receiver and buttons.

in order to facilitate readers to better know the composition of machine, we have made

- 12 -

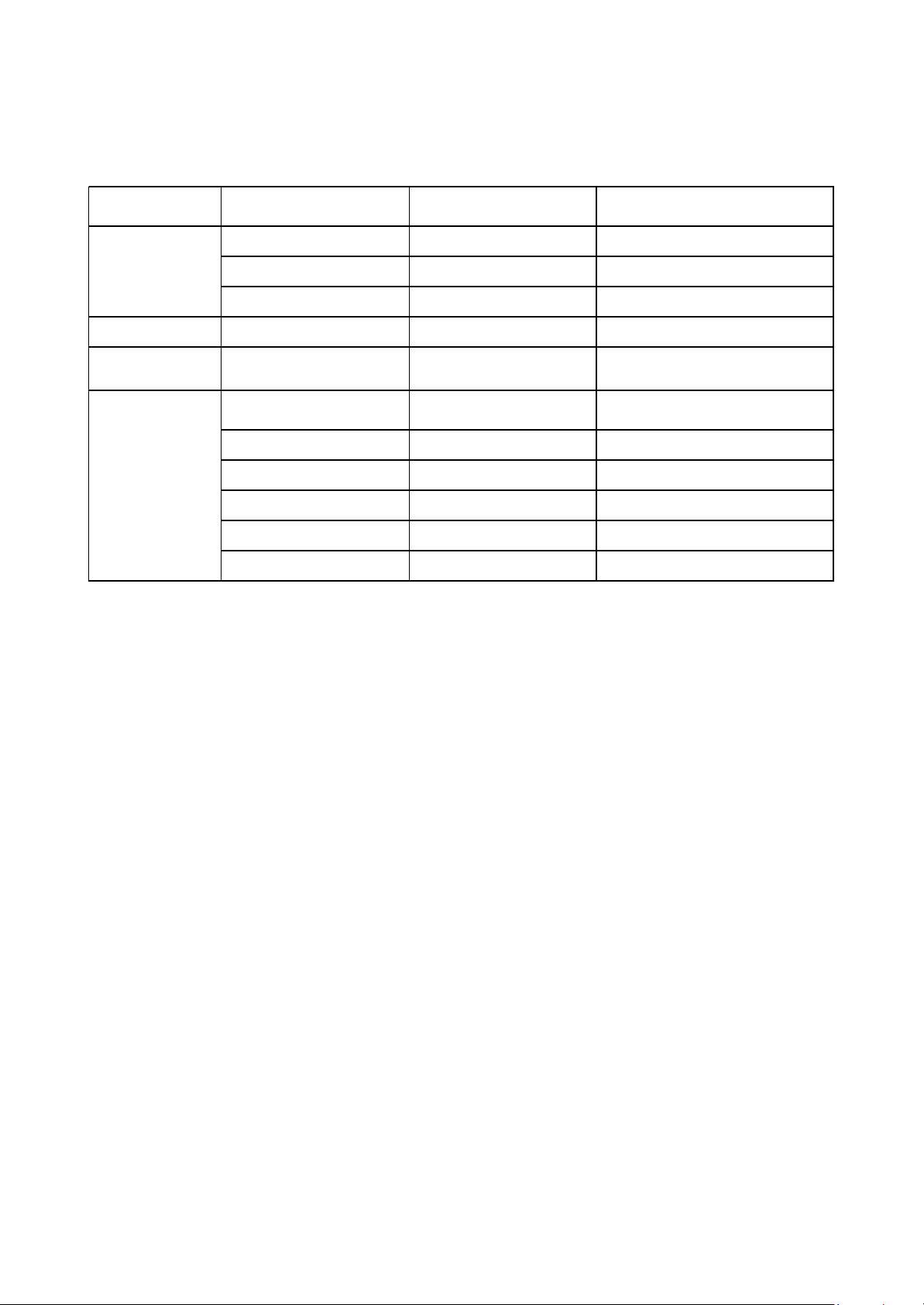

3.1.3 How to use IC

DV112SI IC usage instruction is shown as in the following table:

Semi-finished PCB

nam

e

Power board

OKI-DV300

OKI-P00807A

panel 4911S-1 HS0038B3V U403 Remote control receiver

Main

OK

board 6112S-1 KA4558 U13

2DV112

board

S-0

Decode

IC

model name Location Function

TL431 U603 Precise voltage regulator

EC817 U602 Photoelectric coupler

TN4275PN U601 Power switch IC

Opera

tional amplifier (MIC

amplifying

Opera

NJ

M4558 U5

HY57

V641620HGT-7 U8 SDRAM

2 U11 EEPROM

24C0

MT1389 D version U3 Decode chip

AM 5888S U2 Servo drive

29LV160

BE U9 FLASH

tional amplifier (audio

amplifying

)

)

- 13 -

Section Two Unit Circuit Principle

Pin Name

Signal flow

direction

DVD disc CD disc No disc Function description

1 F- Input loader 2.52 2.34 0.46

2 F+ Input loader 2.49 2.49 0.93

3 T+ Input loader 2.53 2.51 0.94

4 T- Input loader 2.58 2.51 0.93

5 C Input MT1389 2.2 2.25 2.04 Disc data signal

6 D Input MT1389 2.2 3.2 2.04 Disc data signal

7 IOA Input MT1389 0.01 3.2 3.21

Disc identification signal, CD is 3.3V, DVD

is 0V

8 RF Input MT1389 2.21 2.53 1.28 The sum of disc data signal

9 A Input MT1389 2.17 2.22 2.04 Disc data signal

10 B Input MT1389 2.19 2.27 2.04 Disc data signal

11 F Input MT1389 2.07 2.44 2.03 Supplementary signal used in trace

12 GND Ground 0.01 0.01 0 Grounding

13 V20 Input loader 2.04 2.06 2.03 Reference voltage

14 Vcc Input loader 5.04 5.04 5.02 Supply voltage for loader

15 E Input MT1389 2.06 2.45 2.03 Disc data signal

16 Blanking haning in air 0.01 0 0 unused

17 VR-CD Input loader 0.21 0.01 0

Through the handling inside loader, make

sure MD11 is 180mV when reading CD

18 VR-DVD Input loader 0.01 0.2 0

Through the handling inside loader, make

sure MD11 is 180mV when reading DVD

19 LD-CD Input loader 0.09 2.1 0 CD laser power control signal

20 MDII Input MT1389 0.21 0.2 0 CD and DVD laser power monitoring signal

Focus error signal is added to two sides of

pick-up focus coil

Trace error signal is added to two sides of

pick-up trace coil

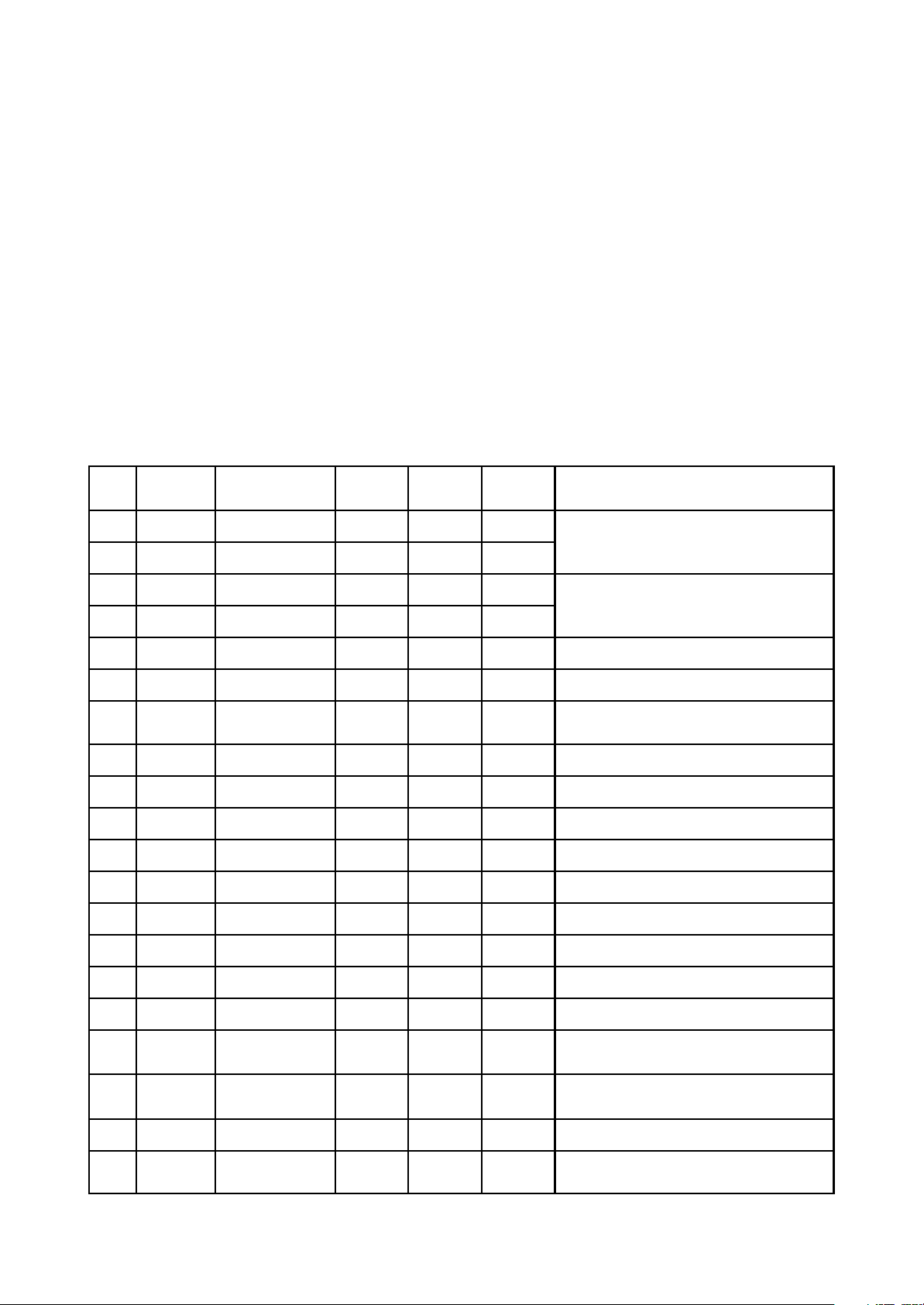

3.2.1 Introduction to laser head

Function introduction to laser head flat cable is shown as the following table:

- 14 -

Note: 1. When reading DVD, there are only A, B, C, D signals.

Pin Name

Signal flow

direction

DVD disc CD disc No disc Function description

21 HFM Input loader 5.04 5.04 5.02

High frequency overlapping signal produces

laser with different wave length inside

loader

22 Blanking unused 0.01 0.1 0

23 LD-DVD Input loader 2.21 0.1 0 DVD laser power control signal

24 GND unused 0.01 0.01 0 Grounding

2. When reading CD, there are A, B, C, D, E, F signals.

3. RFO=A+B+C+D.

4. Focus error signal=(A+C)-(B+D) Trace error signal=E-F.

2. Working principle

(1) Laser tube: wave length of loader DVD laser diode is 650nm, wave length of CD laser diode is

790nm, the wave length which is within 370nm and 750nm is visible light, the laser in the course of

reading DVD disc is visible light, and that when reading CD disc is infrared light.

(2) Principle about laser head picks up signal: laser beam projects onto disc, when laser beam focus

projects onto disc vertically, laser beam will produce reflection, reach on light sensor through reflection

loop and converse into electronic signal through photoelectric cell. For the reflection loop produced in

non pit information area and pit information area in disc has difference and reflects into different position

of light sensor, photoelectric diode in different positions on light sensor will produce different signals to

process all signals on light sensor and then produce digital signals.

(3) Focus, trace coil: when laser head is reading signals normally, information side should be in the

focus of laser beam, because of factors of disc error, high speed rotation and machine error, it is

unavoidable that laser beam focus deviates from information face to produce phenomena of orbit boas

and refocusing. Focus , trace coil is added on loader to adjust laser beam to make it correctly focus in

information area.

(4) Formation of RF signal: when disc reading is normal, light sensor will have 160MV, vague and

eye pattern waveform which is added on A, B, C, D respectively, and output RF signal from FRO pin after

being overlapped by adder inside light sensor, the frequency when reading DVD disc is much higher

than that when reading CD disc, output amplitude is about 1.4V.

- 15 -

3.2.2 Servo circuit

1.

Servo system of this player adopts SANYO loader + MTK decode solution (MT1389D+FLASH

(16M)

+ SDRAM (64M)), and its servo circuit is mainly composed of front end signal processing, digital

servo

processing, digital signal processing IC MT1389D and drive circuit AM5888S , in which MT1389D

is

also the main composed part of decode circuit. Servo circuit block diagram is shown as in the

following

figure

3.2.2.1:

HA1

electri c machine

Feed

Main axi s electric machine

Main

detect

A B C D E F RFO

TK- 15

TK+

FC+

FC-

SL+

SL-

SP-

SP+

axis control

circuit

Switch circuit

circuit

APC

16

14

13

17

Am5888

18

12

11

23

26

LOAD

LOAD

1

4

7

6

+

-

FOSO

O

FMS

TRS

O

O

DMS

TRCLOSE

TROPE

10

Disc in/out

9

electri c machine

IOA

MD1

1

LDO2

LDO

2

MT1389

N

D

U3

Figure 3.2.2.1 Servo circuit block diagram

2. Working principle

After

power on or disc in to proper position (on loader frame for general DVD players, on PCB board

below

door for PDVD players), loader laser head begins reset, after laser head reaches to proper

position,

emission

whether

disc

adjusts

conversion

of

MT1389 respectively, after amplifying processing of pre-amplifier inside MT1389, now signals are

divided

detect switch will give a signal to MT1389, MT1389 begins to output focus, main axis and light

signals, disc begins to rotate, laser head begins to recognize disc information and judge

disc is CD or DVD according to disc information to facilitate to output level from IOA pin, control

switch circuit and laser head PD IC to make corresponding acts. At the same time, MT1389 also

laser power output through laser power control circuit.

After

loader reads disc information, A, B, C, D, E and F signal are formed through photoelectric

to MT1389 (DVD only has A, B, C, D signals) and RF signal and output from pin 2~11, 18, 19

into 2 ways inside MT1389: one part, through summation amplifying and subtraction circuit

- 16 -

Inside MT1389, produces servo error signal, after digital servo signal circuit processing, forms

corresponding servo control signals, outputs FOO, TRO, DMO and FMSO servo control signal from pin

42, 41, 37 and 38 of MT1389 respectively and then send to servo drive circuit for drive amplifying

through the integration circuit composed by resistor and capacitor and bring along focus coil, trace coil,

main axis electric machine and feed electric machine after drive amplifying. Among these, focus and

trace servo are used to correct objective position accurately; feed servo is used to bring along laser

head to make radial large-scale move which belongs to the preliminary adjustment to laser head

position; and main axis servo is used to control main axis electric machine to make it read signals in

means of constant linear velocity and bring along disc to rotate. After processing of amplification by VGA

voltage control amplifier and equalization frequency compensation inside MT1389, another part of

signals are changed into digital signals through internal A/D converter. When loader is reading CD/VCD

signals, these signals are conducted EFM demodulation inside MT1389, and then outputted to latter

stage for AV decoding after finishing CIRC (Cross-Interleaved Reed-Solomon Code) error correction

inside. When loader is reading DVD signals, these signals are conducted ESM demodulation inside

MT1389, and then sent to latter stage for decoding after finishing RSPC error correction inside. General

DVD players have a disc in/out circuit to control disc tray door in/out acts to reach the purpose of making

disc in and out. For PDVD, we adopt manual disc in/out means and we can judge whether disc in to

proper position through detect switch.

3. Explanation to servo terms

(1) FOO: for disc make differences, and when rotating disc may probably move upwards or

downwards slightly to make the focus of laser emitted by laser head cannot justly fall on data pit of disc,

now focus point of objective lens is required to adjust to make focus aim at data pit exactly. The acts are

mainly to make objective lens move upwards and downwards.

(2) TRO: data information is saved in disc in form of tracks. When disc is rotating, disc deviation will

produce, now laser head is required to adjust. In this process, objective lens makes forward and

backward movement with small moving range.

(3) FMO: similar to acts of trace, the acts of feed are larger than those of trace. Feed conducts a

large scale movement firstly, and then trace moves slightly in this range. Feed moves for a while, and

does not move for another while; but trace moves all the time. Feed is rough adjustment and trace is fine.

And acts are obvious when power on and selecting track.

(4) DMO: it is the top that holds up disc. Its rotation speed decides that of disc. Its rotation is

generated by an individual DC electric machine, in which rotation speed of DVD is twice over that of CD.

- 17 -

3.2.3 Open/close drive circuit

1. Open/close drive circuit is shown as in the following figure 3.2.3.1:

27

K

R204

15

27

K

K

MT1389D

R201

K

10

K

TRSO

FC

+

FCSPSP

+

+

LOAD

LOADTK-

TK+

+

SL

SL

-

Working principle: when the machine is reading discs normally, pin 6, 7, 9 10 of AM5888S are all

2.

0V

. After OPEN button is pressed, pin 6 inputs high level, pin 10 LOAD+ outputs high level, electric

AM5888S

Figure 3.2.3.1 Open/close drive circuit diagram

STB

V1P

FMS

TRCLOSE

TROPE

DMS

FOS

R203

Y

4

R202

O

N

R314

O

10

O

machine

electric

proper

scheme,

rotates to perform OPEN acts. When closing, pin 9 LOAD- outputs high level to pin 9 through

machine to form loop, electric machine rotates reversely to perform CLOSE acts. After closing to

position, all pins are all low level. Servo drive principle is the same with the drive of D5954

so we will not describe here.

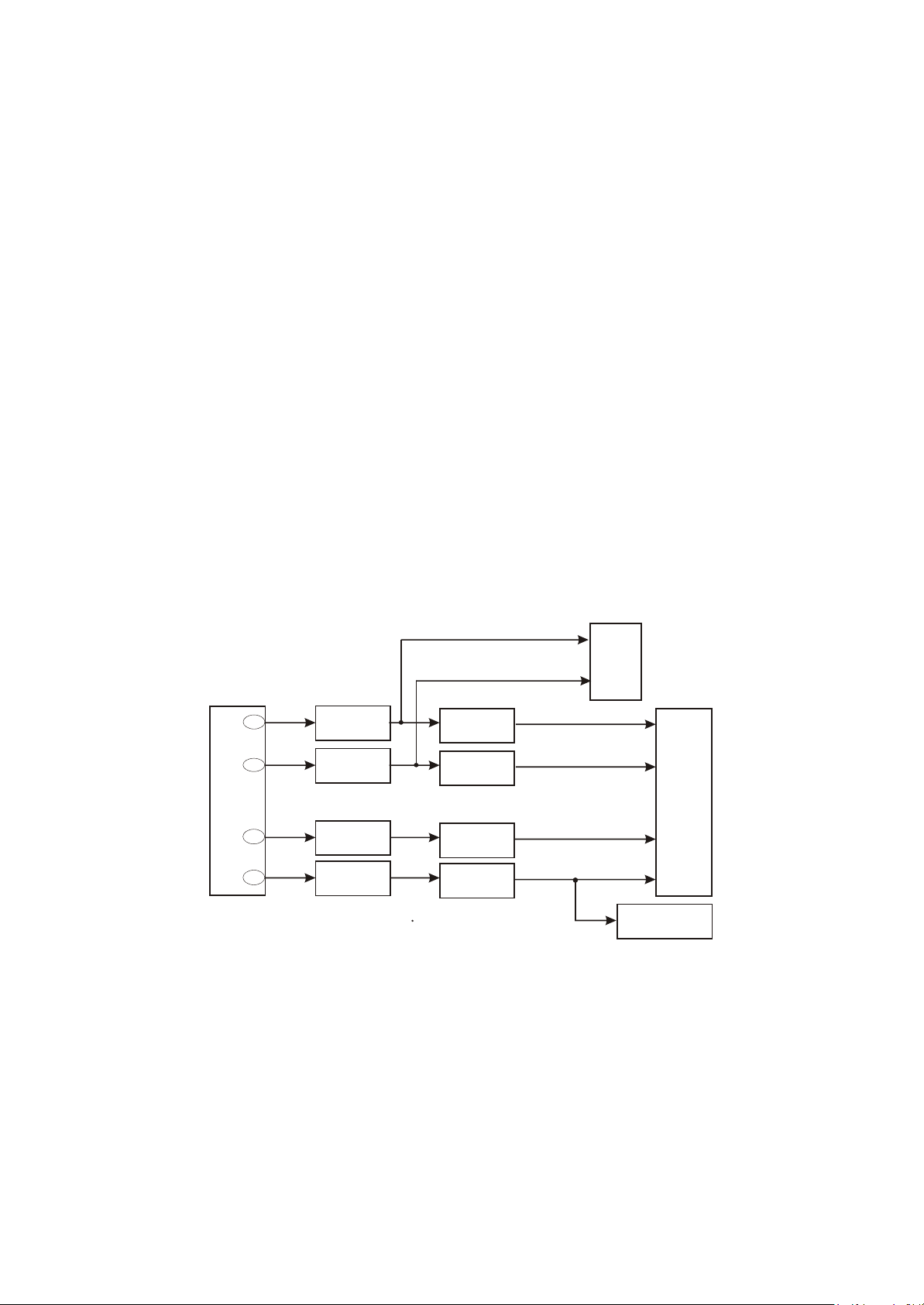

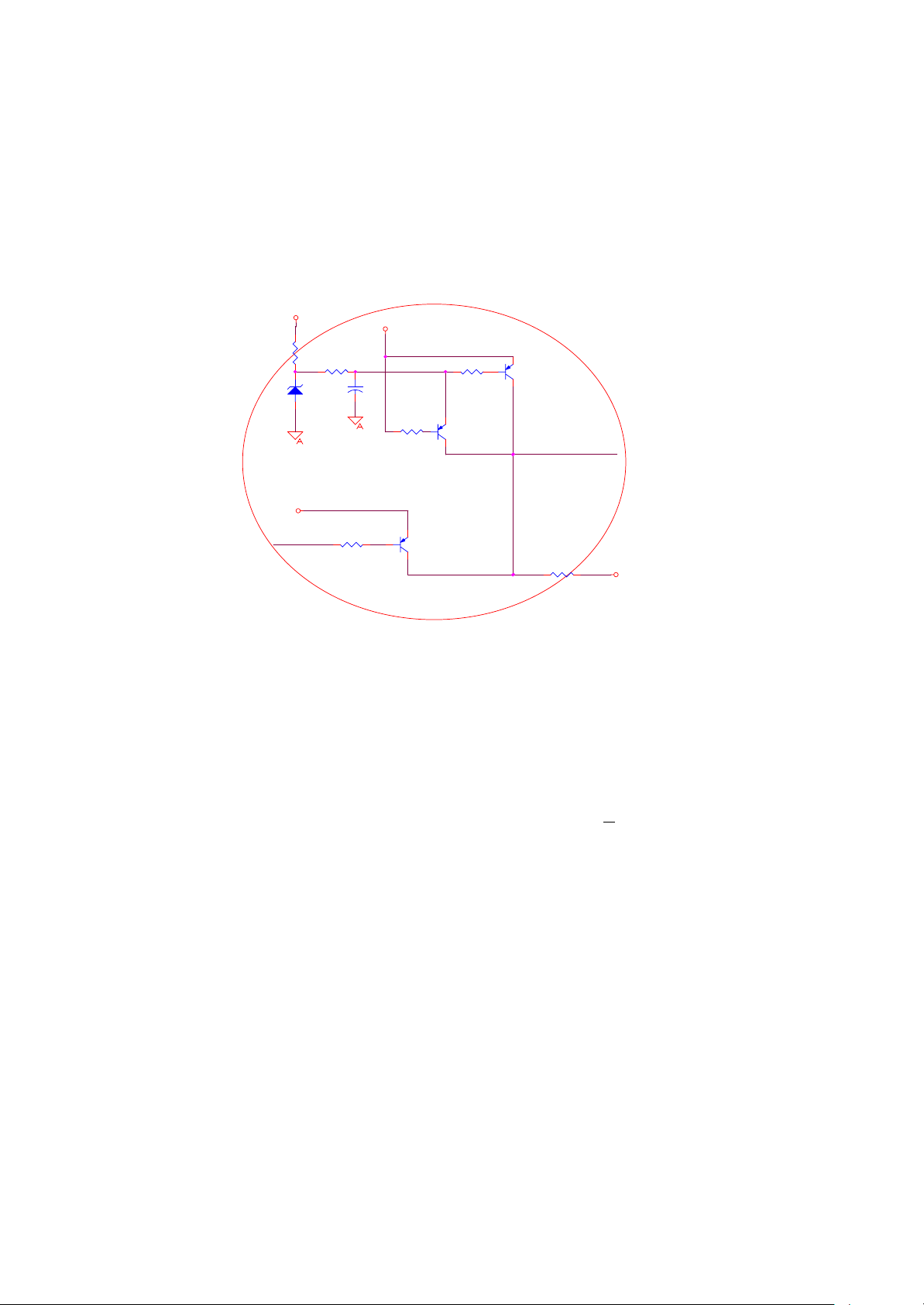

3.2.4 Laser power control circuit

Laser power control circuit is shown as in the following figure 3.2.4.1:

LDO-AV33

R

4.7

V301

2SB1132-

1

V302

2SB1132-

TC302

47uF/16

LDO2

S

S

LDO

HA1

R301

23

MD

20

19

20/2

V

1

MT1389D

1

TC303

47uF/16

R

4.7

R302

Figure 3.2.4.1 Laser power control circuit diagram

LDO-AV33

- 18 -

V

2. Working principle

Location number Read DVD disc Read VCD disc Location number Read DVD disc Read VCD disc

V301_

E 2.9V 3.2V V302_B 3.2V 2.2V

V301_

B 2.2V 3.2V V302_E 3.2V 2.9V

V301_

C 2.2V 0 MT1389_20 0.2V 0.2V

V302_

C 0 2.2V

Pin

20/21 of MT1389 is laser power detect signal input pin, pin 21 is DVD laser power strong/weak

detect

signal input pin, pin 23 is VCD laser power drive control output pin, pin 22 is DVD laser power

drive

control output pin.

When

reading VCD disc, laser power becomes weak, voltage of MDII pin decreases, voltage

decrease

laser

MT1389

power

working

of pin 23 of MT1389 makes voltage of pin 19 of XS301 increase to reach the purpose of raising

power. When laser power is too strong, voltage of MDII pin increases to lead to voltage of pin 23 of

increase to make voltage of pin 19 of XS301 decrease to reach the purpose of reducing laser

to form an auto power control circuit.

When

reading DVD disc, pin 21 is detect signal input pin, pin 22 is drive control input pin, and the

principle is the same with that when playing VCD disc.

3.

Key point voltage (unit: V) is shown as the following table:

3.2.5 CD/DVD conversion circuit

1. CD/DVD conversion circuit is shown as in the following figure 3.2.5.1:

AVCC

V305

3904-

R309

10

R311

10

S

R310

100

S

K

IOA

K

MT1389D

K

HA1

R308

100

K

V303

17

2SK3018-

18

Figure 3.2.5.1 CD/DVD conversion circuit diagram

S

V304

2SK3018-

2. Working principle

After

on

and form loop together with CD laser power control circuit on CD. At the same time, IOA also goes to

loading disc in the player, IOA port of MT1389 is defaulted high level to make V305 saturation

- 19 -

Base

electrode

B

Collecto

r C Emitter E

Gri

d

electrode

G

Drai

n

electrode

D

Sourc

e

electrode

S

G D S IOA

DVD disc 0 3.86 0 3.81 0.18 0 0 0 0 0

VCD disc 0.64 0.1 0 0 0 0 3.27 0.18 0 3.3

Stat

e

V30

5 V303 V304

Loader PD IC to switch, disc begins to rotate, when servo management system recognizes that the disc

in

player is not CD disc, IQA pin outputs low level to make V305 cut off and make V303 on, and form loop

together

opens,

IQA

with DVD laser power control circuit on loader to perform disc reading acts. After disc tray door

IOA keeps the state before opening disc tray door. If the player cannot recognize which disc it is,

pin will switch continuously until reading disc or system judges that there is no disc.

Note:

V303 and V304 are MOS tube

3.

Key point voltage (unit: V) is shown as the following table:

3.2.6 Main axis control circuit

1. Main axis control circuit is shown as in the following figure 3.2.6.1:

2

4

C

1

1

R

1

R

5

1

05

k

02R

-P

S

S

+P

-LS

+LS

33VD

2R

TIMIL

p00

F

2

k086

O

1

C

N

13

5C

.

0

CN/Fu1

D

I

N

OP

61R

k0

5

039

R

61C

2

J

1

2

3

4

5

6

/W 1x6

A

-PO

O

+P

R

71

86

k0

Fp0022

GNISUOH

4P1V

2R

4

k01

Figure 3.2.6.1 Main axis control circuit diagram

2. Function: disc is always in high speed rotation in the course of disc reading, when you need to

open

the door to change disc, MT1389 stops the positive direction drive signal which is given to main

axis

drive circuit, for the function of inertia disc is still rotating. If disc out order is performed at this time,

disc

will be abrasively damaged. Therefore, machine must be baking to main axis, that whether disc

hasstopped

main Axi

stopped

3.

OP+

is the in-phase input end of operational amplifier, OP- is reverse input end, OPO is output end,

rotating and whether disc is reversing, decode chip of the machine cannot recognize. So a

s control circuit is added to make decode chip can effective monitor that whether disc has

rotating.

Working principle: MT1389 has a comparator inside composed of operational amplifier, in which

- 20 -

When playing disc normally, for electric machine is positive direction rotating, voltage of OP+ is higher

Key point Position Normal working voltage (V) Volateg change when disc out (V)

SP+

Pin 11 of AM5888S, pin 5 of

XS307

3.79 3.79 0.70 1.80

SP-

Pin 12 of AM5888S, pin 6 of

XS307

1.38 1.38

3.40 1.80

OP+ Pin 36 of MT1389 1.38 1.38 3.10 1.80

OP- Pin 35 of MT1389 1.53 1.53 3.08 1.98

OPO Pin 34 of MT1389 2.44 2.44 0.40 2.50

AD IN Pin 47 of MT1389 2.44 2.41 0.41 2.44

DMSO Pin 4 of AM5888S 1.42 1.42

VIP 4 Pin 30 of MT1389 1.41 1.41

than that of OP-, voltage of OPO is more than 1.4V. When disc out is needed, main axis drive signal

stops, for electric machine is permanent magnetic, when in rotating, induced electromotive force

produces in two ends to give to decode chip through R320, R319 sampling to make OPO output less

than 1.4V voltage and transmit to input pin of MT1389 ADIN through R331. When ADIN is high level,

main axis drive output end has not any drive signal output, when ADIN is low level, MT1389 outputs a

reversing drive signal to main axis drive circuit to make main axis electric machine speed down. Thus

circular working goes on until main axis stops rotating. PDVD is manual disc out means, so after disc out,

disc is still rotating, but will stop very son.

4. Key point voltage (unit: V) is shown as the following table:

3.2.7 Decode circuit

1. Decode circuit block diagram is shown as in the following figure 3.2.7.1:

2. Working principle: this decode circuit is mainly composed of MT1389, SDRAM and FLASH.

Working condition of decode circuit has:

(1) Reset: refer to reset circuit working principle for details.

(2) Clock: this system adopts 27M external clock input, and produces clock signal required by

system inside through internal frequency doubling circuit.

(3) Power: decode chip adopts twp groups power supply of 3.3V and 1.8V, in which 1.8V mainly

supply power for internal logic control circuit and we call it core voltage.

After power on, reset circuit performs reset to MT1389 built-in CPU (8032) and FLASH, decode chip

outputs reset signal at the same time and performs reset to other circuit. After system reset, it firstly

Sends out read signal to FLASH to read out in formation saved in FLASH, the machine displays power-

on picture, servo system begins to work to check whether machine closes door to proper position and

- 21 -

FLASH

R

PW

PR

D

PC

E

A0~A20

AD0~AD7

URST

MT 1389

SDCLK

E

SDCK

DC

S

S

DRA

SW

E

DQM

0

1

DQM

DQ0~DQ1

MA0~MA1

SDRAM

5

1

Rese

circui

SDA

SC

L

EEPROM

t

t

24C0

Clock

M

2

27

V18

1.8V

voltag

e

regulatin

g

3.3V

voltag

e

regulatin

g

Figure 3.2.7.1 Decode circuit block diagram

Whether detect switch has been closed, if not, the door close action is performed. After detect switch of

door

is closed, the machine begins to perform preparations of disc reading and performs panel display

at

the same time of working.

Playback

send

to decode circuit for decoding, signal after being decoded is saved in SDRAM for the moment.

When

machine needs to replay signal, decode circuit calls information inside SDRAM to perform D/A

conversion

User

refresh

or reset this information, it will saved in IC permanently.

Audio,

process: laser head picks up disc signal from disc, after servo system processing, then

and then output.

information storage: information content set by user is saved inside EEPROM, if user does not

video output circuit: at present, MT1389 all integrates video D/A converter, MT1389D inside

integrates

circuit

audio D/A converter, manufactures select according to their own needs. Please refer to

principle diagram and audio circuit explanation for details.

3.2.8 Reset circuit

1. Reset circuit is shown as in the following figure 3.2.8.1:

3

3VD

9EC

+

V01/Fu0

1

7R

R001

3

D

R

6

1

K0

1N4148

Figure 3.2.8.1 Reset circuit diagram

tiucriC TESER

3R

K01

RU

#TS

81Q

1

093N2

4

2TOS

3

2 3

- 22 -

2. Working principle: after power on, voltage of DV33 increases to 3.3V, main chip power supply is

normal.

current

emitter

voltage

low

CE9

3.3Vgradually

0V

Now, voltage of CE9 to DV33 cannot change suddenly to make base electrode of Q18 has

flow in, Q18 is saturation on, URST is low level. DV33 charges CE9 in two paths through

junction of R6 and Q18 make negative pole voltage of CE9 decrease slowly. When this

decreases below 0.7V, V310 cuts off, URST changes into high level, the process for URST from

to high is called effective reset signal of low level by us. After power off, voltage of DV33 decreases,

decreases together with DV33 voltage, D3 performs suge discharge and clamping to CE9.

3.

Key point voltage (unit: V)

Q18_B is

low level when in normal condition, at the moment of power on, it decreased to 0V from

.

Q18_C

is high level when in normal condition, at the moment of power on, it increases to 3.3V from

.

3.2.9 Video circuit

1. Video signal flow chart diagram is shown as in the following figure :

3.2.9.

1

SY

S-Video

SC

Y4

179

Y5

1

18

9

8

MT13

Y6

18

2

Y3

5

17

L21

L23

L22

L25

R/V/S

CUBS

Figure 3.2.9.1 Video signal flow chart

L240

L239

Y

L241

R284

CV BS#

Jk202A

11

7

SCART

Termina l

15

19

Jk202B

CVBS -Video

2. Working principle: MT1389D has built-in video D/A conversion circuit, video output has R/B/G

Y/Pb/Pr

Y/Cb/Cr CVBS Y/C output mode, in which R/B/G Y/Pb/Pr Y/Cb/Cr Y/C cannot output at the

same

time and need the switch through software. CVBS is a separate output mode, 4-path video signal

outputted

to

filter high frequency disturbance signal except useful signal; dual diode Q10 composes a limiter

by MT1389, through video filtering clamping, output to .

Shown

as in the figure 3.2.9.2, capacitor C61, C50 and inductor L25 compose a low-pass filter

- 23 -

Terminal

Circuit, known from features of diode that the max amplitude of composite video signal CVBS cannot be

over

5.7, and the mix cannot be less than -0.7, thus the high voltage signal from TV set can be avoided

VV5

burning

down the player.

V5

68R

C

N

7L

R0

BVC

S

09

R

%1,57

Hu8.152L

16C

P001

23

Q

5

1

CN

05

C

P001

+

2

1

01Q

B

99VA

3

BVC

OS

28

C

P

001

Figure 3.2.9.2 Video output circuit

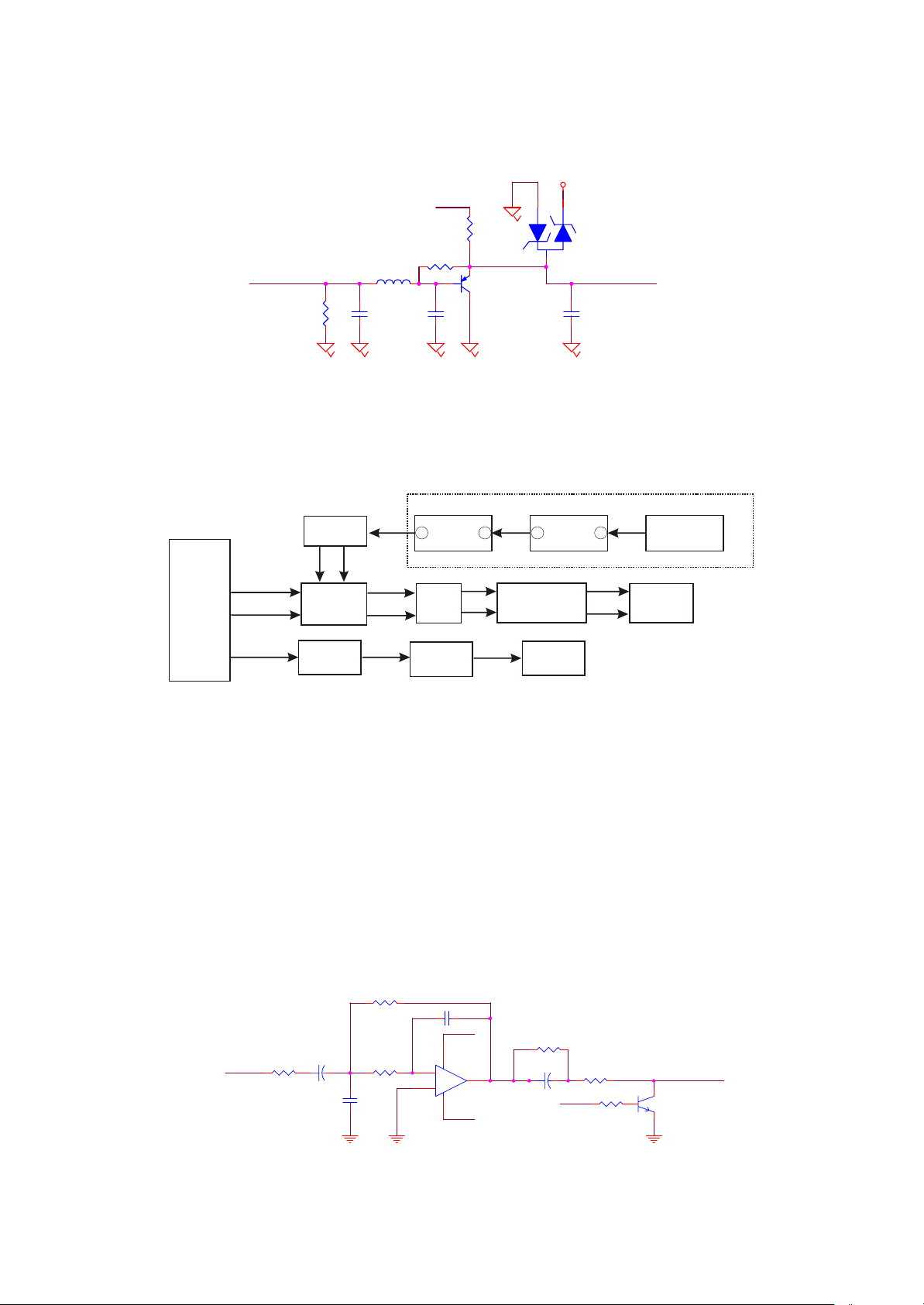

3.2.10 Audio circuit

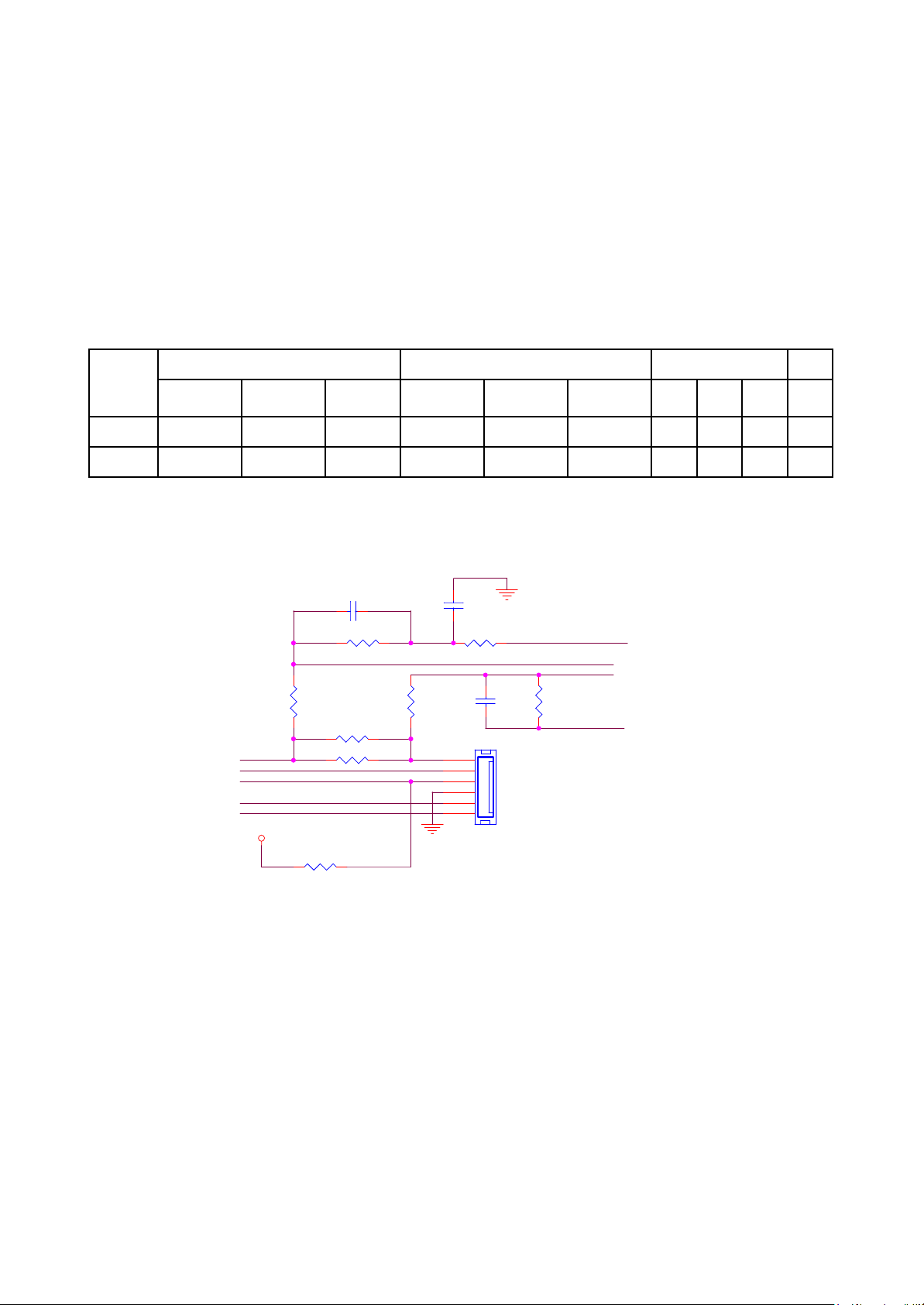

1. Audio signal flow chart block diagram is shown in the figure 3.2.10.1:

MIC board

R2132

R215

OKA

7

6

U5A

6

1

U5B

3

MIC holder

1

7

CH-L

CH-R

AL

189

AR

7

18

MT1389

6

U13

2

L235

L23

13

Audio

Jk201

14

6

terminal

L#

R#

SCART

SAPDIF

170

R72

C81

Coaxial

Figure 3.2.10.1 Audio signal flow chart block diagram

2.

Working principle: MT1389D has built-in audio DAC conversion circuit, which stimulates signals

and

outputs from decode chip directly, through audio amplifying and filtering circuit, and outputs audio

signals

are

filter

being

feedback

directly. Shown in the figure 3.2.10.2, the right channel analog signals outputted by decode chip

coupled by and then the high frequency component in audio signals is filtered by the low pass

composed of , for signals are damped through filtering circuit, the audio signals after

filtered require the amplifying output by the amplifying circuit composed of , is

C75

R97

C77

U13A R122

resistor, this circuit is a active filter on the whole.

611

R

k

13

F

C

00147

p

-

2

V

1

811

R

k1.5

79R

1NIAML

k01

6/Fu

.

157

0

C

v3

+

77C

F

p

0001

A31

U

-

2

1

+

3

J

8554

N

AP

O

M

8 4

21+

V

4

L

2

C

N

R

1

9

1

0

1

+

0

3

1

.6/Fu

C

0

7

R0

0

K

01R

1

E

_A

v

TUM

CL

H

3

41Q

1

409

2

3

N

OS

32T

2

3.2.10.2 Amplifying circuit diagram

Figure

- 24 -

3. External Karaoke signal input and output

After

being amplified, MIC signals input to pin 2, 6 of U13 separately for amplifying output.

3.2.11 Mute circuit

1. Mute circuit is shown as in the figure 3.2.11.1:

21+

V

19R

8R

4

R07

1

5

D

V7.4

M

C

3

3V

CAD_ETU

V

CC

7

K5

9

2E

+

1

0

V

/FU022

R

1

1

01431R

K

R

0

2

23

K01

23

12Q

1

6093

7

Q

1

93

6

0

23

51Q

1

609

3

K0198

M

E

_A

TU

5753

0

k

1R

V

21-

-

1

2

V

Figure 3.2.11.1 Mute circuit

2. Working principle of quieting circuit

the player is working normally, shown in the figure 3.2.11.1, MT1389E outputs analog audio

When

signal,

about

0.7V

added

outputs

no

signal

transmits

to

switch

DAC

and a low level signal to

2.7V, collector electrode of Q17 is about 3.3V, so Q15 is also on, voltage of B electrode is about

, voltage of Q21 E electrode is near to zero, Q21 cuts of f, MUTE 1 is negative voltage, which is

to base electrode of mute tube of audio output end to make mute tube cut off, and audio signal

after being amplified by 4558. When pressing MUTE button on remote controller, MT1389 has

audio signal that outputs to operational amplifier, so audio output end of the player has no audio

output, but because electronic elements in circuit will produce some noise when working that

to output end of the player, in order to filter there noise, decode chip outputs a high level signal

MUTE-DAC to make Q21 cut off, so Q15 cuts off, +5V power is transmitted to base electrode of

pipe Q15 through EC electrode of Q21 , mute circuit is in mute state.

When

player is not playing disc or stops playing, MT1389D outputs a high level signal to MUTE-

to make audio circuit enter mute state.

MUTE-DAC

at the same time to make Q17 on, B electrode of Q17 is

After

microphone is inserted into the machine, DET pin outputs low level, Q21E electrode is low

level,

now no matter the former circuit outputs mute circuit, rear mute circuit does not work, and sound

outputs

normally.

- 25 -

Loading...

Loading...