BBK DV311, DV313, DV314, DV315SI Service Manual

DV311SI DV313SI

DV314SI DV315SI

service manual

Catalog

Chapter One About Maintenance

1.1 Safety precautions

1.1.1 Power supply

1.1.2 Precautions for antistatic

1.1.3 Precautions for laser head

1.1.4 About placement position

1.2 Maintenance method

1.2.1 Visualized method

1.2.2 Electric resistance method

1.2.3 Voltage method

1.2.4 Current method

1.2.5 Cutting method

1.2.6 Element substitution method

1.2.7 Comparison method

1.3 Required device for maintenance

1

1

1

1

1

2

2

2

2

2

2

2

3

3

3

Chapter Two Functions and Operation Instructions

2.1 Features

2.2 Control Button Locations and Explanations

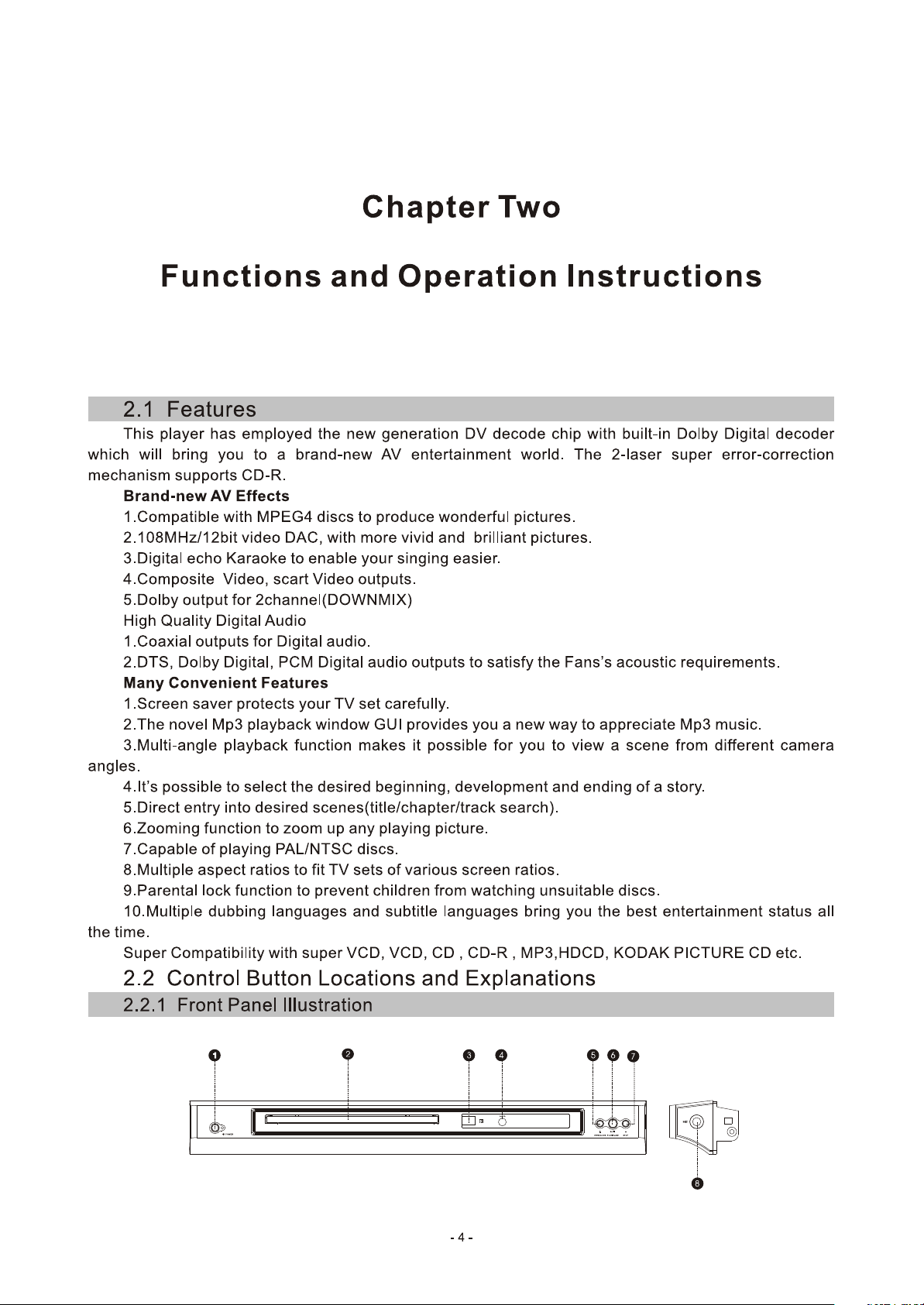

2.2.1 Front Panel Illustration

2.2.2 Rear Panel Illustration

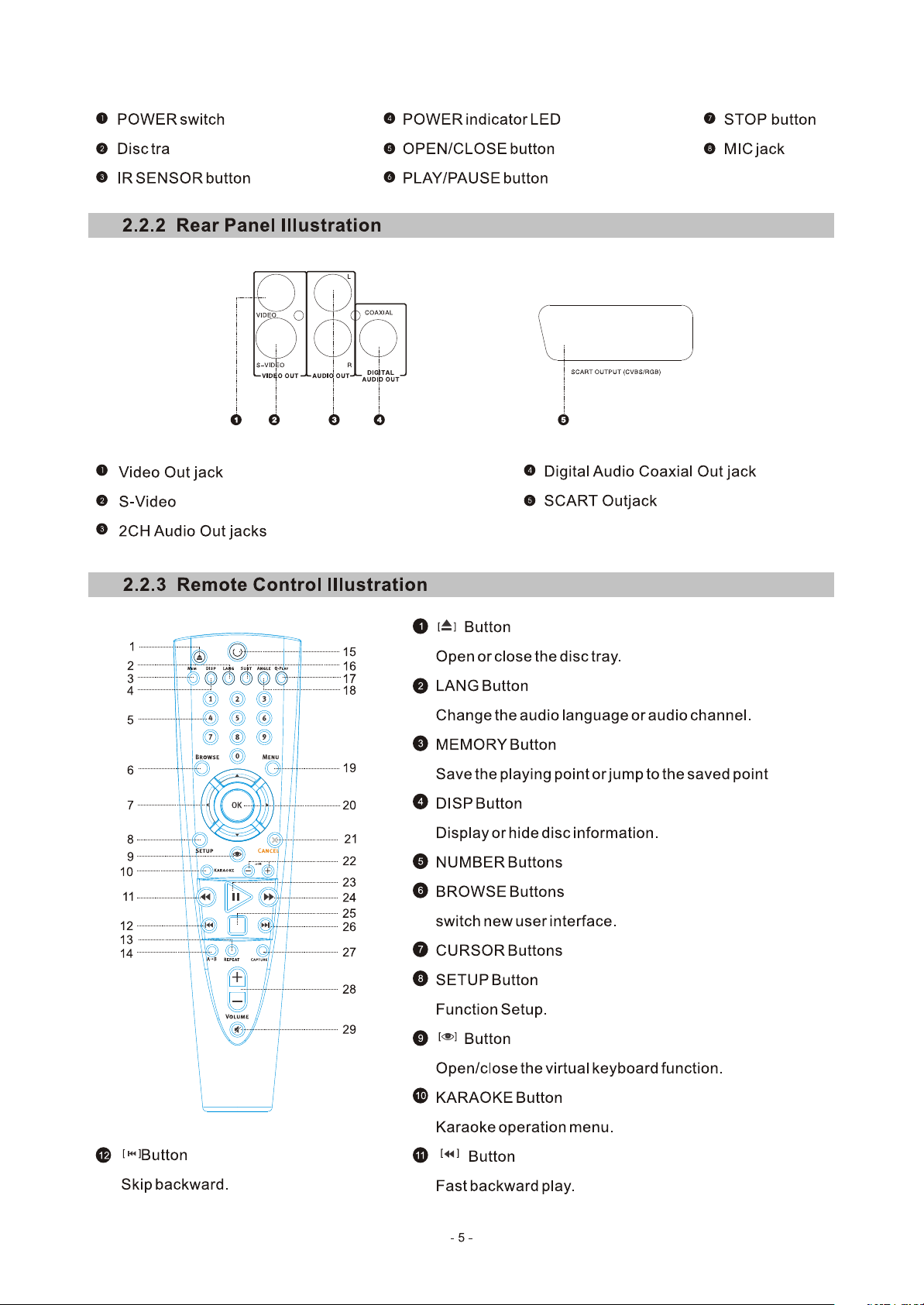

2.2.3 Remote Control Illustration

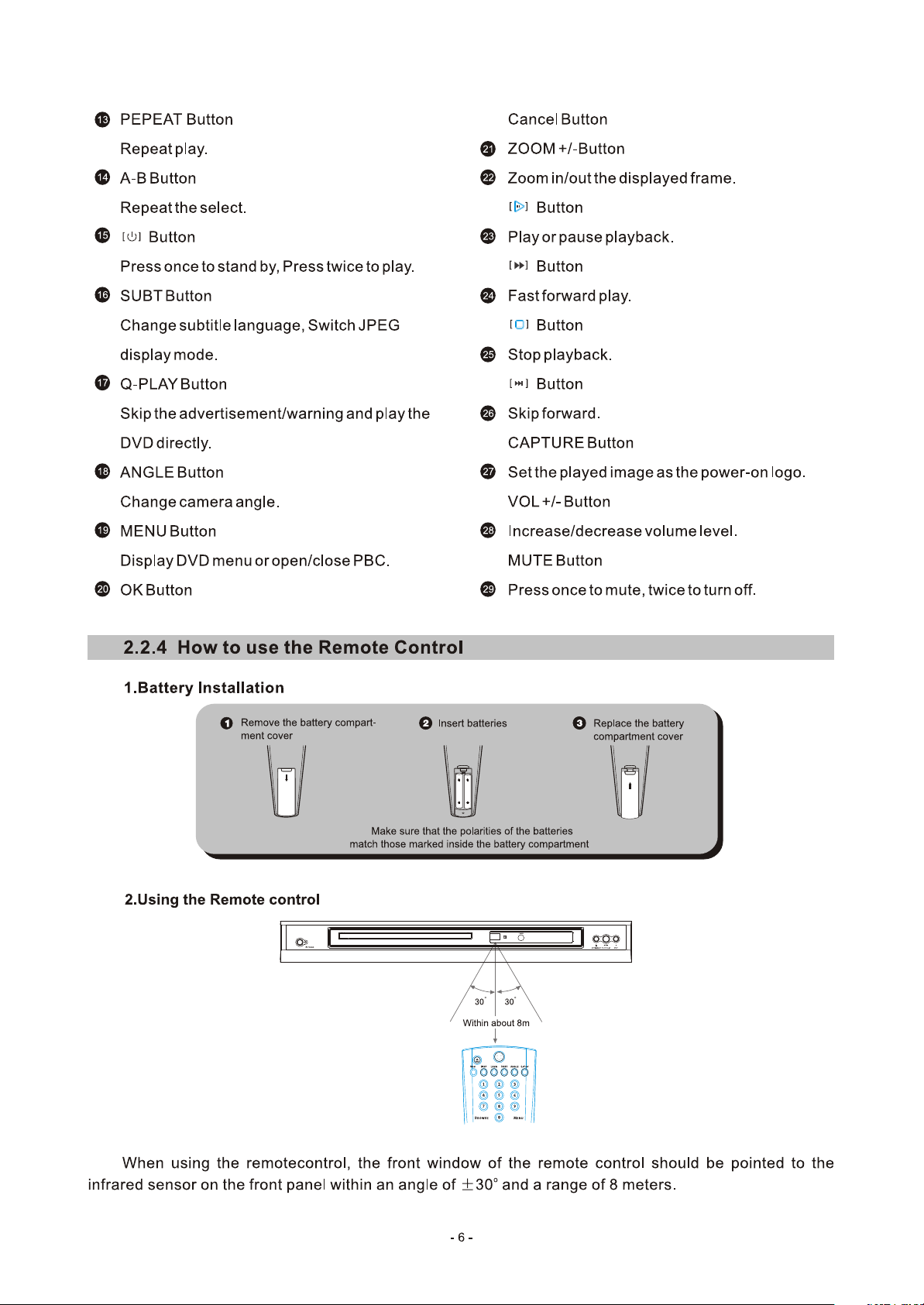

2.2.4 How to use the Remote Control

2.3 Accessories

2.4 Function setup

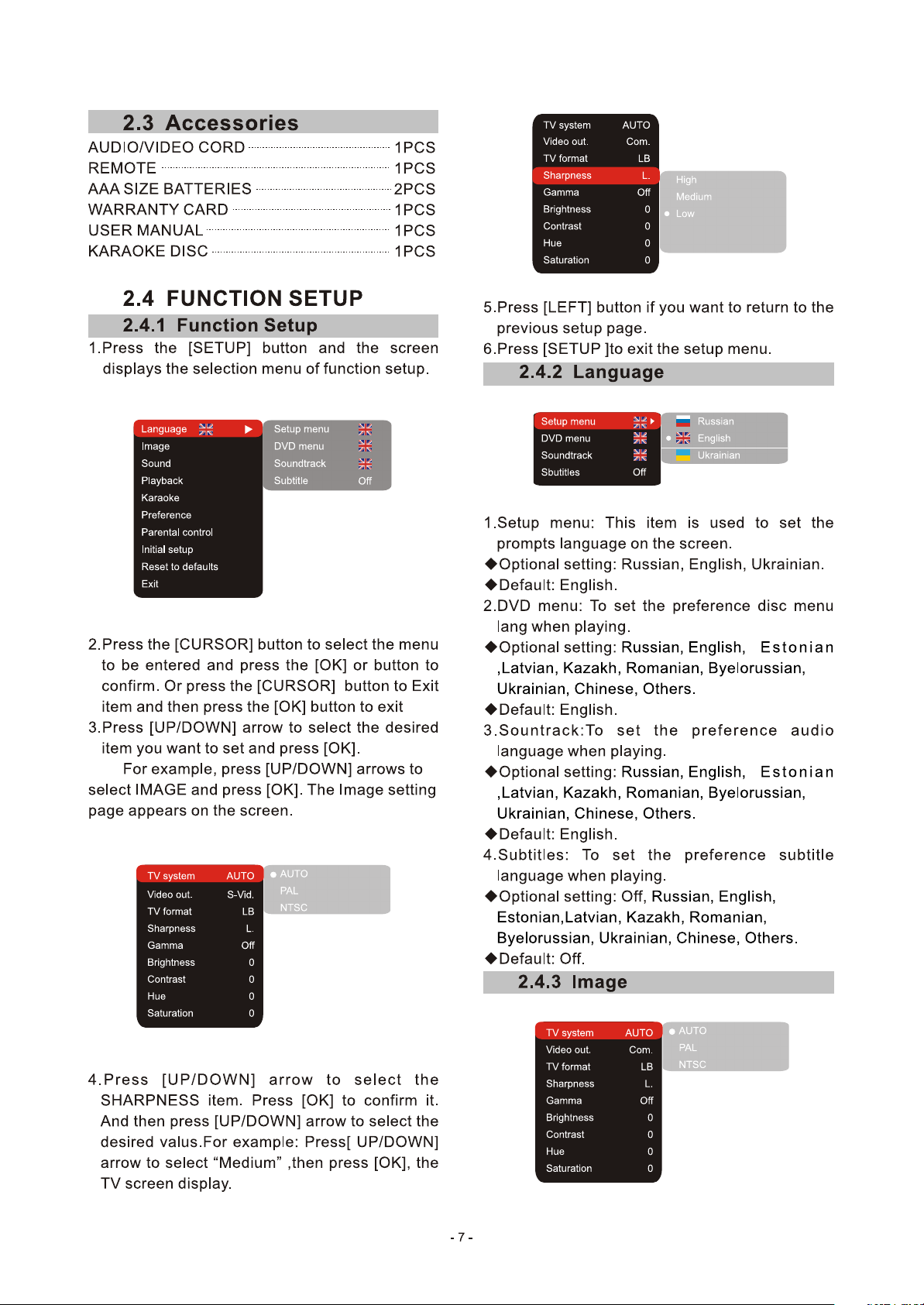

2.4.1 Function setup

2.4.2 language

2.4.3 Image

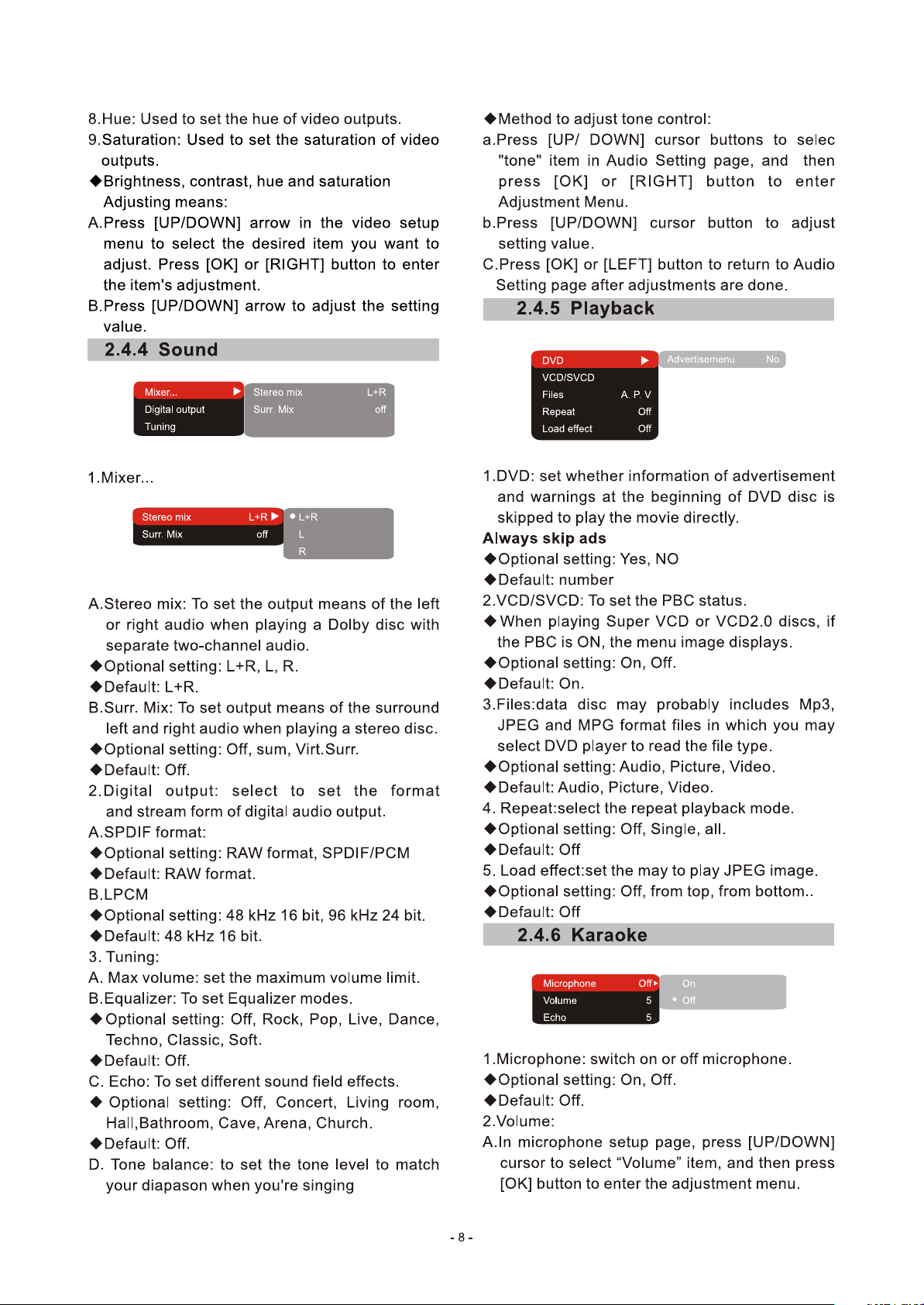

2.4.4 Sound

2.4.5 Playback

4

4

4

4

5

5

6

7

7

7

7

7

8

8

2.4.6 Karaoke

8

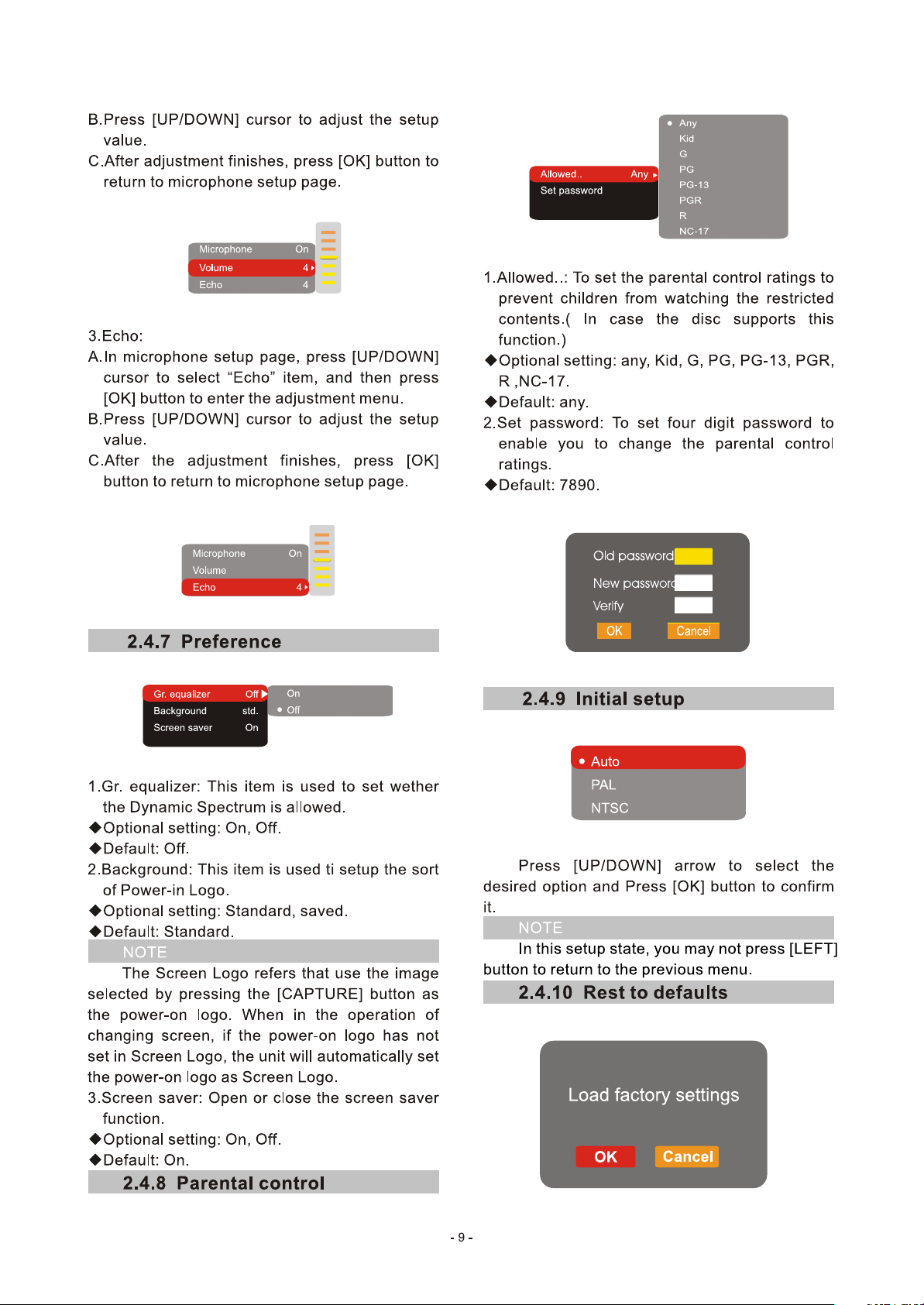

2.4.7 Preference

2.4.8 Parental Control

2.4.9 Initial setup

2.4.10 Rest to defaults

2.4.11 Exit

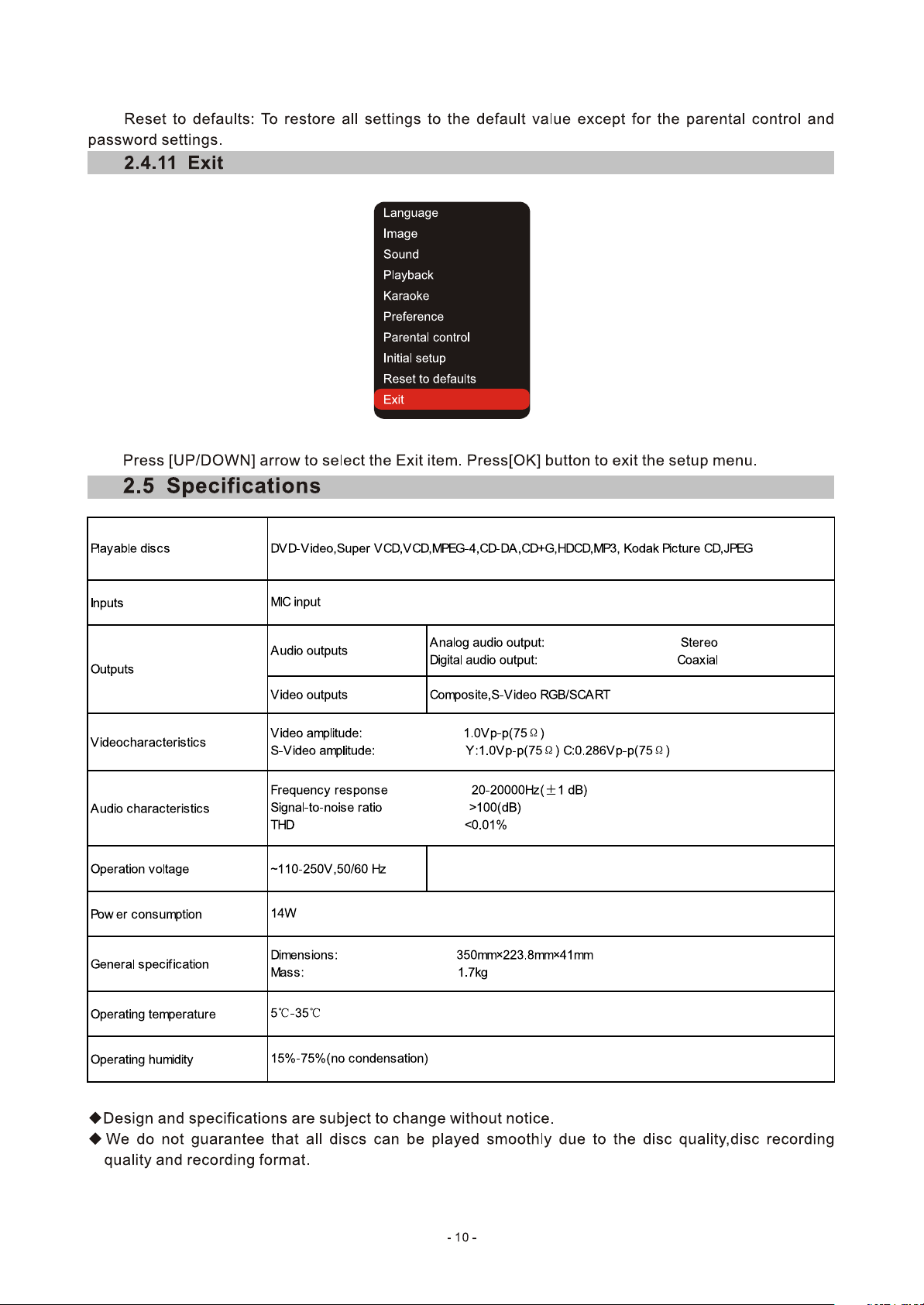

2.5 Specifications

Chapter Three Principle and Servicing

Section one principle of the player

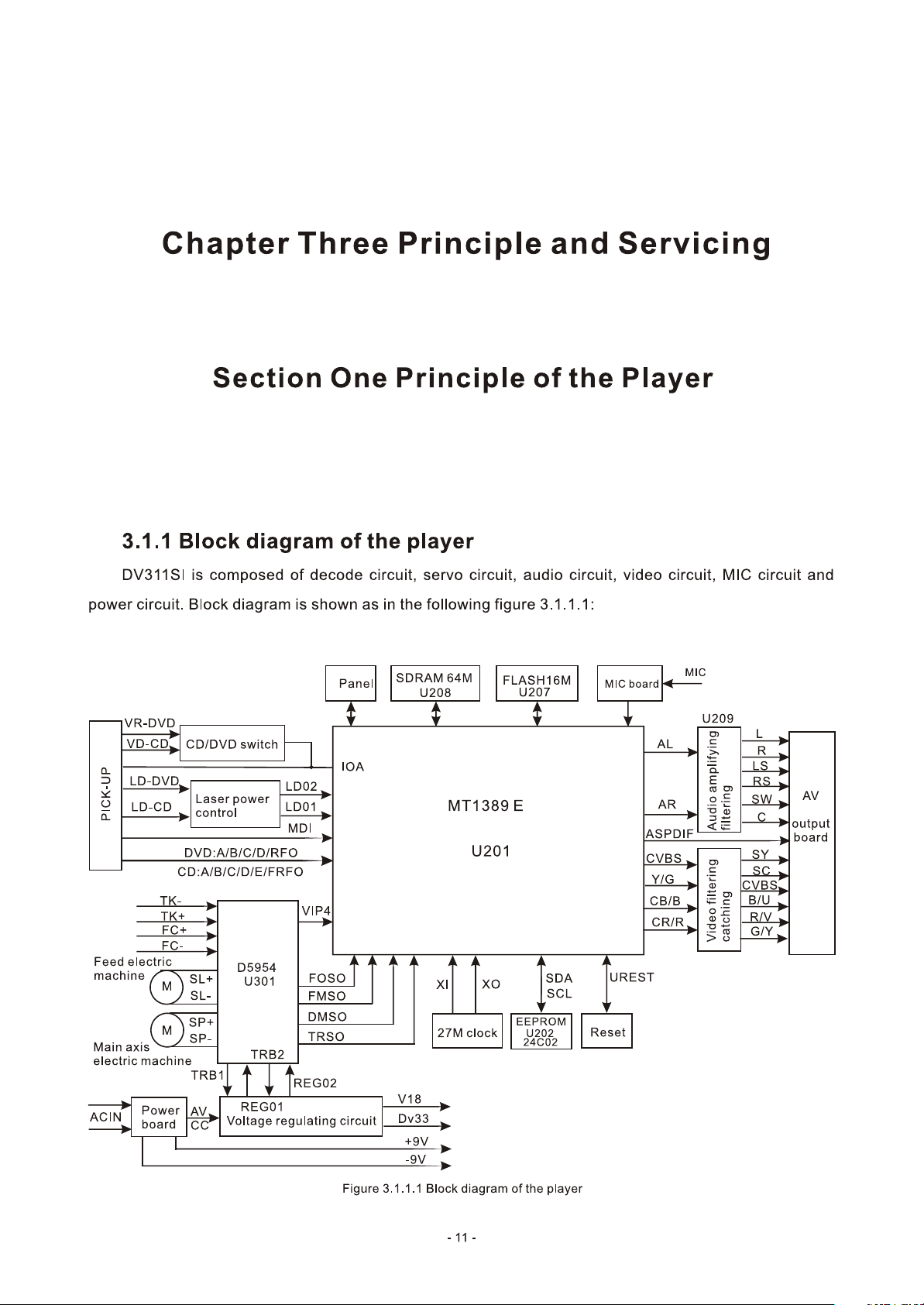

3.1.1 Block diagram of the player

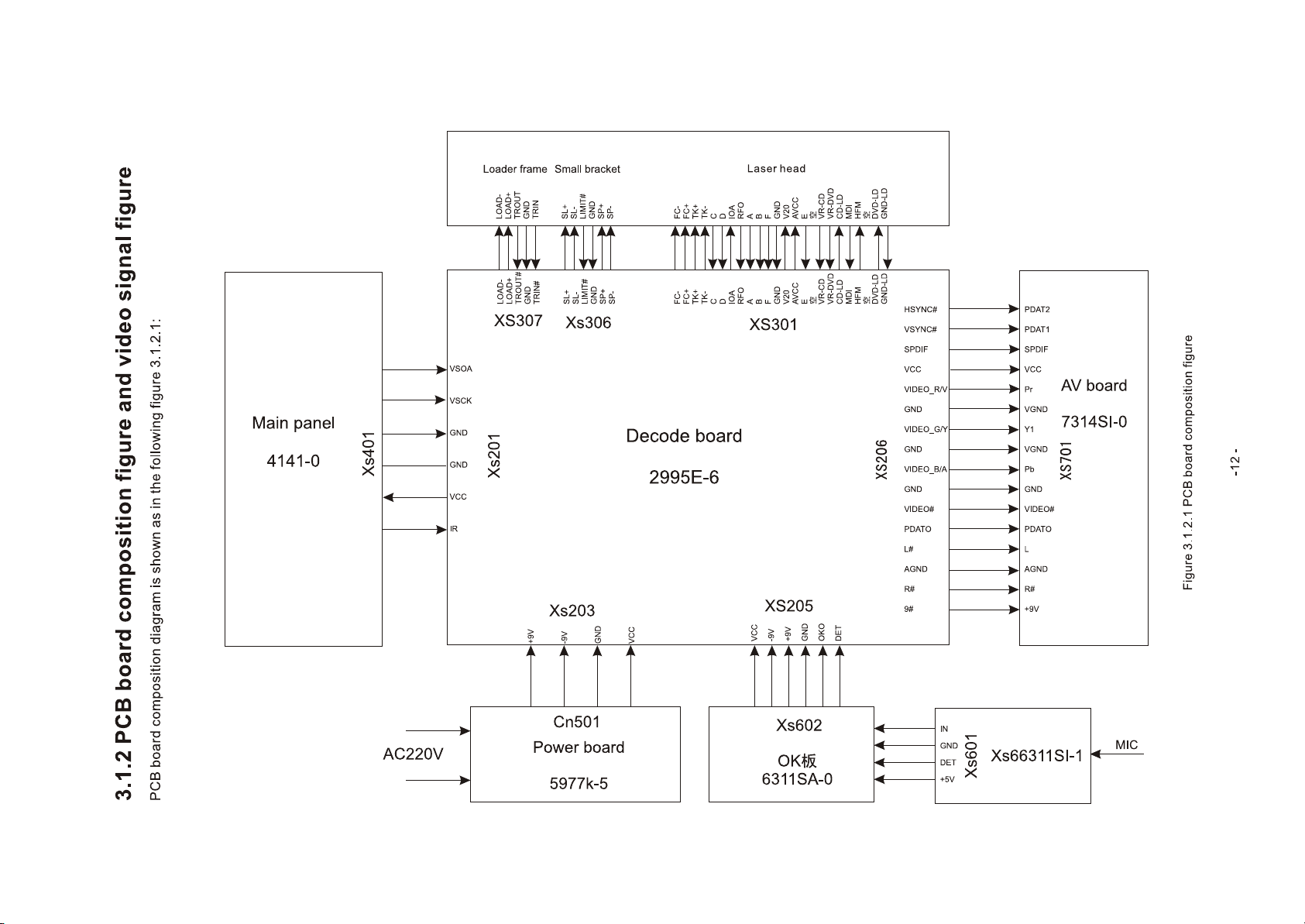

3.1.2 PCB board composition figure and video signal figure

Section Two Unit Circuit Principle

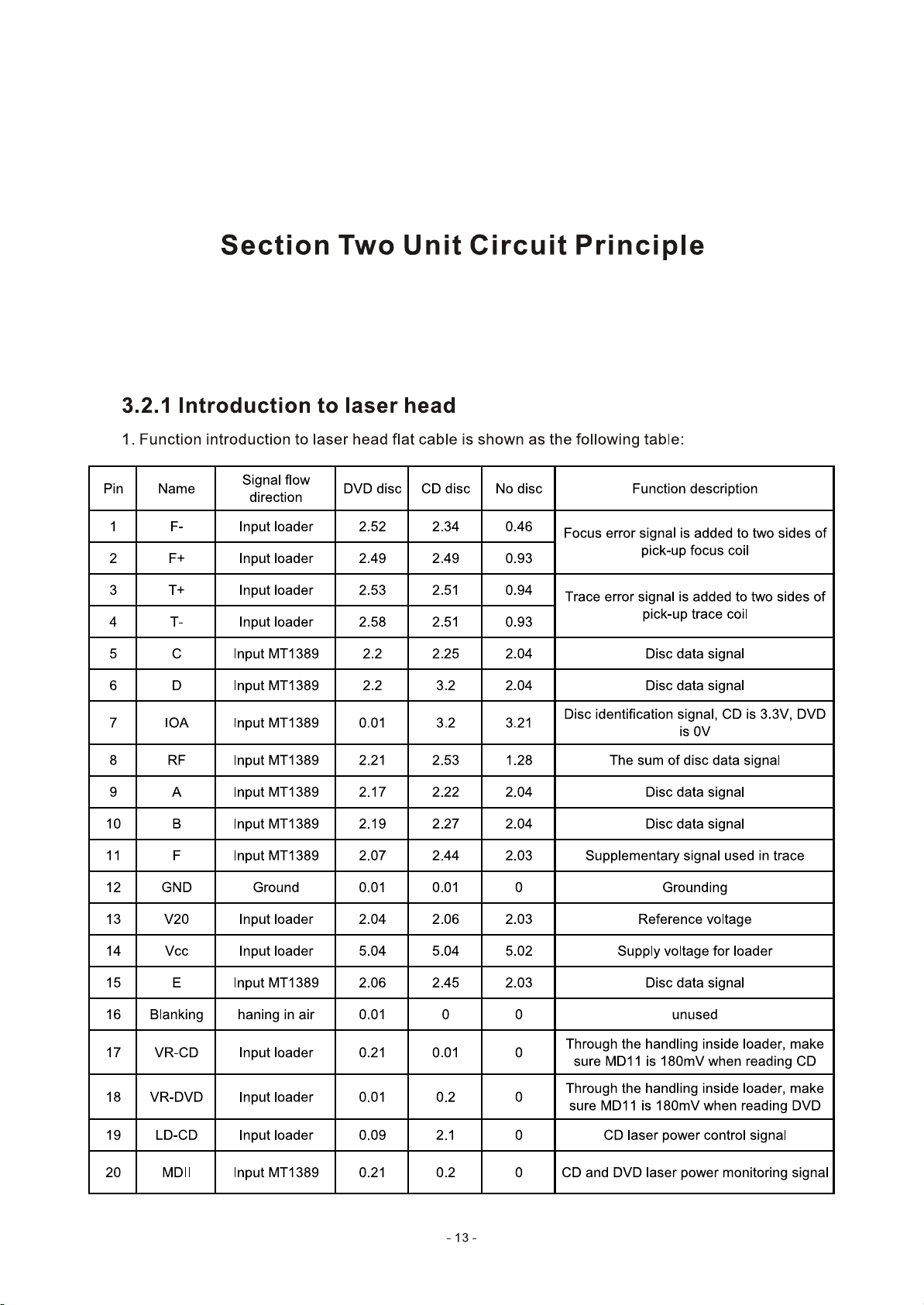

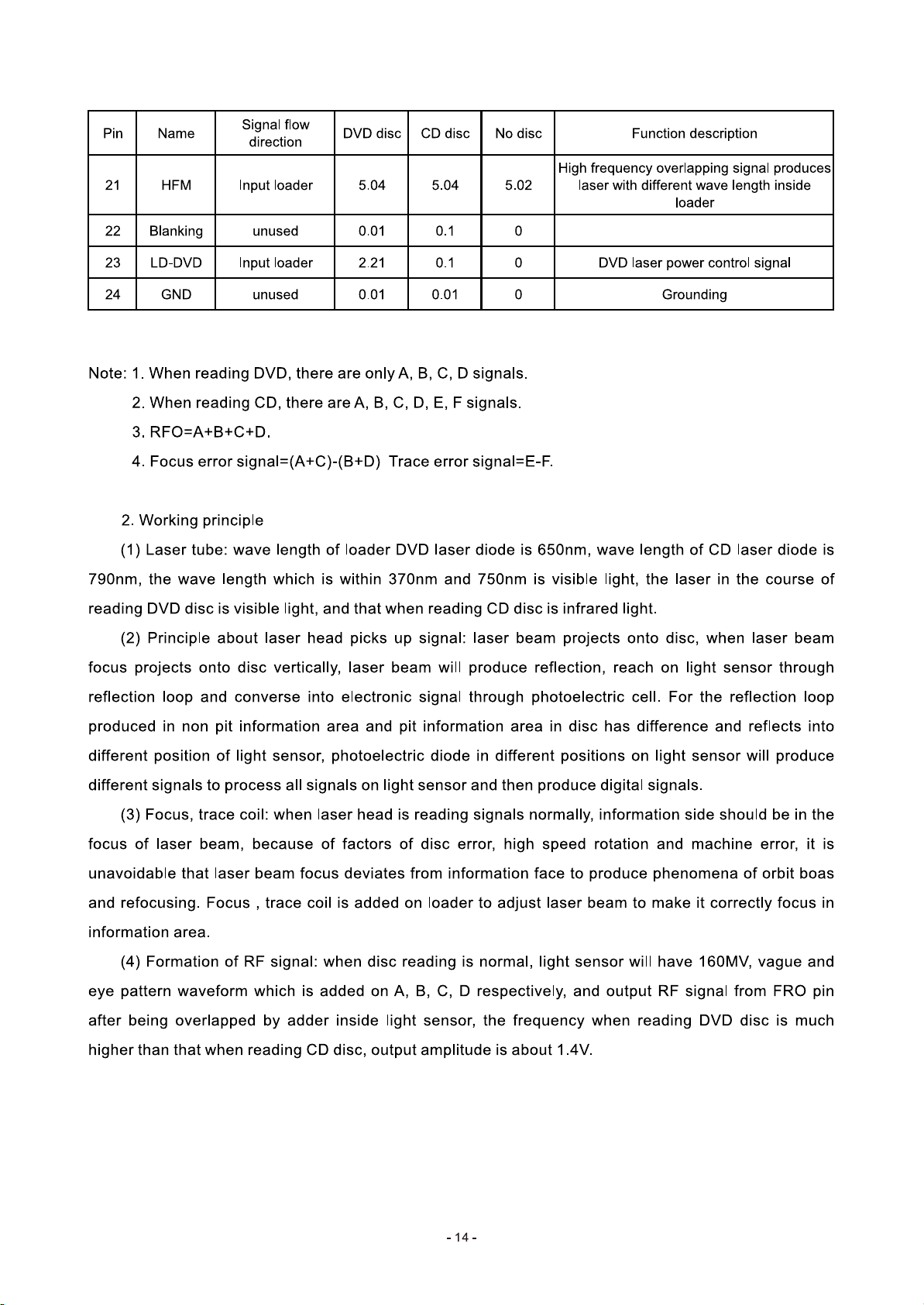

3.2.1 Introduction to laser head

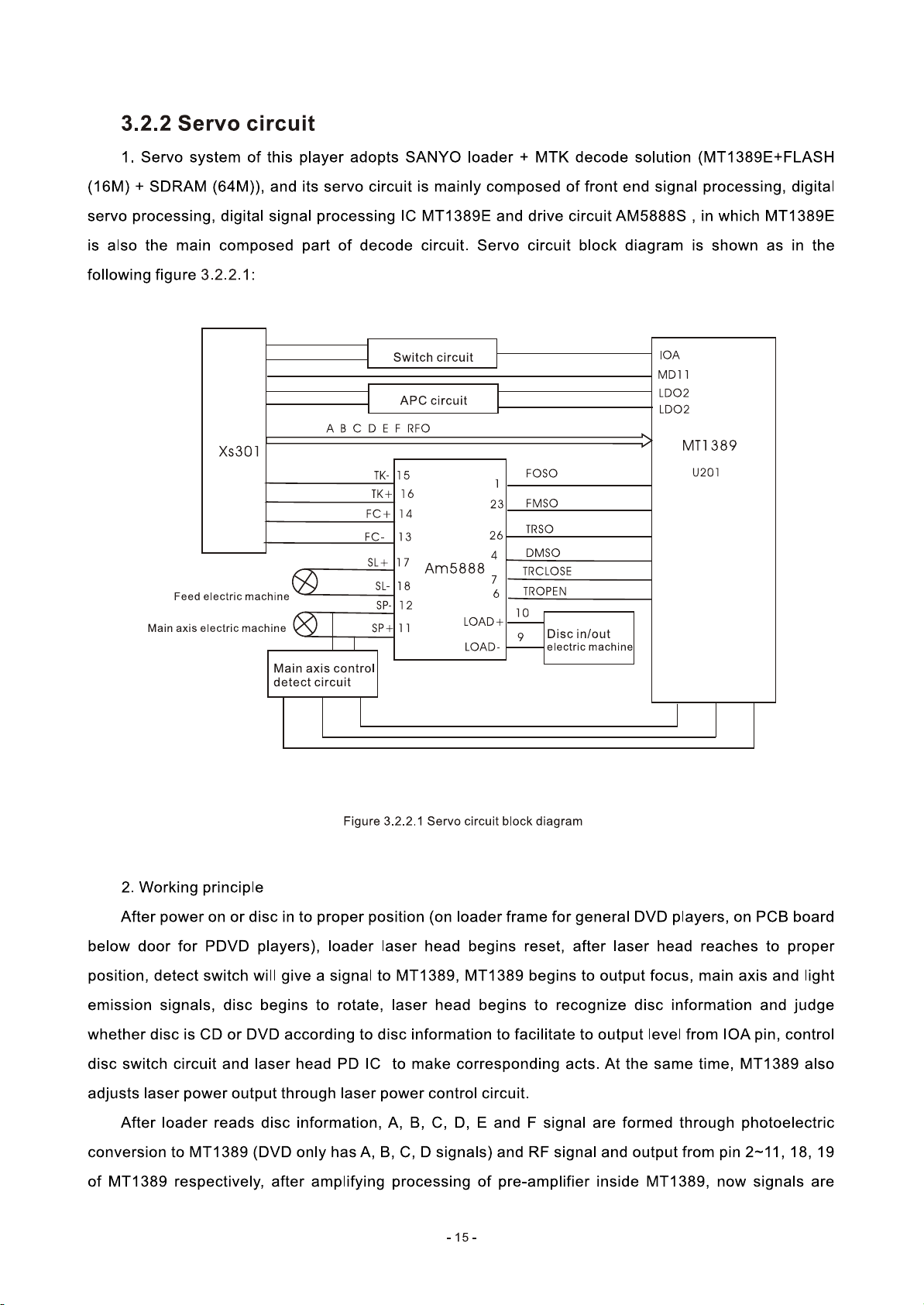

3.2.2 Servo Circuit

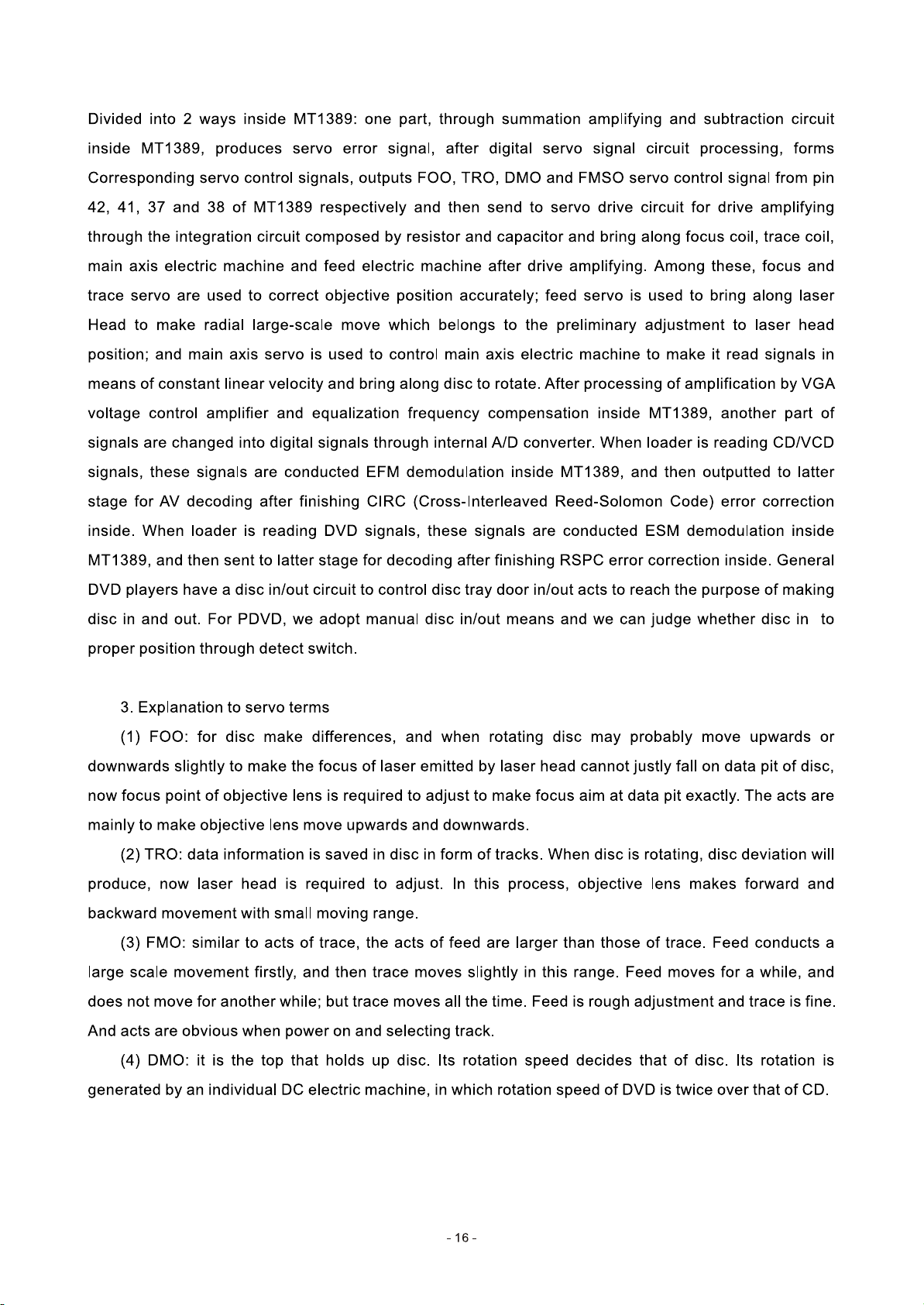

3.2.3 Open/Close drive circuit

9

9

9

9

10

10

11

11

11

12

13

13

15

17

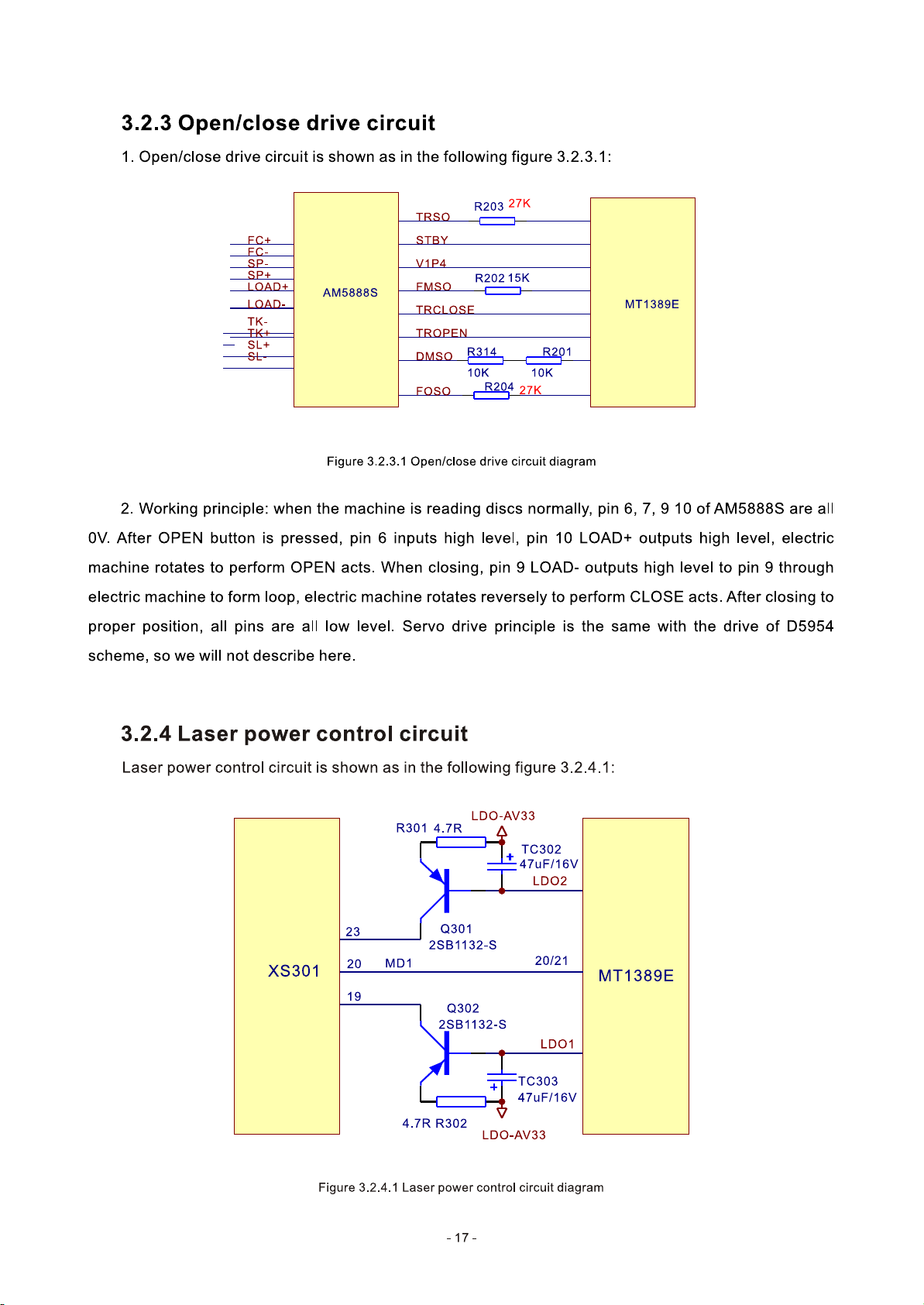

3.2.4 Laser power control circuit

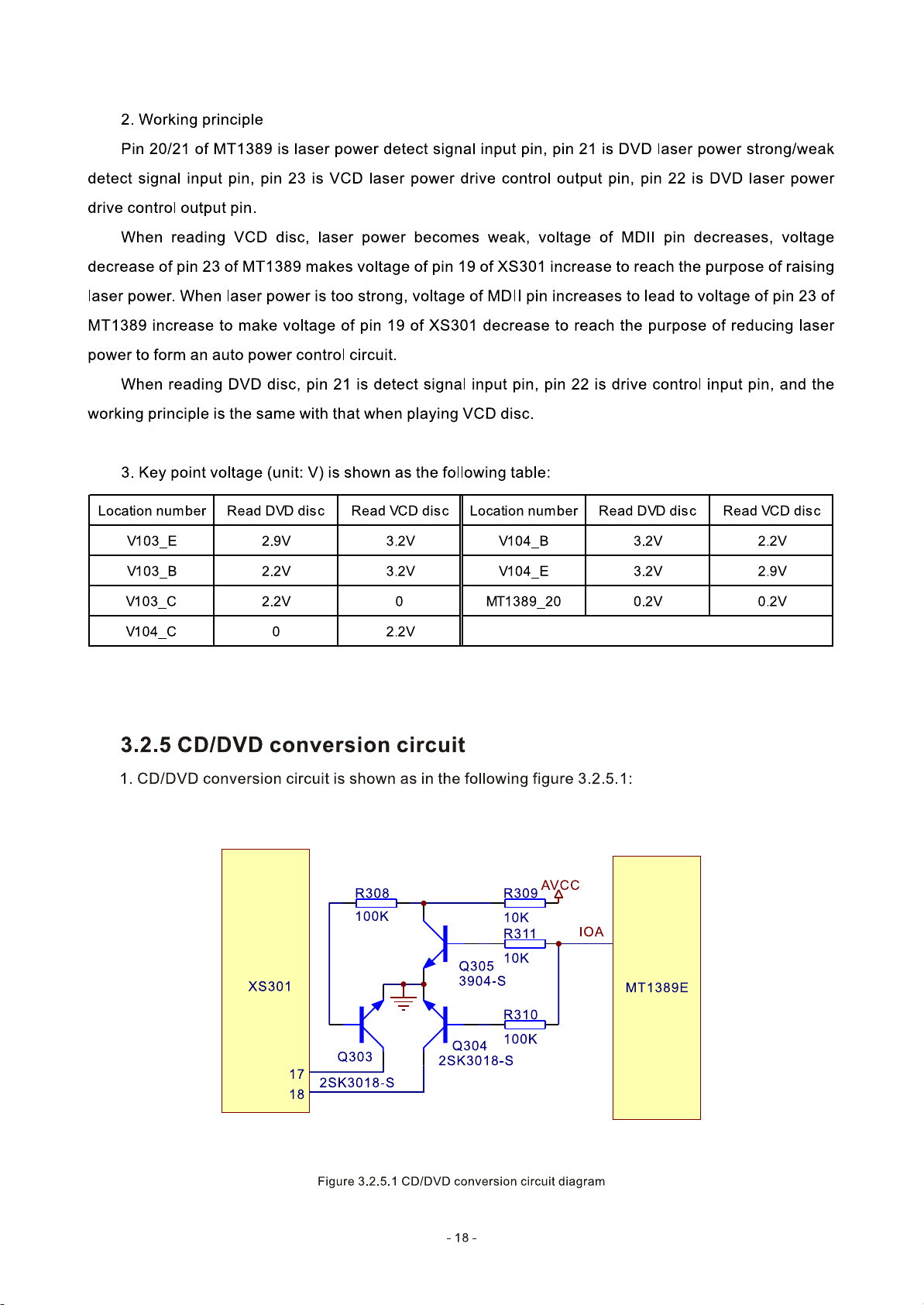

3.2.5 CD/DVD Conversion circuit

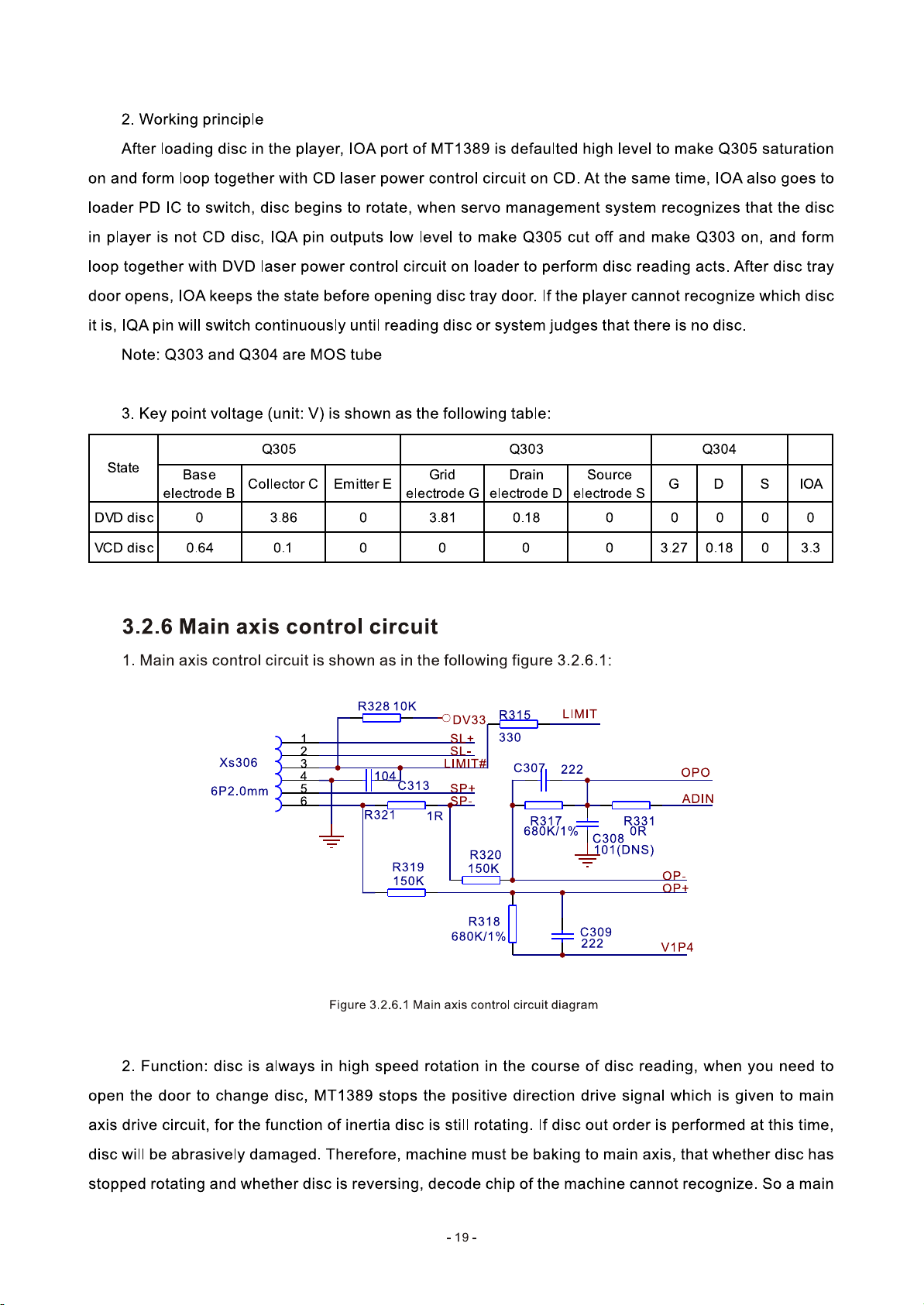

3.2.6 Main axis control circuit

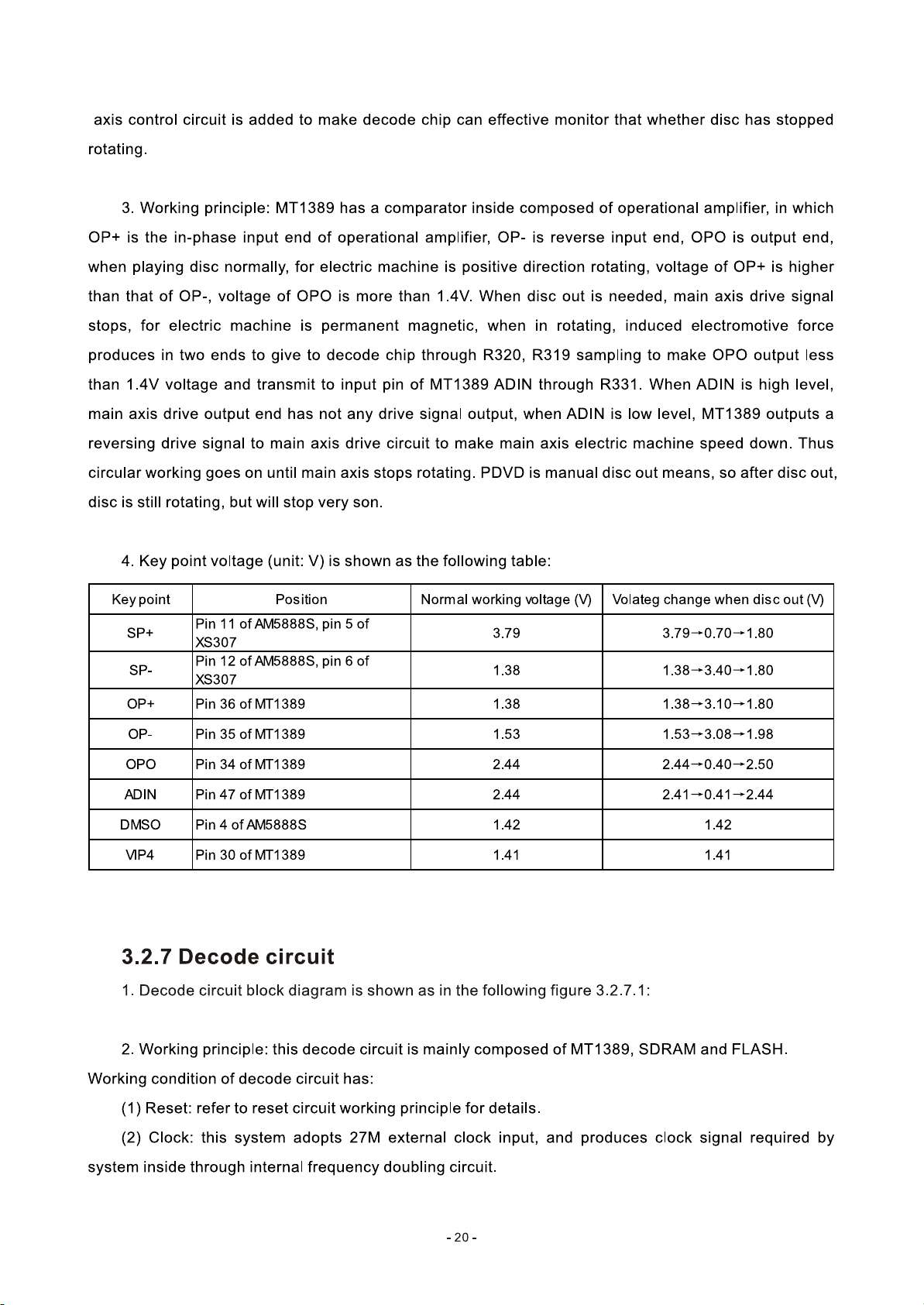

3.2.7 Decode circuit

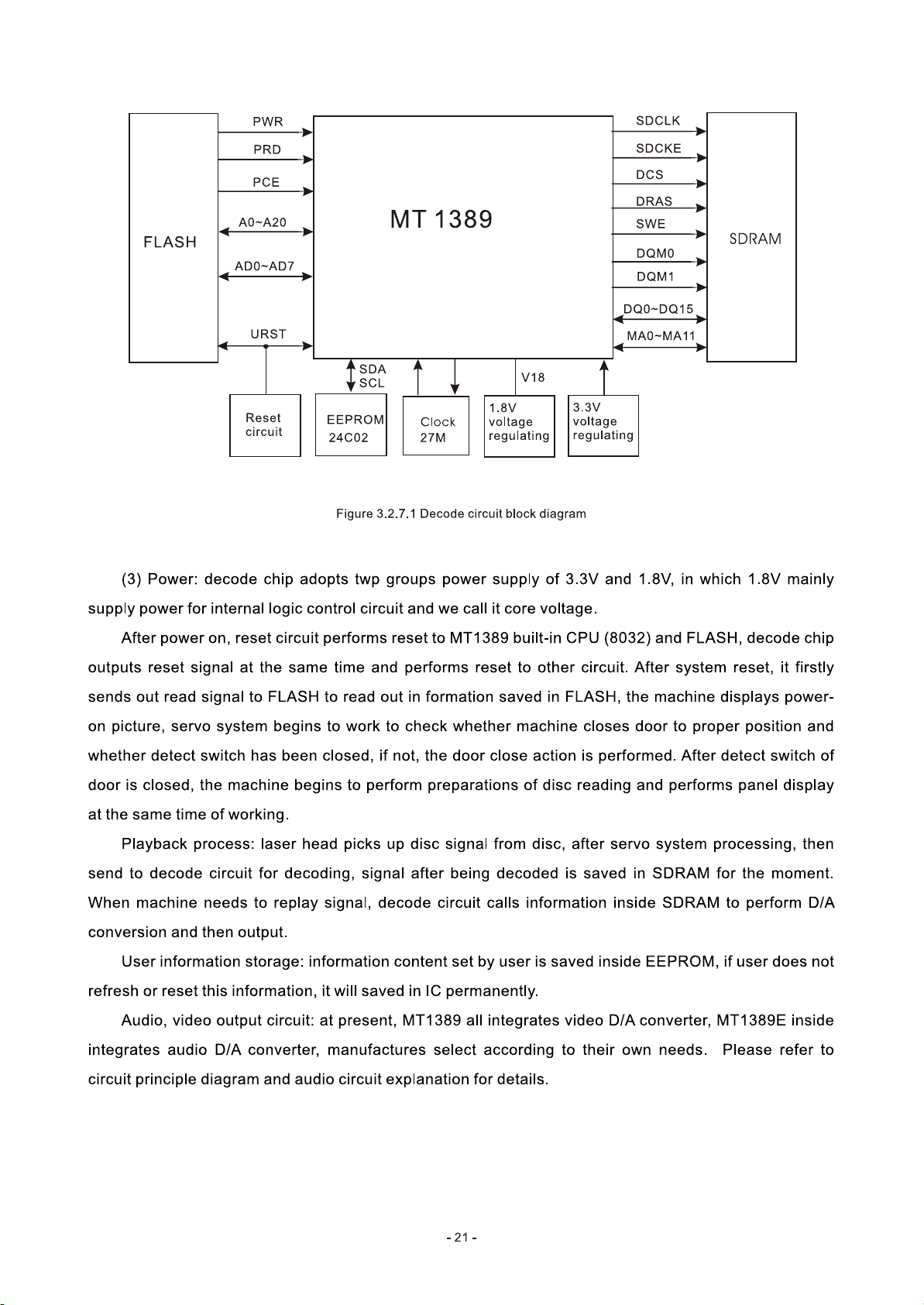

3.2.8 Reset circuit

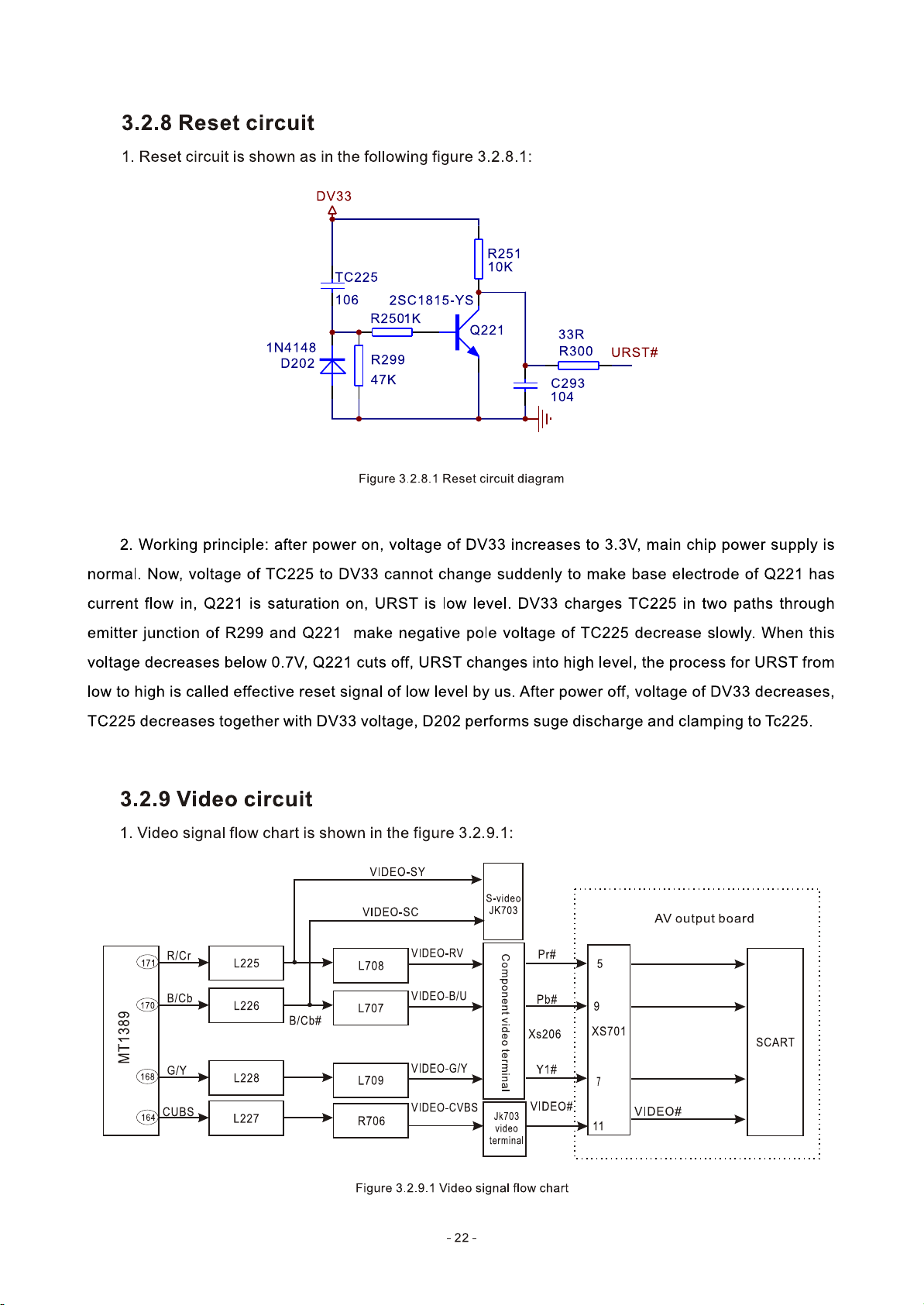

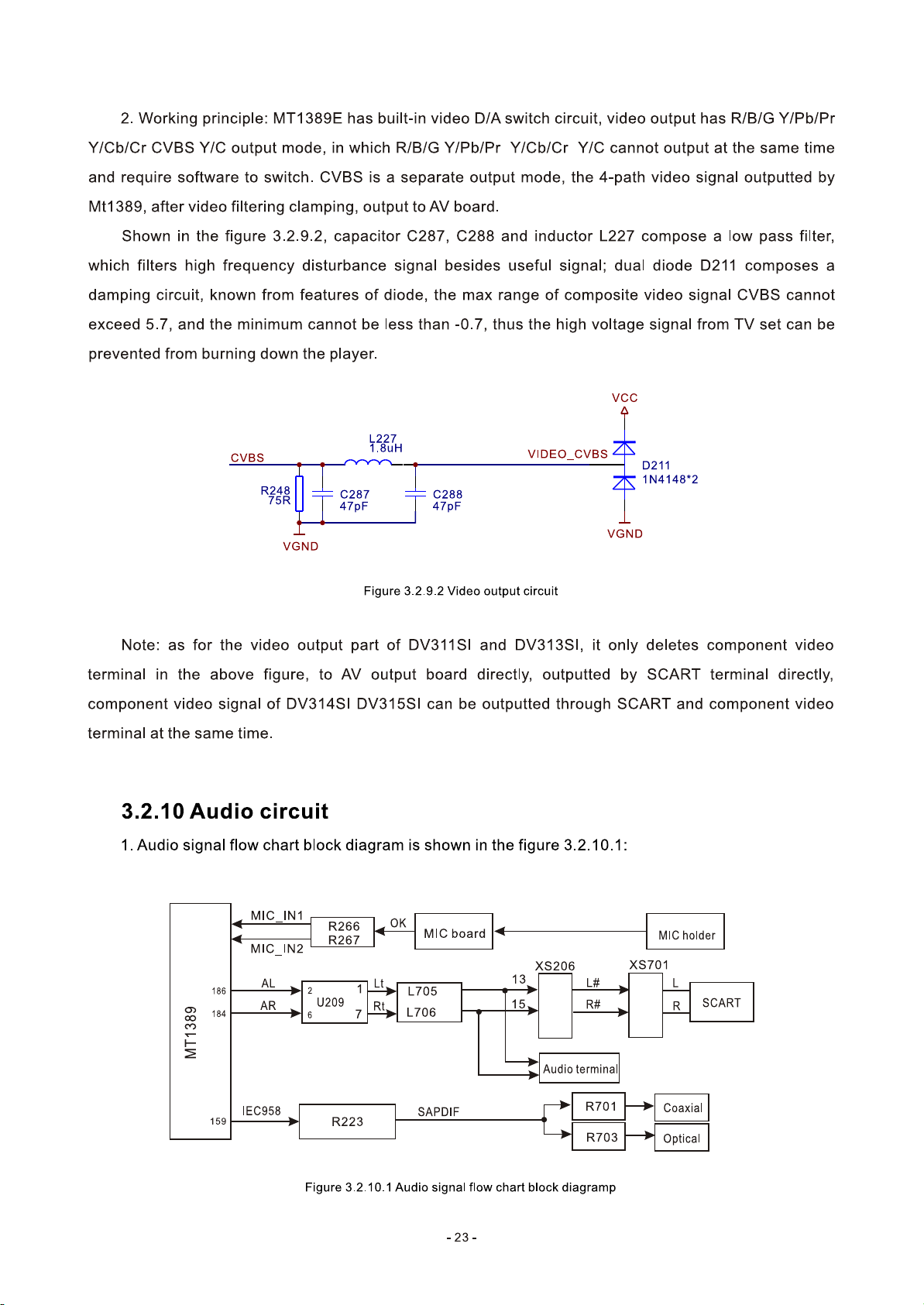

3.2.9 Video circuit

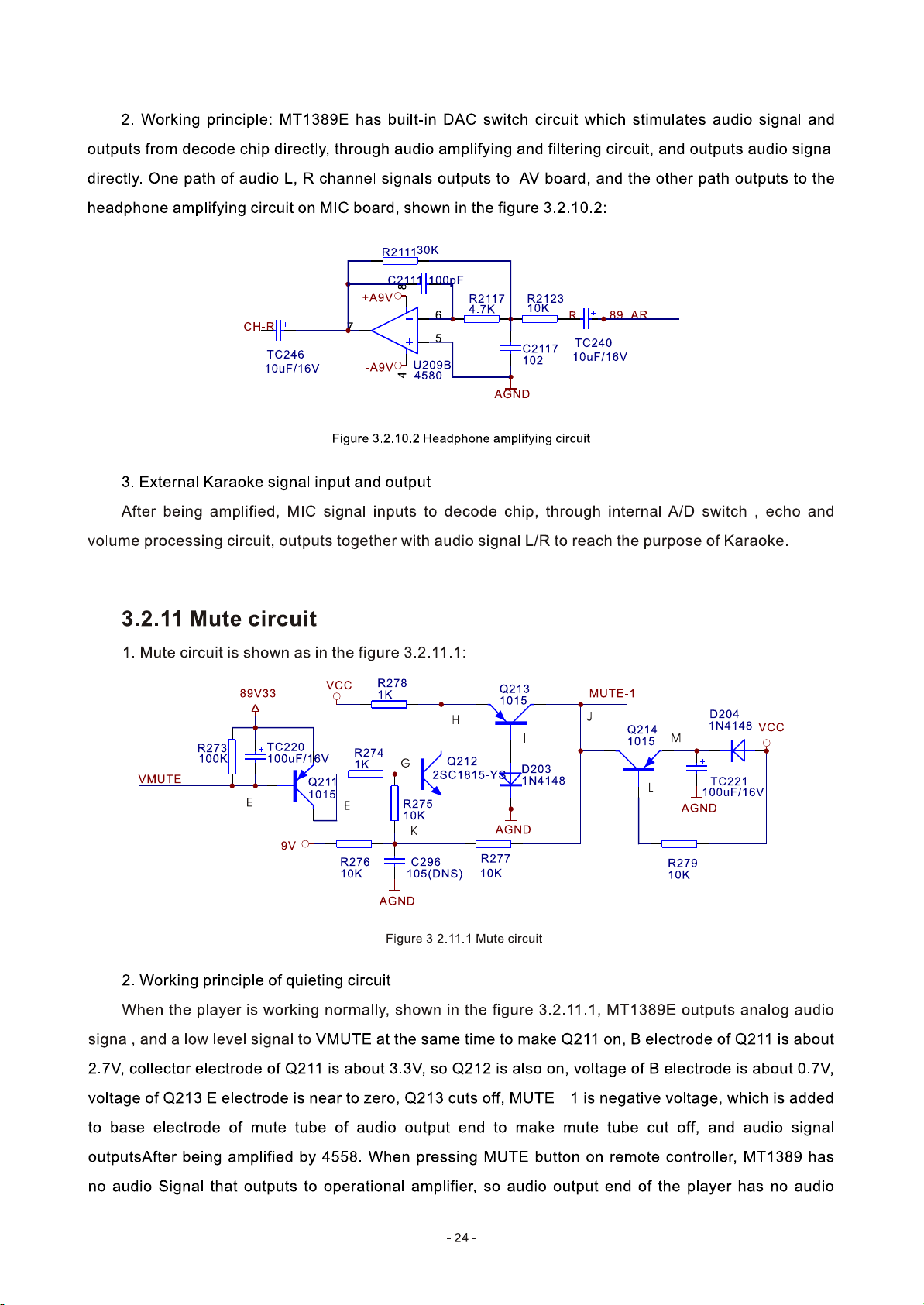

3.2.10 Audio circuit

3.2.11 Mute circuit

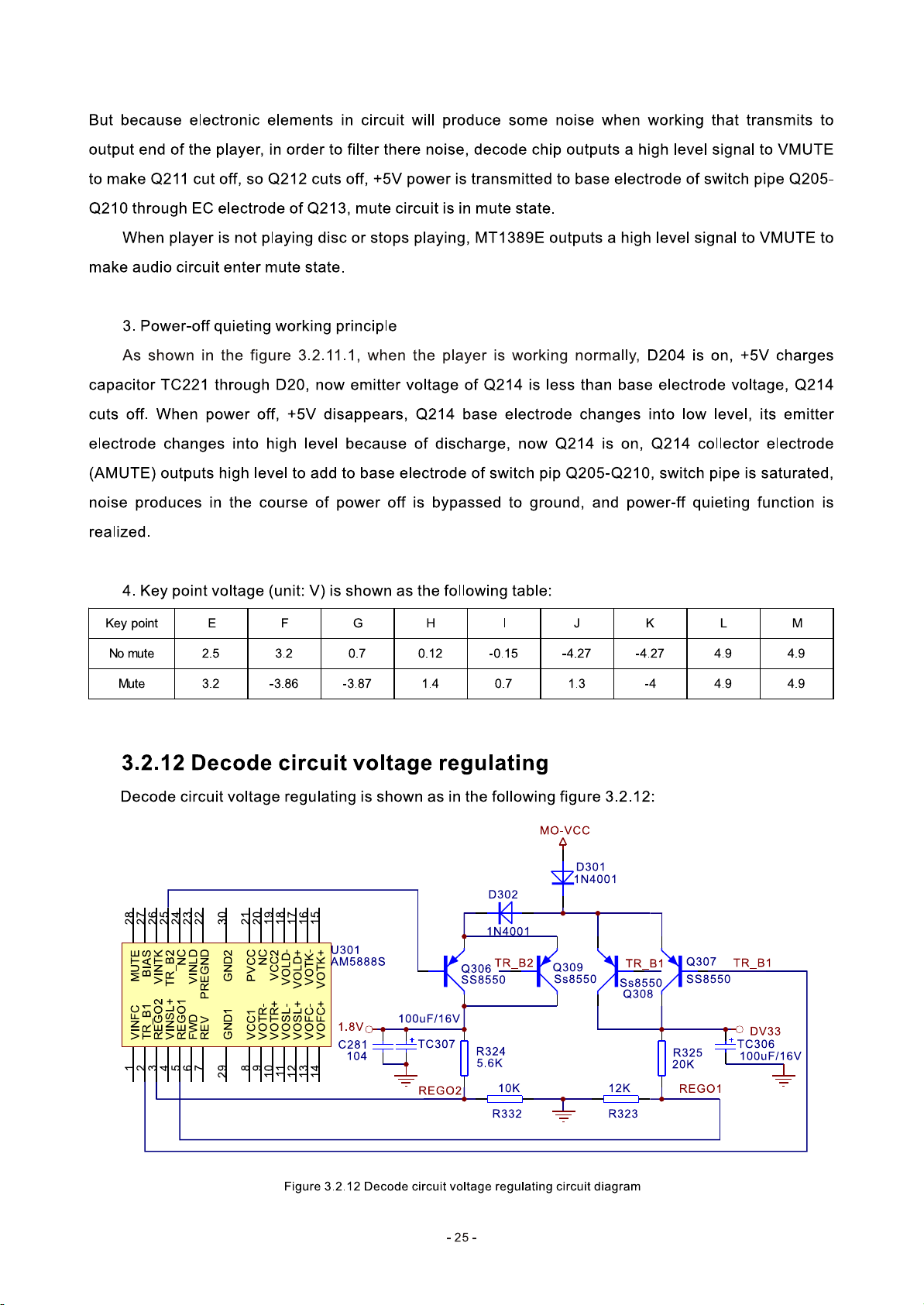

3.2.12 Decode circuit voltage regulating

3.2.13 Power circuit

3.2.14 Control panel circuit

3.2.15 XIC circuit

3.2.16 AV output board circuit

Section Three Servicing Cases

3.3.1 Servicing instances

17

18

19

20

22

22

23

24

25

26

27

27

28

30

30

3.3.2 Troubleshooting flow chart

Section Four Waveform diagram

Section Five Function Introduction to IC

3.5.1 function introduction to MT1389E

32

45

50

50

3.5.2 function introduction to 4558

64

3.5.3 function introduction to AT24C02

3.5.4 function introduction to VIPer22ADIP

3.5.5 function introduction to AM5888S

3.5.6 function introduction to PT6961(4dv315)

3.5.7 Function introduction to SDRAM

3.5.8 Function introduction to FLASH

3.5.9 Function introduction to LM431A

3.5.10 Function introduction to Pc817

Chapter Four Disassembly and Assembly Process

Chapter Cinque PCB board & Circuit diagram

Section One PCB board

Section Two circuit diagram

65

66

67

69

70

72

72

73

74

75

75

82

Chapter six BOM List

DV313SI Service Manual

7.1.1 Features

7.2.1 PCB board block diagram of the player

7.3.1 Control panel circuit

7.4.1 Servicing instances

7.5.1 PCB board

7.5.2 Circuit diagram

DV314SI Service Manual

8.1.1 Features

8.2.1 PCB board block diagram of the player

8.3.1 Control panel circuit

8.4.1 Servicing instances

89

97

97

98

99

99

101

102

103

103

104

105

105

8.5.1 PCB board

8.5.2 Circuit diagram

108

110

DV315SI Service Manual

111

9.1.1 Features

9.2.1 PCB board block diagram of the player

9.3.1 Servicing cases

9.3.2 Troubleshooting flow chart

9.4.1 PCB board

9.4.2 Circuit diagram

111

112

113

114

115

116

Chapter One About Maintenance

1.1 Safety precautions

1.1.1 Power supply

When maintenance personnel are repairing DVD players, he should pay special attention to the

power board with 220V AC and 330V DC which will cause hurt and damage to persons!

1.1.2 Precautions for antistatic

Movement and friction will both bring static electricity which causes serious damages to integrated

IC. Though static charge is little, when a limited quantity of electric charge is added to large-

scaleintegrated IC, as the capacitance is very small in the meantime, now the integrated IC is very much

easy to be struck through by static electricity or the performance will decrease. Thus static electricity

prevention is of extraordinary importance. The following are several measures to prevent static

electricity:

1. Use a piece of electric conduction metal with the length of about 2 metres to insert into the earth,

and Fetch the lead wire from the top of the surplus metal and connect to the required static electricity

device. The length and depth of the metal embedded under the earth should be determined according to

the wettability of the local soil. For humid places, it may be shorter, and longer and deeper for dry places.

If possible, it can be distributed and layed in terms of “#” shape.

2. On operating table-board, the antistatic table cushion should be covered and grounded.

3. All devices and equipments should be placed on the antistatic table cushion and grounded.

4. Maintenance personnel should wear antistatic wrist ring which should be grounded.

5. Places around the operating position should also be covered with electric conduction cushion or

Painted with antistatic paint.

1.1.3 Precautions for laser head

1. Do not stare at laser head directly, for laser emission will occur when laser head is working, which

will Hurt your eyes!

2. Do not use wiping water or alcohol to clean laser head, and you may use cotton swab.

- 1 -

1.1.4 About placement position

1. Never place DVD player in positions with high temperature and humidity.

2. Avoid placing near high magnetic fields, such as loudspeaker or magnet.

3. Positions for placement should be stable and secure.

1.2 Maintenance method

1.2.1 Visualized method

Directly view whether abnormalities of collision, lack of element, joint welding, shedding welding,

rosin joint, copper foil turning up, lead wire disconnection and elements burning up among pins of

elements appear. Check power supply of the machine and then use hands to touch the casing of part of

elements and check whether they are hot to judge the trouble spot. You should pay more attention when

using this method to check in high voltage parts.

1.2.2 Electric resistance method

Set the multimeter in resistance position and test whether the numerical value of resistance of each

point in the circuit has difference from the normal value to judge the trouble spot. But in the circuit the

tested numerical value of resistance is not accurate, and the tested numerical value of integrated IC's

pins can only be used for reference, so the elements should be broken down for test.

1.2.3 Voltage method

Voltage method is relatively convenient, quick and accurate. Set the multimeter in voltage position

and test power supply voltage of the player and voltage of a certain point to judge the trouble spot

according to the tested voltage variation.

1.2.4 Current method

Set the multimeter in current position and test current of the player of a certain point to judge the

trouble spot. But when testing in current method, the multimeter should be series connected in the

circuit, which makes this method too trivial and troublesome, so it is less frequently used in reality.

1.2.5 Cutting method

Cutting method should be combined with electric resistance method and voltage method to use.

This method is mainly used in phenomena of short circuit and current leakage of the circuit. When

cutting the input terminal voltage of a certain level, if voltage of the player rises again, it means that the

trouble lies in this level.

- 2 -

1.2.6 Element substitution method

When some elements cannot be judged good or bad, substitution method may de adopted directly.

1.2.7 Comparison method

A same good PC board is usually used to test the correct voltage and waveform. Compared these

data with those tested through fault PC board, the cause of troubles may be found.

Through the above maintenance method, theoretical knowledge and maintenance experience, all

difficulties and troubles will be readily solved.

1.3 Required device for maintenance

Digital oscillograph ( 100MHE)

TV set

SMD rework station

Multimeter

Soldering iron

Pointed-month pincers

Cutting nippers

Forceps

Electric screw driver

Terminals connecting cord

Headphone

Microphone

- 3 -

Loading...

Loading...