BBK DV113S Service Manual

SERVICE MANUAL

DV113S

CONTENTS

1. SAFETY PRECAUTIONS

2. PREVENTION OF ELECTRO STATIC DISCHARGE(ESD)TO ELECTROSTATICALLY

SENSITIVE(ES)DEVICES

3. CONTROL BUTTON LOCATIONS AND EXPLANATIONS

4. PREVERTION OF STATIC ELECTRICITY DISCHARGE

5. ASSEMBLING AND DISASSEMBLING THE MECHANISM UNIT

5.1 OPTICAL PICKUP UNIT EXPLOSED VIEW AND PART LIST

5.2 BRACKET EXPLOSED VIEW AND PART LIST

5.3 MISCELLANEOUS

6. ELECTRICAL CONFIRMATION

6.1 VIDEO OUTPUT (LUMINANCE SIGNAL) CONFIRMATION

6.2 VIDEO OUTPUT(CHROMINANCE SIGNAL) CONFIRMATION

1

1

2

3

4

4

6

7

8

8

9

7. MPEG BOARD CHECK WAVEFORM

8. IC BLOCK DIAGRAM & DESCRIPTION

8.2 MT1389

10

11

19

8.3 U214 HY29F800 14

8.4 U203 SDRAM-HY57V1610D

9. SCHEMATIC & PCB WIRING DIAGRAM

17

19

10. SPARE PARTS LIST 32

1.1 GENERAL GUIDELINES

1. SAFETY PREAUTIONS

2.PREVENTION OF ELECTRO STATIC DISCHARGE(ESD)TO

ELECTROSTATICALLY SENSITIVE(ES)DEVICES

1

1. When servicing, observe the original lead dress. if a short circuit is found, replace all parts which have

been overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barrier, insulation papers

shields are properly installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed

to shock hazards.

Some semiconductor(solid state)devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive(ES)Devices. Examples of typical ES devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques

should be used to help reduce the incidence of component damage caused by electro static discharge(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any ESD on your body by touching a known earth ground. Alternatively, obtain and wear a commercially

availabel discharging ESD wrist strap, which should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices,place the assembly on a conductive

surface such as alminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as anti-static

(ESD protected)can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are

ready to install it. (Most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, alminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can

generate static electricity(ESD).

notice (1885x323x2 tiff)

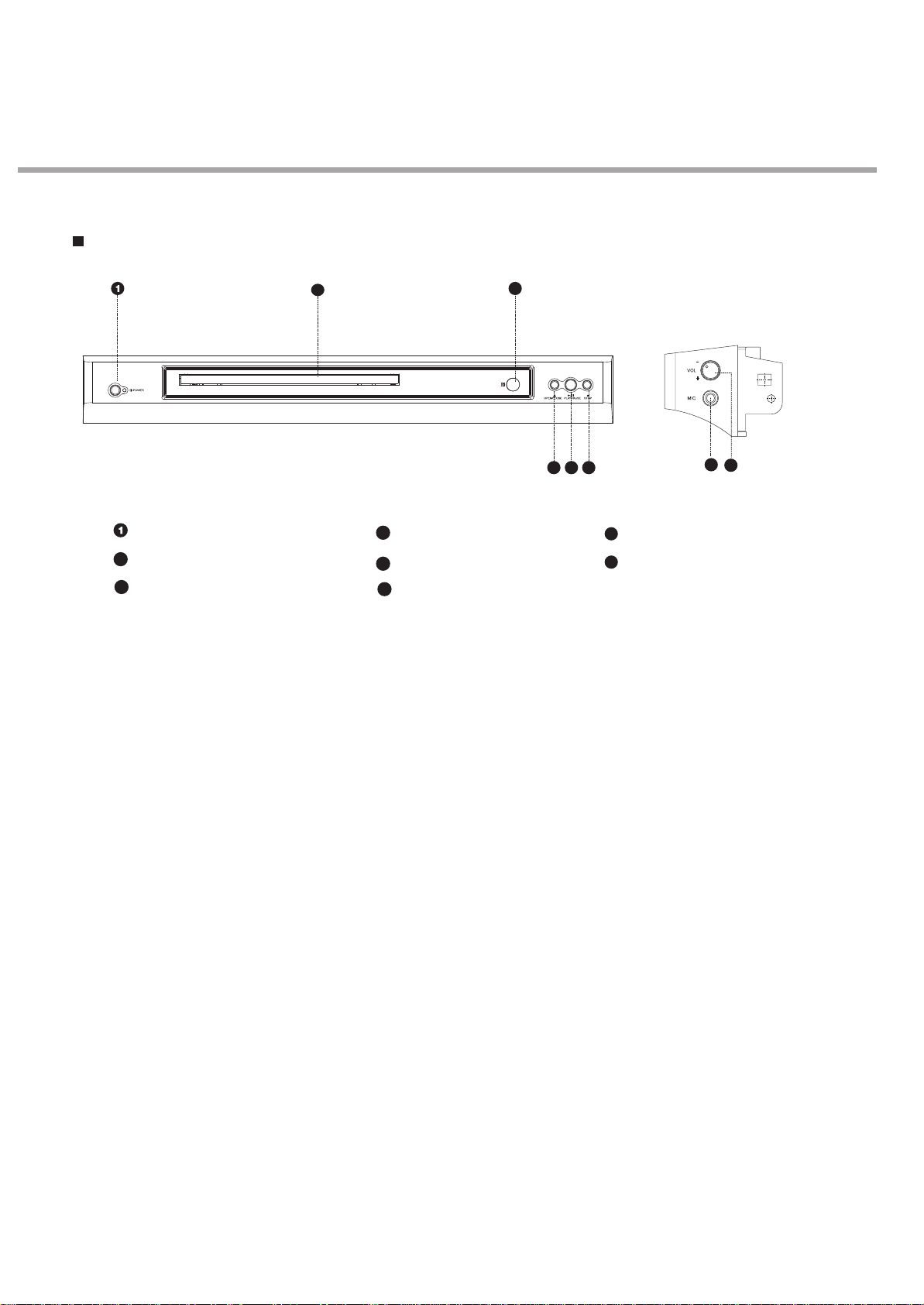

3.Control Button Locations and Explanations

2

Front Panel Illustration

POWER switch

Disc tray

2

3

IR SENSOR button

2

4

OPEN/CLOSE button

PLAY/ buttonPAUSE

5

6

STOP button

3

7

4

5

6

7

MIC jack

8

MIC VOLUME button

8

The laser diode in the traverse unit (optical pickup)may brake down due to static electricity of clothes or human

body. Use due caution to electrostatic breakdown when servicing and handling the laser diode.

Some devices such as the DVD player use the optical pickup(laser diode)and the optical pickup will be damaged

by static electricity in the working environment.Proceed servicing works under the working environment where

1. Put a conductive material(sheet)or iron sheet on the area where the optical pickup is placed,and ground the

3. The flexible cable may be cut off if an excessive force is applied to it.Use caution when handling the cable.

3

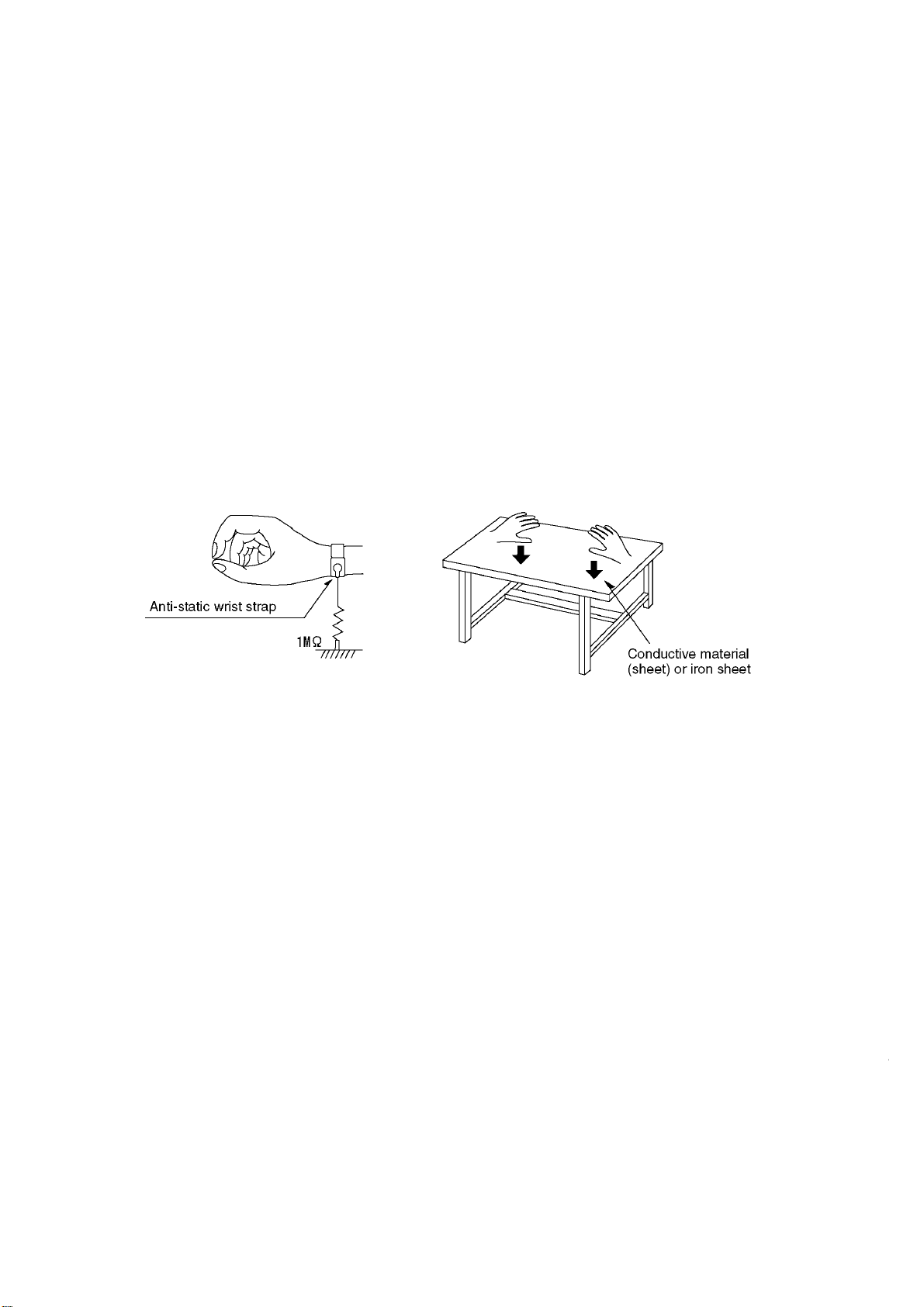

4.PREVENTION OF STATIC ELECTRICITY DISCHARGE

4.1.Grounding for electrostatic breakdown prevention

grounding works is completed.

4.1.1. Worktable grounding

sheet.

4.1.2.Human body grounding

1 Use the anti-static wrist strap to discharge the static electricity from your body.

safety_3 (1577x409x2 tiff)

4.1.3.Handling of optical pickup

1. To keep the good quality of the optical pickup maintenance parts during transportation and before

installation, the both ends of the laser diode are short-circuited.After replacing the parts with new ones,

remove the short circuit according to the correct procedure. (See this Technical Guide).

2. Do not use a tester to check the laser diode for the optical pickup .Failure to do so willdamage the laser

diode due to the power supply in the tester.

4.2. Handling precautions for Traverse Unit (Optical Pickup)

1. Do not give a considerable shock to the traverse unit(optical pickup)as it has an extremely high-precise

structure.

2. When replacing the optical pickup, install the flexible cable and cut is short land with a nipper. See the

optical pickup replacement procedure in this Technical Guide. Before replacing the traverse unit, remove

the short pin for preventingstatic electricity and install a new unit.Connect the connector as short times as

possible.

4. The half-fixed resistor for laser power adjustment cannot be adjusted. Do not turn the resistor.

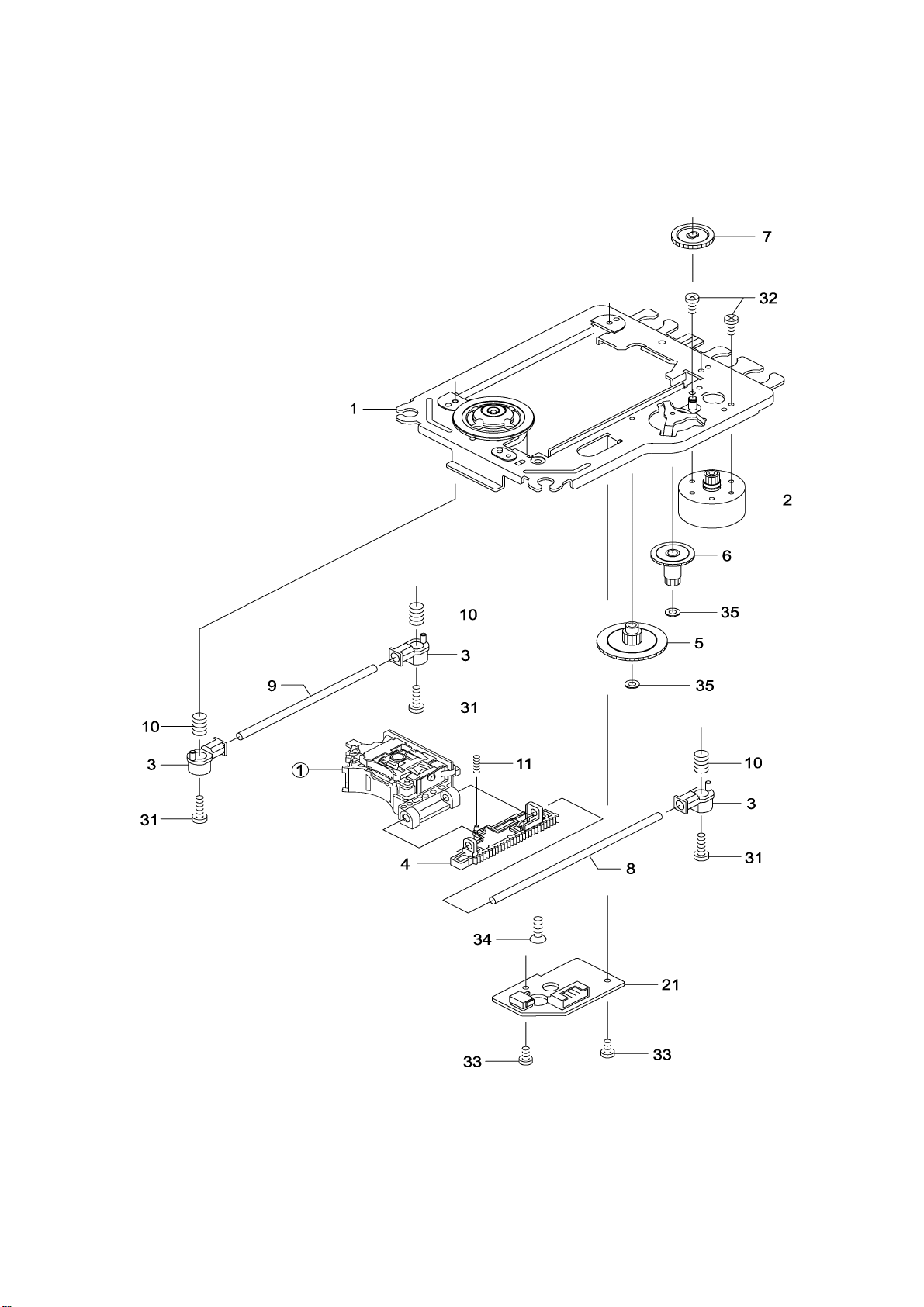

5.1 Optical pickup Unit Explosed View and Part List

5. Assembling and disassembling the mechanism unit

4

Pic (1)

Materials to Pic (1)

5

No. PARTS CODE PARTS NAME Q ty

14692200 SF-HD60 1

1

1EA0311A06300 ASSY, CHASSIS, COMPLETE 1

2

Or

3

4

5

6

7

8

9

10

11

21

Or

31

32

1EA0M10A15500 ASSY, MOTOR, SLED 1

1EA0M10A15501 ASSY, MOTOR, SLED 1

1EA2451A24700 HOLDER, SHAFT 3

1EA2511A29100 GEAR, RACK 1

1EA2511A29200 GEAR, DRIVE 1

1EA2511A29300 GEAR, MIDDLE, A 1

1EA2511A29400 GEAR, MIDDLE, B 1

1EA2744A03000 SHAFT, SLIDE 1

1EA2744A03100 SHAFT, SLIDE, SUB 1

1EA2812A15300 SPRING, COMP, TYOUSEI 3

1EA2812A15400 SPRING, COMP, RACK 1

1EA0B10B20100 ASSY, PWB 1

1EA0B10B20200 ASSY, PWB 1

SEXEA25700--- SPECIAL SCREW BIN+-M2X11 3

SEXEA25900--- SPECIAL SCREW M1.7X2.2 2

33

34

35

Note : This parts list is not for service parts supply.

SFBPN204R0SE- SCR S-TPG PAN 2X4 2

SFSFN266R0SE- SCR S-TPG FLT 2.6X6 1

SWXEA15400--- SPECIAL WASHER 1.8X4 X0.25 2

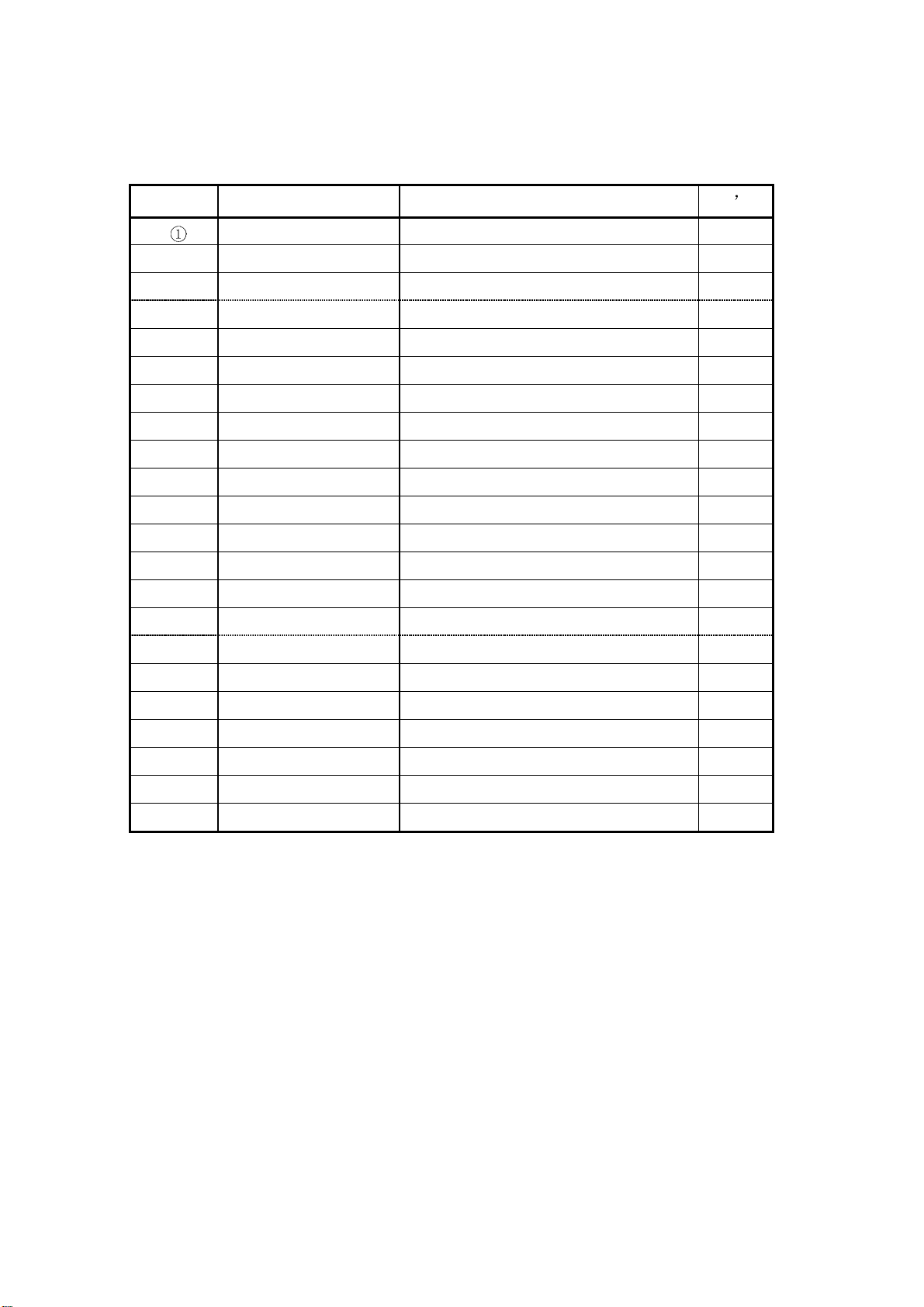

5.2 Bracket Explosed View and Part List

6

Pic (2)

Materials to Pic(2)

1.bracket 14. front silicon rubber

2.belt 15. Back silicon rubber

3.screw 16. Pick-up

4.belt wheel 17. Pick-up

5.gearwheel 18. switch

6.iron chip 19. Five-pin flat plug

7. Immobility mechanism equipment 20. screw

8. Magnet 21. PCB

9. Platen 22. motor

10. Bridge bracket 23. Motor wheel

11. screw 24. screw

12. screw 25.tray

13. Big bracket

Before going process with disassembly and installation, please carefully both

peruse the chart and confirm the materials.

5.3 MISCELLANEOUS

7

5.3.1 Protection of the LD(Laser diode)

Short the parts of LD circuit pattern by soldering.

5.3.2 Cautions on assembly and adjustment

Make sure that the workbenches,jigs,tips,tips of soldering irons and measuring instruments are

grounded,and that personnel wear wrist straps for ground.

Open the LD short lands quickly with a soldering iron after a circuit is connected.

Keep the power source of the pick-up protected from internal and external sources of electrical

noise.

Refrain from operation and storage in atmospheres containing corrosive gases (such as H2S,SO2,

NO2 and Cl2)or toxic gases or in locations containing substances(especially from the organic silicon,cyan,

formalin and phenol groups)which emit toxic gases.It is particularly important to ensure that none of the

above substances are present inside the unit.Otherwise,the motor may no longer run.

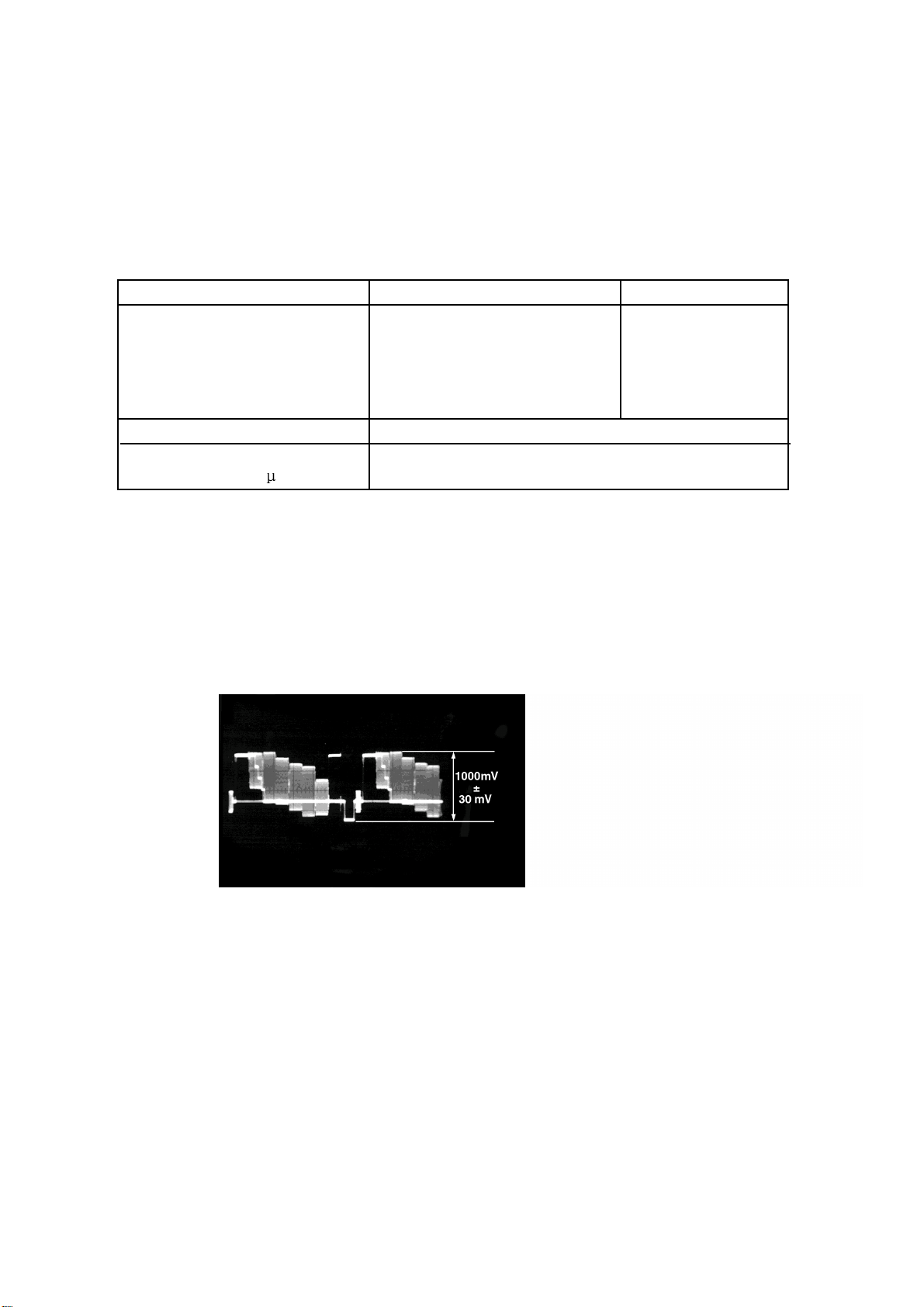

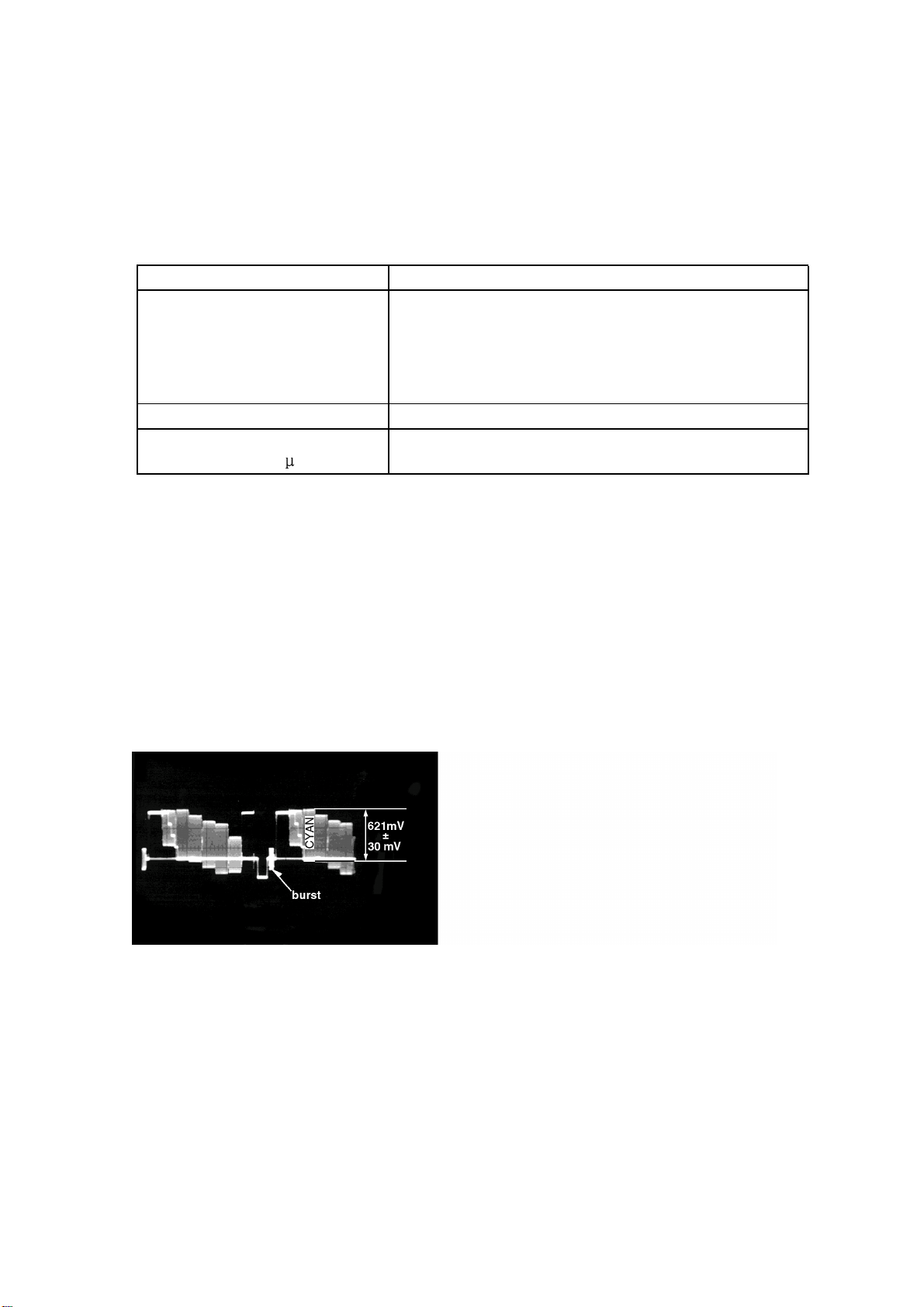

6.1. Video Output (Luminance Signal) Confirmation

6.Electrical Confirmation

8

DO this confirmation after replacing a P.C.B.

Measurement point

Video output terminal

Measuring equipment,tools

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohms.

2.Confirm that luminance signal(Y+S)level is 1000mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Mode Disc

Color bar 75%

Confirmation value

1000mVp-p±30mV

DVDT-S15

or

DVDT-S01

Do the confirmation after replacing P.C.B.

Screwdriver,Oscilloscope

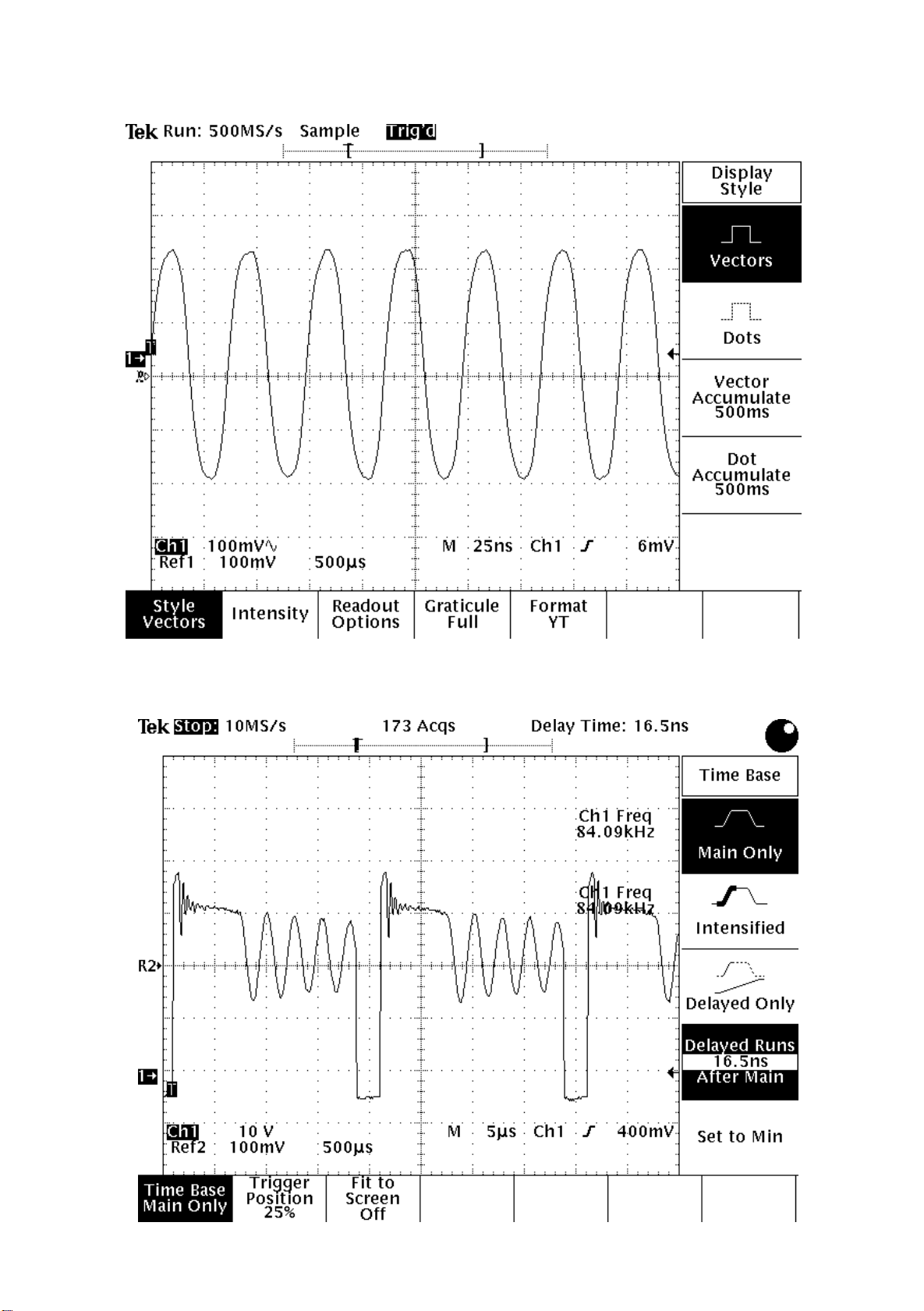

6.2 Video Output(Chrominance Signal) Confirmation

9

Measurement point

Video output terminal

Measuring equipment,tools Confirmation value

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohme.

2.Confirm that the chrominance signal(C)level is 621 mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Mode Disc

Color bar 75%

621mVp-p±30mV

DVDT-S15

or

DVDT-S01

7.MPEG BOARD CHECK WAVEFORM

7.1 27MHz WAVEFORM

7.2 ICVIPER22 PIN.5 WAVEFORM DIAGRAM

10

Loading...

Loading...