Page 1

DV112SI

DV113SI

DV123SI

service manual

Page 2

Catalog

Chapter One About Maintenance

1.1 Safety precautions

1.1.1 Power supply

1.1.2 Precautions for antistatic

1.1.3 Precautions for laser head

1.1.4 About placement position

1.2 Maintenance method

1.2.1 Visualized method

1.2.2 Electric resistance method

1.2.3 Voltage method

1.2.4 Current method

1.2.5 Cutting method

1.2.6 Element substitution method

1.2.7 Comparison method

1.3 Required device for maintenance

1

1

1

1

1

2

2

2

2

2

2

2

3

3

3

Chapter Two Functions and Operation Instructions

2.1 Features

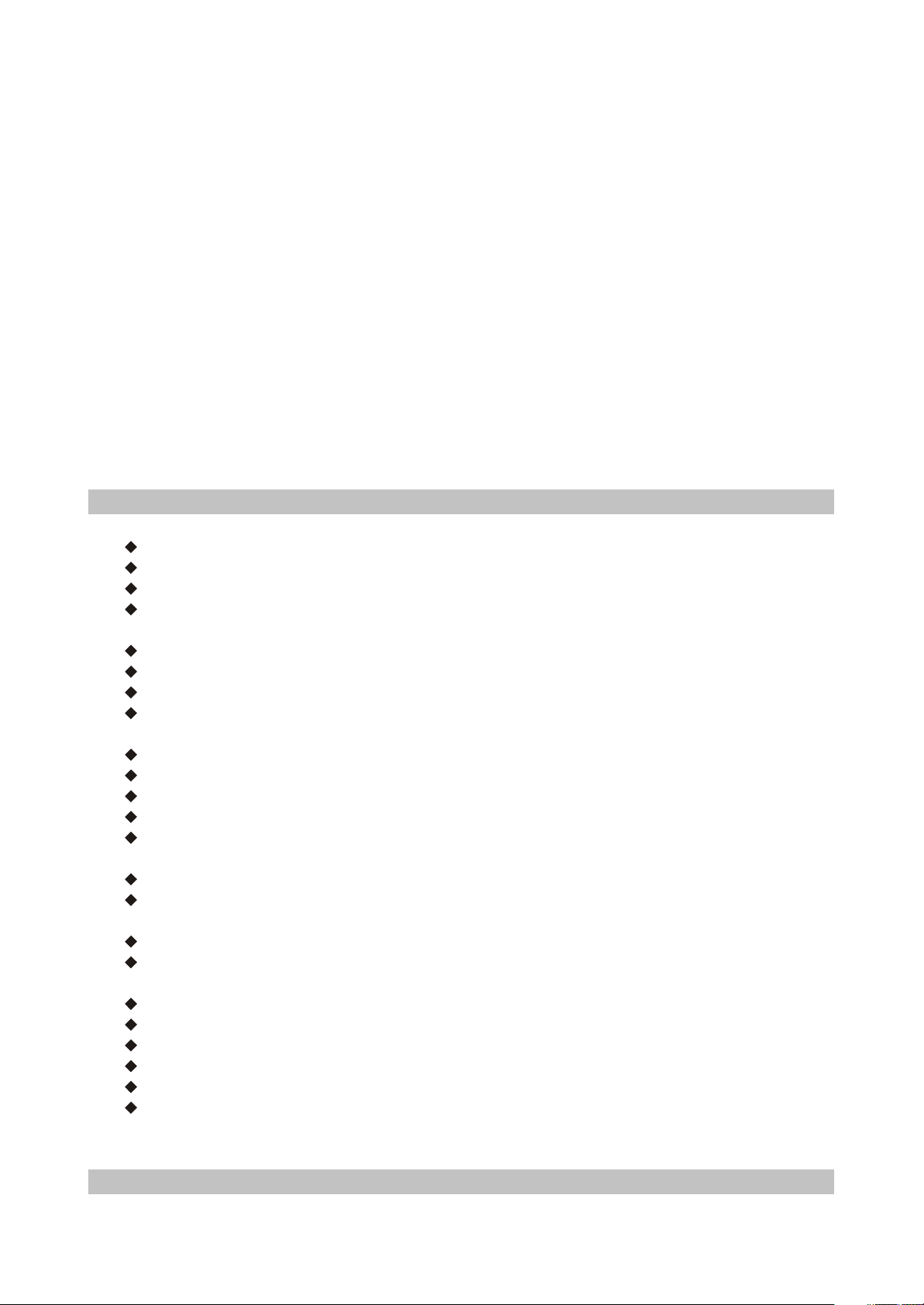

2.2 Control Button Locations and Explanations

2.2.1 Front Panel Illustration

2.2.2 Rear Panel Illustration

2.2.3 Display Window Illustration

2.2.4 Remote Control Illustration

2.3 Accessories

2.4 FUNCTION SETUP

2.4.1 Function Setup

2.4.2 Language

2.4.3 Image

2.4.4 Sound

2.4.5 Playback

4

4

4

4

5

5

5

6

7

7

7

7

8

8

Page 3

2.4.6 Preference

9

2.4.7 Parental control

2.4.8 Initial setup

2.4.9 Rest to defaults

2.4.10 Exit

2.5 Specifications

Chapter Three Principle and Servicing

Section One Principle of the Player

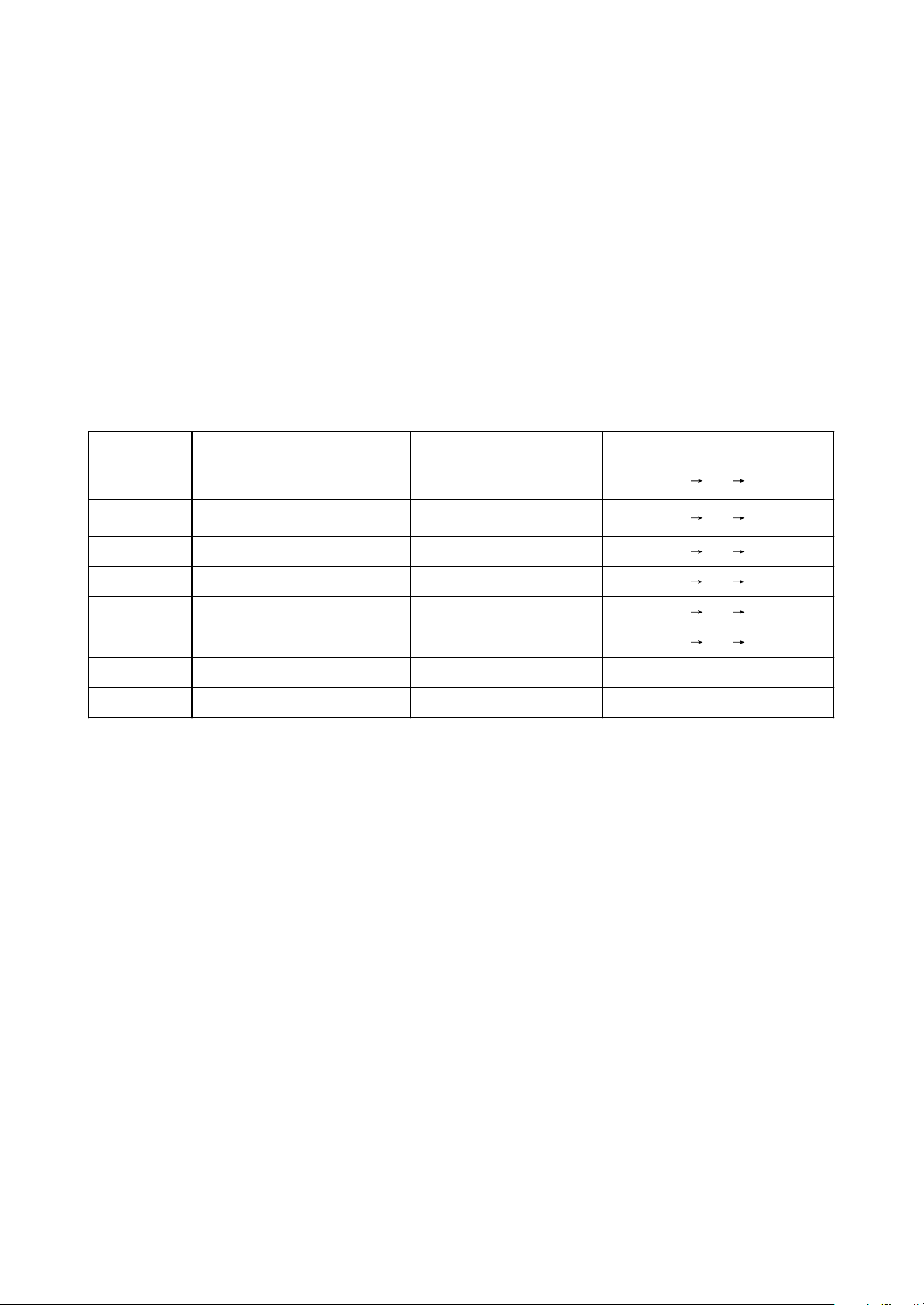

3.1.1 Block diagram of the player

3.1.2 PCB board block diagram of the player

3.1.3 How to use IC

Section Two Unit Circuit Principle

3.2.1 Introduction to laser head

3.2.2 Servo circuit

3.2.3 Open/close drive circuit

9

9

9

9

9

11

11

11

12

13

14

14

16

18

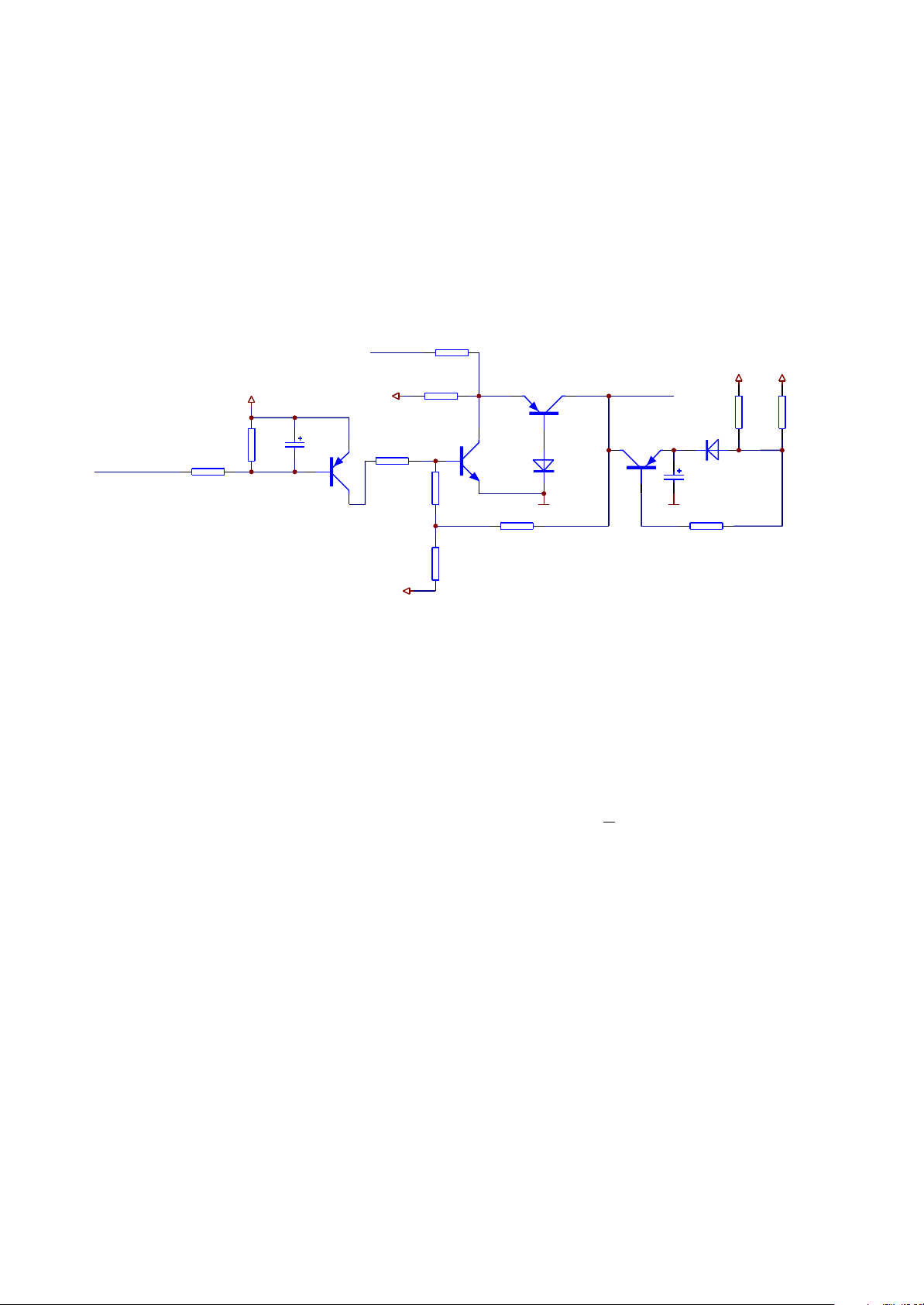

3.2.4 Laser power control circuit

3.2.5 CD/DVD conversion circuit

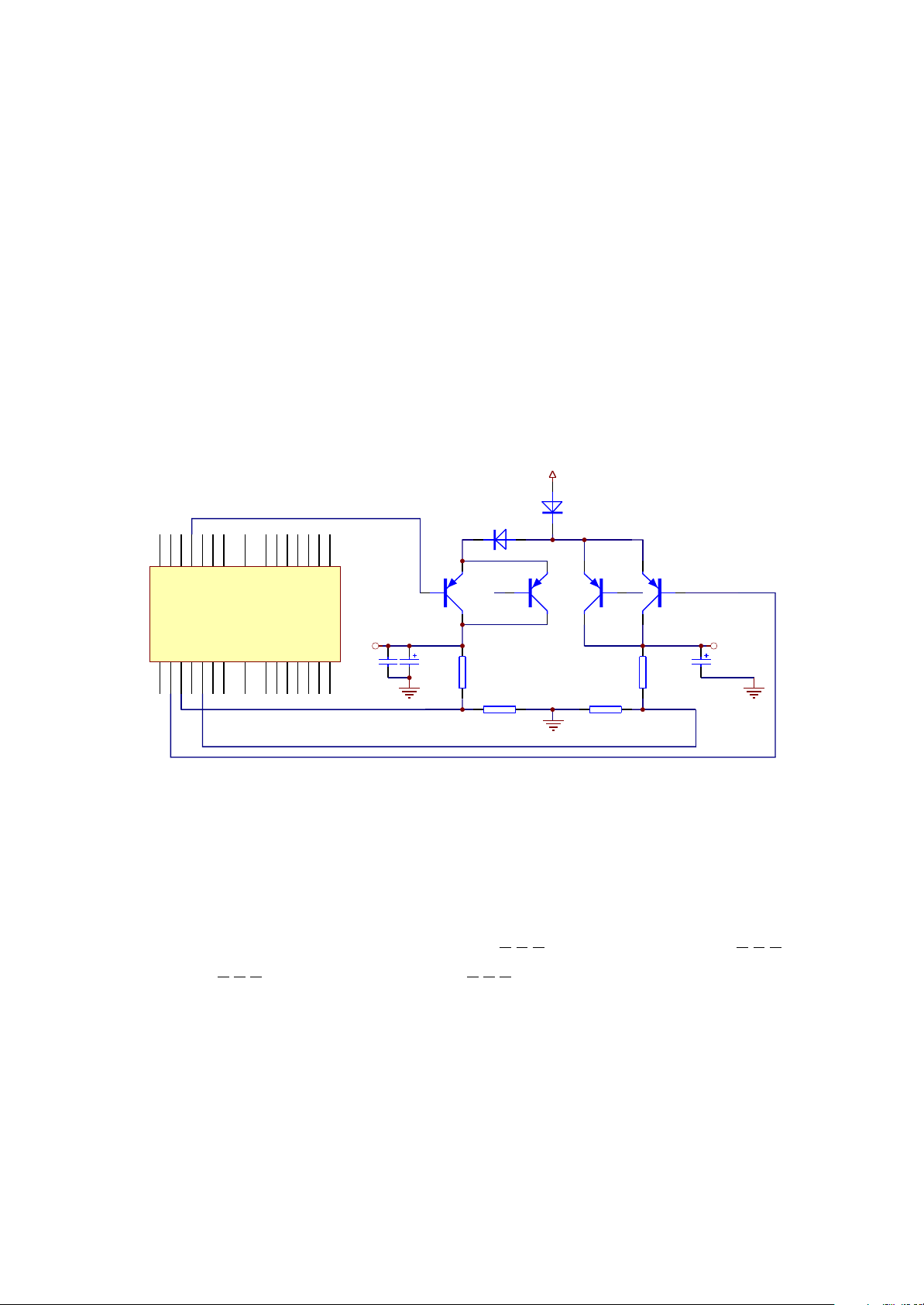

3.2.6 Main axis control circuit

3.2.7 Decode circuit

3.2.8 Reset circuit

3.2.9 Video circuit

3.2.10 Audio circuit

3.2.11 Mute circuit

3.2.12 Decode circuit voltage regulating

3.2.13 Panel control circuit

3.2.14 MIC circuit

3.2.15 Power circuit

Section Three Servicing Cases

3.3.1 Servicing cases

3.3.2 Troubleshooting flow chart

18

19

20

21

22

23

24

25

26

27

27

27

29

29

35

Section Four

Section Five Function Introduction to IC

3.5.1 function introduction to MT1389 D

3.5.2 function introduction to 4558

Waveform diagram

47

53

53

61

Page 4

3.5.3 function introduction to AT24C02

62

3.5.4 function introduction to TDA1308

3.5.5 function introduction to VIPer22ADIP

3.5.6 function introduction to AM5888S

3.5.7 function introduction to PT6961(4dv315)

3.5.8 Function introduction to SDRAM

3.5.9 Function introduction to FLASH

3.5.10 Function introduction to LM431A

3.5.11 Function introduction to Pc817

Chapter Four Disassembly and Assembly Process

Chapter Cinque PCB board & Circuit diagram

Section One PCB board

Section Two circuit diagram

63

64

65

67

68

69

70

71

72

73

73

80

Chapter six BOM List

DV123SI Service Manual

7.1.1 PCB composition figure of the player

7.2.1 Panel control circuit

7.2.2 MIC circuit

7.3.1 PCB board

7.3.2 circuit diagram

87

94

94

95

95

96

100

Page 5

Chapter One About Maintenance

1.1 Safety precautions

1.1.1 Power supply

When maintenance personnel are repairing DVD players, he should pay special attention to the

power board with 220V AC and 330V DC which will cause hurt and damage to persons!

1.1.2 Precautions for antistatic

Movement and friction will both bring static electricity which causes serious damages to integrated

IC. Though static charge is little, when a limited quantity of electric charge is added to large-

scaleintegrated IC, as the capacitance is very small in the meantime, now the integrated IC is very much

easy to be struck through by static electricity or the performance will decrease. Thus static electricity

prevention is of extraordinary importance. The following are several measures to prevent static

electricity:

1. Use a piece of electric conduction metal with the length of about 2 metres to insert into the earth,

and Fetch the lead wire from the top of the surplus metal and connect to the required static electricity

device. The length and depth of the metal embedded under the earth should be determined according to

the wettability of the local soil. For humid places, it may be shorter, and longer and deeper for dry places.

If possible, it can be distributed and layed in terms of “#” shape.

2. On operating table-board, the antistatic table cushion should be covered and grounded.

3. All devices and equipments should be placed on the antistatic table cushion and grounded.

4. Maintenance personnel should wear antistatic wrist ring which should be grounded.

5. Places around the operating position should also be covered with electric conduction cushion or

Painted with antistatic paint.

1.1.3 Precautions for laser head

1. Do not stare at laser head directly, for laser emission will occur when laser head is working, which

will Hurt your eyes!

2. Do not use wiping water or alcohol to clean laser head, and you may use cotton swab.

- 1 -

Page 6

1.1.4 About placement position

1. Never place DVD player in positions with high temperature and humidity.

2. Avoid placing near high magnetic fields, such as loudspeaker or magnet.

3. Positions for placement should be stable and secure.

1.2 Maintenance method

1.2.1 Visualized method

Directly view whether abnormalities of collision, lack of element, joint welding, shedding welding,

rosin joint, copper foil turning up, lead wire disconnection and elements burning up among pins of

elements appear. Check power supply of the machine and then use hands to touch the casing of part of

elements and check whether they are hot to judge the trouble spot. You should pay more attention when

using this method to check in high voltage parts.

1.2.2 Electric resistance method

Set the multimeter in resistance position and test whether the numerical value of resistance of each

point in the circuit has difference from the normal value to judge the trouble spot. But in the circuit the

tested numerical value of resistance is not accurate, and the tested numerical value of integrated IC's

pins can only be used for reference, so the elements should be broken down for test.

1.2.3 Voltage method

Voltage method is relatively convenient, quick and accurate. Set the multimeter in voltage position

and test power supply voltage of the player and voltage of a certain point to judge the trouble spot

according to the tested voltage variation.

1.2.4 Current method

Set the multimeter in current position and test current of the player of a certain point to judge the

trouble spot. But when testing in current method, the multimeter should be series connected in the

circuit, which makes this method too trivial and troublesome, so it is less frequently used in reality.

1.2.5 Cutting method

Cutting method should be combined with electric resistance method and voltage method to use.

This method is mainly used in phenomena of short circuit and current leakage of the circuit. When

cutting the input terminal voltage of a certain level, if voltage of the player rises again, it means that the

trouble lies in this level.

- 2 -

Page 7

1.2.6 Element substitution method

When some elements cannot be judged good or bad, substitution method may de adopted directly.

1.2.7 Comparison method

A same good PC board is usually used to test the correct voltage and waveform. Compared these

data with those tested through fault PC board, the cause of troubles may be found.

Through the above maintenance method, theoretical knowledge and maintenance experience, all

difficulties and troubles will be readily solved.

1.3 Required device for maintenance

Digital oscillograph ( 100MHE)

TV set

SMD rework station

Multimeter

Soldering iron

Pointed-month pincers

Cutting nippers

Forceps

Electric screw driver

Terminals connecting cord

Headphone

Microphone

- 3 -

Page 8

Functions and Operation Instructions

2.1 Features

Compatible Disc Types:

Digital video playback:DVD-Video, Super VCD, VCD Compatibility.

Digital audio playback:CD-DA and HDCD compatibility

Fully compatible with compressed audio files such as Mp3and WMA.

Digital graphic albums playback:kodak picture CD, JPEG compatibility.

Audio:

Coaxial output for Dolby Digital/DTS/LPCM digital audio.

Mixed audio output for amplifier or TV connection.

Digital multi-channel decoders, providing Dolby Digital/DTS audio stream playing.

MIC input for karaoke function.

Video:

108 MHZ/12 bit video Digital/Analog converter.

Composite, S-Video and RGB/SCART outputs for various types of connections.

Capable of playing NTSC/PAL discs.

Multiple dubbings, angles, subtitles support.

Sharpness, gamma, brightness, contrast, hue, saturation adjustment.

Others:

Compatible disc types:CD-R/CD-RW, DVD-R/DVD-RW, DVD+R/DVD+RW

Russia, CIS and Baltic States adaptation interface and filenames, ID3-tags and CD-Text support

simplifies device operation.

"Memory” function enables to save the last point after stop playback.

"Q-play” function provides direct playback and allows to skip commercial that is not possible to

rewind.

"Captrue” function allows to save any picture as background.

"Virtual Keyboard” function provides more convenient DVD playback control.

"Browser” function provides easy access to playback control.

Automatic Screenaver function.

Parental control function to protect children from watching inappropriate discs.

Super wide range of operating power supplies(~110-250V, 50/60Hz), automatic short circuit

protection.

Chapter Two

2.2 Control Button Locations and Explanations

2.2.1 Front Panel Illustration

- 4 -

Page 9

1

1

DV112SI and DV113SI

2

2

3

3

4

5

8

4

6

7

5

6

7

8

2.2.4 Remote Control Illustration

1

POWER switch

2

;Disc tray

3

OPEN/CLOSE button

:

4

5

6

2.2.2 Rear Panel Illustration

1

Digital Audio Coaxial Out jack

2

2CH Audio Out jacks

3

S-Video

2.2.3 Display Window Illustration

Display window*

PLAY/PAUSE button

STOP button

4

5

9

Video Out jack

SCART Out jack

7

MIC jack

8

MIC volume control

9

IR sensor button

2.2.4 Remote Control Illustration

1

[ ]

Button

Open or close the dis tray.

2

LANG Button

Change the audio language or audio channel.

3

MEMORY Button

Save the playing point or jump to the saved point

4

DISP Button

Display or hide disc information.

5

NUMBER Buttons

Playback time

- 5 -

6

BROWSE Buttons

Switch new user interface.

7

CURSOR Buttons

8

SETUP Button

Function Setup.

[ ]

9

Button

Open/close the keyboard function.

[ ]

10

Button

Adjust picture ratio

Page 10

[ ]

11

Button

Fast backward play.

[ ]

12

Button

Skip backward.

13

PEPEAT Button

Repeat play.

14

A-B Button

Repeat the select.

[ ]

15

Button

Press once to stand by, Press twice to play.

16

SUBT Button

Change subtitle language, Switch JPEG

Display mode.

17

Q-PLAY Button

Skip the advertisement/warning and play the DVD

directly.

18

ANGLE Button

27

CAPTURE Button

Set the played image as the Power-on logo.

28

VOL +/- Button

Increase/decrease volume level.

29

MUTE Button

Press once to mute, twice to turn off.

2.3 Accessories

AUDIO/VIDEO CORD

REMOTE

AAA SIIZE BATTERIES

WARRANTY CARD

USER MANUAL

KARAOKE DISC

Change camera angle

19

MENU Button

Display DVD menu or open/close PBC.

20

OK Button

21

Cancel Button

22

ZOOM +/- Button

Zoom in/out the displayed frame.

[ ]

23

Button

.

Play or pause playback

[ ]

24

Button

Fast forward play.

[ ]

25

Button

Stop playback.

[ ]

26

Button

Skip forward.

1PCS

1PCS

2PCS

1PCS

1PCS

1PCS

- 6 -

Page 11

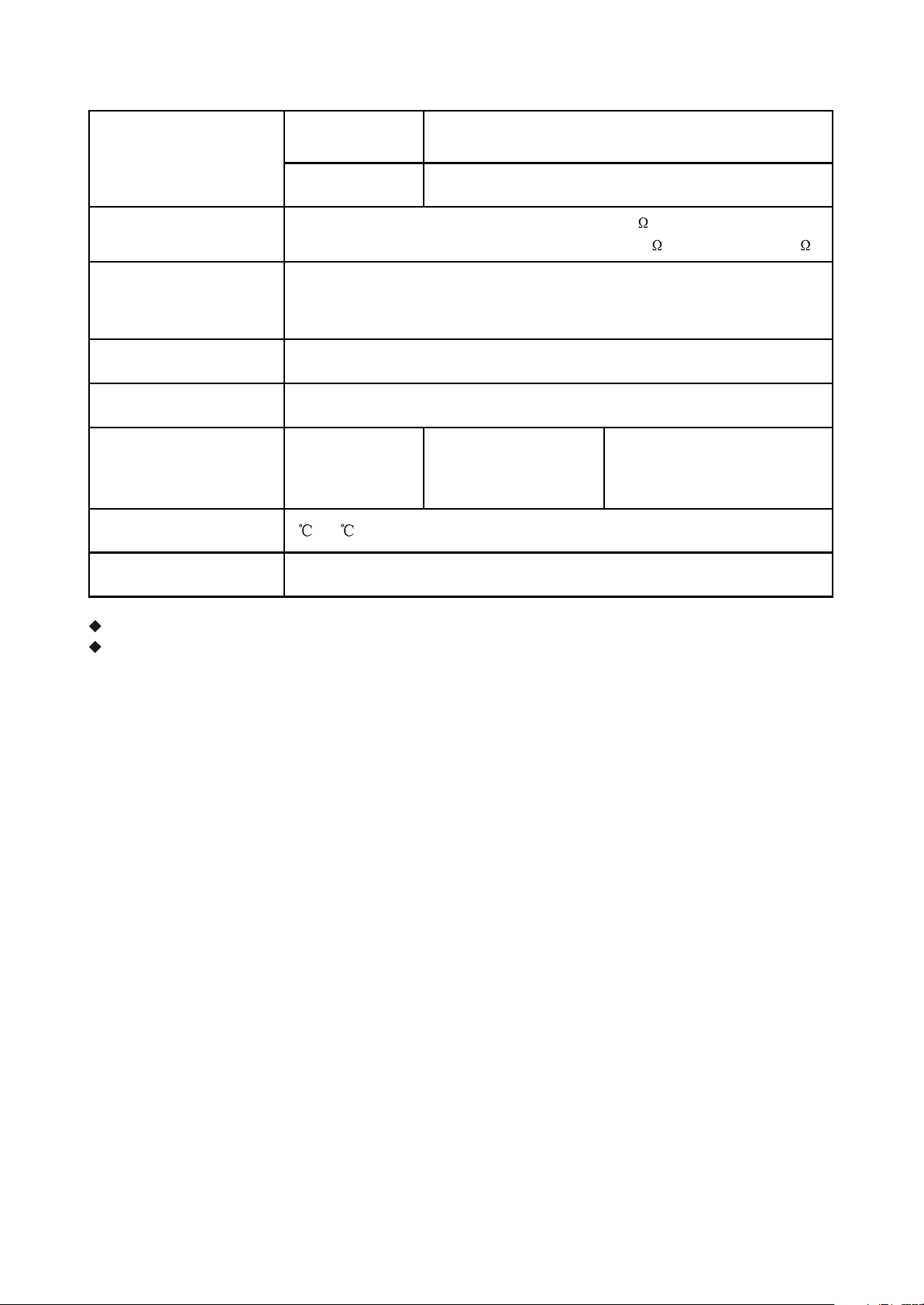

2.4 FUNCTION SETUP

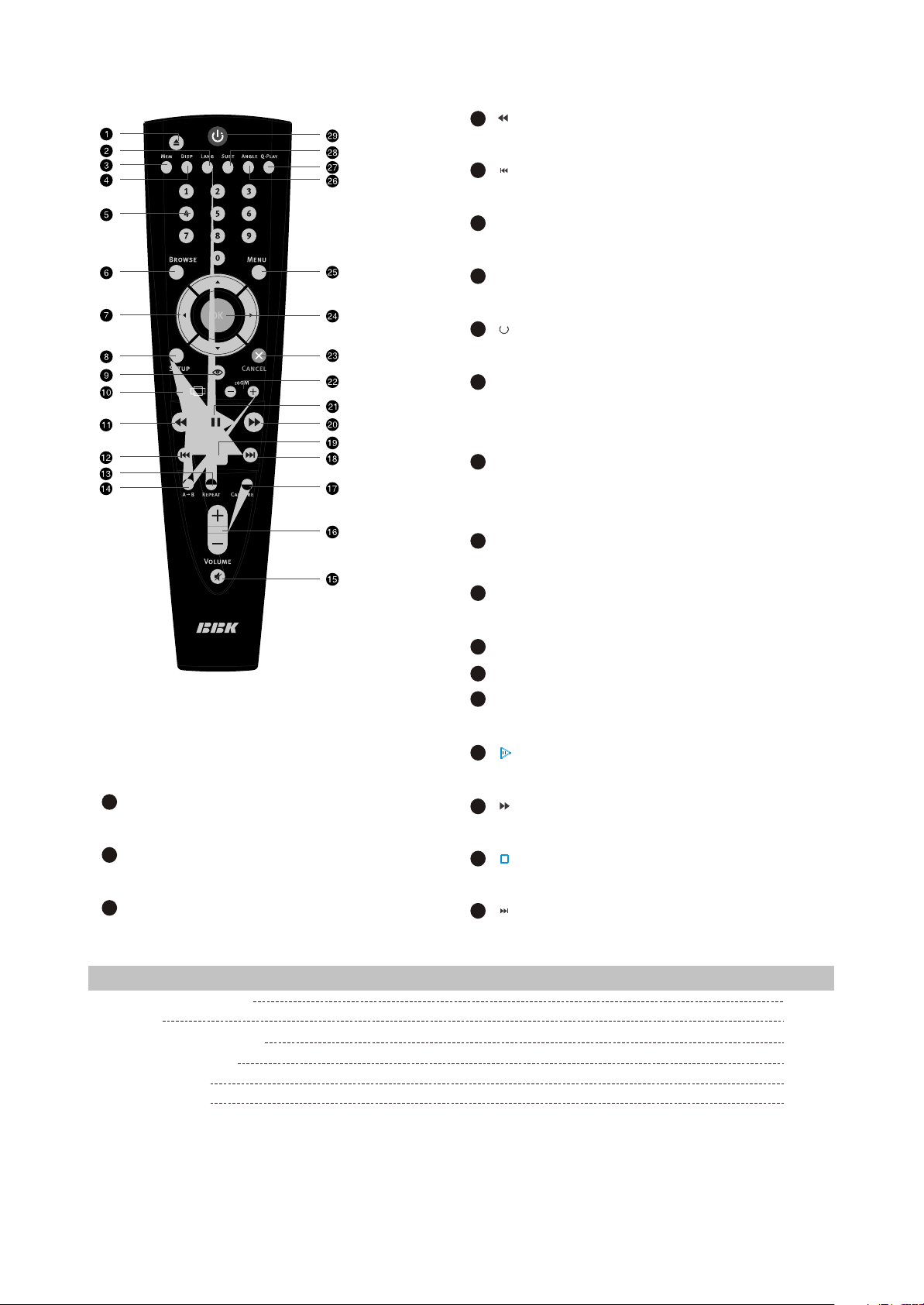

2.4.1 Function Setup

1.Press The [SETUP] Button and The screen

displays the selection Menu of function setup.

Off

Com.

LB

L.

0

0

0

0

LB

L.

Off

0

0

0

0

Setup menu

DVD menu

Soundtrack

Subtitle

AUTO

PAL

NTSC

High

Medium

Low

Off

Language

Image

Sound

Playback

Preference

Parental control

Initial setup

Reset to defaults

Exit

2.Press the [CURSOR] button to select the menu

to be entered and press the [OK] or button to

confirm.Or press the [CURSOR] button to Exit

item and then press the [OK] button to exit .

3.Press [UP/DOWN] arrow to select the desired

item you want to set and press [OK].

For example, press [UP/DOWN] arrows to

select IMAGE and press [OK]. The Image setting

page appears on the screen.

TV system

Video out.

TV format

Sharpness

Gamma

Brightness

Contrast

Hue

Saturation

AUTO

S-Vid.

4.Press [UP/DOWN] arrow to select the

SHARPNESS item. Press [OK] to confirm

it.And then press [UP/DOWN] arrow to select

the desired valus.

For example: Press [UP/DOEN] arrow to

select Medium,then press [OK], the TV screen

display.

TV system

Video out.

TV format

Sharpness

Gamma

Brightness

Contrast

Hue

Saturation

AUTO

5.Press [LEFT] butt on if you not to return to

the previous setup page.

6. Press [SETUP] to exit the setup menu.

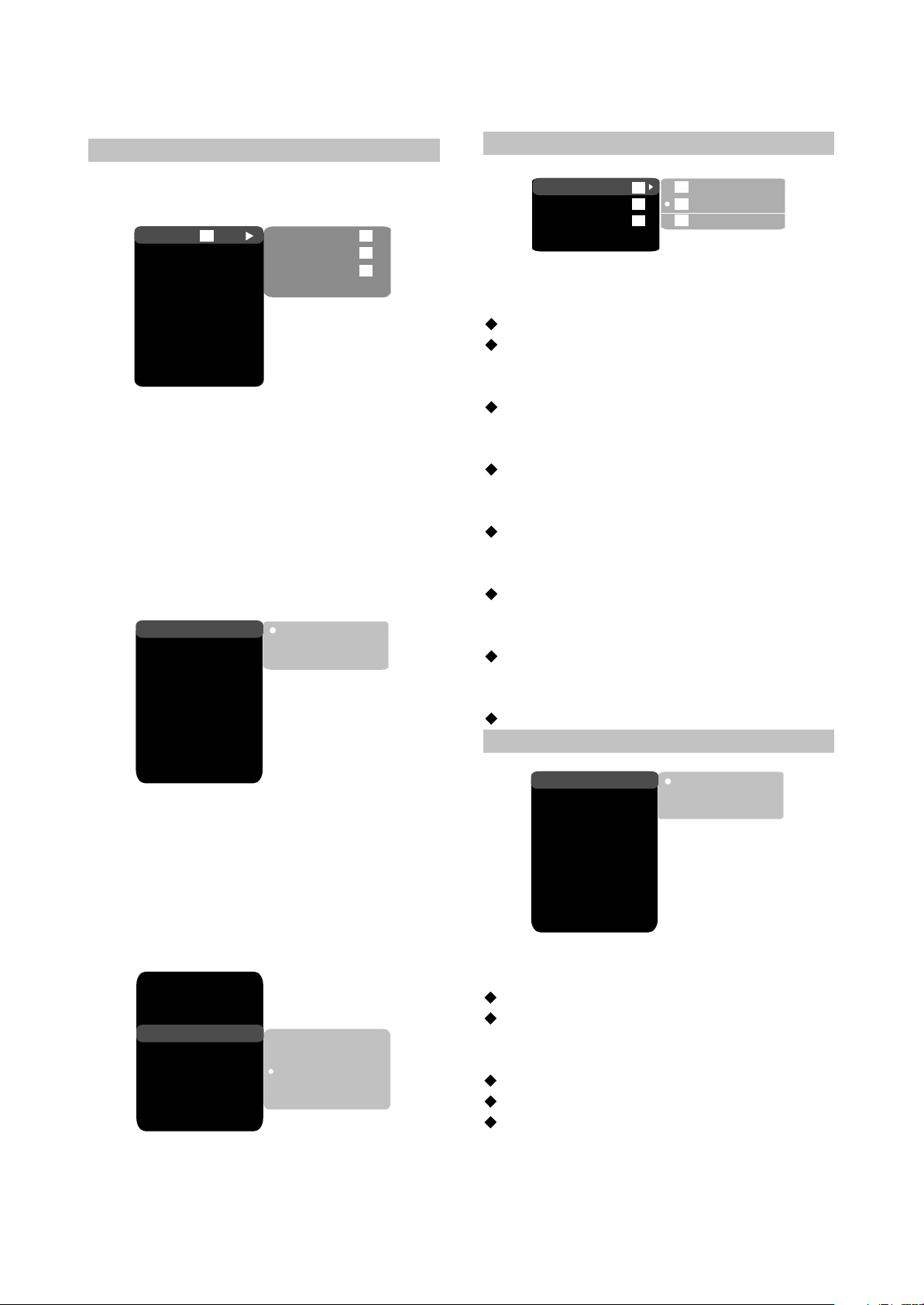

2.4.2 Language

Setup menu

DVD menu

Soundtrack

Sbutitles Off

1.Setup menu:This item Is used to se t the

prompts Language on The screen.

Optional setting: Russian, English, Ukrainian.

Default: English.

2.DVD menu: To Set the preference disc Menu

lang when playing.

Optional setting: Russian, English, Estonian,

Latvian, Kazakh, Romanian, Byelorussian,

Ukrainian, Chinese, Others.

Default: English.

3.Sountrack:To set the preference audio

Language when playing.

Optional setting: Russian, English, Estonian,

Latvian, Kazakh, Romanian, Byelorussian,

Ukrainian, Chinese, Others.

Default: English.

4.Subtitles: To Set the preference subtitle

Language when playing.

Optional setting: Off, Russian, English,

Estonian, Latvian, Kazakh, Romanian,

Byelorussian, Ukrainian, Chinese, Others.

Default: Off.

Russian

English

Ukrainian

2.4.3 Image

Off

AUTO

PAL

NTSC

LB

L.

0

0

0

0

TV system

Video out.

TV

format

Sharpness

Gamma

Brightness

Contrast

Hue

Saturation

AUTO

Com.

1.TV system: This Item is used to the video

output system of this unit.

Optional setting: Auto, PAL, NTSC.

Default: AUTO.

2.Video output: To Set the Types of SCART out

connector.

Optional setting: S-Video,Component, SCART,

Default: Component.

When using RGB outputs from the SCART

interface,Please select RGB.Other,please

select Com-and when using S-Video output

please select S-Video.

- 7 -

Page 12

3.TV format: To set the aspect ratio of This player

output image.

Optional setting: 4:3 Pan-scan, 16:9 letterb.

16:9 TV

Default: 16:9 letterb.

4.Sharpness:Used To set the sharpness of video

outputs.

Optional setting: High, Medium, Low.

Default: Medium.

5.Gamma emendation : This item is used To

setup the Gamma value of video output.

Optional setting: High, Medium, Low, Off.

Default: Off.

6.Brightness:Used to set the brightness of Video

outputs.

7.Contrast:Used to set the contrast of Video

outputs.

8.Hue: Used to set the hue of video outputs.

9. Saturation: Used to set the saturation of video

outputs.

Brightness, contrast, Hue and saturation

adjusting means:

A.Press [UP/DOWN] arrow In the video To select

The desired item you want to adjust.Press [OK]

or [RIGHT button] To enter the item's

adjustment.

B.Press [UP/DOWN] arrow to adjust the setting

value.

2.4.4 Sound

Mixer...

Digital output

Tuning

1.Mixer...

Stereo mix

Surr. Mix

A.Stereo mix: To set the output means of the left

or right audio when playing a Dolby disc with

separate two-channel audio.

Optional Setting: L+R, L, R.

Default: L+R.

B.Surr. Mix: To set output means of the surround

left and right audio when playing a stereo disc.

Optional setting: Off, sum, Virt. Surr.

Default: Off.

2.Digital output: select to set the format and

stream form of digital audio output.

A.SPDIF format:

Optional setting: RAW format, SPDIF/PCM.

Default: RAW format.

Stereo mix

Surr. Mix

L+R

off

L+R

off

L+R

L

R

B.LPCM

Optional setting: 48 kHz 16 bit, 96 kHz 24 bit.

Default: 48 kHz 16 bit.

3.Tuning:

A.Max volume: set the maximum volume limit.

B.Equalizer: To set Equalizer modes.

Optional setting: Off, Rock, Pop, Live, Dance,

Techno, Classic, Soft.

Default: Off.

C.Echo: To set different sound field effects.

Optional setting: Off, Concert, Living room,

Hall, Bathroom, Cave, Arena, Church.

Default: Off.

D.Tone balance : to set the tone level to match

your diapason when you're singing

Method to adjust tone control:

a.Press [UP/ DOWN] cursor buttons to select

"tone" item in Audio Setting page, and then

press [OK] or [RIGHT] button to enter

Adjustment Menu.

b.Press [UP/DOWN] cursor button to adjust

setting Value.

C.Press [OK] or [LEFT] button to return to Audio

Setting page after adjustments are done.

2.4.5 Playback

DVD

VCD/SVCD

Files

Repeat

Load effect

1.DVD: set whether information of advertisement

and warnings at the beginning of DVD disc is

skipped to play the movie directly.

Always skip ads

Optional setting: Yes,

Default: Number

2.VCD/SVCD: To set the PBC status.

When playing Super VCD or VCD2.0 discs, if

the PBC Is ON, The menu image displays

Optional setting: On, Off.

Default: On.

3.Files: data disc may probably includes Mp3,

JPEG format files in which you may select DVD

player to read the file type.

Optional setting: Audio, Picture.

Default: Audio, Picture.

4.Repeat : select the repeat playback mode.

Optional setting: Off, Single, all.

Default: Off.

5.Load effect: set the may to play JPEG image.

Optional setting: Off, from top, from bottom.

Advertisemenu No

A. P

Off

Off

- 8 -

Page 13

Default: Off.

Playable discs

Inputs

DVD-Video, Super VCD, VCD, CD-DA, CD+G, HDCD, MP3, Kodak

piclure CD, JPEG

MIC INPUT

2.4.6 Preference

Gr. equalizer

Background

Screen saver

Off

std.

On

On

Off

Old password

New password

Verify

OK Cancel

1.Gr. equalizer: This item is used to set wether

the Dynamic Spectrum is allowed.

Optional setting: On, Off.

Default: Off.

2.Background: This item is used ti setup the sort

of Power-in Logo.

Optional setting: Standard, saved.

Default: Standard.

NOTE

The Screen Logo refers that use the image

selected by pressing the [CAPTURE] button as

the power-on logo.When in the operation of

changing screen, if the power -on logo has not

set in Screen Logo, the unit will automatically set

the power-on logo as screen logo.

3.Screen saver: Open or close the screen saver

function.

Optional setting: On, Off.

Default: On.

2.4.7 Parental control

Any

Kid

G

Allowed..

Set password

Any

1.Allowed..: To set the parental control ratings to

prevent children from watching the restricted

contents.( In case the disc supports this

function.)

Optional setting: any, Kid, G, PG, PG-13, PGR,

R, NC-17.

Default: any.

2. Set password: To set four digit password to

enable you to change the parental control

ratings.

Default: 7890.

PG

PG-13

PGR

R

NC-17

2.4.8 Initial setup

Auto

PAL

NTSC

Press [UP/DOWN] arrow to select the

desired option and press [OK] button to confirm it.

NOTE

In this setup state, you may not press [LEFT]

button to return to the previous menu.

2.4.9 Rest to defaults

Load factory settings

OK

Cancel

Reset to defaults: To restore all settings to

the default Value except for the parental control

and password settings.

2.4.10 Exit

Language

Image

Sound

Playback

Karaoke

Preference

Parental control

Initial setup

Reset to defaults

Exit

Press [UP/DOWN] arrow to select the Exit

item. Press [OK] button to exit the setup menu.

2.5 Specifications

- 9 -

Page 14

Audio outputs

Video outputs Composite, S-Video RGB/SCART

Video characteristics

Audio characteristics

Operating voltage

Power Consumption

General Specification

Dimensions:

Mass:

DU112SI, DV113SI

320×224×41mm

1.7kg

DV123SI

420×275×47mm

2.3kg

Operating temperature

Operating humldlty

Outputs

20W

5 -35

15%-75%(no conden sation)

Analog audio output: Stereo

Digital audio output: Coaxial

Video amplitude: 1.0Vp-p(75 )

S-Video amplitude: Y:1.0Vp-p(75 ) C:0.286Vp-p(75 )

Frequency response 20-20000Hz(±1dB)

Signal-to-noise ratio >100(dB)

THD <0.01%

~100V-250V, 50/60Hz

Design and specifications are subject to change without notice.

We do not guarantee that all discs can be played smoothly due to the disc quality, disc recording

quality and recording format.

- 10 -

Page 15

Chapter Principle and Servicing

Section One Principle of the Player

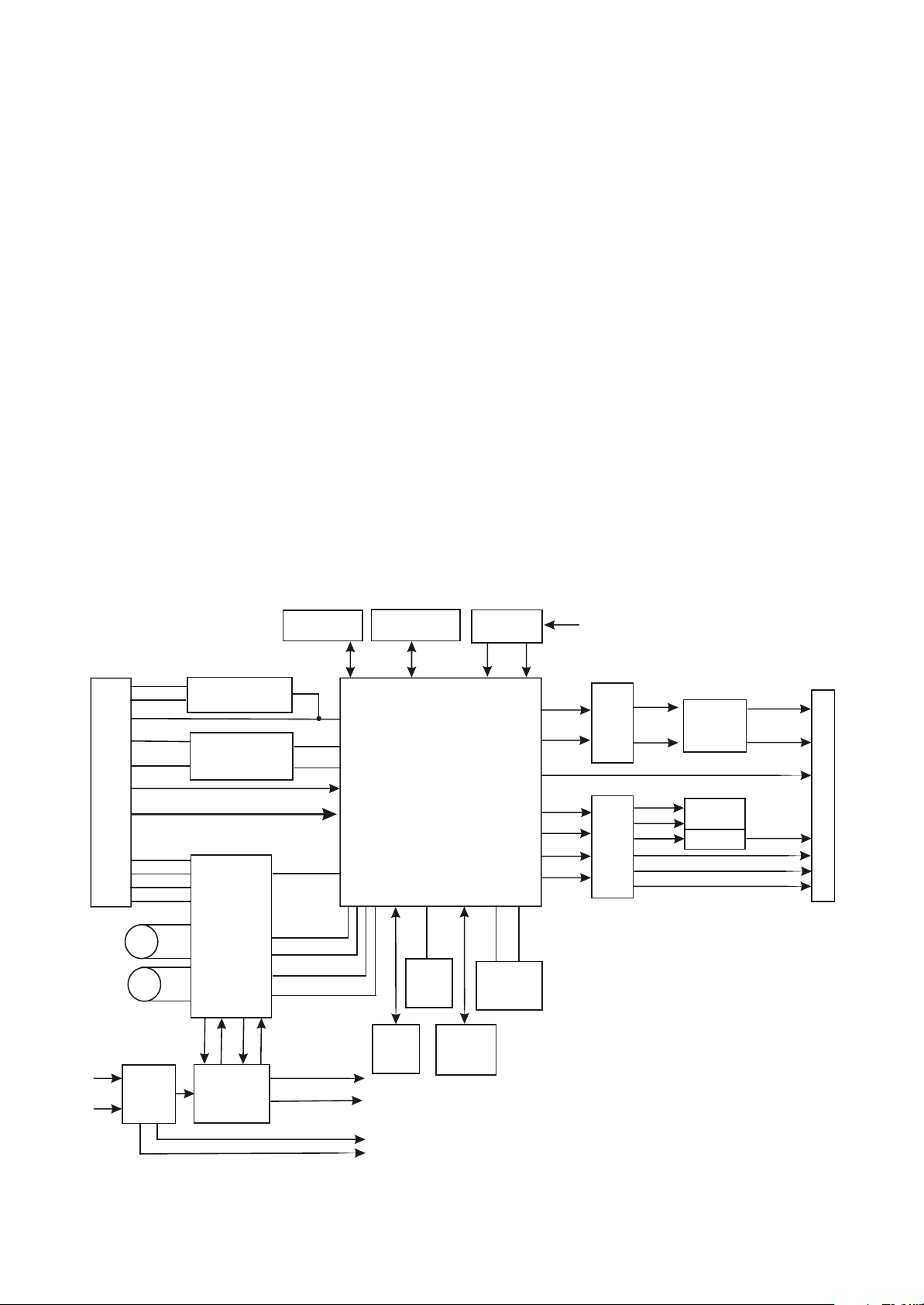

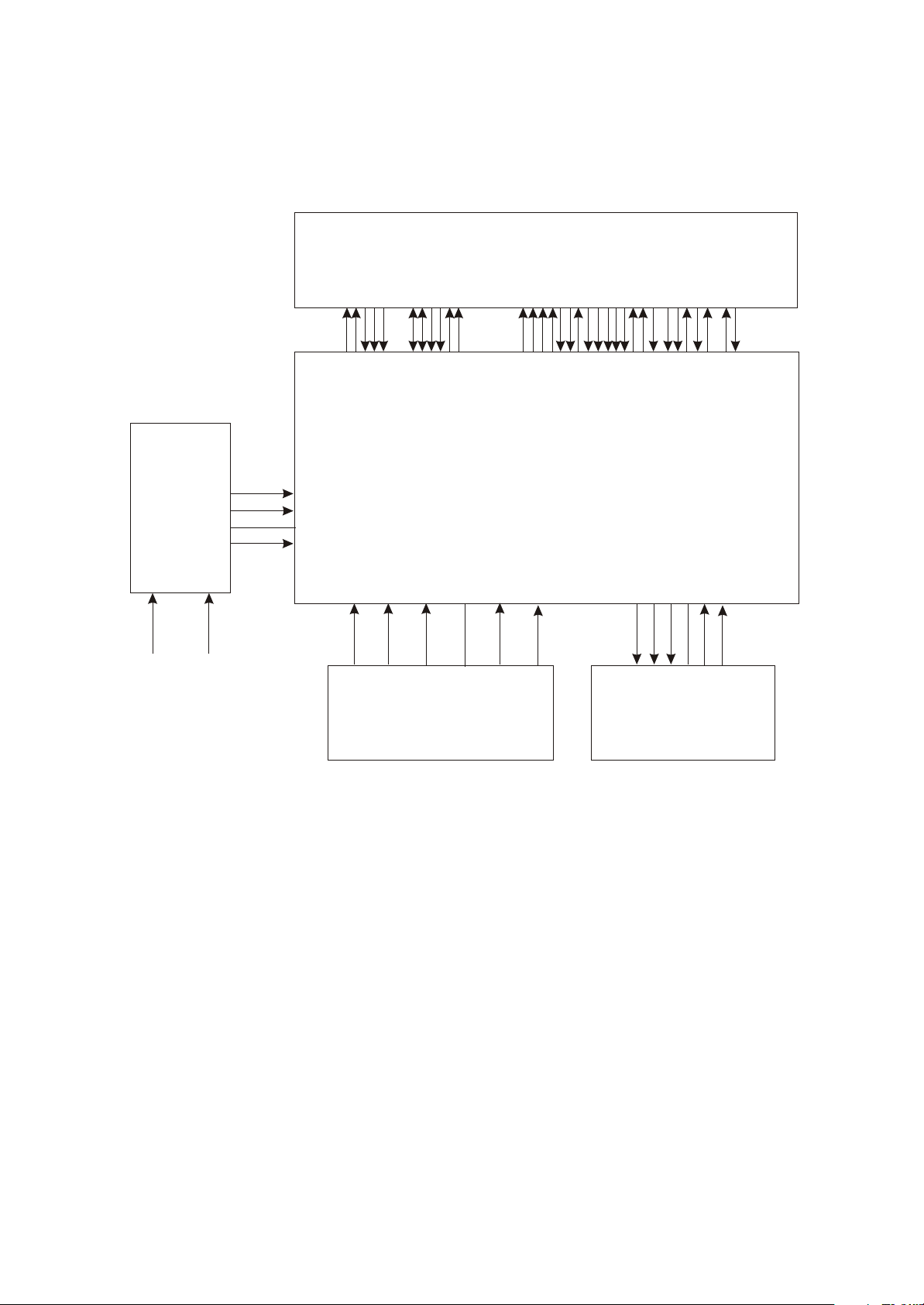

3.1.1 Block diagram of the player

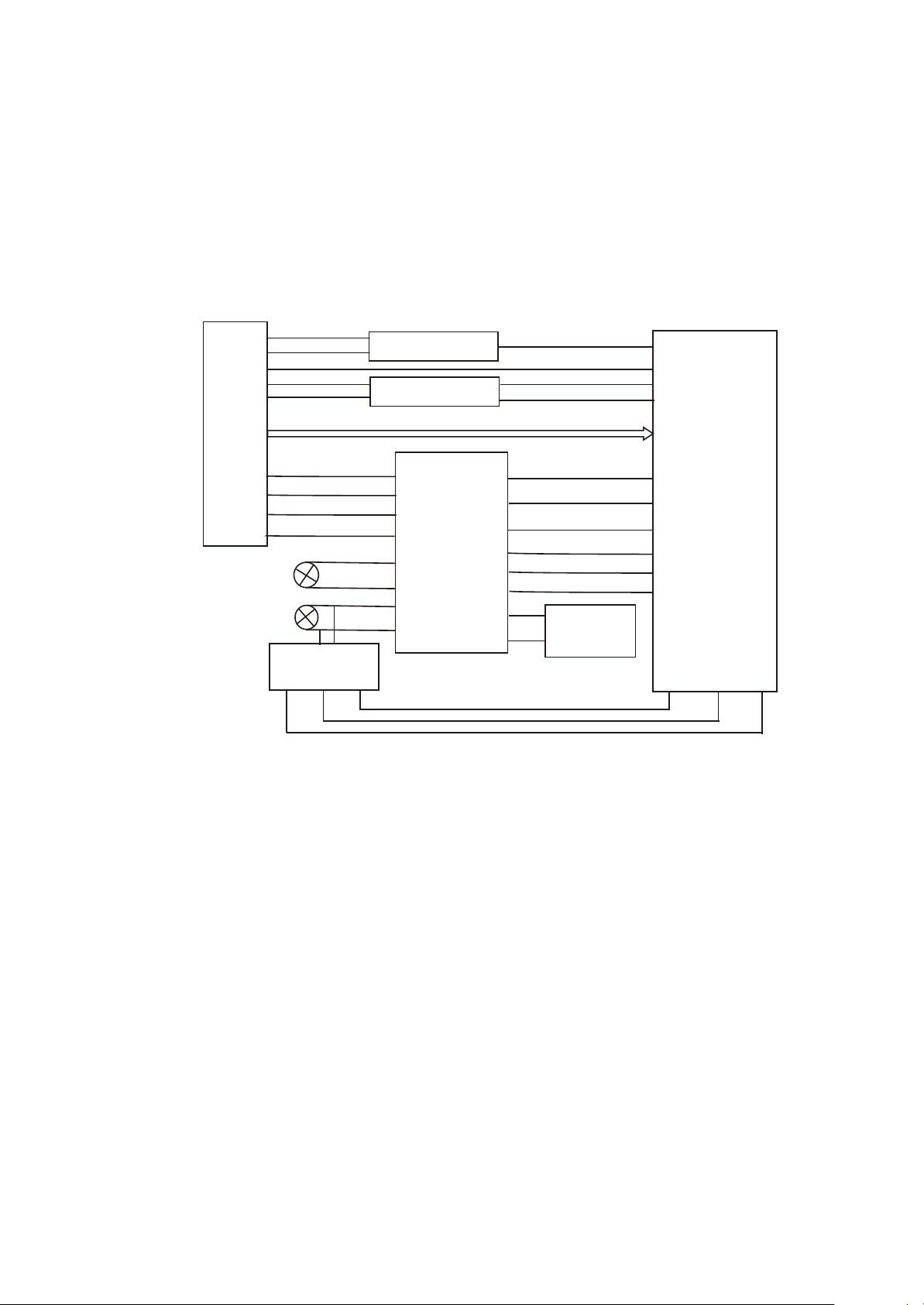

DV317SI is composed by decode circuit, servo circuit, audio circuit, video circuit, MIC circuit and

power circuit, the block diagram of the player is shown as in the following figure 3.1.1.1:

PICK-UP

Feed

electric

machine

Main

axis

electric

machine

ACIN

VR-DVD

VD-CD

LD-DVD

LD-CD

TK-

TK+

FC+

FC-

SL+

M

M

SL-

SP+

M

SP-

Power

board

CD/DVD switch

Laser power

control

DVD:A/B/C/D/RFO

CD:A/B/C/D/E/FRFO

Am5888

U301

TRB2

TRB1

REGO1

Voltage

regulating

circuit

SDRAM 64M

U208

Ld02

Ld01

MDI

VIP4

FOSO

FMSO

DMSO

TRSO

REGO2

V18

Dv33

+9V

IOA

FLASH16M

U207

MT1389 D

U201

UREST

Reset

Panel

MIC board

XI

SDA

SCL

27M clock

EEPROM

U202

24C02

XO

MIC1

AL

AR

CVBS

Y/G

CB/B

CR/R

Audio

amplifying

filtering

U209

CVBS

B/U

R/V

G/Y

Video filtering

catching

L

R

SY

SC

Audio

output

terminal

S-video

Terminal

Video output

L#

R#

SPDIF

VIEDO#

PB#

PR#

Y#

SCART output terminal

-9V

Figure 3.1.1.1 Block diagram of the player

- 11 -

Page 16

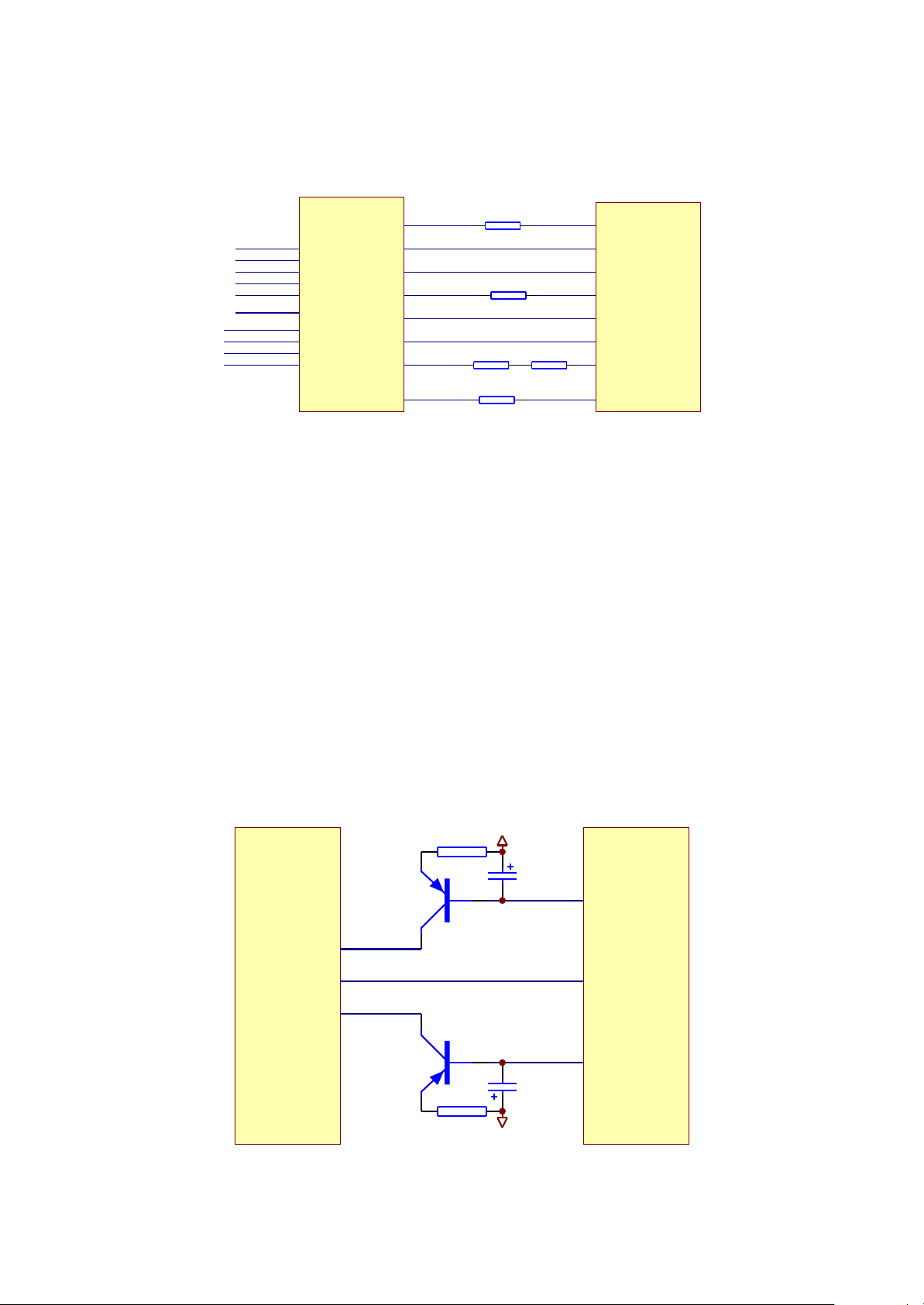

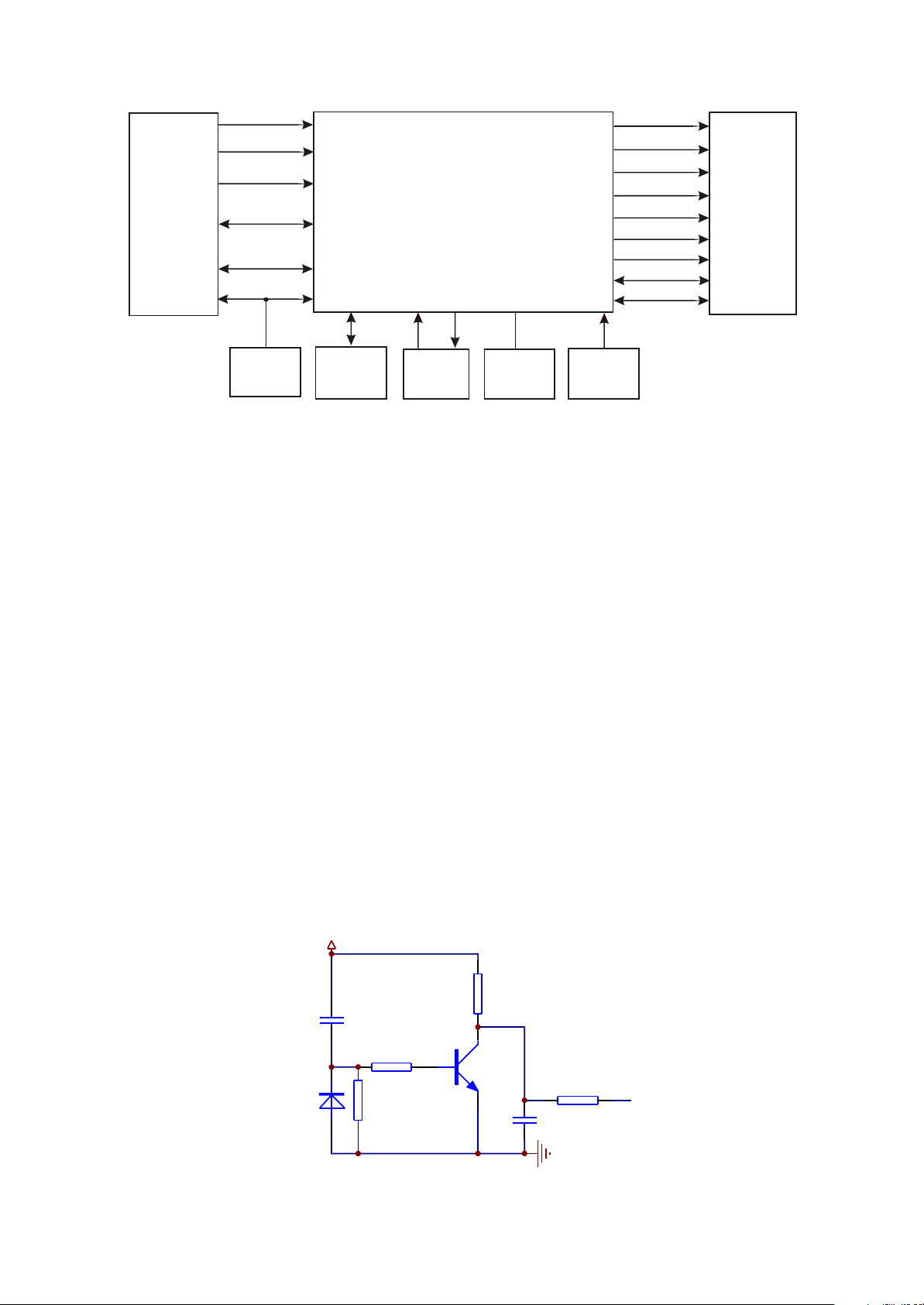

3.1.2 PCB board block diagram of the player

PCB board block diagram of the player is show as in the following figure 3.1.2.1:

Power board

5241-0

BCN501

AC220V

IOA

C

D

Laser head

RFO

ABF

F

A

B

IOA

RFO

XS301

GND

V20

V20

GND

+5V

E

VR-CD

AVCC

E

AVCC

VR-CD

XS205

_9V

+9V

XS601

VR-DVD

CD-LD

MDI

CD-LD

VR-DVD

GNDOKDET

HFM

DVD-LD

GND-LD

MDI

HFM

DVD-LD

GND-LD

Loader frame Small bracket

FC-

FC+

TK+

LOAD-

LOAD+

TROUT

LOAD-

LOAD+

TROUT#

SL+

SL-

LIMIT#

GND

SP+

GND

TRIN

GND

TRIN#

SP-

SL-

SP-

SL+

SP+

GND

LIMIT#

TK-CD

TK-

FC-

TK+

FC+

XS307 Xs306

CN501

+12V

-12V

GND

VCC

XS203

Decode board

2DV112S-0

Xs201

2

VSDA

3

VSCK

4

6

5

GNDVSTB

VCC

7

IR

Main panel

4911S-1

MIC board

6112S-2

Figure 3.1.2.1 PCB board block diagram of the player

This machine is mainly composed of decode board, power board, MIC board, main panel buildup

Decode board: includes decode, servo, audio, video output circuit.

Power board: provides working voltage for each circuit, output voltage has +12V, -129V and +5V.

MIC board: with single-way microphone input, MIC signals input to decode board after being

amplified.

Main panel: this panel is simple and mainly composed of remote control receiver and buttons.

Remark: in order to facilitate readers to better know the composition of machine, we have made

PCB composition figure, the connecting lines in PCB composition figure are the main control line, signal

line and power cord connected through flat cable, but all connected flat cable are not included.

- 12 -

Page 17

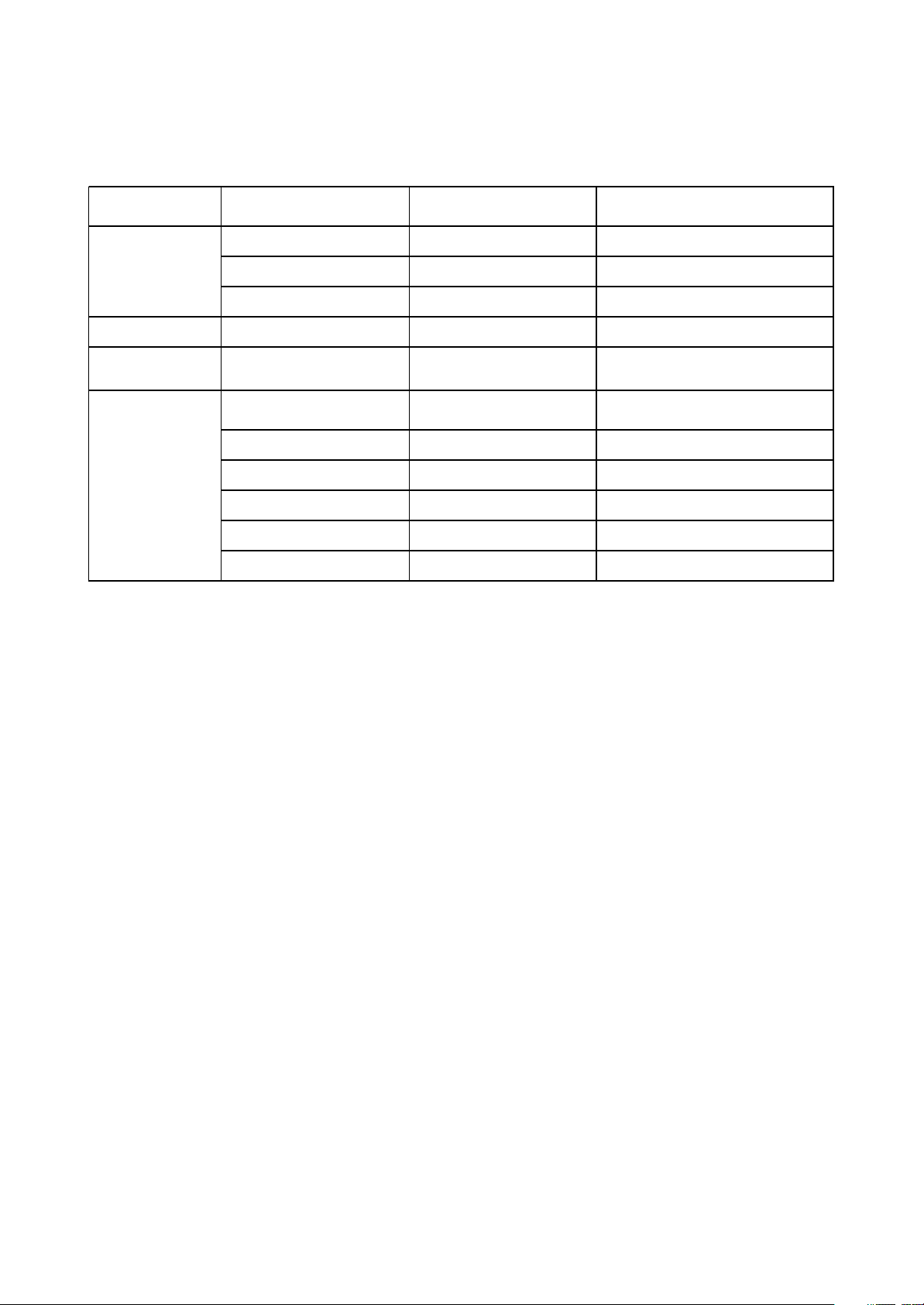

3.1.3 How to use IC

Semi-finished PCB

name

IC model name Location Function

AZ431 U503 Precise voltage regulator

PC817 U502 Photoelectric coupler

VIPER22A U501 Power switch IC

Main panel 4911S-1 HS0038B3V U403 Remote control receiver

OK board 6112S-1 KA4558 U601

Operational amplifier (MIC

amplifying)

NJM4558 U219

Operational amplifier (audio

amplifying)

HY57V641620HGT-7 U206 SDRAM

24C02 U202 EEPROM

MT1389 D version U201 Decode chip

AM5888S U301 Servo drive

29LV160BE U214 FLASH

Decode board

2DV112 S-0

Power board

5241-0

DV112SI IC usage instruction is shown as in the following table:

- 13 -

Page 18

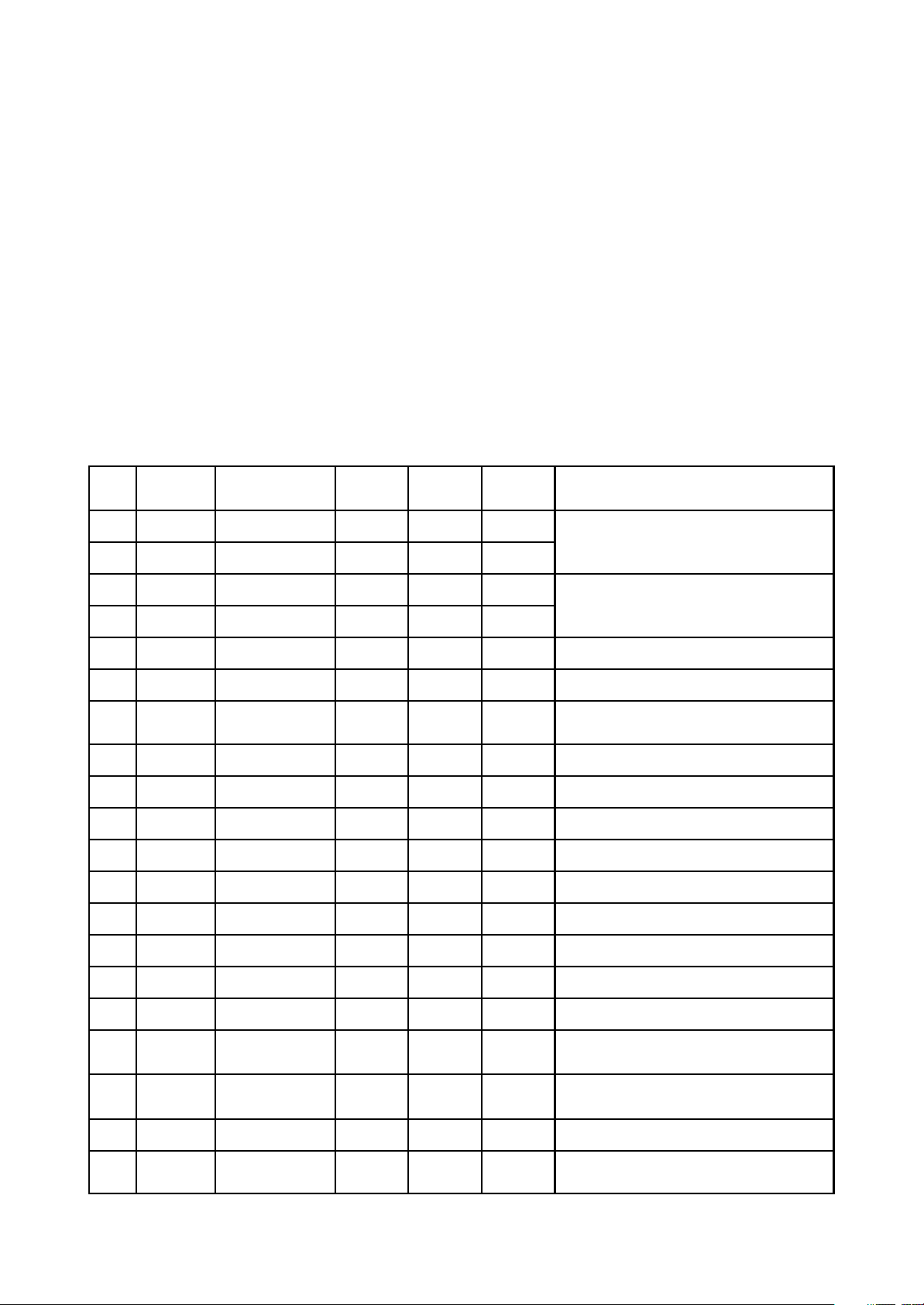

Section Two Unit Circuit Principle

Pin Name

Signal flow

direction

DVD disc CD disc No disc Function description

1 F- Input loader 2.52 2.34 0.46

2 F+ Input loader 2.49 2.49 0.93

3 T+ Input loader 2.53 2.51 0.94

4 T- Input loader 2.58 2.51 0.93

5 C Input MT1389 2.2 2.25 2.04 Disc data signal

6 D Input MT1389 2.2 3.2 2.04 Disc data signal

7 IOA Input MT1389 0.01 3.2 3.21

Disc identification signal, CD is 3.3V, DVD

is 0V

8 RF Input MT1389 2.21 2.53 1.28 The sum of disc data signal

9 A Input MT1389 2.17 2.22 2.04 Disc data signal

10 B Input MT1389 2.19 2.27 2.04 Disc data signal

11 F Input MT1389 2.07 2.44 2.03 Supplementary signal used in trace

12 GND Ground 0.01 0.01 0 Grounding

13 V20 Input loader 2.04 2.06 2.03 Reference voltage

14 Vcc Input loader 5.04 5.04 5.02 Supply voltage for loader

15 E Input MT1389 2.06 2.45 2.03 Disc data signal

16 Blanking haning in air 0.01 0 0 unused

17 VR-CD Input loader 0.21 0.01 0

Through the handling inside loader, make

sure MD11 is 180mV when reading CD

18 VR-DVD Input loader 0.01 0.2 0

Through the handling inside loader, make

sure MD11 is 180mV when reading DVD

19 LD-CD Input loader 0.09 2.1 0 CD laser power control signal

20 MDII Input MT1389 0.21 0.2 0 CD and DVD laser power monitoring signal

Focus error signal is added to two sides of

pick-up focus coil

Trace error signal is added to two sides of

pick-up trace coil

3.2.1 Introduction to laser head

Function introduction to laser head flat cable is shown as the following table:

- 14 -

Page 19

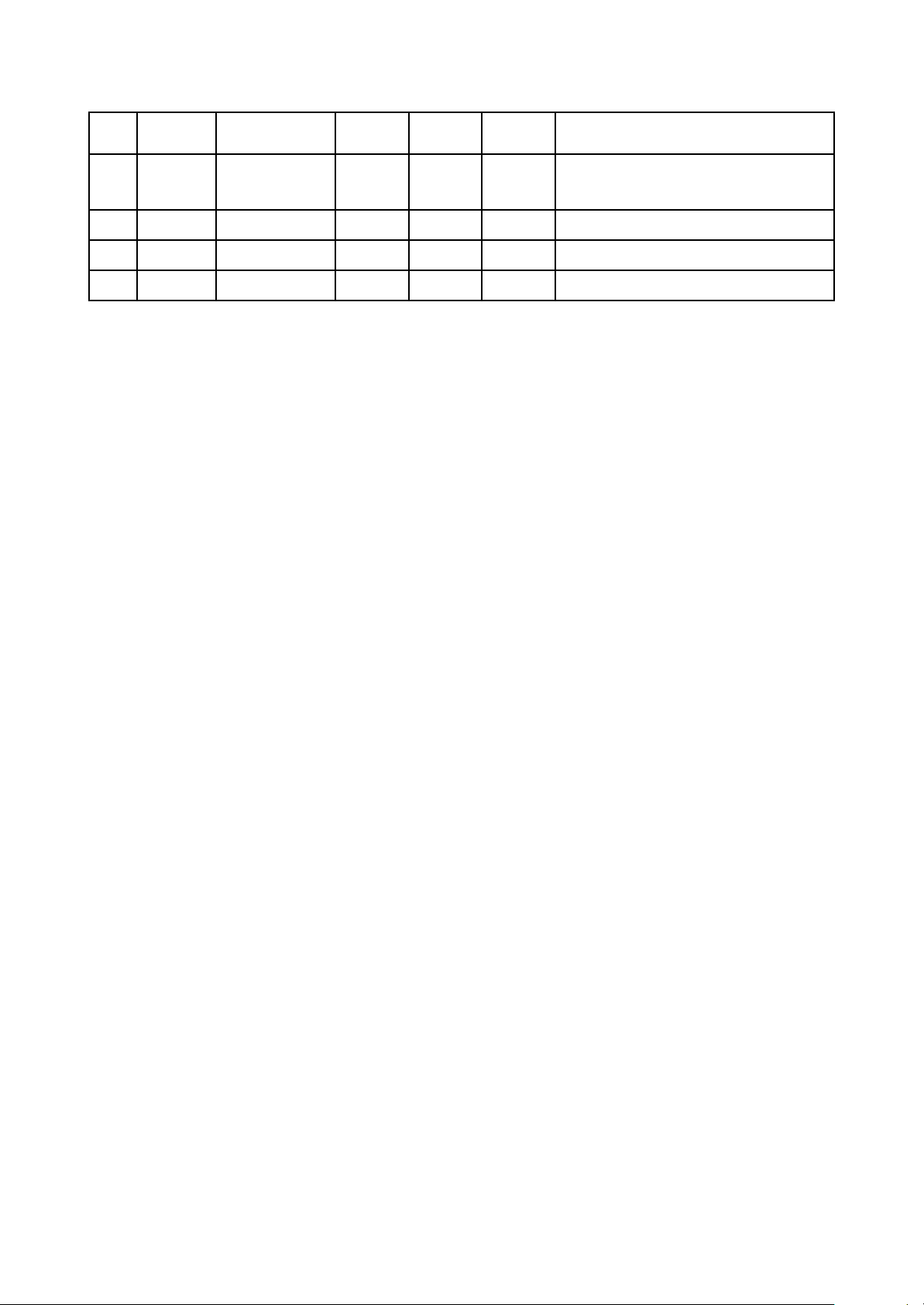

Note: 1. When reading DVD, there are only A, B, C, D signals.

Pin Name

Signal flow

direction

DVD disc CD disc No disc Function description

21 HFM Input loader 5.04 5.04 5.02

High frequency overlapping signal produces

laser with different wave length inside

loader

22 Blanking unused 0.01 0.1 0

23 LD-DVD Input loader 2.21 0.1 0 DVD laser power control signal

24 GND unused 0.01 0.01 0 Grounding

2. When reading CD, there are A, B, C, D, E, F signals.

3. RFO=A+B+C+D.

4. Focus error signal=(A+C)-(B+D) Trace error signal=E-F.

2. Working principle

(1) Laser tube: wave length of loader DVD laser diode is 650nm, wave length of CD laser diode is

790nm, the wave length which is within 370nm and 750nm is visible light, the laser in the course of

reading DVD disc is visible light, and that when reading CD disc is infrared light.

(2) Principle about laser head picks up signal: laser beam projects onto disc, when laser beam focus

projects onto disc vertically, laser beam will produce reflection, reach on light sensor through reflection

loop and converse into electronic signal through photoelectric cell. For the reflection loop produced in

non pit information area and pit information area in disc has difference and reflects into different position

of light sensor, photoelectric diode in different positions on light sensor will produce different signals to

process all signals on light sensor and then produce digital signals.

(3) Focus, trace coil: when laser head is reading signals normally, information side should be in the

focus of laser beam, because of factors of disc error, high speed rotation and machine error, it is

unavoidable that laser beam focus deviates from information face to produce phenomena of orbit boas

and refocusing. Focus , trace coil is added on loader to adjust laser beam to make it correctly focus in

information area.

(4) Formation of RF signal: when disc reading is normal, light sensor will have 160MV, vague and

eye pattern waveform which is added on A, B, C, D respectively, and output RF signal from FRO pin after

being overlapped by adder inside light sensor, the frequency when reading DVD disc is much higher

than that when reading CD disc, output amplitude is about 1.4V.

- 15 -

Page 20

3.2.2 Servo circuit

1. Servo system of this player adopts SANYO loader + MTK decode solution (MT1389D+FLASH

(16M) + SDRAM (64M)), and its servo circuit is mainly composed of front end signal processing, digital

servo processing, digital signal processing IC MT1389D and drive circuit AM5888S , in which MT1389D

is also the main composed part of decode circuit. Servo circuit block diagram is shown as in the

following figure

Feed electric machine

Main axis electric machine

3.2.2.1:

Xs301

A B C D E F RFO

TK+ 16

FC+ 14

FC- 13

SL+ 17

Main axis control

detect circuit

Switch circuit

APC circuit

TK- 15

SL- 18

SP- 12

SP+ 11

Am5888

LOAD+

LOAD-

1

23

26

4

7

6

FOSO

FMSO

TRSO

DMSO

TRCLOSE

TROPEN

10

Disc in/out

9

electric machine

IOA

MD11

LDO2

LDO2

MT1389D

U201

Figure 3.2.2.1 Servo circuit block diagram

2. Working principle

After power on or disc in to proper position (on loader frame for general DVD players, on PCB board

below door for PDVD players), loader laser head begins reset, after laser head reaches to proper

position, detect switch will give a signal to MT1389, MT1389 begins to output focus, main axis and light

emission signals, disc begins to rotate, laser head begins to recognize disc information and judge

whether disc is CD or DVD according to disc information to facilitate to output level from IOA pin, control

disc switch circuit and laser head PD IC to make corresponding acts. At the same time, MT1389 also

adjusts laser power output through laser power control circuit.

After loader reads disc information, A, B, C, D, E and F signal are formed through photoelectric

conversion to MT1389 (DVD only has A, B, C, D signals) and RF signal and output from pin 2~11, 18, 19

of MT1389 respectively, after amplifying processing of pre-amplifier inside MT1389, now signals are

divided into 2 ways inside MT1389: one part, through summation amplifying and subtraction circuit

- 16 -

Page 21

Inside MT1389, produces servo error signal, after digital servo signal circuit processing, forms

corresponding servo control signals, outputs FOO, TRO, DMO and FMSO servo control signal from pin

42, 41, 37 and 38 of MT1389 respectively and then send to servo drive circuit for drive amplifying

through the integration circuit composed by resistor and capacitor and bring along focus coil, trace coil,

main axis electric machine and feed electric machine after drive amplifying. Among these, focus and

trace servo are used to correct objective position accurately; feed servo is used to bring along laser

head to make radial large-scale move which belongs to the preliminary adjustment to laser head

position; and main axis servo is used to control main axis electric machine to make it read signals in

means of constant linear velocity and bring along disc to rotate. After processing of amplification by VGA

voltage control amplifier and equalization frequency compensation inside MT1389, another part of

signals are changed into digital signals through internal A/D converter. When loader is reading CD/VCD

signals, these signals are conducted EFM demodulation inside MT1389, and then outputted to latter

stage for AV decoding after finishing CIRC (Cross-Interleaved Reed-Solomon Code) error correction

inside. When loader is reading DVD signals, these signals are conducted ESM demodulation inside

MT1389, and then sent to latter stage for decoding after finishing RSPC error correction inside. General

DVD players have a disc in/out circuit to control disc tray door in/out acts to reach the purpose of making

disc in and out. For PDVD, we adopt manual disc in/out means and we can judge whether disc in to

proper position through detect switch.

3. Explanation to servo terms

(1) FOO: for disc make differences, and when rotating disc may probably move upwards or

downwards slightly to make the focus of laser emitted by laser head cannot justly fall on data pit of disc,

now focus point of objective lens is required to adjust to make focus aim at data pit exactly. The acts are

mainly to make objective lens move upwards and downwards.

(2) TRO: data information is saved in disc in form of tracks. When disc is rotating, disc deviation will

produce, now laser head is required to adjust. In this process, objective lens makes forward and

backward movement with small moving range.

(3) FMO: similar to acts of trace, the acts of feed are larger than those of trace. Feed conducts a

large scale movement firstly, and then trace moves slightly in this range. Feed moves for a while, and

does not move for another while; but trace moves all the time. Feed is rough adjustment and trace is fine.

And acts are obvious when power on and selecting track.

(4) DMO: it is the top that holds up disc. Its rotation speed decides that of disc. Its rotation is

generated by an individual DC electric machine, in which rotation speed of DVD is twice over that of CD.

- 17 -

Page 22

3.2.3 Open/close drive circuit

1. Open/close drive circuit is shown as in the following figure 3.2.3.1:

27K

TRSO

FC+

FCSPSP+

LOAD+

LOAD-

TKTK+

SL+

SL-

AM5888S

Figure 3.2.3.1 Open/close drive circuit diagram

STBY

V1P4

FMSO

TRCLOSE

TROPEN

DMSO

FOSO

2. Working principle: when the machine is reading discs normally, pin 6, 7, 9 10 of AM5888S are all

0V. After OPEN button is pressed, pin 6 inputs high level, pin 10 LOAD+ outputs high level, electric

R203

R202

R314

10K

R204

15K

MT1389D

R201

10K

27K

machine rotates to perform OPEN acts. When closing, pin 9 LOAD- outputs high level to pin 9 through

electric machine to form loop, electric machine rotates reversely to perform CLOSE acts. After closing to

proper position, all pins are all low level. Servo drive principle is the same with the drive of D5954

scheme, so we will not describe here.

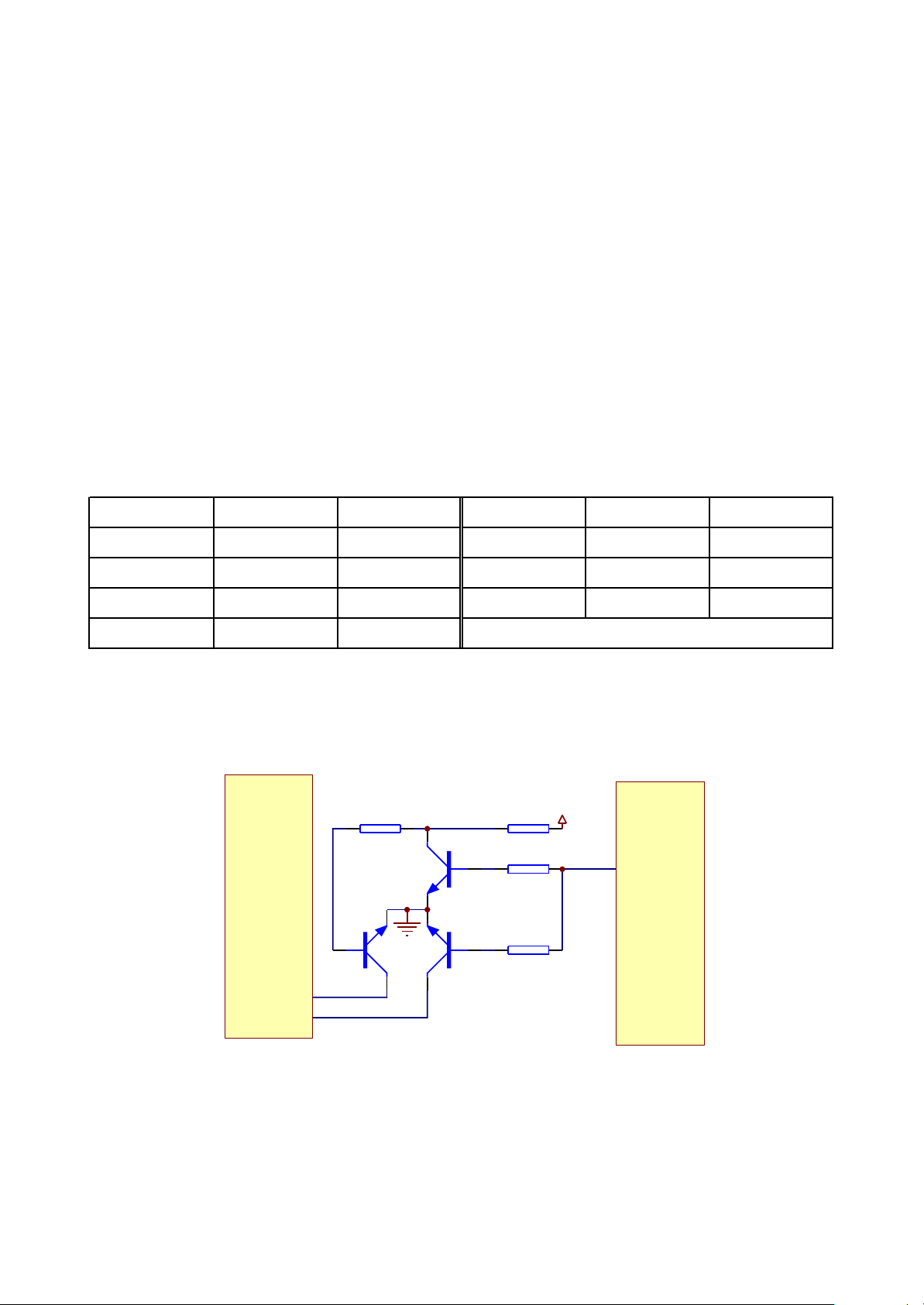

3.2.4 Laser power control circuit

Laser power control circuit is shown as in the following figure 3.2.4.1:

LDO-AV33

4.7R

TC302

47uF/16V

LDO2

V301

2SB1132-S

20/21

MT1389D

V302

2SB1132-S

LDO1

XS301

R301

23

MD1

20

19

TC303

47uF/16V

4.7R

R302

Figure 3.2.4.1 Laser power control circuit diagram

LDO-AV33

- 18 -

Page 23

2. Working principle

Location number Read DVD disc Read VCD disc Location number Read DVD disc Read VCD disc

V301_E 2.9V 3.2V V302_B 3.2V 2.2V

V301_B 2.2V 3.2V V302_E 3.2V 2.9V

V301_C 2.2V 0 MT 1389_20 0.2V 0.2V

V302_C 0 2.2V

Pin 20/21 of MT1389 is laser power detect signal input pin, pin 21 is DVD laser power strong/weak

detect signal input pin, pin 23 is VCD laser power drive control output pin, pin 22 is DVD laser power

drive control output pin.

When reading VCD disc, laser power becomes weak, voltage of MDII pin decreases, voltage

decrease of pin 23 of MT1389 makes voltage of pin 19 of XS301 increase to reach the purpose of raising

laser power. When laser power is too strong, voltage of MDII pin increases to lead to voltage of pin 23 of

MT1389 increase to make voltage of pin 19 of XS301 decrease to reach the purpose of reducing laser

power to form an auto power control circuit.

When reading DVD disc, pin 21 is detect signal input pin, pin 22 is drive control input pin, and the

working principle is the same with that when playing VCD disc.

3. Key point voltage (unit: V) is shown as the following table:

3.2.5 CD/DVD conversion circuit

1. CD/DVD conversion circuit is shown as in the following figure 3.2.5.1:

AVCC

V305

3904-S

R309

10K

R311

10K

R310

100K

IOA

MT1389D

R308

100K

XS301

V303

17

2SK3018-S

18

Figure 3.2.5.1 CD/DVD conversion circuit diagram

V304

2SK3018-S

2. Working principle

After loading disc in the player, IOA port of MT1389 is defaulted high level to make V305 saturation

on and form loop together with CD laser power control circuit on CD. At the same time, IOA also goes to

- 19 -

Page 24

Base

electrode B

Collector C Em itte r E

Grid

electrode G

Drain

electrode D

Source

electrode S

G D S IOA

DVD disc 0 3.86 0 3.81 0.18 0 0 0 0 0

VCD disc 0.64 0.1 0 0 0 0 3.27 0.18 0 3.3

State

V305 V303 V304

Loader PD IC to switch, disc begins to rotate, when servo management system recognizes that the disc

in player is not CD disc, IQA pin outputs low level to make V305 cut off and make V303 on, and form loop

together with DVD laser power control circuit on loader to perform disc reading acts. After disc tray door

opens, IOA keeps the state before opening disc tray door. If the player cannot recognize which disc it is,

IQA pin will switch continuously until reading disc or system judges that there is no disc.

Note: V303 and V304 are MOS tube

3. Key point voltage (unit: V) is shown as the following table:

3.2.6 Main axis control circuit

1. Main axis control circuit is shown as in the following figure 3.2.6.1:

XS303

6P2.0mm

R330 10K

1

2

3

4

5

6

104

C313

R321

R319

150K

Figure 3.2.6.1 Main axis control circuit diagram

DV33

SL+

SL-

LIMIT#

SP+

SP-

1R

680K/1%

R320

150K

R318

R322

330

C307

LIMIT

222

R317

680K/1%

C308

101(DNS)

C310

222

R331

0R

OPO

ADIN

OPOP+

V1P4

2. Function: disc is always in high speed rotation in the course of disc reading, when you need to

open the door to change disc, MT1389 stops the positive direction drive signal which is given to main

axis drive circuit, for the function of inertia disc is still rotating. If disc out order is performed at this time,

disc will be abrasively damaged. Therefore, machine must be baking to main axis, that whether disc

hasstopped rotating and whether disc is reversing, decode chip of the machine cannot recognize. So a

main Axis control circuit is added to make decode chip can effective monitor that whether disc has

stopped rotating.

3. Working principle: MT1389 has a comparator inside composed of operational amplifier, in which

OP+ is the in-phase input end of operational amplifier, OP- is reverse input end, OPO is output end,

- 20 -

Page 25

When playing disc normally, for electric machine is positive direction rotating, voltage of OP+ is higher

Key point Position Normal working voltage (V) Volateg change when disc out (V)

SP+

Pin 11 of AM5888S, pin 5 of

XS307

3.79 3.79 0.70 1.80

SP-

Pin 12 of AM5888S, pin 6 of

XS307

1.38 1.38 3.40 1.80

OP+ Pin 36 of MT1389 1.38 1.38 3.10 1.80

OP- Pin 35 of MT1389 1.53 1.53 3.08 1.98

OPO Pin 34 of MT1389 2.44 2.44 0.40 2.50

AD IN Pin 47 of MT1389 2.44 2.41 0.41 2.44

DMSO Pin 4 of AM5888S 1.42 1.42

VIP 4 Pin 30 of MT1389 1.41 1.41

than that of OP-, voltage of OPO is more than 1.4V. When disc out is needed, main axis drive signal

stops, for electric machine is permanent magnetic, when in rotating, induced electromotive force

produces in two ends to give to decode chip through R320, R319 sampling to make OPO output less

than 1.4V voltage and transmit to input pin of MT1389 ADIN through R331. When ADIN is high level,

main axis drive output end has not any drive signal output, when ADIN is low level, MT1389 outputs a

reversing drive signal to main axis drive circuit to make main axis electric machine speed down. Thus

circular working goes on until main axis stops rotating. PDVD is manual disc out means, so after disc out,

disc is still rotating, but will stop very son.

4. Key point voltage (unit: V) is shown as the following table:

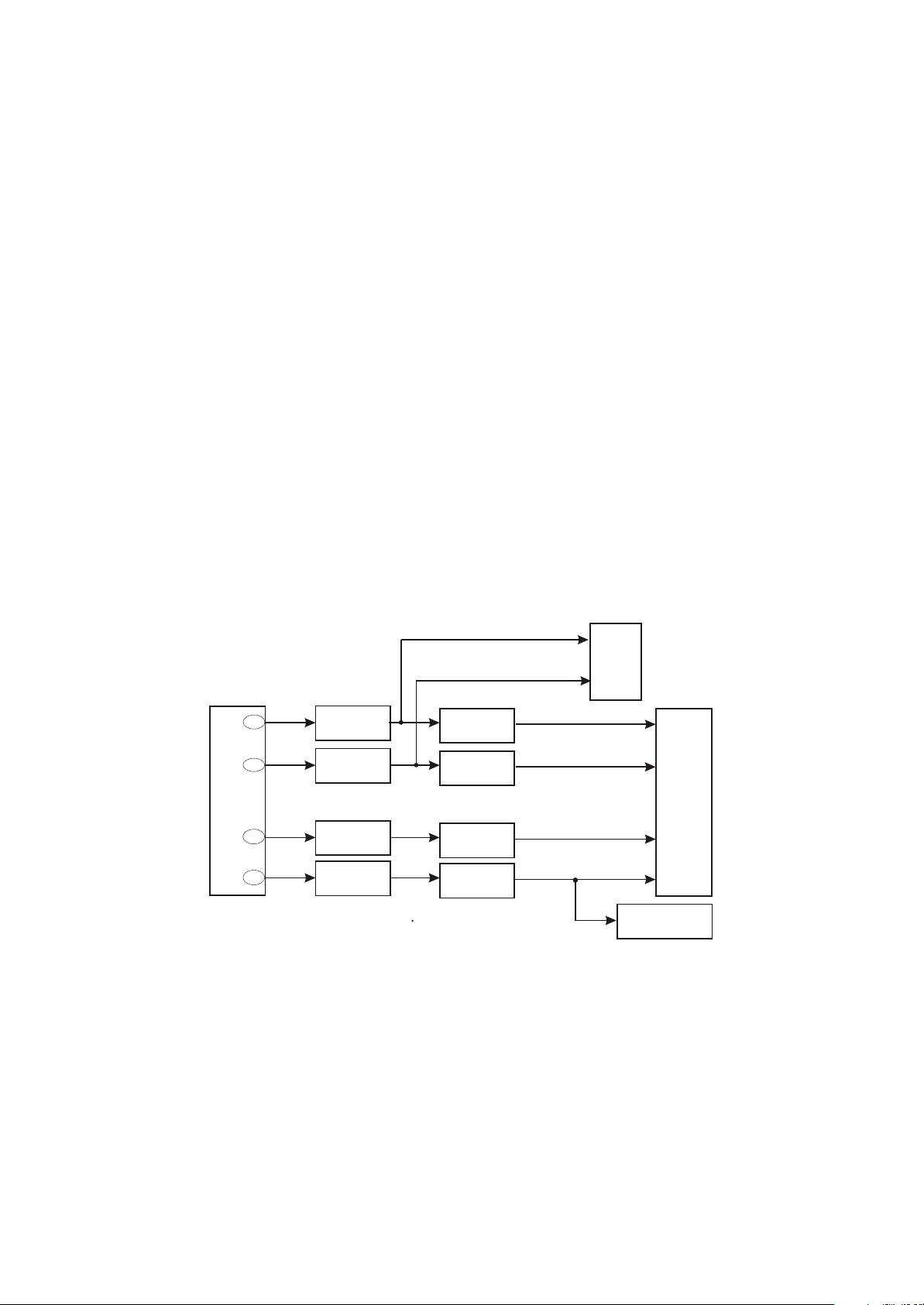

3.2.7 Decode circuit

1. Decode circuit block diagram is shown as in the following figure 3.2.7.1:

2. Working principle: this decode circuit is mainly composed of MT1389, SDRAM and FLASH.

Working condition of decode circuit has:

(1) Reset: refer to reset circuit working principle for details.

(2) Clock: this system adopts 27M external clock input, and produces clock signal required by

system inside through internal frequency doubling circuit.

(3) Power: decode chip adopts twp groups power supply of 3.3V and 1.8V, in which 1.8V mainly

supply power for internal logic control circuit and we call it core voltage.

After power on, reset circuit performs reset to MT1389 built-in CPU (8032) and FLASH, decode chip

outputs reset signal at the same time and performs reset to other circuit. After system reset, it firstly

Sends out read signal to FLASH to read out in formation saved in FLASH, the machine displays power-

on picture, servo system begins to work to check whether machine closes door to proper position and

- 21 -

Page 26

FLASH

PWR

PRD

PCE

A0~A20

AD0~AD7

URST

MT 1389

SDCLK

SDCKE

DCS

DRAS

SWE

DQM0

DQM1

DQ0~DQ15

MA0~MA11

SDRAM

Reset

circuit

SDA

SCL

EEPROM

24C02

Figure 3.2.7.1 Decode circuit block diagram

Clock

27M

V18

1.8V

voltage

regulating

3.3V

voltage

regulating

Whether detect switch has been closed, if not, the door close action is performed. After detect switch of

door is closed, the machine begins to perform preparations of disc reading and performs panel display

at the same time of working.

Playback process: laser head picks up disc signal from disc, after servo system processing, then

send to decode circuit for decoding, signal after being decoded is saved in SDRAM for the moment.

When machine needs to replay signal, decode circuit calls information inside SDRAM to perform D/A

conversion and then output.

User information storage: information content set by user is saved inside EEPROM, if user does not

refresh or reset this information, it will saved in IC permanently.

Audio, video output circuit: at present, MT1389 all integrates video D/A converter, MT1389D inside

integrates audio D/A converter, manufactures select according to their own needs. Please refer to

circuit principle diagram and audio circuit explanation for details.

3.2.8 Reset circuit

1. Reset circuit is shown as in the following figure 3.2.8.1:

DV33

R254

10K

V310

33R

R255

C272

104

URST#

1N4148

VD201

TC217

106

2SC1815-YS

R250

1K

R252

47K

Figure 3.2.8.1 Reset circuit diagram

- 22 -

Page 27

2. Working principle: after power on, voltage of DV33 increases to 3.3V, main chip power supply is

normal. Now, voltage of TC217 to DV33 cannot change suddenly to make base electrode of V310 has

current flow in, V310 is saturation on, URST is low level. DV33 charges TC217 in two paths through

emitter junction of R252 and V310 make negative pole voltage of TC217 decrease slowly. When this

voltage decreases below 0.7V, V310 cuts off, URST changes into high level, the process for URST from

low to high is called effective reset signal of low level by us. After power off, voltage of DV33 decreases,

TC217 decreases together with DV33 voltage, VD201 performs suge discharge and clamping to Tc217.

3. Key point voltage (unit: V)

V310_B is low level when in normal condition, at the moment of power on, it decreased to 0V from

3.3Vgradually.

V310_C is high level when in normal condition, at the moment of power on, it increases to 3.3V from

0V.

3.2.9 Video circuit

1. Video signal flow chart diagram is shown as in the following figure :

SY

SC

Y4

179

Y5

181

MT1389

Y6

182

Y3

175

L212

L213

L214

L210

R/V/SY

CUBS

Figure 3.2.9.1 Video signal flow chart

L240

L239

L241

R284

CUBS#

3.2.9.1

S-Video

Jk202A

11

7

SCART

Terminal

15

19

Jk202B

CVBS -Video

2. Working principle: MT1389D has built-in video D/A conversion circuit, video output has R/B/G

Y/Pb/Pr Y/Cb/Cr CVBS Y/C output mode, in which R/B/G Y/Pb/Pr Y/Cb/Cr Y/C cannot output at the

same time and need the switch through software. CVBS is a separate output mode, 4-path video signal

outputted by MT1389, through video filtering clamping, output to .

Terminal

Shown as in the figure 3.2.9.2, capacitor C253, C254 and inductor L210 compose a low-pass filter

to filter high frequency disturbance signal except useful signal; dual diode D220 composes a limiter

- 23 -

Page 28

Circuit, known from features of diode that the max amplitude of composite video signal CVBS cannot be

over 5.7, and the mix cannot be less than -0.7, thus the high voltage signal from TV set can be avoided

burning down the player.

VCC

L210

C253

47pF

1.8uH

C254

47pF

CVBS

D220

1N4148*2

Y3

R217

75R

VGND

VGND

Figure 3.2.9.2 Video output circuit

3.2.10 Audio circuit

1. Audio signal flow chart block diagram is shown in the figure 3.2.10.1:

MIC board

7

1

OKA

CH-L

CH-R

7

U601B

L235

L236

C2003

13

14

Jk201

1

Audio

terminal

6

U601A

3

L#

R#

MIC holder

SCART

Coaxial

R2132

R2156

AL

189

187

MT1389

AR

6

U219

2

SAPDIF

170

R233

Figure 3.2.10.1 Audio signal flow chart block diagram

2. Working principle: MT1389D has built-in audio DAC conversion circuit, which stimulates signals

and outputs from decode chip directly, through audio amplifying and filtering circuit, and outputs audio

signals directly. Shown in the figure 3.2.10.2, the right channel analog signals outputted by decode chip

are coupled by and then the high frequency component in audio signals is filtered by the low pass

filter composed of , for signals are damped through filtering circuit, the audio signals after

being filtered require the amplifying output by the amplifying circuit composed of , is

TC225

R2131 C2112

U219 R2129

feedback resistor, this circuit is a active filter on the whole.

R2132

24K

R

TC225

10uF/16V

OKA

AR

CH-R

TC240

R2129

30K

C211 1

120

10uF/16V

+12V

1

-12V

8

4

2

3

U219A

4580

R2130

5.1K

Figure 3.2.10.2 Amplifying circuit diagram

- 24 -

C2112

AGND

R2131

10K

222

Page 29

3. External Karaoke signal input and output

After being amplified, MIC signals input to pin 2, 6 of U219 separately for amplifying output,

MIC_DET on MIC board is microphone detect pin.

3.2.11 Mute circuit

1. Mute circuit is shown as in the figure 3.2.11.1:

MUTE-DAC

R274

4.7K

89V33

R2101

100K

TC238

47uF/10V

Q211

2SA1015Y-S

MIC-DET

+12V

R21043.3K

-12V

Figure 3.2.11.1 Mute circuit

R2107

R21031K

R2106

10K

R2105

10K

0R(DNS)

Q212

2SC1815Y-S

R2108

10K

Q218

2SA1015Y-S

VD205

1N4148

AGND

MUTE-OUT

Q219

2SA1015Y-S

AGND

+12V

VD206

1N4148

TC235

100uF/16V

R2109

10K

R2160

0R(DNS)

2. Working principle of quieting circuit

When the player is working normally, shown in the figure 3.2.11.1, MT1389E outputs analog audio

signal, and a low level signal to

MUTE-DAC at the same time to make Q211 on, B electrode of Q211 is

VCC

R2161

0R

about 2.7V, collector electrode of Q211 is about 3.3V, so Q212 is also on, voltage of B electrode is about

0.7V, voltage of Q218 E electrode is near to zero, Q218 cuts off, MUTE 1 is negative voltage, which is

added to base electrode of mute tube of audio output end to make mute tube cut off, and audio signal

outputs after being amplified by 4558. When pressing MUTE button on remote controller, MT1389 has

no audio signal that outputs to operational amplifier, so audio output end of the player has no audio

signal output, but because electronic elements in circuit will produce some noise when working that

transmits to output end of the player, in order to filter there noise, decode chip outputs a high level signal

to MUTE-DAC to make Q211 cut off, so Q212 cuts off, +5V power is transmitted to base electrode of

switch pipe Q205-Q210 through EC electrode of Q218, mute circuit is in mute state.

When player is not playing disc or stops playing, MT1389D outputs a high level signal to MUTE-

DAC to make audio circuit enter mute state.

After microphone is inserted into the machine, DET pin outputs low level, Q218E electrode is low

level, now no matter the former circuit outputs mute circuit, rear mute circuit does not work, and sound

outputs normally.

- 25 -

Page 30

3. Power-off quieting working principle

As shown in the figure 3.2.11.1, when the player is working normally,

VD206 is on, +5V charges

capacitor TC235 through D20, now emitter voltage of Q219 is less than base electrode voltage, Q219

cuts off. When power off, VCC disappears, Q219 base electrode changes into low level, its emitter

electrode changes into high level because of discharge, now Q219 is on, Q219 collector electrode

(MUTE-OUT) outputs high level to add to base electrode of switch pip Q205-Q206, switch pipe is

saturated, noise produces in the course of power off is bypassed to ground, and power-ff quieting

function is realized.

3.2.12 Decode circuit voltage regulating

Decode circuit voltage regulating is shown as in the following figure 3.2.12:

MO-VCC

VD301

1N4001

V307

Ss8550

TR_B1

Ss8550

V308

12K

R327

V309

SS8550

R326

20K

REGO1

TR_B1

DV33

TC309

100uF/16V

23NC24

25

26

27

28

BIAS

MUTE

VINTK

TR_B2

VINFC1TR_B12REGO23VINSL+4REGO15FWD6REV

VD302

15

16

17

18

19NC20

21

22

30

U301

VOLD-

VOTK-

VOLD+

AM5888S

VOTK+

1.8V

C326

104

14

100uF/16V

TC308

REGO2

VCC2

PVCC

GND2

VINLD

PREGND

GND1

VCC18VOTR-9VOTR+10VOSL-11VOSL+12VOFC-13VOFC+

7

29

1N4001

V306

SS8550

R324

5.6K

R325

TR_B2

10K

Figure 3.2.12 Decode circuit voltage regulating circuit diagram

2. Working principle:

DV33 voltage regulating process: VCC reduces voltage through VD301, and supply power for rear

stage circuit through E-C electrode of V309. R326/R327 is feedback end sampling resistor.

Voltage regulating principle: Dv33 voltage increases REGO1 voltage increases TR_B1

voltage increases V309VCE voltage increases DV33 voltage decreases.

Voltage regulating principle of 1.8V is the same with that of DV33, only a diode (VD302) is added to

perform voltage reduction.

3. Key point voltage (unit: V) is shown as follows:

C electrode of # V309: 3.95, B electrode: 3.35, C electrode: 2.25

C electrode of # V306: 3.25, B electrode: 3.55, C electrode: 1.95

# REGO1 REGO2 is 1.25V

- 26 -

Page 31

3.2.13 Panel control circuit

This main panel (4911-1) has no display screen and drive IC. PT6961 is mainly composed of panel

button and remote control receiver, the coding of button function is completed by decode chip.

3.2.14 MIC circuit

MIC board (6112S-1) mainly fulfills the amplifying and output of MIC signal, shown in the figure

3.2.14.1, after microphone is inserted into the machine, MIC signals, after being filtered, are sent by

TC601 to pin 3 of MIC signal amplifying circuit U601 for in-phase amplifying, and then output from pin 1

of U601, through volume adjustment by potentiometer VR602, input to pin 6 of U601 for reverse

amplifying, then output from pin 7 of U601 to decode board and audio amplifying circuit for mixed

amplifying.

TC605

47U/16V

TC601

47U/16V

R601

22K

R603

560R

C603

103

R607

1K

R609 33K

C605 101

2

3

R605

10K

-9VA

8 4

+9VA

U601A

4558

TC603

1

47U/16V

R619

1K

L601

FBSMT

3

VR602

10K

1

R612

2

6.8K

C607

6

5

R613

33K

101

U601B

4558

Figure 3.2.14.1 MIC circuit diagram

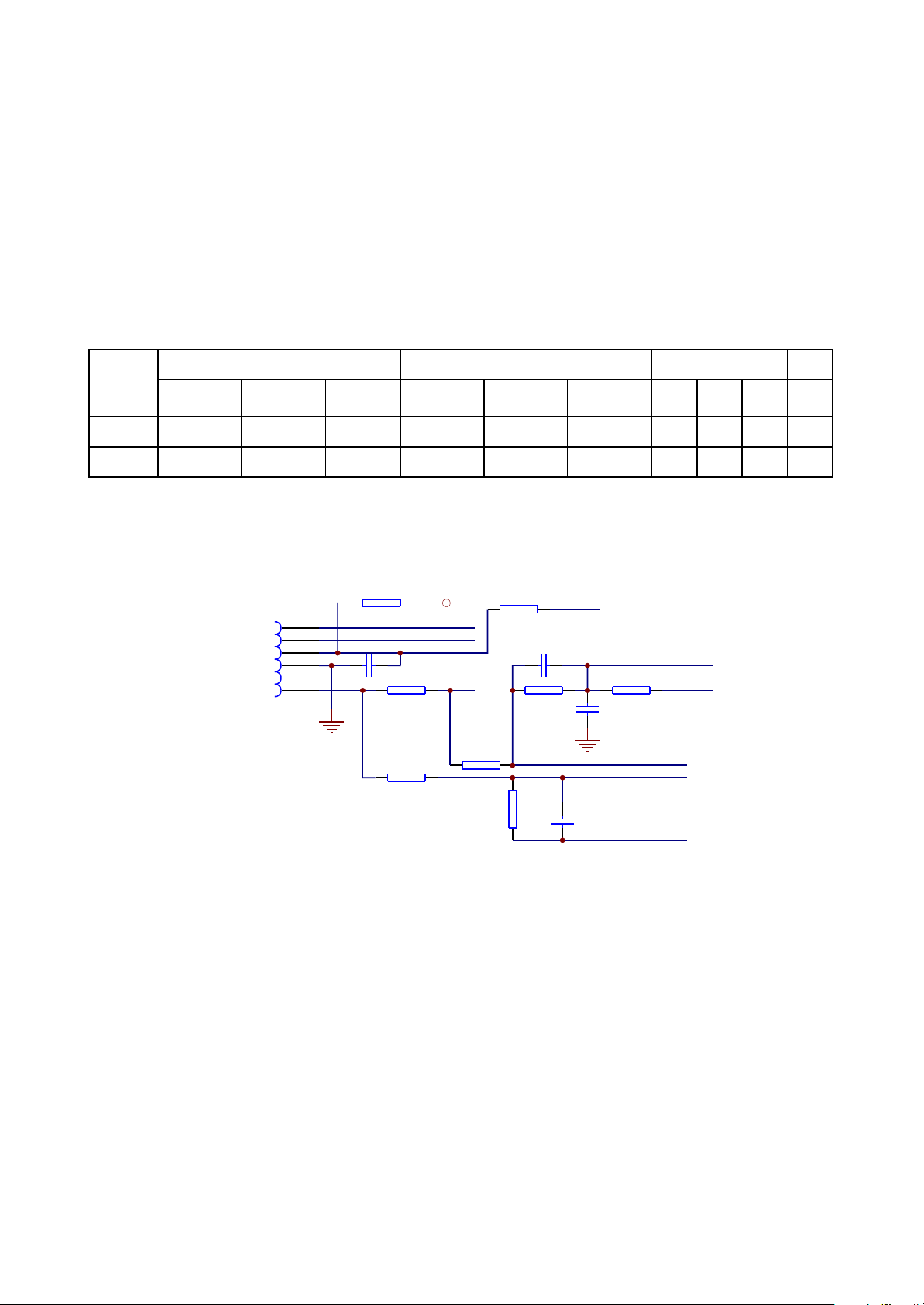

3.2.15 Power circuit

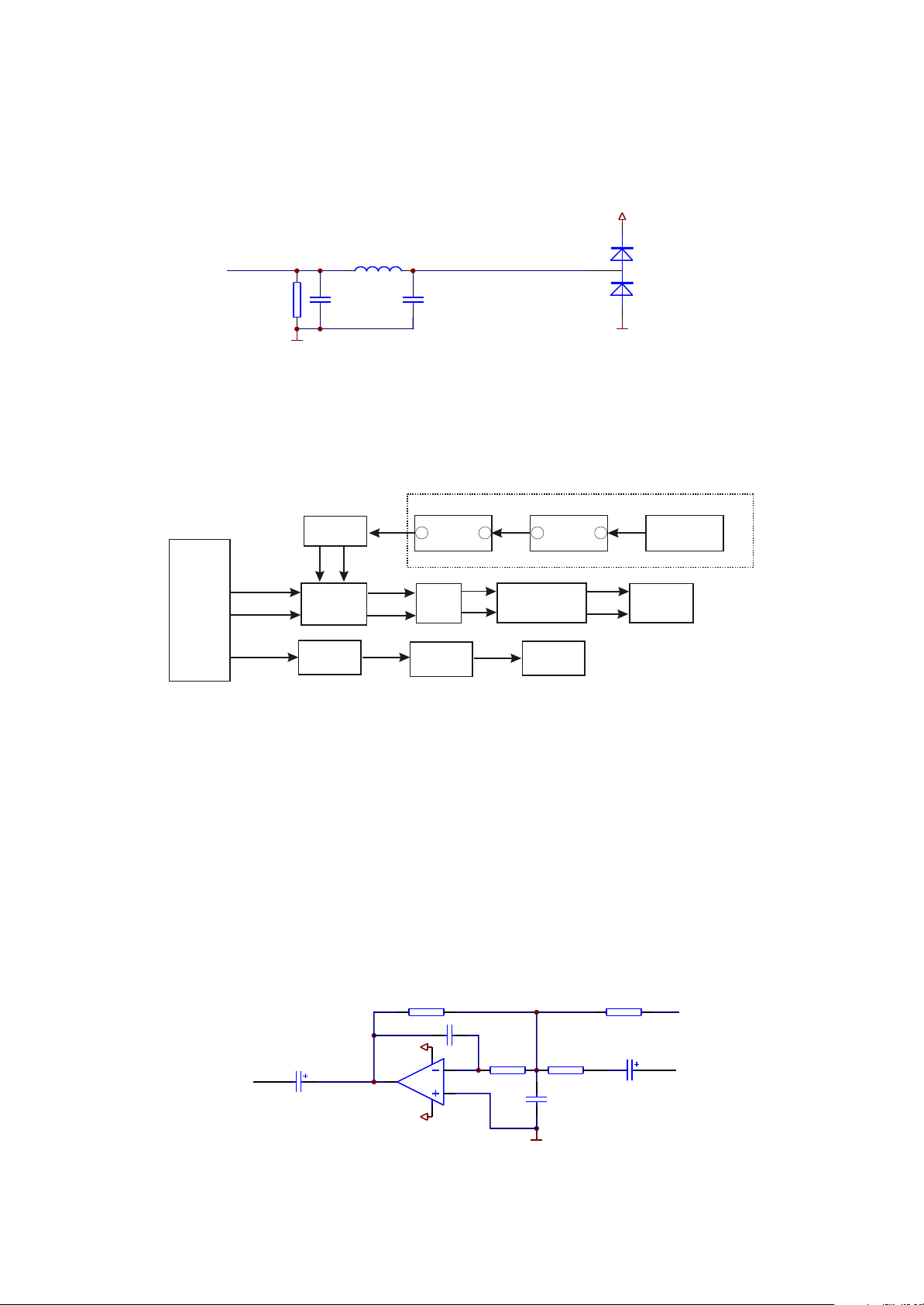

1. Power circuit block diagram is shown as in the following figure 3.2.15.1:

Rectification

Power grid

filtering

Protector tube

Filtering

HOST GND

Switch IC

Absorption loop

FSDH321

Feedback

winding

Transformer

Rectification

Rectification

Rectification

Filtering

Filtering

Filtering

7

TC613

47U/16V

+5V

-9V

R626

1K

+9V

C619

104

OK

Power socket

Photoelectric

coupling

TLV 431

Sampling

circuit

Figure 3.2.15.1 Power circuit block diagram

- 27 -

Page 32

2. Working principle

(1) Power grid filtering circuit: various electromagnetic radiation exists in surroundings, so it will

produce interference to the inputted AC power, and the function of power grid filtering circuit is to filter

these interference to make those that enter bridge rectification circuit are pure 220V AC power.

(2) Bridge rectification and filtering circuit: the function of this circuit is to converse electric supply

into DC power, the voltage after being rectified and filtered is 1.414 times of input power, so the DC

voltage at the two ends of TC501 is about equal to 300V

(3) Absorption loop: for power is always working in on/off state and will produce very high peak

voltage, in order to well protect switch IC, a peak absorption loop is added.

(4) Filtering circuit: the function is to produce a stable and slamm-wave DC voltage. In filtering

circuit, “ " type filter is mostly adopted. The feature of capacitor filtering is high load resistance, when

current is small, filtering is obvious, but inductor filtering is small load resistance, when current is large,

filtering is obvious. To compose capacitor into “ " type filter can make better filtering effect.

(5) Feedback loop: the time length of “on” and “off” within the same cycle inside switch module

is decided by feedback loop. Feedback loop performs sampling to +5V output stage voltage,

when output stage voltage is too high, the sampled voltage is on high side, through feedback loop, to

change the duty ratio of pin 3 signal of and reduce on time, and output voltage begins to reduce.

When output voltage is too low, the sampled voltage is on low side, through feedback loop, to make duty

radio of increase, output voltage increases, through the function of feedback loop, power board

is made to output stable voltage. The used LM431 in this power is a 2.5V comparator, sampling voltage

is compare with this 2.5V voltage, when sampling voltage is more than 2.5V (means that output voltage

is on high side), LM431 is on, light emitting diode in photoelectric diode begins to emit light to make the

other end of photoelectric coupler begin to be on, light emitting diode is stronger, the on degree bigger,

the on time of switch module decreases, output voltage begins to decrease. When sampling

voltage is less than 2.5V (means output stage voltage is on low side), Lm431 is cut off, on time of

increases, output voltage increases. Thus through auto control function of feedback loop,

power board is made to output stable voltage.

- 28 -

Page 33

Section Three Servicing Cases

3.3.1 Servicing cases

Example 1 Symptom: noise appears when power off

Description: at the moment of power off, audio output has noise; TV loudspeaker gives a bump

sound.

Analysis and troubleshooting: when this type of trouble appears, trouble always appears in power-

off noise removing circuit; firstly, test the MUTE-1 voltage of Q219 C electrode at the moment of power

off, shown in the figure 3.3.1.1, voltage of this point changes from -7.8V to 0.5V gradually at the moment

of power off, use multimeter to test elements around Q214, VD206 1N4148 diode has been stricken

through, after changing it, trouble is removed.

MUTE-OUT

Q219

2SA1015Y-S

AGND

Figure 3.3.1.1 Quieting circuit diagram

+12V

VD206

1N4148

TC235

220uF/16V

10K

R2109

VCC

R2160

0R(DNS)

R2161

0R

Example 2 Symptom: no sound

Description: picture output is normal

Analysis and troubleshooting: test sound output, pin 1, 7 of circuit operational am[lifier and there is

no signal output, test power supply voltage of operational amplifier and it is 9V which is on low side with

only two and a little, after removing load, test 9V voltage output of power board and it is normal, so we

confirm that trouble lies in decode board, only U219 of decode board has +9V power supply, test the

resistance to ground of pin 8 of U219 and it is 86 , which should be infinite in normal conditions, so we

doubt that U219 has trouble, change it and trouble is removed.

- 29 -

Page 34

Example 3 Symptom: power not on

Description: no picture, no sound and no screen display

Analysis and troubleshooting: shown in the figure 3.3.1.2, after power on, use voltage level (20V) of

multimeter to test the power supply from power board to decode board ( 9, +5, 3.3V) and it is normal,

check reset circuit V310 working and it is normal, check clock and there is no 27MHZ oscillation

frequency, so it is doubted that the fault of crystal oscillator X201 caused the trouble, after changing it,

disc reading and output are normal and trouble is removed.

R246 100K

XI

C275

33pF

Figure 3.3.1.2 Clock circuit diagram

X201

27MHz

XO

C276

33pF

Example 4 Symptom: picture mosaic when reading disc

Description: power on and read disc, after displaying DVD format, machine down and picture has

mosaic, power on again, picture still has mosaic but not read disc. Put the machine aside for 20 minutes

and trouble disappears.

Analysis and troubleshooting: firstly test voltage of each spot +5V, +3V and core voltage 1.86V and

they are all normal, so we doubt that it is affected by temperature. Use electric hair drier to heat each IC

of decode board and find that when temperature of decode IC 1389D increases 20-degree, machine

down and picture has mosaic, change 1389D chip and trouble is removed.

Example 5 Symptom: no sound

Description: disc reading is normal and there is sound output

Analysis and troubleshooting: use remote controller to restore to default settings firstly, then

connect with audio terminal and check whether there is sound output; check pin 1, 7 of operational

amplifier U219 Ic4558 and there is no sound output, test pin 4, 8 of 4558 and there is no +9V voltage,

Check and find that XS203 has +9V voltage input, test and find that one end of L220 has 9V voltage and

the other end has no voltage output, change L210 and trouble disappears.

Example 6 Symptom: power not on

Description: no picture, no sound and no screen display

Analysis and troubleshooting: check power board and find that voltage of each channel has no

output, check and find that 220V voltage input is normal, test bridge rectification circuit and there is no

voltage output, use multimeter to test protector tube and it has open circuit, change protector tube and

- 30 -

Page 35

trouble is not removed, test anode of Tc501 and there is still no voltage output, protector tube is burnt

out again, check 4 diode of bridge rectification circuit and they are all normal, TC501 has no

abnormalities of liquid leakage and stricken through, test U501 (switch IC) and pin 1, 8 are short-

circuited to ground, so it is judged that IC has been stricken through, change IC and trouble is removed.

Example 7 Symptom: power not on

Description: no screen display and no output

Analysis and troubleshooting: check +5V voltage output of power board and it is normal; check

voltage of pin 4 of XS203 and it is also +5V, which is normal; after power of for a period, use hand to

touch 1389 and find that 1389 does not work (feel the temperature here. If 1389 has began to work, the

temperature will be high), so firstly consider the power supply of 1389; shown in the figure 3.3.1.3, test

anode of Tc307 and there is no +1.8V voltage (output voltage of V309, V308 emitter electrode supplies

+3.3V power for 1389), check V306, V307 and they are all normal, test base electrode voltage of V306

and it is zero, this signal is AM5888 output, test voltage of pin 8, 19, 21 of AM5888 and they are all 5V,

which is normal, so we judge that AM5888 has trouble; change it and trouble is removed.

MO-VCC

1

A

VD301

1N4001

K

VD302

2

1.8V

TR_B2

C326

104

V306

B

SS8550

TC308

100uF/10V

REGO2

E

TR_B2

C

R324

5.1K

1N4001

E

V307

B

SS8550

C

R325

10K

Figure 3.3.1.3 circuit diagram

V308

SS8550

V309

TR_B1 TR_B1

SS8550

R326

20K

100uF/10V

12K

R327

REGO1

TC309

DV33

C327

104

Example 8 Symptom: power not on(DV123SI)

Description: power on, test and find that there is no +5V, 3.3V voltage output.

Analysis and troubleshooting: 1. Insert power cord, use multimeter to test whether 220V AC input is

normal, and the result is normal;

2. Check whether each voltage input of XS203 on decode board is normal, and find that+5V has no

input but others are normal;

- 31 -

Page 36

3. Pull out flat cable of decode board XS203, test each input voltage again and there is still no +5V

voltage;

4. Check whether two ends of +5V on power supply flat cable from power board CN502 to decode

board, and result is normal;

5. Test voltage of two ends of TC506, +5V has no output; after power off, use 200 ohm level of

multimeter to test two ends of TC506 and find that resistance is close to zero, so we doubt that capacitor

TC506 has electricity leakage; take down TC506, test anode welding point of TC506 and find that +5V

output is normal, but there is still no 3.3V output;

6. Test two ends of diode D507 on power board and find that one end is 5V voltage and the other

end has no voltage output. After changing D507, 3.3V output is normal, and machine works normally.

Example 9 Symptom: sound has no output

Description: after power on, each audio channel has no sound output when playing discs, when

switching MUTE function; output has no change, no sound output.

Analysis and troubleshooting: we know from trouble symptom, the common channel of sound

output has abnormality, firstly test operational amplifier IC 4558 +9V and -9V power supply voltage and it

is normal, use multimeter to test voltage of pin 186, 183 of decode chip 1389D and it is 3.3V, which is

normal, use oscillograph to test audio output waveform of pin 189, 187 of 1389D and it is normal, shown

in the figure 3.3.1.4, use multimeter to test voltage of C electrode of mute circuit Q218 and it is 4.6V and

keeps in 4.6V when no disc in and playing discs, when testing electrode resistance of Q218 and Q219

triode, the positive/negative direction resistance of C, E electrode of Q219 is about 500Ù, after changing

Q219 triode, trouble is removed.

R2107

R2106

10K

R2105

10K

0R

Q212

2SC1815Y-S

R2108

10K

Q218

2SA1015Y-S

VD205

1N4148

AGND

MUTE-OUT

Q219

2SA1015Y-S

AGND

+12V

VD206

1N4148

TC235

220uF/16V

R2109

10K

VCC

R2160

0R(DNS)

R2161

0R

MUTE-DAC

R274

4.7K

89V33

R2101

100K

2SA1015Y-S

TC238

47uF/10V

Q211

MIC-DET

+12V

R21043.3K

-12V

R21031K

Figure 3.3.1.4 Quieting circuit diagram

- 32 -

Page 37

Example 10 Symptom: not read DVD

Description: laser head, focus, feed, main axis and trace are all normal, but no light emission.

Analysis and troubleshooting: check emitter electrode voltage of Q301 and it is 3.3V, which is

normal, test the inductor L303between collector electrode and pin 23 of Xs301 and find that inductor has

open circuit; after changing inductor, trouble is removed.

Example 11 Symptom: less screen display

Description: when reading disc, display screen does not emit light for a period.

Analysis and troubleshooting: beat machine and test, screen less display always exists; use diode

level of multimeter, red pen connected with any pin of screen and black pen tested pin of screen tube,

test each screen pin one by one and check light emission segment of screen and a segment of screen

does not emit light, so we may judge that screen is damaged; after changing screen, trouble is removed.

Example 12 Symptom: clutter

Description: disc reading of machine is normal, picture output is normal, sound output has noise

Analysis and troubleshooting: power on and read disc (test disc), use oscillograph to test the

output waveform of pin 1, 7 of decode board operational amplifier U219 IC4558 and it is clutter, test

output waveform of pin n2, 6 of operational amplifier and it is clutter, test AL, AR output waveform of pin

189, 187 of 1389D and it is clutter, test power supply and clock of 1389 and they are both normal, so it is

judge that 1389D has trouble, after changing iot, trouble is removed.

Example 13 Symptom: not read disc

Description: not read any disc, laser head, light emission, feed, main axis and trace are all normal,

but there is no focus acts.

Analysis and troubleshooting: use multimeter to test pin 13, 14 of U301 (5888) and voltage is

normal (about 1.4V), test pin 1, 2 of XS301 and voltage is normal, check nerve flat cable and the contact

is good, so we judge that laser head focus coil is burnt out; after changing loader, trouble is removed.

Pins have 10 ohm resistance (o ohm resistance in normal conditions), so we judge that light touch has

trouble; after changing light touch switch, trouble is removed.

Example 14 Symptom: door not open

Analysis and troubleshooting: press OPEN button, check pin 39 of 1389and it is high level, normal;

check on state between pin 39 of 1389 and pin 6 of U301 (AM5888) and it is good; check pin 9, 10 of

U301and there is no voltage output (pin 9 is low, pin 10 is high), so we doubt that AM5888 has trouble,

after changing it, trouble is removed (AM5888 integrates open/close circuit).

- 33 -

Page 38

Example 15 Symptom: disc rotation speed too fast when door opens

Description: when playing normally, open disc, disc tray cannot come out immediately, after disc

tray out, disc will rotate on the tray for a while and then stop.

Analysis and troubleshooting: if this kind of trouble appears, the problem will appear in main axis

servo drive circuit, when opening door, test voltage change of pin 11, 12 of U301 AM5888S and it is high

and low level alternative, which is normal, shown in the figure 3.3.1.5, test ADIN signal of pin 43 of 1389

and it is always 0V, test voltage of OPO signal of pin 34 of 1389 and it changes in 0.8~2.3V, use

multimeter to test the voltage drop between pin 34 and pin 43 of 1389 and it is in 0.8~2.3V, test R331

resistor and it has open circuit, after changing it, trouble is removed.

XS303

6P2.0mm

1

2

3

4

5

6

R330 10K

C313102

R321

R319

150K

1R

DV33

SL+

SLLIMIT

SP+

SP-

R320

150K

R318

680K/1%

Figure 3.3.1.5 Servo circuit diagram

C307

222

R317

680K/1%

R322

330R

C308

101(DNS)

C310

222

LIMIT#

R331

0R

OPO

ADIN

OPOP+

V1P4

- 34 -

Page 39

3.3.2 Troubleshooting flow chart

1. Troubleshooting process for “Power on (insert “power plug” and turn on “power switch”) is shown

in the following figure 3.3.2.1:

Power on test

Whether

power-on picture

may be displayed

Y

N

Whether

3.3V, 1.8V power is

normal

Y

Check

whether 27M clock is

normal

Y

Whether

reset is normal

Y

Check

whether SDRAM

and FLASH power

supply is

normal

Y

Whether

firmware is normal

N

N

N

N

N

Whether

voltage regulating

circuit of Dv33 1.8V

is normal

Check clock circuit

Check reset circuit

Power supply loop and

filtering circuit

Upgrade again

N

Check voltage regulating circuit

Whether

disc reading is normal

Y

A

Check

whether clock

of SDRAM is

normal

Check

whether SDRAM

works

Change MT1389

N

Servo circuit troubleshooting

Y

Check

N

Y

N

Y

whether FLSAH

and MT1389 has rosin

joint

Y

Weld again

Check

whether SDRAM

MT1389 has rosin

joint

Y

Weld again

N

N

Change

Change

- 35 -

Page 40

A

Whether

sound is normal

Y

Whether

screen display is normal

N

N

whether MT1389

has audio signal

Check audio output circuit

Whether

MT1389 has signal to

Check panel circuit

Check

output

Y

panel

Y

N

Check MT1389 and power supply

N

Whether

firmware is correct

Change 1389

Figure 3.3.2.1 Troubleshooting flow chart for “Power on”

N

Upgrade again

Y

- 36 -

Page 41

2. Troubleshooting process for “Not read disc” is shown in the following figure 3.3.2.2:

Not read disc

Whether

laser head resets

Y

Whether

there is focus acts

Y

N

N N

Whether

pin 26 of AM5888S

has feed signal

input

Y