Page 1

e

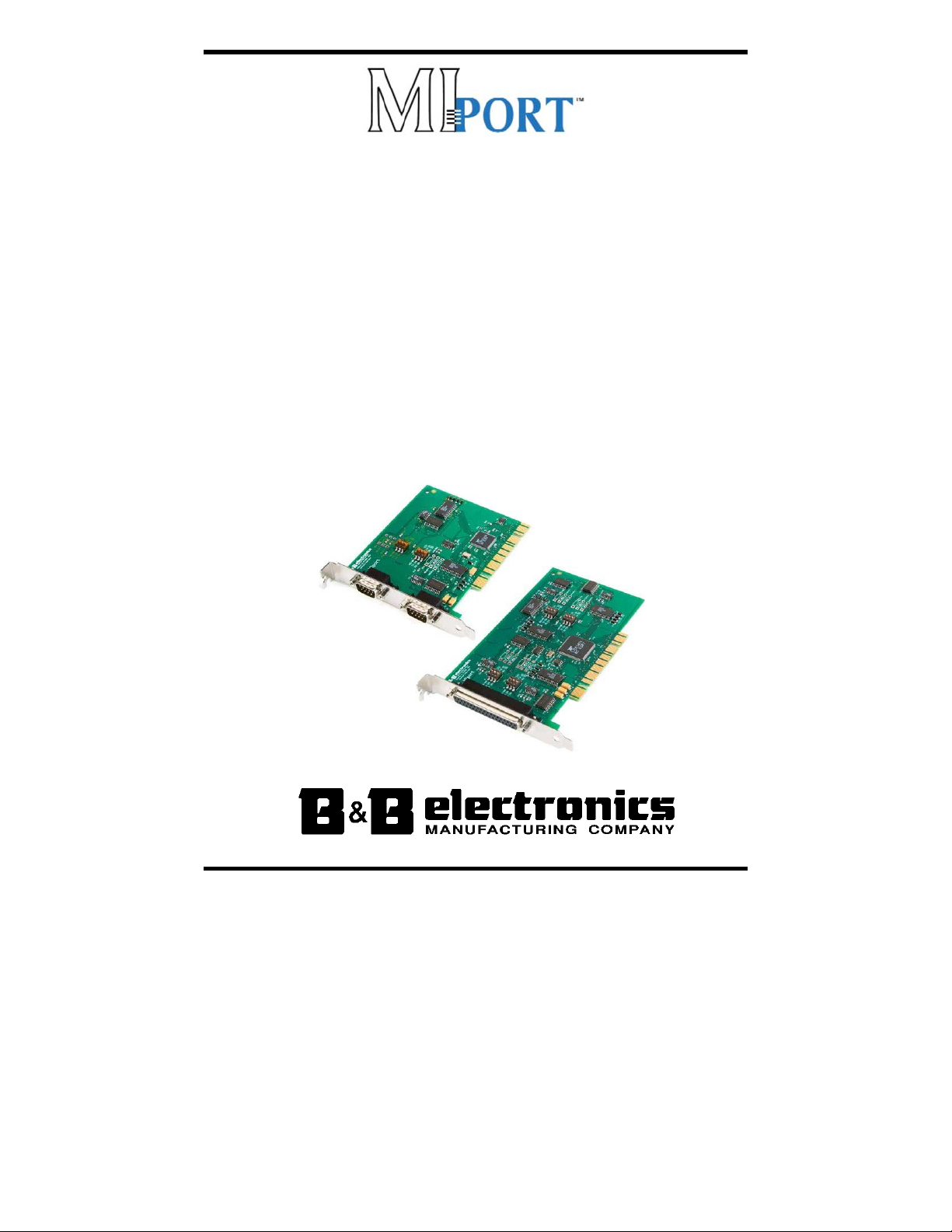

MMuullttii--IInntteerrffaacce

PPCCII BBuuss SSeerriiaall CCaarrdds

s

((RRSS--223322 // RRSS--442222 // RRSS--448855))

MMooddeellss 33PPCCIIUU22,, 33PPCCIIUU44,, 33PPCCIIUU88

)

((NNoonn--IIssoollaatteedd)

aanndd

MMooddeellss 33PPCCIIOOUU11,, 33PPCCIIOOUU22,, 33PPCCIIOOUU44

((IIssoollaatteedd))

Manual Documentation Number 3PCIoUx-1008

Page 2

International Headquarters

B&B Electronics Mfg. Co. Inc.

707 Dayton Road

Ottawa, IL 61350 USA

Phone (815) 433-5100 -- General Fax (815) 433-5105

Website: www.bb-elec.com

Sales e-mail: orders@bb-elec.com

Technical Support e-mail: support@bb.elec.com

European Headquarters

B&B Electronics

Westlink Commercial Park

Oranmore, Co. Galway, Ireland

Phone +353 91-792444 -- Fax +353 91-792445

Website: www.bb-europe.com

Sales e-mail: sales@bb-europe.com

Technical Support e-mail: support@bb-europe.com

© 2008 B&B Electronics – Revised February 2008

-- Fax (815) 433-5109

-- Fax (815) 433-5104

Manual Documentation Number 3PCIoUx-1008

B&B Electronics Mfg Co Inc – 707 Dayton Rd - PO Box 1040 - Ottawa IL 61350 - Ph 815-433-5100 - Fax 815-433-5104 – www.bb-elec.com

B&B Electronics Ltd – Westlink Commercial Park – Oranmore, Galway, Ireland – Ph +353 91-792444 – Fax +353 91-792445 – www.bb-europe.com

Page 3

CAUTION:

This is an Electrostatic Sensitive Device. Use ESD precautions for safe

handling.

Before removing the card from the anti-static protective packaging:

- Discharge any static electricity buildup on your body by touching a large

grounded metal surface or the metal chassis on equipment connected to earth

ground by a 3-wire power cord. Use of a grounding wrist strap is recommended.

- Avoid touching the gold connectors or other parts on the card except when

necessary to set the configuration DIP switches.

- Remove AC power from the computer before inserting the card

©

2008 B&B Electronics. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photography, recording, or any information storage and retrieval system without written consent. Information

in this manual is subject to change without notice, and does not represent a commitment on the part of B&B Electronics.

B&B Electronics shall not be liable for incidental or consequential damages resulting from the furnishing, performance, or use of

this manual.

All brand names used in this manual are the registered trademarks of their respective owners. The use of trademarks or other

designations in this publication is for reference purposes only and does not constitute an endorsement by the trademark holder.

Manual Documentation Number 3PCIoUx-1008 Table of Contents i

Page 4

TTaabbllee ooff CCoonntteennttss

TABLE OF CONTENTS ...........................................................................................II

CHAPTER 1: GENERAL INFORMATION ........................................................... 1

INTRODUCTION ........................................................................................................... 1

FEATURES ................................................................................................................... 1

MIPORT MODELS AND FEATURES ............................................................................... 3

QUICK START GUIDE .................................................................................................. 5

SPECIFICATIONS .......................................................................................................... 7

CHAPTER 2: SERIAL CARD SETUP ..................................................................... 8

PRE-SETUP STEPS ....................................................................................................... 8

ESD Precautions .................................................................................................... 8

Initial Configuration .............................................................................................. 8

OVERVIEW OF OPERATIONAL MODES ......................................................................... 9

RS-232 Mode .......................................................................................................... 9

RS-422 Mode .......................................................................................................... 9

RS-485 Mode .......................................................................................................... 9

OPERATING MODE SELECTION ................................................................................. 10

Setting the DIP Switches on RS-232/422/485 Ports ............................................. 11

Setting the DIP Switches on RS-422/485 Only Ports ........................................... 12

INSTALLING THE SERIAL CARD ................................................................................. 14

CHAPTER 3: DRIVER SOFTWARE INSTALLATION ...................................... 15

INSTALLING WINDOWS VISTA DRIVER SOFTWARE ................................................... 15

Pre-Installation Steps ........................................................................................... 15

Using the Found New Hardware Wizard ............................................................. 16

INSTALLING WINDOWS XP PROFESSIONAL DRIVER SOFTWARE ............................... 17

Windows Settings ................................................................................................. 17

Pre-Installation Steps ........................................................................................... 17

Using the Found New Hardware Wizard ............................................................. 18

Checking the Driver Installation .......................................................................... 20

INSTALLING WINDOWS 2000 PROFESSIONAL DRIVER SOFTWARE ............................ 22

Windows Settings ................................................................................................. 22

Pre-Installation Steps ........................................................................................... 22

Using the Found New Hardware Wizard ............................................................. 23

Checking the Driver Installation .......................................................................... 27

INSTALLING WINDOWS 98 OR ME DRIVER SOFTWARE ............................................. 28

Windows Settings ................................................................................................. 28

Pre-Installation Steps ........................................................................................... 28

Using the Add New Hardware Wizard ................................................................. 29

Checking the Driver Installation .......................................................................... 32

ii Table of Contents Manual Documentation Number 3PCIoUx-1008

Page 5

INSTALLING WINDOWS NT DRIVER SOFTWARE ....................................................... 34

INSTALLING WINDOWS NT DRIVER SOFTWARE ....................................................... 34

Windows Settings ................................................................................................. 34

Pre-Installation Steps ........................................................................................... 34

Installing the Driver Software .............................................................................. 34

Configuring the Serial Ports ................................................................................ 37

CHAPTER 4: SETTING DRIVER OPTIONS ....................................................... 40

CONFIGURING PORT SETTINGS (DOES NOT APPLY TO WINDOWS NT.) ..................... 40

SETTING THE FIFO BUFFERS .................................................................................... 41

SETTING THE RTS CONTROL PARAMETER ................................................................ 42

SETTING THE HARDWARE HANDSHAKING LEVEL ..................................................... 42

CHANGING THE COM PORT NAME/NUMBER ............................................................ 42

CHAPTER 5: INSTALLING LINUX DRIVER SOFTWARE ............................. 44

INSTALLING MIPORT DRIVERS IN LINUX .................................................................. 44

Preparing the Linux Files .................................................................................... 44

Compiling the Driver ........................................................................................... 44

Installing the Driver ............................................................................................. 45

CHECKING THE DRIVER INSTALLATION .................................................................... 47

USING THE EXAR SERIAL GUI EXAMPLE APPLICATION ........................................... 48

Preparing the Example Application Files ............................................................ 48

Running the Exar Serial Test GUI ....................................................................... 48

Configuring Port Settings .................................................................................... 50

CHAPTER 6: REMOVING DRIVERS, PORTS AND CARDS............................ 51

REMOVING MIPORT CARDS FROM WIN98/ME/2000/2003 SERVER/XP/VISTA ......... 51

Uninstalling the MIport Card .............................................................................. 51

Uninstalling the COM ports ................................................................................. 51

Removing INF and PNF Driver Files .................................................................. 52

REMOVING MIPORT CARDS FROM WINDOWS NT ..................................................... 54

Uninstalling the MIport Card .............................................................................. 54

Uninstalling the Driver ........................................................................................ 54

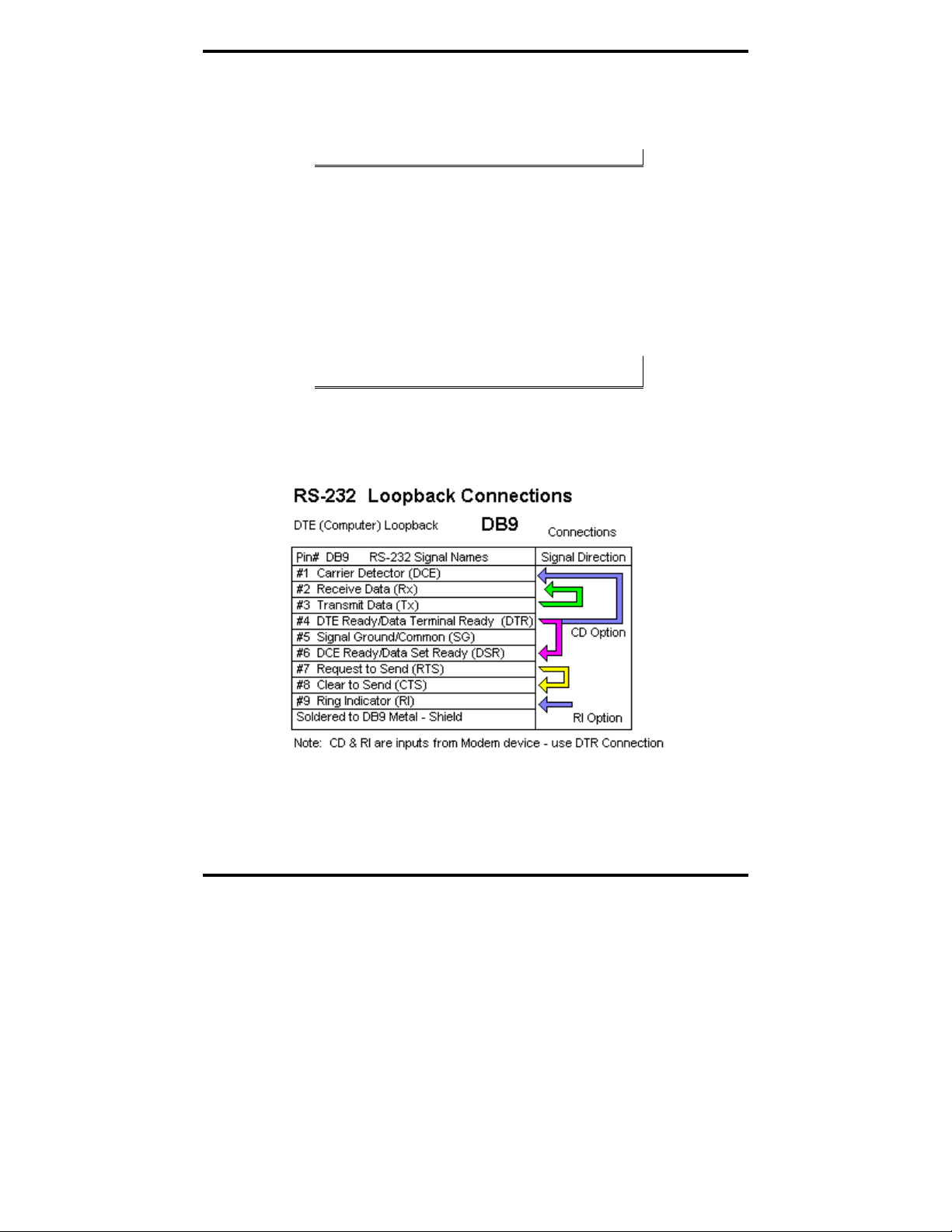

CHAPTER 7: RS-232 CONNECTIONS/OPERATION ......................................... 55

RS-232 MODE .......................................................................................................... 55

RS-232 SIGNAL DESIGNATIONS AND DB-9 PINOUT ................................................. 55

RS-232 Signal Designations ................................................................................. 56

DTE AND DCE ......................................................................................................... 56

RS-232 SIGNAL LEVELS ........................................................................................... 57

HANDSHAKING ......................................................................................................... 57

RTS CONTROL IN RS-232 MODE ............................................................................. 57

CHAPTER 8: RS-422/485 CONNECTIONS/OPERATION ................................. 59

RS-422/485 MODE ................................................................................................... 59

Manual Documentation Number 3PCIoUx-1008 Table of Contents iii

Page 6

RS-422/485 SIGNAL DESIGNATIONS AND DB-9 PINOUT .......................................... 59

RS-422/485 Signal Designations ......................................................................... 60

RS-422/485 DIFFERENTIAL SIGNALS ........................................................................ 60

RS-422 OPERATION .................................................................................................. 61

RS-422 Limitations ............................................................................................... 61

RS-485 OPERATION .................................................................................................. 61

Send Data Control ............................................................................................... 62

RS-485 TERMINATION RESISTORS ............................................................................ 63

RS-485 NETWORK BIASING ...................................................................................... 63

2-WIRE RS-485 CONNECTIONS ................................................................................ 65

2-Wire RS-485 Mode: .......................................................................................... 65

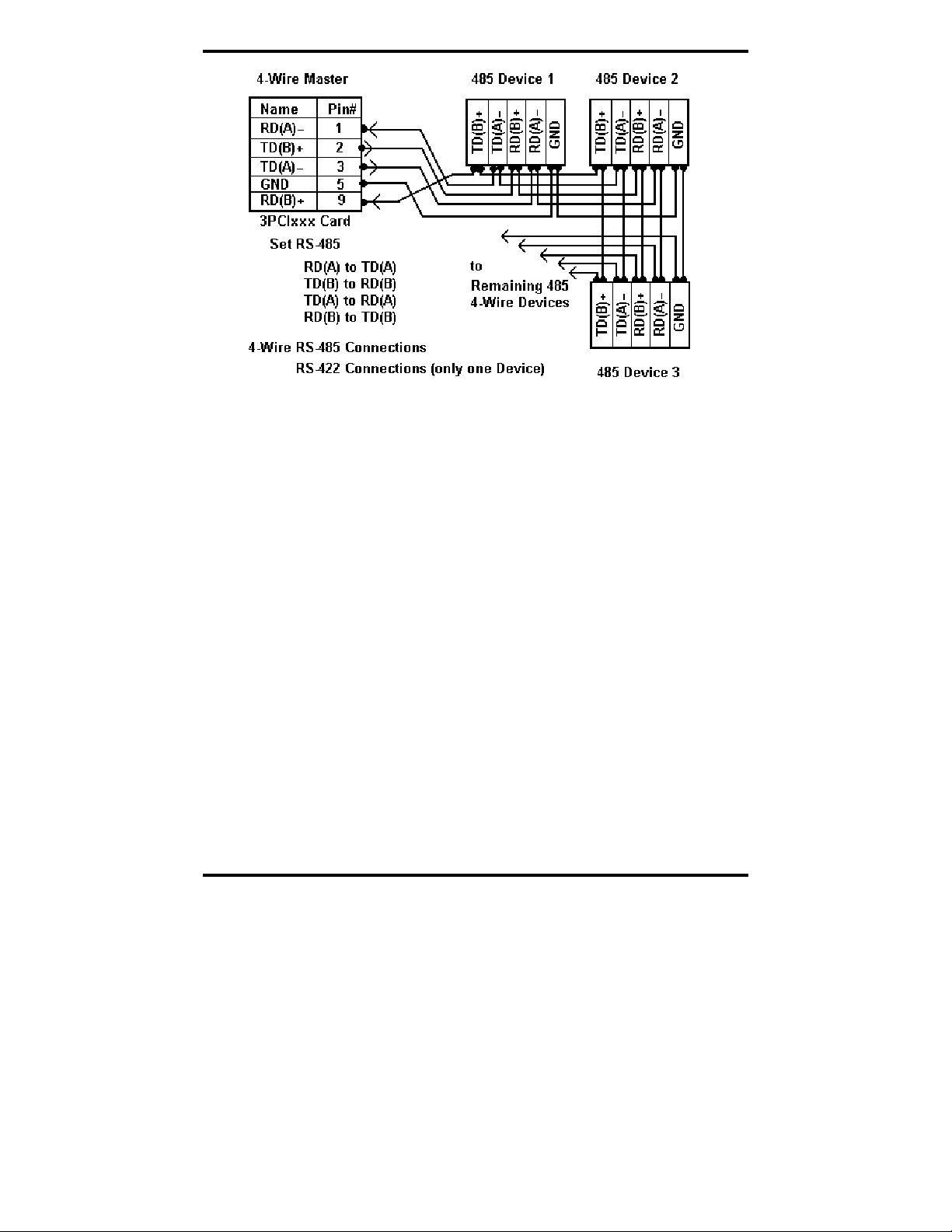

4-WIRE RS-422 AND RS-485 CONNECTIONS ............................................................ 65

RS-422 Point to Point Connection ....................................................................... 65

RS-422 Point to Multipoints Connection ............................................................. 66

4-Wire RS-485 Connection .................................................................................. 66

CHAPTER 9: TROUBLESHOOTING MIPORT CARDS .................................... 68

STARTING UP ............................................................................................................ 68

CHECKING CONNECTIONS ......................................................................................... 68

RS-232/422/485 Operation .................................................................................. 68

RS-232 Operation ................................................................................................ 68

RS-422/485 Operation ......................................................................................... 69

CHECKING THE MIPORT CARD ................................................................................. 69

Support ................................................................................................................. 71

APPENDIX A: DIP SWITCH/MODE SETTINGS .................................................. 1

SETTING THE DIP SWITCHES ON RS-232/422/485 PORTS ........................................... 1

DIP Switch 1 (RS-232/422/485 ports) .................................................................... 1

DIP Switch 2 (RS-232/422/485 ports) .................................................................... 1

DIP Switch 3 (RS-232/422/485 ports) .................................................................... 2

SETTING THE DIP SWITCHES ON RS-422/485 ONLY PORTS ........................................ 2

APPENDIX B: CONNECTOR PINOUTS ............................................................... 1

RS-232 PINOUTS ........................................................................................................ 1

RS-422/485 PINOUTS ................................................................................................. 2

APPENDIX C: TROUBLESHOOTING WITH COMTEST ................................. 1

COMTEST FEATURES .................................................................................................. 1

INSTALLING COMTEST ............................................................................................... 2

LOOPBACK TESTING WITH COMTEST ......................................................................... 2

APPENDIX D: DECLARATION OF CONFORMITY STATEMENT ................ 5

iv Table of Contents Manual Documentation Number 3PCIoUx-1008

Page 7

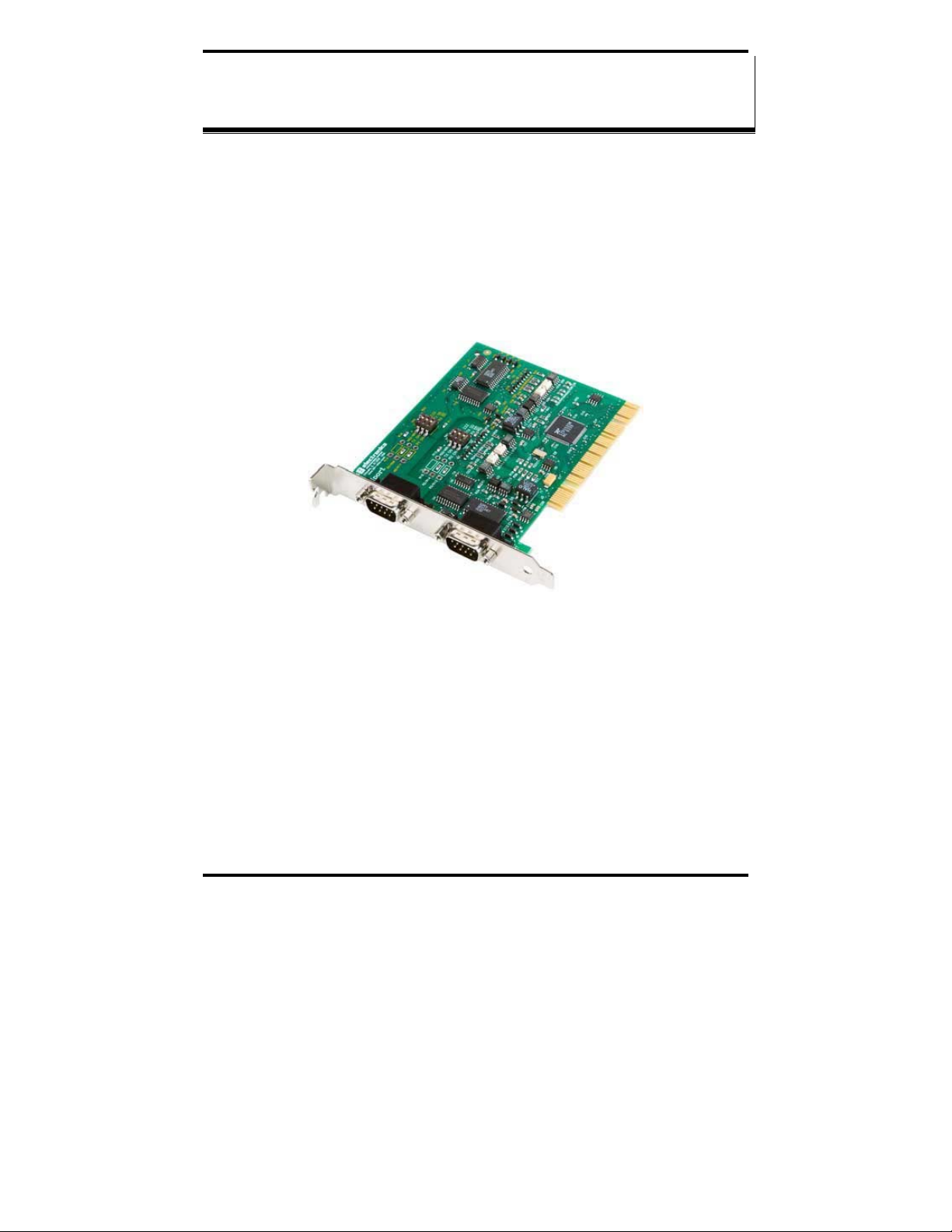

General Information

Introduction

MIport PCI serial interface cards allow you to add RS-232, RS-422 and RS485 interfaces to Windows based computers equipped with a PCI bus.

Depending on your choice of card one, two or four optically isolated serial

ports, or two, four or eight non-isolated serial ports, can be added. MIport

PCI serial cards are Plug and Play compatible, which allows the Windows

Operating System and driver to set the addresses and IRQ used by the card.

CChhaapptteerr 11:: GGeenneerraall IInnffoorrmmaattiioonn

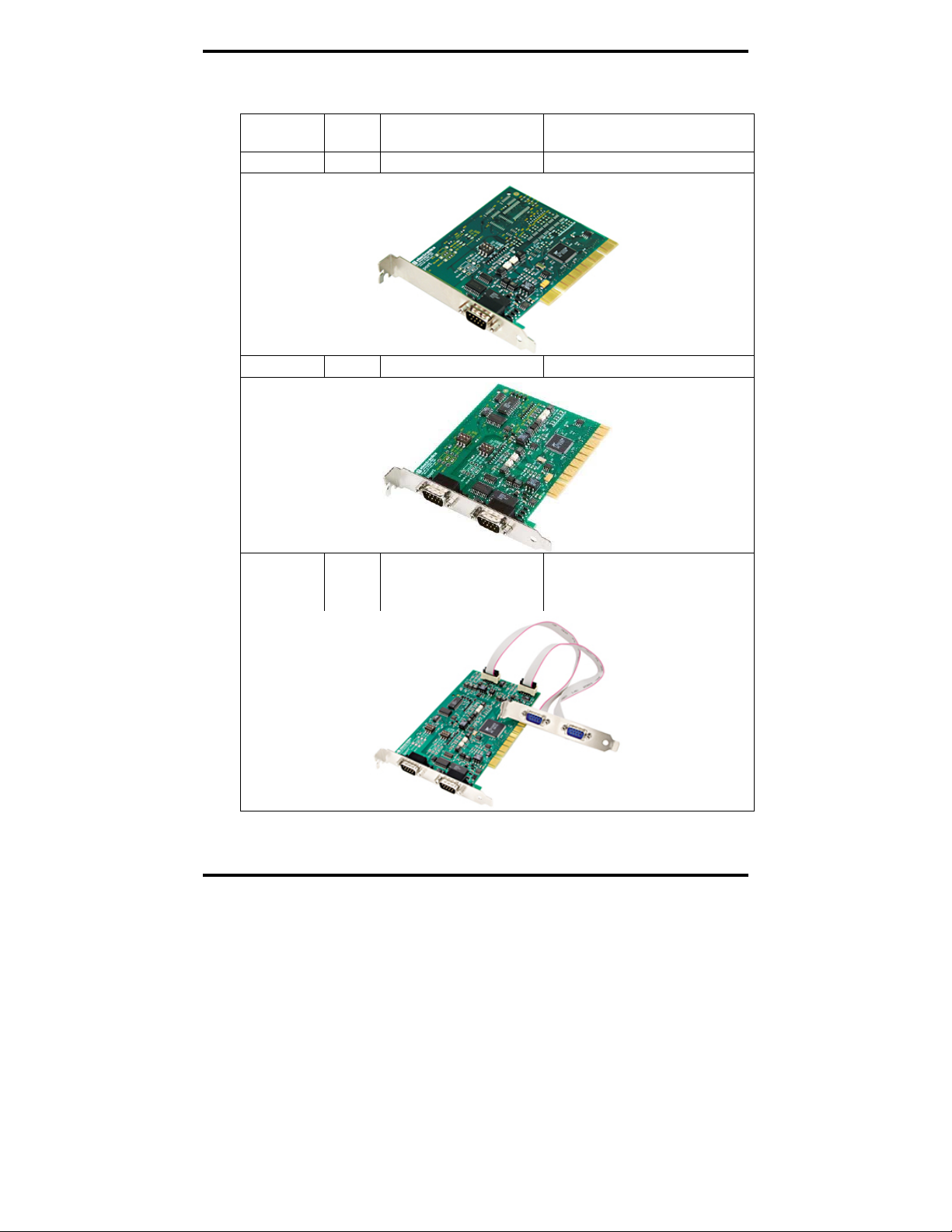

Figure 1. A 3PCIOU2 Optically Isolated Two-Port PCI Serial

Interface Card

Features

• Optically isolated or non-isolated models available

• Isolated models available in 1, 2 or 4 ports

• Non-isolated models available in 2, 4 or 8 ports

• 4 and 8 port models include fanout cables

• Plug & Play compatible – Windows sets addresses and IRQ used

• 5 volt and 3.3 volt PCI bus compatible

• PCI-X compatible

Manual Documentation Number 3PCIoUx-1008 Chapter 1 1

Page 8

General Information

• Conform to the PCI V2.3 Universal PCI specification

• RS-232/RS-422/RS-485 interfaces

• 2-wire or 4-wire RS-485 operation (half or full-duplex)

• Automatic Send Data Control for RS-485 operation

• Buffered high speed XR17D15x PCI Bus UARTs (16C550 compatible)

with 64 byte FIFOs for input/output with programmable trigger

thresholds

• Advanced driver function for COM port rename (Refer to Chapter 4)

• Supports baud rates up to 460.8 kbps

• Windows 98, ME, NT4.0, 2000, 2003 Server, XP, Vista and Linux 2.4

supported

2 Chapter 1 Manual Documentation Number 3PCIoUx-1008

Page 9

General Information

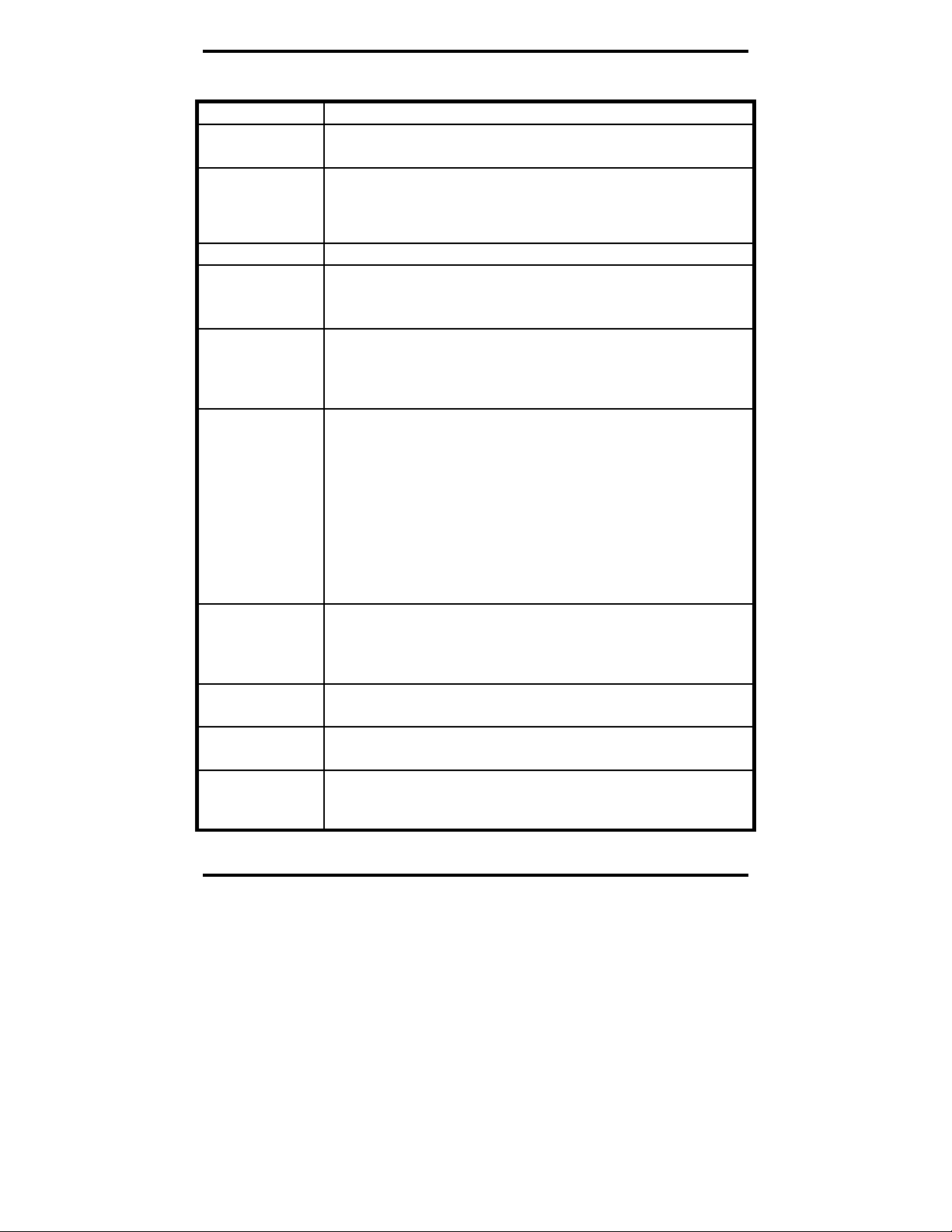

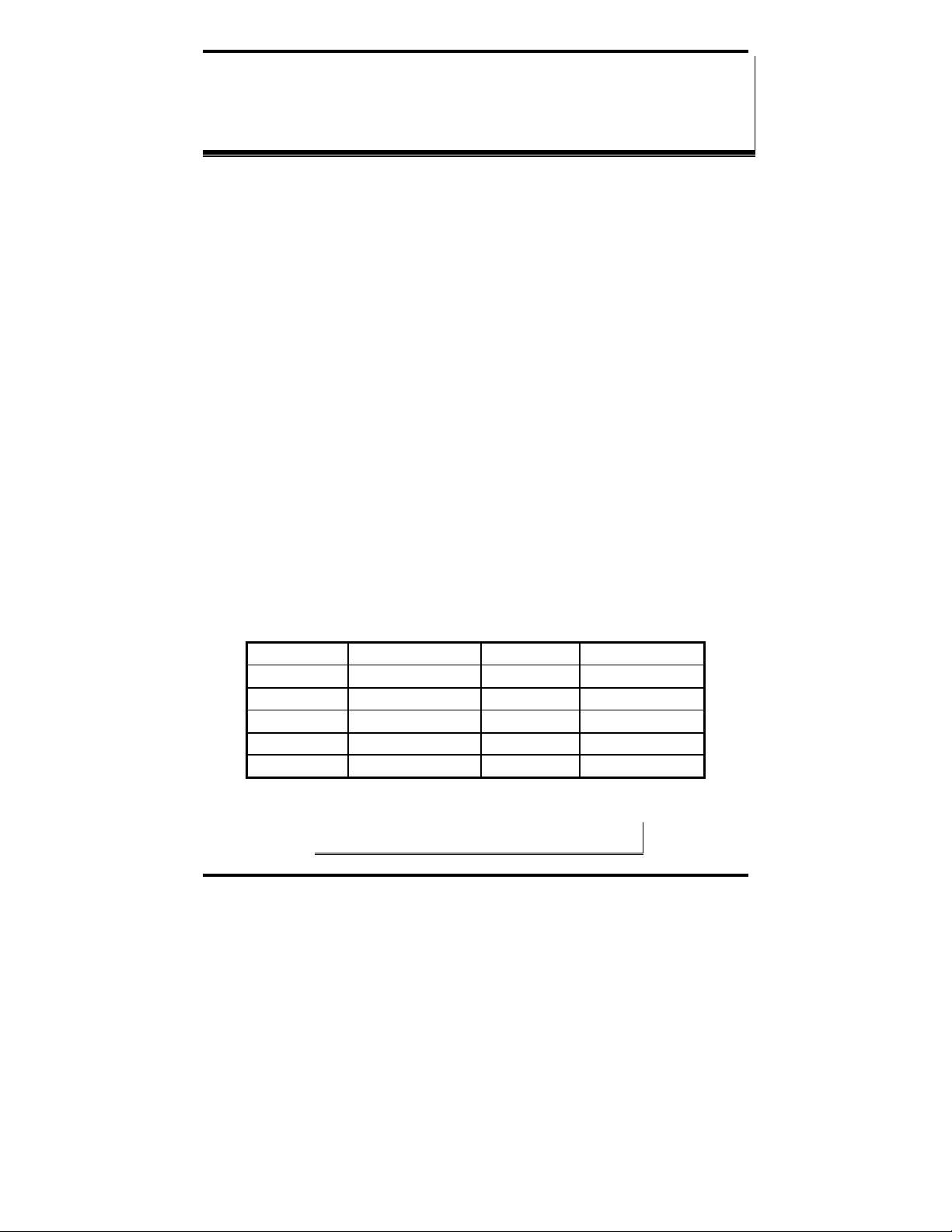

MIport Models and Features

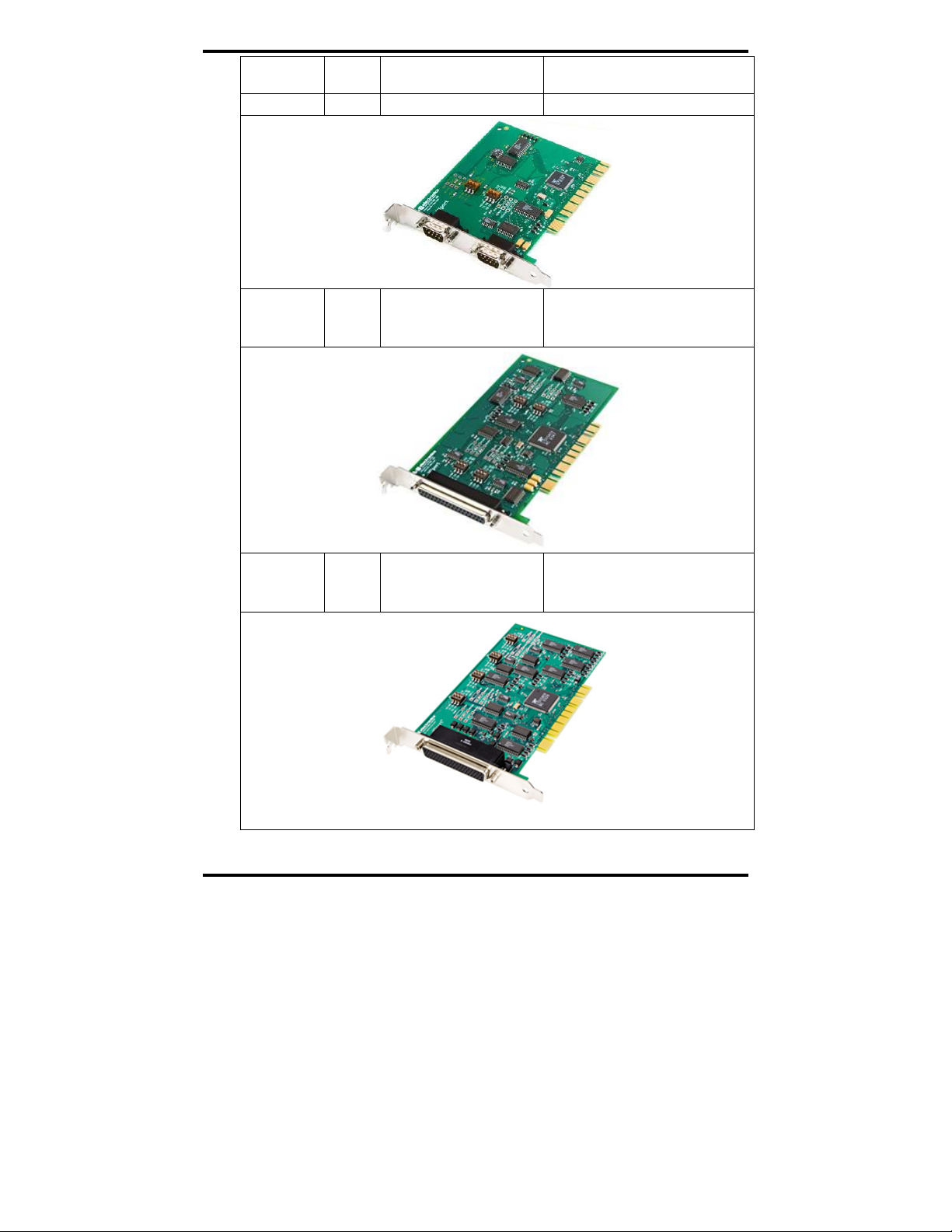

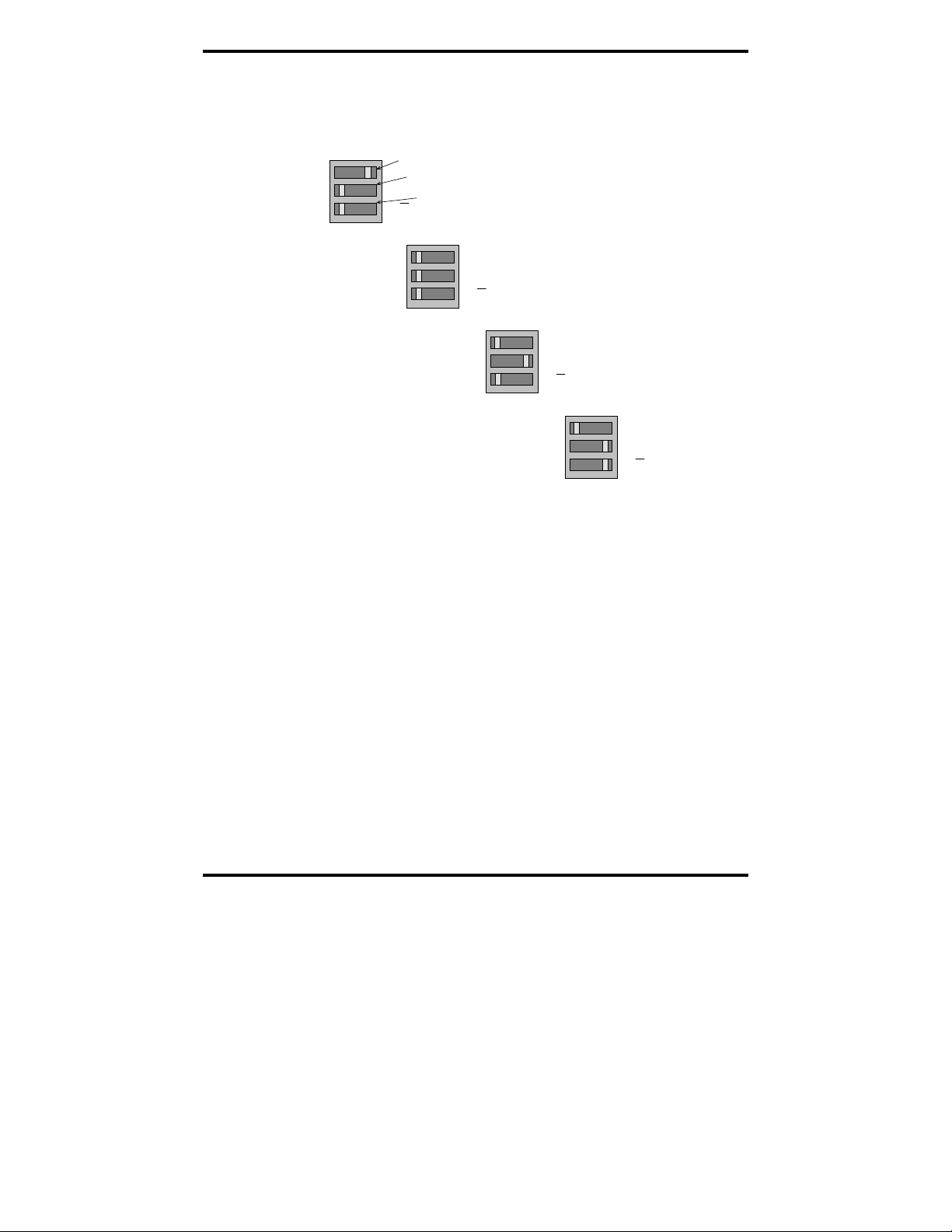

Model

Number

3PCIOU1

3PCIOU2

3PCIOU4

Ports Interface Connectors

1 RS-232/422/485 DB-9 male

2 RS-232/422/485 DB-9 male

4 2 RS-232/422/485 ports

2 RS-422/485 ports

2 x DB-9 male use 2nd expansion

2 x DB-9 male

slot

Figure 2. MIport Optically Isolated PCI Cards

Manual Documentation Number 3PCIoUx-1008 Chapter 1 3

Page 10

General Information

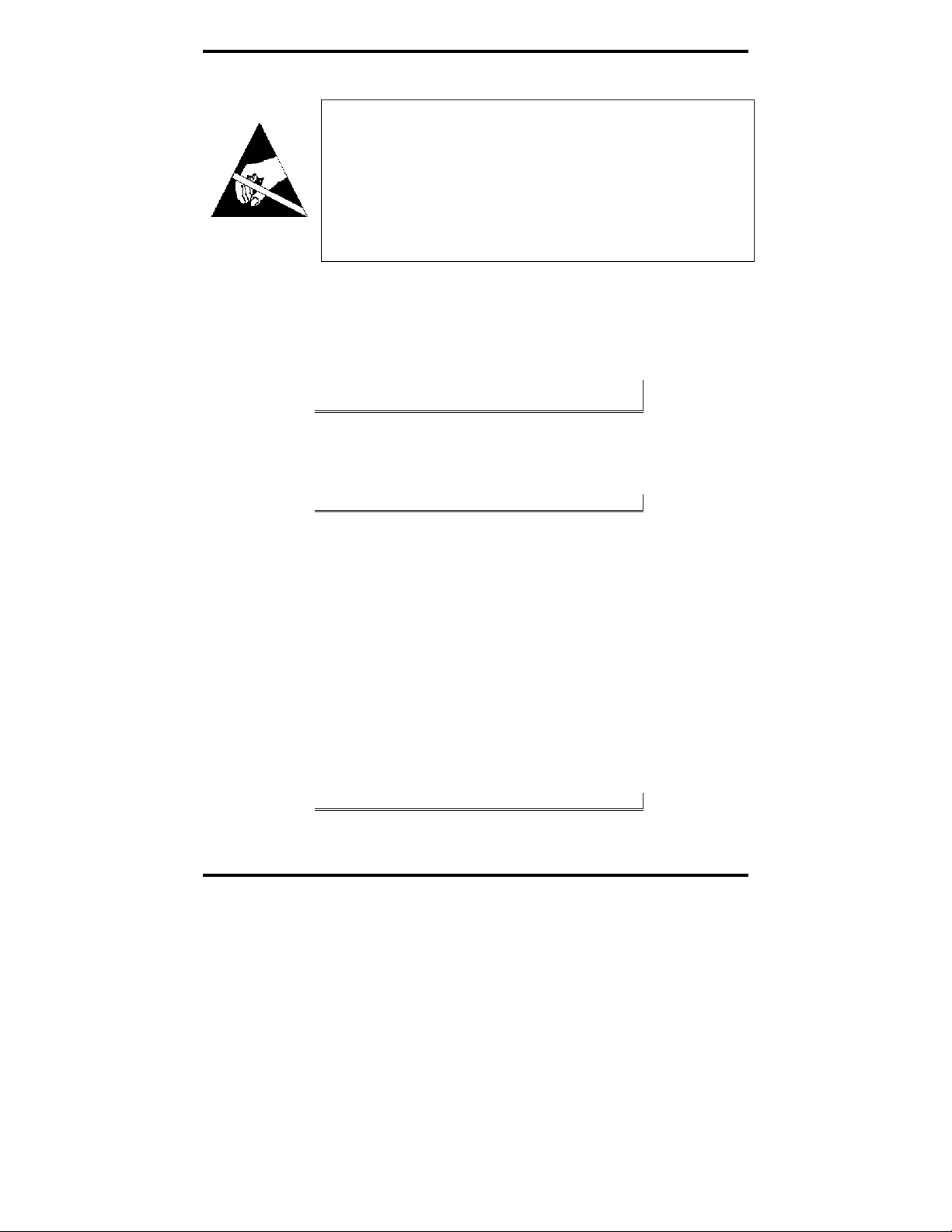

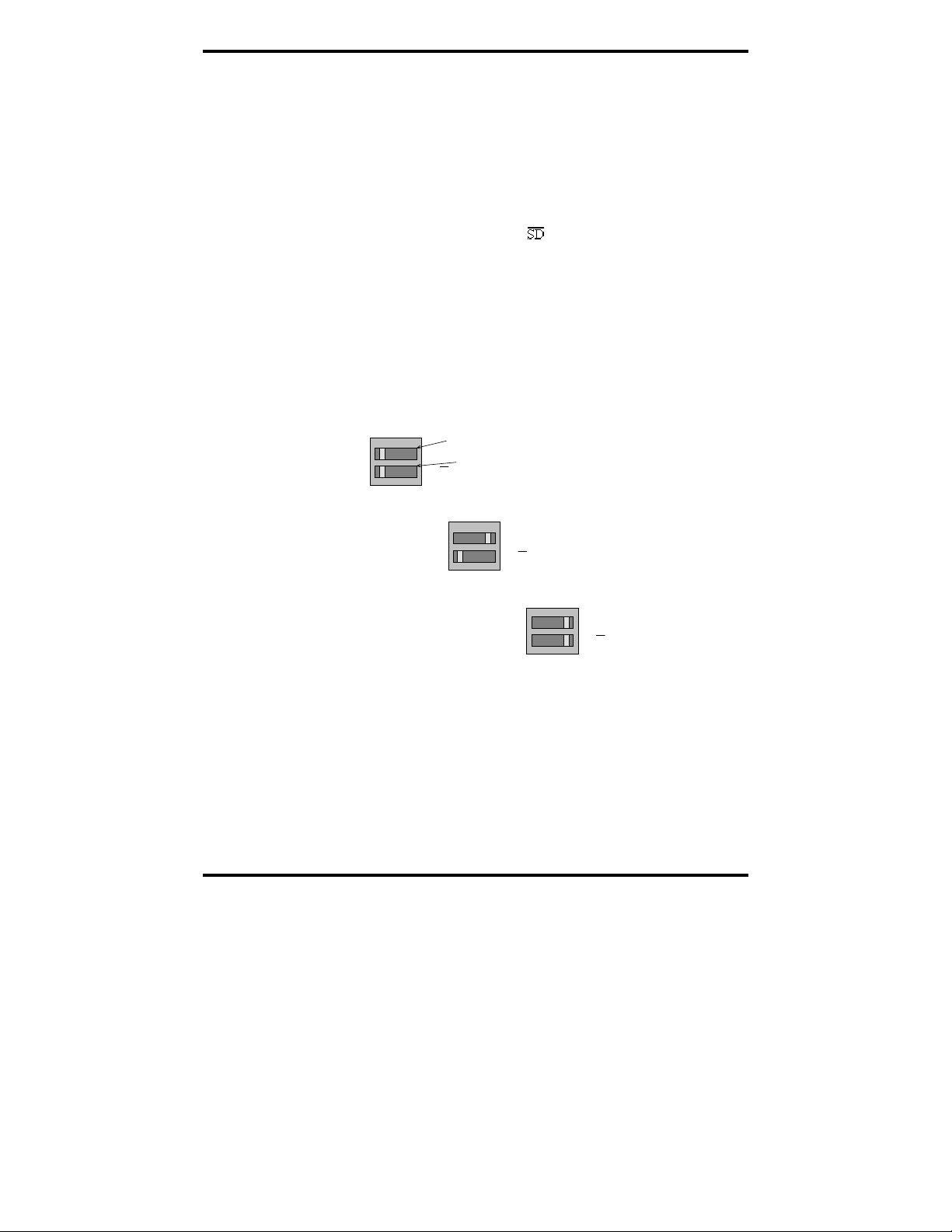

Model

Number

3PCIU2

3PCIU4

Ports Interface Connectors

2 RS-232/422/485 2 x DB-9 male

4 RS-232/422/485 DB-37 female

(plus DB-37 to 4x DB-9 male

cable)

3PCIU8

8 4 RS-232/422/485 ports

4 RS-232 ports

DB-78 female

(plus DB-78 to 8x DB-9 male

cable)

Figure 3. MIport Non-Isolated PCI Cards

4 Chapter 1 Manual Documentation Number 3PCIoUx-1008

Page 11

General Information

Quick Start Guide

CAUTION:

This is an Electrostatic Sensitive Device. Use ESD precautions for safe

handling.

Before removing the card from the anti-static protective packaging:

- Discharge any static electricity buildup on your body by touching a large

grounded metal surface or the metal chassis on equipment connected to earth

ground by a 3-wire power cord. Use of a grounding wrist strap is recommended.

- Avoid touching the gold connectors or other parts on the card except when

necessary to set the configuration DIP switches.

- Remove AC power from the computer before inserting the card

1. Determine the interface requirements of your application, including:

a. Interface standard(s) (RS-232, RS-422 or RS-485)

b. Data transmission mode (Two-wire or four-wire)

c. Cable lengths, connectors, pinouts

Note: For information on cables and pinouts refer to Chapter 5 (RS-

232) or Chapter 6 (RS-422/RS-485).

2. Set the operating mode DIP switches to configure the

communications interface for the required interface standard and

transmit/receive mode.

Note: Refer to the DIP switch table in Chapter 2.

3. Shut down your computer. (You may want to unplug the computer

power cord to prevent accidentally turning the computer on during

installation.)

4. Install the PCI card in your computer and replace the cover.

5. Connect the cable(s) from the card to your peripheral device (Cable

also can be connected/changed later.)

6. Power up the computer

7. Insert the driver disc into your CD-ROM drive

8. Wait until new hardware is detected.

9. Follow the instructions in the Add New Hardware Wizard. (This

varies depending on your operating system.)

Note: Refer to Chapter 3.

10. Check for new COM ports in Device Manager.

Manual Documentation Number 3PCIoUx-1008 Chapter 1 5

Page 12

General Information

11. Select the appropriate COM port, double-click and check properties.

12. Check and set up Port Settings

13. Under Advanced Settings, set Buffer, RTS Control and Hysteresis

14. If your card was not connected to a peripheral device in Step 5,

15. Use a communications test program (such as ComTest) to check

Level. Change the COM port name, if necessary.

make your connections now. (Powering down the computer while

making connections is recommended.)

communications between the computer and your peripheral device.

6 Chapter 1 Manual Documentation Number 3PCIoUx-1008

Page 13

General Information

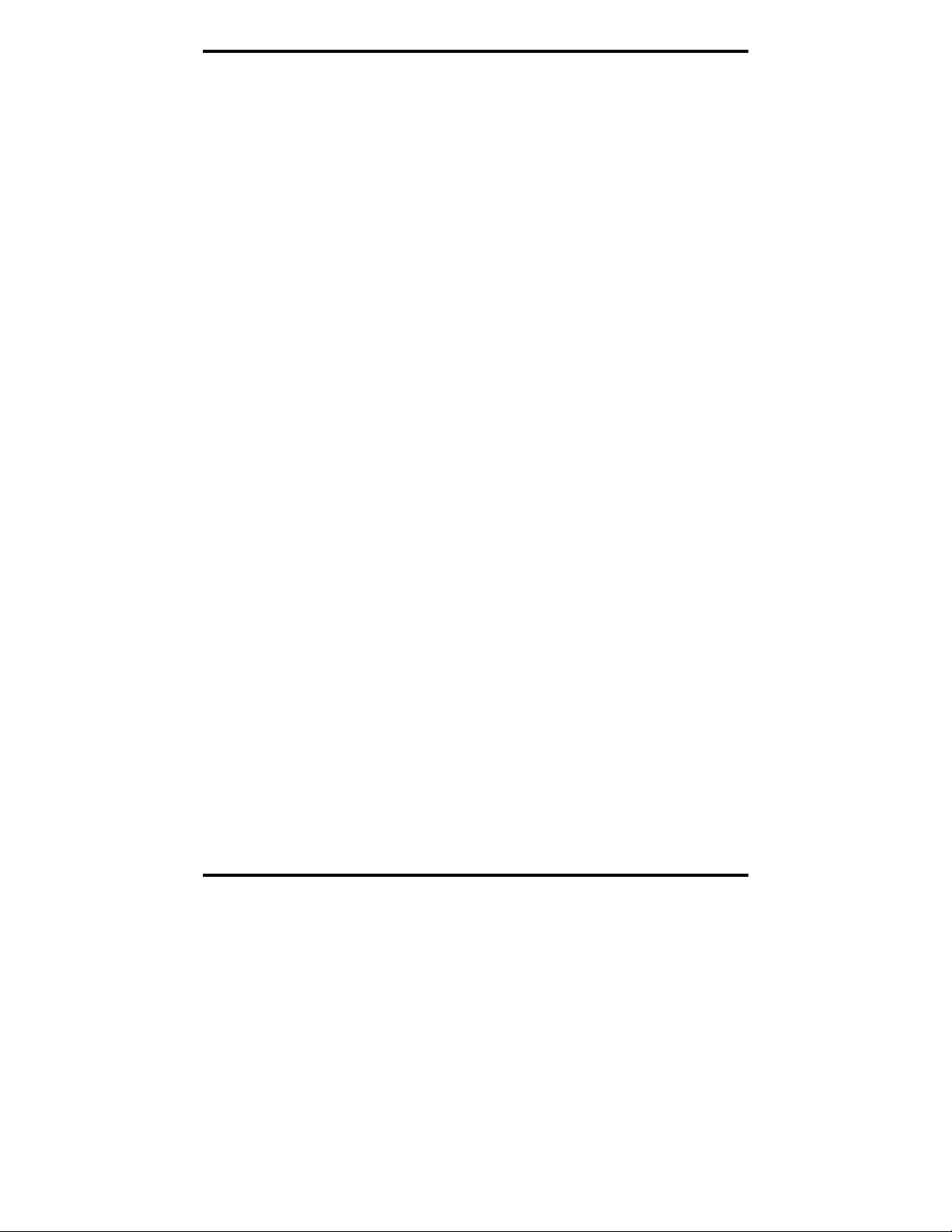

Specifications

OS Supported

Bus

Slot

Baud Rates

UARTs

Character Length

Parity

Stop Bits

Optical Isolation

(3PCIOU1,

3PCIOU2,

3PCIOU4 only)

Connectors

Data Signals

Environmental

Dimensions

Accessories

Windows 98, ME, NT 4.0, 2000, 2003 Server, XP, Vista and Linux 2.4

PCI bus (33MHz/32-bit) PCI Bus specification

Requires one PCI slot (3.3V or 5V signaling)

Maximum: Up to 460.8 kbps (RS-232/422/485)

Typical: 75, 110, 134, 150, 300, 600, 1200, 1800, 2400, 4800,

7200, 9600, 14.4k, 19.2k, 38.4k, 57.6k, 115.2k,

230.4k, 460.8k

XR17D15x (16C550 compatible) with 64 byte FIFO buffers

5, 6, 7 or 8 bits

Even, odd, none, space or mark

1, 1.5 or 2

2000 VDC minimum on all lines

Ports are isolated from the PC power and ground, as well as other ports

on the same card.

3PCIOU1: 1 – DB-9 male

3PCIOU2: 2 – DB-9 male

3PCIOU4: 2 – DB-9 male (RS-232/422/485 ports)

nd

2 – DB-9 male via ribbon cable on 2

expansion slot

bracket (RS-422/485 ports)

3PCIU2: 2 – DB-9 male

3PCIU4: 1 – DB-37 female with DB-37 to 4 x DB-9 male

cable

3PCIU8: 1 - DB-78 female with DB-78 to 8 x DB-9 male

cable (4 x RS-232/422/485 and 4 x RS-232)

RS-232: TD, RD, RTS, CTS, DTR, DSR, DCD, RI and GND

(TD, RD, RTS, CTS, GND only on 3PCIOU4)

RS-422: TD(A)-, TD(B)+, RD(A)-, RD(B)+ and GND

RS-485: Data(A)-, Data(B)+ and GND

Operating temperature range: 0º to 50ºC minimum

Operating humidity: 5% to 95%, non-condensing

4.8 x 3.8 in (12.2 x 9.6 cm) card edge

(Mounting bracket, 1.2 x 12.1 x 0.9 cm)

Software: Driver CD-ROM disc for Windows 98, ME, NT,

4.0, 2000, 2003 Server, XP, Vista, and Linux 2.4

Manual: Instruction Manual Contained on CD ROM

Figure 4. MIport Serial Card Specifications

Manual Documentation Number 3PCIoUx-1008 Chapter 1 7

Page 14

Serial Card Setup

CChhaapptteerr 22:: SSeerriiaall CCaarrdd SSeettuupp

The following Serial Card Setup section applies to the following PCI cards:

• 3PCIOU1 one port optically isolated PCI serial card

• 3PCIOU2 two port optically isolated PCI serial card

• 3PCIOU4 four port optically isolated PCI serial card

• 3PCIU2 two port non-isolated PCI serial card

• 3PCIU4 four port non-isolated PCI serial card

• 3PCIU8 eight port non-isolated PCI serial card

Any deviations from the procedure for specific models are noted.

Pre-Setup Steps

Your serial card has been tested for proper operation before packaging and

shipping. It should be in perfect mechanical and electrical condition upon receipt.

ESD Precautions

To ensure a successful installation and setup it is important that you follow the

standard ESD precautions outlined below:

CAUTION:

This is an Electrostatic Sensitive Device. Use ESD precautions for safe

handling.

Before removing the card from the anti-static protective packaging:

- Discharge any static electricity buildup on your body by touching a large

grounded metal surface or the metal chassis on equipment connected to earth

ground by a 3-wire power cord. Use of a grounding wrist strap is recommended.

- Avoid touching the gold connectors or other parts on the card except when

necessary to set the configuration DIP switches.

- Remove AC power from the computer before inserting the card

Initial Configuration

The ports in your MIport card are normally pre-configured for RS-232

operation. To ensure the card is configured correctly for your desired operating

mode, you will have to check and/or set the three operating mode DIP switches

on the card. If you are configuring for RS-485 Mode you also may have to set

up the RTS Control parameter in the device driver.

Note: Refer to Chapter 4 for information on Setting Driver Options.

8 Chapter 2 Manual Documentation Number 3PCIoUx-1008

Page 15

Serial Card Setup

Overview of Operational Modes

RS-232 Mode

In RS-232 Mode MIport serial ports function as buffered standard PC serial

ports and operate as DTEs (Data Terminal Equipment). RS-232 interfaces are

commonly used for communications with modems, serial printers, and

computer-controlled devices such as security equipment, bar code scanners

and point-of-sale devices.

For most MIport models, RS-232 Mode supports eight single-ended signal

lines and signal ground (GND) including transmit (TD), receive (RD) and six

hardware handshake lines (DTR, DSR, RTS, CTS, DCD, RI). The only

exception to this is the MIport Model 3PCIOU4 card, which supports TD,

RD, RTS, CTS and GND.

RS-422 Mode

In RS-422 mode MIport serial ports provide two sets of differential signal

pairs (TD and RD) and signal ground for each port. The RS-422 standard

uses balanced differential drivers and receivers for each signal. This

facilitates greater communication distances than unbalanced systems such as

RS-232. In RS-422 mode the transmitter and receiver are always enabled (TX

ON, RX ON).

RS-422 operation is suitable for interconnecting a computer and one device

for full duplex (point-to-point) bi-directional communication, or a computer

and several devices for unidirectional (point-to-multipoints) communication.

RS-422 interfaces are commonly used for video editing/control, camera

control, electronic signage, television studio/satellite dish control,

performance lighting and audio equipment control.

RS-485 Mode

In RS-485 Mode MIport cards provide RS-485 interfaces which operate with

the same signals and signal levels as RS-422. RS-485 interfaces differ from

RS-422 in that they allow multiple devices to share the same communication

link using half duplex (2-wire) or full duplex (4-wire) connections. Since it is

possible to have more than one transmitter connected to the media,

transmitters must be enabled only while sending data, and tri-stated at all

other times so other devices can use the wire pair. MIport cards automatically

enable the transmitter at the appropriate time using Automatic Send Data

Control, based on the contents of the output buffer. When the buffer has data

to send, the transmitter is enabled (TX SD). When all data in the buffer has

been sent, the transmitter is disabled and tri-stated to a high impedance state.

Manual Documentation Number 3PCIoUx-1008 Chapter 2 9

Page 16

Serial Card Setup

In half-duplex operation, the receiver is disabled during transmit (RX ),

and enabled when not transmitting. In full-duplex operation the receiver is

always enabled (RX ON). Since RS-485 transmitters are tri-stated when not

transmitting, the receive inputs must be biased to ensure the media floats in

the Mark state so that the first Space state is detected correctly at the start of

the next transmission.

These serial cards incorporate the necessary biasing to accommodate up to 32

standard nodes. (Typical input resistance (Rin) for each load is 12kΩ).

Provisions are made for custom biasing and/or termination.

Note: For more information on RS-485 Mode refer to Chapter 6

Operating Mode Selection

The hardware address and IRQ for the serial card is set by the Windows

Operating System using driver information files and the Plug and Play OS.

The Operating Mode is set using DIP switches, Device Manager Driver

Settings and by your cable connections and software. Each port on a MIport

card has an associated DIP switch to set its operating mode. The port number

associated with the DIP switch is clearly silk screened on the printed circuit

board.

Note: Refer to Appendix x for DIP switch locations on various MIport

cards.

10 Chapter 2 Manual Documentation Number 3PCIoUx-1008

Page 17

Serial Card Setup

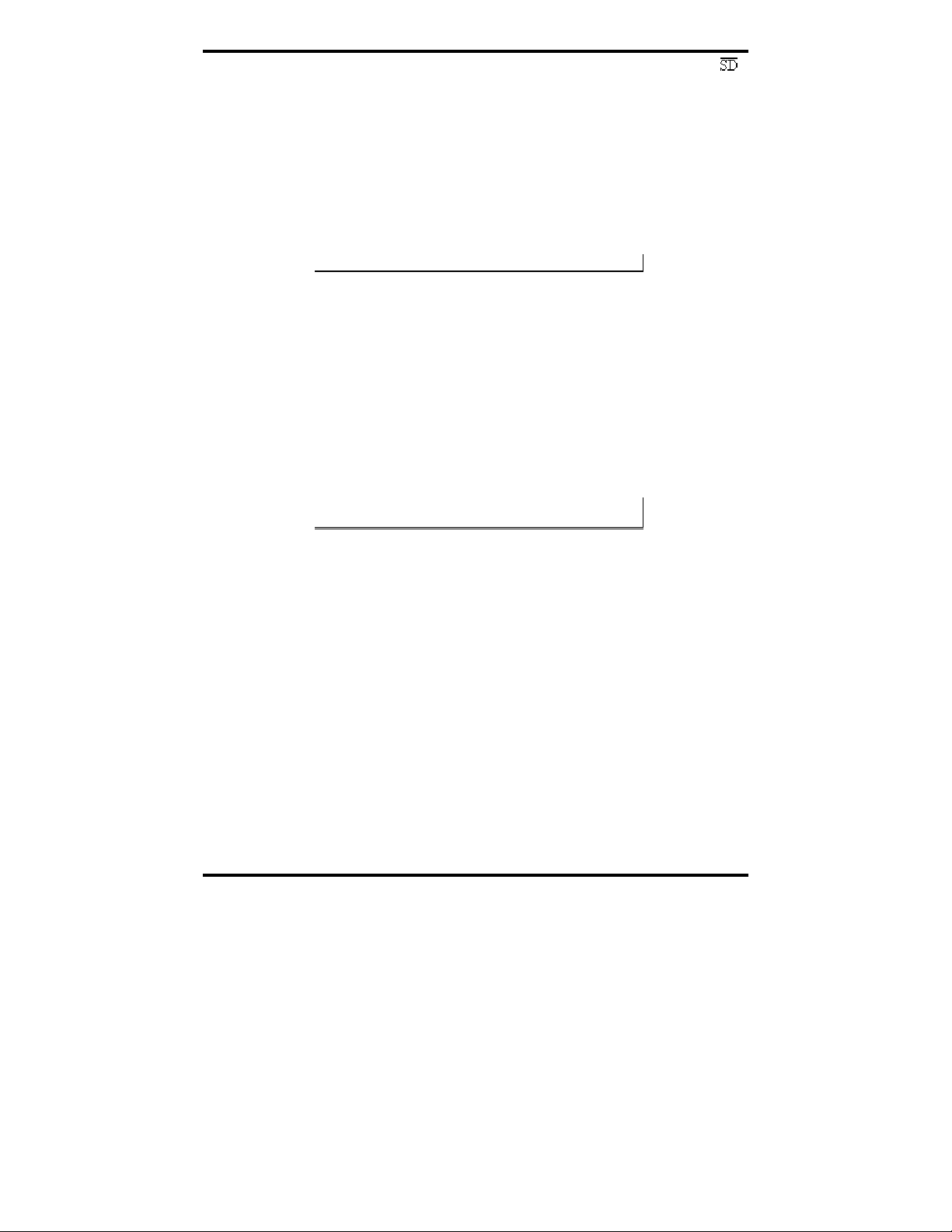

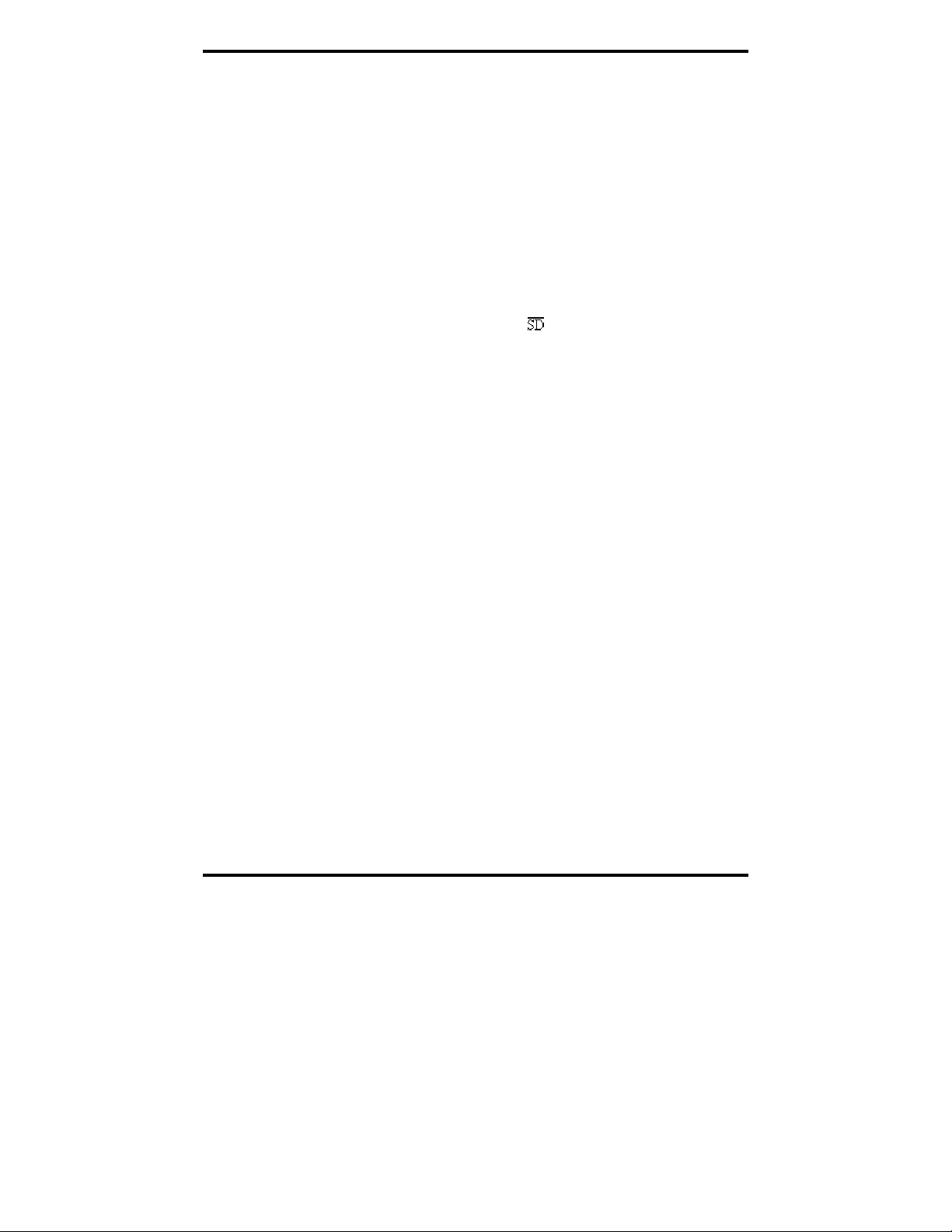

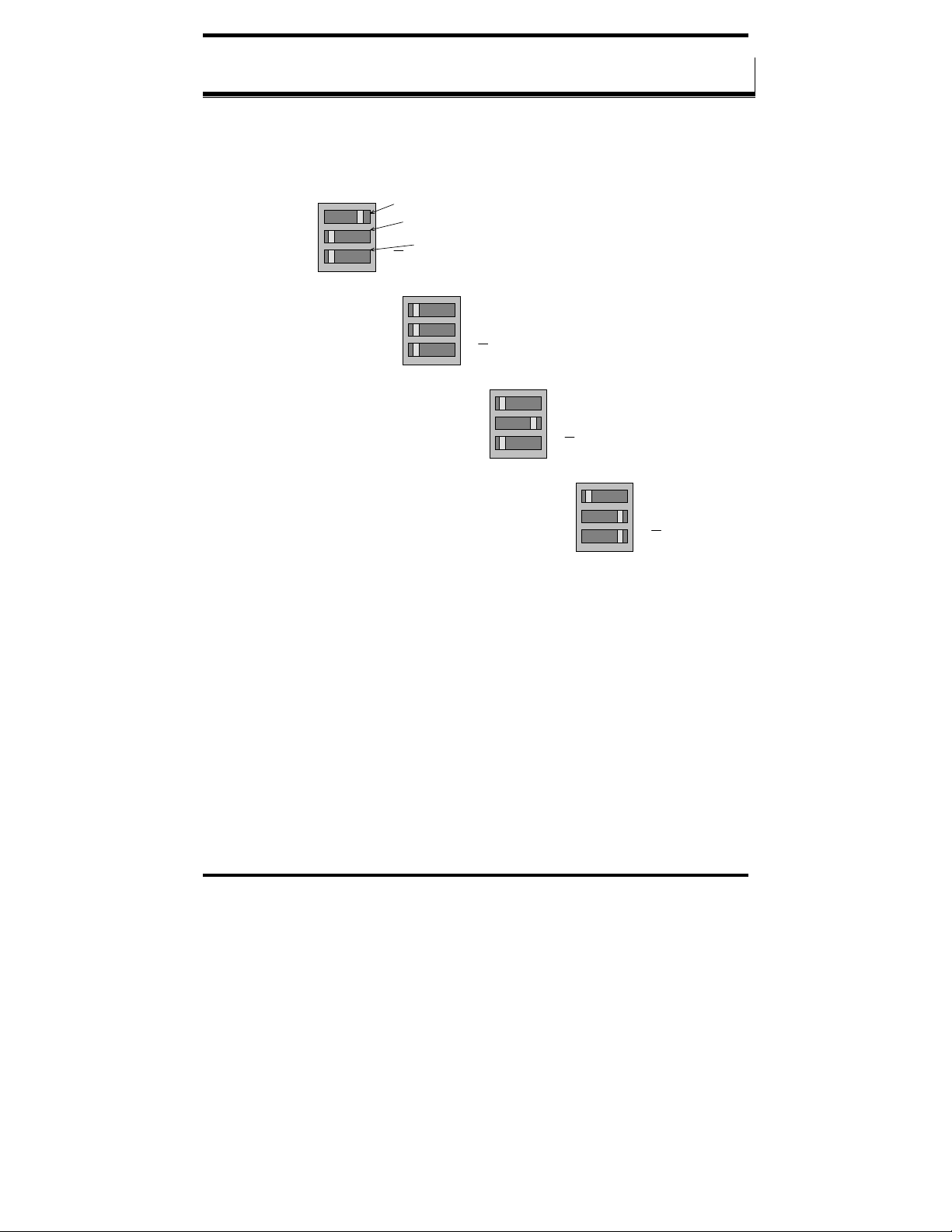

Setting the DIP Switches on RS-232/422/485 Ports

Set the DIP switches to configure the desired operating mode as follows:

422/485

TX On

RX On

Switch 1

232

TX SD

RX SD

Switch 2

Switch 3

RS-232 Mode

422/485

TX On

RX On

232

TX SD

RX SD

RS-422 Mode

422/485

TX On

RX On

232

TX SD

RX SD

4-wire RS-485 Mode

422/485

TX On

RX On

2-wire RS-485 Mode

232

TX SD

RX SD

Figure 5. RS-232/422/485 DIP Switch Settings.

DIP Switch 1 (RS-232/422/485 ports)

The top DIP switch (1) configures the port for RS-232 or RS-422/485

operation. This switch is the only one that is required to be set for RS-232

operation. The positions of switches 2 and 3 do not matter when switch 1 is

set for RS-232 operation.

DIP Switch 2 (RS-232/422/485 ports)

The middle DIP switch (2) configures the port for RS-485 or RS-422

operation. For RS-422 operation (which uses two wire pairs and sends pointto-point or point-to-multipoints) the transmitter can be enabled all the time.

Placing the middle DIP switch in the TX ON position accomplishes this.

For RS-485 operation the middle DIP switch is placed in the TX SD position.

In this position the transmitter is only enabled when data is being sent. The

transmitter is tri-stated when not sending data, allowing other transmitters on

the communications line to transmit without interference.

Manual Documentation Number 3PCIoUx-1008 Chapter 2 11

Page 18

Serial Card Setup

DIP Switch 3 (RS-232/422/485 ports)

The bottom DIP switch (3) configures the port for half-duplex (two-wire)

RS-485 operation or full-duplex (four wire) RS-422/RS-485 operation.

Placing the bottom DIP switch in the RX ON position configures the port for

four wire operation. In this mode the receiver is continuously enabled,

allowing it to receive all data on the communications line. Since the

transmitter sends data on the other wire pair the port does not receive its own

transmissions.

Placing the bottom DIP switch in the RX

position configures the port for

two wire operation. In this mode the transmitter and receiver are connected to

the same wire pair. The receiver is disabled when its transmitter is sending,

preventing the port from receiving its own data.

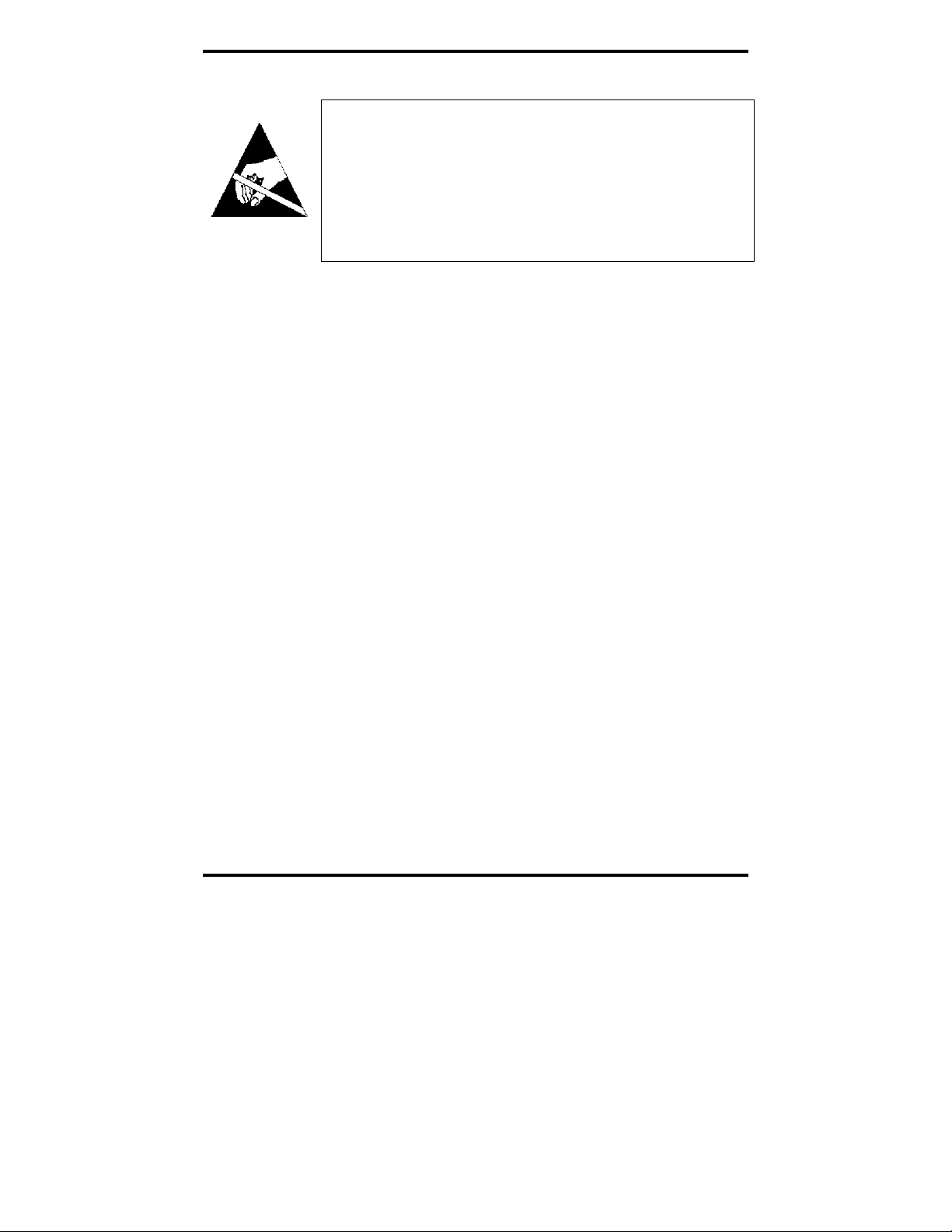

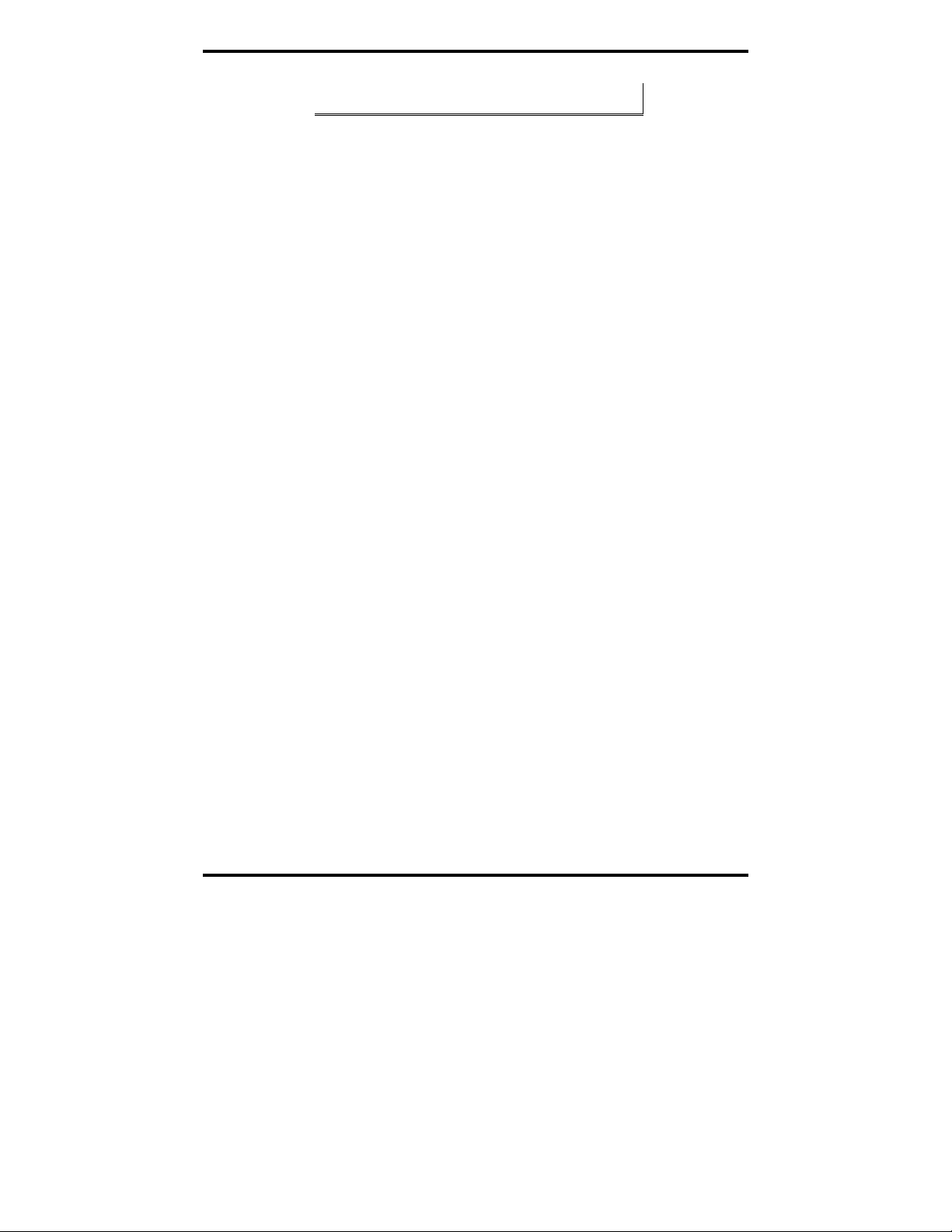

Setting the DIP Switches on RS-422/485 Only Ports

The 3PCIOU4 MIport card provides a combination of RS-232/422/485 and

RS-422/485 only ports. Ports that do not include RS-232 operation use

double DIP switches rather than triple DIP switches. These DIP switches

operate the same as the two bottom DIP switches in the RS232/422/485 ports

TX On

RX On

RS-422 Mode

Figure 6. RS-422/485 only DIP Switch Settings

Switch 1

TX SD

Switch 2

RX SD

TX On

RX On

4-wire RS-485 Mode

TX SD

RX SD

TX On

RX On

2-wire RS-485 Mode

TX SD

RX SD

DIP Switch 1 (RS-422/485 only)

The top DIP switch (1) configures the port for RS-485 or RS-422 operation.

For RS-422 operation (which uses two wire pairs and sends point-to-point or

point-to-multipoints) the transmitter can be enabled all the time. Placing the

middle DIP switch in the TX ON position accomplishes this.

12 Chapter 2 Manual Documentation Number 3PCIoUx-1008

Page 19

Serial Card Setup

For RS-485 operation the middle DIP switch is placed in the TX SD position.

In this position the transmitter is only enabled when data is being sent. The

transmitter is tri-stated when not sending data, allowing other transmitters on

the communications line to transmit without interference.

DIP Switch 2 (RS-422/485 only)

The bottom DIP switch (2) configures the port for half-duplex (two-wire)

RS-485 operation or full-duplex (four wire) RS-422/RS-485 operation.

Placing the bottom DIP switch in the RX ON position configures the port for

four wire operation. In this mode the port’s receiver is continuously enabled,

allowing it to receive all data on the communications line. Since the port’s

transmitter sends data on the other wire pair the port does not receive its own

transmissions.

Placing the bottom DIP switch in the RX

position configures the port for

two wire operation. In this mode the port’s transmitter and receiver are

connected to the same wire pair. The receiver is disabled when its transmitter

is sending, preventing the port from receiving its own data.

Manual Documentation Number 3PCIoUx-1008 Chapter 2 13

Page 20

Serial Card Setup

Installing the Serial Card

CAUTION:

This is an Electrostatic Sensitive Device. Use ESD precautions for safe

handling.

Before removing the card from the anti-static protective packaging:

- Discharge any static electricity buildup on your body by touching a large

grounded metal surface or the metal chassis on equipment connected to earth

ground by a 3-wire power cord. Use of a grounding wrist strap is recommended.

- Avoid touching the gold connectors or other parts on the card except when

necessary to set the configuration DIP switches.

- Remove AC power from the computer before inserting the card

1. Shut down your computer.

2. Unplug the power cord to remove power to prevent accidentally

turning on the computer during installation.

3. Remove the cover of the computer.

4. Locate an empty PCI expansion slot.

5. Remove the expansion slot cover. Save the retaining screw.

6. Ground yourself to the computer chassis before and while inserting

the card.

7. Install the card into the unused slot. Be certain that the card is

inserted completely (fully seated) in the slot.

8. Secure the card with the mounting screw from Step 5.

9. Replace the cover; plug in the power cord.

10. Connect your cables.

11. Power up the system.

12. Install the drivers as described in Chapter 3.

14 Chapter 2 Manual Documentation Number 3PCIoUx-1008

Page 21

Driver Software Installation

CChhaapptteerr 33:: DDrriivveerr SSooffttwwaarree IInnssttaallllaattiioonn

Installing Windows Vista Driver Software

Installation of the MIport driver software on Windows Vista is a three-step

process:

1. Windows Vista searches and identifies new hardware that has been

installed.

2. You use the Found New Hardware Wizard to install the driver

software for the card.

3. You use the Found New Hardware Wizard to install the software for

each port on the card.

There are several possible methods for installing the software. The procedure

outlined here is recommended for most situations.

Note: If at some point in the future, you want to update these drivers,

remove the old drivers before installing the new version. Refer to

Chapter 6 for driver removal procedures.

Pre-Installation Steps

1. Configure the port(s) on the card for the desired mode (RS-232, RS-

422 or RS-485) using the three DIP switches on the card.

2. If configuring for RS-422 or RS-485 Modes, and bias or termination

resistors are needed, add them at this time.

Note: Refer to Chapter 2 of information on DIP switch settings and

bias/termination resistors.

3. Install the card in the slot. Use appropriate ESD handling

precautions.

4. Power up the computer

5. Insert your driver disc in the CD-ROM drive.

Manual Documentation Number 3PCIoUx-1008 Chapter 3 15

Page 22

Driver Software Installation

Using the Found New Hardware Wizard

Windows will detect the PCI card and start the Found New Hardware

Wizard

to begin the driver installation. The following dialog box will appear:

Drive software (on CD-ROM) is provided with your MIport card. Do not

connect to Windows Update to search for software.

6. Select No, not at this time and click Next.

PCI Card Software Installation

Once the new hardware has been detected, the wizard will proceed to install

the software for the card. The following dialog box will appear:

7. To begin the installation of the software for the PCI card, click

Install the software automatically. Click Next.

Windows will find the appropriate files on the CD, then display a

dialog box concerning Window Logo testing for Vista. This feature

of Vista simply indicates that these drivers have not yet undergone

the Microsoft testing procedure required to use the Windows Vista

Logo on the packaging. Diver compatibility is not affected.

8. Click Continue Anyway.

A dialog box will appear indicating the software installation is

proceeding.

9. When the Completing the Found New Hardware Wizard dialog

appears, click Finish.

Port Driver Installation

The Welcome to the Found New Hardware Wizard will appear again, indicating it has

detected a port on the PCI card. Repeat the steps above to install the port driver

software.

If the cared you are installing has more than one port, Windows Vista will find each

port in sequence and re-launch the Found New Hardware Wizard for each port.

Repeat the previous steps for each port.

Checking the Driver Installation

You may want to check to verify that the new B&B COM ports are now available.

1. From the Widows Desktop, click Start → Control Panel

→System and Maintenance → Device Manager

2. In the Device Manager, click Multi-port serial adapters.

16 Chapter 3 Manual Documentation Number 3PCIoUx-1008

Page 23

Driver Software Installation

All serial adapter cards should appear in the list. Additional

information about the cards can be obtained by double-clicking the

name of the card.

3. Click Ports (COM & LPT)

All installed ports should appear in the list. The COM port number

assigned to each port will be shown.

Installing Windows XP Professional Driver Software

Installation of the MIport driver software on Windows XP Professional is a

three-step process:

1. Windows XP searches for and identifies new hardware that has

been installed.

2. You use the Found New Hardware Wizard to install the driver

software for the card.

3. You use the Found New Hardware Wizard to install the software for

each port on the card.

There are several possible methods for installing the software. The procedure

outlined here is recommended for most situations.

Note: If at some point in the future, you want to update these drivers,

remove the old drivers before installing the new version. Refer to

Chapter 6 for driver removal procedures.

Windows Settings

Windows Classic settings are used in the following screenshots. To configure

Windows XP for Windows Classic settings, position the mouse pointer over

the

Taskbar (at the bottom of the Desktop), then right click. On the menu

that appears, click Properties. The Taskbar and Start Menu Properties

dialog will appear. Click the Start Menu tab, then click Classic Start Menu.

Click

OK.

Pre-Installation Steps

4. Configure the port(s) on the card for the desired mode (RS-232, RS-

422 or RS-485) using the three DIP switches on the card.

5. If configuring for RS-422 or RS-485 Modes, and bias or termination

resistors are needed, add them at this time.

Manual Documentation Number 3PCIoUx-1008 Chapter 3 17

Page 24

Driver Software Installation

Note: Refer to Chapter 2 of information on DIP switch settings and

bias/termination resistors.

6. Install the card in the slot. Use appropriate ESD handling

precautions.

7. Power up the computer

8. Insert your driver disc in the CD-ROM drive.

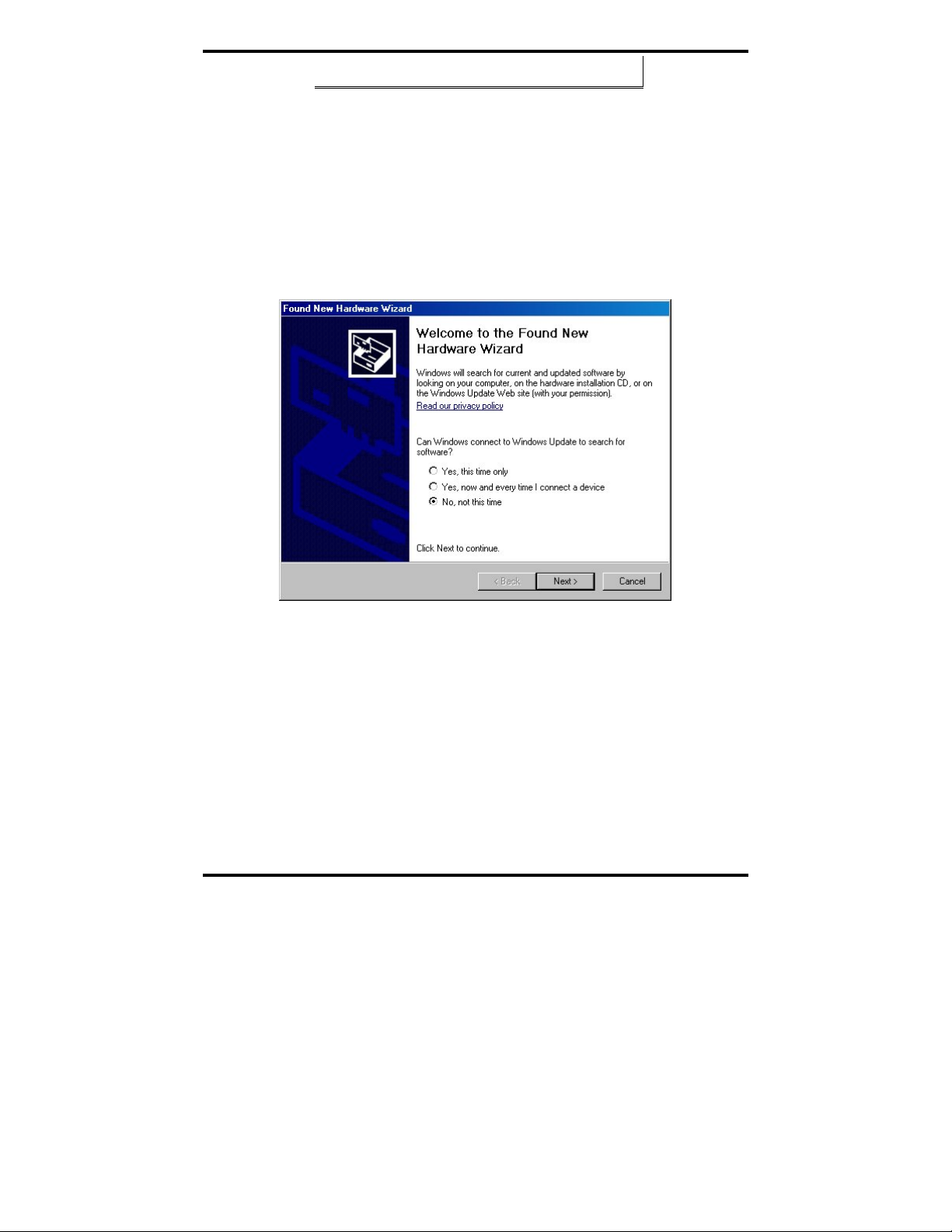

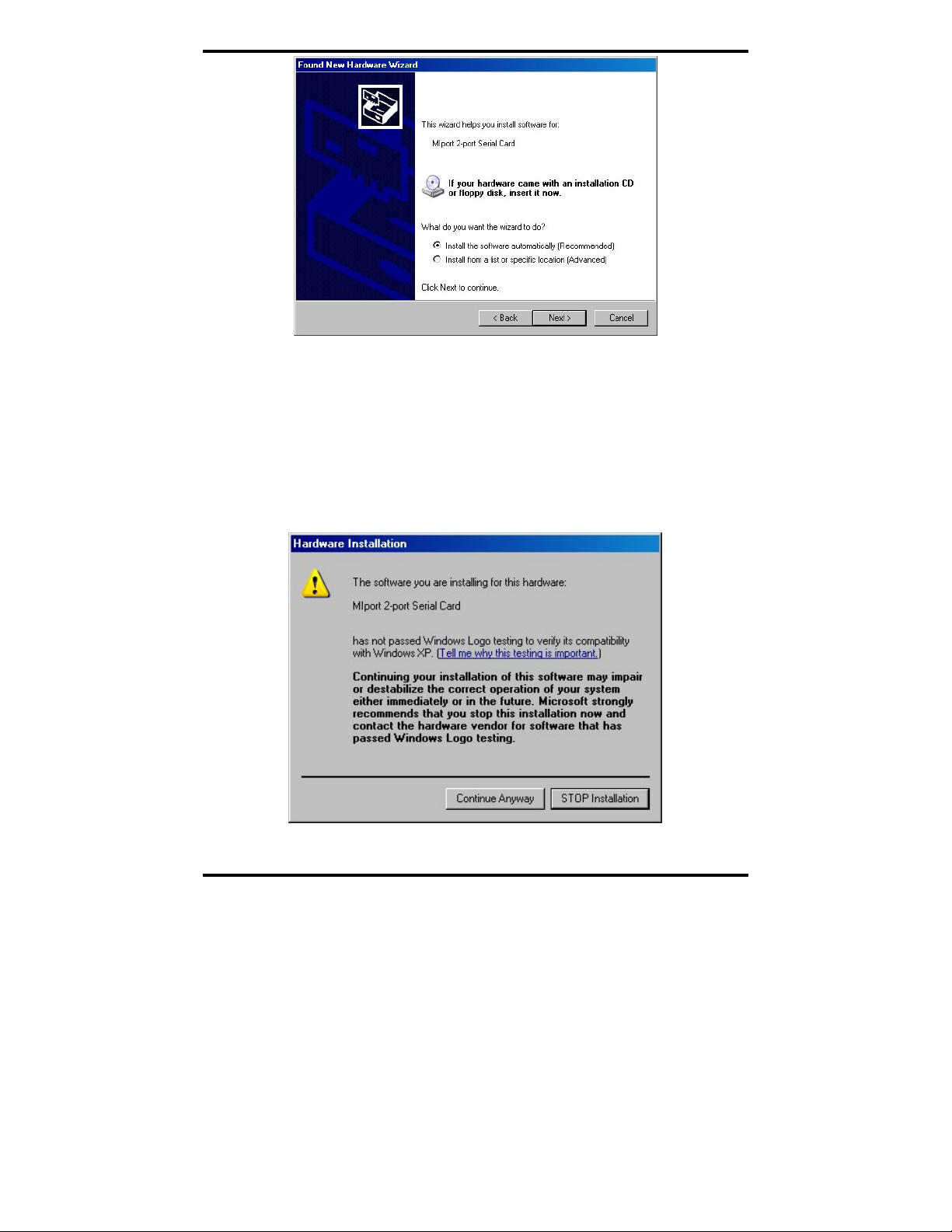

Using the Found New Hardware Wizard

Windows will detect the PCI card and start the Found New Hardware

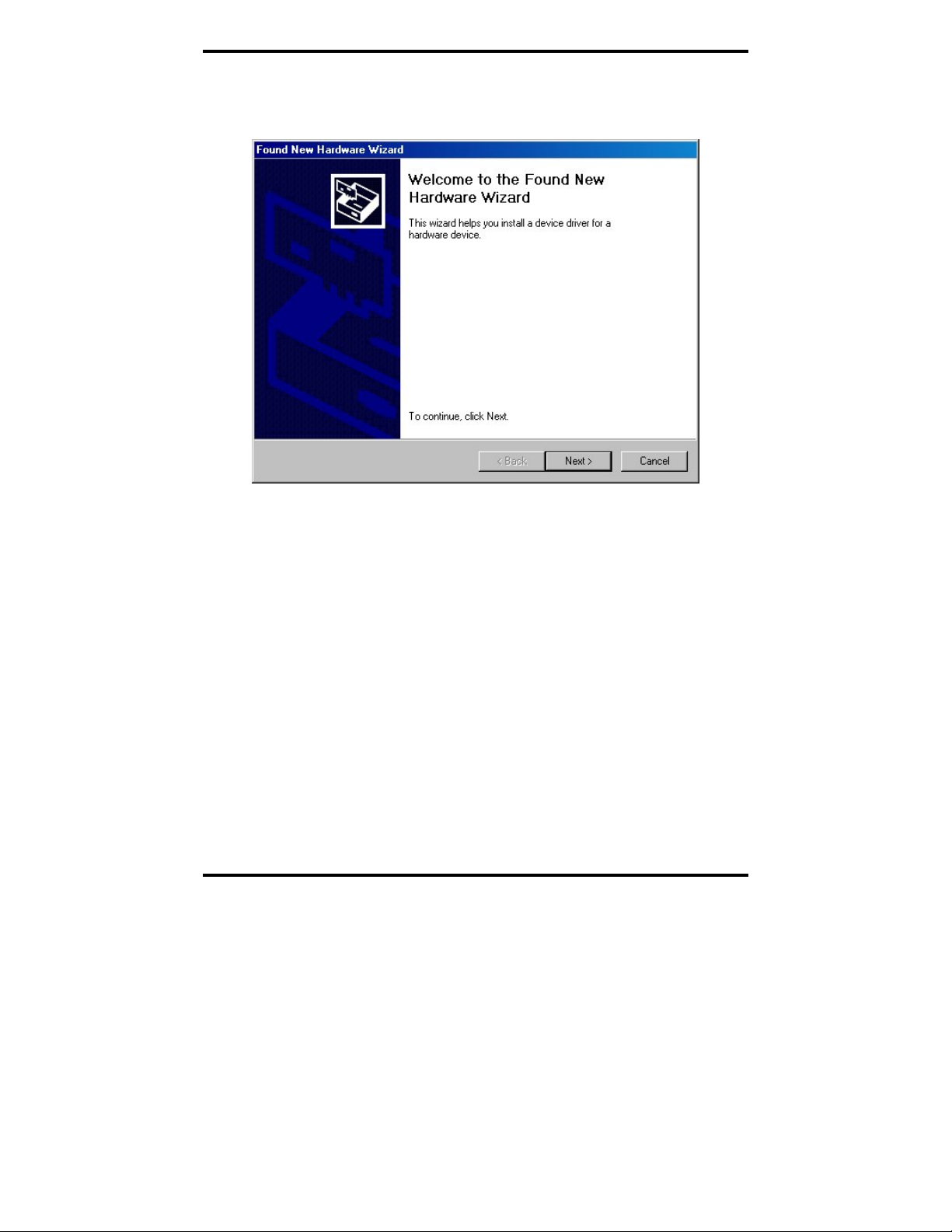

Wizard to begin the driver installation. The following dialog box will appear:

Figure 7. The XP Found New Hardware Wizard

Driver software (on CD-ROM) is provided with your MIport card.

Do not connect to Windows Update to search for software.

9. Select

PCI Card Software Installation

No, not this time and click Next.

Once the new hardware has been detected, the wizard will proceed to install

the software for the card. The following dialog box will appear:

18 Chapter 3 Manual Documentation Number 3PCIoUx-1008

Page 25

Driver Software Installation

Figure 8. The “Install the Card Software Automatically” Dialog

10. To begin the installation of the software for the PCI card, click

Install the software automatically. Click Next.

Windows will find the appropriate files on the CD, then display a

dialog box concerning Windows Logo testing for XP. This feature

of XP simply indicates that these drivers have not yet undergone the

Microsoft testing procedures required to use the Windows XP Logo

on the packaging. Driver compatibility is not affected.

Figure 9. Windows Logo Testing Screen

Manual Documentation Number 3PCIoUx-1008 Chapter 3 19

Page 26

Driver Software Installation

11. Click Continue Anyway.

A dialog box will appear indicating the software installation is

proceeding.

12. When the

Completing the Found New Hardware Wizard dialog

appears, click Finish.

Port Driver Installation

The Welcome to the Found New Hardware Wizard will appear again,

indicating it has detected a port on the PCI card. Repeat the steps above to

install the port driver software.

If the card you are installing has more than one port, Windows XP will find

each port in sequence and re-launch the

each port. Repeat the previous steps for each port.

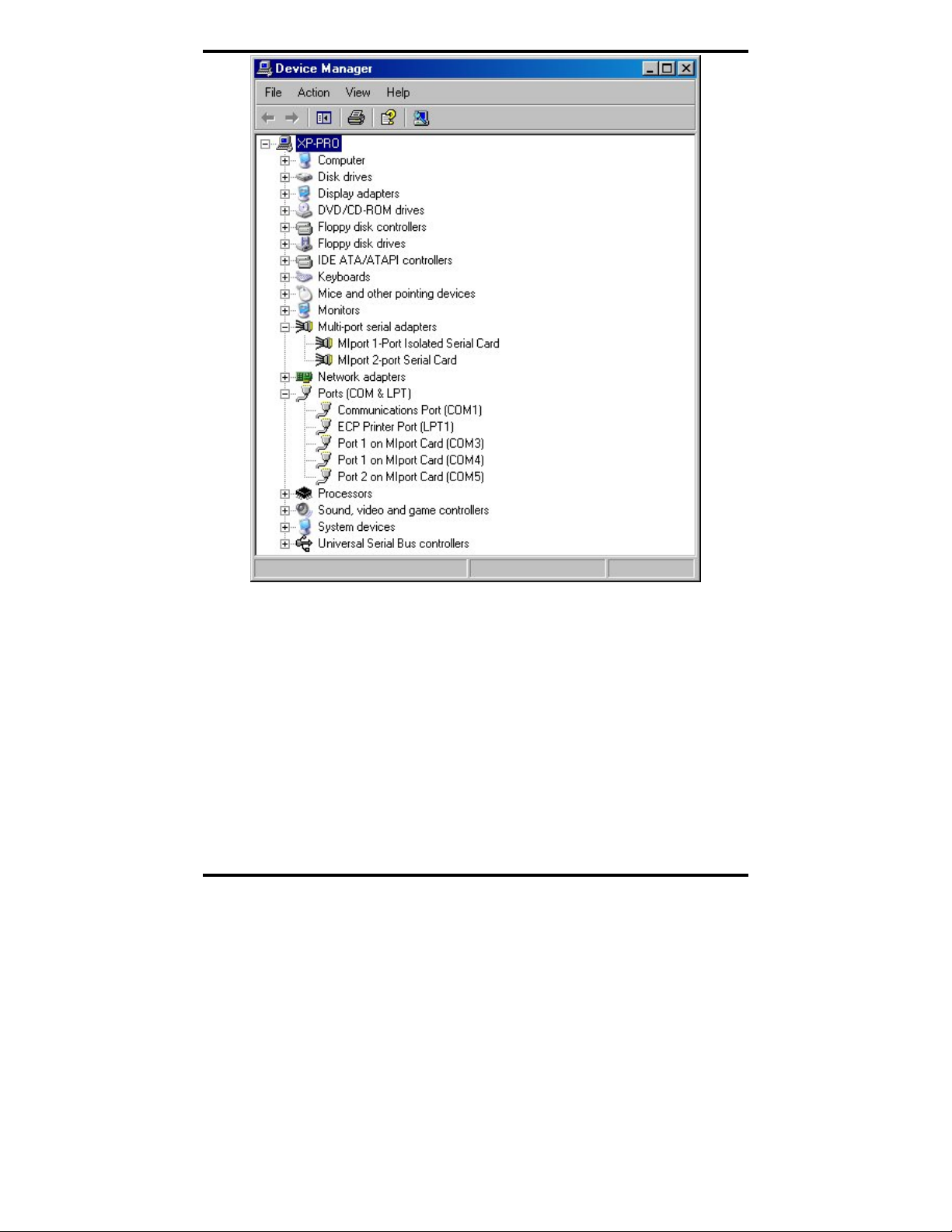

Checking the Driver Installation

You may want to check to verify that the new B&B COM ports are now

available.

1. From the Windows Desktop, click

Panel → System

2. On the

System Properties dialog box, click the Hardware tab, then

click the Device Manager button. The Device Manager window

will appear:

Found New Hardware Wizard for

Start → Settings → Control

20 Chapter 3 Manual Documentation Number 3PCIoUx-1008

Page 27

Driver Software Installation

Figure 10. The Device Manager Window

3. In the Device Manager, click Multi-port serial adapters.

All serial adapter cards should appear in the list. Additional

information about the cards can be obtained by double-clicking the

name of the card.

4. Click

Ports (COM & LPT)

All installed ports should appear in the list. The COM port number assigned

to each port will be shown.

Manual Documentation Number 3PCIoUx-1008 Chapter 3 21

Page 28

Driver Software Installation

Installing Windows 2000 Professional Driver

Software

Installation of the MIport driver software on Windows 2000 Professional is a

three-step process:

1. Windows searches for and identifies new hardware that has been

installed.

2. You use the Found New Hardware Wizard to install the driver

software for the card.

3. You use the Found New Hardware Wizard to install the software for

each port on the card.

There are several possible methods for installing the software. The procedure

outlined here is recommended for most situations.

Note: If at some point in the future, you want to update these drivers,

remove the old drivers before installing the new version. Refer to

Chapter 6 for driver removal procedures.

Windows Settings

Windows Classic settings are used in the following screenshots. To configure

Windows for Windows Classic settings, position the mouse pointer over the

Taskbar (at the bottom of the Desktop), then right click. On the menu that

appears, click Properties. The Taskbar and Start Menu Properties dialog will

appear. Click the

Start Menu tab, then click Classic Start Menu. Click OK.

Pre-Installation Steps

4. Configure the port(s) on the card for the desired mode (RS-232, RS-

422 or RS-485) using the three DIP switches on the card.

5. If configuring for RS-422 or RS-485 Modes, and bias or termination

resistors are needed, add them at this time.

Note: Refer to Chapter 2 of information on DIP switch settings and

bias/termination resistors.

6. Install the card in the slot. Use appropriate ESD handling

precautions.

7. Make sure PnP OS is set in the BIOS.

8. Power up the computer

9. Insert your driver disc in the CD-ROM drive.

22 Chapter 3 Manual Documentation Number 3PCIoUx-1008

Page 29

Driver Software Installation

Using the Found New Hardware Wizard

Windows will detect the PCI card and start the Found New Hardware

Wizard

to begin the driver installation. The following dialog box will appear:

Figure 11. The Windows 2000 Add New Hardware Wizard

The driver installation goes through several steps, after finding the

driver files. The first part installs the driver for the card, then after

Finish, the second part installs the serial driver for the COM port.

Do not remove the CD until completed.

10. Click Next.

PCI Card Software Installation

Once the new hardware has been detected, the wizard will proceed to install

the software for the card. The following dialog box will appear:

Manual Documentation Number 3PCIoUx-1008 Chapter 3 23

Page 30

Driver Software Installation

Figure 12. The “What do you want Windows to do?” dialog

11. To begin the installation of the software for the PCI card, click

Search for a suitable driver for my device, then click Next.

Figure 13. The “Windows will search for new driver” dialog

12. Select CD-ROM Drive, then click Next.

24 Chapter 3 Manual Documentation Number 3PCIoUx-1008

Page 31

Driver Software Installation

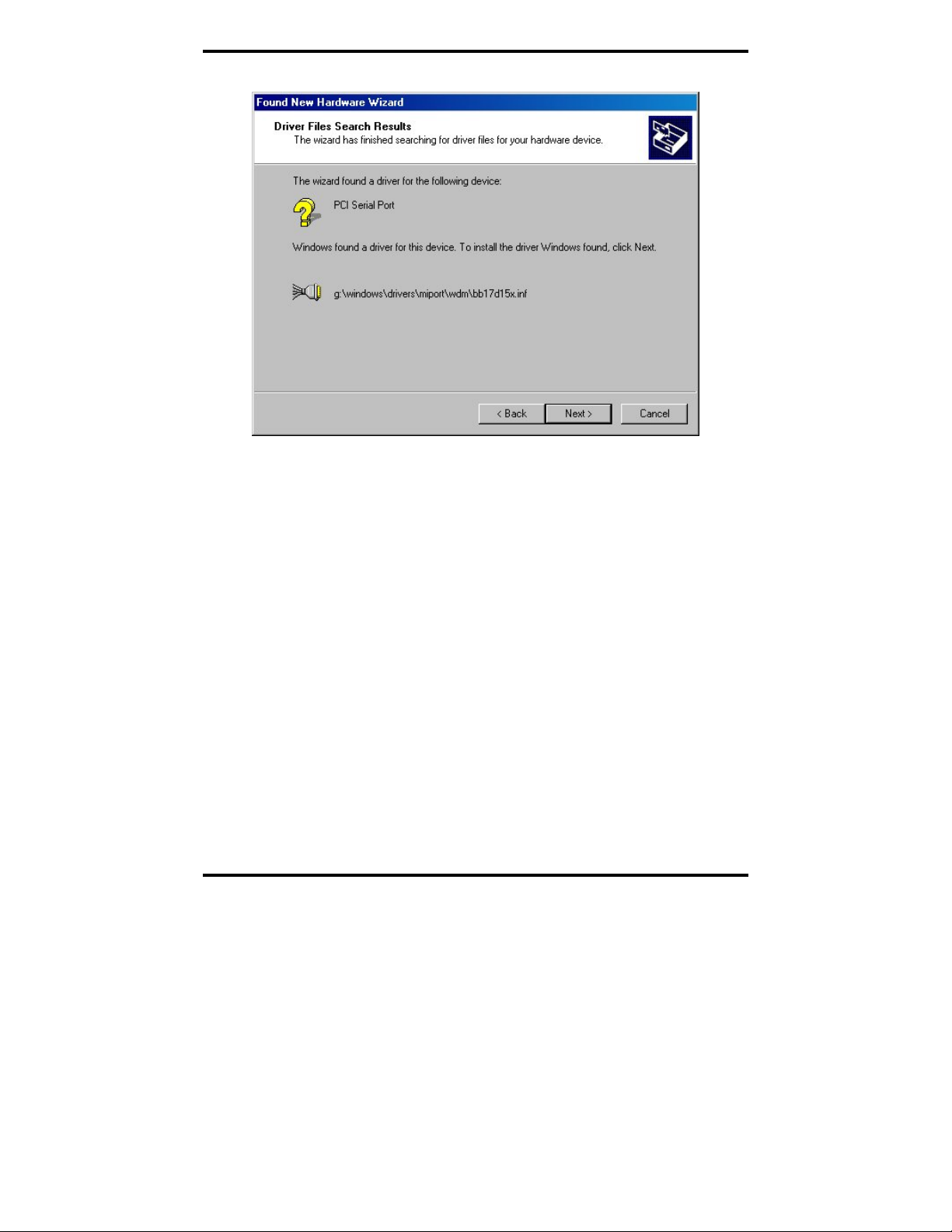

Windows will find the appropriate files on the CD.

Figure 14. The “Windows driver file search for the device” dialog

13. To begin the installation of the software for the PCI card, click

Next.

Windows will display the

Digital Signature Not Found dialog box.

This feature simply indicates that these drivers have not yet

undergone the Microsoft testing procedures required to use the

Windows logo on the packaging. Driver compatibility is not

affected.

Manual Documentation Number 3PCIoUx-1008 Chapter 3 25

Page 32

Driver Software Installation

Figure 15. The Digital Signature Not Found Dialog

14. Click Yes

A dialog box will appear indicating the software installation is

proceeding.

15. When the

Completing the Found New Hardware Wizard dialog

appears, click Finish.

Port Driver Installation

The Add New Hardware Wizard will appear again, indicating it has detected

a port on the PCI card. Repeat the steps above to install the port driver

software.

If the card you are installing has more than one port, Windows will find each

port in sequence and re-launch the

Found New Hardware Wizard for each

port. Repeat the previous steps for each port.

26 Chapter 3 Manual Documentation Number 3PCIoUx-1008

Page 33

Driver Software Installation

Checking the Driver Installation

You may want to check to verify that the new B&B COM ports are now

available.

1. From the

Panel → System

2. On the

Windows Desktop, click Start → Settings → Control

System Properties dialog box, click the Hardware tab, then

click the Device Manager button. The Device Manager window

will appear:

Figure 16. System Properties Screen

3. In the Device Manager, click Multi-port serial adapters

All serial adapter cards should appear in the list. Additional

information about the cards can be obtained by double-clicking the

name of the card.

4. Click

Ports (COM & LPT)

All installed ports should appear in the list. The COM port number

assigned to each port will be shown.

Manual Documentation Number 3PCIoUx-1008 Chapter 3 27

Page 34

Driver Software Installation

Installing Windows 98 or ME Driver Software

Installation of the MIport driver software on Windows 98 is a three-step

process:

1. Windows searches for and identifies new hardware that has been

installed.

2. You use the Found New Hardware Wizard to install the driver

software for the card.

3. You use the Found New Hardware Wizard to install the software for

each port on the card.

There are several possible methods for installing the software. The procedure

outlined here is recommended for most situations.

Note: If at some point in the future, you want to update these drivers,

remove the old drivers before installing the new version. Refer to

Chapter 6 for driver removal procedures.

Windows Settings

Windows Classic settings are used in the following screenshots. To configure

Windows for Windows Classic settings, position the mouse pointer over the

Taskbar (at the bottom of the Desktop), then right click. On the menu that

appears, click

will appear. Click the Start Menu tab, then click Classic Start Menu. Click

OK.

Properties. The Taskbar and Start Menu Properties dialog

Pre-Installation Steps

1. Configure the port(s) on the card for the desired mode (RS-232, RS-

422 or RS-485) using the three DIP switches on the card.

2. If configuring for RS-422 or RS-485 Modes, and bias or termination

resistors are needed, add them at this time.

Note: Refer to Chapter 2 of information on DIP switch settings and

bias/termination resistors.

3. Install the card in the slot. Use appropriate ESD handling

precautions.

4. Make sure PnP OS is set in the BIOS.

5. Power up the computer

6. Insert your driver disc in the CD-ROM drive.

28 Chapter 3 Manual Documentation Number 3PCIoUx-1008

Page 35

Driver Software Installation

Using the Add New Hardware Wizard

Windows will detect the PCI card and start the Add New Hardware Wizard

to begin the driver installation. The following dialog box will appear:

Figure 17. The Add New Hardware Wizard dialog

The driver installation goes through several steps, after finding the

driver files. The first part installs the driver for the card, then after

Finish, the second part installs the serial driver for the COM port.

Do not remove the CD until completed.

7. Click Next.

PCI Card Software Installation

Once the new hardware has been detected, the wizard will proceed to install

the software for the card. The following dialog box will appear:

Manual Documentation Number 3PCIoUx-1008 Chapter 3 29

Page 36

Driver Software Installation

Figure 18. The “What do you want Windows to do?” dialog

8. To begin the installation of the software for the PCI card, click

Search for the best driver for your device, then click Next.

Figure 19. The “Windows will search for new drivers” dialog

30 Chapter 3 Manual Documentation Number 3PCIoUx-1008

Page 37

Driver Software Installation

9. Select “Specify a location” and choose the

E:\ Windows\Drivers\MIport\98_ME folder.

NOTE: In Windows ME you will need to select the Driver from this folder:

E:\ Windows\Drivers\MIport\98_ME

Windows will find the appropriate files on the CD.

Figure 20. The “Windows driver file search for the device” dialog

10. Click Next.

Figure 21. The “Windows has finished installing” dialog

Manual Documentation Number 3PCIoUx-1008 Chapter 3 31

Page 38

Driver Software Installation

11. Click Finish. Installation will complete automatically.

Port Driver Installation

The Add New Hardware Wizard will appear again, indicating it has detected

a port on the PCI card. Repeat the steps above to install the port driver

software.

If the card you are installing has more than one port, Windows will find each

port in sequence and re-launch the

port. Repeat the previous steps for each port.

Checking the Driver Installation

You may want to check to verify that the new B&B COM ports are now

available.

1. From the Windows Desktop, click Start → Settings → Control

Panel → System

Found New Hardware Wizard for each

2. On the

System Properties dialog box, click the Hardware tab, then

click the Device Manager button. The Device Manager window

will appear:

32 Chapter 3 Manual Documentation Number 3PCIoUx-1008

Page 39

Driver Software Installation

Figure 22. System Properties Screen

3. In the

Device Manager, click Multiport Serial Cards

All serial adapter cards should appear in the list. Additional

information about the cards can be obtained by double-clicking the

name of the card.

4. Click

Ports (COM & LPT)

All installed ports should appear in the list. The COM port number

assigned to each port will be shown.

Manual Documentation Number 3PCIoUx-1008 Chapter 3 33

Page 40

Driver Software Installation

Installing Windows NT Driver Software

Installation of the MIport driver software on Windows NT is a two-step process:

1. Installing the driver software.

2. Configuring the ports

Note: If at some point in the future, you want to update these drivers,

remove the old drivers before installing the new version. Refer to

Chapter 6 for driver removal procedures.

Windows Settings

Windows Standard settings are used in the following screenshots. To

configure Windows NT for Windows Standard settings, open the Control

Panel

and double-click the Display icon. Click the Appearance tab and

select Windows Standard under Scheme, then click OK.

Pre-Installation Steps

1. Configure the port(s) on the card for the desired mode (RS-232, RS-

422 or RS-485) using the three DIP switches on the card.

2. If configuring for RS-422 or RS-485 Modes, and bias or termination

resistors are needed, add them at this time.

Note: Refer to Chapter 2 of information on DIP switch settings and

bias/termination resistors.

3. Install the card in the slot. Use appropriate ESD handling

precautions.

4. Power up the computer and login as the Administrator, or as a user

that is a member of the Administrators group.

5. Insert your driver disc in the CD-ROM drive.

Installing the Driver Software

The driver software only has to be installed once regardless of how many

MIport cards and/or ports are added to the system. If the driver software

already has been installed you can go directly to

Ports later in this section.

1. Using

Windows NT Explorer find the NT install.exe file on the

MIport installation CD. The file is located on the CD-ROM at:

E:\Windows\Drivers\MIport\NT4

34 Chapter 3 Manual Documentation Number 3PCIoUx-1008

Configuring the Serial

Page 41

Driver Software Installation

Figure 23. The Install.exe file in Windows NT Explorer

2. Double-click the install.exe file. The MIport Driver v1.0.0 for

Windows NT 4.0 Installation Welcome dialog will appear.

Figure 24. The NT Driver Installation Welcome Dialog

Manual Documentation Number 3PCIoUx-1008 Chapter 3 35

Page 42

Driver Software Installation

3. Click Next on the Welcome dialog. The Copyright Information

dialog will appear.

4. Click

5. Click

Next on the Copyright Information dialog. The Select

Destination Directory dialog will appear.

Next to install the files in the suggested directory.

Figure 25. The Select Destination Directory Dialog

The Ready to Install! dialog will appear.

6. Click

7. Click

36 Chapter 3 Manual Documentation Number 3PCIoUx-1008

Next. The Installation Completed! dialog will appear.

Finish. The driver software is now installed.

Page 43

Driver Software Installation

Configuring the Serial Ports

Before using the serial ports, they must be configured.

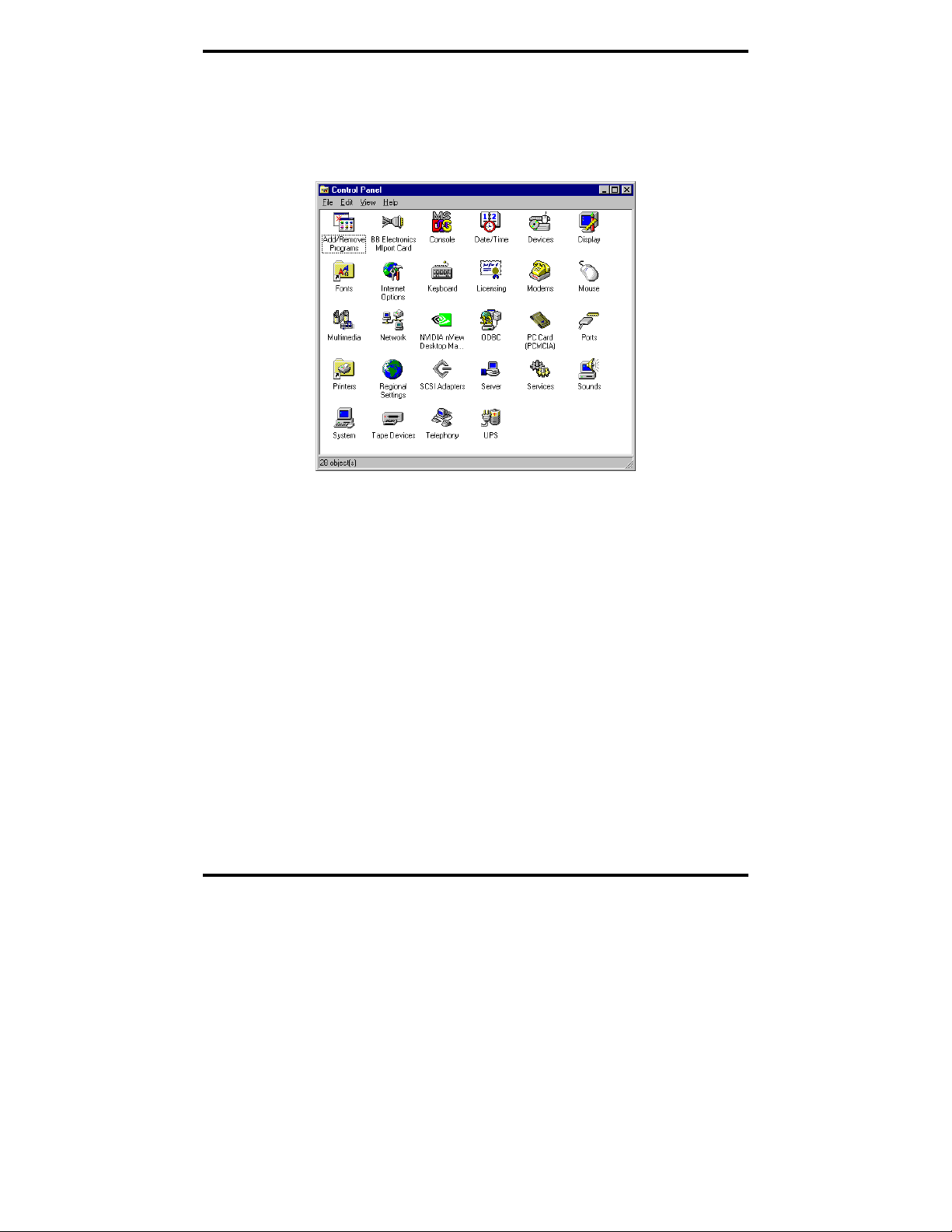

1. Open the

Control Panel.

Figure 26. The NT Control Panel Showing the BB Electronics

MIport Card Applet Icon

2. Double-click the BB Electronics MIport Card applet icon. The

B&B Electronics Multiport Boards dialog will appear showing the

port(s) on the MIport card as not assigned.

3. Select a name for the first port from the dropdown list.

Make a Note: If more than one MIport card is installed, select the

board in the Boards dropdown list first.

Manual Documentation Number 3PCIoUx-1008 Chapter 3 37

Page 44

Driver Software Installation

4. Click Settings for the port.

Figure 27. Selecting Port Names

5. In the

Communications Port Settings dialog that appears set the

bits per second, data bits, parity, stop bits and flow control if they

need to be changed from the default values.

Figure 28. Communications Port Settings

6. If you change any parameters the OK button will become available.

Click

OK to accept the changes.

7. Click

38 Chapter 3 Manual Documentation Number 3PCIoUx-1008

Advanced. The Advanced Setting dialog will appear.

Page 45

Driver Software Installation

8. In the Advanced Settings dialog set the Receive buffer: Low,

Transmit buffer: Low, RTS Control and Hardware handshaking

Hysteresis level (characters)

Note: For more information on advanced settings refer to Chapter 4

as necessary.

Figure 29. The Advanced Port Setting Dialog

9. Click OK to return to the Communications Port Settings.

10. Click

Cancel to return to the Assign Ports dialog.

11. Repeat the procedure for any additional ports on the list.

12. Re-start your computer so the changes will take effect.

Note: After restarting the computer, you can check the Ports applet to

make sure that the driver assigned the COMx names to the serial

ports; however, you must not change the settings of the serial port

within the Ports applet.

Manual Documentation Number 3PCIoUx-1008 Chapter 3 39

Page 46

Setting Driver Options

CChhaapptteerr 44:: SSeettttiinngg DDrriivveerr OOppttiioonnss

Configuring Port Settings (Does not apply to Windows NT.)

By entering the Properties dialog a variety of information can be obtained

and several port parameters can be configured.

1. On the

2. On the

The dialog will display the current settings for Bits per second, Data

Ports (COM & LPT) list, double-click the name of the port to

be configured.

Port Properties dialog, click the Port Settings tab.

bits, Parity, Stop bits and Flow control. If necessary,

change these settings to the required values.

Figure 30. The Port Settings Dialog

3. Click Advanced…

40 Chapter 4 Manual Documentation Number 3PCIoUx-1008

Page 47

Setting Driver Options

The Advanced Port Settings dialog will appear. This screen allows

you to set the Receive and Transmit FIFO buffer thresholds, RTS

Control parameters, Hardware handshaking hysteresis level and the

COM port name.

Figure 31. The Advanced Settings for COM# dialog

Setting the FIFO Buffers

MIport cards use UARTs that contain 64-byte transmit and receive FIFO

(first in, first out) buffer registers. The transmit buffer holds the data to be

sent; the receive buffer holds the data received.

The

Transmit buffer: Low parameter in the Advanced Port Settings dialog

allows you to set the minimum value at which the UART will request more

data from the computer. As the MIport card is transmitting data, the number

of bytes left in the transmit buffer will decrease. When the buffer reaches the

value set, the UART will request more data from program memory. This is

intended to optimize the throughput of the data. Typically this parameter is

set at zero and usually does not have to be changed.

The

Receive buffer: Low parameter in the Advance Port Settings dialog

allows you to set the value at which the UART will request that the computer

read the data that has been received. As the MIport card is receiving data the

contents of the receive buffer increases, when it reaches the value set, the

Manual Documentation Number 3PCIoUx-1008 Chapter 4 41

Page 48

Setting Driver Options

UART will request that the computer transfer the contents of the buffer to

program memory. This is intended to optimize the throughput of the data.

The default value is 14. Usually this parameter does not have to be changed.

Setting the RTS Control Parameter

1. Set RTS Control to Normal for RS-232; set RTS Control to RS-

485 Mode for 2-wire or 4-wire RS-485 operation. Either setting can

be used for RS-422.

Typically the COM parameters set in this dialog box are overridden

by the software application.

Note: For proper operation the DIP switches on the PCI card must be

set for the same mode. Refer to Chapter 2 for more information on

configuring the DIP switches.

2. The Direction control delay (bit times) box allows you to set the

length of time the Transmit driver continues to be enabled after the

last bit of data in the transmit register has been sent. The purpose of

this setting is to maintain the transmission line in a know (idle) state

until the data has reached its destination. If the line is released too

soon it can pick up noise that could cause problems on the

communications system. This parameter is preset to a value of 10

bit times and typically will not have to be changed. For longer

transmission lines this value may have to be increased.

Setting the Hardware Handshaking Level

The Hardware handshaking Hysteresis level (characters) parameter

allows you to set how long the local UART will continue to accept data after

its receive buffer has reached the point at which it asks the computer to

transfer the data to program memory. When this point is reached the UART

de-asserts the RTS hardware handshake line (which is connected to the

remote UART’s CTS line), stopping the remote device from sending data

until its CTS line is re-asserted. This will occur when the local receive FIFO

buffer has been cleared. The default value for this parameter is 0. Typically

this value will not need to be changed.

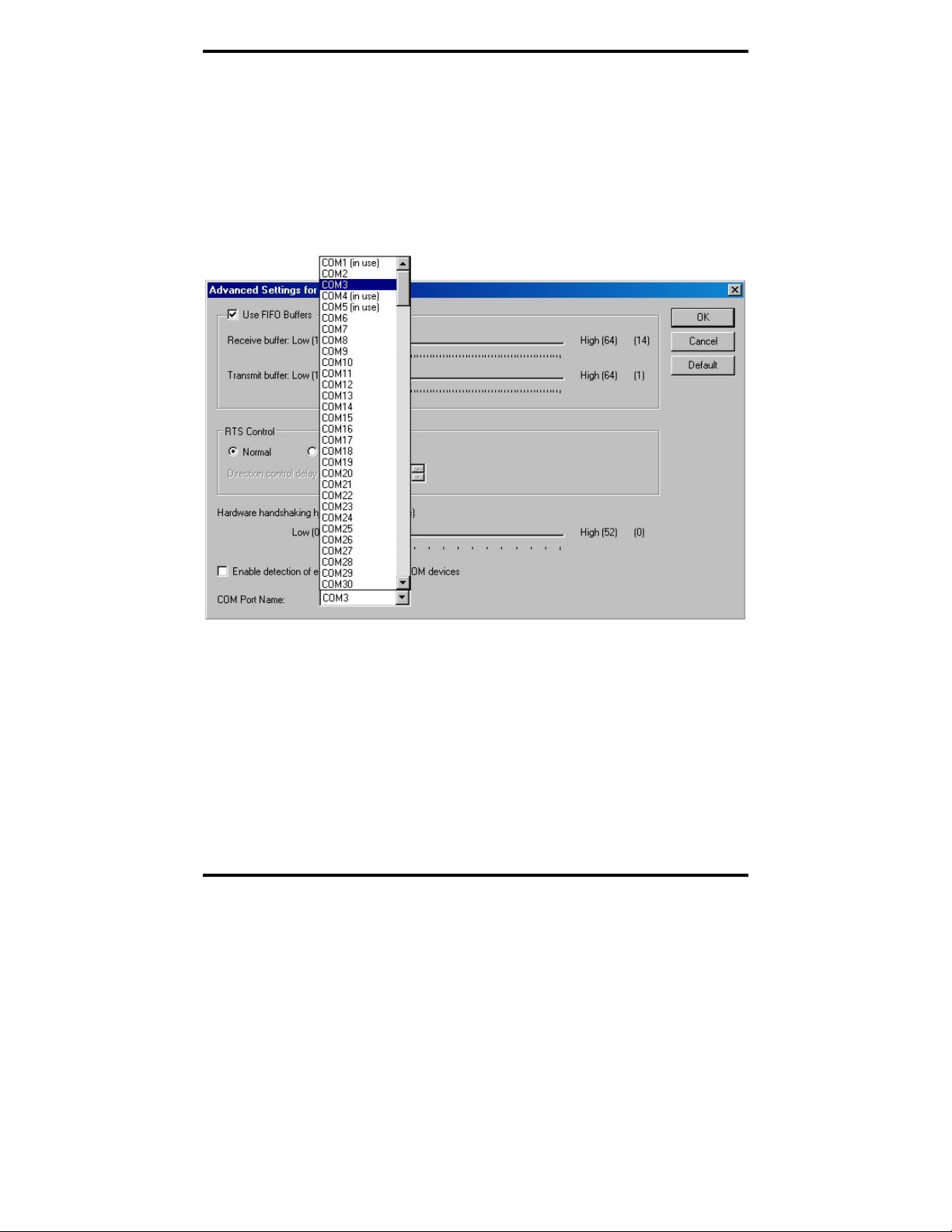

Changing the COM Port Name/Number

1. To change the COM port number assigned to the port, click the

COM Port Name arrow and select the new COM Port Name from

the list.

42 Chapter 4 Manual Documentation Number 3PCIoUx-1008

Page 49

Setting Driver Options

Available names for COM numbers are shown. Select a new number

from those not “in use”. COM numbers from COM1 to COM256

may be available. COM numbers “in use” may be used by

motherboard ports, modems, virtual COM ports for network serial

server devices or FAX modems. Formerly installed USB to serial

adaptors, PCI cards or other hardware may have reserved a COM

number. The device may need to be added back to the system, then

the software removed. Advanced editing of the registry may

required to clean up the problem. Special permissions are required

with 2000 or XP.

Figure 32. Changing the COM Port Name/Number

2. After selecting a new COM name/number, Click OK, then click

OK again on the Settings page.

After returning to the

Device Manager screen, it should refresh

automatically. The name/number of the port in the Device Manager

list should now show the change.

Manual Documentation Number 3PCIoUx-1008 Chapter 4 43

Page 50

Installing Linux Driver Software

CChhaapptteerr 55:: IInnssttaalllliinngg LLiinnuuxx DDrriivveerr

Installing MIport Drivers in Linux

Note to the Editor(s): All commands and directories are case sensitive in

Linux. When updating this section, be very careful about then things are

uppercase or lowercase.

Installation of the Linux driver software for MIport cards is a three-step

process:

1. Preparing the Linux files

2. Compiling the driver

3. Installing the driver

Preparing the Linux Files

The following procedure assumes you have mounted your MIport driver CDROM under /mnt/cdrom

1. Open a terminal window and execute the following steps at the

command prompt.

SSooffttwwaarree

2. Change to a user directory on your system:

cd /home/username

3. Untar the driver files

tar zxpf /mnt/cdrom/Linux/Drivers/MIport-1.0.0.tar.gz

Compiling the Driver

Open a terminal window and execute the following steps at the command

prompt to ompile and install the driver:

1. Change to installation directory:

cd /home/username/bbelec/drivers/MIport

44 Chapter 5 Manual Documentation Number 3PCIoUx-1008

Page 51

Installing Linux Driver Software

2. Remove any temporary files:

make clean

3. Make a dependency file:

make dep

4. Make the driver file:

make

Installing the Driver

1. If the user is not root, switch to the root user

su

2. Install the driver files as root

make install

Figure 33. Building the Driver in a Terminal Window

Manual Documentation Number 3PCIoUx-1008 Chapter 5 45

Page 52

Installing Linux Driver Software

3. Make the device nodes:

a.

b.

4. Modify the startup script to automatically start the driver:

cp /home/username/bbelec/drivers/MIport/rc.bb17d15x /etc/rc.d

WARNING: Do not overwrite /etc/rc.d/rc.serial if it already exists!

Note: These scripts will create the device nodes /dev/tty/M0/ and/dev/cum0

for each port, where the 0 is the number of the port.

If

/etc/rc.d/rc.serial already exists append the commands from:

/home/username/bbelec/drivers/MIport/rc.serial

to

/etc/rc.d/rc.serial

The commands in /home/username/bbelec/drivers/MIport/rc.serial are:

./bbmknod_sh if the system uses sh for its shell

./bbmknod_csh if the system uses a c-shell environments

#!/bin/sh

if [ -f /etc/rc.d/rc.bb17d15x ]; then

sh /etc/rc.d/rc.bb17d15x

fi

5. Restart the computer

/sbin/shutdown –r now

Note: Only the root user and members of the “uucp” group will have

access to the driver. Add users to the “uucp” group as needed.

46 Chapter 5 Manual Documentation Number 3PCIoUx-1008

Page 53

Installing Linux Driver Software

Checking the Driver Installation

Open a terminal window and execute the following steps at the command

prompt to check the driver installation:

1. If the user is not root, then switch to the root user:

su

2. Check that the driver is running:

/sbin/lsmod | grep bb17d15x

3. Switch from the root user back to the user

4. a. Copy rc.bb15d15x

cp /home/username/bbelec/drivers/MIport/rc.bb17d15x/etc/rc.d

b. Modify or create /etc/rc.serial to call /etc/rc.d/rc.bb.17d15x

WARNING: DO NOT OVERWRITE AN EXISTING

/etc/rc.serial

If /etc/rc.serial already exists

following commands to the end of the file:

if [ -f /etc/rc.d/rc.bb17d15x ]; then

sh /etc/rc.d/rc.bb17d15x

fi

If /etc/rc.serial does not exist

command:

cp /home/username/bbelec/drivers/MIport/rc.serial/etc/rc.d

c. Modify /etc/rc.d/rc.local to call /etc/rc.d/rc.serial

If the following commands are not in /etc/rc.d/rc.local , then

add them to the end of the file:

if [ -f /etc/rc.d/rc.serial ]; then

sh /etc/rc.d/rc.serial

fi

5. Switch from the root user back to the user with the command:

in /etc/rc.d then add the

, then copy it with the following

exit

Manual Documentation Number 3PCIoUx-1008 Chapter 5 47

Page 54

Installing Linux Driver Software

Using the Exar Serial GUI Example Application

The Exar Serial Test GUI is a program included on your MIport software CD

that can be used to check the operation of your MIport card. The following

procedure describes how to set up and run this application.

Preparing the Example Application Files

1. Open a terminal window and execute the following steps at the

command prompt.

2. Change to a user directory on your system:

cd /home/username

3. Untar the driver files

tar zxpf /mnt/cdrom/Linux/Programs/exser.tar.gz

4. See /home/username/GUI/INSTALL for instructions on compiling

and installing the application.

Running the Exar Serial Test GUI

5. To run the Exar Serial Test GUI:

a. Launch the application from a terminal window:

/home/username/GUI/exser/exser &

or

b. Edit the menu for your windows manager and add

/home/username/GUI/exser/exser as an application.

48 Chapter 5 Manual Documentation Number 3PCIoUx-1008

Page 55

Installing Linux Driver Software

Figure 34. The Blank Application Window

6. Click File, Open. The Open Device dialog will appear.

Figure 35. The Open device dialog box

7. Type the name of the device in the File name box. The name will be

ttyM0, ttyM1, etc. Click Open.

The screen will change from gray to white and the name of the file

will appear at the top of the screen.

Manual Documentation Number 3PCIoUx-1008 Chapter 5 49

Page 56

Installing Linux Driver Software

Figure 36. The Open Application Window

Configuring Port Settings

1. Click Serial, Port Settings. The Serial port parameters dialog will

appear. The dialog will display the current serial port settings. Enter

the parameters required for your application.

Note: Refer to Chapter 4 for detailed explanations of serial port

settings.

Figure 37. The Exar Serial Port Parameters dialog

50 Chapter 5 Manual Documentation Number 3PCIoUx-1008

Page 57

Removing Drivers, Ports and Cards

CChhaapptteerr 66:: RReemmoovviinngg DDrriivveerrss,, PPoorrttss aanndd

CCaarrddss

You may need to remove the card from your system or remove the current

driver before installing a driver upgrade. The following sections describe

removal procedures.

Removing MIport Cards from Win98/ME/2000/2003

Server/XP/Vista

Uninstalling the MIport Card

1. In the Device Manager, under Multi-port serial adapters, right-

click the card to be uninstalled. NOTE: The card must still be

physically installed in the computer, otherwise it will not show up in

the Device Manager.

2. In the pop-up menu that appears, click

3. On the

4. After a few seconds the dialog will disappear. In the

Confirm Device Removal dialog that appears, click OK.

Manager the listings for the card (under Multi-port serial adapters)

and all associated COM ports (under Ports (COM & LPT)) will be

gone.

Uninstall.

Device

5. Physically remove the MIport card from the computer.

Uninstalling the COM ports

1. In the Device Manager, under Ports (COM & LPT), right-click

the COM port to be uninstalled.

2. On the

3. After a few seconds the dialog will disappear. In the

This procedure will not affect other ports or the card itself. To

uninstall the card and all its ports use the preceding procedure.

Manual Documentation Number 3PCIoUx-1008 Chapter 6 51

Confirm Device Removal dialog that appears, click OK.

Device

Manager the listings for the port (under Ports (COM & LPT)) will

be gone.

Page 58

Removing Drivers, Ports and Cards

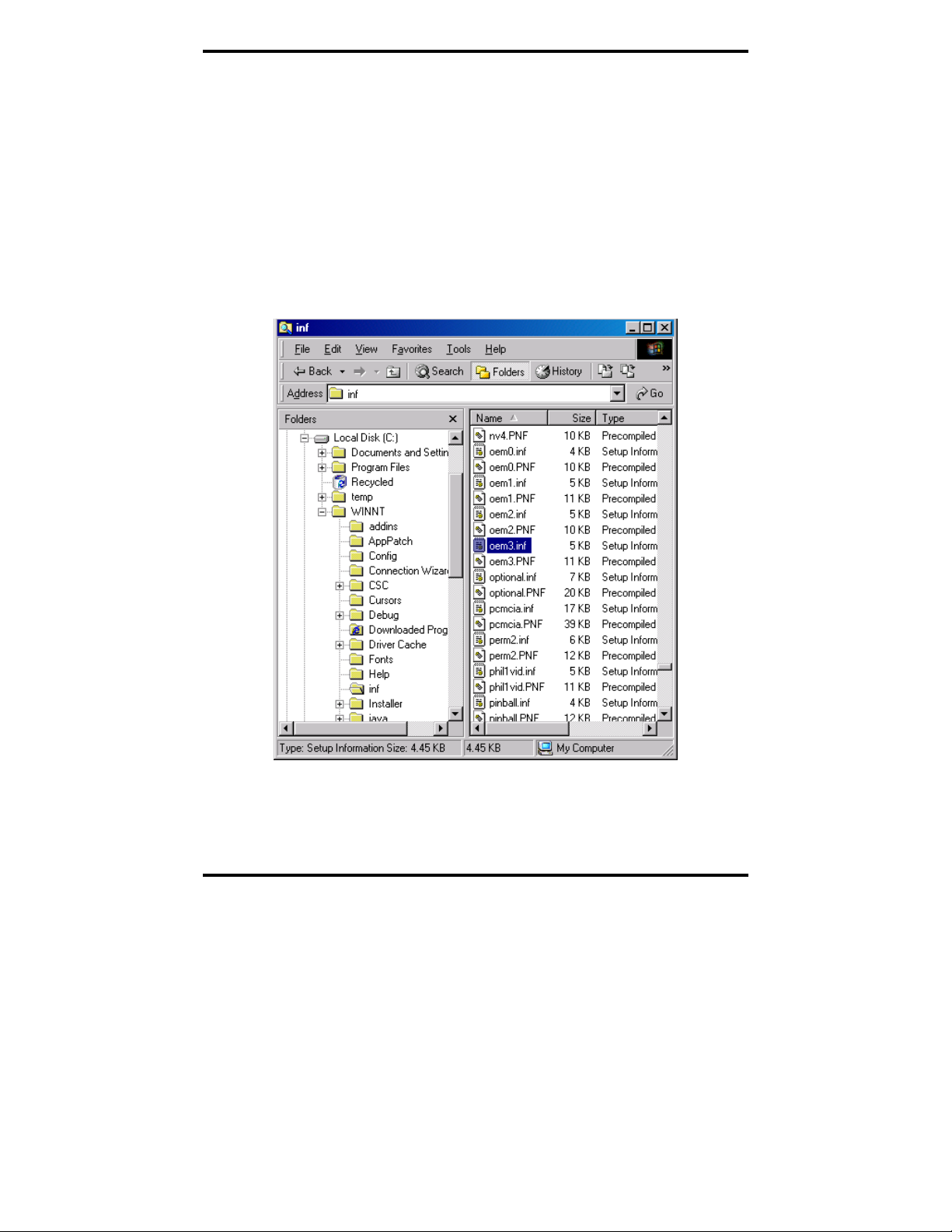

Removing INF and PNF Driver Files

1. Open Windows Explorer as follows: From the Windows Desktop,

click

Programs → Accessories → Windows Explorer

2. Under the Windows directory expand the inf sub-directory and find

the oemX.inf and oemX.PNF files (where X represents the number

of the file).

The operating system names these files during the installation

process. To locate the correct INF files, search for files in

C:\Windows\Inf and its subdirectories for a file named *.INF that

contains the text “Disk #6404”. There will be two files, unless the

installation failed, then there might only be one file. Then, the

customer can double-check that it is in fact a B&B Electronics file.

Figure 38. Finding the INF files in Windows Explorer

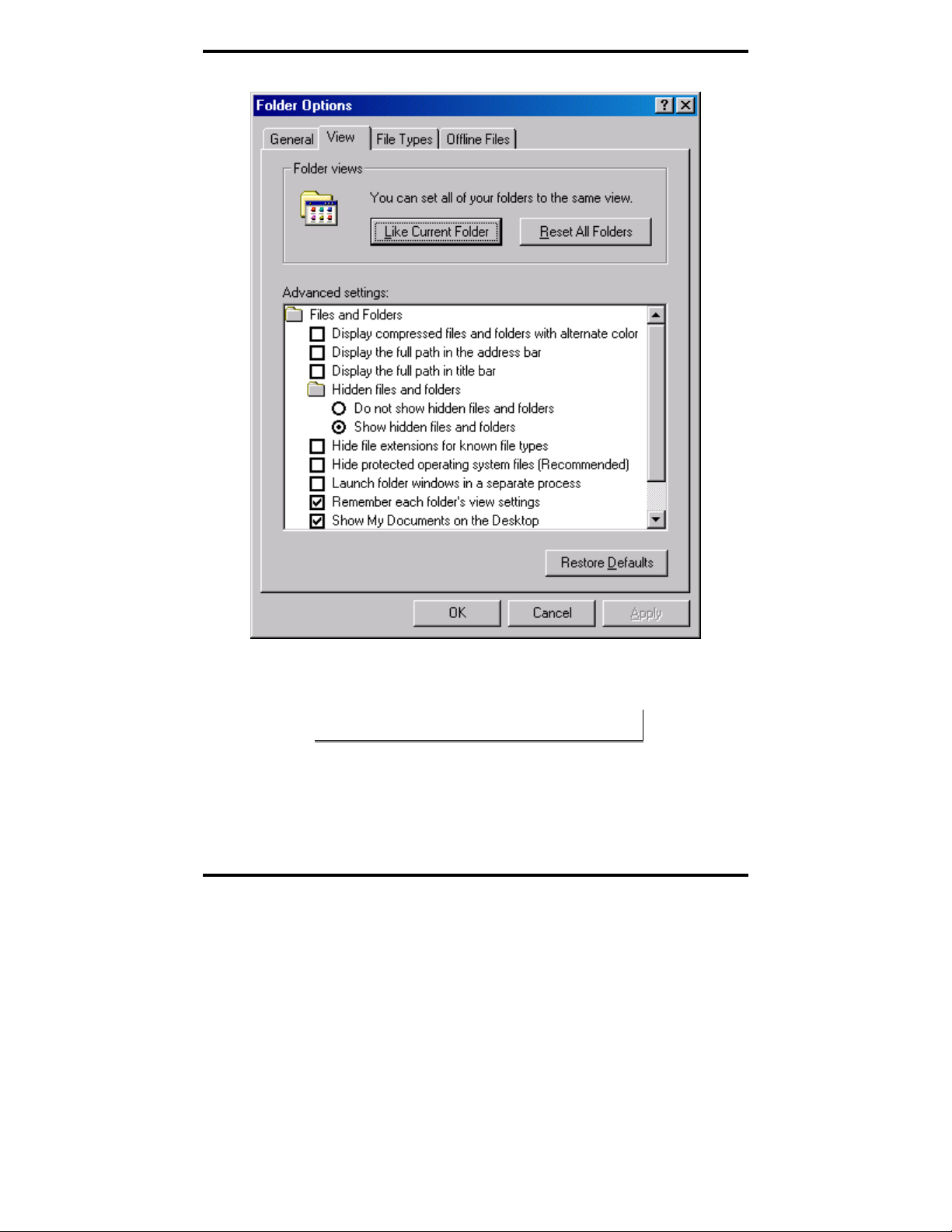

To find these files you may need to set your Views (under My

Computer) to show all files and folders if the INF directory and .inf

files are not visible.

52 Chapter 6 Manual Documentation Number 3PCIoUx-1008

Page 59

Removing Drivers, Ports and Cards

Figure 39. Setting the Folder Options to Display Hidden Files

3. Delete the oemx.inf and oemx.pnf files found in Step 2..

CAUTION! Be careful to delete only the files associated with the PCI

card you are trying to uninstall.

Manual Documentation Number 3PCIoUx-1008 Chapter 6 53

Page 60

Removing Drivers, Ports and Cards

Removing MIport Cards from Windows NT

Uninstalling the MIport Card

1. The Driver must be uninstalled.

Uninstalling the Driver

1. Using Windows NT Explorer locate the uninstall.exe file in the

B&B installation directory. (The default installation directory is

C:\Program Files\B&B Electronics\MIport)

Figure 40. Uninstall.exe in the B&B Program Files

2. Double-click the Uninstall.exe file name. The Select Uninstall

Method

3. Select

dialog will appear.

Automatic and click Next. The Perform Uninstall dialog

will appear.

4. Click

5. Return to

Finish.

Windows NT Explorer and refresh the window (Click

View, then click Refresh). The MIport subdirectory under

C:\Program Files\B&B Electronics should no longer be there.

54 Chapter 6 Manual Documentation Number 3PCIoUx-1008

Page 61

RS-232 Connections/Operation

CChhaapptteerr 77:: RRSS--223322

CCoonnnneeccttiioonnss//OOppeerraattiioonn

RS-232 Mode

In RS-232 Mode MIport serial ports function as buffered standard PC serial

ports and operate as DTEs (Data Terminal Equipment). RS-232 interfaces are

commonly used for communications with modems, serial printers, and

computer-controlled devices such as security equipment, bar code scanners

and point-of-sale devices.

RS-232 Signal Designations and DB-9 Pinout

RS-232 Mode supports eight single-ended signal lines and signal ground. The

DB-9 male connector is configured as a standard RS-232 (DTE) serial port.

The table below shows the signal names and pin numbers.

RS-232 Signal

Name

DCD Data Carrier Detect Input 1

RD Receive Data Input 2

TD Transmit Data Output 3

DTR Data Terminal Ready Output 4

GND Signal Ground ------ 5

DSR Data Set Ready Input 6

RTS Request to Send Output 7

CTS Clear to Send Input 8

RI Ring Indicator Input 9

RS-232 Signal

Description

Direction

(DTE)

DB-9M

Pin

Figure 41. RS-232 Signal Designations and DB-9 Pinout

Note: Refer to Appendix B for additional cable configurations and

pinouts

Manual Documentation Number 3PCIoUx-1008 Chapter 7 55

Page 62

RS-232 Connections/Operation

RS-232 Signal Designations

The primary RS-232 signals are TD (transmit) and RD (receive). Together