Page 1

Sound Inc.

S 0 N I C MAXIMIZER

USER MANUAL

Page 2

Important Safeguards

WARNING

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK).

NO USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

A

To prevent fire or shock hazard, do not expose

the unit to rain or moisture.

ATTENTiON: RISQUE DE CHOC

The lightning flash with arrowhead symbol, within

an equilateral triangle, is intended to aiert the user

to the presence of uninsulated "dangerous

voltage" within the product’s enclosure that may

be of sufficient magnitude to constitute a risk of

electric shock to persons.

The exclamation point, within a equilaterai triangie

is intended to alert the user to the presence of

important operating and maintenance (servicing)

instructions in the iiterature accompanying the

appliance.

ELECTRIC- NE PAS

OUVRIR.

For your protection, please read these safety instructions completely before operating the appliance, and keep this manual for future reference.

Carefully observe all warnings, precautions and instructions on the appliance and described in the

operating instructions supplied with the appliance.

INSTALLATION-------------------------------------------------------------------------------------------------------------------------------------

Water and Moisture - Do not install the

appliance near water: for example, near a

bathtub, washbowl, kitchen sink, laundry tub,

in a wet basement, or near a swimming pooi.

Heat - Do not instaii the appliance near

sources of heat such as radiators, heat regis

ters, stoves, or other appliances that pro

duce heat.

Ventilation - Situate the product so its

location or position does not interfere with its

proper ventilation. For example, you should

not place the product on a bed, sofa, rug, or

similar surface that might block the vent

openings, or placed in a built-in installation,

such as a bookcase or cabinet that might

impede the flow of air through the ventilation

openings.

Wall or Ceiling Mounting - If your

appliance can be mounted to a wall or ceil

ing, mount it only as recommended.

USE

Power Source - Connect the appliance

to a power supply only of the type described

in the operating instructions or as marked on

the appliance.

Power-Cord Protection - Route the

power cord so that it is not likely to be walked

on or pinched by having objects placed on it,

paying particular attention to the plugs,

receptacles, and the point where the cord

exits from the appliance.

SERVICE

Unplug the appliance from the wall outlet and

consult qualified service personnel when:

• the power cord or the plug has been

damaged.

* a solid object or liquid has fallen into the

cabinet.

Grounding or Poiarization - Do not

defeat the grounding or polarization feature of

the AC power cord. If your AC receptacle will

not accept the power cord plug, contact your

electrician to install a proper AC receptacle.

When not in use - unplug the power

cord of the appliance from the outlet when left

unused for a long period of time.

To disconnect the cord, pull it out by grasping

the plug. Never pull the plug out by the cord.

■ the appliance has been exposed to rain or

moisture.

‘ the appliance does not appear to operate

normally or exhibits a marked change in

performance.

> the appliance has been dropped, or thé

enclosure damaged.

AC Receptacie - Check to make sure

that the AC receptacle holds the power cord

plug firmly and securely. If the power cord

plug is loose, contact your electrician to

replace the defective and unsafe AC

Foreign Objects - Be careful that foreign

objects and liquids do not enter the enclosure

through openings.

Do not attempt to service the appliance

beyond that described in the operating

instructions. For all other sen/icing, refer to

qualified sen/ice personnel only.

Page 3

A

TABLE OF CONTENTS

Precautions............................................................................................................................................................................................... 1

BBE Process Description......................................................................................................................................................................... 1

Product Description.................................................................................................................................................................................. 2

Controls/Connections............................................................................................................................................................................... 3

Applications ............................................................................................................................................................................................. 4

Application Diagrams........................................................................................................................................................................... 5-9

Specification/Service/Maintenance/Warranty....................................................................................................................................... 10

Calibration Procedures........................................................................................................................................................................... 11

Schematic Diagrams......................................................................................................................................................................... 12-13

Congratulations on your purchase of the BBE 362 Sonic Maximizer, a two channel signal processor that will benefit any

sound reproduction system. You now own a very unique signal processing device with no other equal in the audio world. Whether

you purchased the BBE 362 for your home studio or club P.A. system, you will find the unit’s rugged construction and careful

electronic design a welcome addition to your audio system.

This manual will help you use BBE more effectively and in ways of which you may not be aware. Reviewing of the

information contained in this manual will answer most of the common questions that our service department receives. But if you

still have questions, please feel free to call (714) 897-6766.

The BBE Process-"What it is"

Loudspeakers have difficulty dealing with the electronic signals supplied by an amplifier. These difficulties cause such

major phase and amplitude distortion that the sound reproduced by a speaker differs significantly from the sound produced by the

original source.

In the past, these problems proved unsolvable and were thus delegated to a position of secondary importance in audio

system design. However, phase and amplitude integrity is essential to accurate sound reproduction. Research shows that the

information which the listener translates into the recognizable characteristics of a live performance are intimately tied into complex

time and amplitude relationships between the fundamental and harmonic components of a given musical note or sound. These

relationships define a sound’s "sound".

When these complex relationships pass through a speaker, the proper order is lost. The higher frequencies are delayed.

A lower frequency may reach the listener’s ear first or perhaps simultaneously with that of a higher frequency. In some cases, the

fundamental components may be so time-shifted that they reach the listener’s ear ahead of some or all of the harmonic components.

This change in the phase and amplitude relationship on the harmonic and fundamental frequencies is technically called

"envelope distortion." The listener perceives this loss of sound integrity in the reproduced sound as "muddy" and "smeared." In

the extreme, it can become difficult to tell the difference among musical instruments, for example, an oboe and a clarinet.

BBE Sound, Inc. conducted extensive studies of numerous speaker systems over a ten year period. With this knowledge

it became possible to develop an ideal speaker and to distill the corrections necessary to return the fundamental and harmonic

frequency structures to their correct order. While there are differences among various speaker designs in the magnitude of their

correction, the overall pattern of correction needed is remarkably consistent.

The BBE process is so unique that 42 patents have been awarded by the U.S. Patent Office.

"How It Works"

The BBE Process imparts a pre-determined phase correction to the high frequencies where most harmonic information

exists. This is done by breaking the signal into three sub-bands or groups; the low frequency group which is crossed over at 150Hz,

the mid-range group which is crossed over at 1200Hz and the high frequency group that handles everything else up to 20kHz.

The low group is delayed about 2.5 ms (milliseconds) via a group delay within a passive low pass filter. The front panel

control allows for either a flat response or a boost of the lows at 50Hz.

The mid-range group is delayed only about 0.5ms and passes through an active band-pass filter while the high frequency

group is passed through a high quality VGA (Voltage Controlled Amplifier). The high group is used as a point of reference to make

dynamic amplitude corrections to the high frequencies.

The RMS average loudness detectors continuously monitor both the mid-range and high frequencies to compare the relative

harmonic content levels of the two bands and apply the appropriate amount of control voltage to the VGA, thereby determining

the amount of high frequency harmonic content present at the final output of the BBE processor.

1

Page 4

PRODUCT DESCRIPTION

The BBE 362 is an intelligent audio processor designed to solve a series of complex problems as described in the previous

section. It is, however, very simple to set-up and operate and once installed will function flawlessly without further attention.

It is a dual channel, rack-mountable device for use in -lOdBu unbalanced line level applications such as those found in

semi-professional and musical instrument applications. The BBE 362 takes up one EIA standard rack space of 19 inches width and

1.75 inches height (lU). There are two separate channels that share common front panel controls to allow for either full stereo

program or two independent mono channels: A house P.A. mix feed for one channel and the stage monitor feed for the other

channel.

BBE applies different phase and algorithms to three separate frequency bands. The variable front panel control allows the

user to adjust the amount of process desired.

Using Your New BBE 362

BBE is a process to be added before all other mixing of reverb, special effects or equalization in order to increase

the clarity and intelligibility of the program material.

Unlike many aural exciters or equalizers, the BBE 362 does not add any extra noise or harmonics to the sound.

Thus, there will be no future problems in duplication or mastering caused by aberrant high frequency distortion. Since the

BBE technology is a single-stage process, there is no need for encoding or decoding.

Always "A-B" the processed to unprocessed sound with the Process In/Out Switch to adjust the amount of processing

required to suit your own musical tastes.

Things to Remember

The BBE 362 is designed to work in -lOdBu levels. This is suitable for most semi-pro mixers, P.A. consoles, home

stereos or disco equipment. The BBE 362 drives load impedance down to about IK Ohms and supplies a maximum level

of + 16dBu. Plugging a guitar or a microphone directly into the BBE 362 will not work, as the impedance level is much too

low.

If the program material has excessive background noise, the noise may be modulated with the program. In this case,

an equalizer or some type o noise reduction system should be inserted in front of the BBE 362 to roll off the noise first.

Set-Up

The BBE 362 is connected into the chain in series with the signal path—the same way a graphic equalizer or limiter

is connected. The output of the mixer, pre-amp or tape recorder feeds the input of the BBE 362. Remember, source outputs

connect to the BBE’s inputs and as long as the signal source level is within the nominal range as mentioned in the previous

section, the BBE 362 will function perfectly.

Setting-up and using the BBE 362 as an echo send device like a digital reverb is not recommended. The processing

effect is not fully realized when the output of the BBE 362 is summed with the original source audio.

WARNING!

It is good to turn on any effects boxes such as BBE, equalizers, expanders, surround sound accessories, etc, and the preamp

BEFORE turning on the power amplifier. Otherwise damage to the speakers or amplifier may result.

Page 5

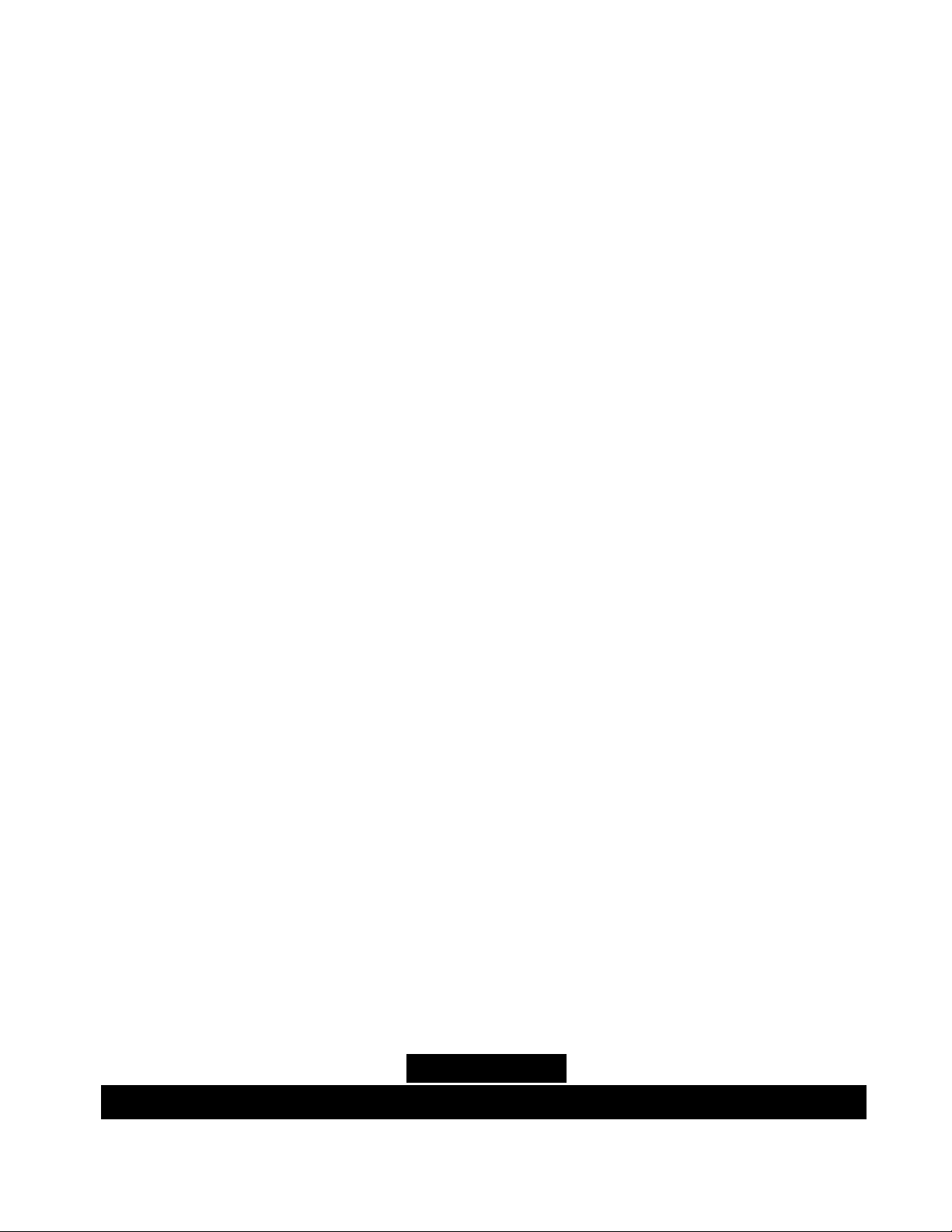

PANEL CONTROLS

© O 0 0 0

©

Front Panel

^_COOTQ^R: Each channel shares a common Lo Contour control that regulates the amount of phase compensated

bass equalization. This adjustment ranges from OdBu (fully counter-clockwise) to -f lOdBu (fully clockwise) at 50Hz

relative to the input.

raQCEgg: Each channel shares a common Process control that regulates the amount of phase compensated high

frequency equalization. This adjustment ranges from OdB (fully counter clockwise) to -I- lOdB (fully clockwise) at 2.5kHz

relative to the input.

n.TP T,F.T>; This LED indicates that the output of the BBE 362 has reached the maximum output level of -I- 15dBu.

This unit is equipped with a function push-button switch which allows for a quick comparison of processed

with unprocessed sound. When the switch is depressed, the green "In" LED lights. When the switch is out, the LED will

be red.

POWER: This switch controls primary power to the BBE 362.

©

© ©

Rear Panel

L AC POWER CORD: Plugs into AC power receptacle. U.S. Model, 100-120Vac, 50/60Hz. Standard Model, 200-240Vac,

50/60HZ.

2. FUSE: Turn cap on fuse holder counter-clockwise to remove fuse. (Note: For U.S. Model, replace with 250Vac, 'hk

Fastblow type fuse. For standard Model, replace with 250Vac, .125A Fastblow type fuse.)

3- Each channel is equipped with a 14” phone jack that is a low impedance

unbalanced line level output and can deliver up to -l-16dBu into IK Ohms.

4. Each channel is equipped with a '4” phone jack that accepts a high impedance

unbalanced line level input with an average of -lOdBu. (Note: -f 16dBu is the maximum input before clipping.)

Page 6

APPLICATIONS

Music and P.A. Systems

The BBE 362 has become a popular addition to many P.A. systems because it makes a dramatic improvement to

the clarity of the vocals without the usual excessive brightness associated with equalizers. In addition, the intelligibility of

the monitor mix is greatly improved with the BBE process. To add the BBE process to the entire mix, insert the BBE 362

between the console output buss and the amplification stage in the P.A. System.

The BBE 362 unit is placed before any house graphic equalizers. All pink noise checks should be made with the

BBE units switched "out” to obtain the desired house curve. The BBE process is then dialed in to suit the music production.

Extreme console equalization normally used during live performance may be reduced due to the dynamic enhancement effect

of the BBE 362.

The BBE 362 has unbalanced inputs and outputs and the user should be aware of the level and impedance of the

insert point to insure proper operation on the BBE 362.

With this in mind, the BBE 362 may be inserted in any places within the console’s signal path to achieve specialized

and dramatic results. In the case of non-VCA sub-groups, the BBE 362 is inserted between "buss out" and "sub-group fader

in". If the BBE process is to be used on only one microphone source, the BBE 362 is inserted in the normal "insert send

and receive" points as a limiter or equalizer is patched.

Figure 1 shows the BBE 362 in a P.A. system application where both channels are used for the main house mix.

Figure 1A shows a powered mixer where the BBE 362 is inserted between the program out and graphic equalizer in. Figure

IB shows the BBE 362 in the insertion point of a mixing console for added clarity to that channel.

Home Studios

The BBE 362 gives a pro-edge to otherwise dull recordings on multi-track recorders. Snare drums and guitars take

on a brighter tonal quality without equalization. Tape tracks recorded without BBE can be processed after the fact by placing

the BBE 362 between the tape track output and the mixer channel input. The BBE 362 saves poorly recorded low-level

instruments and brightens them without bringing up the tape hiss as equalizers do. The program transients are audibly

improved on just about any sound source because the BBE 362 reduces the mid-range "smear" and the associated masking

effects.

Figure 2, 2A and 2B show applications of the BBE 362 in a home studio. Figure 2 shows that when recording, the

BBE 362 is inserted between "buss out" and "tape track in." By monitoring the tape track the amount of processing can be

adjusted to suit your needs. Figure 2A illustrates the hook-up configuration for mastering a multi-track recording down to

a two-track format. This is a mixdown set up and can help restore lost clarity.

Figure 2B shows that when in playback, the BBE 362 can be applied to a previously recorded tape track by inserting

the BBE 362 between the tape track output and the mixer input.

Cassette Copies

Since the BBE 362 is a single-ended playback process without encoding or decoding, the stereo BBE 362 is inserted

between the master two-track and the cassette recorder for punchier and crisper cassette copies. If you are very carefixl of

the amount of processing you are using and know the material, you should never have any trouble with "thin" sounding

copies. Figure 3 shows the BBE 362 in the cassette copy mode.

Page 7

APPLICATIONS

LEFT

RIGHT

Figure 1: Live Sound System

Page 8

APPLICATIONS cont.

MICROPHONES

MICROPHONE

Figure 1B: Powered Mixer System Application

Page 9

APPLICATIONS coni.

Figure 2: Recording Home Studio Application

Page 10

APPLICATIONS cont.

4-TRACK

Figure 2A: Recording Mix Down

Page 11

APPLICATIONS cont.

TAPE DECK

MIXING CONSOLE

0©

o

LINEIN(L&R)

Figure 2B: Playback/Home Studio Application

CASSETTE RECORDER

o o

OUT IN OUT IN

362 9 9 9 9

Figure 3: Cassette Copies

Page 12

SPECIFICATIONS

Frequency Response

Bypass............................................................................. DC to 20kHz

Process............................................................................ program controlled

Absolute Noise in Process Mode

Total Harmonic Distortion in Process Mode

Input Characteristics

Input Impedance...............................................................50K Ohms

Nominal Input Level

Output Characteristics........................................................ +16dBu

Minimum Load Impedance for full output level

Nominal Output Level.................................................... -lOdBu

Maximum Ouqjut Level................................................. + 16dBu

.......................................

....................

........................................................

............

Note: Due to continuing product improvement, specifications and design are subject to change withoitf notice.

-90dfiubelowratedmaxoutput

of OdBu

less than 0.1 %@*10dBu level

-lOdBu

IK Ohm

Power Requirements

U.S. Model

Standaid Model.............................. 200-240Vac, 50/60Hz, 10 Watts

AC Line fuse protected..................... U.S. Model; 250Vac/ViA Fastblow type fuse

Terminations/Connectors-rearpancl V4" Phone jacks

Dimensions....................................... Standard lU single rack

Weight

Note; OdBu = 0.775 Vims

.....................................

............................................

100-120Vac,50/60Hz, 10 Watts

StandardModel: 250Vac/. 125 AFastblow type fuse

l^"Hxl9"Wx5%"D

.

4'A lbs. (2.5Kgs)

Service

We recommend that if at all possible, a BBE 362 which requires service be sent to our facility in Huntington Beach, California. We

request that a "RETURN AUTHORIZATION" be issued by the dealer from whom you purchased the unit. If this is not possible, call

BBE Sound, Inc. directly (714) 897-6766, to obtain a "RETURN AUTHORIZATION", include a copy of the bill of sale with the unit

when it is shipped to BBE Sound, Inc. so that the service can be expedited.

As the repair turnaround time is minimal, we request that the unit be sent to BBE Sound, Inc. We also need to add reliability data

to our files so that future revision may be undertaken, if necessary, to improve the product.

Warranty

Warranty registration of the unit to BBE Sound, Inc. is not necessary. It is strongly recommended that you retain a copy of the bill of

sale for future reference.

IT IS THE SOLE RESPONSIBILITY OF THE END USER TO PROVIDE THE BILL OF SALE OR OTHER MEANS OF

PROOF OF PURCHASE TO VALIDATE THE WARRANTY IF WARRANTY SERVICE IS REQUESTED.

The BBE 362 is warranted against defects in material and workmanship for a period of five (5) years from date of purchase from BBE

Sound Inc. or from an authorized dealer. During this period, we will repair units free of charge providing that they are shipped prepaid to

BBE Sound, Inc. 5381 Production Drive, Huntington Beach, CA 92649. We will pay return UPS shipping charges within the USA. All

charges related to non-UPS shipping, including customs clearance, will be billed. The warranty will be honored for the longer of either 90

days from the date of any service or the remainder of the original 5 Year factory warranty.

This warranty will be consider null and void by BBE Sound, Inc. if any of the following is found:

1. The equipment has been physically damaged.

2. The equipment shows signs of abuse.

3. The equipment has been electrically damaged by improper connection or attempted repair by the customer or a third party.

4. The equipment has been modified without authorization.

5. The bill of sales indicates that the purchase date of the equipment is not within the warranty period.

All non-warranty repairs are warranted for a period of 90 days from the date of service.

BBE Sound, Inc. is NOT LIABLE FOR CONSEQUENTIAL DAMAGES. Should the unit fail to operate for any reason, our sole obligation

is to repair it as described above.

DO NOT RETURN ANY PRODUCT TO THE ABOVE ADDRESS WITHOUT INSTRUCTIONS AND AUTHORIZATION ISSUED BY

THE ABOVE LOCATION.

Maintenance

Maintenance of the BBE 362 is limited to proper cleaning of the unit with mild household cleaner such as Formula 409™ or Windex™,

The chassis and cover are steel finished with a durable polyurethane paint, while the front panel is an anodized aluminum extrusion.

There are no user replaceable parts and the unit should not be opened for any reason unless you are a qualified technician. Calibration

should be performed if parts are replaced or if a performance check-out indicates a problem with calibration. Long term use has shown

that over the life of this unit there is little or no drift of the components in the BBE 362 which would cause a change in calibration. A

very conservative design philosophy has resulted in a piece of equipment which runs very cool and should give years of trouble-free

10

Page 13

CALIBRATION PROCEDURES FOR THE BBE 362

NOTE: THIS UNIT WAS CALIBRATED AT THE FACTORY. THIS PROCEDURE IS FOR

QUALIFIED SERVICE PERSONNEL ONLY.

INITIAL SETTINGS:

1. BBE Process control VR2 and Lo Contour control VRl to minimum (fully C.C.W.).

2. Power switch on and Function switch in (Process on).

POWER SUPPLY TEST:

1. With DVM set to DC volts, measure the positive end of Cl. You should read less than +30 VDC.

2. With DVM set to DC volts, measure the negative end of C2. You should read less than -30 VDC.

3. Measure DC voltage on IMP 4. Reading should be +12 VDC, (+/1.5 VDC).

4. Measure DC voltage on IMP 11. Reading should be -12 VDC, (+/1.5 VDC).

BBE PROCESS TEST:

1. Input a 5kHz signal @ -lOdBu into Channel A [B] input.

2. Measure the Channel A [B] output with the DVM set to AC volts.

3. With Process control at minimum (fully C.C.W.), DVM should read -lO.SdBu (+/- 0.5dBu).

4. With Process control at maximum (fully C.W.), DVM should read -2dBu (+/- 0.5dBu).

LO CONTOUR TEST:

1. Input a 50Hz signal @ -lOdBu into channel A [B] input.

2. Measure the channel A [B] output with the DVM set to AC volts.

3. With Lo Contour control at minimum (fully C.C.W.) DVM should read -lOdBu (+/- 0.5dBu).

4. With Lo Contour control at maximum (fully C.W.) DVM should read -l.SdBu (+/- 0.5dBu).

BYPASS TEST:

1. Input a 500Hz signal @ -lOdBu into channel A [B] input.

2. Measure the channel A [B] output with the DVM set to AC volts.

3. With the Process in, the DVM should read -lldBu (+/- 0.5dBu) and the Process LED should

illuminate green.

4. With the Process out, the DVM should read -lO.SdBu (+/- 0.5dBu) and the Process LED should

illuminate red.

CLIP INDICATOR TEST:

1. Input a 500Hz signal @ +15dBu into the channel A [B] input.

2. Verify that the channel A [B] clip indicator is on.

3. Change signal input level to +13dBu and verify that the channel A [B] clip indicator turns off.

END TEST

11

Page 14

POWER SUPPLY CIRCUIT

CLIP CIRCUIT CHANNEL A

CLIP CIRCUIT CHANNEL В

------------

i----------------3

-------

T

BBE Sound« Zncorporatod

SSOO Bol*« Avenue

Huntlnaton Beech, Cellfornie 92649

Titl

BBC 362 POWER SUPPLY AND CLIP CIRCUITS

151ТГ

Docum#nt Numbtr

в

ВТПГ

riLE = 362POW.SCH

•F«^ru.r:~;s. BFiVf

T

•g of"

P?E7

12

Page 15

1

DXO

1N4146

JKi

R6

iK

~l

D9 4

1N4X46

<2Zo:

D&

.1N4148

'1.0uf/25V NP

V- V+

BBE Proc»t« 1« DEFEPTED uh«n V+ 1« applied

CPROCESS IS ENCPiED WHEN IN THE "OUT" POSITION?

1

|220pf

£ 019

0.0047uf C17

VRl

100

b Cil

220pf

___________e___

lb.047u

2

<

10uf/25V

2

1

C27

1 ^

lO.OOiuf

02S|| 4

>>

J_4.7wf/2SV NP

1023 s

l2.2uf/25V NP

021 II 6

1 1

2.2uf/25V NP

1 7

1

1.0uf/25V NP

_____l\___2___

<»7uf/25V

__ __

jia_

r

12

1 13

___

ii—

IS

2.2uf/25V NP

1

2

3 30

4

5 28

8

7

8

9

10 23

11 22

12

13 20

14 19

16

32-

32

31

22.

90 C26 |i4.7uf/25V NP

29

aa_

12_

27

26

1.0wf/25V NP i

2S-

2S

24

C28 iiO.OOluf

02« ||2.2uf/25V NP

C22 ||2.2wf/25V NP

0.47uf/25V

¿2-

21

21

20

____

^13

____

-Ifi

_________________________

ir.

17

030 1/ 1.0uf/25V

1

/C18

>‘0.047uf

s

'.N

VRIB

lOOK

220pf

1

=i= C16

______

C12 Z

T

-f- C32 I DU

I 220pf Z AN4148

0.0047

,

i.0uf/25V NP

CIO ,,

_

<2nEE>

<'iLIP t>

<2lies:

D12

1N4146

R7

IK

CHASSIS CROUNO

BBE CIRCUIT CROUND

08

.1N4X48

R5

IK

07

’ 1N4148

Peuar SlippIv. and Clip Cireultl

:SEE PAGE 2

34SP4W.S4H

i:

sw

1

JK4_

jO-j '

R15

lOOK

1

BBE Sound Incorporated

SSOO Bolea Avenue Suite *24S

Huntington Beach, California 92649

Title

B

Date

BBE 362 SONIC MAXIHIZER

Document Number

February 23, 1993ISheet 1 of

R3

3.3K Proc*«« £ng«9ed

51B

i/2 OPDT-OUT

-4c

R2

2.2K

RED 2a Screen

Di3

DUAL COLOR LED

REV

FILE = 362 A

2

Page 16

Sound Inc.

5381 Production Drive

Huntington Beach, CA 92649

714-897-6766 • FAX 714-896-0736

www.bbesound.com

covered by U.S. Patent 4,482,866 and other U.S. and foreign patents pending.

BBE is the registered trademark of BBE Sound, Inc.

Loading...

Loading...