Page 1

PL-56150

SP600 SERIESSP600 SERIES

SP600 SERIES

SP600 SERIESSP600 SERIES

WW

AA

W

WW

TER METERTER METER

A

TER METER

AA

TER METERTER METER

Hobart Bakery Systems

Phone

A

FORM 31196 Rev. A (July 2002)

Page 2

TABLE OF CONTENTS

GENERAL ........................................................................................................................................... 3

INSTALLATION................................................................................................................................... 3

Unpacking................................................................................................................................. 3

Location ................................................................................................................................... 3

Wall Mounting ........................................................................................................................... 3

Installation Codes and Standards ............................................................................................4

Electrical Connections............................................................................................................. 4

Water Supply .............................................................................................................................5

Drain Connections ....................................................................................................................6

Plumbing Connections ............................................................................................................. 7

Assembly .................................................................................................................................10

Setting Water Pressure ..........................................................................................................10

OPERATION.......................................................................................................................................11

Controls ...................................................................................................................................11

Before First Use ......................................................................................................................13

Using the SP600 Water Meter................................................................................................14

Using the Temperature Probe ................................................................................................15

Locking and Unlocking the Units of Measure........................................................................15

Water Chiller Flush Time ........................................................................................................16

Shutdown ................................................................................................................................. 17

Cleaning ...................................................................................................................................17

MAINTENANCE..................................................................................................................................18

Service and Parts Information................................................................................................18

Calibration Check....................................................................................................................18

TROUBLESHOOTING.......................................................................................................................19

– 2 –

Page 3

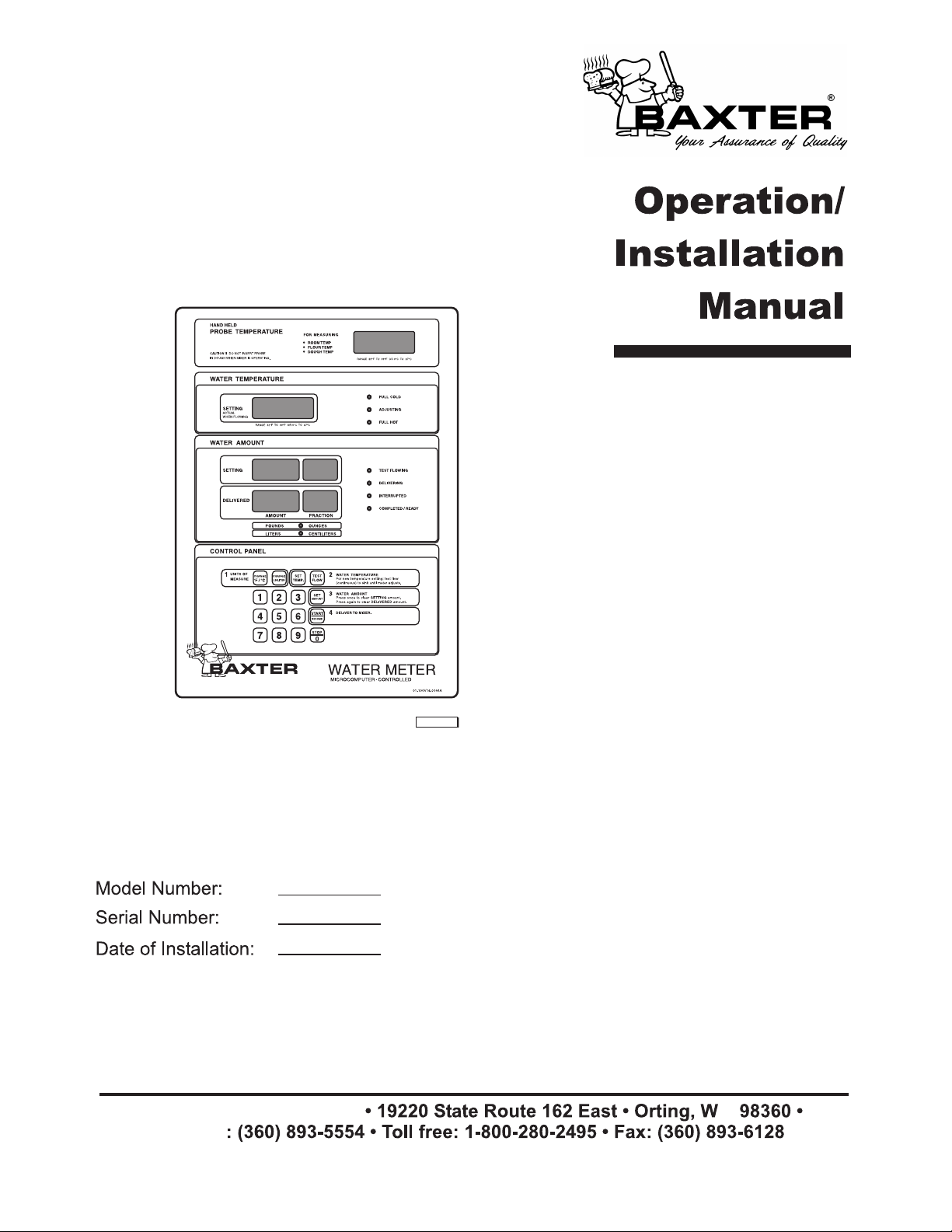

INSTALLATION, OPERATION AND CARE OF

BAXTER MODEL SP600 WATER METER

SAVE THESE INSTRUCTIONS

GENERAL

The SP600 Water Meter is a microcomputer-controlled water delivery system that enables you to

accurately control the water requirements for your baking needs. Through the proper control of water

temperature and volume, the SP600 will help you gain uniform baking results and maximum productivity.

Baxter Water Meters are produced with quality workmanship and material. Proper installation, usage

and maintenance of your water meter will result in many years of satisfactory performance.

It is suggested that you thoroughly read this entire manual and carefully follow all of the instructions

provided.

INSTALLATION

The water meter requires separate hot and cold supply lines. Each line should have a manual shutoff

valve (not supplied) at the water meter for servicing and shutdown. Before installing, verify that the

electrical service agrees with the specifications on the data plate located on the left panel of the water

meter. If the supply and equipment requirements do not agree, do not proceed with the installation.

Contact the Bakery Systems service department immediately.

UNPACKING

This water meter was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage. If the water meter is found to be damaged, save the packaging material

and contact the carrier within 15 days of delivery.

LOCATION

Before finalizing location, make sure that consideration has been given for water supply, draining,

electrical outlets and service clearances.

WALL MOUNTING

The water meter has a detachable base for wall mounting. It is secured by a machine screw located

on the bottom panel.

1. With the water meter lying flat, control face up, remove the machine screw and angle hold down.

2. Slide the water meter forward and set aside.

3. Position the base on the wall and level left-to-right using a carpenter’s level.

– 3 –

Page 4

4. Mark the position and hole location.

5. Mount the base to the wall using the appropriate mounting fasteners.

6. Slide the water meter, with the control panel facing up, downward onto the base. Make sure the

horizontal groove on the back of the water meter is lined up with the top edge of the base.

7. Secure water meter to the base with the

machine screw and angle holddown.

8. Check to make sure the water meter is level.

INSTALLATION CODES AND STANDARDS

The water meter must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Electrical Code, ANSI/NFPA-70 (latest edition). Copies may be obtained from The

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. Canadian Electric Code, CSA C22.1 (latest edition). Copies may be obtained from The Canadian

Standard Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

(electric

equipment)

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: APPLIANCES EQUIPPED WITH A FLEXIBLE ELECTRIC SUPPLY CORD ARE

PROVIDED WITH A THREE-PRONG GROUNDING PLUG. THIS PLUG MUST BE CONNECTED

INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. IF THE RECEPTACLE IS NOT

THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT REMOVE THE

GROUNDING PRONG FROM THIS PLUG.

ledoMLF0ELERB0ELE

stloV

021042-802042/021

NOITPOLACIRTCELE

HCTIWSYRAILIXUA

GNITAR

ztreH

pmA

sttaW

06/0506/05esahPelgniS

2/14/1.xaM7

0606rewopesroH6/1

Electrical data is located on the left panel as you face the water meter. Route the power cord safely out

of the way of other equipment, personnel and moisture.

– 4 –

Page 5

Water Chiller Option

If water chiller is pump-driven, connect the chiller to the water meter as described in the steps below.

Connection to the water chiller circuit should be done by a qualified electrician or service technician.

The auxiliary switch is located in the top-mounted junction box.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

1. Verify that the water chiller circuit does not exceed the auxiliary switch rating.

2. Remove the junction box cover screws, cover and gasket.

3. Connect water chiller and meter per Fig. 1 below.

5. Install the junction box gasket and cover. Secure with the previously removed junction box

screws.

6. Connect power to the meter. While test is flowing, verify that the water chiller pump motor is

running in the proper direction.

WATER METER JUNCTION BOX

(LOCATED ON TOP OF THE WATER METER)

BLACK BLACK

TO METER

WATER CHILLER

PUMP MOTOR

Fig. 1

WIRE PROVIDED

BY OTHERS

PUMP

POWER

SUPPLY

L1

N

PL- 53595

WATER SUPPLY

The water meter requires separate hot and cold supply lines. A manual shutoff valve (not supplied)

should be installed on each supply line at the water meter to accommodate servicing and shutdown.

• HOT WATER INLET TEMPERATURE: 140°F (60°C) recommended.

• HOT AND COLD WATER FLOWING PRESSURE: 30 psi minimum.

• WATER HARDNESS: 4 to 6 grains per gallon is recommended.

– 5 –

Page 6

DRAIN CONNECTIONS (FIG. 2)

On standard water meters, no drain connection is required. However, the water meter should be

located near a sink for the water dispensing hose to drain into while test flowing or when water is

adjusting to a set temperature.

For water meters equipped with a water chiller, a bypass return line should be connected back to the

water chiller reservoir. Chillers without a water reservoir will need a sink, or a drain may be required

for the flushed water to drain into when testing or autoflushing (adjusting to temperature set point).

WATER METER AND HAND SINK SETUP

2' - 6"

1/2" HOT & COLD

66-1/2" AFF

WATER CONN.

W/SHUTOFFS

1-1/2" WASTE

H

18"

WATER

METER

H C

HAND SINK

C

W/SHUTOFFS. HARD COPPER

120V/1/1A.

1/2" HOT & COLD WATER

LINE TO WATER METER

24"

LEGEND

ELECTRIC CONNECTION

J BOX

H

HOT WATER W/SHUTOFFS

H

COLD WATER W/SHUTOFFS

C

DRAIN CONNECTION

D

36" AFF

H C

4"

12" AFF

FLOOR

NOTE: The hot and cold water supply lines can vary in location.

Fig. 2

– 6 –

PL-53607

Page 7

PLUMBING CONNECTIONS

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY,

SAFETY AND PLUMBING CODES.

Connection to the water supply should be done by a qualified plumber or service technician.

Make sure the water lines are thoroughly flushed out

before

connecting to the water meter. This

flushout is necessary to remove all foreign matter, such as chips (resulting from cutting or threading

of pipes), pipe joint compound from the lines or, if soldered fittings are used, bits of solder or cuttings

from the tubing. Debris, if not removed, may lodge in the valves and render them inoperative.

Manual valves or solenoid valves damaged by foreign matter, and any expenses resulting from this

damage, may not be covered under warranty.

Water Chiller Option

1. Connect the water meter cold water supply tubing to the water chiller pump outlet tubing (Fig. 3).

2. Connect the bypass line (supplied) from the water chiller tank to the test flow bypass port on the

bottom of the water meter (Fig. 3). Use the bypass line hose fittings (supplied).

3. If not provided, drill a 1

1

/32" hole through the lid of the water chiller tank, and install the bypass line

hose fitting and nut (supplied).

– 7 –

Page 8

/COMPONENTS

WATER METER WITH OPTIONAL WATER CHILLER AND PLUMBING CONNECTIONS

Cold Water

Supply Line

Hot Water

Supply Line

Test Flow

Bypass Port

Water Chiller Tank

Pump

PL-53597

Water Chiller

Bypass Line

NOTE: The Hot and Cold Water Supply lines can vary in location.

Fig. 3

– 8 –

Page 9

WATER METER WITH PLUMBING CONNECTIONS

Hot Water

Supply Line

Shutoff Valve

(Not Supplied)

T-Fitting with

Pressure Gauge

(Set at 20 PSIG)

90 Elbow

Union

Connector

Power Cord

Vacuum

Breaker

Junction

Box

Cold Water

Supply Line

Pressure

Regulator

Y-Strainer

Dual Check

Valve

Dispenser

Hose Hook

Dispenser

Hose

Hand Held

Temperature Probe

Test Flow Bypass Port

(Optional)

Water Chiller Bypass Line

(Optional)

PL-53572

NOTE: The Hot and Cold Water Supply lines can vary in location.

Fig. 4

– 9 –

Page 10

ASSEMBLY

The water meter is supplied with external fittings/components that must be assembled before the water

supply is connected.

.YTQ STNENOPMOC/GNITTIF .YTQ STNENOPMOC/GNITTIF

2rotalugeRerusserP2 evlaVkcehClauD

2woblE°091 rekaerBmuucaV

1esoHresnepsiD2 eguaGerusserPhtiwgnittiF-T

2reniartS-Y1 eborPerutarepmeTdleHdnaH

1

sgnittiFdnaesoHeniLssapyB'02

)snoitcennoCgnibmulPrednu3.giFeeS.ylnonoitporellihcretawroF(

• Assemble the fittings to the water meter as shown in Fig. 4. Use teflon tape or pipe joint compound

when assembling.

• The union connection on the water meter has a flat doughnut gasket. Make sure the gasket is

in place before connecting any fittings.

• Plug the hand held temperature probe into the end of the flexible cable attached to the bottom

panel of the meter.

SETTING WATER PRESSURE

For the water meter to operate properly, the water pressure should be set at 30 psi on each regulator

while it is operating at 99°F (37°C). See Operation on the following pages for a description of the control

panel.

1. Press CHANGE °F/°C to select Fahrenheit or Celsius (If the CHANGE °F/°C key is locked, see

Locking and Unlocking the Units of Measure on page 15).

2. Press SET TEMP and enter 99°F (37°C) on the numeric key pad. The water temperature value

is displayed in the WATER TEMPERATURE window.

3. Hook the dispensing hose over the rim of a sink or drain.

4. Press TEST FLOW. The water begins dispensing. The actual water temperature of the flowing

water is displayed in the WATER TEMPERATURE window.

5. Allow the flowing water temperature to reach 99°F (37°C).

6. Adjust both hot and cold water regulators until the pressure gauges read 30 psi.

7. Press STOP/0 when complete.

8. Place the dispensing hose on the hook located on the side of the water meter.

– 10 –

Page 11

CONTROLS

Hand Held Temperature Probe

HAND HELD

PROBE TEMPERATURE

CAUTION !! DO NOT INSERT PROBE

IN DOUGH WHEN MIXER IS OPERATING.

OPERATION

FOR MEASURING

ROOM TEMP

FLOUR TEMP

DOUGH TEMP

RANGE 32˚F TO 99˚F OR 0˚C TO 37˚C

PL-56130

The temperature window displays the temperature recorded by the hand held probe. The probe

measures the temperature of the room, dough or flour. The temperature range is 32°F

to 99°F (0°C to

37°C).

Water Temperature

WATER TEMPERATURE

FULL COLD

SETTING

ACTUAL

WHEN FLOWING

RANGE 32˚F TO 99˚F OR 0˚C TO 37˚C

ADJUSTING

FULL HOT

PL-56131

SETTING window - Displays the water temperature as the water meter is dispensing. It also displays

the selected water temperature when the meter is idle.

FULL COLD light - Indicates the mixing valve is using cold water only.

ADJUSTING light - Indicates the mixing valve is adjusting the water temperature.

FULL HOT light - Indicates the mixing valve is using hot water only.

– 11 –

Page 12

Water Amount

WATER AMOUNT

POUNDS: 0-999 OUNCES: 0-15

SETTING

DELIVERED

AMOUNT

POUNDS OUNCES

LITERS CENTILITERS

FRACTION

TEST FLOWING

DELIVERING

INTERRUPTED

COMPLETED / READY

PL-56132

SETTING window - Displays the amount of water to be delivered, in pounds and ounces, or liters and

centiliters. Up to five digits may be entered; the last two digits are always for ounces or centiliters.

Setting ranges are as follows:

Pounds: 0 to 999 Ounces: 0 to 15

Liters: 0 to 461 Centiliters: 0 to 99

DELIVERED window - Displays the amount of water dispensed in pounds and ounces, or liters and

centiliters.

TEST FLOWING light - Indicates the meter is dispensing continuously in the test flow mode.

DELIVERING light - Indicates the meter is dispensing the entered water amount.

INTERRUPTED light - Indicates the meter has stopped before all of the water amount could be

delivered.

COMPLETED/READY light - Indicates the meter has dispensed the entered water amount, and is

ready for the next dispensing cycle.

UNITS OF MEASURE light - Indicates which convention of measurement is selected for display in the

SETTING and DELIVERED windows.

– 12 –

Page 13

Control Panel

CONTROL PANEL

UNITS OF

1

MEASURE

CHANGE CHANGE

˚F / ˚C

LB/LITER

231

564

897

SET

TEMP.

TEST

TEST

FLOW

FLOW

SET

AMOUNT

START

RESUME

STOP

0

WATER TEMPERATURE

2

For new temperature setting: test flow

(continuous) to sink until meter adjusts.

WATER AMOUNT

3

Press once to clear SETTING amount.

Press again to clear DELIVERED amount.

DELIVER TO MIXER.

4

NOTE: FLUSH FOR 30 SECONDS

BEFORE USE.

PL-56133

For complete control of the water meter functions, a numeric key pad and the following control keys are

provided.

CHANGE °F/°C key - Press to choose Fahrenheit or Celsius.

CHANGE LB/LITER key - Press to choose Pounds/Ounces or Liters/Centiliters.

SET TEMP key - Press to enter desired water temperature. Enter the value on the numeric keypad.

TEST FLOW key - Dispenses water continuously. The meter brings the water up to the entered set

temperature.

SET AMOUNT key - Press to enter the amount of water you would like to dispense. Enter the value

on the numeric key pad.

START/RESUME key - Press to dispense the entered water amount. Press to resume dispensing

cycle after an interruption.

STOP/0 key - Press to stop dispensing water.

BEFORE FIRST USE

The water meter should be checked for dispensing accuracy before operation begins. See Calibration

Check on page 18.

– 13 –

Page 14

USING THE SP600 WATER METER

Setting Water Temperature

1. Make sure water meter is in proper units - Fahrenheit or Celsius.

2. Press SET TEMP.

3. Enter desired temperature on the numeric key pad. The water temperature value is displayed in

the WATER

TEMPERATURE window.

4. Hook the dispensing hose over the rim of a sink or drain.

5. Press TEST FLOW. The water begins dispensing. The actual water temperature of the flowing

water is displayed in the WATER

TEMPERATURE window.

6. When the water reaches the selected temperature, press STOP/0.

7. Place the dispensing hose on the hook, located on the side of the water meter.

NOTE: Do not drain the remaining water from the hose. If the dispensing hose is dropped or drained,

repeat steps 4 through 7.

Setting Water Amount

1. Press CHANGE LB/LITER to select Pounds/Ounces or Liters/Centiliters (If the CHANGE LB/

LITER key is locked, see Locking and Unlocking the Units of Measure on page 15).

2. Press SET AMOUNT.

3. Enter the desired water amount value on the numeric key pad. The entered value is displayed in

the WATER AMOUNT SETTING window.

NOTE: When entering Pounds/Ounces, the value for Ounces must be 15 or less; otherwise, the

OUNCES display will blink and no water will dispense.

Dispensing Water

NOTE: Before each use of the water heater, flush the hose for 30 seconds.

1. Hook the dispensing hose over the rim of the mixer bowl or other container.

2. Press START/RESUME to begin dispensing water.

3. If the actual water temperature fluctuates more than 5°F (-15°C) from the set temperature:

a. Press STOP/0 to interrupt dispensing.

b. Hook the dispensing hose over the rim of a sink or drain and press TEST FLOW.

c. When the water returns to the selected set temperature, press STOP/0.

d. Place the dispensing hose on the rim of the mixing bowl. Press START/RESUME to

complete the water delivery.

4. When dispensing is complete, remove the hose from the mixing bowl and place it on the hook

located on the side of the water meter. Do not drain the hose.

– 14 –

Page 15

Operating Hints

• To interrupt the water delivery, press STOP/0.

• To continue dispensing, press START/RESUME.

• To cancel dispensing, press SET AMOUNT.

• The amount of water dispensed is displayed in the WATER AMOUNT DELIVERED window.

When the delivery is complete, the display will blink and indicate 000 POUNDS (LITERS) 000

OUNCES (CENTILITERS).

USING THE TEMPERATURE PROBE

1. Verify that the hand held temperature probe is plugged into the end of the flexible cable attached

to the bottom panel of the meter.

2. Place the end of the probe where the temperature needs to be measured. The HAND HELD

TEMPERATURE window will display the temperature reading.

NOTE: The probe can be used to measure the temperature of the room, dough or flour in the range

of 32°F to 99°F (0°C to 37°C). The probe must be in place for 30 seconds to get an accurate temperature

reading.

LOCKING AND UNLOCKING THE UNITS OF MEASURE

The CHANGE LB/LITER and the CHANGE °F/°C key can be locked to prevent them from being

changed. To determine if the keys are locked:

• Press CHANGE °F/°C. If the water meter beeps, and the units of measure displayed in the

WATER TEMPERATURE SETTING window change from °F to °C or vice versa, then the units

of measure are not locked.

• If the units of measure DO NOT change, then they are locked.

Locking

1. Press CHANGE °F/°C to select Fahrenheit or Celsius.

2. Press CHANGE LB/LITER to select Pounds/Ounces or Liters/Centiliters.

3. Press SET TEMP and enter 32 on the numeric keypad.

4. Press SET AMOUNT and enter 94404 on the numeric keypad. The WATER AMOUNT SETTING

window displays 944 lb 04 oz.

5. Press START/RESUME. The

WATER TEMPERATURE SETTING window displays 000.

6. Enter 001 using the numeric keypad.

7. Press START/RESUME to save setting.

8. The units of measure are now locked.

– 15 –

Page 16

Unlocking

1. Press SET TEMP and enter 32 on the numeric keypad.

2. Press SET AMOUNT and enter 94404 on the numeric keypad. The WATER AMOUNT SETTING

window displays 944 lb 04 oz.

3. Press START/RESUME. The WATER TEMPERATURE SETTING window displays 001.

4. Enter 000 using the numeric keypad.

5. Press START/RESUME to save setting.

WATER CHILLER FLUSH TIME

This procedure is for water meters equipped with the water chiller option.

Water is circulated through the water chiller bypass line to the chiller tank. The flush time setting allows

this water to stabilize to the entered water temperature before it is dispensed to the mixing bowl. The

default flush time is 30 seconds.

Checking Flush Time

1. Press SET TEMP.

2. Enter the lowest desired temperature using the numeric key pad.

3. Hook the dispensing hose over the rim of the sink or drain.

4. Press TEST FLOW.

5. If the actual water temperature displayed reaches the desired set temperature when water begins

flowing through the dispensing hose, DO NOT adjust the flush time.

6. Press STOP/0.

Changing Flush Time

The flush time should be set long enough so the desired set temperature is reached before switching

from the water chiller bypass line to the dispensing hose.

1. Press SET TEMP.

2. Enter 32 using the numeric keypad.

3. Press SET AMOUNT.

4. Enter 91101 using the numeric keypad. The WATER AMOUNT SETTING window displays

911 lb 01 oz.

5. Press START/RESUME. The WATER TEMPERATURE SETTING window displays the current

flush time in seconds.

6. Enter a new flush time value between 0 and 120 using the numeric key pad.

7. Press START/RESUME to save this setting.

– 16 –

Page 17

SHUTDOWN

Shutdown procedures should be followed when the water meter is not used for an extended period of

time.

1. Hook the dispensing hose over the rim of a sink or drain.

2. Close the hot and cold water supply valves.

3. Press TEST FLOW.

4. When the water stops flowing, press STOP/0.

5. Empty any remaining water from the dispensing hose.

6. Place the dispensing hose on the hook located on the side of the water meter.

7. Unplug the power cord from the electrical outlet.

CLEANING

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

• Clean the hand held temperature probe daily with warm, soapy water. Follow with a warm water

rinse. Wipe with a soft, dry cloth.

• Clean the stainless steel surfaces with a damp cloth and polish with a soft, dry cloth. To remove

discolorations, use a nonabrasive cleaner.

• Clean the control panel with a damp cloth only.

• Do not use any cleaners containing oil or other flammable ingredients.

• Do not spray the water meter with a hose, pressure washer or steam cleaner.

– 17 –

Page 18

MAINTENANCE

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT/TAGOUT PROCEDURES.

On an annual basis, have the temperature, water volume and water weight settings calibrated by an

authorized Bakery Systems service technician.

At regular intervals, check the temperature probe, water volume and weight against a known constant

for accuracy (see Calibration Check below).

SERVICE AND PARTS INFORMATION

Contact your local authorized Bakery Systems service office.

CALIBRATION CHECK

Checking Delivery Repeatability

You will need three 12 oz. sample containers and a digital scale that has a minimum precision of

0.1 oz. for this test. Make sure to zero the scale with an empty sample container before starting.

NOTE: Wait 30 seconds between filling each of the containers.

1. Set the water meter to measure in pounds and ounces.

2. Set water delivery amount to 0 lb 12 oz.

3. Hook the dispensing hose over the rim of a sample container.

4. Press START/RESUME to dispense a water sample. Do not drain the remaining water from the

hose between deliveries. If the dispensing hose is dropped or drained, start at step 1 again.

5. Discard the first sample. Repeat steps 2 and 3 to collect three 12 oz. samples.

6. When the dispensing is complete, place the hose on the hook located on the side of the water

meter.

7. Weigh each sample on the digital scale and record the results.

8. If the weights of the sample are not within 1 oz. of each other, repeat steps 1 through 7.

9. If the second pair of sample measurements still vary more than 1 oz. of each other, call your local

authorized Bakery Systems service office.

Checking Meter Accuracy

1. Take the average weight of the samples collected above (add the three sample weights and

divide the total by 3). Compare the result with the water amount displayed in the WATER

AMOUNT SETTING window (0 lb 12 oz.).

2. If the sample average result is ±1.5 oz. or more from the set water amount, call your local

authorized Bakery Systems service office.

– 18 –

Page 19

TROUBLESHOOTING

motpmyS melborP noitcAevitcerroC

dnasthgilrotacidniretemretaW

.ffoerasyalpsid

.ezilibatstonseoderutarepmetretaW .retemotdeilppusretawdlocrotohoN

TSETnehwesnepsidtonseodretaW

.desserpsiyekWOLF

nehwesnepsidtonseodretaW

.desserpsiyekEMUSER/TRATS

.rewopoN tiucrickcehcro/dnanirewopgulP

elihw,isp03ottestonsierusserP

.)C°73(F°99ottessierutarepmet

.desolcera

wolebsierutarepmetretawtesehT

.knalbsiro)C°0(F°23

.desolc

wolebsierutarepmetretawtesehT

.knalbsiro)C°0(F°23

.deretneneebsahtnuomaretawoN

neebsahtnuomaretawtcerrocnI

.deretne

.srekaerb

retawdlocdnatohhtobtahtkcehC

.nepoerasevlavylppus

gnitteSees(erusserpretawtsujdA

erusserPretaW.)01egapno

sevlavylppusretawdlocdnatohehT

.sevlav

.)C°0(

erasevlavylppusretawdlocrotohehT

.sevlav

.)C°0(

.tnuomaretawaretnE

ylppusretawdlocdnatohehtnepO

F°23evobaerutarepmetretawehtteS

ylppusretawdlocdnatohehtnepO

F°23evobaerutarepmetretawehtteS

dnasretilrosecnuodnasdnuopretnE

.egnartcerrocehtnihtiwsretilitnec

51ot0:secnuO999ot0:sdnuoP

99ot0:sretilitneC164ot0:sretiL

tonseodtnuomaretawdesnepsidehT

.dereviledtnuomaehthctam

.erutarepmettesehthctamtonseod

onsahyekRETIL/BLEGNAHCehT

.tceffe

.tes

.erusserpylppus-retawwoL

.noitarbilacfotuosiretemehT

dereviledretawehtfoerutarepmetehT

.retawgnisnepsiderofeb

.tceffeonsahyekC°/F°EGNAHCehT ehtnodelbanesituokcolehT

.noitcnufC°/F°EGNAHC

ehtnodelbanesituokcolehT

.noitcnufRETIL/BLEGNAHC

yltcerrocnineebevaherusaemfostinU

.deniardsawesohgnisnepsidehT

enodtonsawerudecorpwolFtseTehT

.41egap

.erusaemfostinuteseR

ehtnokoohgnisnepsidehtesusyawlA

otsksatgnisnepsidneewtebretem

.eganiardlatnediccatneverp

ees(erusserpretawtsujdAgnitteS

.)01egapnoerusserPretaW

.81egapnokcehCnoitarbilaCeeS

erutarepmeTretaWgnitteSeeSno

kcolnuot61egapnognikcolnUeeS

.noitcnufC°/F°EGNAHCeht

kcolnuot61egapnognikcolnUeeS

.noitcnufRETIL/BLEGNAHCeht

If symptom(s) persist, call your local authorized Bakery Systems service office.

– 19 –

Page 20

NOTES

FORM 31196 Rev. A (July 2002) PRINTED IN U.S.A.

– 20 –

Loading...

Loading...