Page 1

OV851

Model Number: ___________

Serial Number: ___________

Date of Installation: ___________

Baxter Manufacturing Co. • 19220 State Route 162 East • Orting, WA 98360 •

Phone: (360) 893-5554 • Toll free: 1-800-280-2495 • Fax: (360) 893-6128

REVOLVING

TRAY OVEN

FORM 31199 Rev. B (July 2009)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND ADJUSTMENTS

OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED FROM THE

LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY

OF THIS OR ANY OTHER APPLIANCE.

IMPROPER INSTALLATION,

ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE,

INJURY OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

© ITW FOOD EQUIPMENT GROUP L.L.C., 2009

– 2 –

Page 3

Table of Contents

GENERAL ............................................................................................................................................. 4

INSTALLATION ..................................................................................................................................... 4

OPERATION .......................................................................................................................................... 4

General Oven Description (Fig. 1) ................................................................................................... 5

OV851G Digital Control Panel Without Auto Start ........................................................................... 7

OV851G Digital Control Panel With Auto Start ................................................................................ 8

Start Up Preheat .............................................................................................................................. 9

Basic Operation ............................................................................................................................... 9

Timer Options ................................................................................................................................ 10

Clock .............................................................................................................................................. 12

Auto Start ....................................................................................................................................... 12

Customized Operation ................................................................................................................... 13

Shutdown ....................................................................................................................................... 15

CLEANING .......................................................................................................................................... 16

MAINTENANCE .................................................................................................................................. 16

Inspecting the Oven ....................................................................................................................... 16

Preventive Maintenance ................................................................................................................ 16

Service and Parts Information ....................................................................................................... 17

TROUBLESHOOTING ........................................................................................................................ 18

Temp Display Error Codes ............................................................................................................. 19

Emergency Tray Operation ............................................................................................................ 20

– 3 –

Page 4

OPERATION AND CARE OF

MODEL OV851G REVOLVING TRAY OVEN

SAVE THESE INSTRUCTIONS

GENERAL

The Baxter OV851G Revolving Tray Oven has been carefully engineered and tested to deliver an excellent

baking environment for a wide variety of products. It is equipped with easy-to-understand digital controls

and a large, easy-to-read tray indicator display.

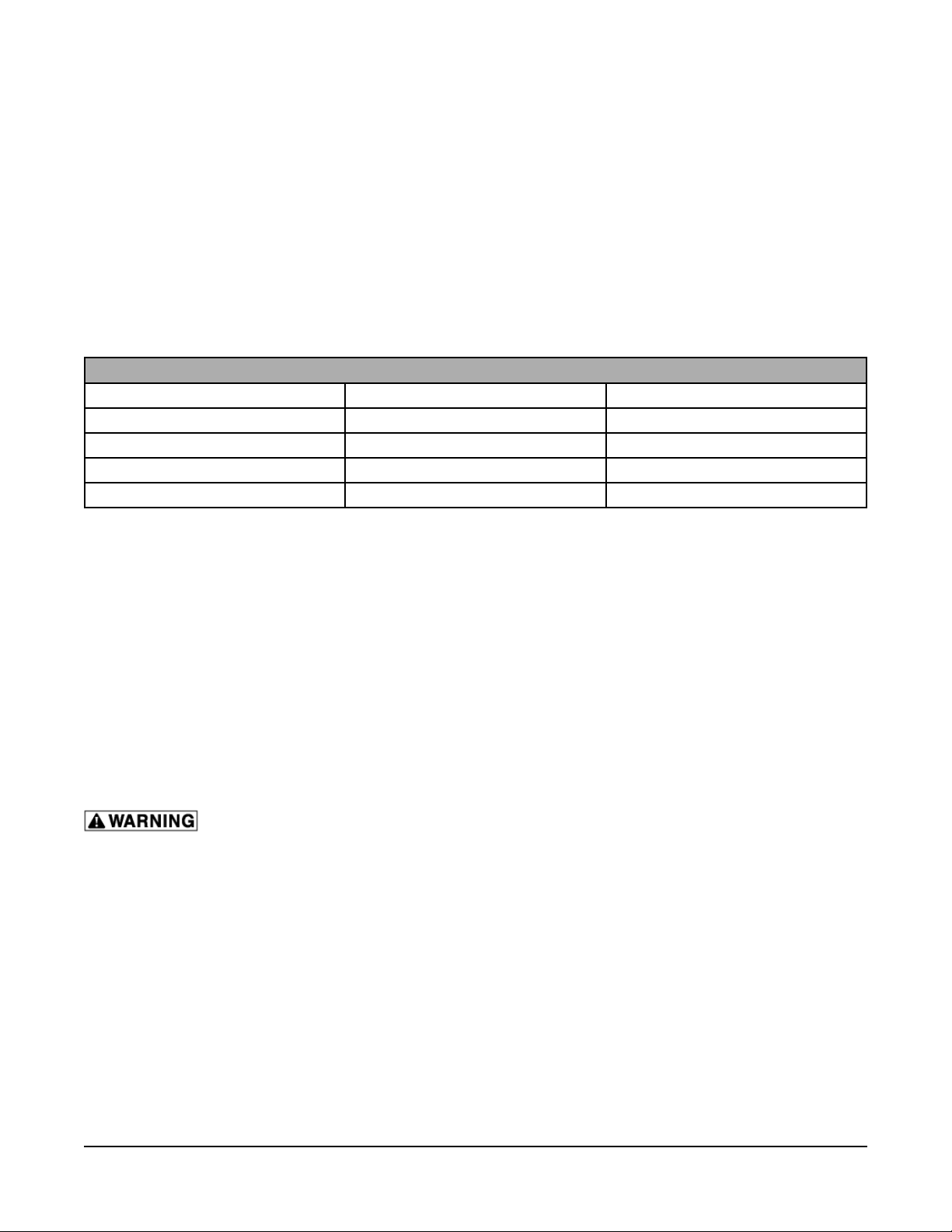

Model Sizes and Gas Ratings

Model Size BTU/hr Natural Gas BTU/hr LP Gas

18-Pan Capacity 250,000 200,000

24-Pan Capacity 300,000 250,000

30-Pan Capacity 300,000 250,000

36-Pan Capacity 350,000 300,000

INSTALLATION

Models OV851G must be installed, moved or serviced only by authorized Bakery Systems trained service

technicians.

OPERATION

The oven and its parts are hot. Use care when operating, servicing or cleaning the

oven.

– 4 –

Page 5

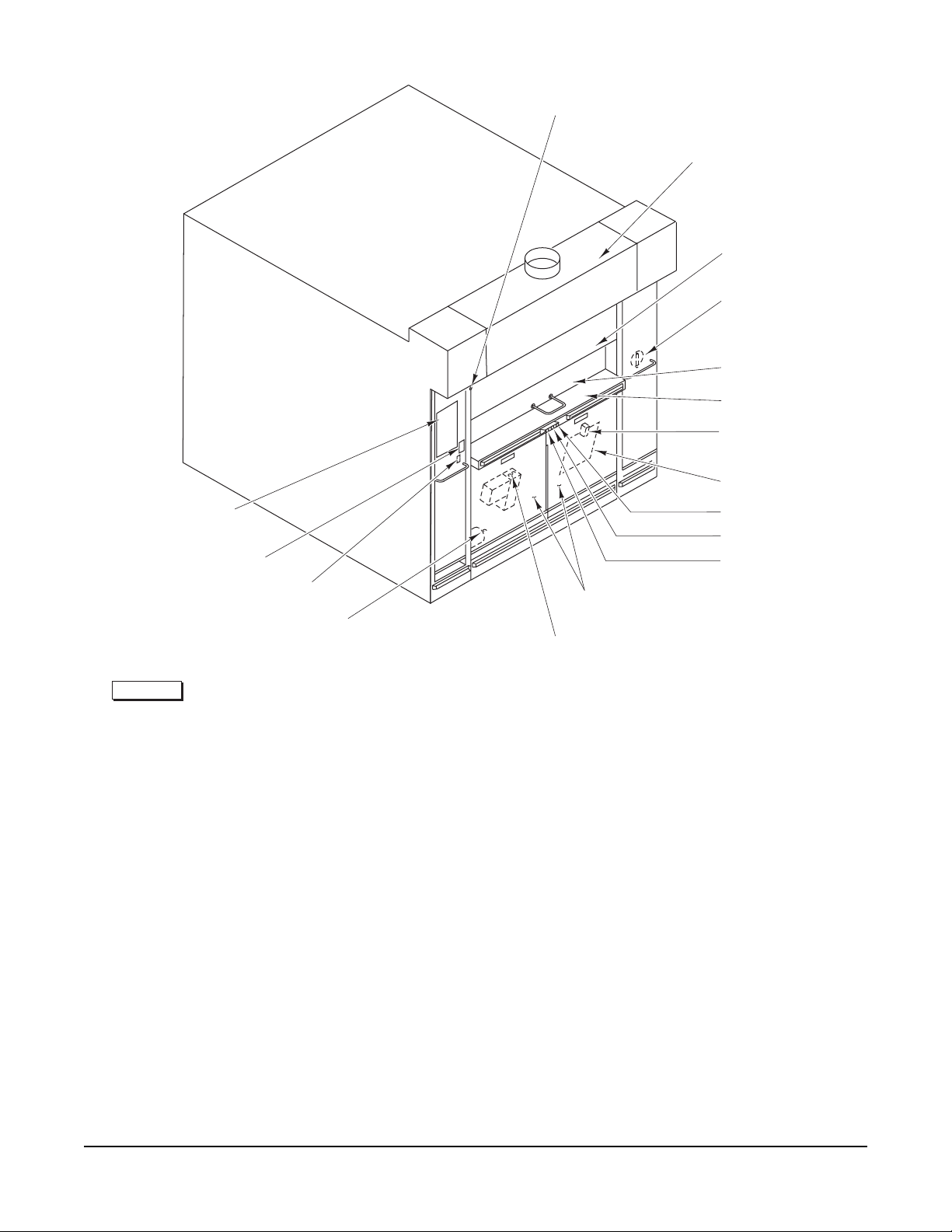

GENERAL OVEN DESCRIPTION (Fig. 1)

Panel Stop Clip

Ventilation

Hood

Emergency

Stop Panel

Gas Shut

Off Valve

Loading Door

Loading Door Sill

Service Door

Interlock

Digital

Control Panel

Quick-View Panel

Power Switch

Lower Front Panel

Motor Shaft

Manual-Auto Switch

PL-56261

Fig. 1

Service Door

AUTO Button

RUN Button

REVERSE Button

DIGITAL CONTROL PANEL - Displays temperature, time and oven functions.

QUICK-VIEW PANEL - Displays the status of oven systems.

POWER SWITCH - Oven ON/OFF switch.

MOTOR SHAFT - The hand crank attaches to the motor shaft to manually move the trays in the event of

power failure. (See Emergency Tray Operation Procedures on page 19 for details.)

MANUAL-AUTO SWITCH - Use Auto for normal operation. Use Manual to unload product in the event of

a control malfunction.

LOWER FRONT PANELS - Gives access to Motor Shaft, Manual-Auto Switch and Service Door.

– 5 –

Page 6

REVERSE BUTTON - Press to move trays in a downward direction. The next tray will stop when it is even

with the loading door sill.

RUN BUTTON - Press to start the trays moving in a continuous upward direction.

AUTO BUTTON - Press to stop the trays. The next tray will stop when it is even with the loading door sill.

Use the Auto button for all routine stops.

SERVICE DOOR - Gives access to the interior of the oven for cleaning and servicing.

OVEN SERVICE DOOR INTERLOCK - Prevents oven operation when door is removed.

LOADING DOOR SILL - Use for loading and unloading.

LOADING DOOR - Slides up for easy product loading.

GAS SHUT OFF VALVE - Shuts off the gas supply to the oven.

EMERGENCY STOP PANEL - Press the panel bottom to stop tray movement. A buzzer will sound; to

silence the buzzer, lift loading door.

VENTILATION HOOD - Captures and vents oven exhausts.

PANEL STOP CLIP - Stop for the Emergency Stop Panel. Unscrew and remove to tilt door for cleaning

of the hood, fi lters and grease cup.

– 6 –

Page 7

OV851G DIGITAL CONTROL PANEL WITHOUT AUTO START

TRAY NUMBER window - Displays the tray that is

currently at the loading door sill.

OVEN TEMP.

UP and DOWN arrows - Press to set the

desired temperature.

Temperature window - Displays the current

temperature and set temperature if arrow key

is pressed.

TIMER

STOP/START - Press to stop or start the

timer.

UP and DOWN arrows - Press to set the

desired time on the timer.

Hours and Minutes window - Displays the

hours and minutes remaining on the timer.

POWER ON/OFF switch - Turns the oven on and

off.

NOTE: Every time the oven power switch is turned

on the purge cycle will run for 6 minutes before the

oven will begin heating.

– 7 –

Page 8

OV851G DIGITAL CONTROL PANEL WITH AUTO START

TRAY NUMBER window - Displays the tray that is

currently at the loading door sill.

OVEN TEMP.

TIMERS

UP and DOWN arrows - Press to set the

desired temperature.

Temperature window - Displays the current

temperature and set temperature if arrow key

is pressed.

STOP/START - Press to stop or start the

selected timer.

RIGHT arrow - Press to select a timer (1 to

6).

Time # window - Displays the number of the

last timer viewed. Also displays, timed out,

timer number after count down.

UP and DOWN arrows - Press to set the

desired time on the selected timer.

Hours and Minutes window - Displays the

hours and minutes remaining on the timer.

FLIP TIME

HOLD TO SET - Press to set an interrupt time

in a full bake time.

AUTO-START

ON/OFF - Press to start the Auto Start feature.

This allows the oven to turn itself on and preheat

to a preset time and temperature.

HOLD TO SET - Press to set the time and day

when you want the oven to auto start.

UP and DOWN arrows - Press to set the

desired time.

Hour and Minute window - Displays the hours

and minutes of the day.

DAY OF WEEK arrow - Press to set current

day and/or day for auto startup.

POWER ON/OFF switch - Turns the oven on and

off.

NOTE: Every time the oven power switch is turned

on the purge cycle will run for 6 minutes before the

oven will begin heating.

– 8 –

Page 9

START UP PREHEAT

The oven and its parts are hot. To prevent burns, use hot pads or protective mitts

when loading or unloading the oven.

For the best results, the oven must be preheated before baking begins.

1. Ensure all panels are in place and all personnel are

clear of oven before preheating/starting oven.

2. Turn the POWER switch to the ON position.

NOTE: Every time the oven power switch is turned on the

purge cycle will run for 6 minutes before the oven will begin

heating.

3. Press the UP or DOWN arrow located in OVEN TEMP. section to set the desired temperature. The

temperature will appear in window.

4. Confi rm that the loading door is closed.

NOTE: The loading door must be closed during the purge cycle, or an alarm will sound. The tray rotation

cannot be started until the 6-minute purge cycle is complete. Also during this cycle, the emergency stop

panel will tilt and remain tilted until the purge cycle is complete. A buzzer will sound at the end of the cycle

to indicate when the tray operation can be started. Press the RUN button to start the tray and silence the

buzzer.

5. Allow the oven to reach the set temperature. The actual oven temperature is displayed in the OVEN

TEMP. window.

6. The oven is now ready for baking operations.

BASIC OPERATION

1. Preheat the oven.

2. Confi rm that the loading door is closed.

3. Press the RUN button and observe that the trays are

moving in an upward direction. The tray number will

change in the tray number window as the trays move

past the loading door sill.

4. Open the loading door.

5. Press the AUTO button and observe that the trays move in an upward direction and automatically

stop even with the loading door sill. Use the AUTO button for all routine stops.

6. Press the REVERSE button and observe that the trays move in a downward direction and automatically

stop even with the loading door sill.

Loading

Loading and unloading techniques will vary, depending upon the product. However, a few basic guidelines

will always apply.

1. Press the AUTO button to bring the desired tray to the loading door sill. Load the tray and, if desired,

start a timer for this tray. (See Timer Options on page 10.)

2. Divide the load evenly among all the trays.

3. Press the AUTO button to bring the next tray to the loading door sill and load the tray. If desired,

start a timer for this tray. (See Timer Options on page 10.)

– 9 –

Page 10

4. Continue this same procedure until all the product has been loaded.

5. When the loading door is closed, a buzzer will sound.

6. Press RUN to silence the buzzer and start the trays rotating throughout the entire bake process.

Unloading

1. Open the loading door.

2. Press the AUTO button to bring the desired tray to the

loading door sill.

3. Unload the baking product from the tray.

4. Press the AUTO button again to bring the next desired

tray to the loading door sill for unloading.

5. Continue this same procedure until all the product has

been unloaded, or close the loading door and press

RUN to continue baking of the remaining trays.

When the loading door is closed and the AUTO button is

pressed, the next tray will stop at the loading door sill and a

buzzer will sound. Open the loading door to silence the buzzer.

Operational Hints

• The OVEN TEMP. display shows the actual temperature inside the oven or the set temperature.

To view the set temperature, momentarily press the UP or DOWN arrows next to temperature

window.

• There is a dot in the temperature display window that is on when the oven is calling for heat.

• For best results, use RUN, AUTO and REVERSE for all loading, unloading and baking

operation.

TIMER OPTIONS

Single Timer

Ovens without Auto Start are equipped with a single timer for timing operations. The timer runs independently

and will not start or stop an operation.

1. Enter the desired time by pressing the UP or DOWN arrows next to the Hours and Minutes window

in the TIMER section.

2. Press the STOP/START key to activate the timer. The ON dot fl ashes in the top window, indicating

the timer is running.

3. When the timer expires, a beeper sounds. Press STOP/

START to silence the beeper.

– 10 –

Page 11

Multiple Timers

Ovens equipped with Auto Start have six individual timers that can be used for timing operations. Timers

run independently and will not start or stop an operation.

1. Press the single RIGHT arrow key next to the top window in the TIMERS section to select one of six

timers. The Timer Number will be displayed in the top window.

2. Enter the desired time by pressing the UP or DOWN

arrows next to the Hours and Minutes window.

3. Press the STOP/START key to activate the timer. The

ON dot fl ashes in the top window, indicating the timer(s)

is running.

4. When the timer expires, a beeper sounds and the Timer

Number fl ashes in the top window. Press STOP to silence the beeper.

5. If more than one timer is needed, select another timer by pressing the single RIGHT arrow and enter

the desired time. To begin the timing countdown on the timer you want to run, select the timer and

press the STOP/START key. The STOP/START key only starts or stops the timing operation for the

timer shown in the top window.

6. When multiple timers are in use, the Timer Number will fl ash in the top window as each one times

out.

NOTE: Previous time settings remain in the timers until changed.

Flip Time

Flip Time is a term used to describe a time less than the full bake time. Each of the six timers can be set

with a fl ip time. This can be useful for intermediate operations such as fl ipping a bagel. For example; a

bagel has a baking time of 12 minutes, but needs to be fl ipped over after 4 minutes. A fl ip timer can be

set to remind you to fl ip the bagel at 4 minutes during the full 12-minute bake time.

1. Press the single RIGHT arrow key next to the top window in the TIMERS section to select one of six

timers. The Timer Number will be displayed in the top window.

2. Enter the desired bake time by pressing the UP or

DOWN arrows next to the bottom Hours and Minutes

window.

3. To set the Flip Time, press and hold the FLIP TIME,

HOLD TO SET key. The set FLIP TIME will appear in

the Hours and Minutes window.

4. While pressing and holding the FLIP TIME, HOLD TO SET key, set the desired Flip Time and release

key when fi nished. The initial bake time will now appear in the Hours and Minutes window.

5. Press the STOP/START key. To view Flip Time, press the FLIP TIME, HOLD TO SET key.

6. When the fl ip timer has expired, a beeper will sound and the Hours and Minutes window will fl ash,

indicating the remaining bake time.

7. Press the STOP/START key to turn off the beeper and pause the bake time.

8. Flip the product and press the STOP/START key to restart the bake time. The bake time continues

to time out. When the bake time expires, a beeper sounds and the Timer Number fl ashes in the top

window. Press STOP/START to silence the beeper.

9. If a fl ip time is not desired, press and hold the FLIP TIME, HOLD TO SET key and set the fl ip time

to 0. If the fl ip time feature is not desired at all, see Customized Operation on page 13 for details to

disable this feature.

– 11 –

Page 12

CLOCK

Displays the current time and day of the week. It is also used as a 7-day, single-event programmable timer

for the Auto Start cycles. See below.

Set the Current Time and Day

Hour

• Press and hold the UP or DOWN arrows next to

the Hours and Minutes window. First, the minutes

will begin to change; then after a few seconds,

the minutes will stop and the hours will begin to

change.

• Set the current hour in the AM or PM.

Minute

• After the Hours are set, quickly press the UP or DOWN arrows next to the Hours and Minutes

window until the desired minutes are reached.

Day of Week

• To set the current day of the week, press the RIGHT arrow key next to the DAY OF WEEK

lights.

AUTO START

Oven will start automatically when in auto start mode. Stand clear of oven and hood

ventilator fan when alarm sounds.

The Auto Start feature allows the oven to turn itself on and preheat to a preset temperature in the absence

of an operator. An alarm will sound for 15-seconds before the hood ventilator fan is engaged, followed by

a 30-second alarm before the trays start rotating and the burner is lit.

1. To set the time and day the oven is to start baking, do the following:

NOTE: The AUTO START, HOLD TO SET key must be pressed during entire procedure.

• Press and hold the AUTO START, HOLD TO SET key. The AUTO START indicator light is lit, and

the auto start time and day will be displayed.

• Still pressing the AUTO START, HOLD TO SET key, press and hold the UP or DOWN arrow next

to the Hours and Minutes window. The minutes will begin to change fi rst; then after a few seconds,

the minutes will stop and the hours will begin to change. Set the desired hour in the AM or PM. To

set the minutes, quickly press the UP and DOWN until the desired minutes are reached.

• Continue to hold the AUTO START, HOLD TO SET key and press the RIGHT arrow in DAY OF

WEEK to select the day to auto start. Release all keys when fi nished.

2. Toggle the power ON/OFF switch to OFF, then turn back to ON. Oven purge cycle will run for 6

minutes then upper stop panel will rotate to a vertical position.

3. Press ON/OFF key in AUTO START section. The red light next to the ON/OFF key slowly fl ashes.

The oven will start automatically. Pressing the ON/OFF key again will place the oven in a sleep

mode.

NOTE: The POWER switch must be in the ON position for Auto Start to come on.

4. The oven will start automatically at the Auto Start time and day, and will heat the oven to the preset

temperature.

– 12 –

Page 13

Auto Start Hints

• Do not use the Auto Start feature when the manual tray operation is engaged or if the ventilation

motor is controlled by an external source.

• The oven will not Auto Start if the loading door is open.

• To turn the Auto Start feature off, press the ON/OFF key under AUTO START section.

• The Auto Start feature cannot be turned off once the purge cycles have started. A zero will be

displayed in the Timer number window when the purge cycles are in progress. The timer functions

cannot be adjusted during this time.

• The oven has the ability to automatically select the auto start day of the week to match the operator’s

weekly schedule. (See Customizing Auto Start on page 14 for details.)

CUSTOMIZED OPERATION

The OV851G Rotary oven controls have the capability of being customized to fi t your specifi c needs using

the Setup Mode.

Before entering the Setup Mode, read all the instructions to make sure you are completely clear on what

to do. If you need assistance, please call your authorized Bakery Systems service agency.

Entering/Exiting Setup Mode (without Auto Start)

1. Press and hold the DOWN arrow in the TIMER section while pressing the

2. The setup number will appear in the TIMER Hour and

Minutes window. The Tray Number window will fl ash.

An alarm will momentarily sound.

3. Release both keys. You are now in Setup Mode.

4. To exit Setup Mode, press and hold the same keys used

in step 1.

Entering/Exiting Setup Mode (with Auto Start)

1. Three keys need to be pressed at the same time to

enter Setup Mode:

• The single RIGHT arrow in the TIMERS section

• The FLIP TIME, HOLD TO SET key

• The AUTO START, HOLD TO SET key

2. The setup number will appear in the TIMERS Hour and

Minutes window. The Tray Number window will fl ash.

An alarm will momentarily sound.

3. Release all keys. You are now in Setup Mode.

.

4. To exit Setup Mode, press and hold the same three

keys used in step 1.

– 13 –

Page 14

Changing Items in Setup Mode

The number in the TIMERS section Hour and Minutes window is the Setup Number. The other windows

display the setup item(s) (the settings that can be changed). Depending on what setup number is being

displayed will determine what windows are lit.

1. To change the setup number displayed in the Hour and Minutes window, press the UP or DOWN

arrow. The setup item(s) will be displayed in the appropriate windows.

2. To make a change to the displayed setup item, go to the window where you want to make a change

and use the arrow keys to the left of the window to adjust the setting. Do not attempt to change the

items in Setup number 16 and up; these are for factory use only.

Where applicable, the Setup item window will display an E for enabled (turned on) or a

for disabled

(turned off). Press the UP arrow next to the window to enable or the DOWN arrow to disable.

Customizing Auto Start

NOTE: For Auto Start to work correctly, Setup number 7 must be enabled and each individual day must

be enabled or disabled. Also, start time and temperature must be the same for each enabled day. Different

start times and temperature can not be programmed.

For operators who use Auto Start on a regular weekly schedule, this feature will automatically advance

the Auto Start day of the week to the next enabled day, without having to manually set it each day. Any

day(s) can be enabled or disabled.

1. Ensure that Setup number 7 is enabled.

2. Go to Setup number 8, displayed in Hour and Minutes window of Timer Section.

3. In the Auto Start section, select the day of the week to be enabled or disabled by pressing the arrow

key to the left of the DAY OF WEEK indicators.

4. In the Hours and Minutes window of Auto Start section, an E for enabled or a

for disabled will

appear. The display can be changed by pressing the UP arrow to enable, or the DOWN arrow to

disable.

5. Repeat steps 2 and 3 for each day of the week. Each day must be enabled or disabled.

6. To exit Setup Mode, see appropriate Entering/Exiting Setup Mode on page 13.

– 14 –

Page 15

Setup Guide

Items designated with a * are for ovens with Auto Start.

Setup

Setup Item

Numbers

0 Displays program version number in Temperature window and oven type number in Hour and

Minutes window.

1 The oven can be set to display the temperature in Celsius or Fahrenheit.

2 This is the minimum temperature that the oven can be set.

3 This is the maximum temperature that the oven can be set.

4 Select military (24 hour) or standard time. When both AM and PM indicator lights are lit, the oven

is set for military time. When the AM indicator light is lit, the oven is set for standard time.

5* Select the desired timer option. Option #0 is the standard time mode. Option #1 functions the

same as option #0, except that timer numbers and tray numbers are linked together.

6* Enable or disable the Flip Timer feature.

7* Enable or disable the Auto Start feature.

8* Enable or disable auto selection of the Auto Start Day.

9 This item allows for a temperature offset calibration of ±15°F.

10 This item enables or disables the automatic fault testing of the hood airfl ow switch during power-

up.

15* This item sets the oven back to factory default. Press the arrow key next to the TIMERS number

window.

16 This item sets the oven back to factory default. Press the TIMERS START key.

SHUTDOWN

1. Unload all remaining product from the oven.

2. If Auto Start has been customized, press the ON/OFF key in Auto Start section. The red light next

to the ON/OFF key will start fl ashing, indicating the oven is in Auto Start mode. The POWER switch

must be in the ON position.

3. If Auto Start has not been customized, turn POWER switch to the OFF position.

Extended Shutdown

1. Turn POWER switch to the OFF position.

2. Turn the gas shutoff valve, located behind the right-hand door, and burner gas valve, located behind

the lower front panels, to OFF.

3. Disconnect electrical supply from oven.

– 15 –

Page 16

CLEANING

The oven and its parts are hot. Use care when operating, servicing or cleaning the

rack oven.

• Allow the oven to cool.

• Clean the outside of the oven daily with a clean, damp cloth.

MAINTENANCE

The oven and its parts are hot. Use care when operating, servicing or cleaning the

oven.

Disconnect the electrical power to the machine and follow lockout / tagout

procedures.

INSPECTING THE OVEN

Every Other Week

1. Check the stop panel for proper operation.

2. Inspect the area around the oven. The area must be free and clear from combustibles, and there

must be no obstructions to the fl ow of combustion and ventilation air.

3. Empty the grease cup and fi lters in the exhaust hood. To allow for easy access to the hood, fi lters

and grease cup, the EMERGENCY STOP PANEL can be tilted backward after removing the panel

stop clip.

4. Remove any droppings or debris from fl oor of oven, including baking pans.

PREVENTIVE MAINTENANCE

The oven should be kept on a regular preventive maintenance schedule. Ovens require specifi c preventive

maintenance based on usage and environmental factors. The failure to have the oven properly maintained

by following recommended preventive maintenance procedures may result in higher repair costs, a

shortened equipment life or an unsafe operating condition.

A copy of the Semiannual maintenance and inspection procedure is located behind the access panels

below the oven sill.

The performance of routine preventive maintenance on any oven, which is the owner’s responsibility, will

help to ensure continued safe and reliable operation.

A preventive maintenance program is your best option for continued safe and reliable oven operation. We

believe that the Bakery Systems Service is your best choice for performing preventive maintenance.

– 16 –

Page 17

Recommended Lubrication

Dow Corning C-40 High Temperature Chain Lubricant

• Hobart Part No. 01-10G108-00001 (4 oz)

• Hobart Part No. 01-10G108-00002 (1 qt.)

Lubrication Frequency Based on Usage

Duty Cycle

Light Duty

56 hours per week

(8 hours per day, 7 days per week)

Medium Duty

57 to 84 hours per week

(12 hours per day, 7 days per week)

Heavy Duty

Oven 84 hours per week

Lubrication Procedure

Lubrication

Frequency

Monthly

X

Every 3

Months

X

X

1. Allow oven to cool below 250°F (121°C).

NOTE: Application above 250°F is ineffective as the lubrication base is vaporized prior to penetration of

the bearing surface.

NOTE: Lubrication must be applied directly to the bearing shaft.

2. Lubricate main bearings.

3. Lubricate guide wheels.

4. Lubricate tray bearings.

5. With oven rotating, apply sparingly to drive chain.

6. Check drive chain for proper tension.

7. Check transmission for proper oil level.

8. With trays running in reverse, heat oven to 400°F and allow to cycle for 30 minutes.

SERVICE AND PARTS INFORMATION

Contact your authorized Bakery Systems service agency.

– 17 –

Page 18

TROUBLESHOOTING

The Quick-View oven status display (Fig. 2) on the control panel shows the status for the various systems

of the oven. The Quick-View Status Lights (Fig. 3) explains what each light means. Some problems can be

corrected by the user. If the corrective action does not solve the problem, contact your authorized Bakery

Systems service agency.

1

SERVICE DOOR

CLOSED

2

HOOD AIRFLOW

VERIFIED

3

TEMP. LIMIT CLOSED

ALL OVENS

GAS

PURGE

4

THERMOSTAT

OUTPUT POWER

56GAS VALVE

POWERED

FLAME FAILURE

7

LOADING DOOR

CLOSED

8

PURGE MOTOR

POWERED

9

PURGE POSITION

VERIFIED

10

PURGING

11 DRIVE MOTOR

POWERED

MOTOR

Fig. 2

– 18 –

Page 19

Quick View Status Lights

Light

Number

1 Light is on. Light is off. Service door is open. Close service door.

2 Light is on. Light is off. Inadequate hood

3 Light is on. Light is off. Temperature limit

4 Light is on when

5 Light is on when

6 Light is off. Light is blinking. Burner fl ame has

7 Light is on. Light is blinking. Loading door is open

8 Light is on during

9 Light is on during

10 Light is on during

11 Light is on when

Normal

Operation

calling for heat.

calling for heat.

purge cycle.

purge cycle.

purge cycle.

trays are moving.

Problem Probable Cause Corrective Action

Call service.

airfl ow.

Cool oven down.

of oven has been

exceeded.

Light is off when

the oven is calling

for heat.

Light is off when

the oven is calling

for heat.

Light is off during

purge cycle.

Light is off during

purge cycle.

Light is blinking. Problem with status

Light is off when

trays should be

moving.

Control PC board is

not sending power to

ignition module.

Control PC board is

not sending power to

gas valve.

gone out.

during purge or Auto

Start.

Purge motor not

getting power.

Emergency stop

panel is not in the

purge position.

light number 2, 7, 8,

and/or 9.

Drive motor not

getting power.

Call service.

Call service.

Turn off oven then back on.

Close loading door.

Call for service.

Turn oven off and then back on.

Check correctiove action to

corresponding numbers.

Switch to manual motor control

(See Emergency Tray Operation on

page 20).

Fig. 3

TEMP DISPLAY ERROR CODES

1. Check for error code HSO. If control temp display reads HSO troubleshoot the following.

A) Stack fan malfunction or pressure switch open.

B) Service access door off or interlock open.

2. Check for error code HPSF. If control temp display reads HPSF troubleshoot the following.

A) Hood or purge pressure switch malfunction.

– 19 –

Page 20

EMERGENCY TRAY OPERATION

The emergency tray operation procedures are used only if the trays will not operate by normal pushbutton

operation and tray movement is required to unload the product.

Electrical Tray Operation

If there is a component or electrical part failure in Auto Mode, this procedure allows the trays to be operated

with the power on.

1. Turn POWER SWITCH to the OFF position.

2. Lift out the two Lower front panels from the oven (Fig. 1).

3. Turn the Manual-Auto Switch to the MANUAL position (Fig. 1).

4. Reinstall the front panels and turn POWER SWITCH to the ON position.

5. Use the RUN or REVERSE buttons to start the trays, depending on which direction you want to move

them to the loading door sill. Use the EMERGENCY STOP PANEL to stop the trays at the loading

door sill for unloading.

6. Notify your authorized Bakery Systems trained service technician to correct the problem.

7. If this procedure does not work, use the Manual Tray Operation procedure below to unload the

oven.

Manual Tray Operation

Disconnect the electrical power to the machine and follow lockout / tagout

procedures.

A power failure is indicated by no control panel lights and/or interior oven light when the Power Switch is

in the ON position. Use the following procedure to manually move the trays to the loading door sill.

1. Turn POWER SWITCH to the OFF position.

2. Lift out the two Lower Front Panels from the oven (Fig. 1).

3. The hand crank assembly is located in the compartment behind the front panels. Insert the male end

of the crank into the female end of the motor shaft. Turn the crank to move the trays to the loading

door sill.

4. After completing the unloading operation, remove the hand crank and return it to the compartment

for future use.

5. Reinstall the front panels and notify your authorized Bakery Systems trained service technician to

correct the problem.

FORM 31199 Rev. B (July 2009) PRINTED IN U.S.A.

– 20 –

Loading...

Loading...