Baxter OV500G2-EE User Manual

Project:

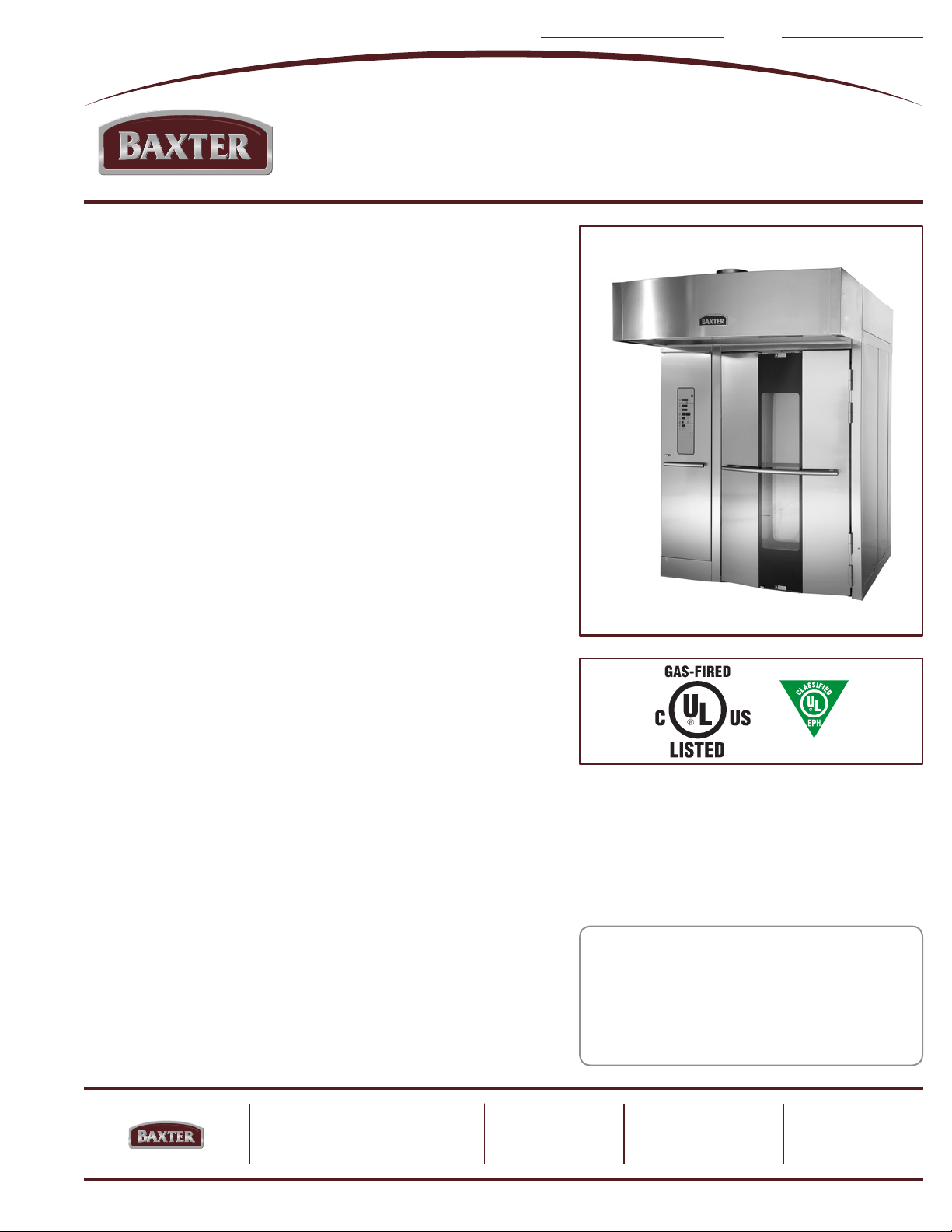

Rotating Double Rack Oven – Energy Efficient Gas

STANDARD ENERGY SAVING FEATURES

■ Halogen lighting in the bake chamber provides better visibility and better bulb

life in high temperature environments

■ Efficient 275k BTU/Hr. in-shot burner system consumes less gas, but provides

high-impact results

■ Improved airflow design maximizes heat exchanger use, reduces energy

consumption and reduces cook time by up to 5%

■ Energy saving idle mode reduces oven to a stand-by temperature when left

idle. Idle time and stand-by temperature can be customized to maximize

energy savings in your operation

■ Programmable digital control with Auto on/Auto off controls

■ Three pane viewing window provides safe to touch exterior

• Dual panes of low-E glass on the interior of the window reflects heat

inward, saving energy

• Airwash gap within the door decreases exterior temperatures

• Single exterior pane is hinged to allow cleaning access to both sides

Item#

C.S.I. Section 11400

OV500G2-EE

STANDARD FEATURES

■ Stainless steel construction

■ Heat exchanger with weldless construction for longer life. Tubes carry an

additional 9 year extended parts and labor warranty

■ Patented self-contained spherical cast steam system

■ Hood with plenum and single point vent connection for Type II installations

■ Field reversible bake chamber door (left or right hinged to fit your needs)

■ Patented flush floor – no ramp required

■ 99 programmable recipes

■ Oven body shipped split

• Minimum intake: 37" x 104.5" x 62" (uncrated)

■ Holds 2 single or 1 double oven rack

OPTIONS & ACCESSORIES

❏ UL Listed, Type I hood with grease filters. Listed to UL 710 standard and meets

requirements of NFPA-96.

❏ Manual back-up control

❏ Oven body shipped whole (hood, steam system & floor are field installed)

• Minimum intake: 72" x 104.5" x 68.5" (uncrated)

❏ Kosher package

❏ Prison package

❏ Floor extender package

Area Reserved For Consultant & Contractor Approvals

BX56068 (03-15) – Printed In USA

19220 State Route 162 East

Orting, WA 98360

www.baxtermfg.com

Factory

(360) 893-5554

Customer Care

(800) 462-2778

Customer Care Fax

(937) 332-2852

Page 1 of 2

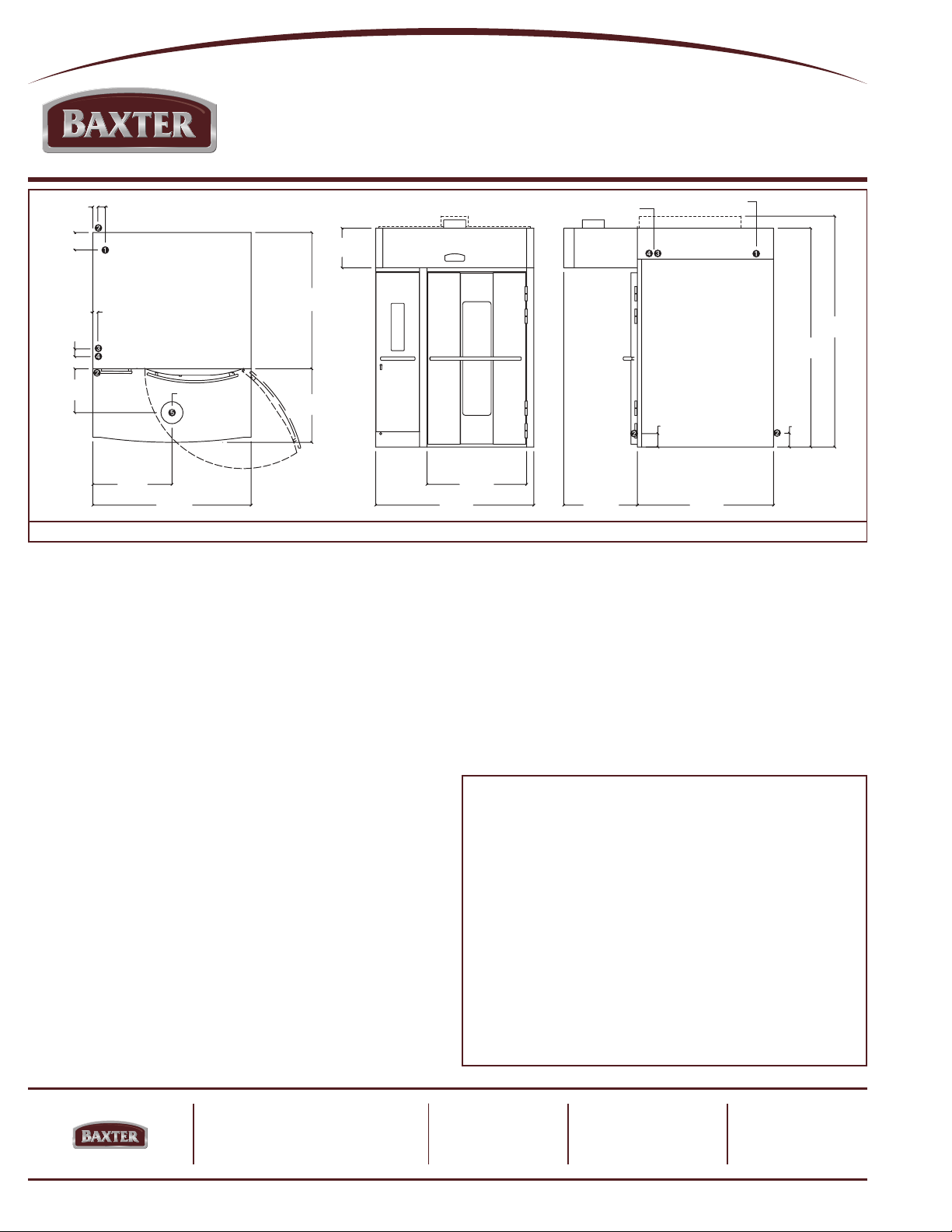

(182.9 cm)

(182.9 cm)

(1

cm)

WATER

C.S.I. Section 11400

2.3”

(5.8 cm)

8.0”

(20.3 cm)

2.3”

(5.8 cm)

3.5”

(8.9 cm)

20.0”

(50.8 cm)

GAS

DRAIN

5.5”

4.0 cm)

3.4”

(8.6 cm)

DRAIN

WATER

POWER

VENT

OV500G2-EE

Rotating Double Rack Oven – Energy Efficient Gas

GAS, POWER

6.1”

(15.5 cm)

99.5”

(252.7 cm)

6.3”

(16.0 cm)

104.5”

(265.4

62.0”

(157.5 cm)

33.5”

(85.1 cm)

17.8”

(45.2 cm)

HOOD VENT

72.0”

45.3”

(115.1 cm)

33.5”

(85.1 cm)

36.0”

(91.4 cm)

72.0”

• Highest Point on Oven: 104.5" (265cm). • KD shipping weight: 4,185 lbs (1898kg). • Rack swing diameter: 49.9" (126.7 cm) • Freight Class: 70

UTILITIES & NOTES

➊ Water:

1

⁄2” NPT connection @ 94" AFF. Cold water @ 30 psi minimum @ 3.0 GPM flow

rate. Max water usage 6.0 GPH.

Note: Water supply must have the proper hardness, pH & Chloride concentration.

Consult your local water company and/or water conditioner dealer before

installation.

• Recommended water hardness range: 2-4 grains per gallon.

• Recommended pH range: 7.0 to 8.0.

• Acceptable range for chloride concentration: 0-30 ppm.

➋ Drain: Choose either rear or front drain and plug the connection not in use. Route to

air-gap drain.

• Front drain: 1⁄2" NPTM @ 6.1" AFF

• Rear drain: 1⁄2" NPTM @ 6.3" AFF. Kit supplied to extend drain to either side of oven.

➌ Power: 2 supplies required:

1. Heating Circuit - Choose one:

❏ 208-240V/60/1 8.6 amps

against the underside thereof, or on non-combustible slabs or arches having no combustible

material against the underside. Refer to NFPA 54 for further clarification.

Important: • Do not rout e utilities (wiri ng, plumbing, etc .) in or under the non -combust ible

floor beneath the oven.

• 115" AFF required for oven tilt-up.

• 130" AFF recommended for service access.

The purchaser is responsible for all installation costs and for providing: Disposal

of packing materials, labor to unload oven upon arrival, installation mechanics, and all local

service connections including electricity, gas, water, vents and drain per local code. A factor y

authorized installation technician must super vise and approve any installation. In order to

validate the warrant y, star t-up must be performed by an authorized service company. All

services must comply with federal, state, and local codes.

Minimum clearances to combustible construction:

• 0 inches from sides and back

• 18 inches from top

❏ 208-240V/60/3 4.2-4.4 amps

❏ 440-480V/60/3 2.2-2.4 amps

2. Control Circuit:

120V/60/1 15 amp dedicated circuit. 20 amp max.

➍ Gas: 1-

1

⁄4" NPT connection @ 102" AFF.

• Natural gas (std): 275k BT U/hr @ 5-14"w.c.

• Propane (opt): 275k BTU/hr @ 10-14"w.c.

Note: Input rates will be reduced when oven is installed at elevations above 300 0'

(915m). Consult factory for elevation correction.

➎ Hood vent: 10" dia. connection collar. Min. 900 cfm req. with 0.6" w.c. static pressure

drop through hood. Customer to supply duct and ventilator fan per local code. Airflow

proving switch is factory installed and integrated with burner system operation. Oven

provided relay with max. 10.0 amp 1⁄2 H.P. @ 120V output for fan operation.

Ventilator fan is required. Consult local authorities to determine whether Type I (grease)

or Type II (vapor) duct will be required. Hood connection suitable for connection to

Type B vent, except when products of baking are grease laden.

INSTALLATION

Floor must be level within 1⁄8" per foot for proper installation. Slope must not exceed 3⁄4” in

all directions under the unit. Floor anchors require minimum of 1" thick solid floor substrate.

Cautio n – To reduce t he risk of fire, the a ppliance must be m ounted on floo rs of non-co mbustible

const ruction wi th non-co mbustible floor ing and surf ace finish and wit h no combustibl e material

SHORT SPECIFICATION

The oven shall be of stainless steel construction, manufactured in the United States

by Bax ter Mfg. The footprint shall be no larger than 72.0” W x 62.0”D x 104.5.0”H and

shall have an integral hood with a minimum of 31” overhang to ensure proper vapor

capture. The Type I hood must be UL710 Listed and have a single point exhaust. Oven

shall have independent electrically interlocked air safety switches for the draft inducer

and hood. Control panel shall have programmable settings with auto on/off feature and

4-step bake/roast setting.

The oven shall include an in-shot burner system with a heat exchanger consisting of

18 independent high-temperature, stainless steel tubes. The in-shot burners will have

no moving parts. The oven shall also include a patented self-contained spherical cast

steam system which shall convert 1.0 gallon of water into steam within 20 seconds

at a temperature of 400°F or better. The field reversible oven door shall utilize three

panes of glass in the viewing window to ensure a safe to the touch exterior. A patented

adjustable flush floor shall be used for easy access without a ramp. The oven shall be

equipped with a diagnostic center with status indicator lights and be equipped with

built-in levelers.

The oven will bear the following agency approvals: UL for safet y, sanitation, and gas

for the U.S. & Canada, UL710 for the hood. The exhaust hood shall meet construction

requirements of IMC section 507 and NFPA-96.

Manuf acturer r eserves t he right to mak e changes in siz es and speci fications.

62.0”

(157.5 cm)

Page 2 of 2

19220 State Route 162 East

Orting, WA 98360

www.baxtermfg.com

Factory

(360) 893-5554

Customer Care

(800) 777-2828

or

(800) 462-2778

Customer Care Fax

(937) 332-2852

BX56068 (03-15) – Printed In USA

Loading...

Loading...