Page 1

Operator

Manual

OV500G1-EE

OV500G2-EE

OV500 ROTATING RACK OVEN

WITH ADVANCED ELECTRONIC

OVEN CONTROL

Model Number: ___________

Serial Number: ___________

Date of Installation: ___________

Baxter Mfg, a Division of ITW FEG, LLC • 19220 State Route 162 East • Orting, WA 98360-9236

Phone: (360) 893-5554 • Fax: (360) 893-1337

www.baxterbakery.com

OV500G1 GAS

OV500G2 GAS

OV500E1 ELECTRIC

OV500E2 ELECTRIC

OV500G1-EE GAS

OV500G2-EE GAS

FORM 36715 Rev. B (February 2016)

Page 2

IMPORTANT FOR YOUR SAFETY

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED FROM THE

LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS

AT MAIN SHUTOFF VALVE AND CONTACT THE LOCAL GAS

COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO

OPERATE THIS DEVICE.

KEEP AREA AROUND OVEN CLEAR OF COMBUSTIBLES. DO

NOT OBSTRUCT COMBUSTION AND VENTILATION OPENINGS

ON THE OVEN.

© BAXTER MFG., 2016

– 2 –

Page 3

MODEL OV500 SINGLE RACK OVEN

– 3 –

Page 4

TABLE OF CONTENTS

GENERAL ............................................................................................................................................. 5

INSTALLATION ..................................................................................................................................... 5

OPERATION .......................................................................................................................................... 6

OV500 Digital Controls .................................................................................................................... 6

Back-Up Control Operation (optional) ............................................................................................11

Safety Alarm (Standard Feature, No Parameter Setup Required) .................................................11

Pulse or Food Service Steam Mode .............................................................................................. 12

Kosher Operation Mode (Ovens Equipped With Kosher Package) ............................................... 12

Programming the Oven ................................................................................................................. 13

Customized Operation ................................................................................................................... 17

Energy Saving Mode ..................................................................................................................... 20

Shutdown ....................................................................................................................................... 20

Restarting Oven ............................................................................................................................. 20

TROUBLESHOOTING ........................................................................................................................ 21

Burners Will Not Light on Gas Oven .............................................................................................. 21

Alarms and Display Messages ...................................................................................................... 21

Other Troubleshooting Topics ........................................................................................................ 21

CLEANING .......................................................................................................................................... 22

MAINTENANCE .................................................................................................................................. 23

General ......................................................................................................................................... 23

Preventive Maintenance ................................................................................................................ 23

Service and Parts Information ....................................................................................................... 23

OWNER PREVENTIVE MAINTENANCE PROCEDURE .................................................................... 24

Introduction .................................................................................................................................... 24

Preventive Maintenance Procedure .............................................................................................. 24

– 4 –

Page 5

OPERATION AND CARE OF

MODEL OV500 RACK OVEN

RETAIN THIS MANUAL FOR FUTURE REFERENCE

GENERAL

The Baxter OV500 Rack Oven accommodates a roll-in rack. It is equipped with an electronic oven control

for baking, roasting and/or steaming applications. A mechanism in the oven ceiling picks up and rotates

the rack during the baking or cook cycle.

Model OV500G1 is rated at 180,000 Btu/hr, natural or propane gas.

Model OV500G2 is rated at 300,000 Btu/hr, natural or propane gas.

Model OV500G1-EE is rated at 180,000 Btu/hr, natural or propane gas.

Model OV500G2-EE is rated at 275,000 Btu/hr, natural or propane gas.

Model OV500E1 is rated at 25.7 - 34.2 kW.

Model OV500E2 is rated at 38.5 - 51.3 kW.

Baxter Rack Ovens are produced with quality workmanship and material. Proper installation, usage, and

maintenance of your oven will result in many years of satisfactory performance.

It is suggested that you thoroughly read this manual and carefully follow the instructions provided.

INSTALLATION

The Baxter OV500 Series Rack Oven must be installed or moved only by authorized Bakery Systems

trained service technicians.

– 5 –

Page 6

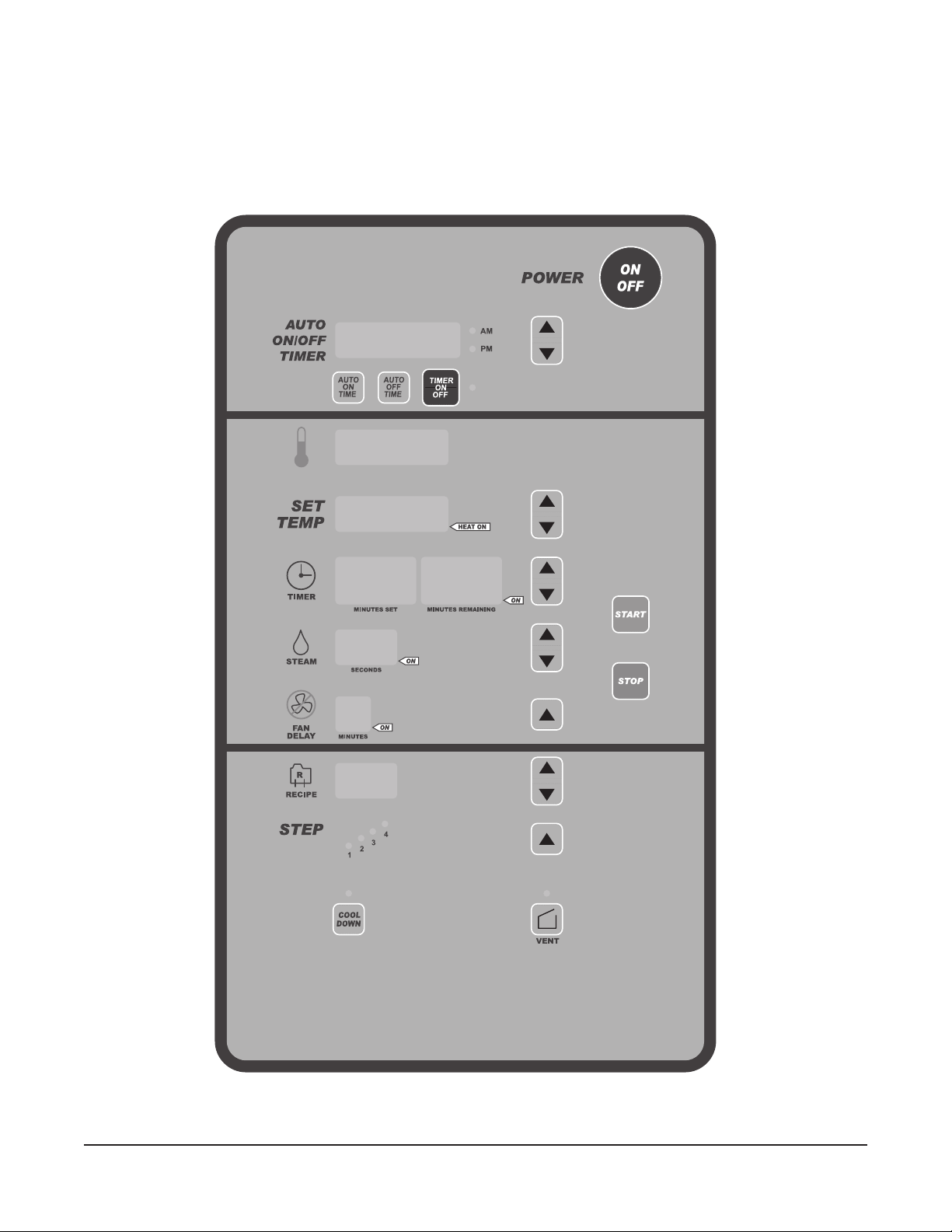

OV500 DIGITAL CONTROLS

OPERATION

– 6 –

Page 7

Control Guide - Advanced

AUTO ON/OFF

AUTO ON TIME

AUTO

OFF

TIME

AUTO

OFF

TIME

AUTO

OFF

TIME

BAKE TIMER

AUTO

OFF

TIME

STEAM TIMER

AUTO

OFF

TIME

STEP

AUTO

OFF

TIME

STEP

AUTO

OFF

TIME

STEP

BUTTON ACTION DISPLAY

Press to turn the oven ON or OFF. Control panel displays are lit when the oven is on. Oven

defaults to Program 0. If oven is turned OFF and back

ON within 2 minutes, the oven will come up in the last

mode and oven setting.

TIMER

AUTO

ON

TIME

Press to enter current time or time for

oven to automatically turn ON or OFF,

when corresponding Auto On Time or

Auto Off Time button is pressed.

Press arrow keys to set the desired

time of oven to automatically turn ON.

The AUTO ON/OFF TIMER window displays the current

time or the time the oven will automatically turn ON or

OFF.

The AUTO ON/OFF TIMER window displays the time

the oven will automatically turn ON.

AUTO OFF TIME

AUTO

OFF

TIME

TIMER ON/OFF

TIMER

ON

OFF

SET TEMP

FAN

DELAY

Press arrow keys to set the desired

time of oven to automatically turn OFF.

Press to turn the automatic timer ON

or OFF.

Press to set the desired temperature

(5-degree increments).

Press arrow keys to enter the BAKE

time (1 minute increments). Press the

up arrow key to enter additional time at

the end of the bake program.

Press to enter the STEAM time

(5-second increments in Burst steam or

Bakery mode; 1-second increments in

Pulse steam or Food Service mode).

Press to enter the FAN DELAY time

(1-minute increments).

The AUTO ON/OFF TIMER window displays the time

the oven will automatically turn OFF.

The indicator light beside the timer ON/OFF button is lit

when the function is enabled.

The SET TEMP window displays the set temperature.

The HEAT ON light is lit while the oven is heating. The

actual temperature in the oven cavity is displayed in the

OVEN TEMP window.

The BAKE TIMER window displays the amount of time

for the current baking cycle. The minutes set are the

left two digits and minutes remaining are the right two

digits. The windows can be set to display hours and

minutes remaining. The ON light is lit when bake time

is active. See Customized Operation to congure this

setting.

The STEAM TIMER window displays the amount of

time set for the steam cycle. The ON light is lit when the

steam system is active.

The FAN DELAY TIMER window displays the amount of

time set for the circulation blower delay cycle

0-9 minutes.

START

STOP

RECIPE

Press to start the BAKE TIMER. The ON light blinks when the BAKE TIMER is active.

Press to stop the BAKE TIMER or

The ON light is off when the BAKE TIMER is inactive.

silence the beeper after the BAKE

TIMER has timed out.

Press the arrow keys to select a bake

program.

Press to select one of four baking

steps.

The RECIPE window displays the number of the current

program.

The corresponding indicator light will be lit (1 to 4),

depending on which step is selected.

– 7 –

Page 8

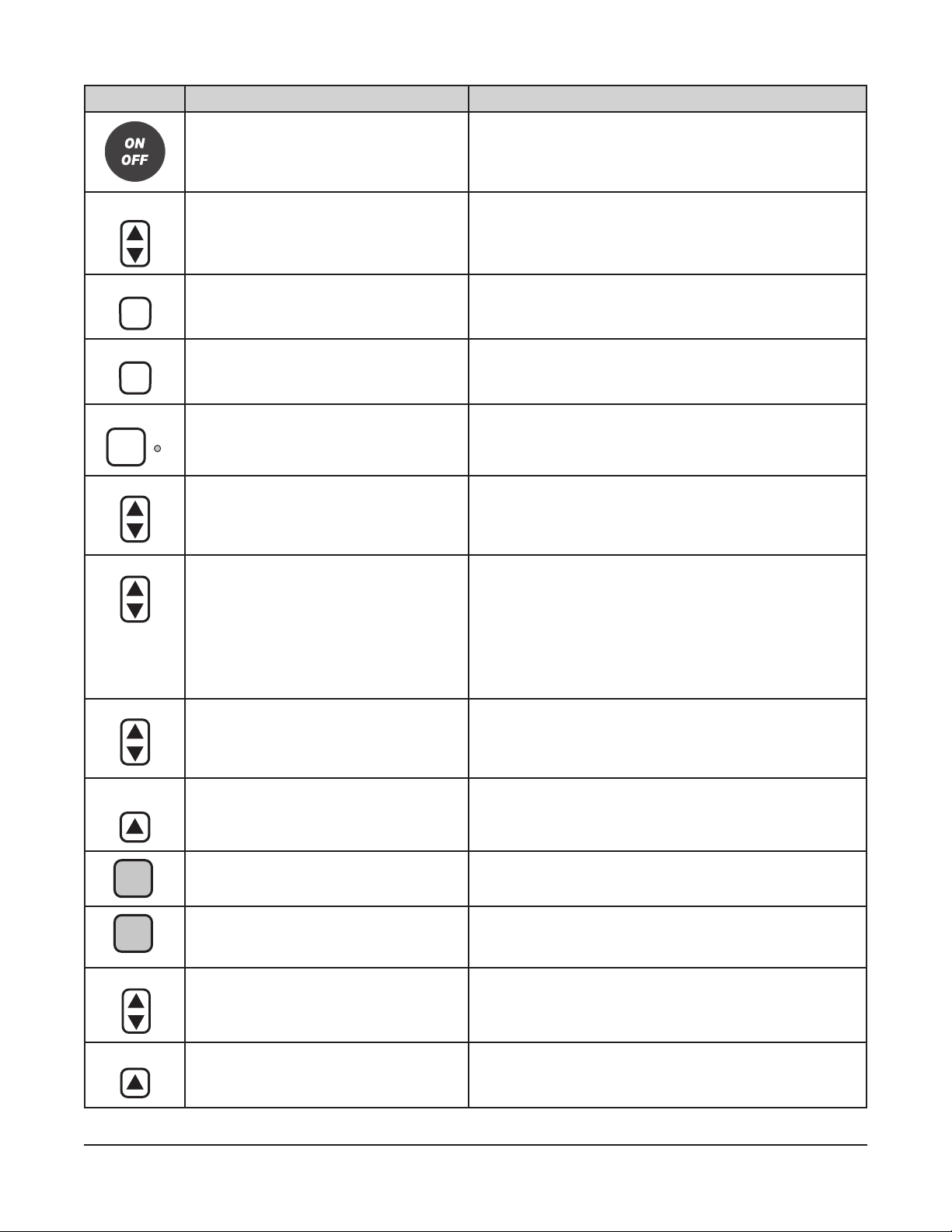

BUTTON ACTION DISPLAY

AUTO

OFF

TIME

STOP

STEP

Press to open or close the vent. The indicator light next to the VENT button is lit when

the vent cycle is enabled.

Use to cool down the oven. To enable this feature, set a temperature at least 25°F

COOL

DOWN

Auto On/Off Timer and Clock

The Auto ON/OFF Timer display shows the current time of day. To set the clock, the control must be turned

on. Press and hold either arrow button to initiate clock setting, then adjust time using arrow buttons. A few

seconds after the time is adjusted, the colon in the time display will resume ashing.

Timer Settings

The oven can be set to turn itself on and off. After the AUTO ON/OFF TIMER is set, the POWER ON

OFF button can be pressed to turn the oven off. This will not disrupt the AUTO ON/OFF setting. Electrical

power to the oven must remain on.

NOTE: Auto On/Off has restricted access when P21 (Advanced Energy Savings Mode) is set to 1.

(14°C) cooler than the oven temperature. Press the

COOL DOWN button. The COOL DOWN mode is exited

when the oven reaches the new set temperature, or if

door is opened when temperature is 25°F (14°C) below

set temperature, or by pressing any button.

1. To set the oven to turn on, press and hold the AUTO ON TIME button. The previously entered start

time will appear in the display. Use the UP and DOWN arrows to adjust the start time. Then release

the AUTO ON TIME button.

2. To set the oven to turn off, press and hold the AUTO OFF TIME button. The previously entered end

time will appear in the display. Use the UP and DOWN arrows to adjust the end time. Then release

the AUTO ON TIME button.

3. To enable the automatic start, press and hold the TIMER ON/OFF button until the indicator LED to

the right of the TIMER ON/OFF button is illuminated.

NOTE: When using AUTO ON/OFF to preheat the oven, if the oven is not disturbed for the time set in

parameter P17 (Temperature setback time), it will revert to the Setback temperature stored in parameter

P18 (Setback temperature) setup.

Backup Battery

The clock is backed up by a lithium battery which keeps the clock circuitry operating when all external power

is off. If the battery becomes low or dead while the external power is off, the display will read 12:00 (12

hr mode) or 0:00 (24 hr mode) and will not increment until a new time is set. The clock will operate with a

dead or missing battery, but must be set each time external power is turned on. Batteries must be replaced

when low or dead to avoid corrosive damage to the circuitry. Contact your local authorized service ofce.

– 8 –

Page 9

Oven Preheat

For best results, the oven must be preheated to bake temperature before baking begins.

1. The door must be closed for oven to heat. The rack carrier will lift and rotate only during timed

bake.

NOTE: The rack carrier will be in the unload position from the last bake. If the rack carrier was moved

out of the home position, the rack carrier will lift and turn to the unload position when the door is opened.

2. Press the POWER ON OFF button to turn the oven on.

3. Press the UP or DOWN arrows next to the SET temp window to enter the desired baking temperature.

Actual temperature of the oven will appear in the OVEN TEMP window.

4. For optimum steaming capability, allow 30 minutes after the oven has reached the set temperature

for the steam system to charge.

5. The oven is now ready for baking operations.

Basic Operation

The oven and its parts are hot. To prevent burns, use hot pads or protective mitts

when loading or unloading the oven.

Hot air and steam are released from the oven interior when the loading door is

opened. To avoid burns, open the door slowly and keep clear of the opening.

1. Preheat the oven (See Oven Preheat).

2. Manually select baking settings:

• Press the UP or DOWN arrows next to TIMER

to enter the desired value.

• Press the UP or DOWN arrows next to

STEAM TIMER to enter the desired value.

• Press the UP arrow next to FAN DELAY to enter the desired value.

• The steam and airow delay settings are optional and can be left at 0 if desired.

3. Slowly open the door and load product.

4. Press the start button and close the door. The on light in the Timer window blinks as the timer counts

down.

5. Rack lifts from oor and rotates from right to left.

6. The oven beeps after the TIMER times out. Press STOP to silence the beeper.

7. Open door. Allow rack carrier to stop and lower. Remove product.

– 9 –

Page 10

Loading Procedure

1. Type B and C rack carriers are equipped with stops on both ends. For B lifts, ensure stop ap is in

the up position to load the rack on the rack carrier. For C lifts, push rack stop to the left after rack is

loaded.

2. Roll the rack into the oven so the end brackets channel onto the rack carrier. When using racks

equipped with pan stops, load racks so stops will prevent movement of trays toward user when racks

are unloaded. Position pans so they do not extend beyond the rack. If the pans extend beyond the

rack it may cause the rack to get jammed when rotating.

3. Close the loading door. The rack carrier will lift and rotate only during timed bake.

Unloading Procedure

The oven and its parts are hot. To prevent burns, use hot pads or protective mitts

when loading or unloading the oven.

Hot air and steam are released from the oven interior when the loading door is

opened. To avoid burns, open the door slowly and keep clear of the opening.

1. Press STOP and/or open the loading door to silence the beeper.

2. Wait for the rack carrier to stop and lower.

3. For B lifts, push the rack stop down to unload the rack from the rack carrier. For C lifts, push rack

stop to the right to open.

4. Roll the rack from the rack carrier.

5. Close the loading door.

Cooling Oven

• To cool the oven more than 20 degrees below its current temperature; change SET TEMP to the

desired new temperature, open the oven door, and press COOL DOWN. The SET TEMP display

will alternate between ‘COOL’ and the SET TEMP until the oven has cooled. When the oven has

reached the set temperature, the alarm will beep and the control will return to normal operation.

Closing the oven door or pressing any control button during Cool-Down mode will also return the

control to normal operation.

• The VENT control can provide a means of cooling down the oven. When the oven is in the off

mode and the door is open, press the VENT button once to start or stop the circulation fan. Vent

light will be lit. The fan will also stop when the door is closed or the oven is put into the on mode.

• If the oven temperature is more than 20 degrees higher than the set temperature, and the bake

timer is not activated, the oven will automatically open the vent. The vent will remain open until

the oven temperature is within 20 degrees of the set temperature.

Operational Hints

• On the initial startup, the oven temperature will default to the factory setting of 375°F (190°C)

unless changed.

• During a baking cycle, the START and STOP buttons control the TIMER, STEAM, and FAN DELAY

settings only. They have no effect on the oven heat. When the TIMER times out, the oven heat will

cycle on and off to maintain the set temperature. Care should be taken not to overbake products.

• To adjust the temperature during a baking cycle, press the UP or DOWN arrows in the Oven Temp

section to enter the new temperature. If P20 (Restricted operator mode) is set for 1 then oven

temperature cannot be changed during the bake cycle.

– 10 –

Page 11

• To adjust steam settings, press the corresponding arrows to enter the new values. The steam timer

cannot be adjusted during bake operation.

• You can adjust the time remaining with the arrows. The set time remains unchanged unless you

“0” out the remaining time. If P20 (Restricted operator mode) is set for 1 the bake time cannot be

changed during the bake cycle.

• If the door is opened at any time during the baking cycle, the TEMP, TIME, STEAM, and FAN

DELAY settings will pause. Close the door to resume all functions.

• The FAN DELAY option turns off the airow at the beginning of the baking cycle for the total time

entered in this window. The heat is off while the FAN DELAY is activated.

• The oven monitors the heating system by comparing the current oven temperature to the set

temperature. If a problem arises in the heating system or there is a heating system failure, both

temperature displays will ash after 15 minutes. If the problem continues, contact your authorized

Bakery Systems service agency.

BACK-UP CONTROL OPERATION (OPTIONAL)

If the main control panel ceases to function properly, baking can continue with the use of the Back-up

Controls, if equipped. The Back-up Controls are located behind the control door on rear wall of the

component panel.

To activate the Back-up Controls, ip the toggle switch to BACK-UP position. Temperature and steam are

now controlled by the thermostat dial and steam rocker switch, located on the back-up control panel. Set

the thermostat dial to the desired temperature. Once the oven has reached temperature, steam can be

injected by pressing and holding the steam rocker switch up to a maximum of 20 seconds. More than this

will cool down the oven and steamer excessively. Venting the oven must be done manually by opening

the door. The rack carrier will stop and lower when door is open. Close door after venting is complete for

rack carrier to lift and resume rotating. While in the backup mode the timer feature will not function.

SAFETY ALARM (STANDARD FEATURE, NO PARAMETER SETUP REQUIRED)

If the temperature at the probe is in the range of 570 - 600 degrees Fahrenheit for 10 seconds, the unit

will do the following:

1. Shut off all features.

2. Sound an alarm.

3. Flash the OVEN TEMP display (actual temperature is displayed).

4. Display the letters ‘SHdn’ in the TIMER display.

The oven will remain in the shutdown mode until the 120VAC power is shut off. Turning on and off the

circuit breakers will restore the oven to normal operation if the temperature is below 570 degrees.

Disconnect the electrical power to the machine and follow lockout / tagout procedures.

There may be multiple circuits. Be sure all circuits are disconnected.

Shut off gas. Contact your authorized bakery systems service ofce.

– 11 –

Page 12

PULSE OR FOOD SERVICE STEAM MODE

This mode can be used to provide steam on a periodic basis throughout operation. When this mode is

enabled, the STEAM TIMER controls how many seconds of steam are provided to the oven, while a value

entered in the Parameter 14 (Steam timer mode) setup controls how frequently the steam is operated.

To enable the Pulse Steam mode:

1. Enter the parameter set up mode by pressing and holding the START button and POWER ON OFF

button.

2. Select Parameter 14 (Steam timer mode).

3. If the TIMER window displays ‘0’, it is set up for Burst Steam or Bakery Mode (factory default). Press

the UP or DOWN arrow buttons to enter FSS mode (display will change to a 3-digit number).

4. Set the desired time between steam cycles using the UP or DOWN arrow buttons. The range is from

300 seconds (5 min.) to 990 seconds (approximately 17 min.), and increments by 10 seconds at a

time.

5. After setting the desired cycle, press the POWER ON OFF button to save the settings.

6. The STEAM TIMER will now operate in 1-second increments, up to 10 seconds, to set the duration

of steaming.

Examples: ‘300’ is selected for P14 (Steam timer mode)

‘3’ is entered in STEAM TIMER

= steam is turned on for 3 seconds every 300 seconds (5 min.)

‘990’ is selected for P14

‘3’ is entered in STEAM TIMER

= steam is turned on for 3 seconds every 990 seconds (17 min.)

To return the oven to Burst Steam Mode, repeat the above process to access P14 and set the value in

the TIMER window to ‘0’. The STEAM TIMER will now operate in 5-second increments.

KOSHER OPERATION MODE (OVENS EQUIPPED WITH KOSHER PACKAGE)

NOTE: The oven will be put into Kosher operation mode by authorized personnel at the time

of start-up.

NOTE: Setting up the parameters and adding programs to the controller should be done before the initial

start-up since the oven controller has to be shut off to do this.

For Kosher operations, the oven must maintain a minimum temperature in order to retain Kosher approval.

The oven control will make the minimum set temperature 200°F in order to maintain minimum temperature

requirements. The oven controller can not be set below 200° F.

If the oven temperature is at risk of falling below the approved range, a rapid beep alarm will sound (faster

than the normal TIMER alarm). If you hear this alarm, do the following:

• Check that the oven door is closed.

• If the Vent mode is active, turn the Vent off.

If the oven temperature falls below 150°F, the control will lock out. The display will read ‘LOC OUT’ and

the unit will not operate. Authorized personnel must be contacted to restart the oven.

If the control is inadvertently turned OFF while in kosher mode, when powered ON, the control will re-start

in kosher mode as long as the temperature has not dropped below the minimum requirements.

– 12 –

Page 13

PROGRAMMING THE OVEN

Single Step Recipes

The recipe menu stores up to 99 recipes that can be recalled by number when needed. A recipe is a set

of baking instructions (temperature, time & steam time, vent and fan delay settings) that the operator

denes for any baking operation.

1. With the oven in the OFF mode, press and hold the UP arrow in the STEP section. While pressing

and holding the UP arrow, press and hold the POWER ON OFF button for 3 seconds. When all the

displays light, the oven is in the recipe mode.

2. Press the RECIPE UP or DOWN arrows until the recipe number that is desired is displayed.

3. Press the TEMP UP or DOWN arrows to enter the desired temperature.

4. Set the Time, Steam, Fan Delay, and Vent settings:

• Press the UP or DOWN arrows next to TIMER to enter the desired time.

• Press the UP or DOWN arrows next to STEAM TIMER to enter the desired time.

• Press the UP arrow next to FAN DELAY to enter the desired time.

NOTE: Steam and fan delay settings are optional and can be left at 0 if desired.

• Press the VENT button to vent the cavity for the entire time of the step. When step is complete,

vent will close.

5. To store the recipe, press the RECIPE UP or DOWN arrows to move to the next recipe number or

press the POWER ON OFF button to exit the recipe mode. To store additional recipe settings, repeat

steps 2 to 4.

– 13 –

Page 14

Multi-Step Recipes

Additional steps can be entered within the original recipe number. Up to four individual steps can be added

by the operator, each with different bake settings.

For example, Recipe 1 has temperature, time, steam, and fan delay time settings set by the operator. This

is known as Step 1. After the timer times out in Step 1, the oven automatically starts the programmed bake

settings in Step 2. The system continues with each step until all steps have been timed out.

1. With the oven in the OFF mode, press and hold the UP arrow in the STEPS section. While pressing

and holding the UP arrow, press the POWER ON OFF button for 3 seconds. When all the displays

light, the oven is in the recipe mode.

2. Press the RECIPE UP or DOWN arrows until the recipe number that is desired is displayed. The

Step 1 light is lit.

3. Press the TEMP UP or DOWN arrows to enter the desired temperature.

4. Set the Time, Steam, Fan Delay, and Vent settings:

• Press the UP or DOWN arrows next to TIMER to enter the desired time.

• Press the UP or DOWN arrows next to STEAM TIMER to enter the desired time.

• Press the UP arrow next to FAN DELAY to enter the desired time.

NOTE: The steam and fan delay settings are optional and can be left at 0 if desired.

• Press the VENT button to vent the cavity for the entire time of the step. When step is complete,

vent will close.

5. Press the UP arrow in the STEPS section to advance to the next step within the recipe. The selected

step light is lit. Repeat steps 3 and 4 above to set each step, if needed, in the program.

6. To store all the steps in the program, press the RECIPE UP or DOWN arrows to move to the next

recipe number, or press the POWER ON OFF button to exit the recipe mode.

– 14 –

Page 15

Editing the Recipes

1. With the oven in the OFF mode, press and hold the UP arrow in the STEPS section. While pressing

and holding the UP arrow, press the POWER ON button for 3 seconds. When all the displays light,

the oven is in the recipe mode.

2. Press the RECIPE UP or DOWN arrows until the recipe number that is desired is displayed.

3. Enter the new Time, Steam, and Fan Delay settings:

• Press the UP or DOWN arrows next to TIMER to enter the desired time.

• Press the UP or DOWN arrows next to STEAM TIMER to enter the desired time.

• Press the UP arrow next to FAN DELAY to enter the desired time.

NOTE: The steam and fan delay settings are optional and can be left at 0 if desired.

4. To change the settings in a Step, press the UP arrow in the STEPS section and make changes in

each step accordingly.

5. To store the recipe, press the RECIPE UP or DOWN arrows to move to the next recipe number or

press the POWER ON OFF button to exit the recipe mode.

– 15 –

Page 16

Using the Recipes

1. With the oven on, press the RECIPE UP or DOWN arrows to select the desired recipe number (1-

99). The TEMP, TIMER, STEAM, and FAN DELAY settings are displayed.

2. Conrm that the oven is at the set temperature.

3. Slowly open the doors.

4. Roll the rack into the oven so the end brackets channel onto the rack lifting carrier. (See Loading

Procedure.)

5. Press START, and then close and latch the door.

6. A beeper will sound after the TIMER times out. Press STOP to silence the beeper.

Recipe Hints

• The oven defaults to the Recipe 0 settings when rst turned on. Recipe 0 settings are as follows:

Temp = 375°F, Timer = 0, Steam Timer = 0, Delay Timer = 0, Recipe = 0.

• Any combination of bake settings can be manually entered for one-time custom baking operations.

These settings are not saved to the recipe memory.

• If any of the parameters are changed in a recipe before or during a bake cycle, the oven reverts to

a manual program (Recipe 0). If P20 (Restricted Mode) is set for 1 the settings can not be changed

during a bake cycle.

• The RECIPE UP and DOWN arrows have no effect while the bake cycle is in progress. However,

if the TIMER has been stopped, either by pressing the STOP button or by opening the door, then

pressing the RECIPE UP and DOWN arrows will select a new recipe and cancel the baking cycle

that was in progress.

• When selecting recipes, the system will skip over unprogrammed numbers. For example, if Recipe

1 is displayed in the RECIPE window and no recipes are stored in 2, 3, and 4, then the system will

skip over 2, 3, and 4. Recipe 5 will be the next recipe displayed.

– 16 –

Page 17

CUSTOMIZED OPERATION

The OV500 oven controls have the capability of being customized to t your own personal needs using

the setup mode.

Before entering the setup mode, read all the instructions to make sure you are completely clear on what

to do. If you need assistance, please call your authorized Baxter service ofce.

Entering Setup Mode

With the oven in the OFF mode, press and hold the START button. While pressing and holding the Start

button, press the POWER ON OFF button for 3 seconds. The oven is now in Setup mode and P1 is

displayed in the SET TEMP window.

Changing Items in Setup Mode

The number in the SET TEMP window is the setup number. The TIMER window displays the setup item

(the settings that can be changed).

1. To change the setup number, press the SET TEMP UP or DOWN arrows. The setup item will be

displayed in the TIMER window.

2. To make a change in the setup item being displayed, press the TIMER UP or DOWN arrows. To

adjust the setting, see Setup Guide. Do not attempt to change item numbers P4, P5, P6, and P8.

Consult your authorized Baxter service ofce for help with these features.

3. To exit the setup mode, press the POWER ON OFF button.

– 17 –

Page 18

Setup Guide

SETUP

NUMBER

P1 Maximum

P2 Preheat

P3 Minimum

P4 Temperature

P5 Heat OFF Offset This value adjusts the temperature difference between the set point and

P6 Heat Difference

P7 Maximum Steam

P8 Temperature

P9 Timer Mode The TIMER can be set up to display minutes set/minutes remaining or hours

P10 Vent Evacuate

P11 Vent Open

P12 End of Bake

P13 End of Bake

SETUP ITEM DISPLAY

This is the maximum temperature at which the oven can be set. Range is 50°F

Temperature

Setpoint

Temperature

Temperature

Setpoint

Offset

Hysteresis

Time

Units

Time

Percentage

Automatic

Vent - Enable

Automatic

Vent Time

to 525°F (10°C to 275°C).

This is the default temperature setpoint when the oven is rst turned on

(Program 0). The preheat temperature cannot be set higher than the value in

P1 or lower than the value in P3.

Range is 10°F to 525°F (10°C to 275°C).

This is the minimum temperature at which the oven can be set. Range is 10°F

to 200°F (10°C to 200°C).

This value permits an offset of correction between the oven temperature

display and the real baking chamber temperature. Call your authorized service

agency for help with this feature.

stopping of the heating system. Call your authorized service agency for help

with this feature.

This value adjusts the temperature difference between the on temperature and

off temperature of the heating system. Call your authorized service agency for

help with this feature.

Time set is the maximum time (in seconds) that water is supplied during the

STEAM TIMER operation.

The oven can be set to display temperature in Fahrenheit or Celsius. To ensure

accurate temperature parameters, call your authorized Bakery Systems service

agency for help with this feature.

and minutes. Select 0 for minutes set/minutes remaining or 1 for hours and

minutes. (If this parameter is changed to hours and minutes, a label has been

provided to place on the control panel to indicate the change.)

Time set is the time (in seconds) that the vent is 100% open at the beginning of

the venting cycle. Range is 0 to 180 seconds.

This value is the percentage the bake chamber vent is open after the vent

evacuate time has expired. Range is 5 to 100%.

This feature enables the Automatic Vent Cycle. Select 0 to disable or 1 to

enable this feature (see P13 for entering time).

This is the number of minutes before the end of the bake cycle that the vent is

open.

– 18 –

Page 19

SETUP

NUMBER

P14 Steam Timer

P15 Interior Light

P16 Clock Operation This selects either 12 hours (AM/PM) or 24 hours real time display. Press the

P17 Temperature

P18 Setback

P19 Lights Mode Select 1 for lights on continuously (when oven is on) or select 0 for automatic

P20 Restricted

P21 Advanced

P22 OV210

P23 Unused

P24 Unused

P25 Communication

SETUP ITEM DISPLAY

The steam timer can be set up to display in seconds or operate in food service

Mode

Brightness

Setback Time

Temperature

Operator Mode

Energy Savings

Mode

Operation Mode

Mode

mode. Select 0 for seconds or 300 to 990 for food service mode.

This value is the brightness of the interior lights. The higher the number, the

brighter the lights. Range is 50 to 100.

Bake Time Up button to switch between the two types of display.

This selects the elapsed time from the last timed bake to when the oven will

lower the oven set temperature to the value set in P18. Range is 10 to 180

minutes.

This selects the oven set temperature that the oven will change to when the

temperature setback time has been exceeded in P17. Range is 50°F to 300°F

(50°C to 300°C).

operation. Lights will turn off automatically after 30 minutes of no user activity

(door opened or closed, no buttons pushed).

Select 1 for Restricted Operator Mode. When a recipe is selected by the

operator, the Bake Timer Minutes Set window will display the total bake time

of all steps in the recipe. Standard operation only displays the minutes in

the selected step. When a recipe is selected and the start button is pressed

the operator cannot make changes to the bake time remaining or the oven

set temp. If set for steam, steam is produced in 5-seconds on, 5-seconds off

intervals for the time set in P7. The maximum solenoid on time range that can

be set in P7 increases to 60 seconds. Change P7 to 60 when P20 is set for 1.

When P20 is changed from 1 = restricted operator mode to 0 = standard mode,

P7 must be changed below 30 (range 0 to 30 max) or solenoid will energize

continuously for up to 60 seconds.

Select 1 for Advanced Energy Saving. Forcing the oven into an advanced

Auto On - Auto Off mode to conserve energy. Several steps are necessary to

enable this mode. Set the Auto On time to allow the oven to preheat before

the rst bake time. Set the Auto Off time. Press the Auto On/Auto Off button to

illuminate the Timer On/Off indicator. Set P17 & P18 to customer settings. Auto

ON/OFF time is restricted when this feature is set to 1. Auto ON/OFF times

can only be changed while in P21.

Select 1 for installation of an HBA control panel and control door on an OV210.

When enabled, the OV210 will emulate all the functions of an HBA.

Select 1 for NAFEM protocol compliant communication.

– 19 –

Page 20

ENERGY SAVING MODE

Set back

Set back mode provides the ability to dial down the set temperature of the oven automatically when it is

not being used, but needs to be in a standby mode for baking. When the oven is switched to set back

temperature, the heating system remains in standby mode until it reaches that temperature. This leads to

a reduction in the amount of energy used.

Parameter 17 (Temperature Setback Time) allows the user to set the desired time for the oven to sit idle

before dropping the temperature to the value entered in Parameter 18 (Setback Temperature). Adjust

P18 to the desired setback temperature. A setting of 250°F is recommended to keep the steam system

above the water ash point.

Advanced

Advanced energy savings (Parameter 21) mode allows the user to use the features of “Setback” as well

as locking the time that the oven can be turned on or off. This will prevent the oven from being turned on

to early or left on overnight. Follow the instructions for P21 (Advance energy savings mode) to set the

oven for advanced energy savings mode.

The oven will automatically shut down at the pre-determined time, unless there is a bake in process.

If you need to operate the oven after the pre-determined shutoff time, turn the oven back on by pressing

the ON/OFF button and immediately set the Bake Timer to at least 30 minutes and press start. If the bake

timer has not been set to at least 30 minutes the oven will shut down.

NOTE: If you do not use the oven within 30 minutes, after timer counts down to 00:00, the oven will shut

down.

SHUTDOWN

NOTE: Before restarting a gas oven, the power switch and the gas burner valve must be off for a minimum

of 5 minutes.

1. Remove all remaining product.

NOTE: Vent can be used to evacuate steam from oven.

2. Allow the oven to cool, then press the POWER ON/OFF button. If desired, quicker cool down time

can be accomplished through the use of the COOL DOWN button.

3. Clean the baking chamber. See Cleaning page 22.

4. For lengthy shutdowns, disconnect the main power and shut off the gas and water supply.

RESTARTING OVEN

NOTE: Before restarting a gas oven, power switch and gas burner valve must be off for a minimum of

5 minutes.

1. Press the POWER ON OFF button to turn the oven on.

2. Press the UP or DOWN arrows next to the SET TEMP window to enter the desired temperature.

– 20 –

Page 21

TROUBLESHOOTING

BURNERS WILL NOT LIGHT ON GAS OVEN

1. Check that the loading door is shut and the door switch is actuated.

2. Press the OFF button to turn the oven off and wait 5 minutes.

3. Make sure the gas shutoff valve and gas valve are in the ON position.

4. Press the ON button to turn the oven back on.

If the above suggestions do not remedy the problem, contact a Bakery Systems service ofce.

ALARMS AND DISPLAY MESSAGES

Alarm or Message Cause Action

Temperature display changes

between a number and ‘COOL’.

Display is ashing with no

beeping, while oven is in a timed

bake cycle and is calling for heat.

Display shows ‘SHdn’. Safety Alarm has

Control beeps continuously. Rack Rotation

Controls beeps rapidly (faster

beep than Baker Timer).

Display shows ‘LOC OUT’. Oven in Kosher

Cool Down mode

is active.

Temperature

recovery alert.

disabled oven.

alert.

Temperature alert

for Kosher Mode.

Lock-Out Mode.

To return to normal mode, close oven door or press any

button.

Open oven door and close to reset heat control. If

unit does not begin heating, contact your local Bakery

service ofce.

TURN OFF ALL POWER AND GAS TO THE OVEN.

Contact your local Bakery service ofce.

Check that rack is rotating; check for pans that may be

protruding from rack. If problem persists contact your

local Bakery service ofce.

Turn VENT off, if activated. Gas ovens: check that

burner is ring. If not ring, briey open door and close

to reset temperature control.

Contact your local Bakery service ofce.

OTHER TROUBLESHOOTING TOPICS

Condition Cause Action

Oven circulation fan is running but

oven is turned off.

STEAM TIME cannot be set above

10 seconds, and time increments

by 1-second.

Rack does not lift and rotate. Bake time has not been entered

Oven is in Cooling mode. Close oven door to cancel cooling

Oven is in Food Service or Pulse

steam mode.

in timer and/or timer has not been

started.

– 21 –

mode. If door was not open, contact

your local Bakery service ofce.

See Food Service Mode

instructions to return oven to

Bakery mode.

Enter time in TIMER and press

START. If problem persists, contact

your local Bakery service ofce.

Page 22

CLEANING

Disconnect the electrical power to the machine and follow lockout / tagout procedures.

There may be multiple circuits. Be sure all circuits are disconnected.

The rack oven and its parts are hot. Use care when operating, servicing or cleaning

the rack oven.

Hot air and steam are released from the oven interior when the loading door is

opened. To avoid burns, open the door slowly and keep clear of the opening.

• Allow the oven to cool.

• Clean the outside of the oven daily with a clean, damp cloth.

• Remove rack(s) and clean as you would any cooking utensil. Use warm, soapy water and a brush.

Rinse with clear water and dry with a clean cloth.

• Use care when cleaning around sensitive interior parts such as probes, sensors or the rotating

mechanism.

• Using a clean cloth and warm, soapy water, wash the stainless steel interior of the oven. Rinse

with clear water and dry with a clean cloth.

• Gently scrape heavy buildup off door glass. Residue can be removed with a glass cleaner when

oven is cool.

• Clean hood lters (if equipped) with soap and warm water.

• Do not use oven cleaners or steel wool on stainless steel surfaces. Never spray down the oven

with water or steam.

• Never use cleaners that contain chlorine. Chlorine corrodes stainless steel.

– 22 –

Page 23

MAINTENANCE

The rack oven and its parts are hot. Use care when operating, servicing or cleaning

the rack oven.

Hot air and steam are released from the oven interior when the loading door is

opened. To avoid burns, open the door slowly and keep clear of the opening.

Disconnect the electrical power to the machine and follow lockout / tagout procedures.

There may be multiple circuits. Be sure all circuits are disconnected.

On gas ovens, annually check the ue to be sure it is free of obstructions.

GENERAL

As Needed

• Inspect the area around the oven. The area must be free and clear from combustibles. There must

be no obstructions to the air ow.

Daily

• Clean Exterior (See Cleaning).

Weekly

• Clean the oven interior and remove loose debris (See Cleaning).

• Clean the windows.

• Empty grease catcher (if equipped).

Monthly

• Clean exhaust hood lters (if equipped) with soap and water.

Bi-Monthly

• Owner Preventive Maintenance Procedure.

PREVENTIVE MAINTENANCE

The OV500 Rack Oven must be kept on a regular preventive maintenance schedule. Ovens require

specic preventive maintenance based on usage and environmental factors. The failure to have the oven

properly maintained by following recommended preventive maintenance procedures may result in higher

repair costs, shortened equipment life, or unsafe operating conditions.

It is the owner’s responsibility to make sure preventative maintenance is performed on the rack oven.

This will ensure continued safe and reliable operation. Contact an authorized Bakery Service agency to

provide this skilled service for you.

SERVICE AND PARTS INFORMATION

Contact your authorized Bakery Systems service ofce.

– 23 –

Page 24

OWNER PREVENTIVE MAINTENANCE PROCEDURE

INTRODUCTION

This customer preventive maintenance (PM) section includes procedures to inspect for proper operation

and cleaning of components. Owner Preventive Maintenance Procedures are written for gas ovens. They

can also be used for electric ovens by omitting the steps that refer to components found only on gas ovens.

To maintain the safety and performance of bakery ovens a program of scheduled periodic maintenance

must be implemented. It is the sole responsibility of the user to establish, schedule, and enforce such a

program. Although the service interval will vary depending on the environment in which the equipment

is operating it is recommended that Preventive Maintenance be performed and all safety devices are

checked at a minimum of 12 month intervals. Check with the authority having local jurisdiction if there are

specic maintenance requirements specied by local, state, or national codes. A convenient PM Checklist

is provided at the end of this section.

NOTE: This PM procedure does not discuss repair or replacement of components. Upon completion of

the PM procedure you will need to contact a qualied servicer for any needed repairs.

Tools Used For Inspection Procedure

• Standard set of hand tools

• Vacuum cleaner - shop vac

PREVENTIVE MAINTENANCE PROCEDURE

Disconnect the electrical power to the machine and follow lockout / tagout procedures.

There may be multiple circuits. Be sure all circuits are disconnected.

Shut off the gas before servicing the unit.

Certain procedures in this section may require electrical test or measurements while

power is applied to the machine. Exercise extreme caution at all times. If test points are not easily

accessible, disconnect power and follow lockout / tagout procedures, attach test equipment and

reapply power to test.

Inspect Oven Lamps

1. Lamps should be on when oven is powered.

2. If not, replace lamps (Fig. 1).

A. Remove lens cover by turning out of lamp

housing.

B. Remove oven lamp by turning lamp out of

lamp socket.

3. Reverse the procedure to install new lamps.

– 24 –

Fig. 1

Page 25

Clean and Vacuum Components and Control/Burner Compartment Area (Gas Only)

1. Clean the control/burner compartment (Fig. 2) area of dust and/or lint accumulation.

2. Vacuum the control/burner compartment oor of dust and/or lint accumulation.

3. Gain access to the top of oven and clean dust that may have accumulated on top of circulation blower

motor (Fig. 3) and motor cooling fan.

Fig. 2 Fig. 3

Rack Lift and Rotation Assemblies

1. Check rack lift assembly for proper operation.

A. Open door. Rack lift should lower to correct height of rack and be in forward loading position

to accept rack entry.

B. The oven rack should be easily rolled in and out of oven and the wheels completely off the

oven oor when raised.

2. Tighten all set screws (4) in carrier (Fig. 4).

A. Check and tighten all set screws on carrier.

Fig. 4

– 25 –

Page 26

Inspect Door Components

1. Check loading door latch.

A. Check door gasket for good condition. If

door gasket needs replacement, contact

your local Bakery Systems ofce for service.

B. Check that the loading door lock ramps are

clean (Fig. 5) and rollers on the door move

up and down and spin freely (Fig. 6).

C. Adjust latch ramps in or out by loosening

the two screws. DO NOT REMOVE THEM.

Slide ramp in or out to loosen or tighten

door (Fig. 5).

D. Tighten screws.

2. Check door sweep.

A. The door sweep should hit the oor evenly

across door width, when door is in the closed

position.

B. Turn oven on.

Fig. 5

C. If air (or steam) blows out from underneath

the door, door will need to be adjusted. If door

sweep needs replacement or adjustment,

contact your local Bakery Systems ofce for service.

3. Check interior door release (Fig. 7) for proper operation.

4. Check door switch for proper operation.

A. When door switch actuator rod is in the open position

(door open), the door switch rollers should be

positioned on the small part of the rod (Fig. 8).

Fig. 6

Fig. 7

– 26 –

Fig. 9Fig. 8

Page 27

5. Check door handle operation.

A. Pull out on door handle (Fig. 10) to open door, then push door shut (Fig. 11). If the door is too

hard to open or close, see door ramps adjustment (Fig. 5).

Fig. 10 Fig. 11 Fig. 12

6. Clean door glass.

A. With the loading door shut, pull door handle lock pin out

(Fig. 12).

B. Pull door handle out (Fig. 13).

C. Swing handle open (Fig. 14).

NOTE: Make sure not to dent door on hinged side.

D. Check that there is no residue buildup on the handle lock

Fig. 13

mechanism (Fig. 14).

NOTE: The handle for the glass is located at the top or bottom of glass.

E. Pull out on handle (Fig. 14) to open glass door. If glass door needs to be adjusted, contact your

local Bakery Systems ofce for service.

Failure to contact service for glass door adjustment may result in the glass breaking.

Fig. 14

– 27 –

Page 28

F. To close the glass door simply push shut.

G. To close handle, the lock mechanism needs to

be in the unlock orientation (Fig. 15).

NOTE: If lock is not in the unlock orientation, pull lock

pin out and rotate lock to the unlock orientation.

H. Place lock box over hex bolt and slowly push

handle in to door (Fig. 15). Check to see if

the handle latch engaged by opening door

(Fig. 10). Repeat if necessary.

Inspect Air Louvers

1. Check air louvers (shutters) (Fig. 16) inside oven and

tighten any loose screws.

2. Check oven interior, tighten or replace loose or missing

panel screws. Also check oor anchors.

Inspect Cavity Vent

1. Check cavity vent for proper operation.

A. Push VENT (Fig. 17) button on control panel to

open vent and then push again to close vent.

B. Visually check that vent opens (Fig. 18) and

closes (Fig. 19) when button is pressed.

C. Check that vent gasket is intact.

Fig. 15

Fig. 16

Fig. 17

Fig. 18 Fig. 19

Visually Inspect Electrical Connections

1. Inspect all wiring connections for discoloration. If discoloration is visible, contact your local Bakery

Systems service ofce.

– 28 –

Page 29

Verify Ignition Module Safety Lockout Functions

(Gas Only)

1. Verify ignition module safety lockout functions.

A. Turn off main gas supply to the oven.

B. Open control panel door to gain access to

burner compartment area.

C. Turn the oven on. Check that electrical

breakers are turned on.

D. Set the oven to call for heat and make sure

convection fan is running.

E. Observe LED light through hole in control

box cover (Fig. 20). After trying to light

the burner three times, the module should

lockout. (See chart below.)

F. Turn off the oven control for a minimum of

ve seconds and then turn the oven control

back on.

G. Turn main gas supply to the oven back on.

H. Set the oven to call for heat, making sure

convection fan is running and the burner has

established a ame.

I. Turn off main gas supply to the oven.

J. Observe LED light through hole in control box cover (Fig. 20). The ignition module should go

into lockout after three trials for ignition. (See chart below.)

LED DIAGNOSTIC INDICATOR CODES

LED LED

LED off No Fault

LED Illuminated Module Fault

‘1’ Flash Air Flow Fault

‘2’ Flash Flame Fault No Call for Heat

‘3’ Flash Ignition Module Lockout

K. If the proper results have been obtained,

proceed to step 2 , if not contact your local

Bakery Systems service ofce.

2. Verify hood exhaust air pressure switch (Fig. 21)

operation.

Fig. 20

Fig. 21

A. Turn on main gas supply and set oven control to call for heat and make sure convection fan is

running.

B. Once ame is established, disconnect tubing from hood pressure switch hose. Burner ame

should go out.

C. Reconnect tubing. Burner should establish a ame. If not, contact your local Bakery Systems

service ofce.

– 29 –

Page 30

3. Verify draft inducer pressure switch (Fig. 22)

operation.

A. Set oven control to call for heat and make

sure convection fan is running.

B. Once ame is established, disconnect tubing

from draft inducer pressure switch. Burner

ame should go out.

C. Reconnect tubing. Burner should establish

a ame. If not, contact your local Bakery

Systems service ofce.

Verify Operation of Steam

1. Check steam system for proper operation.

A. Turn the water supply on.

B. Turn oven on and set to normal bake

temperature.

C. Allow oven to preheat for 30 minutes.

D. Set control to call for steam.

E. Observe operation. If steam is not observed, contact your local Bakery Systems service ofce.

Fig. 22

After completion of the owner PM procedure, you will need to contact a qualied servicer for any

needed repairs.

Keep a copy of the Owner Preventive Maintenance Checklist for your records.

– 30 –

Page 31

DEDEENSAYPOC

SREBMUNLAIRES/LEDOM

RENWODEDNEMMOCER

TSILKCEHCECNANETNIAMEVITNEVERP

SAG-SNEVOKCARYREKAB

=

√=

:ycneuqerFMPylhtnom-iB

YRASSECENSAECIVRESROFLLAC

.NAELCRONOITAREPOREPORPROFKCEHC

spmalnevotcepsnI

saerarenrubdnastnenopmocmuucavdnanaelC

seilbmessanoitatordnatfilkcartcepsnI

stnenopmocroodtcepsnI

srevuolriatcepsnI

tnevytivactcepsnI

snoitcennoclacirtceletcepsniyllausiV

snoitcnuftuokcolytefaseludomnoitingiyfireV

maetsfonoitarepoyfireV

DETELPMOCSSECORP

enaporPsaGlarutaNsaGfoepyT

.oNerotS:noitacoL

:detelpmoCetaD:rotcepsnI

:sriapeRyrasseceNrofdeifitoNecivreS

)etaD(

:stnemmoC

)erutangiSrotcepsnI(

– 31 –

Page 32

NOTES

FORM 36715 Rev. B (February 2016) PRINTED IN U.S.A.

– 32 –

Loading...

Loading...