Page 1

SERVICE MANUAL

INSTALLATION INSTRUCTIONS

OV500-EE SERIES GAS RACK

OVENS AND OV500 SERIES

ELECTRIC RACK OVENS

OV500G1-EE ML-132518

OV500G2-EE ML-132525 (BEFORE MARCH 2015)

OV500E1 ML-132522

OV500E2 ML-132524 (BEFORE APRIL 2015)

OV500G2EE ML-132529 (AFTER FEB 2015)

OV500E2 ML-132531 (AFTER MARCH 2015)

- NOTICE -

This Manual is prepared for the use of trained Baxter Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Baxter Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Baxter Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Baxter, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

A product of Baxter MFG. Co., Inc 19220 State Route 162 East Orting, WA 98360

F45469 Rev. D (1019)

Page 2

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS

TABLE OF CONTENTS

SERVICE UPDATES ....................................................................................... 3

SERVICE UPDATES - OV500EE SERIES ............................................................... 3

IMPORTANT FOR YOUR SAFETY ......................................................................... 4

IMPORTANT FOR YOUR SAFETY ..................................................................... 4

GENERAL .................................................................................................. 6

INTRODUCTION ....................................................................................... 6

GENERAL .......................................................................................... 6

HEATING .......................................................................................... 6

STEAMING SYSTEM ............................................................................... 6

UNPACKING ........................................................................................... 6

LOCATION ............................................................................................. 6

CLEARANCE DIMENSIONS ............................................................................ 6

TESTING THE GAS SUPPLY PIPING SYSTEM ......................................................... 6

INSTALLATION CODES AND STANDARDS ............................................................ 7

SPECIAL TOOLS ....................................................................................... 7

OV500G1-EE GAS OVEN SPECIFICATIONS ........................................................... 7

OV500G2-EE GAS OVEN SPECIFICATIONS .......................................................... 10

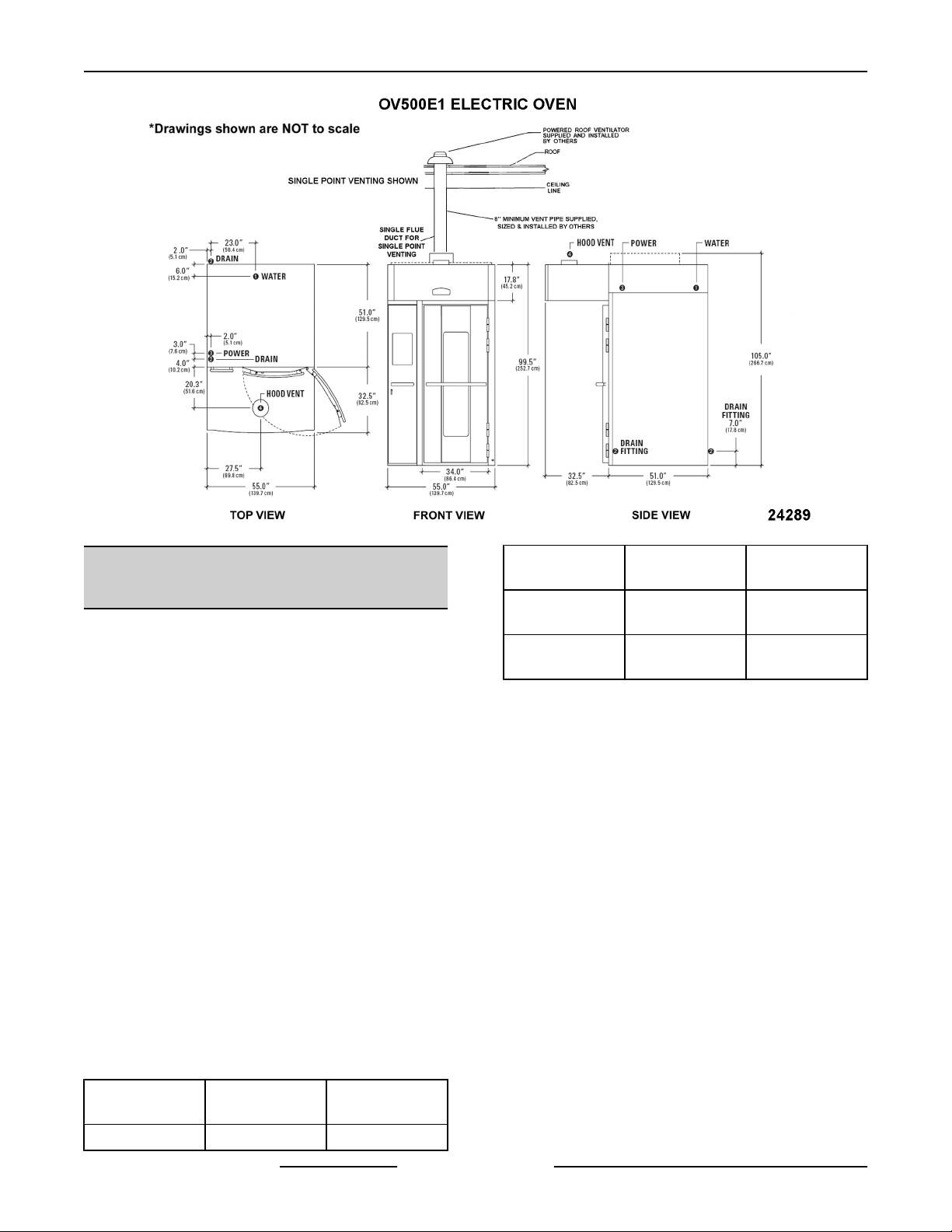

OV500E1 ELECTRIC OVEN SPECIFICATIONS ........................................................ 12

OV500E2 ELECTRIC OVEN SPECIFICATIONS ........................................................ 14

INSTALLING OVEN ....................................................................................... 17

OVEN SECTIONS ..................................................................................... 17

FLOOR / THRESHOLD ................................................................................ 27

STEAM SYSTEM ...................................................................................... 29

DOOR HANDLE ....................................................................................... 32

DOOR ASSEMBLY .................................................................................... 32

DOOR SWITCH ACTUATOR .......................................................................... 35

DOOR SWEEP ........................................................................................ 35

RACK CARRIER - A & C STYLE RACK LIFT ........................................................... 35

RACK CARRIER - B STYLE RACK LIFT ............................................................... 38

HOOD ASSEMBLY .................................................................................... 39

HOOD VENTING ...................................................................................... 42

AIR BAFFLE & GREASE FILTERS .................................................................... 43

CAULK OVEN ......................................................................................... 44

INITIAL START-UP .................................................................................... 44

INITIAL START-UP INFORMATION MATERIAL ........................................................ 48

FINAL CHECKS ....................................................................................... 49

© BAXTER 2017

F45469 Rev. D (1019) Page 2 of 49

Page 3

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - SERVICE UPDATES

SERVICE UPDATES

SERVICE UPDATES - OV500EE SERIES

February, 2017

1. Update ML information on front cover.

Updated Anchor Point in

2.

3. Updated OVEN SECTIONS.

4. Updated FLOOR / THRESHOLD.

5. Updated STEAM SYSTEM.

6. Updated DOOR HANDLE.

7. Updated DOOR ASSEMBLY.

8. Updated HOOD ASSEMBLY.

9. Updated AIR BAFFLE & GREASE FILTERS.

IMPORTANT FOR YOUR SAFETY.

Page 3 of 49 F45469 Rev. D (1019)

Page 4

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - IMPORTANT FOR YOUR SAFETY

IMPORTANT FOR YOUR SAFETY

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS EQUIPMENT, WHO

SHOULD PERFORM THE INITIAL FIELD START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED

BY THIS MANUAL

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE SMELL OF

GAS IS DETECTED. THIS INFORMATION CAN BE OBATINED FROM THE LOCAL GAS SUPPLIER

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO OPERATE THIS DEVICE.

KEEP AREA AROUND OVEN CLEAR OF COMBUSTIBLES.

DO NOT OBSTRUCT COMBUSTION AND VENTILATION OPENING ON THE OVEN.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS AT MAIN SHUTOFF VALVE AND CONTACT

THE LOCAL GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THROUGHLY BEFORE INSTALLING OR SERVICEING THIS EQUIPMENT.

F45469 Rev. D (1019) Page 4 of 49

Page 5

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - IMPORTANT FOR YOUR SAFETY

FOR YOUR SAFETY

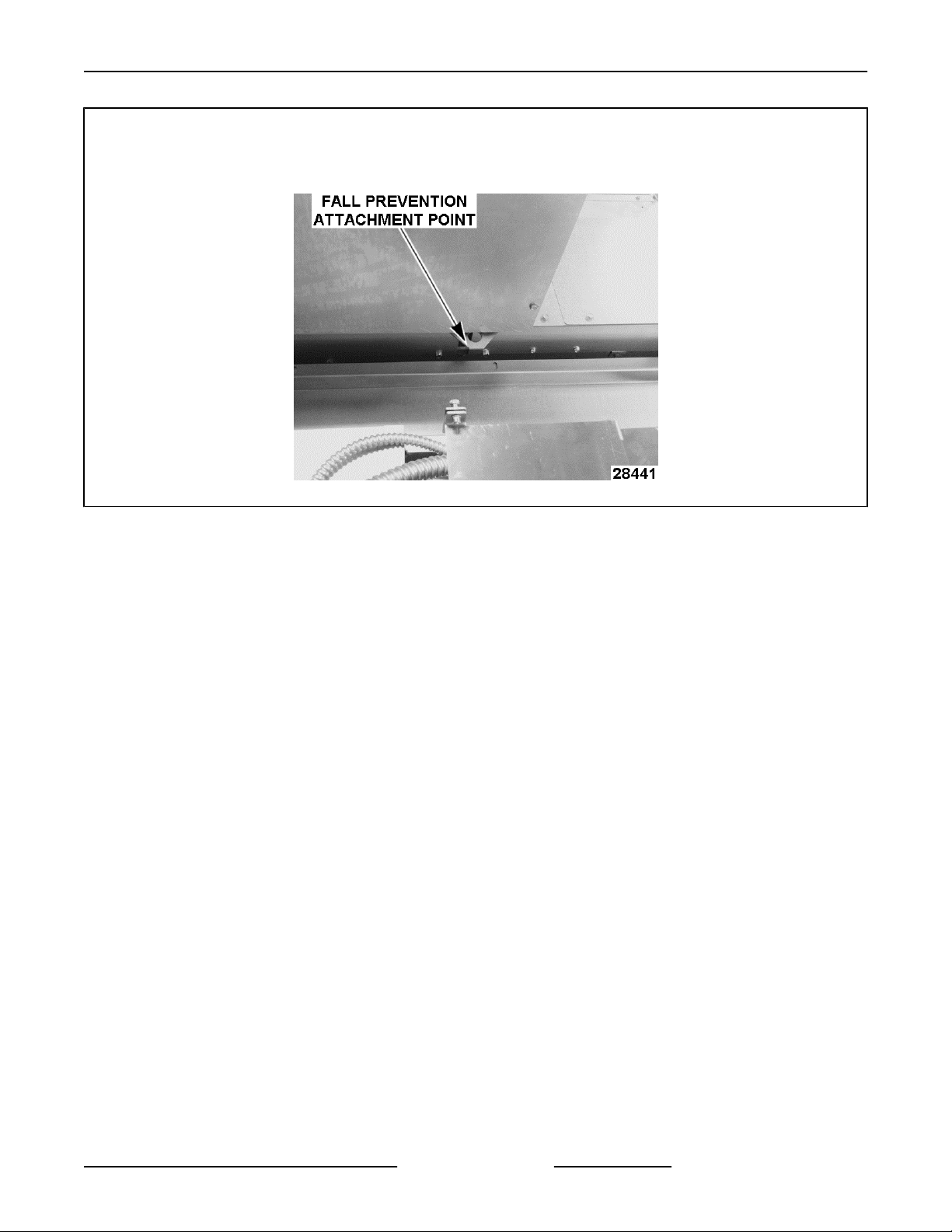

AN ATTACHMENT POINT FOR FALL PREVENTION IS LOCATED ON TOP, IN THE CENTER OF THE OVEN.

WHEN WORKING ON TOP OF OVEN, BE SURE TO SECURELY ATTACH SAFETY HARNESS TO FALL

PREVENTION ATTACHMENT POINT.

Fig. 1

Page 5 of 49 F45469 Rev. D (1019)

Page 6

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - GENERAL

GENERAL

INTRODUCTION

General

OV500G1-EE

rack and OV500G2-EE & OV500E2 rack ovens hold

two single racks or one double rack.

Oven features:

• Powered rack lift with high temperature bearings

and a clutch rotating system designed to stop the

rack in the event of a jam without damage to the

rotation motor or losing rack alignment.

• Digital programmable controller with optional

backup control, flush flooring, and field reversible

bake chamber door.

All of the information, illustrations and specifications

contained in this manual are based on the latest

product information available at the time of printing.

Heating

The rack oven reaches baking temperatures of 350°

in approximately 20 minutes; however, a 30 minute

preheat is recommended to fully heat the steam

generator.

Steaming System

Standard on all rack ovens, is a self-contained

spherical cast steam system providing excellent

steaming conditions.

& OV500E1 rack ovens hold one single

UNPACKING

Remove the crating from the oven exterior, check for

possible shipping damage. If the oven is found to be

damaged after unpacking, save the packaging

material and contact the carrier within 15 days of

delivery.

LOCATION

To reduce the risk of fire, the appliance is

to be installed on non-combustible surface only, with

no combustible material within 18 inches above the

appliance. The appliance is to be mounted on floors

of non-combustible construction with noncombustible

flooring and surface finish and with no combustible

material against the underside, or on non-combustible

slabs or arches having no combustible material

against the underside. Such construction shall in all

cases extend not less than 12 inches beyond the

equipment on all sides.

Oven not provided with a canopy hood, must be

installed under a ventilation hood.

The floor must be level with surrounding area with a

maximum slope of 1/8" per foot up to 3/4" maximum

in all directions. Floor anchors require a minimum 1"

thick solid floor substrate.

A level floor area must be prepared before assembling

oven. The floor area should be at least 104"D x 74"W

for double rack oven and 94"D x 57"W for single rack

oven, to accommodate the oven footprint and door

swing. Check the facilities floor area at the threshold

and door swing opening location to determine if

facilities floor will need to be reworked.

Do not obstruct the flow of combustion and ventilation

air. Keep the appliance area free and clear from

combustibles.

Make sure there is an adequate supply of make up air

in the room to allow for combustion.

The electrical diagram is located on the inside of the

heat exchanger compartment door.

NOTE: If the location has multiple ovens, keep the

serial numbered crates together.

Oven is UL/CSA Listed for zero clearance for back and

side

for plumbing rear drain connection.

Top of oven requires a minimum of 24" clearance for

servicing accessability.

TESTING THE GAS SUPPLY PIPING

When test pressures exceed 1/2 psig (14" W.C.)

(35.6cm W.C.) (3.5kPa), the oven and its individual

F45469 Rev. D (1019) Page 6 of 49

CLEARANCE DIMENSIONS

walls. A 1" to 4" back clearance is recommended

SYSTEM

Page 7

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - GENERAL

shutoff valve must be disconnected from the gas

supply piping system.

test pressures are 1/2 psig (14" W.C.) (35.6cm

When

W.C.) (3.5kPa) or less, the oven must be isolated from

the gas supply piping system by closing its individual

shutoff valve.

INSTALLATION CODES AND

STANDARDS

OV500 ovens must be installed in accordance with:

United States

State and local codes.

1.

2. National Fuel Gas Codes, ANSI Z223.1 (latest

edition), available from American Gas

Association, 1515 Wilson Boulevard, Arlington,

VA 22209.

3. ANSI/NFPA 96, Standard for Ventilation Control

& Fire Protection of Commercial Cooking

Operations (latest edition), available from

National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269.

4. National Electrical Code, ANSI/NFPA-70 (latest

edition).

5. NSF/ANSI 4 - 2007e Standard for Commercial

Cooking, Rethermalization and Powered Hot

Food Holding & Transport Equipment.

Canada

1. Local codes.

2. CAN/CGA-B149-1, Installation for Natural Gas

Burning Appliances and Equipment (latest

edition).

3. CAN/CGA-B149-2, Installation for Propane

Burning Appliances and Equipment (latest

edition).

4. Canadian Electrical Code, Part 2, CSA Standard

C22.1 (latest edition).

Plumbing Connections

1. Water and waste piping and connections shall

comply with the International Plumbing Code

2003, International Code Council (ICC), or to the

Uniform Plumbing Code 2003, International

Association of Plumbing and Mechanical

Officials (IAPMO).

NOTE: Plumbing connections must comply with

applicable sanitary, safety and plumbing codes and

provide adequate backflow protection to comply with

applicable federal, state and local codes.

SPECIAL TOOLS

• Inclined manometer - Dwyer Cat. #1227 or

equivalent.

Combustion analyzer meter Bacharach Fyrite

•

Pro 125 Bacharach model# 24-8105 or Fyrite

"Insight" model# 24-8251(Order from Bakery

Support).

• Rotary hammer / hammer drill to drill holes in floor

for anchor bolts.

• 3/8" masonry drill bit to drill holes in floor for

anchor bolts.

• Temperature tester (thermocouple type) with 10'

lead.

• Gauges for checking air shutters Part No. 011M5689-00001 (shipped with oven).

• Draft meter BACHARACH Model 13-3000 DCL

24490 or equivalent.

• Dolly wheel Part No. 01-1M2335-00001.

• Mini laser level self leveling with tripod Harbor

Freight No. 92703-OVGA.

• 2 ton foldable shop hoist Harbor Freight No.

35915-4VGA for lifting oven section.

• 3/8" chain 20 ft. long with a 4700 lbs. load rating

Harbor Freight No. 40461-7VGA used with hoist.

• Two 7/16" X 5-1/2" bolts used with hoist.

• Two 7/16" nuts used with hoist.

• Four 7/16" fender washers used with hoist.

• Loctite® #242 Part No. 00-520228

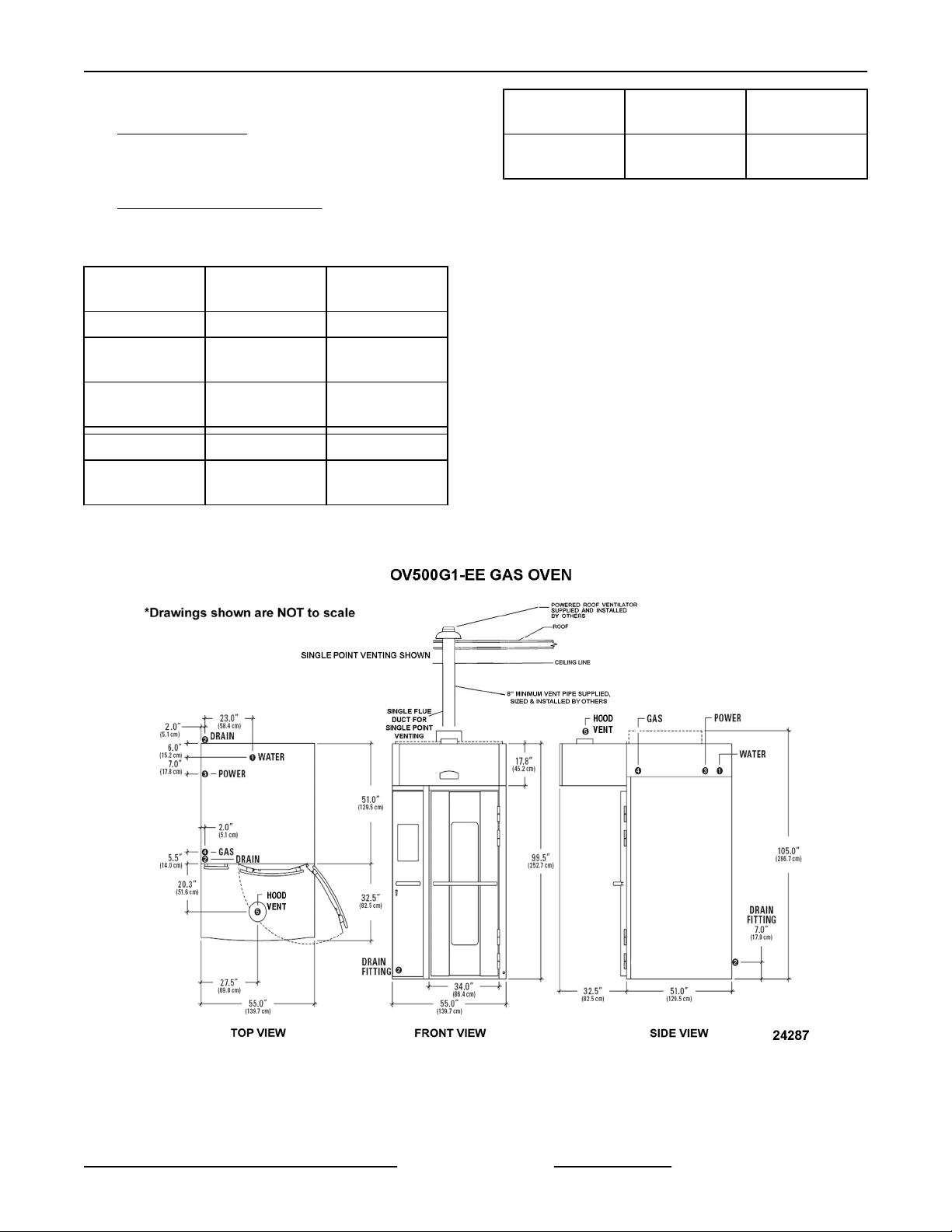

OV500G1-EE GAS OVEN

SPECIFICATIONS

1. WATER:

1/2" NPT, 30-75 PSI cold water required,

customer

line strainer.

2. DRAIN:

6 1/4" (front) or 7" (rear) connection A.F.F.

NOTES. Route to air-gap drain. Do not slope

drain upwards. Plug the drain connection that is

not in use.

Rear Drain: 1/2" NPTF

Front Drain: 1/2" NPTF

3. POWER:

to install in-line filter, shut off valve and

SEE

Page 7 of 49 F45469 Rev. D (1019)

Page 8

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - GENERAL

Two supplies required. 120/60/1 20 AMP

dedicated circuit required and one of the

following voltage options.

Voltage Full Load AMPS

208 - 240/60/1 8.8 - 7.6 AMPS

208 - 240/60/3 5.0 - 4.4 AMPS

440 - 480/60/3 2.4 - 2.2 AMPS

4. GAS:

Natural Gas (N.G.)

NPT, W.C.N.G. (N.G. rated 1025 BTU/CU. FT.

1"

SP. GR. 1.00)

Liquified Propane Gas (L.P.G.)

1" NPT, W.C.L.P.G. (L.P.G. rated 2440 BTU/

CU.FT., SP. GR. 1.52)

Natural Gas

BTU/HR 180,000 180,000

INLET

PRESSURE

MANIFOLD

PRESSURE

5. HOOD VENT:

8" DIA connection collar. Customer to supply

and ventilator fan per state and local codes.

duct

Air proving switch factory installed & integrated

with burner system operation. Oven provided

relay with max. 10 amp 1/2 H.P. @ 120V output

for fan operation. If larger, use oven relay to

control additional separately powered contactor /

relay for hood fan. Chamber vents are factory

ducted to this integral hood. 690 CFM required,

0.6" W.C. static pressure drop through hood.

Hood is UL710 Listed when grease filters are

installed. Type B gas vent can be used except

when bake products are grease laden.

NOTES:

1. A.F.F.: Above finished floor.

2. Customer responsible to finish and install all

utilities to and from oven.

3. All services must comply with all Federal, State

and Local codes.

5.0" - 10.0" W.C.

3.5" W.C. 10.0" W.C.

Liquified

Propane Gas

12.0" - 14.0"

W.C.

To reduce the risk of fire, the appliance is

to be installed on non-combustible surface only, with

no combustible material within 18 inches above the

appliance. The appliance is to be mounted on floors

of non-combustible construction with non-combustible

flooring and surface finish and with no combustible

material against the underside, or on non-combustible

slabs or arches having no combustible material

against the underside. Such construction shall in all

cases extend not less than 12 inches beyond the

equipment on all sides.

4. The floor must be of non-combustible material,

and must be level with surrounding area with a

maximum slope of 1/8" per foot up to 3/4"

maximum in all directions. Floor anchors require

a minimum 1" thick solid floor substrate.

5. Oven is UL/C-UL classified and CSA (AGA/CGA)

approved for 0" clearance on the side and rear

walls. Unit requires 1" to 4" clearance for rear

drain connection.

6. Top of oven requires a minimum of 24" for service

accessibility.

7. Customer responsible to install flue piping. Flue

must be vented outside of building.

8. Manufacturer reserves the right to make changes

in sizes and specifications.

Export Ratings

1. WATER:

1/2" NPT, 2.1-5.2 Bar cold water required,

customer to install in-line filter, shut off valve and

line strainer. Flow rate of 8 l/min..

2. DRAIN:

6 1/4" (front) or 7" (rear) connection A.F.F. SEE

NOTES. Route to air-gap drain. Do not slope

drain upwards. Plug the drain connection that is

not in use.

Rear Drain: 1/2" NPTF

Front Drain: 1/2" NPTF

3. POWER:

Two supplies required. Control Circuit:

100/50/60/1 or 208-240/50/1

1 kVA transformer supplied for control circuit

operation voltage of 110V. This is a multifunction

transformer, so output voltage should be verified

before operation. Some wiring may be required

to obtain proper output voltage.

F45469 Rev. D (1019) Page 8 of 49

Oven fan (1.1kW) 200V/50-60Hz/3ph/5.3A or

380- 415V/50Hz/3ph/ 2.8 - 2.5A.

Page 9

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - GENERAL

4. GAS:

Natural Gas (N.G.)

NPT (N.G. Rated 38.2Mj/m3 or 9120 Kcal/m3

1"

SP Gr 1.00)

Liquefied Propane Gas (LPG)

NPT (LPG Rated 90.9Mj/m3 or 21710 Kcal/m3

1"

SP Gr 1.52)

Natural Gas

RATING 45,400 Kcal/hr 45,400 Kcal/hr

INLET

PRESSURE

MANIFOLD

PRESSURE

RATING 190 Mj/hr 190 Mj/hr

INLET

PRESSURE

12.7 - 25.4 cm

W.C.

8.9 cm W.C. 25.4 cm W.C.

1.25 - 2.50 kPa 3.00 - 3.50 kPa

Liquified

Propane Gas

30.5 - 35.6 cm

W.C.

Natural Gas

MANIFOLD

PRESSURE

NOTE: Pressure not to exceed 35.6 cm W.C. or 3.5

kPa

5. HOOD VENT:

20.3 cm DIA. Connection collar. Customer is to

supply duct and ventilator fan per federal and/or

local codes. Chamber vent (steam) and

combustion exhaust are discharged into the

hood. An air proving switch is factory installed

and integrated with burner system operation. If

proper ventilation is not provided, burner will not

operate. Oven provides a relay to activate a

customer

so that when oven is powered up external fan will

operate. The hood requires a minimum of 19.5

m3/min for safe operation. For fan calculation

purposes you should assume 0.15 kPa

resistance through the hood. Grease filters

(optional) may be installed in the hood instead of

standard baffle.

supplied and powered contactor/relay,

.87 kPa 2.50 kPa

Liquified

Propane Gas

Fig. 2

Page 9 of 49 F45469 Rev. D (1019)

Page 10

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - GENERAL

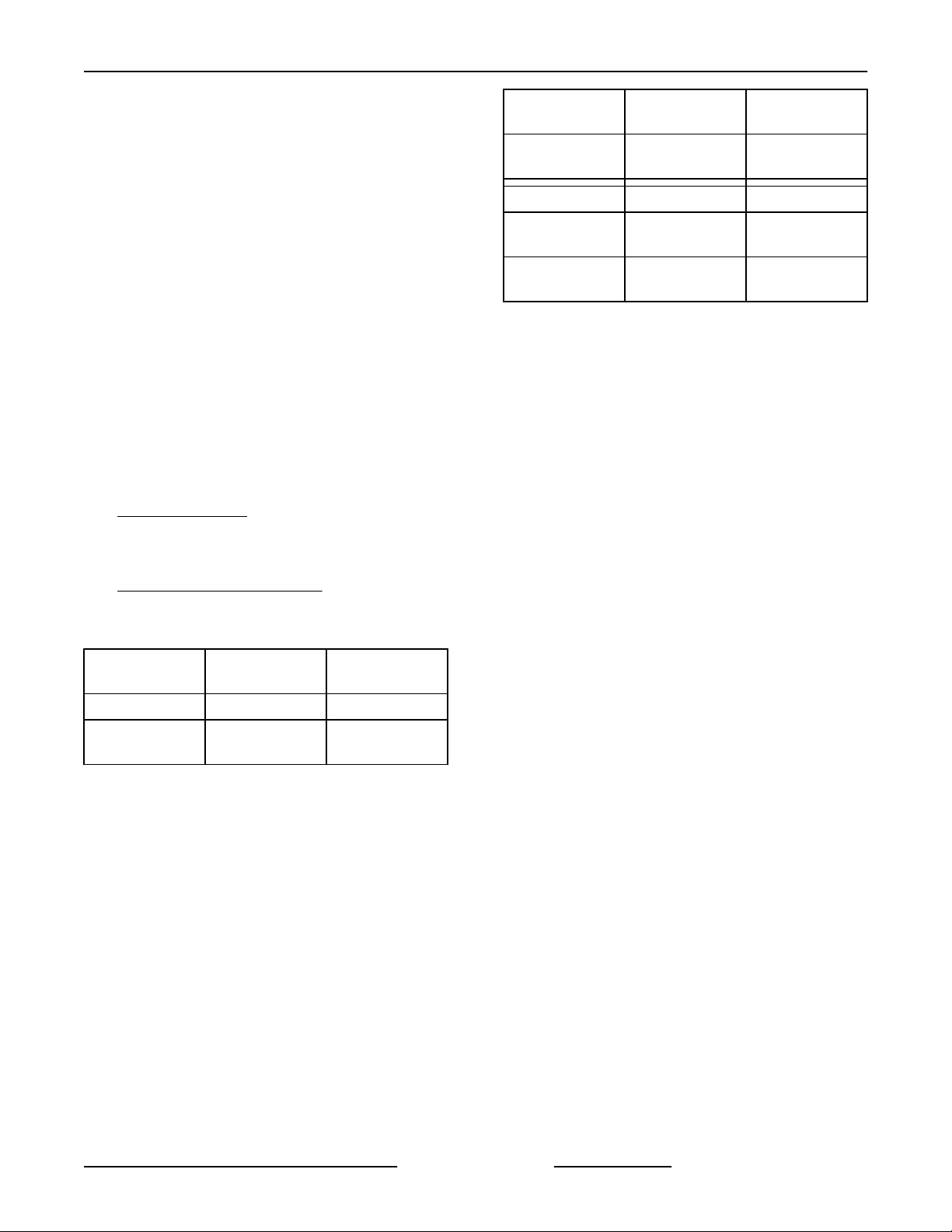

OV500G2-EE GAS OVEN

SPECIFICATIONS

1. WATER:

1/2" NPT, 30-75 PSI cold water required,

customer

line strainer.

2. DRAIN:

2 3/4" (front) or 5 1/2" (rear) connection A.F.F.

SEE NOTES. Route to air-gap drain. Do not

slope drain upwards. Plug the drain connection

that is not in use. Kit provided to extend drain to

either side of oven.

Rear Drain: 3/4" NPTF

Front Drain: 3/8" NPTF

3. POWER:

Two supplies required.

120/60/1 20 AMP dedicated circuit required and

one of the following voltage options.

208 - 240/60/1 8.8 - 7.6 AMPS

208-240/60/3 5.0 - 4.4 AMPS

440 - 480/60/3 2.4 - 2.2 AMPS

4. GAS:

Natural Gas (N.G.)

1/4" NPT, W.C.N.G. (N.G. rated 1025 BTU/CU.

1

FT. SP. GR. 1.00)

Liquified Propane Gas (L.P.G.)

1/4" NPT, W.C.L.P.G. (L.P.G. rated 2440 BTU/

1

CU.FT., SP. GR. 1.52)

BTU/HR 275,000 275,000

INLET

PRESSURE

MANIFOLD

PRESSURE

5. HOOD VENT:

10" DIA connection collar. Air proving switch

factory

operation. Oven provided rely with max. 10 amp

1/2 H.P. @ 120V output for fan operation. If

larger, use oven relay to control additional

separately powered contactor / relay for hood

to install in-line filter, shut off valve and

Voltage Full Load AMPS

Natural Gas

5.0 -10.0" W.C.

3.5" W.C. 8.75" W.C.

installed & integrated with burner system

Liquified

Propane Gas

10.0" - 14.0"

W.C.

fan. Customer to supply duct and ventilator fan

per state and local codes. Chamber vents are

factory ducted to this integral hood. 900 CFM

required, 0.6" W.C. static pressure drop through

hood. Hood is UL710 Listed when grease filters

are installed. Type B gas vent can be used except

when bake products are grease laden.

NOTES:

1. A.F.F.: Above finished floor.

2. Customer responsible to finish and install all

utilities to and from oven.

3. All services must comply with all Federal, State

and Local codes.

To reduce the risk of fire, the appliance is

to be installed on non-combustible surface only, with

no combustible material within 18 inches above the

appliance. The appliance is to be mounted on floors

of non-combustible construction with non-combustible

flooring and surface finish and with no combustible

material against the underside, or on non-combustible

slabs or arches having no combustible material

against the underside. Such construction shall in all

cases extend not less than 12 inches beyond the

equipment on all sides.

4. The floor must be of non-combustible material,

and must be level with surrounding area with a

maximum slope of 1/8" per foot up to 3/4"

maximum in all directions. Floor anchors require

a minimum 1" thick solid floor substrate.

5. Oven is UL/C-UL classified and CSA (AGA/CGA)

approved for 0" clearance on the side and rear

walls. Unit requires 1" to 4" clearance for rear

drain connection.

6. Top of oven requires a minimum of 24" for service

accessibility.

7. Customer responsible to install flue piping. Flue

must be vented outside of building.

8. Manufacturer reserves the right to make changes

in sizes and specifications.

Export Ratings

1. WATER:

1/2” NPT, 2.1-5.2 Bar cold water required,

customer to install in-line filter, shut off valve and

line strainer. Flow rate of 8 l/min..

2. DRAIN:

F45469 Rev. D (1019) Page 10 of 49

Page 11

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - GENERAL

2 3/4" (front) or 5 1/2" (rear) connection A.F.F.

Route to air-gap drain. Do not slope drain

upwards.

use. Kit provided to extend drain to either side of

oven.

Rear Drain: 3/4" NPTF

Front Drain: 3/8" NPTF

3. POWER:

Two supplies required. Control circut:

100/50/60/1 or 208-240/50/1

1 kVA transformer supplied for control circuit

operation voltage of 110V. This is a multifunction

transformer, so output voltage should be verified

before operation. Some wiring may be required

to obtain proper output voltage.

Oven fan (1.1kW) operates @ 200/50/60/3 amps

or 380-415/50/3, 2.8-2.5 amps

4. GAS:

Natural Gas (N.G.)

1/4” NPT (N.G. Rated 38.2Mj/m3 or 9120 Kcal/

1

m3 SP Gr 1.00)

Liquefied Propane Gas (LPG)

3/4” NPT (LPG Rated 90.9Mj/m3 or 21710 Kcal/

m3 SP Gr 1.52)

RATING 69,300 Kcal/hr 69,300 Kcal/hr

INLET

PRESSURE

Plug the drain connection that is not in

Natural Gas

12.7 - 25.4 cm

W.C.

Liquified

Propane Gas

30.5 - 35.6 cm

W.C.

Natural Gas

MANIFOLD

PRESSURE

RATING 290 Mj/hr 290 Mj/hr

INLET

PRESSURE

MANIFOLD

PRESSURE

NOTE: Pressure not to exceed 35.6 cm W.C. or 3.5

kPa

5. HOOD VENT:

25.4 cm DIA. Connection collar. Customer is to

supply duct and ventilator fan per federal and/or

local codes. Chamber vent (steam) and

combustion exhaust are discharged into the

hood. An air proving switch is factory installed

and integrated with burner system operation. If

proper ventilation is not provided, burner will not

operate. Oven provides a relay to activate a

customer

so that when oven is powered up external fan will

operate. The hood requires a minimum of 25.5

m3/min for safe operation. For fan calculation

purposes you should assume 0.15 kPa

resistance through the hood. Grease filters

(optional) may be installed in the hood instead of

standard baffle.

8.9 cm W.C. 22.22 cm W.C.

1.25 - 3.50 kPa 3.00 - 3.50 kPa

.87 kPa 2.18 kPa

supplied and powered contactor/relay,

Liquified

Propane Gas

Page 11 of 49 F45469 Rev. D (1019)

Page 12

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - GENERAL

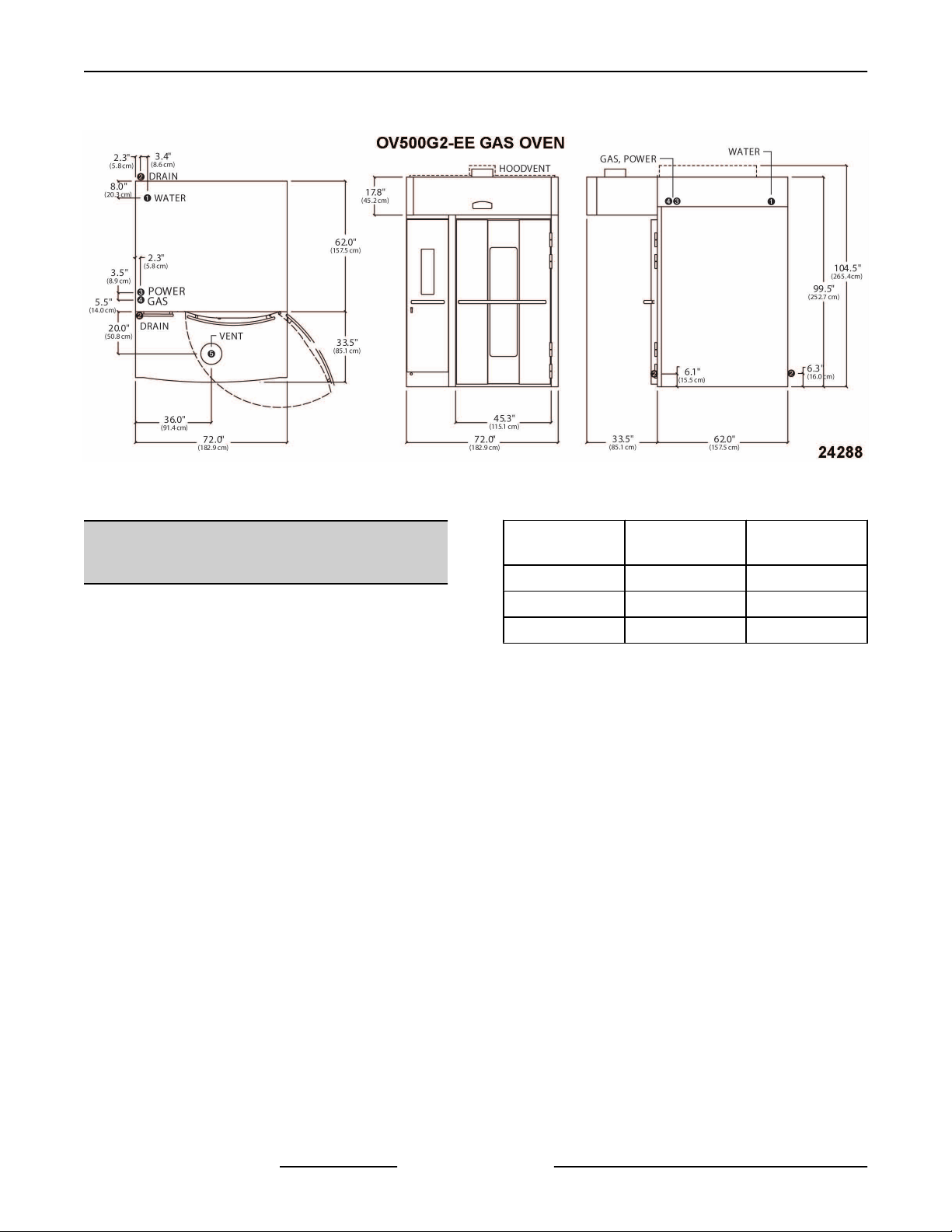

Fig. 3

OV500E1 ELECTRIC OVEN

SPECIFICATIONS

1. WATER:

1/2" NPT, 30-75 PSI cold water required,

customer to install in-line filter, shut off valve and

line strainer.

2. DRAIN:

6 1/4" (front) or 7" (rear) connection A.F.F. .

Route to air-gap drain. Do not slope drain

upwards. Plug the drain connection that is not in

use.

Rear Drain: 1/2" NPTF

Front Drain: 1/2" NPTF

3. POWER:

Two supplies required.

120/60/1 20 AMP dedicated circuit required and

one of the following voltage options.

Heating Circuit: KW rating in following chart per

supply voltage.

Blower Motor: 1 1/2 H.P.

Voltage

208/60/3 100 AMPS 34 KW

208 - 240/60/3 76 - 87 AMPS 26 - 34 KW

440 - 480/60/3 40 - 43 AMPS 29 - 34 KW

4. HOOD VENT:

8" DIA connection collar. Customer to supply

duct and ventilator fan per state and local codes.

Oven provided relay with max. 10 amp 1/2 H.P.

@ 120V output for fan operation. If larger, use

oven relay to control additional separately

powered contactor / relay for hood fan. Chamber

vents are factory ducted to this integral hood. 690

CFM required, 0.6" W.C. static pressure drop

through hood. Hood is UL710 Listed when

grease filters are installed. Type B gas vent can

be used except when bake products are grease

laden.

NOTES:

1. A.F.F.: Above finished floor.

2. Customer responsible to finish and install all

utilities to and from oven.

3. All services must comply with all Federal, State

and Local codes.

Full Load

AMPS

Heaters Rating

F45469 Rev. D (1019) Page 12 of 49

Page 13

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - GENERAL

To reduce the risk of fire, the appliance is

to be installed on non-combustible surface only, with

no combustible material within 18 inches above the

appliance. The appliance is to be mounted on floors

of non-combustible construction with noncombustible

flooring and surface finish and with no combustible

material against the underside, or on non-combustible

slabs or arches having no combustible material

against the underside. Such construction shall in all

cases extend not less than 12 inches beyond the

equipment on all sides.

4. The floor must be of non-combustible material,

and must be level with surrounding area with a

maximum slope of 1/8" per foot up to 3/4"

maximum in all directions. Floor anchors require

a minimum 1" thick solid floor substrate.

5. Oven is UL/C-UL classified and CSA (AGA/CGA)

approved for 0" clearance on the side and rear

walls. Unit requires 1" to 4" clearance for rear

drain connection.

6. Top of oven requires a minimum of 24" for service

accessibility.

7. Customer responsible to install flue piping. Flue

must be vented outside of building.

8. Manufacturer reserves the right to make changes

in sizes and specifications.

Export Ratings

1. WATER:

1/2” NPT, 2.1 - 5.2 Bar cold water required,

customer to install in-line filter, shut off valve and

line strainer. Flow rate of 8 l/min.

2. DRAIN:

N/A

3. POWER:

Two supplies required. 100V/50-60Hz/1Ph or

208-240V/50Hz/1Ph

⅛ kVA transformer supplied for control circuit

operation

transformer, so output voltage should be verified

before operation. Some wiring may be required

to obtain proper output voltage.

Oven fan (1.1kW) operates @ 200V/50-60Hz/

3Ph, 5.3 amps or 380-415V/3Ph/50Hz/ 2.4-2.2A

Voltage

200/50 - 60/3 74 AMPS 24 KW

380 - 415/50/3 46 - 50 AMPS 29 - 34 KW

4. HOOD VENT:

20.3 cm DIA. Connection collar. Customer is to

supply duct and ventilator fan per federal and/or

local codes. Chamber vent (steam) and

combustion exhaust are discharged into the

hood. Oven provides a relay to activate a

customer

so that when oven is powered up external fan will

operate. The hood requires a minimum of 19.5

m^3/min for safe operation. For fan calculation

purposes you should assume 0.15 kPa

resistance through the hood. Grease filters

(optional) may be installed in the hood instead of

standard baffle.

voltage of 110V. This is a multifunction

Full Load

AMPS

supplied and powered contactor/relay,

Heaters Rating

Page 13 of 49 F45469 Rev. D (1019)

Page 14

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - GENERAL

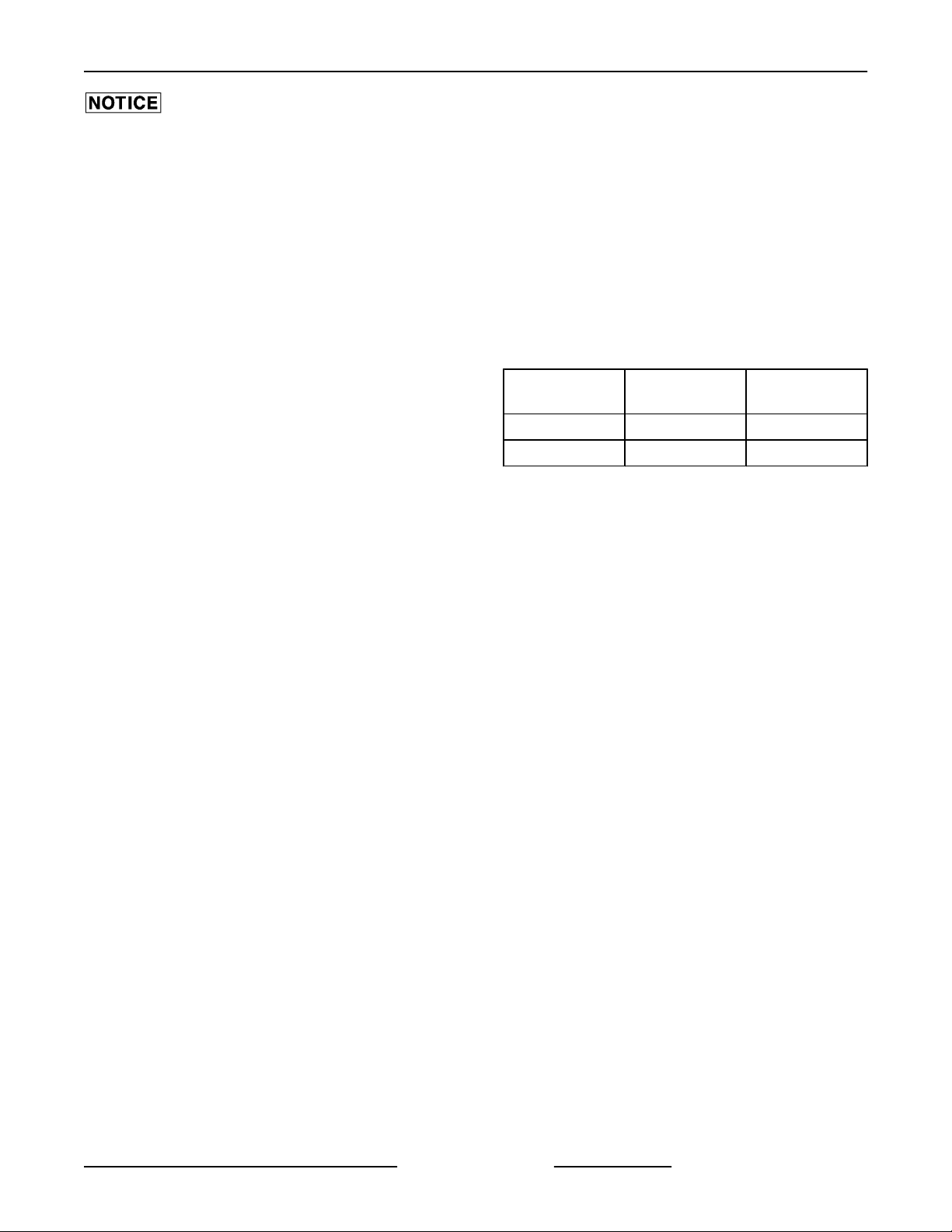

OV500E2 ELECTRIC OVEN

SPECIFICATIONS

1. WATER:

1/2" NPT, 30-75 PSI cold water required,

customer

line strainer.

2. DRAIN:

2 3/4" (front) or 5 1/2" (rear) connection A.F.F. .

Route to air-gap drain. Do not slope drain

upwards. Plug the drain connection that is not in

use. Kit provided to extend drain to either side of

oven.

Rear Drain: 3/4" NPTF

Front Drain: 3/8" NPTF

3. POWER:

Two supplies required.

120/60/1 20 AMP dedicated circuit required and

one of the following voltage options.

Heating Circuit: KW rating in following chart per

supply voltage.

Blower Motor: 1 1/2 H.P.

Voltage

208/60/3 146.4 AMPS 51.3 KW

to install in-line filter, shut off valve and

Full Load

AMPS

Heaters Rating

Fig. 4

Voltage

208 - 240/60/3

440 - 480/60/3

4. HOOD VENT:

10"DIA connection collar. Customer to supply

duct

and ventilator fan per state and local codes.

Oven provided relay with max. 10 amp 1/2 H.P.

@ 120V output for fan operation. If larger, use

oven relay to control additional separately

powered contactor / relay for hood fan. Customer

to supply duct and ventilator fan per state and

local codes. Chamber vents are factory ducted to

this integral hood. 900 CFM required, 0.6" W.C.

static pressure drop through hood. Hood is

UL710 Listed when grease filters are installed.

Type B gas vent can be used except when bake

products are grease laden..

NOTES:

1. A.F.F.: Above finished floor.

2. Customer responsible to finish and install all

utilities to and from oven.

3. All services must comply with all Federal, State

and Local codes.

Full Load

AMPS

111.2 - 127.2

AMPS

59.1 - 64.1

AMPS

Heaters Rating

38.5 - 51.3 KW

43 - 51.3KW

F45469 Rev. D (1019) Page 14 of 49

Page 15

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - GENERAL

To reduce the risk of fire, the appliance is

to be installed on non-combustible surface only, with

no combustible material within 18 inches above the

appliance. The appliance is to be mounted on floors

of non-combustible construction with noncombustible

flooring and surface finish and with no combustible

material against the underside, or on non-combustible

slabs or arches having no combustible material

against the underside. Such construction shall in all

cases extend not less than 12 inches beyond the

equipment on all sides.

4. The floor must be of non-combustible material,

and must be level with surrounding area with a

maximum slope of 1/8" per foot up to 3/4"

maximum in all directions. Floor anchors require

a minimum 1" thick solid floor substrate.

5. Oven is UL/C-UL classified and CSA (AGA/CGA)

approved for 0" clearance on the side and rear

walls. Unit requires 1" to 4" clearance for rear

drain connection.

6. Top of oven requires a minimum of 24" for service

accessibility.

7. Customer responsible to install flue piping. Flue

must be vented outside of building.

8. Manufacturer reserves the right to make changes

in sizes and specifications.

Export Ratings

1. WATER:

1/2” NPT, 2.1 - 5.2 Bar cold water required,

customer to install in-line filter, shut off valve and

line strainer. Flow rate of 8 l/min.

2. DRAIN:

N/A

3. POWER:

Two supplies required. 100V/50-60Hz/1Ph or

208-240V/50Hz/1Ph

⅛ kVA transformer supplied for control circuit

operation

transformer, so output voltage should be verified

before operation. Some wiring may be required

to obtain proper output voltage.

Oven fan (1.1kW) operates @ 200V/50-60Hz/

3Ph/5.3A or 380-415V 3ph 50 Hz 2.4- 2.2A

Voltage

200/50 - 60/3 108 AMPS 36 KW

380 - 415/50/3 68 - 73AMPS 43 - 51 KW

4. HOOD VENT:

25.4 cm DIA. Connection collar. Customer is to

supply duct and ventilator fan per federal and/or

local codes. Chamber vent (steam) and

combustion exhaust are discharged into the

hood. Oven provides a relay to activate a

customer

so that when oven is powered up external fan will

operate. The hood requires a minimum of 25.5

m3/min for safe operation. For fan calculation

purposes you should assume 0.15 kPa

resistance through the hood. Grease filters

(optional) may be installed in the hood instead of

standard baffle.

voltage of 110V. This is a multifunction

Full Load

AMPS

supplied and powered contactor/relay,

Heaters Rating

Page 15 of 49 F45469 Rev. D (1019)

Page 16

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - GENERAL

Fig. 5

F45469 Rev. D (1019) Page 16 of 49

Page 17

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

INSTALLING OVEN

manual is written for a new installation where you can position the oven sections while the oven is on the shipping

This

skids. Some installations may require that oven sections on the skids be lifted on there side and manipulated through

doorways prior to positioning sections for installation.

Prior to installing the oven, check facilities floor for being level within a maximum of 1/8" per foot up to 3/4" in all

directions using the laser level technique to determine if oven will need to be shimmed. Also check facilities floor

area at the threshold and door swing opening location to determine if facilities floor will need to be reworked.

OVEN SECTIONS

Remove all assemblies except oven sections from

skids prior to lifting oven sections. In some cases

OV500G1-EE

sections assembled together.

NOTE: On split OV500 single rack ovens, remove the

rack lift/rotate assembly and center insulation cover

from the top of the oven prior to standing up.

1. Place the oven sections as close to the final

position as possible, allowing enough room to

work, with the sections positioned for lifting.

& OV500E1 ovens will be shipped with

A. Check for ceiling clearance. The oven is

tallest when it is approximately 60 degrees

to the floor during the raising process. If

oven section has been turned on its narrow

side in order to navigate through a doorway,

turn the oven section back to the shipping

position prior to raising.

B. Remove the bottom hold down brackets

from both pallets, but do not remove oven

sections from pallets.

DO NOT remove the two top

brackets prior to lifting units.

2. Lift the oven sections upright, using the hoist

technique. Both oven sections should be as close

as possible, but not touching.

NOTE: Single rack ovens have a one piece floor. The

floor will need to be put into location with a bead of red

high temp silicone around the outer edge of floor

flange before oven sections are slid together. The right

front corner of oven will need to be lifted, to clear

flange on the floor (door jamb retainer) when installing

a one piece floor.

Fig. 6

Fig. 7

Page 17 of 49 F45469 Rev. D (1019)

Page 18

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

Fig. 8

3. Once the oven is in the upright position, remove

the top two brackets securing the oven to the

skid.

B. Lower the skid to the floor making sure that

the Z channel does not scratch the oven

side.

C. Perform the same procedure for other oven

section.

Fig. 10

Fig. 9

The z bracket location on the bottom

of the skid must be disengaged before lowering the

skid. If engaged when lowering the skid, the oven

section could fall.

4. Remove the header support bracket.

A. Remove the two screws from hinge side of

bracket.

B. Move bracket and reinstall the hinge

screws.

C. Remove the single screw from the header

side of bracket and discard screw and

bracket.

A.

Pull the bottom of the skid away from the

oven to clear the Z channel.

5.

F45469 Rev. D (1019) Page 18 of 49

Fig. 11

Slide the oven sections together.

Page 19

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

NOTE: Caulk inner seam before placing halves

together.

Fig. 12

NOTE: Ensure ceiling offset flange slides under

opposite oven section ceiling.

Fig. 13

6. Install ½-13

in rear frame connection points of oven, both top

and bottom.

x 1-1/2" bolt with lock washer and nut

Fig. 15

NOTE: If you have trouble aligning the holes in the

rear frame, you may have to manipulate the oven

sections using the levelers, using shims, or by prying.

Use care not to damage building floor.

Fig. 16

Fig. 14

7. Install 5/16-18

header connections.

NOTE: Ensure oven sections upper header front

surfaces are flush.

x 1" gimlet screws in upper & lower

Page 19 of 49 F45469 Rev. D (1019)

Page 20

INSTALLATION INSTRUCTIONS

NOTE: You may have to move oven front corners to

make the holes in the outer header align with the holes

in the oven.

Fig. 17

8. Install 5/16-18 X1" gimlet screws in the flanges

of the mating sections around the oven

perimeter, both top and back.

OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

Fig. 19

10. For OV500G1-EE & OV500E1 ovens only: Install

insulation cover onto top of oven.

11. For OV500G1-EE & OV500E1 ovens only: Install

rotator assembly onto lifter assembly.

NOTE: Start a few screws at several locations around

the flange to help align the flange holes.

9. Install all flange mating section screws and

insure mating surfaces are flush in the interior &

exterior of the oven before tightening the screws.

NOTE: If you have trouble aligning the mating holes

in the flange, you may have to manipulate the oven

sections using the levelers or by prying.

Fig. 20

12. Install upper header support plate with #10 Tek

screws.

Fig. 18

F45469 Rev. D (1019) Page 20 of 49

Page 21

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

Fig. 21

13. Install lower header cover with two 10-32 screws

lose to hold cover in place.

Fig. 22

14. Install

upper header cover with #10 X 3/4" screws

on top and 1/4-20 screws on the bottom with front

edge of cover flush with door jambs.

Fig. 24

A. Cut off gasket material to length of retainer.

B. Install upper door gasket & upper gasket

retainer by removing the two lower header

cover screws then secure gasket & retainer

to cover with 10-32 gimlet screws.

Fig. 25

16.

Install 1/4-20 X 3/4" hex head serrated flange

screws onto ceiling offset inside baking

compartment.

Fig. 23

15.

Install upper door gasket to upper gasket

retainer.

Fig. 26

17.

Install insulation pieces.

NOTE: Before installing rear panel on double rack

ovens, tighten the drain line union fitting.

Page 21 of 49 F45469 Rev. D (1019)

Page 22

INSTALLATION

A. On the rear seam, bend the copper studs so

they

installing the insulation, make sure the

insulation is held by these studs.

INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

are 90 degrees to the oven wall. When

Fig. 27

OVENS - INSTALLING OVEN

B. At the rear wall, place the push nuts over the

copper studs to secure the insulation.

Fig. 29

B. Push the panel up until the bottom of the

panel clears the bottom rail of the oven

section frame.

Fig. 28

18. Install rear cover panel.

NOTE:

F45469 Rev. D (1019) Page 22 of 49

This panel will also have a layer of insulation.

A. Start the top of the panel behind the top rail

of the upper frame.

Fig. 30

C. Make sure that the panel is behind the rail

of the lower frame and will rest against the

stop when lowered into position.

Page 23

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

D. Push the panel down against the stop.

Fig. 33

Fig. 31

19. Connect rear drain if required.

A. Using materials from provided drain kit

(double rack ovens only), route the drain to

either side of oven.

B. Ensure drain slopes downward 1/4"per ft.

20. For OV500G2-EE & OV500E2 ovens only: Install

insulation into ceiling channel.

22. Remove junction box cover to access connection

plugs for rack rotation and rack lift. Connect plugs

together and install raceway to top of oven.

NOTE: Gas ovens will not have junction box, but

conduit directly to component. Electric double rack

ovens will have an additional cover (1, Fig. 36) to be

installed over exposed wiring (2, Fig. 36).

Fig. 32

21. For OV500G2-EE & OV500E2 ovens only: Install

ceiling channel cover with #10 Tek screws over

the ceiling channel.

Page 23 of 49 F45469 Rev. D (1019)

GAS OVENS

SINGLE ELECTRIC OVENS

Page 24

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

Fig. 36

23. If

rear drain of oven is used install before oven is

placed in final location.

24. Remove protective plastic from rear and sides of

the oven that won't be accessible once the oven

is in place.

NOTE: Do not damage building floor while installing

dolly wheel or using front levelers. Use shims under

floor levelers to prevent damage to building floor.

B. Lower the rear wheels to raise the back of

the oven from touching the floor.

Fig. 38

25. Install the dolly wheel.

Fig. 37

NOTE:

the front of the oven to install the dolly wheel. Use care

not to damage building floor.

You may have to use the front levelers to raise

A. Raise the front oven levelers so the weight

of the oven is on the dolly wheel.

Fig. 39

NOTE: Raising the rear of the oven too much can

cause the front of the oven to contact the floor.

26.

Move the oven into the final position before

lowering.

27. Place shim(s) per the height determined by the

laser level technique to level oven.

NOTE: Review HOST course for laser level

technique.

NOTE: After oven is leveled and shimmed, raise the

levelers to take the oven weight off all the levelers.

F45469 Rev. D (1019) Page 24 of 49

Page 25

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

Fig. 42

C. If diagonal measurements are not within

1/8" of each other add additional shims as

needed.

1) If diagonal 'Y' measurement is greater

than diagonal 'X' measurement add

Fig. 40

28. Raise the back wheels to lower the oven. Weight

of oven should be completely off back wheels.

shims under the right front door jamb.

Place shims on top of threshold

underneath the door jamb.

29. Remove the dolly wheel and replace lower latch

ramp.

NOTE: Retain the dolly wheel for future oven

installations.

30. Place threshold into door jamb.

NOTE: Do not anchor threshold at this time.

31. Verify door opening is square.

A. Measure diagonal 'X' from top right

innermost hinge screw to the bottom

innermost hinge screw on the left door jamb.

Fig. 43

2) If diagonal 'X' measurement is greater

than diagonal 'Y' measurement add

shims under the left front door jamb.

Fig. 41

B. Measure diagonal 'Y' from the top left

innermost hinge screw to the bottom

innermost hinge screw on the right door

jamb.

Fig. 44

Page 25 of 49 F45469 Rev. D (1019)

Page 26

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

D. Repeat procedure until diagonal

measurements are within 1/8" of each other.

NOTE: If shims are required to level the oven at the

front right corner, shims(s) will need to be placed on

top of threshold underneath the door jamb.

NOTE: If shims are required to level the oven at the

rear corners, place shim(s) in front of the back wheels.

If the rear of the oven is not accessible, place shims

under heat exchanger floor and inner wall base angle.

32. Install the door.

A. Open glass compartment door to remove

door handle and set aside.

NOTE: Tab for opening to gain access to

compartment.

Fig. 45

B. Close glass compartment door.

NOTE: Do not allow glass compartment door to slam

shut.

C. Position the door at 90 degrees to the oven

near the door opening.

D. Use a J bar to lift the door close to the hinge

side of the door.

NOTE: Use care not to place J bar under black glass

door hinge pin or the door glass.

E. Position the door over the hinges and then

lower onto the hinge pins.

33. With the door open, visually check if door swings

towards oven (closed position) on its own.

A. If door swings towards oven, add shims to

back corners of oven until door stops

swinging on its own.

34. Remove bolts securing steam panel to oven.

F45469 Rev. D (1019) Page 26 of 49

Page 27

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

A. Lift panel up while tilting top of panel

towards center of oven to remove from

oven.

Fig. 48

37. Install drain pan cover.

FLOOR / THRESHOLD

1. Move threshold halfway out from oven.

Fig. 46

35. Remove screws securing drain pan cover to

oven.

A. Pull cover out from suction panel while lifting

up right side of cover then pushing cover

towards the right rear corner of baking

compartment and out from oven.

NOTE: Use care when removing cover not to scratch

baking compartment walls.

2. Caulk around baking compartment to facility floor

seam with red RTV silicone.

NOTE: The sealant used inside the oven cavity must

be NSF Listed; suitable for food zone and minimum

275ºC/525ºF. The sealant used on the exterior of the

unit must be NSF Listed.

Fig. 47

36.

Lower drain pan support bolt until bolt comes in

contact with the floor.

NOTE: Bolt used to support steam system weight.

Fig. 49

3.

Run a bead of red RTV silicone on the entire

outer edge of both floor panels.

4. Install floor panel without offset. Flange goes up.

Page 27 of 49 F45469 Rev. D (1019)

Page 28

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

5. Run

NOTE: Double Rack only.

6. Install floor panel without offset. Flange goes up.

7. Run two beads of red RTV silicone on the flange

8. After the Oven has been Leveled and shimmed .

two beads of red RTV silicone on the flange

of floor panel without offset.

of floor panel without offset.

Attach the floor trim to the inner wall.

Fig. 52

Slide threshold under door jamb. Ensuring the

10.

three threshold tabs are installed over the oven

floor.

NOTE: Use a hammer and 2X4 to tap threshold

against oven floor. A 1/8" gap between oven floor and

threshold is acceptable.

NOTE: If shims were required to level oven and

square the door jamb at the front right corner, place

shims(s) on top of threshold underneath the door

jamb. Threshold is approximately one shim thick.

Fig. 50

9. After oven is leveled and shimmed, remove

screws and washers holding the floor in place.

NOTE: Single Whole Ovens only.

Fig. 51

Fig. 53

11. Use

NOTE: Left side, Rear wall, and Right side flanges

need to be silicone.

12. Install floor trim. Wait until later in the procedure

13. Drill & tap into door jamb at threshold clearance

Red NSF listed silicone to seal the top edge

of the floors flange, prior to installing floor trim.

to tighten screws.

holes.

F45469 Rev. D (1019) Page 28 of 49

A. Secure threshold to door jamb with 10-32 X

1/2" screws, secure left side first.

Page 29

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

17. Caulk door jamb gaps with gray NSF listed

silicone.

Fig. 54

14. Anchor threshold to facility floor.

Fig. 57

STEAM SYSTEM

Fig. 55

15.

Tighten floor trim screws.

16. Caulk gap between oven floor and threshold with

gray NSF listed silicone.

1. Remove top & left air guides from oven wall.

2. Run a bead of red NSF listed silicone between

drain pan and rear oven wall.

Fig. 58

NOTE: Fig. 58 shows Double Rack Oven.

3.

Start by setting the first steam ball assembly flat

on the oven baking compartment floor (left rear

corner).

NOTE: For OV500G1-EE & OV500E1 ovens, place

first steam ball assembly on spacers to obtain correct

height.

Fig. 56

Page 29 of 49 F45469 Rev. D (1019)

Page 30

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

Fig. 59

NOTE: Fig. 59 shows Single Rack Oven.

NOTE:

are not oriented correctly.

6. Before last couple sets of assemblies are

The assemblies will not set level if the sections

Fig. 62

installed, slide spray guard onto manifold. Align

manifold with steam ball assemblies. Allow spray

guard to hang on manifold.

Fig. 60

4.

(Only on ovens with 38 castings) Install splash

panel with angled ledge on top of first steam ball

assembly and the baffle supported by the back

wall .

Fig. 61

5.

The next steam ball assembly must be put in

place matching the female post with male post of

previous assembly (total of 30 or 38 sections for

OV500G2-EE & OV500E2 ovens, total of 15

sections for OV500E1, and total of 20 sections

for OV500G1-EE ovens to install).

Fig. 63

7.

After all assemblies are installed, place spray

guard on last set of steam balls & install water

guides to edge of assemblies.

8. Begin with the top assembly and install water

guides over front rim of the top, then every other

assembly (total of 7 water guides for all ovens.

F45469 Rev. D (1019) Page 30 of 49

Page 31

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

Fig. 64

9. Install both corner air guides.

Fig. 66

11. Install left baking compartment panel.

12. Align steam panel with screw inserts in baking

compartment ceiling (left rear corner) and loosely

secure panel to ceiling with 1/4-20 X 3/4" hex

head serrated flange screws.

Fig. 65

10.

Position spray guard to rest on top of steam ball

assemblies.

OVEN

OV500G2EE 30 PSC

OV500G1EE 20 PCS

OV500E2 30 PSC

OV500E1 15 PCS

NOTE: For SEF ovens, pieces may very.

NUMBER OF PIECES

Fig. 67

13. Secure

panel with 1/4-20 X 3/4" hex head serrated flange

screws.

Page 31 of 49 F45469 Rev. D (1019)

steam panel to rear baking compartment

Fig. 68

Page 32

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

14. Secure steam panel to left baking compartment

with 1/4-20 X 3/4" hex head serrated flange

panel

screws.

Fig. 69

15. Tighten screws at top of steam panel.

DOOR HANDLE

1. Remove pivot screw from door handle pivot

bracket on door assembly.

NOTE: Ensure lock mechanism is in the unlocked

position.

Fig. 72

Fig. 70

2.

Install door handle onto pivot bracket and insert

screw removed earlier.

Fig. 73

DOOR ASSEMBLY

1. Observe the following:

A.

With the door closed, visually check gap

around door jamb and edge of door, gap

should be equal on both sides.

Fig. 71

A.

Push door handle locking end onto door

handle locking mount until handle locks onto

mount.

F45469 Rev. D (1019) Page 32 of 49

Page 33

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

B. If paper is loose, door latches will need

adjusted.

NOTE: Latch

door rollers with latch ramps during installation. This

should be done after loading door is installed and oven

is level.

3. To align door latches:

A. With both door latch ramps having gauge

NOTE: Vertical lines for adjusting the ramps so the

wheels hit at the same time.

NOTE: If necessary, Horizontal lines to help select

which latch arms to use for correct positioning of the

wheels.

alignment instructions are to help align

installed.

Fig. 74

NOTE: If the door rubs against the jamb or drags the

facility floor when opening, verify oven for levelness.

If leveling does not correct the problem then call

Bakery Service Support.

B. Adjust door hinge inward or outward until

door has an air tight seal against door

gasket.

Fig. 75

Fig. 76

B. Close the loading door to check roller shaft

alignment with latch ramp gauge. The roller

shaft should fit inside cutout on gauge as

shown.

2.

Verify door latches properly.

A. Insert a piece of paper between door jamb

and door gasket on both sides & top of door.

Fig. 77

C. If

roller shaft does not align with gauge, then

the latch arms will have to be replaced.

Page 33 of 49 F45469 Rev. D (1019)

Page 34

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

NOTE: The horizontal line closest to bottom of roller

shaft will determine which latch arm to use. The

horizontal lines and latch arms are identified with a

different number of holes. Diagram below shows you

would need

two oo’s.

to replace latch arms using latch arms with

Fig. 78

A.

Place a piece of paper at bottom hinge side

between door and door gasket.

Close oven door and slowly pull on paper.

B.

There should be just enough drag to hold

paper from falling. Repeat this procedure

around door every couple of feet. If door is

too tight on hinge side, loosen the hinges on

the door and adjust door outward, reverse if

to loose. For latch side adjustment, loosen

screws on ramp(s) and move ramp(s) in or

out.

C. After adjusting the ramps for proper gasket

seal, make sure rollers contact ramps at the

same time. To check this, push the door

closed until one roller lightly touches a ramp,

check to see where door edge aligns with

vertical lines on the ramp gauge. The door

edge should align with the same vertical line

on each ramp gauge.

4. To install latch arms:

A. Remove inner door handle cover.

B. Remove 3/8” bolt. DO NOT discard the tube,

bolt or washer.

C. Remove E-clip and pin. DO NOT discard the

E-clip or Pin.

D. Replace two latch arms with parts supplied.

Reassemble inner mechanism, making sure

linkage arms are located in the up position.

Re-attach inner door handle.

NOTE: For left hand hinge, bolt and arms must be

flipped and mounted to hole. place unused arms to

latch box and secure with 1/4-20 bolt.

Fig. 80

D. If adjustment is required, move a ramp so

that both rollers contact the ramps at the

same time.

NOTE: Keep in mind the door gasket seal. Both

ramps need to be in correct location to equalize

pressure on rollers.

6. Repeat the process until desired results are

obtained or call Bakery Product Support.

7. After desired results obtained, bend alignment

gauges back & forth to break off and discard.

Fig. 79

5. To adjust door gasket seal:

F45469 Rev. D (1019) Page 34 of 49

Page 35

INSTALLATION INSTRUCTIONS

OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

DOOR SWITCH ACTUATOR

1. Check door switch actuator for proper operation

and adjust switch as needed.

Fig. 81

Fig. 83

DOOR SWEEP

1. Install door sweep.

NOTE: Door sweep shipped with door assembly.

A. Adjust the door sweep so the metal door

seal plate is 5/16" from the highest point on

the floor.

NOTE: Door sweep has slots for adjustment.

Fig. 82

Fig. 84

RACK CARRIER - A & C STYLE

RACK LIFT

NOTE: After oven has been leveled.

1. Remove snap ring (C lift) or pin and washer (A

lift) from rotation shaft and save for carrier

installation. Cardboard tube can be discarded.

Page 35 of 49 F45469 Rev. D (1019)

Page 36

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

Fig. 85

Installing "A" Lift (1.25" shaft)

A. Position carrier on shaft with arrows on the

shaft and carrier aligned.

B. Insert ½” pin through holes in carrier hub

and shaft.

NOTE: Pin should be centered and fit snug in shaft.

Fig. 86

C. Install

cover plate to the bottom of the carrier

with screws provided.

Fig. 88

C. Slide the carrier onto the lift mechanism

shaft and install the snap ring.

NOTE: Do Not allow the lift mechanism shaft to move

upward. Hold shaft down from top of oven.

2. Roll baking rack onto carrier and check for proper

carrier height.

NOTE: Carrier should be approximately 0.125" to

0.25" from rack lifting channels. Check multiple baking

racks.

Fig. 87

Installing "C" Lift (1.25" shaft)

A.

Install rack carrier.

B. Apply food grade Never Seize to set screw

threads on (C lift) and start the set screws

into the carrier.

F45469 Rev. D (1019) Page 36 of 49

Fig. 89

Fig. 90

Page 37

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

A. If carrier height needs adjusted, remove

baking

ladder and blocks of wood to correct height.

rack and support carrier with i.e. step

Fig. 93

E. Factory Installed shim washers 5 above & 5

below retaining ring. Position shim washers

above or below the retaining ring for correct

carrier height.

Fig. 91

B. Access rotate/lift assembly at top of oven.

C. Loosen rotate/lift shaft collar set screw 1/4

turn.

Fig. 92

D.

Remove screws securing Teflon bearing

bracket to rotate/lift assembly and lift from

assembly.

Fig. 94

F.

If carrier needs to be lower than snap ring

will allow, access clevis pins on rear of lift

and lower both equally.

NOTE: Always lower left and right clevis pins the

same distance. One hole location equals 1/4"

adjustment.

Page 37 of 49 F45469 Rev. D (1019)

Page 38

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

RACK CARRIER - B STYLE RACK

LIFT

NOTE: After oven is leveled.

Remove snap ring, shim washers, & card board

1.

shipping tube from lift shaft.

Fig. 95

3. Install snap ring, teflon plate and tighten set

screw.

NOTE: You made need to lift up on rotator body while

tightening set screw to get shims flush with the snap

ring.

NOTE: Check multiple racks.

Fig. 96

4.

Remove shipping ties from vent lid.

Fig. 98

2. Install rack carrier.

3. Apply food grade Never Seize to set screw

threads and start the set screws into the carrier.

Fig. 99

4. Slide

5. Roll baking rack onto carrier and check for proper

NOTE: Carrier should be approximately 0.125" to

0.25" from rack lifting channels. Check multiple baking

racks.

the carrier onto the lift mechanism shaft and

install snap ring.

carrier height.

Fig. 97

F45469 Rev. D (1019) Page 38 of 49

Page 39

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

Fig. 102

7. Snug the set screws to hold the carrier in place.

Fig. 100

A. Access rotate/lift assembly at top of oven.

B. If carrier needs to be lower than snap ring

will allow, access clevis pins and lower

location to correct carrier height.

NOTE: Always lower left and right clevis pins the

same distance. One hole location equals 1/4"

adjustment.

Fig. 101

6.

If the carrier needs to be adjusted to get proper

spacing, remove rack and add shims between

snap ring and carrier as shown. Ten shims are

provided with each oven.

8. Remove shipping ties from vent lid.

Fig. 103

HOOD ASSEMBLY

NOTE: After the hood is installed the door assembly

can

not be lifted off the hinge pins. The door assembly

would have to be removed & installed from the door

hinges.

1. Set hood on the floor in front of oven (if hood

supplied). Remove only the necessary protective

plastic from the hood.

NOTE: Check multiple racks

A. Attach side panels with 10-32 screws 10

screw holes to the back of the hood, and

ensure that the 3 screw holes are to the rear

on each side panel. Align top of hood up with

the top edge of side trim panels before

tightening the screws.

Page 39 of 49 F45469 Rev. D (1019)

Page 40

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

Fig. 104

Fig. 107

E. Ensure hood support bracket sets on front

top edge of oven.

F. Ensure bottom edge of hood is aligned with

bottom edge of oven support.

Fig. 105

B.

Attach rear panel to each side panel with

10-32 X 3/4" screws.

NOTE: If clearance is a problem, don't install the rear

panel, set hood with side panels in place first.

C. Apply gray NSF listed silicone around face

of overpressure duct.

Fig. 106

D.

Set hood in place on top of oven.

Fig. 108

G. Secure

top of oven.

H. If not attached in previous steps, attach rear

panel of hood.

I. Secure hood support bracket to top of oven

with #10 Tek screws.

side panels with #10 Tek screws into

F45469 Rev. D (1019) Page 40 of 49

Page 41

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

Fig. 111

4. Install over pressure damper to over pressure

vent (right side of hood) using #10 Tek screws.

Fig. 109

2. Remove perforated air baffle from hood.

Fig. 110

3.

Connect the over pressure vent (Right side of

hood) using #10 Tek screws 8 places total.

Fig. 112

5. Caulk

header and seams at hood and side panels

also bottom edge seam of hood along oven front

with gray silicone.

Fig. 113

Page 41 of 49 F45469 Rev. D (1019)

Page 42

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

Fig. 114

6. Customer is responsible for having a flue pipe

connected to the center hood connection. See

appropriate oven specification.

Fig. 117

Fig. 115

7.

Install bracket between top of hood and hood

side trim (2 places).

Fig. 116

HOOD VENTING

1. Install exhaust connection plate to hood

assembly.

NOTE: Electric

plate to close off exhaust opening in hood.

oven install a hood exhaust inclosure

Fig. 118

2.

Insert exhaust duct thru hood and connect to

draft inducer.

Fig. 119

F45469 Rev. D (1019) Page 42 of 49

Page 43

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

Fig. 120

3. Secure exhaust duct to exhaust connection

plate.

4. Secure exhaust duct with #10 Tek screws to draft

inducer.

Fig. 122

Fig. 121

5. Connect

pressure switch. Switch location on side of

control panel inside control compartment. Leave

tubing coiled in control compartment.

NOTE: Defer connecting hood vent tube to the

exhaust connection until start up.

the hood exhaust tube at hood exhaust

AIR BAFFLE & GREASE FILTERS

1. Install perforated air baffle with 1/4-20 acorn

nuts.

2. Install grease filters for type 1 hood or install

perforated plenum panel for type 2 hood.

hood

Fig. 123

Page 43 of 49 F45469 Rev. D (1019)

Page 44

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

• Gas supplied matches data plate and gas

valve on oven.

Gas valve is in the OFF position.

•

• Electrical connections have been made by

electrician. 120V control, high voltage, and

powered roof ventilator (external device).

NOTE: Refer to the service entrance label on the

oven for electrical connections.

• Turn the 120V supply power ON.

• Turn the circuit breakers ON.

• Drain connected (with air gap) by plumber

and opposite end of drain plugged.

Fig. 124

CAULK OVEN

• Water line is connect by plumber to flow

restrictor located on top left rear corner of

oven.

1. Caulk around oven with gray NSF listed silicone.

Fig. 125

INITIAL START-UP

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

There

may be multiple circuits. Be sure

all circuits are disconnected.

• Water shut off is installed in supply line.

NOTE: If a water filtration unit is installed in supply

line, verify that a filter cartridge is installed in unit

(performed by customer).

NOTE: Refer to oven installation checklist and

complete during initial start-up.

Start Up

1. Connect hood exhaust pressure switch tubing to

hood exhaust connection.

NOTE: Make sure that there is a point in the tubing

that is higher than flue pipe connection before tubing

is routed to the hood exhaust pressure switch. This

will help prevent the tube from clogging.

NOTE: Remove all protective plastic sheeting from

oven surfaces and wipe down to remove all

fingerprints, prior to heating oven.

NOTE: All utility connections by others.

Power and Plumbing Connections

• Verify the following:

• Gas supply line shut-off valve is in the OFF

position.

F45469 Rev. D (1019) Page 44 of 49

2. Close oven door.

3. Turn oven power ON. Use DOWN ARROW keys

Fig. 126

select lowest bake temperature so oven will not

initiate a call for heat.

Page 45

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

4. Verify operation of roof mounted ventilator.

NOTE:

5. Verify air louvers are set at factory settings.

NOTE: Factory louver settings located inside of

control compartment door.

6. Verify that rack carrier height will accept racks

NOTE: Racks expand when hot. There should be

approximately 1/2" clearance from bottom of carrier to

top of rack. Check at least two racks to verify rack

acceptance into carrier.

7. Verify that rack is level and rotating properly

8. Verify that baking compartment circulation

9. Verify steam system operation.

Verify plenum panel or grease filters installed.

A. Remove vacuum line near hood exhaust

pressure switch and connect incline

manometer or equivalent.

1) Venting Minimum reading should be:

-1.10" W.C., -2.74 mm W.C., or

-0.28kPa.

B. Disconnect manometer and reconnect

vacuum line onto hood exhaust pressure

switch.

when loading and no drag when rack is in the

raised position.

when door is closed; and rack stops in the correct

loading position when door is opened.

blower is turning in direction indicated on motor.

If not, disconnect power and switch any two of the

three phase lead wires.

A. Set oven control to have 1 plus minutes on

bake timer display.

B. Set steam time for 20 seconds.

D. Spark igniter arcs indicating that it is

energized.

E. 2 seconds after igniter was energized, gas

valve solenoid is energized.

F. After igniter has been energized for 4

seconds, flame sensor will not have

recognized a flame.

1) Power is removed from igniter and gas

valve.

2nd ATTEMPT

G. 15 second inter-purge cycle.

H. Spark igniter arcs indicating that it is

energized.

I. 2 seconds after igniter was energized, gas

valve solenoid is energized.

J. After igniter has been energized for 4

seconds, flame sensor will not have

recognized a flame.

1) Power is removed from igniter and gas

valve.

3 rd ATTEMPT

K. 15 second inter-purge cycle.

L. Spark igniter arcs indicating that it is

energized.

M. 2 seconds after igniter was energized, gas

valve solenoid is energized.

N. After igniter has been energized for 4

seconds, flame sensor will not have

recognized a flame.

1) Power is removed from igniter and gas

valve.

C. Press START key to begin timer countdown.

1) Water solenoid should energize.

D. Press STOP key to silence beeper.

10.

IGNITION SEQUENCE TIMING DIAGRAM

NOTE: Ignition module will make three attempts to

light burner before locking out.

A. Ensure

ignition sequence check.

B. Set oven to call for heat by pressing bake

temperature display UP ARROW key, until

HEAT ON LED illuminates.

1st ATTEMPT

C. Draft inducer energized for 15 seconds pre-

purge cycle.

gas valve is in the off position to test

O. After three tries for ignition and the burner

has not lit, the draft inducer will shut off.

P. LED on ignition control will flash in a 3 flash

sequence indicating a flame recognition

failure and that the control is in lock-out

mode.

Q. Opening the door for 5 seconds will reset

ignition module.

R. This indicates the safety lock-out circuit is

functioning properly.

11. Gas Pressure Adjustment.

A. Connect a manometer or equivalent to inlet

and outlet pressure taps on gas valve.

Page 45 of 49 F45469 Rev. D (1019)

Page 46

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

B. Turn gas supply ON to oven and check for

leaks between gas valve and supply line

shut-off valve.

C. Verify that the static line pressure to the

oven does not exceed 14" W.C. (1/2 psig,

35.6 cm W.C., 3.5 kPa)

NOTE:

psig, 35.6 cm W.C., 3.5 kPa) the customer must

supply and install a line pressure regulator to drop the

pressure below 14" W.C., 35.6 cm W.C., 3.5 kPa

NOTE: It may take several ignition attempts to light

burner initial time.

If static line pressure exceeds 14" W.C. (1/2

D. Turn gas valve ON.

E. Set the oven to call for heat.

F. With oven burner flame established and with

the burners lit for all other equipment that

are common to supply line, check

FLOW PRESSURE CHARTS.