Page 1

Project:

STANDARD FEATURES

■ Each deck is purchased and operated independently

■ Stainless steel exterior

■ Self-contained steam system

■ Glazed stone baking surface

■ Separately controlled top and bottom elements

■ Easy-to-operate digital control

• Temperature

• Time

• Steam

■ Single point vent exhaust

■ Illuminated bake chamber with exterior access to replace light bulbs

■ Glass loading door opens into the bake chamber – minimal loading space

required

■ Stack up to four decks in height

■ Oven stand sold separately

OPTIONS & ACCESSORIES

❏ OV450W-KIT: Kit of component parts required to complete an OV450W deck

oven package. Includes: Stainless steel top, drain collector box, water supply

assemblies and stacking connector hardware.

❏ OV450W-ACCPKG: Deck oven accessory kit for wide deck ovens

• Includes: (3) peels, (1) brush, and (1) dust pan

❏ STAND-450WADJ: Adjustable height stand for OV450W ovens. 31.0" to

40.0"H, adjusts in 3" increments. Use with 1 to 3 decks.

❏ STAND-450W18: 18"H Fixed stand base for OV450W ovens

❏ OV450W-BASPLT: Stainless steel oven base plate for OV450W ovens.

Required if ordering ovens without a stand base.

❏ OV450W-HOOD: 14.8"H Stainless steel vapor (Type II) hood for OV450W

ovens.

❏ OV450-HOODFAN: Exhaust fan for use with Baxter supplied hood.

8"D ventilation duct supplied & installed by others.

❏ Spacer kits for hoods to ensure operator clearance with oven configurations.

Contact factory for details.

❏ OV450W-208SGLPT: 208V Single point power kit for up to 4 OV450W decks.

❏ OV450W-480SGLPT: 480V Single point power kit for up to 4 OV450W decks.

Item#

C.S.I. Section 11400

OV450W

Wide Deck Oven – Electric

Image shows 3 OV450 W ovens on a stand base.

Each oven and base are sold separately.

Area Reserved For Consultant & Contractor Approvals

BX56070 (03-15) – Printed In USA

19220 State Route 162 East

Orting, WA 98360

www.baxterbakery.com

Factory

(360) 893-5554

Customer Care

(800) 777-2828

or

(800) 333-7447

Customer Care Fax

(937) 332-2852

Page 1 of 2

Page 2

C.S.I. Section 11400

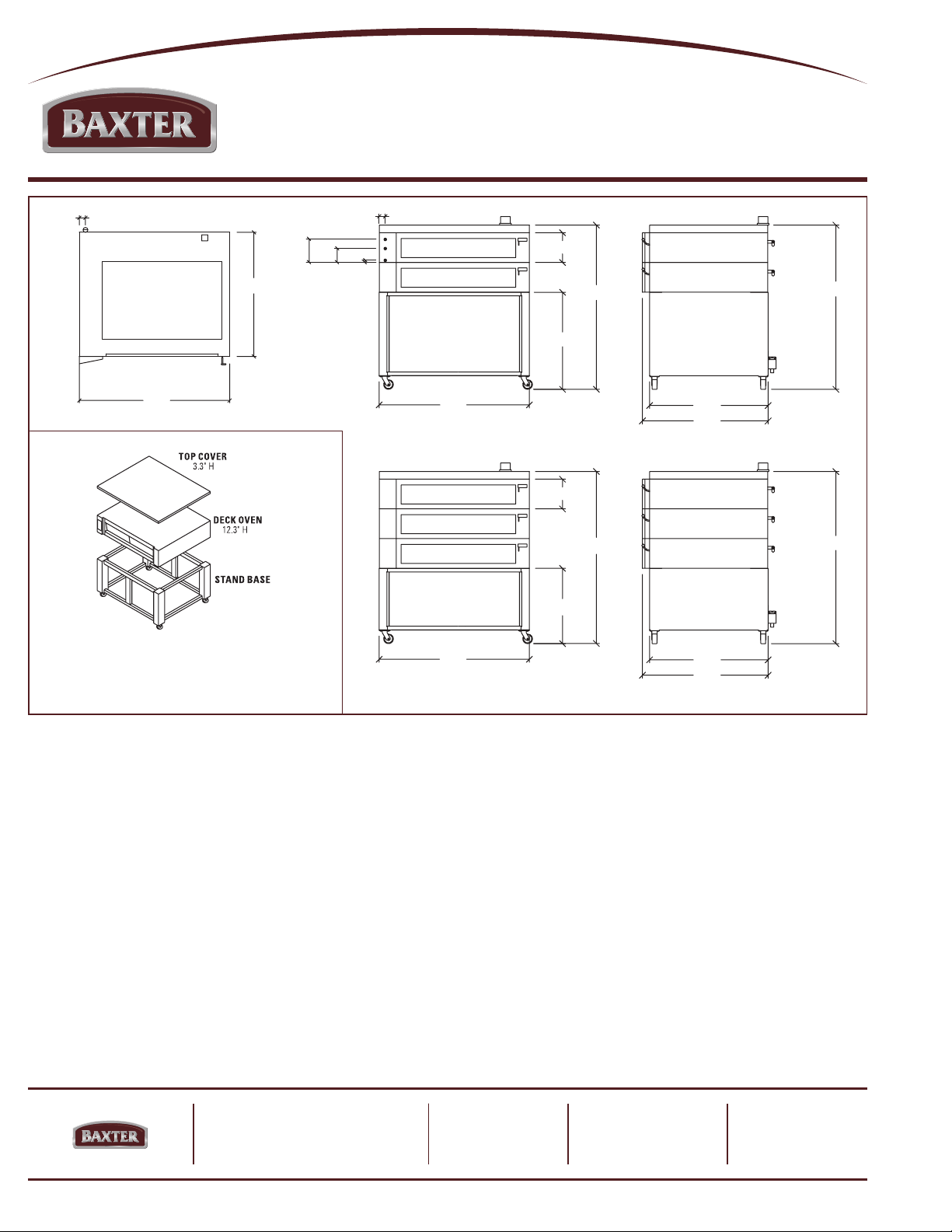

61.8"

2.50"

"

52.0"

71.1"

67.8"

2.50"

Power

OV450W

Wide Deck Oven – Electric

9.5"

STONE SURFACE

47.2"W x 34.1"D

52.0

Note: Exact overall height and utility connection locations

will vary per your oven configuration. To determine exact

dimensions, add together the applicable dimensions above.

Typical 2 oven and 3 oven examples are shown to the right.

5.75"

Water

.75"

Drain

Door Opening: 7"H

61.8"

61.8"

12.3"

67.8"

40.0"

49.0"

52.0"

2 OV450W CONFIGURATION

12.3"

71.1"

31.0"

49.0"

3 OV450W CONFIGURATION

UTILITIES

➊ Water Connect Point – 1 supply required per deck: 3⁄8" NPT. Cold water

@ 30-80 psi @ 0.5 GPM maximum flow rate. Max water usage 1.5 GPH per deck.

NOTE: Water supply must have the proper hardness, pH & chloride concentration.

Consult your local water company and/or water conditioner dealer before

installation.

• Recommended water hardness range: 2-4 grains per gallon

- TDS less than 60 ppm

- Un-dissolved solids less than 5 ppm

• Recommended range for silica: 0 - 13 ppm

• Recommended pH range: 7.0 - 8.0

• Acceptable range for alkalinity: 0 - 20 ppm

• Acceptable range for total chlorides: 0 - 30 ppm

- 0 ppm acceptable for chlorine & chloramine

➋ Drain Fitting: Drain tubing supplied f rom each deck to the single 3⁄4" NPT rear drain

connection on the stand base. Exact drain height varies with oven configuration.

Route to air-gap drain.

➌ Power – 1 supply required per deck:

• 208V/60/3 22.5 amps, 30 amp breaker

• 480V/60/3 9.4 amps

➍ Steam Vent: 3"D exhaust to hood. Customer to supply hood, duct and ventilator fan

per local code. 500cfm when steaming.

19220 State Route 162 East

Orting, WA 98360

www.baxterbakery.com

INSTALLATION

Floor should be level within 1⁄8" per foot for proper installation. Slope should not exceed

3

⁄4" in all directions under the unit.

The purchaser is responsible for all installation costs and for providing: Disposal

of pack ing materials; labor to unloa d oven upon arrival; inst allation mechanic s; and all local

service connections including electricity, vents, water and drain per local code. A factory

technician or factory authorized installation technician must supervise and approve any

installation. In order to validate the warranty, start-up must be per formed by an authorized

service company. All services must comply with federal, state and local codes.

Minimum clearances to combustible construction:

• 1 inch from sides

• 3 inches from back

• 6 inches from top

Factory

(360) 893-5554

Manuf acturer r eserves t he right to mak e changes in siz es and speci fications.

Customer Care

(800) 777-2828

or

Customer Care Fax

(937) 332-2852

(800) 333-7447

Page 2 of 2

BX56070 (03-15) – Printed In USA

Loading...

Loading...