Page 1

DECK OVENS

Operator & Installation

Manual

OV401N

OV400N

OV401W

OV400W

Model Number: ___________

Serial Number: ___________

Date of Installation: ___________

Baxter Mfg, a Division of ITW FEG, LLC • 19220 State Route 162 East • Orting, WA 98360-9236

Phone: (360) 893-5554 • Fax: (360) 893-1337

www.baxterbakery.com

FORM 36718 (July 2010)

Page 2

TABLE OF CONTENTS

GENERAL ............................................................................................................................................. 3

INSTALLATION ..................................................................................................................................... 4

Unpacking ........................................................................................................................................ 4

Installation Codes and Standards .................................................................................................... 4

Location ........................................................................................................................................... 4

Water Requirements ........................................................................................................................ 4

Plumbing Connections ..................................................................................................................... 5

Drain Connections ........................................................................................................................... 5

Electrical Connections ..................................................................................................................... 5

Vent Hood ........................................................................................................................................ 5

Before First Use ............................................................................................................................... 6

Dimensions Diagram ....................................................................................................................... 7

OPERATION .......................................................................................................................................... 8

Door Opening and Closing .............................................................................................................. 8

CLEANING ............................................................................................................................................ 9

Daily Cleaning ................................................................................................................................. 9

Weekly Cleaning ............................................................................................................................ 10

MAINTENANCE .................................................................................................................................. 13

Baking Chamber Lamp Replacement ............................................................................................ 13

Steam Generator ........................................................................................................................... 13

Service and Parts Information ....................................................................................................... 13

TROUBLESHOOTING ........................................................................................................................ 14

©BAXTER MFG, 2010

– 2 –

Page 3

INSTALLATION, OPERATION AND CARE OF

OV400 & OV401 SERIES DECK OVENS

SAVE THESE INSTRUCTIONS

GENERAL

The OV400 & OV401 Series Deck Ovens (Fig. 1) are designed and suited for your baking needs. The

deck ovens are available in four sizes, with up to four individual decks. They are produced with quality

workmanship and material. Proper installation, usage and maintenance of the ovens will result in years

of satisfactory performance.

It is suggested that you thoroughly read this manual and carefully follow the instructions provided.

Fig. 1

– 3 –

Page 4

INSTALLATION

The OV400 & OV401 Series Deck Ovens require some assembly and must be installed by authorized

Bakery Systems trained service technicians.

UNPACKING

This oven was inspected before leaving the factory. The transportation company assumes full responsibility

for safe delivery upon acceptance of the shipment. Immediately after unpacking, check for possible shipping

damage. If the oven is found to be damaged, save the packaging material and contact the carrier within

15 days of delivery.

Carefully unpack the oven and place in a work-accessible area as near to its fi nal installed position as

possible. Verify all packaging material has been removed from the interior of each deck. Remove protective

covering from exterior surfaces prior to placing oven in its fi nal location.

Prior to installation, verify that the electrical and the water service agrees with the specifi cations on the

oven data plate and in this manual.

INSTALLATION CODES AND STANDARDS

In the United States, the Deck Oven must be installed in accordance with:

1. State and local codes.

2. National Electrical Code (ANSI/NFPA No.70, latest edition) available from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269.

In Canada, the Deck Oven must be installed in accordance with:

1. Local codes.

2. Canadian Electrical Code (CSA C22.2 No.3, latest edition) available from the Canadian Standards

Association, 5060 Spectrum Way, Mississauga, Ontario, Canada L4W 5N6.

LOCATION

Allow space for operating the oven. The oven requires approximately 6

the vent piping. Do not obstruct the ventilation ports on the sides or back of the oven. To prevent heat

accumulation, 1" clearance is required from any wall. The oven must be installed on an approved stand.

Minimum clearance of 42" must be provided in front of the oven so the oven can be pulled forward for

servicing.

WATER REQUIREMENTS

As with all steam related products, water fi ltration and regular fi lter replacements, coupled with

routine deliming, are required. Your local Service offi ce can recommend a water treatment system to meet

the needs of your local water conditions. Contact your local Service representative for water treatment

offerings.

1

/2" from the back of the oven for

Proper water quality can improve the taste of the food prepared in the oven, reduce liming and extend

equipment life. Local water conditions vary from one location to another. The recommended proper water

treatment for effective and effi cient use of this equipment will also vary depending on the local water conditions.

Ask your municipal water supplier for details about your local water supply prior to installation.

– 4 –

Page 5

WATER REQUIREMENTS (CONT.)

Recommended water hardness is 2.0 to 6.0 grains of hardness per gallon with pH from 7.0 to 8.0. Chlorides

must not exceed 30 parts per million. Water hardness above 6.0 grains per gallon should be treated by

a water conditioner (water softener and/or in-line water treatment). Water hardness below 4.0 grains per

gallon may also require a water treatment system to reduce potential corrosion. Water treatment has

been shown to reduce costs associated with machine cleaning, reduce deliming and reduce corrosion of

metallic surfaces.

PLUMBING CONNECTIONS

Water and waste piping and connections shall comply with the International Plumbing Code 2003,

International Code Council (ICC), or to the Uniform Plumbing Code 2003, International Association of

Plumbing and Mechanical Offi cials (IAPMO).

Plumbing connections must comply with applicable sanitary, safety and plumbing

codes and provide adequate backfl ow protection to comply with applicable federal, state and local

codes.

Connect the cold water supply to the

3

/8" NPT connection located at the rear of the oven. Water supply should

have a pressure of 20 to 80 psi. The oven is supplied with a fl ow regulator which must be installed.

DRAIN CONNECTIONS

In order to avoid any back pressure in the oven, do not connect solidly to any drain. Drain

connections from each deck to the collector box must be high temperature hose.

Connect the

1

/2" drain connection from each deck to the collector box on the deck oven stand. A condensate

drain line must also be run from the lower vent elbow to the collector box. Route the drain line from the

collector box to a fl oor drain. An air gap is provided by the collector box. No air gap required at fl oor

drain.

ELECTRICAL CONNECTIONS

NOTE: The oven must be installed with the provided lanyard securely attached to the stand and to the

wall. Verify that all connections are long enough so that the oven can be pulled forward to the extent of

the lanyard without straining any connections.

Electrical and grounding connections must comply with the applicable portions of

the National Electrical Code and/or other local electrical codes.

Disconnect the electrical power to the unit and follow lockout / tagout

procedures.

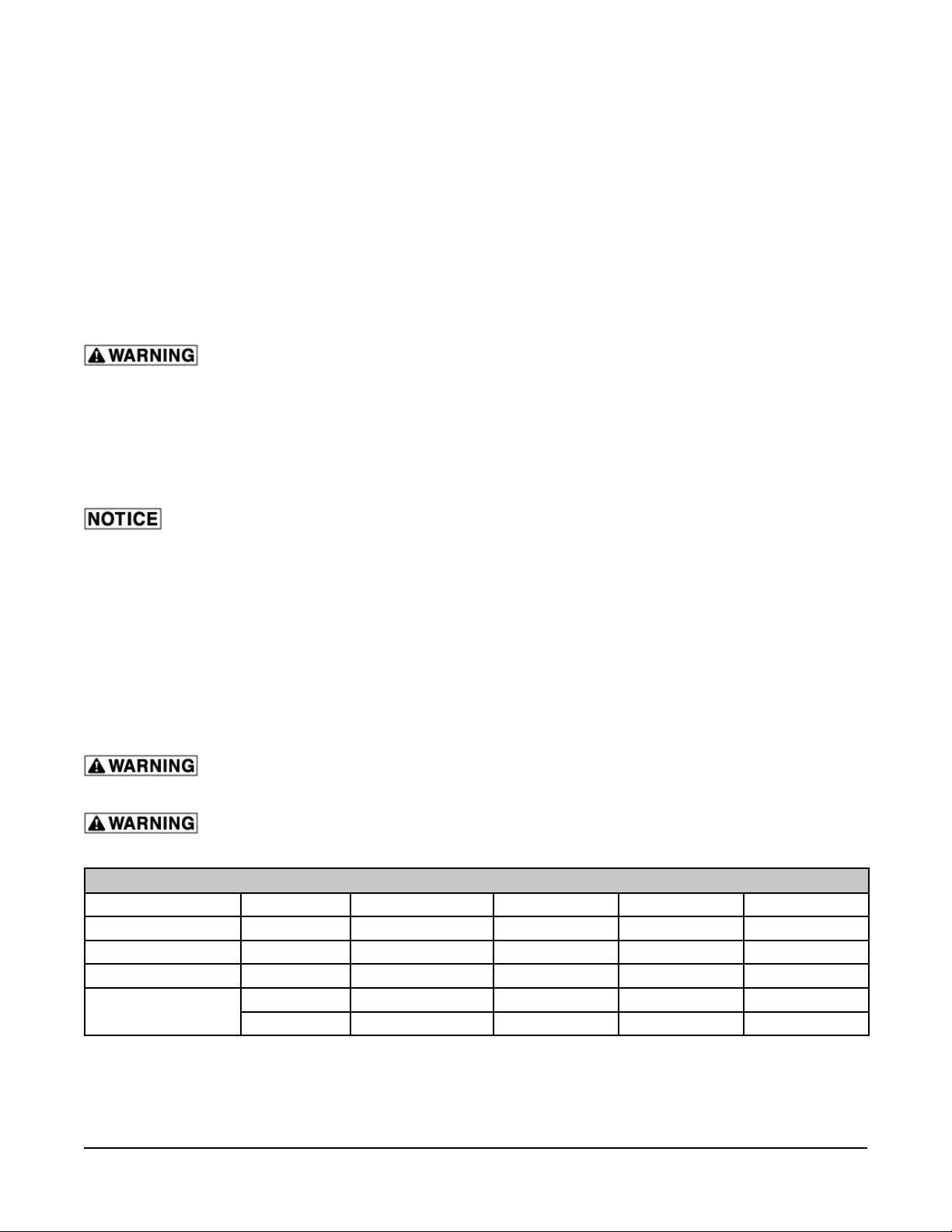

ELECTRICAL DATA (Per Deck)

Model Voltage Total Heater kW Line L1 Line L2 Line L3

OV401N 208-240 4.1 - 5.5 11.6 - 13.4 10.9 - 12.6 11.6 - 13.4

OV400N 208-240 5.6 - 7.4 14.7 - 17.0 17.0 - 19.6 14.7 - 17.0

OV401W 208-240 6.9 - 9.2 19.1 - 22.0 19.1 - 22.0 19.1 - 22.0

OV400W

208 10.7 28.1 32.5 28.1

208-240 9.2 - 12.2 24.0 - 27.7 28.6 - 33.0 24.0 - 27.7

VENT HOOD

Some local codes may require the oven to be located under an exhaust hood. Information on the construction

and installation of ventilating hoods may be obtained from Vapor Removal from Cooking Equipment, NFPA

Standard No. 96 (latest edition).

– 5 –

Page 6

BEFORE FIRST USE

Before using the oven for the fi rst time, when new stones are installed, or if the stones have been cleaned

with water, the baking stones need to be slowly "baked in" prior to start-up. Use the following chart as a

guide for the fi rst start-up to properly season the baking stones.

FOR PANERA CONTROLS

Parameter Step 1 Step 2 Step 3 Step 4 Step 5

Heat

Top Setting 99 99 99 99 99

Bottom Setting

Baking Time 30 Minutes 30 Minutes 30 Minutes 30 Minutes 30 Minutes

Steam None None None None None

Steam Vent Open Open Open Open Open

Parameter Step 1 Step 2 Step 3 Step 4 Step 5

Top Heat

Bottom Heat

Baking Time 30 Minutes 30 Minutes 30 Minutes 30 Minutes 30 Minutes

Steam None None None None None

Steam Vent Open Open Open Open Open

150°F 250°F 350°F 450°F 550°F

99 99 99 99 99

FOR SDC CONTROLS

150°F 250°F 350°F 450°F 550°F

150°F 250°F 350°F 450°F 550°F

– 6 –

Page 7

DIMENSIONS DIAGRAM

10 3/4"

Nominal

"C"

3 1/2" O.D.

7 7/8"

1 3/4"

14""D"

40" For 1 or 2 Decks

31" For 3 Decks

18" For 4 Decks

2 1/2"

Stand Height

"B"

"A"

"E"

Model A B C D E

OV401N

OV400N 51

OV401W

OV400W 51

1

35

/4" 411/2" 365/8" 263/4"

1

57

/4" 365/8" 263/4"

1

35

/4" 411/2" 601/4" 483/8"

1

57

/4" 601/4" 483/8"

22

38

22

38

– 7 –

Page 8

OPERATION

The oven and its parts are hot. Use care when operating, cleaning or servicing the

oven. The baking compartment contains live steam. Stay clear when opening door.

DOOR OPENING AND CLOSING

To open the door (Fig. 2), pull down on the door

handle slightly to allow steam to escape.

After steam escapes, continue pulling down on the

door handle until the door is fully open.

To close the door (Fig. 2), lift the door with the door

handle until the door closes.

Fig. 2

– 8 –

Page 9

CLEANING

Disconnect the electrical power to the machine and follow lockout / tagout

procedures.

The oven and its parts are hot. Use care when operating, servicing or cleaning the

oven.

DAILY CLEANING

• Always allow the oven to cool before cleaning. Never attempt to cool the oven down with cold

water. Sudden temperature changes could damage the glass or baking stones.

• Use care when cleaning around sensitive interior parts, such as probes and sensors.

• Sweep loose particles off the baking stones. Gently scrape off any hardened material on baking

stone.

• Using a clean cloth moistened in warm, soapy water, wash the interior of the oven cavity. Rinse

with rag moistened with clean water and dry with a clean cloth.

• Clean the door gasket with a soft, clean, damp cloth. This will ensure a long life for the gasket.

• Clean the outside daily with a clean, damp cloth.

• Do not use cleaners containing grit, abrasive materials, bleach, harsh chemicals or chlorinated

cleaners. Do not use steel wool on stainless steel surfaces. Never spray down the oven with water,

steam or power wash.

• Be cautious with new or improved cleaning formulas; use only after being well tested in an

inconspicuous place.

– 9 –

Page 10

WEEKLY CLEANING

Baking Chamber Glass

(OV400N & OV401N Only)

Allow the glass to cool before

cleaning. Cleaning while hot may cause the glass

to shatter.

NOTE: Make sure the glass does not fall when

removing the attaching hardware. Do not use any

scouring or sharp objects to clean the glass.

1. Remove two knurled screws and four washers

from the top glass panel (Fig. 3). Note the

position of the washers.

2. Position the top glass diagonally (Fig. 4) to

remove it from the oven cavity.

3. Clean the glass with a clean cloth moistened

in warm, soapy water. Rinse with clean water

and dry with a clean cloth. Glass cleaners may

also be used.

4. Replace the top glass panel in the oven cavity

with four washers and two knurled screws.

GLASS PANEL

Fig. 3

NOTE: Make sure the washers are in the correct

order. Hand tighten the screws.

Fig. 4

– 10 –

Page 11

Split Glass (OV400W & OV401W Only)

Allow the glass to cool before cleaning. Cleaning while hot may cause the glass to

shatter.

1. With the door glass in the closed position, slide handle (Fig. 5) down off of pawl and open left door

glass.

Fig. 5

2. Clean inside of right door glass (Fig. 6).

3. Close left door glass and slide back handle to engage pawl (Fig. 7).

4. Pull down on handle and open both door glasses (Fig. 7).

Fig. 7

Fig. 6

– 11 –

Page 12

5. Pull back on detent and twist 90 degrees to insert pin into door lever (Fig. 8).

6. Slide handle back to release pawl and close left door glass (Fig. 8).

Fig. 8

7. Clean inside of left door glass (Fig. 9).

Fig. 9

8. Pull handle and open left door glass, then slide back handle and insert pawl (Fig. 10).

9. Pull back on detent and twist 90 degrees to retracted position (Fig. 10).

10. Door is ready for normal operation.

Fig. 10

– 12 –

Page 13

MAINTENANCE

Disconnect the electrical power to the machine and follow lockout / tagout

procedures.

BAKING CHAMBER LAMP REPLACEMENT

NOTE: Do not touch the replacement bulb with your fi ngers. Touching the replacement bulb will shorten

bulb life. Wear gloves when replacing halogen lamps.

1. On the left side of the oven, loosen thumb screw (Fig. 11) and remove lamp cover.

2. Remove thumb screw and lamp holder (Fig. 11) from the oven.

3. Replace with approved 24V, 50W halogen lamp (Fig. 11).

LAMP COVER LAMP HOLDER LAMP

Fig. 11

STEAM GENERATOR

The steam generator in each deck should be de-scaled by an authorized servicer on an annual basis.

Depending on the hardness of the water and the amount of use of the steam generators, more frequent

de-scaling may be required.

SERVICE AND PARTS INFORMATION

Contact your authorized service offi ce for any repairs or adjustments needed on this equipment.

– 13 –

Page 14

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Water is in the

baking chamber

No steaming

no steam

Oven is not

heating up

Chamber not

venting

Oven cannot be

turned on

1. Too much steam (time/quantity)

2. Drain hose obstructed

3. Solenoid valve defective

4. Flow regulator defective

1. Steam ready LED not on

2. Water supply not opened

3. Hose kinked/clamped

4. Solenoid valve defective

5. Hose connection defective

6. Steam pipe or connections scaled

7. Steam button defective

8. Steam elements defective

1. No power to oven

2. Temperature not set

3. High limit tripped

4. Defective heating element(s)

5. Temperature sensor defective

1. Defective linkage to vent

2. Vent obstructed

1. No power to oven

2. Internal fuse FT1 or FT2 defective

3. Defective keyswitch

4. Defective control board

1. Check procedures.

2. Check drain connection.

3. Contact your authorized service offi ce.

4. Contact your authorized service offi ce.

1. Wait for oven to recover.

2. Check water supply.

3. Check hose.

4. Contact your authorized service offi ce.

5. Contact your authorized service offi ce.

6. Contact your authorized service offi ce.

7. Contact your authorized service offi ce.

8. Contact your authorized service offi ce.

1. Check power supply.

2. Check temperature setting.

3. Contact your authorized service offi ce.

4. Contact your authorized service offi ce.

5. Contact your authorized service offi ce.

1. Contact your authorized service offi ce.

2. Contact your authorized service offi ce.

1. Check power supply.

2. Contact your authorized service offi ce.

3. Contact your authorized service offi ce.

4. Contact your authorized service offi ce.

– 14 –

Page 15

NOTES

– 15 –

Page 16

NOTES

FORM 36718 (July 2010) PRINTED IN U.S.A.

– 16 –

Loading...

Loading...