Page 1

Operator & Installation

Manual

MB100 PROOFER/HOLDING CABINET

MB300 PROOFER

Model Number: ___________

Serial Number: ___________

Date of Installation: ___________

Baxter Mfg, a Division of ITW FEG, LLC • 19220 State Route 162 East • Orting, WA 98360-9236

Phone: (360) 893-5554 • Fax: (360) 893-1337

www.baxterbakery.com

FORM 36750 Rev. B (September 2012)

Page 2

TABLE OF CONTENTS

GENERAL ............................................................................................................................................. 3

INSTALLATION ..................................................................................................................................... 3

Assembly ......................................................................................................................................... 3

Unpacking ........................................................................................................................................ 3

Plumbing Connections ..................................................................................................................... 4

Drain Connections ........................................................................................................................... 4

Electrical Connections ..................................................................................................................... 4

Dimensions and Service Connection Diagram ................................................................................ 5

OPERATION .......................................................................................................................................... 6

Proofi ng ........................................................................................................................................... 6

Temperature .................................................................................................................................... 7

Humidity ........................................................................................................................................... 8

Setting the Timer ............................................................................................................................. 9

Starting/Adjusting the Timer ............................................................................................................ 9

Canceling/Stopping the Timer ......................................................................................................... 9

Proofi ng Instructions ...................................................................................................................... 10

Holding Instructions (MB100 Only) ................................................................................................ 10

Shutdown Procedures ................................................................................................................... 10

CLEANING ...........................................................................................................................................11

MAINTENANCE .................................................................................................................................. 12

Service and Parts Information ....................................................................................................... 12

TROUBLESHOOTING ........................................................................................................................ 13

PARAMETER SET-UP MODE ............................................................................................................. 14

©BAXTER MFG, 2012

– 2 –

Page 3

OPERATION AND CARE OF

MB100/MB300 PROOFER

SAVE THESE INSTRUCTIONS

GENERAL

The MB100/MB300 Proofer cabinet proofs racks of dough product under controlled temperatures and

humidity prior to baking. The MB300 Proofer has a 16-pan capacity that accommodates 18" x 26" (45.7

cm x 66 cm) baking trays with 3" (7.6 cm) slide spacing. The MB100 holds 8 pans and can be used as

a holding cabinet. Temperature and humidity can be set independently to meet your particular proofi ng

needs. Air is circulated continuously to provide positive movement from bottom to top, creating a uniform

distribution of warm, moist air.

All MB100/MB300 Proofers have easy-to-clean stainless steel interior and exterior panels with urethane

foam insulation.

The MB100/MB300 Proofers are produced with quality workmanship and material. Proper installation,

usage and maintenance of the proofer will result in years of satisfactory performance.

It is suggested that you thoroughly read this manual and carefully follow the instructions provided.

INSTALLATION

The MB100/MB300 Proofer must be installed by authorized Bakery Systems trained service technicians.

ASSEMBLY

The proofer comes pre-assembled, but requires qualifi ed personnel to install and make connections. The

proofer must be installed with restraining means to guard against transmission of strain to the connector, as

specifi ed by the manufacturer. Adequate means must be provided to limit the movement of the appliance.

UNPACKING

This proofer was inspected before leaving the factory. The transportation company assumes full responsibility

for safe delivery upon acceptance of the shipment. Immediately after unpacking, check for possible shipping

damage. If the proofer is found to be damaged, save the packaging material and contact the carrier within

15 days of delivery.

Carefully unpack the proofer and place in a work-accessible area as near to its fi nal installed position as

possible. Remove protective covering from exterior surfaces prior to placing proofer in fi nal location.

– 3 –

Page 4

PLUMBING CONNECTIONS

Water and waste piping and connections shall comply with the International Plumbing Code 2003,

International Code Council (ICC), or to the Uniform Plumbing Code 2003, International Association of

Plumbing and Mechanical Offi cials (IAPMO).

Plumbing connections must comply with applicable sanitary, safety and plumbing

codes and provide adequate backfl ow protection to comply with applicable federal, state and local

codes.

The proofer should have its own water supply line, separate from the oven.

The proofer water supply should have a hardness of 4 to 6 grains per gallon, pH of 6.5 to 8.0 and chlorides

less than 30 PPM. Water condition outside of these requirements may void the warranty. Please consult

your local water company and/or water condition dealer before installing proofer.

1

Connect the cold water supply to the

/4" NPT incoming water connection located at the rear of the proofer.

Water supply should have a pressure of 30 to 75 psi.

DRAIN CONNECTIONS

1

Connect a

/2" drain line to the 1/2" NPT drain connection on the MB300 (3/8" NPT drain connection on the

MB100) located at the rear of the proofer. Route the drain line to a fl oor drain, allowing a minimum 1" air

gap between the drain line outlet and fl oor drain.

ELECTRICAL CONNECTIONS

Electrical and grounding connections must comply with the applicable portions of

the national electrical code and/or other local electrical codes.

Disconnect the electrical power to the unit and follow lockout / tagout procedures.

Appliances equipped with a fl exible electric supply cord are provided with a

three-prong grounding plug. This plug must be connected into a properly grounded three-prong

receptacle. If the receptacle is not the proper grounding type, contact an electrician. Do not remove

the grounding prong from this plug.

– 4 –

Page 5

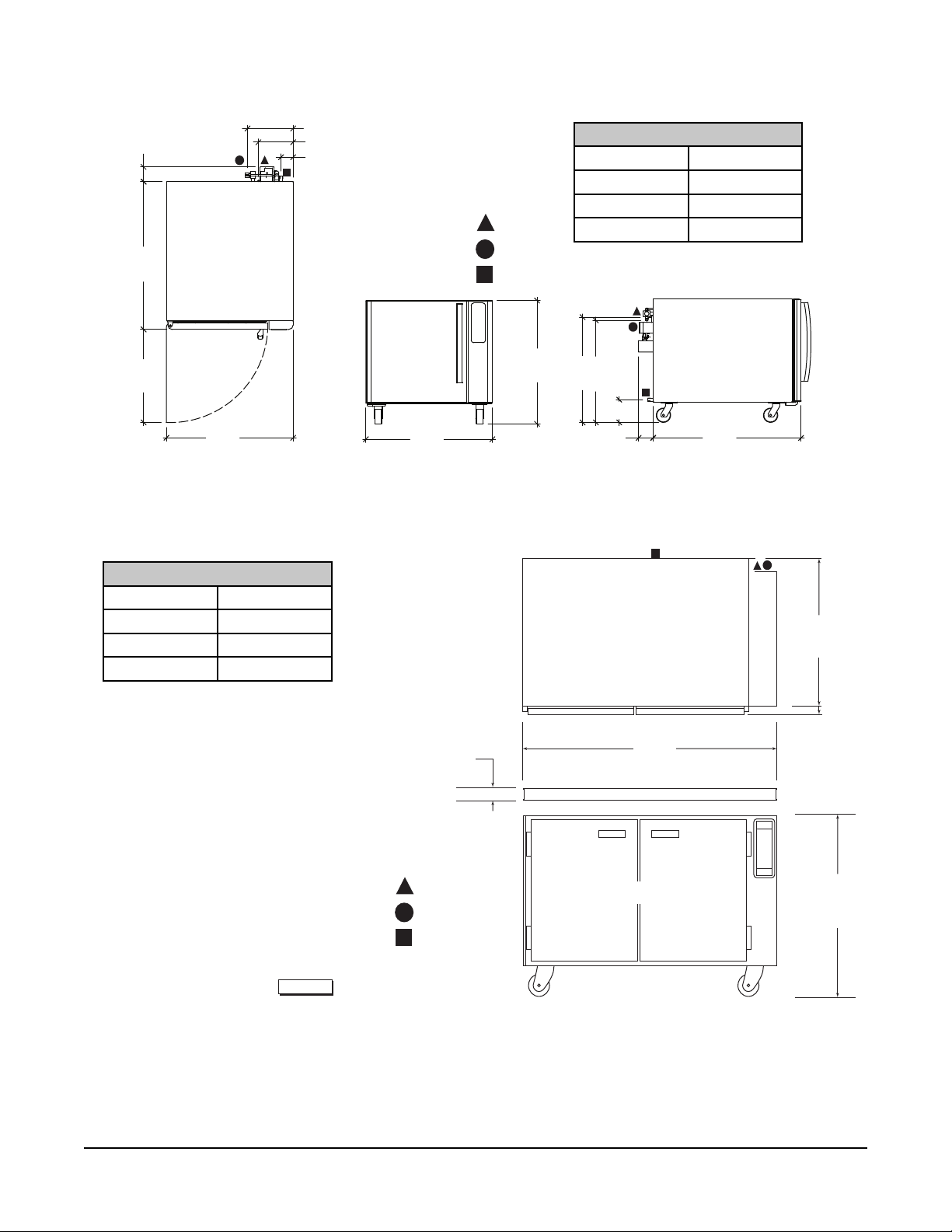

DIMENSIONS AND SERVICE CONNECTION DIAGRAM

4.0"

40.9"

25.7"

35.0"

Electrical Data

Volts 120

Hertz 60

Amps 13

Phase 1

12.6"

9.6"

3.3"

Service Connection Points

Power

Water

Proofer Drain

35.0"

MB100 Proofer/Holding Cabinet

Electrical Data

Volts 120

Hertz 60

Amps 15

Phase 1

Dedicated 20 A circuit breaker and

outlet required.

34.1"

29.1"

28.3"

6.3"

4.0"

40.9"

TOP VIEW

34.61"

(87.9 cm)

Dedicated 20 A circuit breaker and outlet required.

Spacer

Service Connection Points

Power

Water

Proofer Drain

PL-58303

MB300 Proofer

1.37"

(3.5 cm)

48.00"

(121.9 cm)

FRONT VIEW

1.75"

(4.4 cm)

33.00"

(83.8 cm)

– 5 –

Page 6

OPERATION

PROOFING

Controlled temperature and humidity in the proofer promotes yeast fermentation, which generates gas and

causes the dough to rise. Proofi ng takes from 45 to 60 minutes, depending on the product. A temperature

setting of 95°F (35°C) and humidity at 85% are typical but will vary slightly, depending on the product

being proofed. To dry-proof, set the humidity to the lowest setting.

CONTROLS

TEMPERATURE WINDOW - Displays the current or set

temperature. The LED dot will be lit when the heat cycle is

running. The maximum setting is 115°F (46°C).

HUMIDITY WINDOW - Displays the current or set humidity.

The LED dot will be lit when water is being injected into the

proofer cavity.

TIMER WINDOW - Displays the current or set timer. The LED

dot will fl ash to indicate the timer is running.

TIMERS ARROW BUTTON - Press to select a timer (1, 2 or

3). The indicator above the number will be lit to show which

timer is in use.

TEMP BUTTON - Press to adjust or set the temperature.

When the button indicator is lit, the temperature displayed is

the set temperature. When the button indicator is not lit, the

temperature displayed is the current cavity temperature or

set temperature.

HUMIDITY BUTTON - Press to adjust or set the humidity.

When the button indicator is lit, the humidity displayed is the

set humidity. When the button indicator is not lit, the humidity

displayed is the current cavity humidity or set humidity.

TIMER START/STOP BUTTON - Press to select timer function

and to start/stop timer operation. The button indicator is lit

when timer function is entered.

UP or DOWN ARROW - Press to set the temperature, humidity

or timer.

POWER ON/OFF - Press to turn unit on/off.

Fig. 1

– 6 –

Page 7

TEMPERATURE

A

1. Press the POWER ON/OFF button to turn on the

proofer.

2. If the unit is set to display the actual temperature (Fig.

2), the button indicator LED will not be illuminated.

3. If the unit is set to display the set temperature

(Fig. 3), the button indicator LED will be illuminated.

Pressing and holding the TEMP button will display

the actual temperature.

ctual Temperature

Displayed

TEMP Button

LED Not

Illuminated

Fig. 2

Set Temperature

Displayed

TEMP Button

LED Illuminated

Fig. 3

Setting the Temperature

1. Press the TEMP button to adjust the set temperature. The button indicator LED will fl ash and the

set temperature will be displayed for 5 seconds.

2. Press the up or down arrow buttons to adjust the set point while the button indicator LED is

fl ashing.

NOTE: The temperature display will increment by 1° each time the arrow button is pressed. If you

hold down the arrow button for more than 1 second, the temperature display will increment by 5° until

released.

3. After pressing the arrow button, wait 5 seconds to allow the new temperature setting to save.

The indicator LED will stop fl ashing. The TEMP display reverts back to actual or set temperature

mode.

NOTE: If other setups (humidity or timers) are entered within the 5 seconds of idle time, the set temperature

will be saved.

– 7 –

Page 8

HUMIDITY

A

1. If the unit is set to display the actual humidity (Fig. 4),

the button indicator LED will not be illuminated.

2. If the unit is set to display the set humidity (Fig.

5), the button indicator LED will be illuminated.

Pressing and holding the HUM button will display

the actual relative humidity.

ctual

Humidity

Displayed

HUM Button

LED Not

Illuminated

Fig. 4

Set Humidity

Displayed

HUM

Button LED

Illuminated

Fig. 5

Setting the Humidity

1. Press the HUM button to adjust the set humidity. The button indicator LED will fl ash and the set

humidity will be displayed for 5 seconds.

2. Press the up or down arrow buttons to adjust the set point while the button indicator LED is

fl ashing.

NOTE: The humidity display will increment by 1% each time the arrow button is pressed. If you hold

down the arrow button for more than 1 second, the humidity display will increment by 5% until released.

3. After pressing the arrow button, wait 5 seconds to allow the new humidity setting to save. The

indicator LED will stop fl ashing and remain off. The humidity display reverts back to actual or set as

previously selected.

NOTE: If other setups (temperature or timers) are entered within the 5 seconds of idle time, the set

humidity will be saved.

– 8 –

Page 9

SETTING THE TIMER

NOTE: The timer display will initially show "00" in the display window.

1. Press the TIMER START/STOP button to select the timer function. The button indicator LED will

illuminate (Fig. 6) and the timer display will show the current setting.

NOTE: If the TEMP or HUM buttons are pressed while the timer is in setup mode, the timer function will

be canceled.

2. Press the arrow button next to the timers LED indicators to select a timer (1, 2 or 3). The timer display

will show the timer running if the LED dot on the display is on, or the last time set for that timer.

3. Press the up or down arrow buttons to adjust the timer setting. The timer display will show 0 to 60

minutes.

4. Press the TIMER START/STOP button or the arrow button next to the timers LED indicators to save

the set time.

NOTE: The timer setting will also save if no button is pressed for 3 seconds.

STARTING/ADJUSTING THE TIMER

1. After setting the timer, press the TIMER START/STOP

button to start the timer operation. The LED dot on

the timer display will fl ash to indicate the timer is

operating.

2. Press the up or down arrow buttons to adjust the timer

Actual Timer

Displayed

(LED dot flashing)

setting while the timer is in countdown mode.

Timer 1 Selected

NOTE: The timer will pause if the TIMER START/STOP

button is pressed while the timer is running.

3. Press the TIMER START/STOP button to resume timer

running.

TIMER

START/STOP

Button LED

Illuminated

CANCELING/STOPPING THE TIMER

1. Press and hold the down arrow until the timer display

reaches "00". This initiates a stop timer.

NOTE: When the timer completes the time cycle, the buzzer

pulses a short beep and the timer display fl ashes "00".

Fig. 6

2. Press the TIMER START/STOP button to silence the

timer.

NOTE: The temperature or humidity can be changed while the timer is running. See Setting the Temperature

or Setting the Humidity.

– 9 –

Page 10

PROOFING INSTRUCTIONS

1. Press POWER ON/OFF button (Fig. 7). All displays are

now illuminated.

2. Set temperature (as required).

3. Set humidity (as required)

NOTE: Unit will only add humidity 10 minutes after unit has

been turned on. Avoid shutting unit off if used through out

the day. Maximum humidity setting is 95%.

4. Allow cold unit to heat up and balance humidity for 1520 minutes before putting any product in the proofer.

5. Load product using standard 18" x 26" (45.7 cm x 66

cm) pans. Only load as much product as needed for

one oven bake.

6. Set and start timer (as required). (Additional product

may be added to proofer after allowing a lag time of

the typical bake cycle from start of previous batch.)

7. If timer is used, a buzzer will sound and the control

panel will fl ash to indicate the timer has reached "00".

8. Push TIMER START/STOP to silence alarm.

9. Remove product and prepare for oven bake.

HOLDING INSTRUCTIONS (MB100 ONLY)

1. Press POWER ON/OFF button (Fig. 7). All displays are

now illuminated.

2. Set temperature (as required). If Holding is desired,

hold the UP arrow for 5 seconds after it reaches 105

°F and the temperature will jump to 150°F.

Fig. 7

3. Set humidity (as required). The unit will start adding after the fi rst 10 minutes the unit is on. Maximum

humidity setting is 35%.

4. Load product using standard 18" x 26" (45.7 cm x 66 cm) pans.

5. Set and start timer (as required). (Additional product may be added to holding cabinet after allowing

a lag time of the typical bake cycle from start of previous batch.)

6. If timer is used, a buzzer will sound and the control panel will fl ash to indicate the timer has reached

"00".

7. Push TIMER START/STOP to silence alarm.

SHUTDOWN PROCEDURES

1. Remove all product.

2. Press POWER ON/OFF. All displays will not be illuminated.

3. The fan will continue to run for 15-20 minutes after power off. Crack doors during this time frame to

help dry out proofer for MB300.

4. After fan shuts down, the proofer may be cleaned. See Cleaning.

– 10 –

Page 11

CLEANING

1. Using a clean cloth moistened in warm, soapy water, wash the stainless steel interior of the cabinet.

Rinse with clean water and dry with a clean cloth.

2. Clean the outside daily with a clean, damp cloth.

3. Use care when cleaning around sensitive interior parts, such as probes and sensors.

4. Do not use cleaners containing grit, abrasive materials, bleach, harsh chemicals or chlorinated

cleaners. Do not use steel wool on stainless steel surfaces. Never spray down the proofer with water,

steam or power wash.

5. Be cautious with new or improved cleaning formulas; use only after being well tested in an inconspicuous

place.

– 11 –

Page 12

MAINTENANCE

Disconnect the electrical power to the machine and follow lockout / tagout procedures.

SERVICE AND PARTS INFORMATION

Contact your authorized service offi ce for any repairs or adjustments needed on this equipment.

– 12 –

Page 13

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Controller does not turn on after POWER ON/OFF button is

pressed.

Temperature display fl ashes "00". Sensor problem. Contact your authorized service offi ce.

Temperature display fl ashes "Err". Sensor problem. Contact your authorized service offi ce.

Temperature display fl ashes

"OUtP".

Keypad does not respond. Membrane problem. Contact your authorized service offi ce.

Buzzer does not sound when timer

is zero.

Unit will not go to Holding temperature.

1. Unit not plugged in.

2. Control panel fuse blown.

Sensor problem. Contact your authorized service offi ce.

Buzzer problem. Contact your authorized service offi ce.

Unit not set for Holding mode. Check parameter P9 and P14 or contact

1. Check power cord at outlet.

2. Contact your authorized service offi ce.

your authorized service offi ce.

– 13 –

Page 14

PARAMETER SET-UP MODE

FOR SERVICE ONLY

To enter the set-up mode and change parameter setting, the oven should be in the “OFF” mode.

To enable the set-up mode, do the following:

1. Press and hold the “Timer Start/Stop” button and then the power “ON/OFF” button for 5 sec

2. The 2 digit LED humidity window will initially display software version for 2 sec and then displays

the Parameter “P”

3. The 2 digit LED timer window will display parameter number.

4. The 4 digit LED temperature window will display the value.

5. To review the next or previous parameter setting, press either Up or Down arrow button

6. To change the setting of the selected parameter, press the “Timer Start/stop” button then press Up

or Down arrow button to change the value.

7. To save the current setting and selecting another parameter, press the “Timer Start/Stop” button

again

8. To exit the Set-Up Mode, press the “Power ON/OFF” button once.

The PARAMETER NUMBER is displayed in the 4 digit LED temperature display and the values are

displayed in the 3 digit LED timer display.

Each of these values has a PARAMETER NUMBER as follows:

SETUP

NUMBER

P1 Degree Setting This value changes the temperature unit on the

P2 Temperature Offset This number permits an offset, or correction,

P3 Humidity Offset This number permits an offset, or correction,

P4 Minimum Temperature

P5 Maximum Temperature

P6 Minimum Humidity

SETUP ITEM DESCRIPTION DISPLAY

display.

between the temperature read by the probe and

the real proofi ng chamber temperature.

between the humidity read by the probe and the

real proofi ng chamber humidity.

This value acts as a minimum limit for

(Proofi ng Mode)

(Proofi ng Mode)

(Proofi ng Mode)

temperature set point, and the unit will not allow

the operator to set the temperature lower than

this.

This value acts as a maximum limit for

temperature set point, and the unit will not allow

the operator to set the temperature higher than

this.

This value acts as a minimum limit for humidity

set point, and the unit will not allow the operator

to set the humidity lower than this.

F: Fahrenheit (Default)

C: Celsius

Range is +15 to -15°F/C

Default is 0

Range is +15 to -15°F/C

Default is 0

Range is 65 to 115°F

(18 to 46°C)

Default is 65°F (18°C)

Range is 100 to 105°F

(38 to 40°C)

Default is 105°F (40°C)

Range is 35 to 65%

Default is 35

– 14 –

Page 15

SETUP

NUMBER

P7 Maximum Humidity

P8 Temperature Display

P9

(MB100)

P9

(MB300)

P10

(MB100)

P11

(MB100)

P12

(MB100)

P13

(MB100)

P14 Mode Selection This value sets the unit as Proofer only or

SETUP ITEM DESCRIPTION DISPLAY

This value acts as a maximum limit for humidity

(Proofi ng Mode)

Mode

Sensor Mode This value changes the temperature limit on the

Sensor Mode This value changes the temperature limit on the

Minimum Temperature

(Holding Mode)

Maximum Temperature

(Holding Mode)

Minimum Humidity

(Holding Mode)

Maximum Humidity

(Holding Mode)

set point, and the unit will not allow the operator

to set the humidity higher than this.

This value sets what the type of temperature

reading it will display.

controller.

controller.

This value acts as a minimum limit for

temperature set point, and the unit will not allow

the operator to set the temperature lower than

this.

This value acts as a maximum limit for

temperature set point, and the unit will not allow

the operator to set the temperature higher than

this.

This value acts as a minimum limit for humidity

set point, and the unit will not allow the operator

to set the humidity lower than this.

This value acts as a maximum limit for humidity

set point, and the unit will not allow the operator

to set the humidity higher than this.

Proofer/Holder.

Range is 65 to 95%

Default is 90

Actual Mode or Set

Point Mode

Default is Actual

1735 Mode will limit the

controller up to 170°F

(Proof/Hold)

2500 Mode will limit the

controller up to 115°F.

(Proof Only)

Default is 2500

2500 Mode will limit the

controller up to 115°F.

(Proof Only)

Default is 2500

Range is 150 to 155°F

(60 to 66°C)

Default is 150°F (18°C)

Range is 155 to 170°F

(68 to 76°C)

Default is 170°F (76°C)

Range is 15 to 35%

Default is 15

Range is 35 to 50%

Default is 50

ProF = Proofer

Hold = Proofer/Holder MB100 Only

Default is ProF

– 15 –

Page 16

NOTES

FORM 36750 Rev. B (September 2012) PRINTED IN U.S.A.

– 16 –

Loading...

Loading...