Page 1

Ipump Pain Management System

SERVICE MANUAL

For use with Ipump devices with hardware revision 2 (HW Rev 2).

Page 2

Disclaimer

The information in this document has been carefully examined, and is believed to be entirely reliable. However,

no responsibility is assumed for inaccuracies. Furthermore, Baxter reserves the right to make changes to any

products herein to improve readability, function, or design. Baxter does not assume any liability arising out of

the applications or use of any product or circuit described herein; neither does it cover any license under its

patent rights nor the rights of others.

Documentation Copyrights

Duplication or distribution of this manual and any information contained within (except for the data sheets), is

strictly prohibited without the express written permission of Baxter. This manual and any information contained

within, may not be reproduced, distributed, or transmitted in any form, or by any means, for any purpose

without the express written permission of Baxter.

Computer Software Copyrights

Copyright 2006, Baxter Healthcare Corporation. All rights reserved.For use only by Baxter Healthcare

Corporation. The software contains proprietary information belonging to Baxter Healthcare Corporation. The

software must not be reproduced or disclosed to others without prior written approval. Any unauthorized use of

this information may subject the user to substantial liability.

Patent Information

This pump is protected under one or more U.S. and Foreign patents.

Trademark Information

Baxter and Ipump are trademarks of Baxter International Inc.

All other trademarks and product names appearing within this manual are the property of their respective

owners.

Copyright 1999 - 2007, Baxter Healthcare Corporation. All rights reserved.

Page 3

Chapter 1 - Introduction

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Pump Accessories - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Manual Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Factory Service & Assistance - - - - - - - - - - - - - - - - - - - - - 1-3

Technical Assistance, Service, & Repairs - - - - - - - - - - - - - - - 1-4

Safety Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Definitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Warnings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

Cautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

Notes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

Labeling Symbol Definitions - - - - - - - - - - - - - - - - - - - - - 1-6

Contents

Chapter 2 - Theory of Operation

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

System Components - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

MPU Circuit - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

BUS Subsystem - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

Keypad & Sensors - - - - - - - - - - - - - - - - - - - - - - - - 2-4

PROM - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

Supervisory Subsystem (SS) - - - - - - - - - - - - - - - - - - - 2-5

Power Subsystem (PS) - - - - - - - - - - - - - - - - - - - - - - 2-5

LCD Subsystem- - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

Silent Shutdown Circuit - - - - - - - - - - - - - - - - - - - - - - 2-6

Motor Subsystem - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

Occlusion Detection Circuit - - - - - - - - - - - - - - - - - - - - 2-7

Air Sensor Circuit - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

Printer Adapter Interface Circuit - - - - - - - - - - - - - - - - - - 2-7

07-19-A8-092 Ipump Pain Management System Service Manual i

Page 4

Contents

Chapter 3 - Care & Routine Maintenance

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Cleaning and Disinfecting - - - - - - - - - - - - - - - - - - - - - - - 3-1

Chapter 4 - Troubleshooting

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Reviewing the Alarm Log- - - - - - - - - - - - - - - - - - - - - - - - 4-1

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

System Error Codes - - - - - - - - - - - - - - - - - - - - - - - - - - 4-5

Range 10 - 2V -- Peripheral/Sensor Errors - - - - - - - - - - - - - 4-5

Range 30 - 47 -- Motor Control Errors - - - - - - - - - - - - - - - - 4-6

Range 50 - 52 -- RTC Errors - - - - - - - - - - - - - - - - - - - - 4-7

Range 60 - 62 -- Power Supply Errors- - - - - - - - - - - - - - - - 4-7

Range 70 - 74 & L0 -- MPU Errors - - - - - - - - - - - - - - - - - 4-7

Range 75 - 8D -- Processing Errors - - - - - - - - - - - - - - - - - 4-8

Range 90 - 9Z & M0 - P3 -- Data Corruption Errors - - - - - - - - - 4-8

Range A0 - J1 -- Processing Errors - - - - - - - - - - - - - - - - 4-10

Chapter 5 - Functional Tests

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

General Information - - - - - - - - - - - - - - - - - - - - - - - - 5-2

Equipment Required - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Optional Equipment - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Exterior Visual Inspection - - - - - - - - - - - - - - - - - - - - - - - 5-3

Configuration Settings - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

Flow Rate Accuracy Test- - - - - - - - - - - - - - - - - - - - - - - - 5-6

Test Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-7

Procedure Using the Gravimetric Method - - - - - - - - - - - - - - 5-7

Procedure Using the Volumetric Method - - - - - - - - - - - - - - 5-8

Downstream Occlusion Calibration Pressure Test - - - - - - - - - - - 5-8

Operational Checks - - - - - - - - - - - - - - - - - - - - - - - - - - 5-9

Test Set Up - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-9

Power-On Self Test (POST) - - - - - - - - - - - - - - - - - - - - 5-9

Keypad Operation Test - - - - - - - - - - - - - - - - - - - - - - 5-10

Bag Cover Lock/Unlock Test - - - - - - - - - - - - - - - - - - - 5-10

ii Ipump Pain Management System Service Manual 07-19-A8-092

Page 5

Tubing Sensor Test - - - - - - - - - - - - - - - - - - - - - - - - 5-10

Occlusion Sensor Test - Downstream - - - - - - - - - - - - - - - 5-11

Occlusion Sensor Test - Upstream - - - - - - - - - - - - - - - - 5-11

Air Sensor Test - - - - - - - - - - - - - - - - - - - - - - - - - - 5-12

PCA Cable & Button Test - - - - - - - - - - - - - - - - - - - - - 5-13

AC Adapter Test (Optional) - - - - - - - - - - - - - - - - - - - - 5-13

History Retention Test (Backup Battery Check) - - - - - - - - - - 5-14

Printer Test (Optional) - - - - - - - - - - - - - - - - - - - - - - - 5-14

Unintended Shutdown Circuit Test - - - - - - - - - - - - - - - - - 5-14

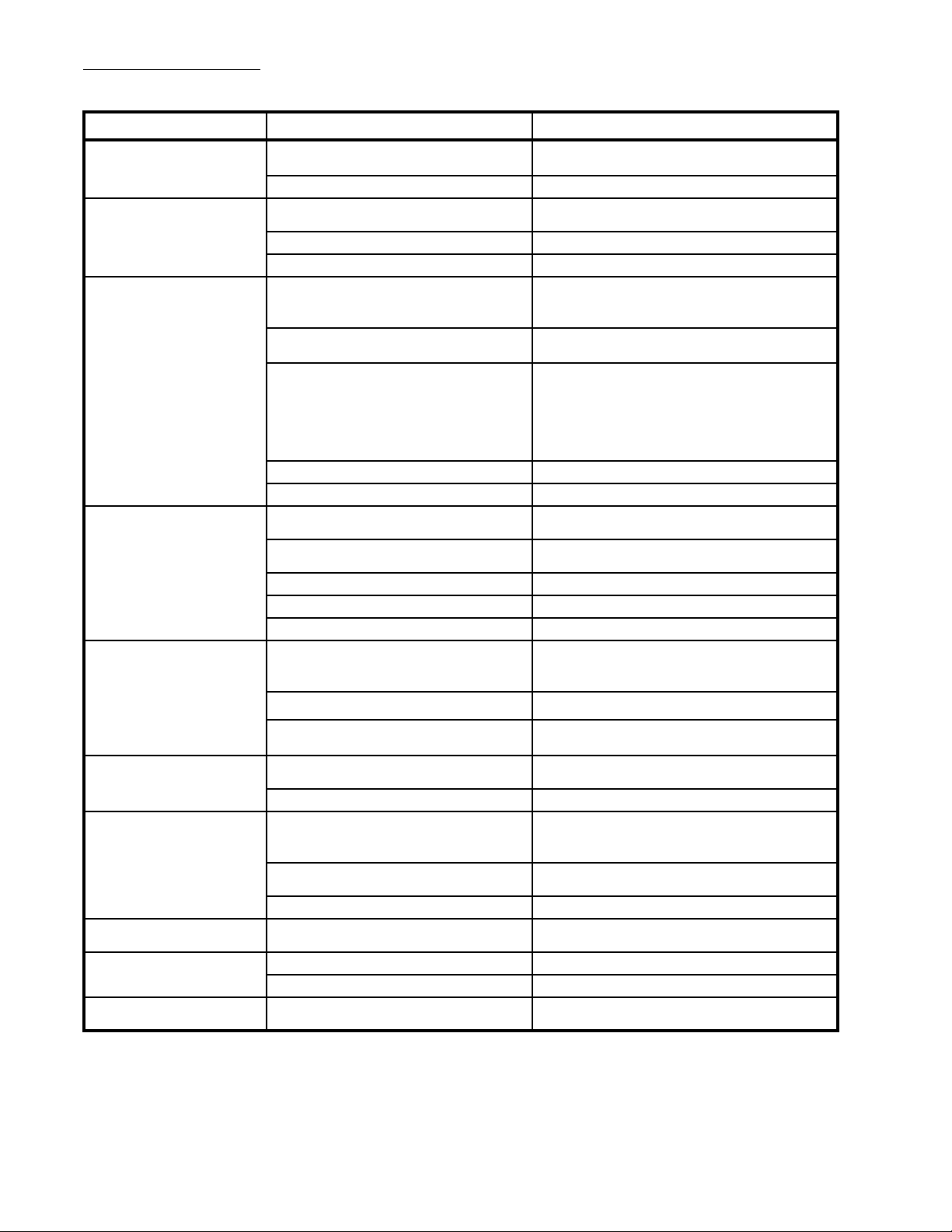

Functional Test Data Sheet - - - - - - - - - - - - - - - - - - - - - - 5-15

Chapter 6 - Disassembly & Reassembly

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

Tools & Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

Contents

Required Tools & Equipment - - - - - - - - - - - - - - - - - - - 6-2

Consumable Materials - - - - - - - - - - - - - - - - - - - - - - 6-3

Baxter-Created Tools & Equipment - - - - - - - - - - - - - - - - 6-3

Disassembly Procedures - - - - - - - - - - - - - - - - - - - - - - - 6-4

General Disassembly Information - - - - - - - - - - - - - - - - - 6-4

Bag Cover Assembly Removal - - - - - - - - - - - - - - - - - - 6-4

MPU PCBA Handling Guidelines - - - - - - - - - - - - - - - - - 6-5

Rear Case Assembly Removal - - - - - - - - - - - - - - - - - - 6-6

Mechanism Assembly, DDMM PCBA, & Battery Wall Removal - - - 6-7

MPU PCBA Removal - - - - - - - - - - - - - - - - - - - - - - - 6-8

ESD Flex Circuit Removal - - - - - - - - - - - - - - - - - - - - - 6-9

LCD Module Removal - - - - - - - - - - - - - - - - - - - - - - - 6-10

Optional Procedures - - - - - - - - - - - - - - - - - - - - - - - - - 6-11

3V Backup Battery Replacement - - - - - - - - - - - - - - - - - 6-11

Initializing the 3V Backup Battery - - - - - - - - - - - - - - - - - 6-12

Keypad Replacement - - - - - - - - - - - - - - - - - - - - - - - 6-12

Assembly Procedures - - - - - - - - - - - - - - - - - - - - - - - - 6-15

Torque Specifications - - - - - - - - - - - - - - - - - - - - - - - 6-15

Installing the Front Case & Keypad Assembly - - - - - - - - - - - 6-15

Installing the ESD Flex Circuit - - - - - - - - - - - - - - - - - - - 6-15

Installing the Display ESD Shield - - - - - - - - - - - - - - - - - 6-18

Installing the LCD Module - - - - - - - - - - - - - - - - - - - - - 6-18

07-19-A8-092 Ipump Pain Management System Service Manual iii

Page 6

Contents

MPU PCBA Handling Instructions - - - - - - - - - - - - - - - - - 6-19

Installing the MPU PCBA - - - - - - - - - - - - - - - - - - - - - 6-19

Installing the Battery Wall & DDMM PCBA - - - - - - - - - - - - 6-23

Installing the DDMM PCBA Hold-down Foam - - - - - - - - - - - 6-24

Installing the Mechanism Assembly - - - - - - - - - - - - - - - - 6-24

Installing the Battery Door - - - - - - - - - - - - - - - - - - - - 6-25

Pump Calibration - - - - - - - - - - - - - - - - - - - - - - - - - 6-25

Internal Inspection - - - - - - - - - - - - - - - - - - - - - - - - 6-26

Closing the Case - - - - - - - - - - - - - - - - - - - - - - - - - 6-27

Pump Functional Tests - - - - - - - - - - - - - - - - - - - - - - 6-28

Optional Assembly Procedures - - - - - - - - - - - - - - - - - - - - 6-28

Installing the Bag Cover Assembly - - - - - - - - - - - - - - - - 6-28

Chapter 7 - Internal Tests & Pump Calibration

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

3V Backup Battery Test - - - - - - - - - - - - - - - - - - - - - - - - 7-2

Battery Load Test - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

Battery No Load Test - - - - - - - - - - - - - - - - - - - - - - - - 7-3

Calibration Procedure - - - - - - - - - - - - - - - - - - - - - - - - - 7-4

Equipment Required - - - - - - - - - - - - - - - - - - - - - - - - 7-4

Initial Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-4

Downstream Occlusion Calibration - - - - - - - - - - - - - - - - - 7-5

Upstream Occlusion Calibration- - - - - - - - - - - - - - - - - - - 7-6

Air Sensor Calibration - - - - - - - - - - - - - - - - - - - - - - - 7-8

Downstream Occlusion Calibration Pressure Test - - - - - - - - - - 7-9

Calibration Data Sheet - - - - - - - - - - - - - - - - - - - - - - - - 7-11

Chapter 8 - Electronic Assembly Drawings

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-1

Interconnecting Wiring Diagram - - - - - - - - - - - - - - - - - - - - 8-1

Keypad Cable & Motor Connectors - - - - - - - - - - - - - - - - - - 8-2

Mechanism Assembly Flex Circuit Connector - - - - - - - - - - - - - - 8-2

MPU PCBA Assembly - - - - - - - - - - - - - - - - - - - - - - - - - 8-3

Direction & Drive Motor Module PCBA (DDMM) Daughter Board - - - - 8-4

iv Ipump Pain Management System Service Manual 07-19-A8-092

Page 7

Chapter 9 - Repair Parts

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-1

Assembly Parts List - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

Bag Cover Assembly - - - - - - - - - - - - - - - - - - - - - - - 9-2

Rear Case Assembly - - - - - - - - - - - - - - - - - - - - - - - 9-3

Pump Mechanism & Battery Compartment Assemblies- - - - - - - 9-4

MPU Board Assembly - - - - - - - - - - - - - - - - - - - - - - - 9-5

LCD Circuit Board & Front Case Assemblies - - - - - - - - - - - - 9-6

Alphabetical Parts List - - - - - - - - - - - - - - - - - - - - - - - - 9-7

Numerical Parts List - - - - - - - - - - - - - - - - - - - - - - - - - 9-9

Chapter 10 - Product Updates

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-1

Contents

Limited Warranty

07-19-A8-092 Ipump Pain Management System Service Manual v

Page 8

Contents

vi Ipump Pain Management System Service Manual 07-19-A8-092

Page 9

1 - Introduction

In this section Page

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Pump Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Manual Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Factory Service & Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Technical Assistance, Service, & Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Labeling Symbol Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

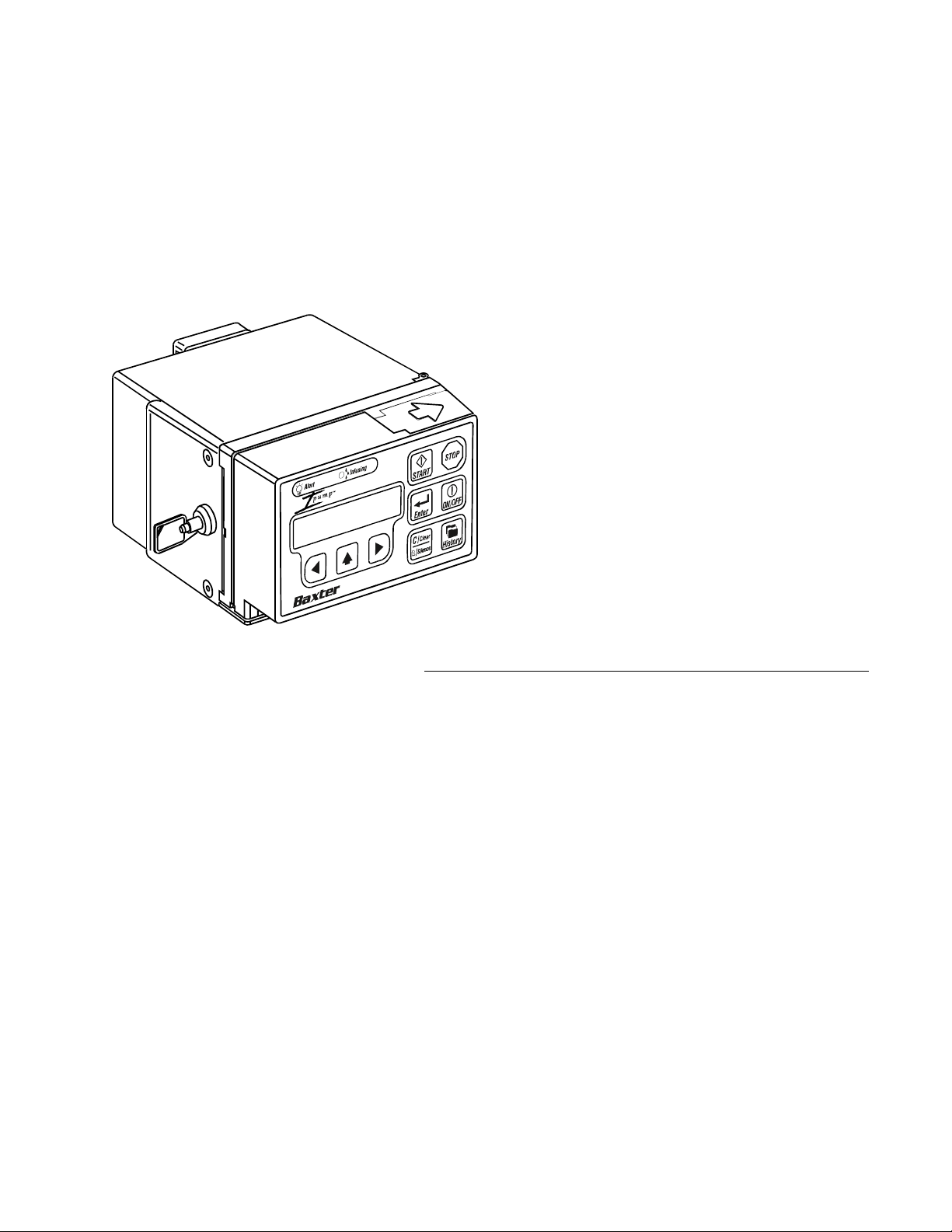

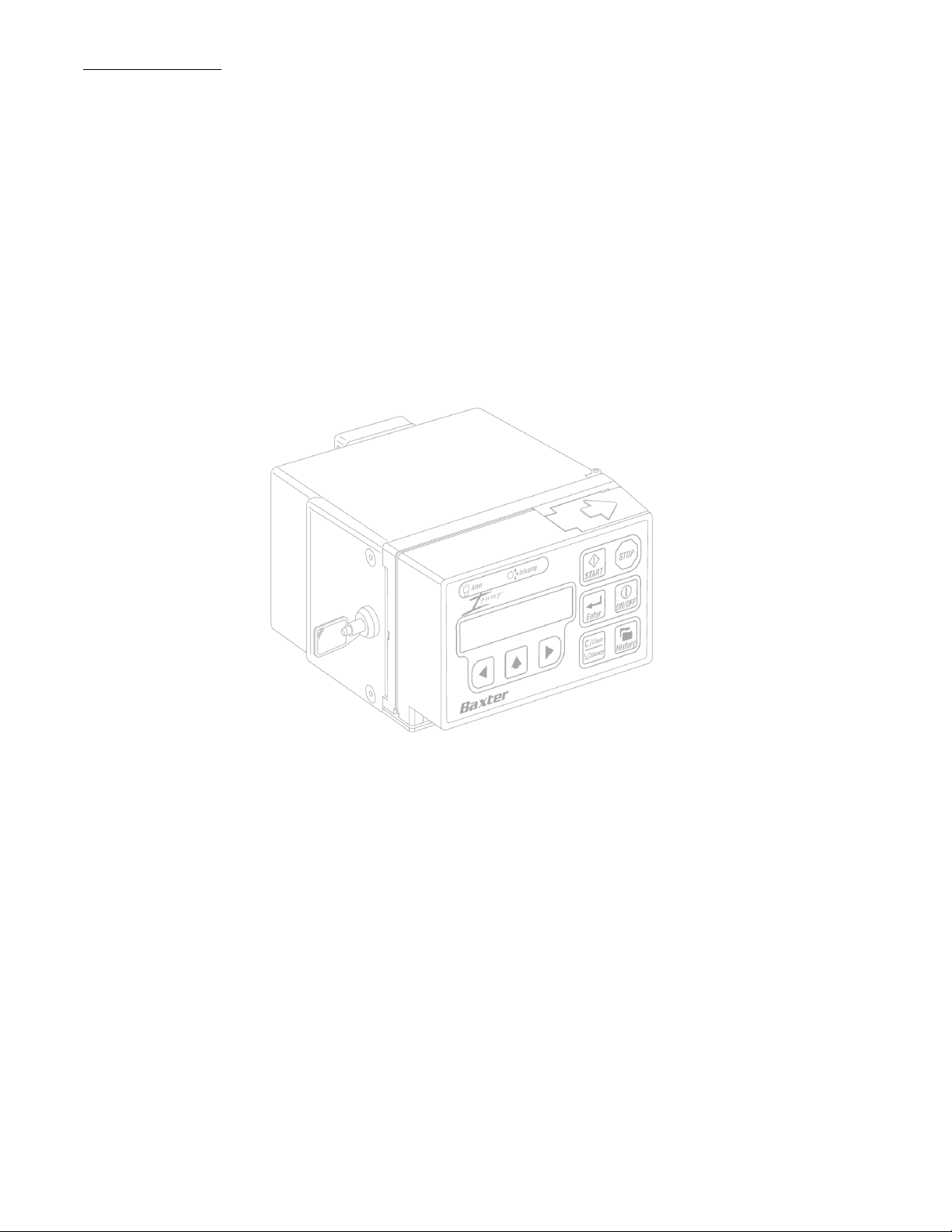

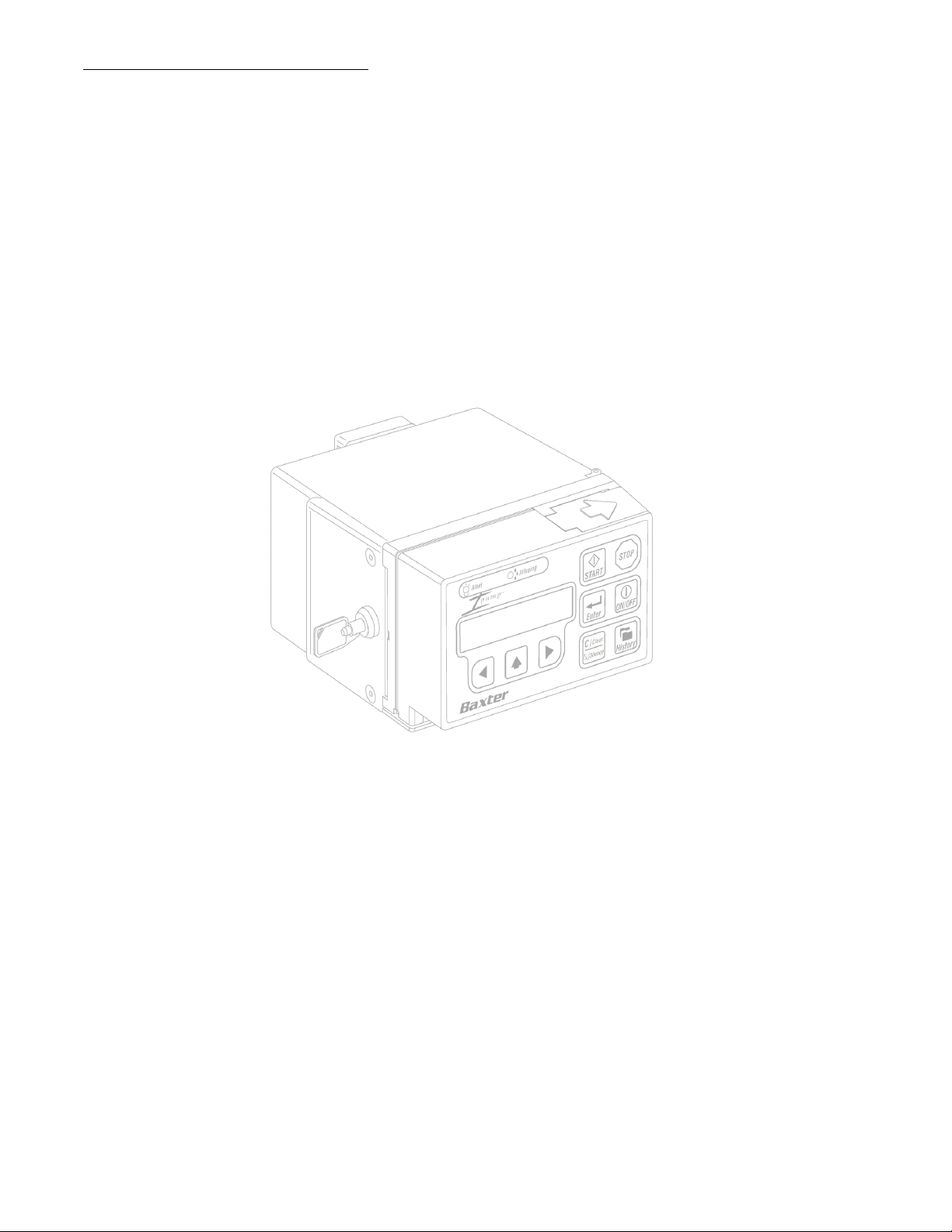

Overview

The Ipump Pain Management System (hereafter referred to as the “pump”) is indicated

for the controlled delivery (continuous, intermittent, and continuous plus intermittent) of

analgesic, sedative, and anesthetic solutions through clinically acceptable routes of

administration including intravenous, subcutaneous, and epidural, and for regional (local)

analgesia applications.

This lightweight, compact pump can be battery o perated for portability or connect ed to an

AC power source for stationary use. A specially designed optional locking pole-mounting

clamp allows the pump to be attached to a standard IV pole. With the pole clamp removed,

the pump can be placed into a comfortable carrying case.

This manual contains service and maintenance information for all Ipump Pain

Management System products (product codes 2L3107, 2L3107R, and 2L3107K) with

hardware revision 2 (HW Rev 2). This information is intended for qualified biomedical

personnel and Baxter authorized service representatives.

This manual provides a basic understanding of the internal workings of the pump,

functional test procedures, troubleshooting, complete assembly/disassembly instructions,

and a replacement parts list.

For complete operational and precautionary information, pump specifications, and

cleaning instructions, refer to the Ipump Pain Management System Operator’s Manual

(p/n 07-19-x4-766). For pump installation and configuration, refer to the Ipump Pain

Management System Configuration Manual (p/n 07-19-x4-768).

Only trained, qualified personnel should perform procedures in this

CAUTION

07-19-A8-092 Ipump Pain Management System Service Manual 1-1

manual. Except for the procedures and replacement parts included in

this document, no other disassembly or repair should be attempted.

Page 10

1 - Introduction

Baxter Healthcare Corporation provides a one-year limited warranty for new Ipump

devices. If a pump requires warranty service, call Baxter Healthcare Corporation for

repair. Unauthorized repair of a pump before the warranty has elapsed voids the warranty.

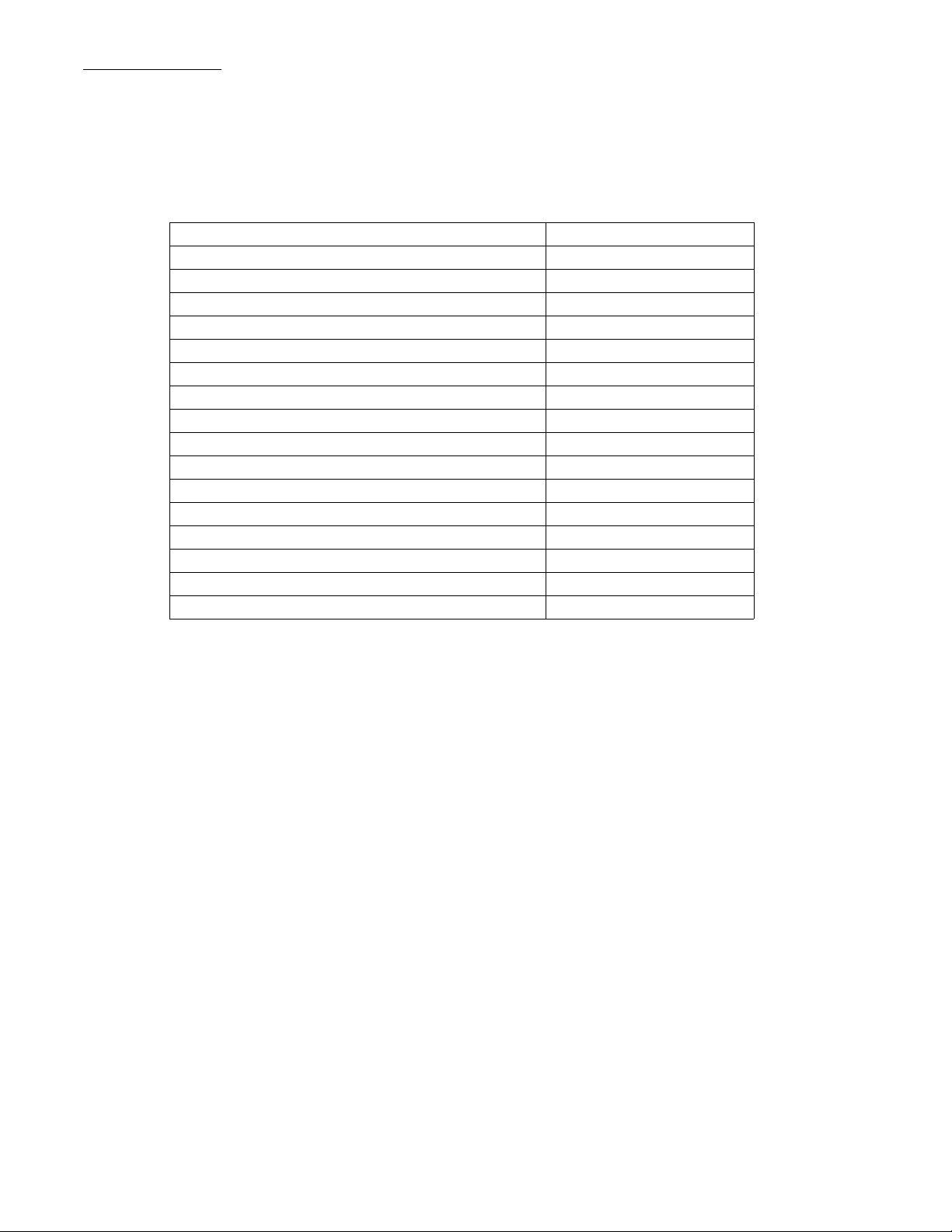

Pump Accessories

100 mL Bag Cover 2L3218

250 mL Bag Cover 2L3220

250 mL Extended Bag Cover 2L3217

250 mL Extended Bag Cover, Amber 2L3261

500 mL Bag Cover 2L3221

Printer Adapter 2L3400

Printer Adapter Cable 2L3402

Patient Controlled Analgesia (PCA) Button B069140003RP

Locking Pole Mount Clamp 2L3211

Non-locking Pole Mount Clamp 2L3212

Pump Carrying Case (250 mL) 2L3219

AC Adapter (220-230V) 2L3205K

AC Adapter (100-120V) 2L3210

AC Adapter Holder 2L3214

Configuration Transfer Cable 2L3112

Yellow Face Plate Label 072742210

Description Catalog Number

Manual Layout

This manual is divided into the following sections:

Chapter 1 (Introduction) provides an overview of the contents of this Service Manual

and includes Warnings and Cautions concerning the use and care of this product.

Warnings and Cautions are also located where needed throughout this manual.

Chapter 2 (Theory of Operation) details the functional features of the pump. A general

overview of the pump’s operation and a functional block diagram are provided.

Chapter 3 (Care & Routine Maintenance) includes the routine maintenance and

cleaning procedures with recommended cleaning agents. Battery replacement procedures

are also included.

Chapter 4 (Troubleshooting) contains troubleshooting tables and procedures for

localizing mechanical or electronic faults. A table of System Error Codes is also included.

1-2 Ipump Pain Management System Service Manual 07-19-A8-092

Page 11

1 - Introduction

Chapter 5 (Functional Tests) provides the tests that are to be used to ensure that the

pump operates properly. Baxter recommends that these tests be performed on an annual

basis as a preventive maintenance procedure. In addition, these tests must be performed

whenever the Mechanism Assembly and/or the MPU PCBA is removed or replaced.

Chapter 6 (Disassembly & Reassembly) provides disassembly, replacement, and

reassembly instructions. Required tools and test equipment are specified. Adjustment

procedures are provided along with the required torques and tolerances. Replacement

procedures for the 3V Backup Battery and the Keypad are also included.

Chapter 7 (Internal Tests & Pump Calibration) contains the procedures required to

test the 3V Backup Battery and to calibrate the pump. The calibration procedures must be

performed after replacement of either the Mechanism Assembly or the MPU PCBA.

Chapter 8 (Electronic Assembly Drawings) contains the assembly drawings for the

interconnecting cables and flex circuits used in the pump.

Chapter 9 (Repair Parts) provides exploded view drawings and parts lists of fieldreplaceable parts and assemblies.

Chapter 10 (Product Updates) contains major updates and additional information for

the pump. This information will be listed by hardware and software revision numbers

and/or product serial number. Product Service Bulletins should also be placed in this

chapter of the manual.

Factory Service & Assistance

Baxter Healthcare Corporation provides a one-year limited warranty for each pump. (See

the inside back cover of this manual for warranty details.) If a pump requires warranty

service, call Baxter Healthcare Corporation for repair. While under Baxter Warranty,

Service Agreement (optional), or Lease Agreement, the pump must not be opened by

unauthorized personnel. Unauthorized repair of a pump before the warranty has elapsed

voids the warranty.

If factory service is desired, pumps may be returned to Baxter Healthcare Corporation for

repair. Always call for a return material authorization number before shipping any pump

to Baxter Healthcare Corporation.

When calling for service, please be prepared to provide the product code and serial

number of the pump. A brief written description of the problem should be attached to the

pump when it is returned for service.

Shipping costs for all pumps returned to Baxter shall be paid for by the customer. The

pump must be packed in its original container or in another container that will provide

adequate protection during shipment. T o ensure prompt return, a Baxter authorized service

representative must be notified before shipping any pump for repair.

Baxter Healthcare Corporation will not be responsible for unauthorized returns or for

pumps damaged in shipment due to improper packing.

07-19-A8-092 Ipump Pain Management System Service Manual 1-3

Page 12

1 - Introduction

Technical Assistance, Service, & Repairs

For technical assistance, parts ordering, and service return authorization, contact the

Baxter Healthcare Service Center:

Inside the U.S.: Call 1-800-THE-PUMP (843-7867)

Outside the U.S.: Contact your local Baxter representative.

Safety Summary

General precautions to observe while using the pump are shown below. Standards under

which this product is designed, built, and marketed are also included.

• Before operating the pump, carefully read the operator’s manual to fully understand the

pump’s functionality and to ensure safe and proper operation. An operator’s manual is

shipped with each pump.

• Although the pump has been designed and manufactured to exacting specifications, it

is not intended to replace trained personnel in the supervision of infusion therapy.

• Read and understand this manual before attempting to perform service or maintenance

on the pump.

• To ensure that the pump continues to perform within specifications, perform the

Routine Maintenance procedures described in Chapter 3 of this manual when

recommended.

• This manual has been developed with consideration to the requirements in the

International Standard, IEC 60601-2-24 (1998-02) Medical Electrical Equipment —

Part 2-24: Particular Requirements for Safety of Infusion Pumps and Controllers.

• This product is classified by Underwriters Laboratories Inc. with respect to electric

shock, fire and mechanical hazards only in accordance with UL 60601-1 Medical

Electrical Equipment - Part 1: General Requirements for Safety.

Definitions

Certain items in this manual are highlighted by special messages. The definitions of the

various types of message are provided below.

! WARNING !

CAUTION

NOTE: Provides supplemental information to the accompanying text.

1-4 Ipump Pain Management System Service Manual 07-19-A8-092

Indicates a possible hazard which, if ignored, could result in

severe personal injury or death.

Indicates a problem or unsafe practice which, if not avoided, could

result in minor or moderate personal injury, or product or property

damage.

Page 13

Warnings

1 - Introduction

! WARNING !

! WARNING !

! WARNING !

! WARNING !

! WARNING !

This pump should be repaired only by trained, qualified

personnel using Baxter-recommended parts. There are risks

associated with using anything other than Baxter-recommended

parts and procedures. Baxter will assume no responsibility for

incidents which may occur if the product was not repaired by

qualified Baxter employees.

If the pump has been dropped or appears to be damaged, it

should be taken out of service and inspected by qualified

service personnel.

To ensure safe and proper operation, read the Ipump Pain

Management System Operator’s Manual and any instructions

accompanying disposables or accessories before operating the

pump.

When attaching the pump to an IV pole, ensure it has been

securely clamped and locked.

As with all medical electronic equipment, care must be exercised

to avoid exposing this pump to powerful sources of

electromagnetic interference. Using the pump near operating

equipment which radiates high energy radio frequencies (such

as electrosurgical/cauterizing equipment, two-way radios, or

cellular telephones) may cause false alarm conditions. If this

happens, reposition the pump away from the source of

interference.

Cautions

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

In the U.S., use of this pump is restricted by federal law (USA) to sale

or use by, on the order of, or under the supervision of a physician or

other licensed health care professional.

DO NOT operate this infusion pump in the presence of flammable

anesthetics, ether, oxygen-enriched, or explosive atmospheres.

DO NOT expose the pump to X-rays, gamma rays, or other ionizing

radiation, or to strong electric or magnetic fields.

Wipe off spills immediately. DO NOT allow fluid or residue to remain

on the pump.

Ensure proper maintenance of the pump by following the cleaning

schedule and methods described in this manual.

Do not clean, disinfect, or sterilize any part of the pump by

autoclaving, or with ethylene oxide gas. Doing so may damage the

pump and void the warranty. Only external parts of the pump should

be disinfected.

Refer all service, repair, and calibration to trained, qualified

personnel.

To reduce the risk of electrical shock, only trained, qualified personnel

should disassemble this product.

CAUTION

07-19-A8-092 Ipump Pain Management System Service Manual 1-5

For best performance, routine maintenance procedures must be

performed. (Refer to Chapter 3 of this manual.)

Page 14

1 - Introduction

Notes

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Wear a grounding wrist strap when disassembling and reassembling

the pump.

DO NOT lay the pump face down on any surface which could scratch

or damage the keypad or the display.

When troubleshooting the pump, do not inject or apply signals of any

kind. Damage to the pump or its sub-assemblies could result.

Motor and sensor magnets may attract metal debris to motors or

circuit boards. To prevent debris from entering the pump mechanism,

always maintain a clean work area when performing procedures

involving the pump mechanism.

To avoid personal injury, ensure that the IV pole is stable and secure.

Ensure that the pole is able to support the pump, along with any other

devices, without tipping or falling. The pole diameter should be

between 0.5" and 1.25" (1.3 cm and 3.2 cm).

Baxter requests that parties acquiring this pump:

• Promptly report the receipt of this pump to the manufacturer.

• Report the pump’s purchase, receipt in trade, return after sale, loss, destruction, or

retirement.

• If this is an initial purchase from the manufacturer, please return a signed copy of the

packing list to the manufacturer.

Labeling Symbol Definitions

IPX1

Drip-proof equipment: enclosed equipment protected against

dripping fluids.

Connection port for the AC to DC converter/adapter.

CAUTION, Consult Accompanying Documents

Type CF applied part. (The

indicates the level of electric shock protection for the patientcontacting parts such as the PCA button and the IV set.

UL/IEC/EN 60601-1 defines Type CF as providing greater

protection than Type B or Type BF.)

Electrostatic Sensitive Devices

(The pins of the PRINTER/COMM connector are subject to

Electrostatic Discharge and should not be touched. Refer to

page 2-7 for additional information.)

“Type CF Applied Part” symbol

1-6 Ipump Pain Management System Service Manual 07-19-A8-092

Page 15

1 - Introduction

Recyclable, dispose of properly.

This product is classified by Underwriters Laboratories Inc.

with respect to electric shock, fire, and mechanical hazards

only in accordance with UL 2601-1 (UL 60601-1),

CAN/CSA C22.2 No. 601.1, and IEC 60601-2-24.

Symbol (WEEE 2002/96/EC) Crossed-out wheeled bin

For product disposal, ensure the following:

- Do not dispose of this product as unsorted municipal waste.

- Collect this product separately.

- Use collection and return systems available to you.

Bar below bin

- Product distributed after August 13, 2005.

For more information on return, recovery, or recycling of

this product, please contact your local Baxter representative.

EC REP

REF

SN

Manufacturer

Authorized Representative in the European Community

Catalog Number

Serial Number

07-19-A8-092 Ipump Pain Management System Service Manual 1-7

Page 16

1 - Introduction

1-8 Ipump Pain Management System Service Manual 07-19-A8-092

Page 17

2 - Theory of Operation

In this section Page

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Ipump System Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . 2-2

MPU Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

BUS Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Keypad & Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

PROM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Supervisory Subsystem (SS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Power Subsystem (PS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

LCD Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Silent Shutdown System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Motor Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Occlusion Detection Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Air Sensor Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Printer Adapter Interface Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

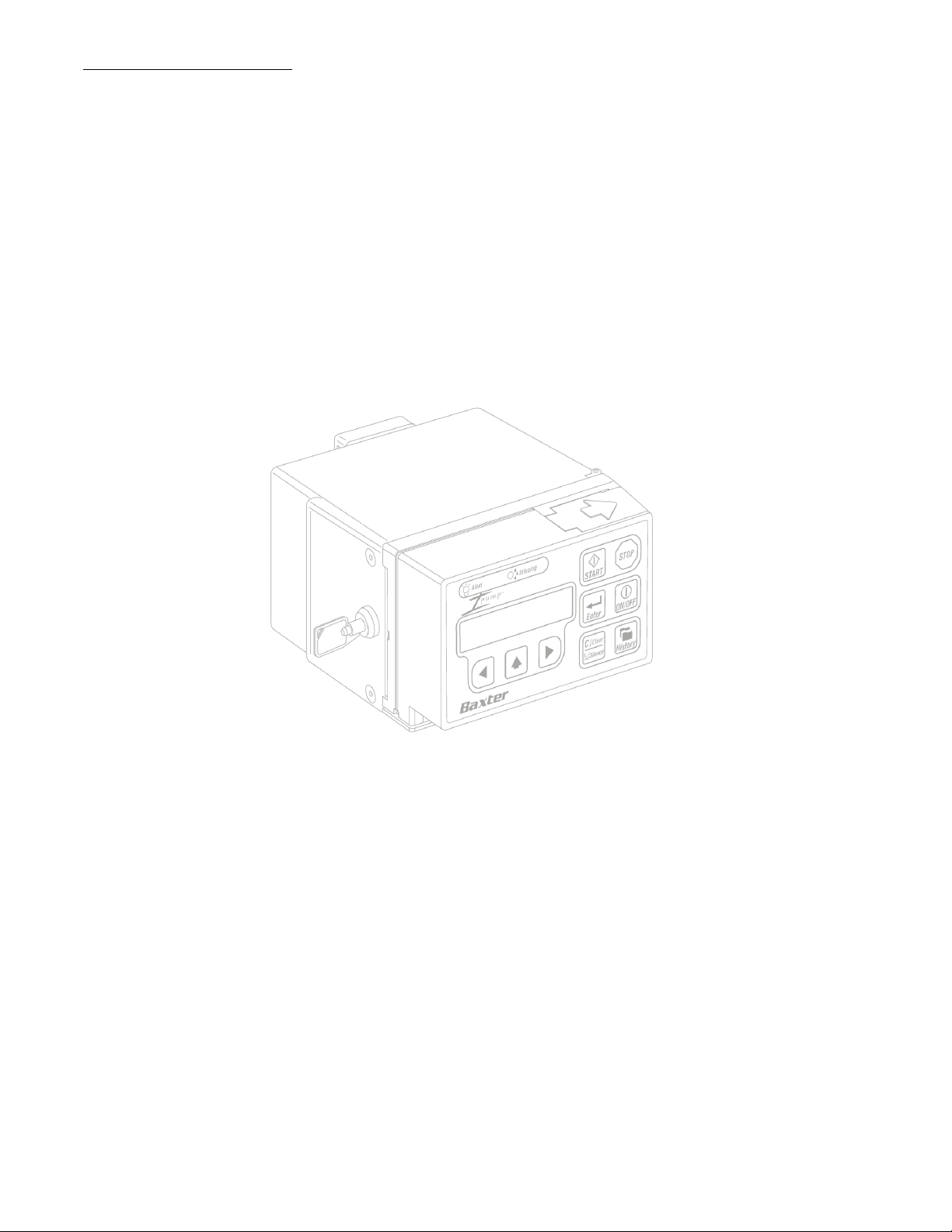

Overview

The Ipump Pain Management System is a small, lightweight, linear peristaltic pump that

may be operated from battery or AC power. An optional pole-mounting clamp allows the

pump to be unlocked and easily removed for pump placement into a convenient carrying

case. See the list of pump accessories on page 1-2.

The user can program the pump with prescribed values for the therapy desired. A number

of security options are available in order to enter prescription parameters from the keypad.

Once programmed with prescription parameters, the pump operates with these settings

until the operator turns the pump off or re-enters the programming screens and changes the

prescription. A record of the previous prescription and therapy history are retained while

the pump is in operation or turned off. The user can choose to use the previous

prescription, review the history by pressing the

pressing the

The pump can be configured to require a key to unlock and open the pump bag cover to

change a prescription. The pump can also be configured to require either a security code,

or both a key and a security code, to gain applicable access.

The pump can be programmed for specific modes, units, and/or prescription limi ts. This is

accomplished by accessing the configuration screens during initial start-up. To access the

configuration mode refer to the Ipump Pain Management System Configuration Manual

and the Ipump Pain Management System Operator's Manual. Once programmed, the

pump will remain in that configuration until purposely changed.

HISTORY key, or clear the history by

CLEAR key.

07-19-A8-092 Ipump Pain Management System Service Manual 2-1

Page 18

2 - Theory of Operation

S E N S O R C I R C U I T P R I N T E R A D A P T E R I N T E R F A C E C I R C U I T

C I R C U I T M P U C I R C U I T B U S S U B S Y S T E M M O T O R S U B S Y S T E M P R O M K E Y P A D S U P E R V I S O R Y S U B S Y S T E M L C D S U B S Y S T E M P O W E R S U B S Y S T E M S I L E N T S H U T D O W N

The pump configuration can be transferred between two Ipump devices for the

configuration of multiple pumps. An optional configuration transfer cable, available from

Baxter, is required. See the list of pump accessories on page 1-2.

The remainder of this chapter provides a basic explanation of the pump's internal

operation.

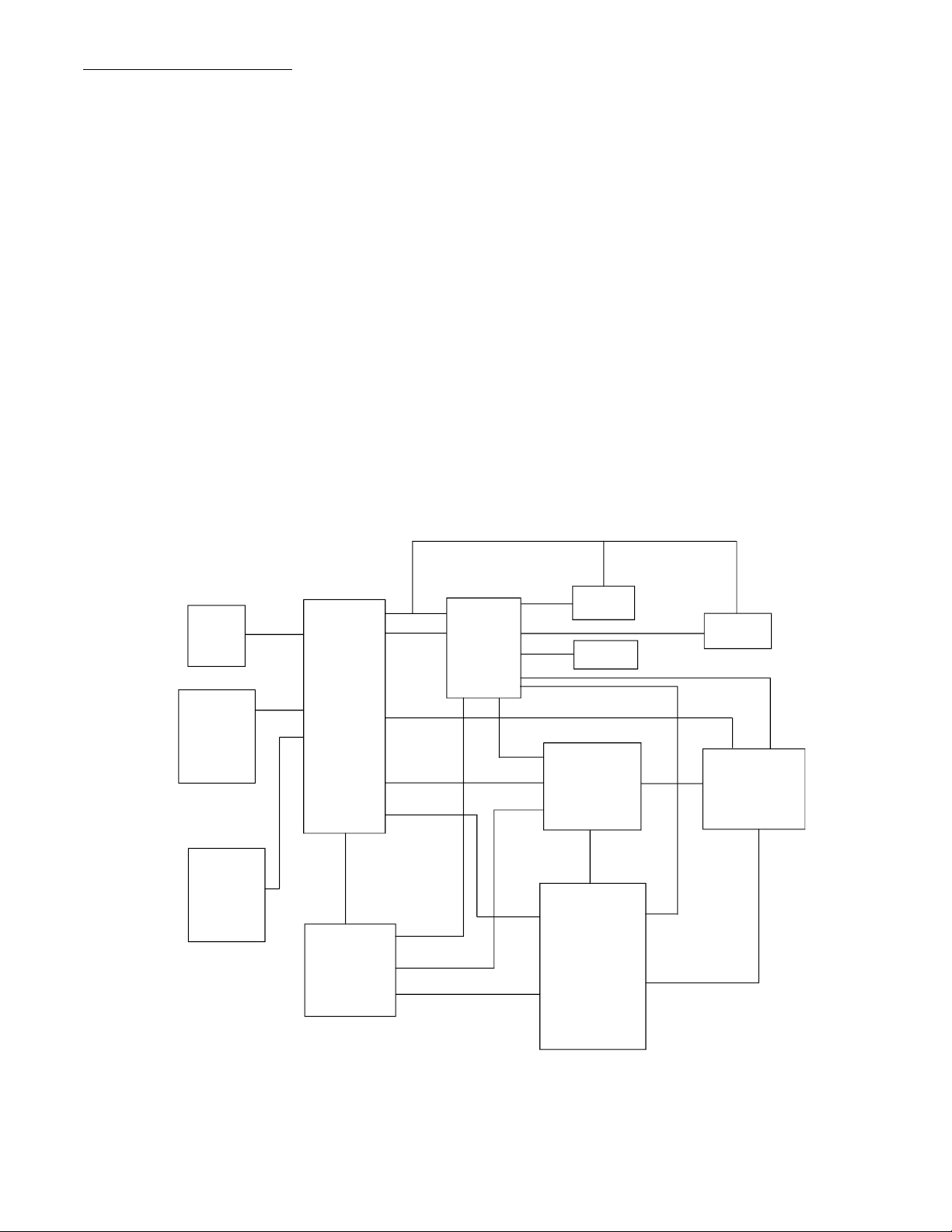

System Components

The pump is divided into modules and subsystems. Figure 2-1 is a functional block

diagram of the system and not intended to illustrate component location. The m odules and

subsystems listed below are discussed later in this chapter.

• MPU Circuit • LCD Subsystem

• Bus Subsystem • Silent Shutdown Circuit

• Keypad • Motor Subsystem

• PROM • Occlusion Detection Circuit

• Supervisory Subsystem • Air Sensor Circuit

• Power Subsystem • Printer Adapter Interface Circuit

A I R

C I R C U I T

O C C L U S I O N

D E T E C T I O N

Figure 2-1. Ipump System Functional Block Diagram

2-2 Ipump Pain Management System Service Manual 07-19-A8-092

Page 19

2 - Theory of Operation

MPU Circuit

The pump uses a 16-bit micro-controller and an external PROM. The 16-bit microcontroller contains hardware timers, analog to digital converter, RAM and PROM, and

the microprocessor. This application of the micro-controller uses the internal RAM and

PROM whenever possible to save power, which is a major feature of this pump. The

memory expansion mode is only used when accessing functions on the external bus. The

microprocessor has eight input/output (I/O) ports which are used to control or monitor the

following functions:

• PROM • LCD Subsystem

• Motor Subsystem • Watchdog

• Keypad • Switches

• Silent Shutdown Circuit • Real Time Clock Circuit

• Occlusion Detection Circuit • Air Sensor Circuit

• Various voltages

A number of power-up tests are performed to ensure that the pump is running properly.

The power-up tests include testing of the LEDs, memory, display, beeper, backup battery,

and input voltages. If an error is detected, the processor will initiate a 2-character error

code which will produce an alert message and an audible alarm.

Included in the processor subsystem is the real time clock (RTC) circuit. The RTC

provides time of day information to the microprocessor. The RTC circuitry keeps track of

time while the pump is off, through the use of a backup battery mounted to the

microprocessor circuit board. The backup battery is also used to preserve the contents of

the microprocessor RAM when operating power drops below a minimum voltage. The

RTC also contains a small amount of RAM that is used by the system software to

determine whether there has been a loss of backup battery power.

BUS Subsystem

The BUS has the capacity to provide for a 24 bit address and 8 bit data path. The

microprocessor uses the BUS subsystem to transfer data or instructions to seven different

functions. These functions are:

• PROM • LCD Command and Data Register

• Motor Drive • Watchdog

• Keypad • Switches

• Real Time Clock (RTC)

07-19-A8-092 Ipump Pain Management System Service Manual 2-3

Page 20

2 - Theory of Operation

Keypad & Sensors

The Keypad is comprised of nine keys which enable the user to turn the pump Off and On,

enter the prescription data, and START and STOP an infusion. In addition to monitoring

each of these keys, the microprocessor also checks the status of ancillary inputs consisting

of internal switches, sensors, and connectors. Refer to Table 2-1 and Table 2-2 for a

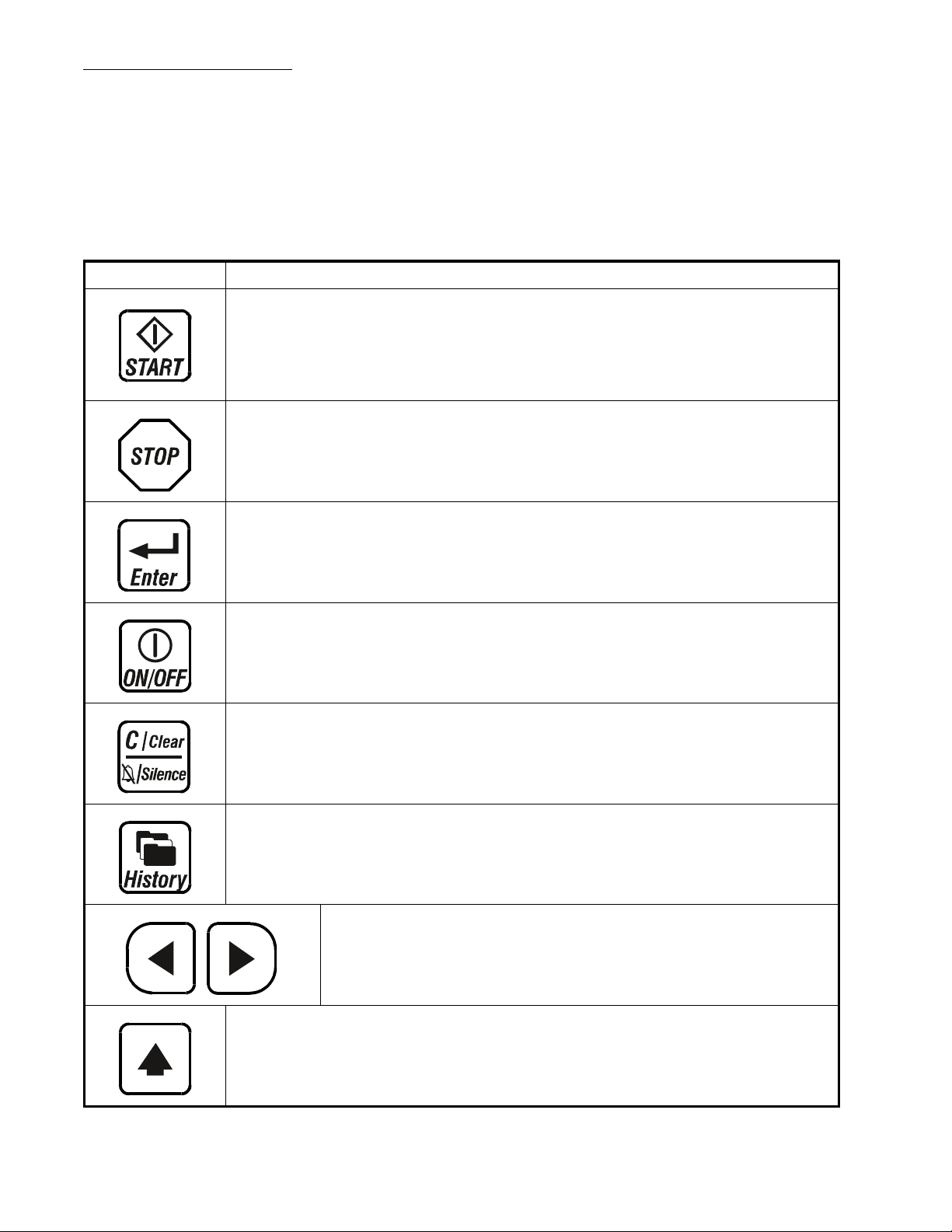

description of the Keypad keys and ancillary inputs.

Key Description

The START key begins the operation of the pump and can also be configured to act as

a PCA button. If all of the required programming values have been entered, the START

key initiates the infusion from any programming screen.

Following the resolution of most alerts or alarms, pressing the START key resumes the

infusion if the condition no longer exists.

The STOP key must be pressed twice within 1 second to stop the operation of the

pump. After the pump is stopped, you can press the ON/OFF key to turn the pump off.

The ENTER key sets the value displayed on the Liquid Crystal Display (LCD) screen.

The ON/OFF key powers up and powers down the pump. If the pump is on, you can

press the key:

• once to deactivate the programmed settings, which can be retrieved.

• twice to power off the pump.

The CLEAR/SILENCE key either clears the data shown on the LCD screen or silences

an alert or alarm signal generated by the pump.

The HISTORY key displays the infusion history on the LCD screen. Pressing this key

again allows you to scroll through the history screens.

The left and right arrow keys move the cursor on the display screen to

the left and right.

The scroll (up arrow) key displays the next available option on the pump’s screen.

Table 2-1. Keypad Keys

2-4 Ipump Pain Management System Service Manual 07-19-A8-092

Page 21

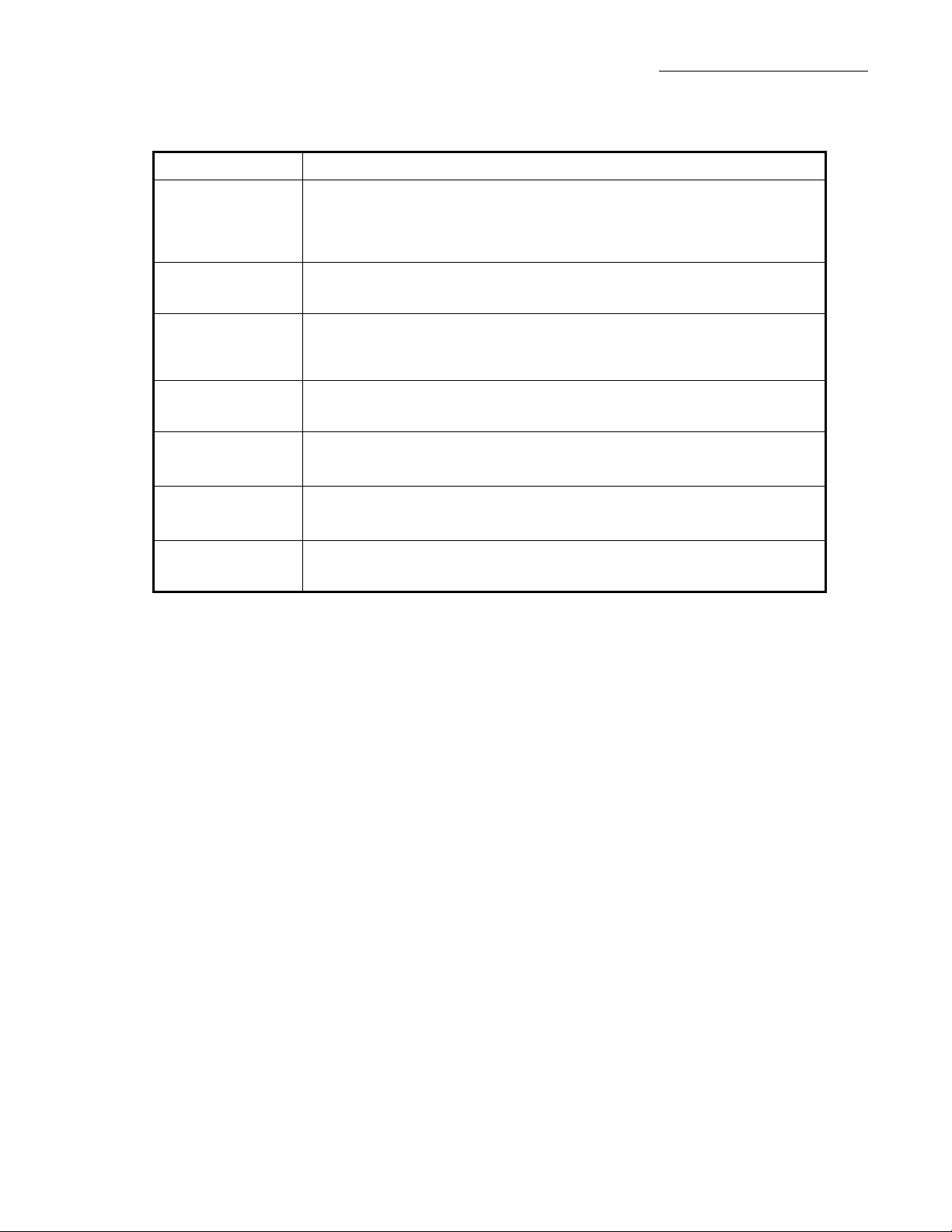

Feature Primary Function

Patient Controlled Analgesia (PCA) connector. The PCA cable connects

PCA Jack

to the pump via a phono jack and plug style connection which is

monitored by the microprocessor to determine the status of the PCA

button.

2 - Theory of Operation

Printer Jack

Bag Cover Lock

Tubing Sensor

Upstream

Occlusion Sensor

Downstream

Occlusion Sensor

Air Sensor

The printer jack allows the connection of the Baxter Printer Adapter

(p/n 2L3400), and a printer (typically a Seiko DPU-414).

An internal sensor detects when the bag cover is locked or unlocked

when the pump is configured with either security method “key + code” or

“key only.”

An internal sensor that detects when the pump tubing cover is open or

closed with the administration set properly installed.

An internal sensor that detects when an upstream occlusion occurs.

An internal sensor that detects when a downstream occlusion occurs.

An internal sensor that detects when there is air in the tubing segment

inside the pump.

Table 2-2. Ancillary Inputs

PROM

The PROM subsystem supplies data to the bus when addressed by the microprocessor to

identify the operation requested. An EEPROM is also provided in the microprocessor and

PROM subsystem to retain configuration information.

Supervisory Subsystem (SS)

The supervisory subsystem performs a major role in the start-up and shutdown of the

pump. It also monitors and responds to error situations reported by the hardware and

software. A “wellness check” is performed by the SS on some of the error detection

hardware circuitry.

The SS also provides the power for the microprocessor and the Real Time Clock (RTC).

As long as the regulated +5V remains above the backup battery voltage, the SS will

produce a +5V source for the microprocessor and the RTC. If the regulated +5V falls

below the backup battery voltage, the SS connects the backup battery to the

microprocessor and the RTC to preserve the contents of the microprocessor RAM and

provide power for RTC operation.

Power Subsystem (PS)

The power subsystem provides the required DC power for the pump from either a 9-volt

battery or an optional AC Adapter. The AC Adapter is an external device, which will

provide 10 volts DC when plugged into an AC wall outlet. The AC Adapter is connected

to the pump at its AC Adapter input jack. When power is available from both the battery

07-19-A8-092 Ipump Pain Management System Service Manual 2-5

Page 22

2 - Theory of Operation

and an AC Adapter, the PS selects the AC Adapter by default to conserve battery life. The

PS automatically switches the LCD backlight on when the AC Adapter power is present.

The PS provides regulated, partially regulated, and unregulated power. In the event that

both the battery and AC Adapter are not present, the PS, in conjunction with the SS, will

switch the microprocessor and RTC power to the backup battery. This maintains the

contents of the microprocessor RAM and keeps the RTC operational.

The unregulated voltage is used primarily to power the motor that drives the peristaltic

pump. The partially regulated voltage is used to power the buzzer and the LCD's backlight

circuit. The partially regulated supply is monitored for low voltage to shut down the

pump. The unregulated voltage is also used as a monitored voltage for the overvoltage

fault detector. The regulated voltage is supplied to all of the IC chips.

LCD Subsystem

The liquid crystal display (LCD) subsystem serves as a module for the microprocessor to

communicate infusion programming information and pump status to the user and facilitate

the entry of data from the keypad. The LCD module displays two rows of 16 characters,

with each character defined by a selection of dots from a 5 x 7 array with a cursor

underneath the array.

The LCD module can be written to by the microprocessor which supplies it with either

data or commands. Information in the LCD's memory is read by the microprocessor. For

its functional operation, the LCD module has two memories; the character generator (CG)

RAM and the display data (DD) RAM. The pump hardware has no need to distinguish

between the two types of RAM. This is accomplished by the operating software in the

microprocessor through the commands sent to the LCD module.

The backlight circuit provides power to the light emitting diodes (LEDs) inside the LCD

module to generate the necessary light for reading the display. These LEDs consume a

significant amount of power. Therefoere, when the pump is powered only by the 9-volt

battery, the display is only lit when needed. The LEDs are driven at less than the nominal

rated current. This provides a dim illumination of the display to reduce the drain on the

battery. When programming the pump on battery power, the backlight will be on. Fifteen

seconds after programming is complete, the backlight will turn off. The backlight will turn

on again when any key is pressed.

When the pump is being powered by the AC Adapter, the LEDs are on all the time. The

LEDs are supplied with nominal full rated current giving a bright backlight. As long as the

AC Adapter is providing power, the display will remain lit.

Silent Shutdown Circuit

When both the AC Adapter and 9-volt battery have been accidentally or intentionally

disconnected, the pump will notify the operator by issuing an intermittent “chirping”

sound. The power supply provides a residual voltage which maintains power to the

speaker circuit. Once this voltage has been depleted, the chirping will fade away (no less

than 20 seconds).

2-6 Ipump Pain Management System Service Manual 07-19-A8-092

Page 23

2 - Theory of Operation

Motor Subsystem

The motor subsystem has the ability to drive the DC motor in a forward or reverse

direction. The pump drive is controlled by the Direction and Drive Motor Module

(DDMM) which receives inputs from two independent shaft position encoders. The

encoder information enables precise control over the motor and therefore the fluid

delivery rate.

T o drive the motor , the microprocessor provides motor drive information using one of two

carrier frequencies. The DDMM uses a frequency discriminator to interrogate the carrier

signal and set the polarity of the voltage to the motor. Once direction is established, the

motor is controlled by the motor drive information directly from the microprocessor.

Occlusion Detection Circuit

A check is made for the possibility of blockage (occlusion) during the delivery

downstream and upstream of the pump. (NOTE: Unless the upstream occlusion alarm is

disabled in the pump’ s configuration.) During downstream occlusion, the elastic section of

the tubing set (in the area where the fingers of the peristaltic pump operate) will expand

slightly if a blockage exists. The expansion causes the deflection of a very sensitive sensor

thereby enabling the pump to sense an occlusion. During upstream occlusion, the elastic

section of the tubing set will contract slightly if a blockage exists upstream thereby

changing the deflection of a second sensor, and allowing the pump to sense the occlusion.

If the motor is operating in the reverse direction, as during the startup upstream occlusion

test, an upstream blockage will cause a slight expansion of the tubing which allows the

pump to sense the occlusion.

Air Sensor Circuit

An ultrasonic sensor is embedded in the plastic housing of the tubing door where the

tubing set is placed. When an air bubble passes through the tubing, the pump will sense

the different properties of fluid versus air and will issue an alarm when a certain amount of

air passes through that section of tubing.

Printer Adapter Interface Circuit

The interface to the printer adapter en ables the microprocessor to produce a printout of the

history data. The pump interfaces with the Baxter Printer Adapter, P/N 2L3400, and a

printer (typically a Seiko DPU-414). The printer interface is a serial port that operates on

TTL levels and provides data at a 600 baud rate.

A label is normally used to cover the PRINTER/COMM connector at the front of the

pump. This label should only be removed when the printer adapter is connected to the

pump. A second label positioned nearby indicates that this connector is sensitive to

Electrostatic Discharge (ESD).

07-19-A8-092 Ipump Pain Management System Service Manual 2-7

Page 24

2 - Theory of Operation

2-8 Ipump Pain Management System Service Manual 07-19-A8-092

Page 25

In this section Page

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Cleaning and Disinfecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Overview

The Ipump device is designed to provide reliable service with only minor routine

maintenance. A periodic functional inspection of the pump should be performed at least

every six months to assure proper operation. The procedures in Chapter 5, “Functional

T ests”, must be used to ensure that the pump operates properly . A review of the Alarm Log

should also be performed to identify system errors encountered by the pump. Refer to

Chapter 4, “Troubleshooting”, for details on reviewing the Alarm Log.

Baxter recommends performing preventive maintenance on an annual basis and cleaning

after every use. For convenience, the pump can be configured to give the operator an alert

whenever maintenance is due. Refer to the Ipump System Configuration Manual for

details.

3 - Care & Routine Maintenance

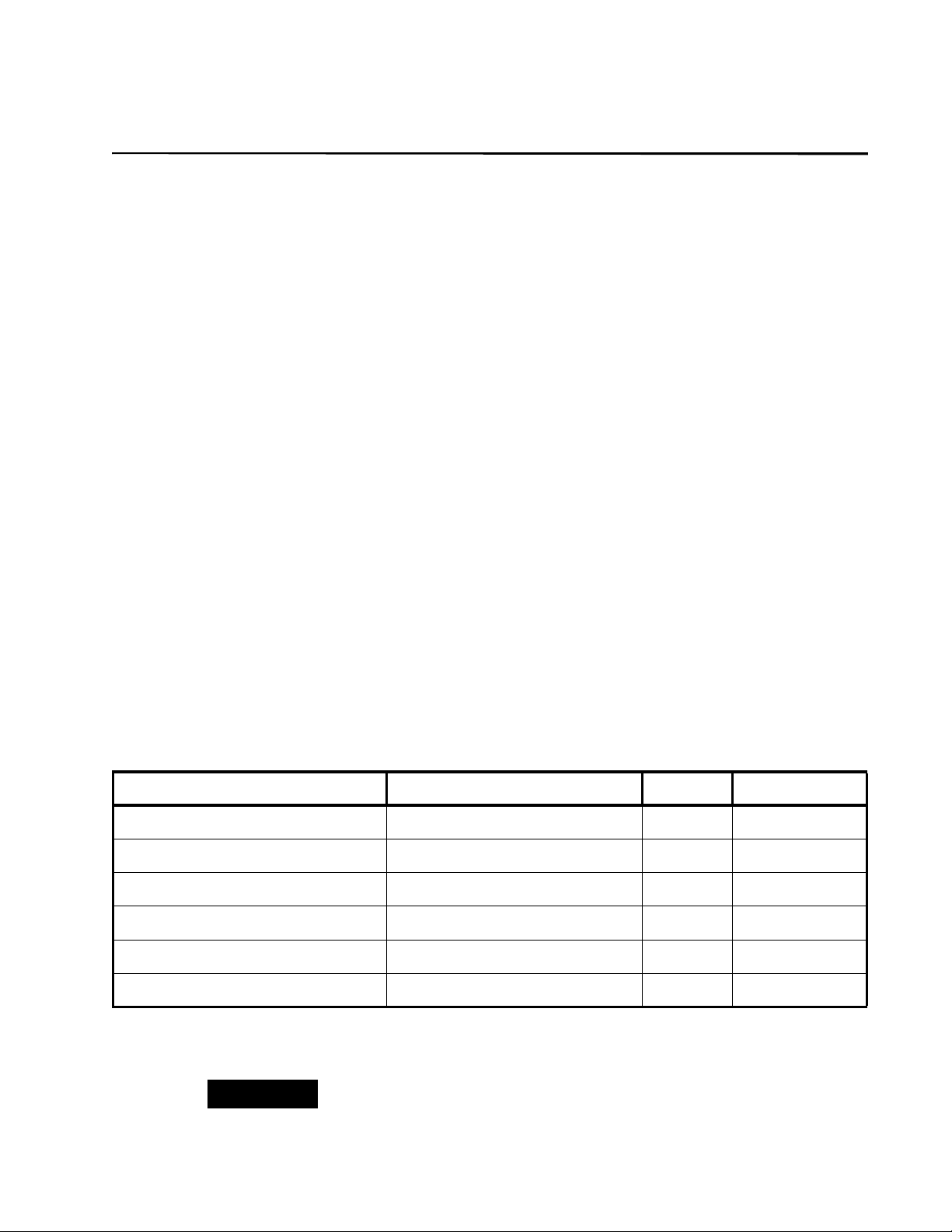

Cleaning and Disinfecting

The exterior surfaces of the pump may be cleaned with a cloth, sparingly dampened with

any of the cleaners listed in the table below. Follow the manufacturer's instructions for

diluting concentrated cleaners. After use, pumps should be cleaned/disinfected with an

agent from the list below before being used on another patient. Spills and dirt should be

cleaned off the pump as quickly as possible.

Recommended Cleaner Manufacturer Cleaner Disinfectant

Soapy water N/A XXX

A solution of 10% bleach and water N/A XXX XXX

LpH STERIS Corporation XXX XXX

Septisol STERIS Corporation XXX XXX

Super-Edisonite Colgate-Palmolive Co. XXX

TOR or Hi-TOR

Plus

CAUTION

Table 3-1. Approved Cleaners and Disinfectants

The Ipump device and the AC Adapter are not waterproof and should

not be immersed. Avoid getting liquids inside the pump or permanent

damage may result. Do not use alcohol for cleaning. Sterilization via

ETO, steam, etc. should not be attempted.

Huntington Professional Products XXX XXX

07-19-A8-092 Ipump Pain Management System Service Manual 3-1

Page 26

3 - Care & Routine Maintenance

3-2 Ipump Pain Management System Service Manual 07-19-A8-092

Page 27

4 - Troubleshooting

In this section Page

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Reviewing the Alarm Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

System Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Range 10 - 2V -- Peripheral/Sensor Errors. . . . . . . . . . . . . . . . . . . . . . . 4-5

Range 30 - 47 -- Motor Control Errors. . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Range 50 - 52 -- RTC Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Range 60 - 62 -- Power Supply Errors . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Range 70 - 74 & L0 -- MPU Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Range 75 - 8D -- Processing Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Range 90 - 9Z & M0 - P3 -- Data Corruption Errors . . . . . . . . . . . . . . . 4-8

Range A0 - J1 -- Processing Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Overview

CAUTION

CAUTION

Pumps under warranty must be returned to the factory for repair. Unauthorized

disassembly/repair will void your warranty. When a pump malfunctions, perform the

following to see if pump operation can be restored. Ensure that the:

• batteries are installed and not depleted.

• batteries are installed correctly (proper polarity).

If this does not restore the pump operation, refer to the Troubleshooting Chart, Table 4-1.

! WARNING !

Only trained, qualified personnel and Baxter authorized service

representatives should perform procedures in this manual.

Contact Baxter Healthcare Corporation to arrange any needed

service support or if you have any questions while servicing the

pump.

The pump must only be serviced by a trained biomedical

engineering technician or Baxter Healthcare personnel.

Reviewing the Alarm Log

Troubleshooting an Ipump device should begin with a review of the alarm log. This

section describes the steps involved for performing this review. For system errors

identified in the alarm log review, refer to the System Error Codes Tables in this chapter to

help determine the component or assembly that may be contributing to the failure.

07-19-A8-092 Ipump Pain Management System Service Manual 4-1

Page 28

4 - Troubleshooting

1. Unlock the Bag Cover and press the <ON/OFF> key to turn the pump on. The Bag

Cover must be open.

2. If the language option is “None,” the display will read “PRESS ENTER FOR

ENGLISH.” The display will cycle through the choices. Press the <ENTER> key

while the ENGLISH choice is being displayed.

3. If a language has been previously configured, the display will be blank and will automatically continue to the next step.

4. When the display reads “SOFTWARE VERSION XX.XX.XX,” hold down the left

arrow key until “TESTING MEMORY” is displayed. “TESTING MEMORY” will

only be displayed momentarily followed by “CONFIGURATION XXXXX.”

5. The display will then read “000 ENTER CONFIG CODE.” Using the left, right and up

arrow keys, input the code 2-1-5 and press the <ENTER> key.

6. Upon entry to the Configuration Set mode, the display will read “CONFIGURATION

PRESS ENTER.” DO NOT PRESS THE ENTER KEY AT THIS TIME.

7. Press the <HISTORY> key .

8. The display will read “ALARM LOG.”

9. Press the right cursor key to display the first system alarm entry. Each system alarm

log entry will be displayed as follows:

SYSTEM ERROR XX

MM/DD/YY HH:MMXM

10. Record all alarms and their associated dates and times.

11. Continue to press the right cursor key to display the next system alarm log entry. The

display will eventually read “END OF ALARM LOG.”

NOTE: If the Alarm Log is empty, the display will read “END OF ALARM LOG.”

12. At the “END OF ALARM LOG” display, press the <ENTER> key. The pump will

then display “CONFIGURATION PRESS ENTER.” To clear the System Alarm Log,

proceed to the next step. T o reta in the System Alarm Log, press the <ON/OFF> key to

turn the pump off.

13. Press the <CLEAR/SILENCE> key. The display will read “RESET CONFIG?”

14. Choose NO and press the <ENTER> key. The display will read “CLEAR HISTORY?” (if there is a history).

15. Choose NO and press the <ENTER> key. The display will read “CLEAR ALARM

LOG?”

16. Choose YES and press the <ENTER> key. The pump will clear the System Alarm

Log and the display will momentarily read “ALARM LOG CLEARED.”

17. When the display reads “CONFIGURATION PRESS ENTER,” press the <ON/OFF>

key to turn the pump off.

4-2 Ipump Pain Management System Service Manual 07-19-A8-092

Page 29

Troubleshooting

The information in this chapter is written for repair to the board or module level. Except

for those items listed, circuit board components are not available from Baxter Healthcare.

Refer to Chapter 6 for disassembly procedures and Chapter 9 for repair parts information.

Symptom Possible Cause Solution

No power (9V)

No power (AC)

(No AC Plug icon)

Constant audible alarm –

no display when battery

or AC Adapter plugged in

No audio alarm Defective Buzzer. Replace the Buzzer.

Constant occlusion alarm

No air alarm or constant

Constant alarm, no LCD

display when ON/OFF

key pressed

Dead/Contaminated 9-volt Battery. Check/replace the 9-volt Battery.

Broken battery leads. Replace the Battery Contact Assembly.

Battery installed with wrong polarity. Remove and re-install the 9-volt Battery.

Defective MPU Board.

Poor AC Adapter connection to pump.

Defective AC Adapter.

Defective AC Connector on the Front

Case.

Defective or disconnected AC Power

Connector inside pump.

Defective MPU Board.

Defective MPU Board. Replace the MPU Board.

Defective MPU Board. Replace the MPU Board.

Damaged/disconnected wiring to Flex

Cable.

Defective occlusion sensors. Replace the Mechanism Assembly.

Defective/damaged Flex Cable or

connector on Mechanism Assembly.

Dirty or jammed Occlusion Sensors.

Defective/damaged J14 connector on

MPU Board.

Defective MPU Board. Replace the MPU Board.

Defective Air Sensor. Replace the Mechanism Assembly.

Air Sensor Disabled. Check the pump configuration.

Bent or broken pin on LCD Module. Replace the LCD Module.

Defective LCD Module. Replace the LCD Module.

Defective MPU Board. Replace the MPU Board.

Check for 9-volt line at J10 connector. If it is

present, replace the MPU Board. If not,

replace the battery contact assembly.

Ensure that the red dots are aligned and

the connector is plugged in fully.

Check the output of the AC Adapter for

10 VDC. Replace the AC Adapter.

Replace the Front Case Assembly.

Check for proper installation of the AC

power connector onto the MPU Board at

J4. Replace the front case assembly.

Check for 10 volts at connector J4. If

present, replace the MPU Board. If not,

replace the Front Case Assembly.

Check wiring to the Flex Cable and resolder

as necessary.

Replace the Mechanism Assembly.

Clean the Occlusion Sensors on the

Mechanism Assembly or replace the

assembly.

Replace the MPU Board.

Table 4-1. Troubleshooting Chart

4 - Troubleshooting

07-19-A8-092 Ipump Pain Management System Service Manual 4-3

Page 30

4 - Troubleshooting

Symptom Possible Cause Solution

LCD not working or

segments missing

No backlighting

“Check Tubing

Placement” screen will

not clear

“Cover Is Unlocked”

alarm will not clear

No input from front panel

keypad

Will not retain memory Low or dead 3V Backup Battery.

Will not accept attempts/

injections from PCA

switch

Will not print

System Error 32 Loose Motor Connector. Tighten the Motor Connector J2 on DDMM.

System Error 33

Defective LCD Module. Replace the LCD Module.

Defective MPU Board. Replace the MPU Board.

Poor connection between J23 and the

LCD Module.

Defective LCD Module. Replace the LCD Module.

Defective MPU Board. Replace the MPU Board.

Tubing segment improperly installed

or not installed.

Dirty or disconnected Flex Cable

Connector to J14 on MPU.

Defective Microswitch.

Defective/damaged Flex Cable. Replace the Mechanism Assembly.

Defective MPU Board. Replace the MPU Board.

Defective Reed Switch on Rear Case. Replace the Rear Case Assembly.

Disconnected Reed Switch.

Missing Magnet (Bag Cover Latch). Repair/replace the Bag Cover.

Defective Lock Assembly. Repair/replace the Bag Cover.

Defective MPU Board. Replace the MPU Board.

Defective Keypad.

Disconnected Keypad Connector. Connect the Keypad Connector.

Bad contact between Keypad Flex

and MPU Board.

Defective MPU Board. Replace the MPU Board.

Defective PCA Cable. Replace the PCA Cable.

Defective PCA Connector on MPU

Board.

Defective MPU Board. Replace the MPU Board.

Defective Printer Connector on MPU

Board.

Defective Motor. Replace the Mechanism Assembly.

Defective/damaged Mechanism

Assembly.

Check to ensure the backlight connector is

properly installed (pins 15 & 16 of J23).

Ensure the tubing set is installed properly.

Refer to the operator’s manual for proper

installation.

Clean and tighten the Flex Cable

Connector.

With a tubing segment properly installed,

check continuity between pins 13 and 14

of the mechanism flex circuit connector

(refer to connector pin-out in Figure 8-3).

If the circuit remains “open,” replace the

Mechanism Assembly.

Connect the Reed Switch Connector to the

MPU Board.

With power removed, check the Keypad for

continuity while pressing the suspected key

(refer to the Keypad pin-out in Figure 8-2).

Check the connector pins and clean/repair

as needed.

Replace the 3V Backup Battery. (Refer to

the 3V Backup Battery Test in Chapter 6.)

Replace the MPU Board.

Check for bent Printer Connector pins.

Replace the Printer Connector if necessary.

Replace the Mechanism Assembly.

Table 4-1. Troubleshooting Chart (Continued)

4-4 Ipump Pain Management System Service Manual 07-19-A8-092

Page 31

System Error Codes

NOTE: If an error code appears on the display, remove all power, then restart the pump. A

problem is indicated if the error persists. Due to the fact that error codes shutdown

the pump, it is difficult to troubleshoot without swapping out suspected assemblies.

As all error codes are software generated, the MPU PCBA is always suspected.

The following tables contain a listing of all error codes that the pump can generate. This

list is provided for reference purposes only.

Range 10 - 2V -- Peripheral/Sensor Errors

Failures specific to components external to the MPU such as switches or the EEPROM.

Code Cause

10 key held, even after warning

11 display RAM failure, pattern 1

12 display RAM failure, pattern 2

13 character generator RAM failure

4 - Troubleshooting

15 display is not responding expeditiously

16 red LED is not functioning

18 green LED is not functioning

19 EEPROM didn't ack write address command preceding read

1A EEPROM didn't ack high address preceding read

1B EEPROM didn't ack low address preceding read

1C EEPROM didn't ack read command

1D EEPROM didn't ack write address command preceding write

1E EEPROM didn't ack high address preceding write

1F EEPROM didn't ack low address preceding write

1G EEPROM didn't ack send byte

1H EEPROM didn't ack write address command within timeout

20 trying to read beyond end of EEPROM

21 trying to write beyond end of EEPROM

22 event log trying to write beyond end of EEPROM

23 system log trying to write beyond end of EEPROM

24 EEPROM read after write failure

25 (Not Used)

26 Rx data int, but Rx buffer is empty

27 error while printing history data

28 Tx could not send config data

29 Tx could not send config data after NAK

07-19-A8-092 Ipump Pain Management System Service Manual 4-5

Page 32

4 - Troubleshooting

2A Tx could not send memory dump data

2B pump turned on by other than the on/off key

2C CRC failure on internal ROM (8000-ffff)

2D CRC failure on external ROM (20000-3ffff)

2E external watchdog circuitry failure during reset test

2F external watchdog circuitry failure during shutdown

2G cat_fmt_str, string too long

2H noise on sensor condition in start_air_sensor

2J upstream occlusion sensor failure

2K downstream occlusion sensor failure

2L air percentage is greater than 100

2M air to_percent macro, attempt to divide by 0

2N Stuck downstream occlusion sensor

2V Stuck upstream occlusion sensor

Range 30 - 47 -- Motor Control Errors

Failures specific to the control of the motor.

Code Cause

30 no forward motion after several control intervals

31 motor runaway

32 can't reach desired speed

33

34

35

36

37 motor moving when it should be stopped

38 motor moving when it should be stopped

39 motor drive transistor failure

40 motor should be stopped, but it is backing up

main encoder counts 25% over nominal value

for one motor rev

main encoder counts 25% under nominal value

for one motor rev

main encoder counts 3% over nominal value

for 8 motor revs

main encoder counts 3% under nominal value

for 8 motor revs

41 motor should be going forward, but it is moving backwards

42 speed nearing mechanical limits

43 not stopping quickly enough

44 Invalid motor control state

4-6 Ipump Pain Management System Service Manual 07-19-A8-092

Page 33

45 Motor should be moving backwards, but it is moving forwards

Attempt to move motor backwards other than during Startup

46

up occlusion test

47 Motor moving while attempting to change direction

Range 50 - 52 -- RTC Errors

Failures specific to real-time clock functionality.

Code Cause

50 RTC vs. system clock comparison error

51 Time read back = time written

52 RTC RAM failure

4 - Troubleshooting

Range 60 - 62 -- Power Supply Errors

Failures specific to power supply voltage checks.

Code Cause

60 power supply voltage is out of range

61 no detectable power source

62 no detectable power source

Range 70 - 74 & L0 -- MPU Errors

Failures specific to the operation of the microprocessor such as the contents of a mode

register being incorrect.

Code Cause

70 a-d converter timeout in voltage check

71 a-d converter timeout in occlusion check

72 illegal interrupt

73 internal watchdog timeout

74 ROM check stack overflow error

L0 CPU test failed

07-19-A8-092 Ipump Pain Management System Service Manual 4-7

Page 34

4 - Troubleshooting

Range 75 - 8D -- Processing Errors

Failures specific to abnormal processing conditions encountered during operation, such as

a stack overflow, or a watchdog timeout.

Code Cause

75 bus_count exceeds maximum limit

76 unknown event received by task

77 tried to remove total not in list

78 software timer out of range

79 B0_isr held off for more than 60ms.

80 stack overflow in BB check_stack()

81 BYTE-BOS stack overflow

82 operations task stack overflow

83 user interface stack overflow

84 serial monitor stack overflow

85 UIT message buffer overflow

86 stop_rx routine called when it should not have been

87 delivery attempt before delay elapsed

88

89 volume given not within +/- 0.5% during bolus

8A

8B volume given not within +/- 0.5% during basal or continuous

8C attempt to infuse at 0 rate

8D BYTE-BOS failure, returned to main

attempt to stop injection when no injection

in progress

volume given not within +/- 0.5% during

PCA injection

Range 90 - 9Z & M0 - P3 -- Data Corruption Errors

Failures specific to Data Corruption Errors -- Error detected during testing of data validity.

Code Cause

90 UIT invalid state during prime

91 UIT invalid state during bolus

92 UIT invalid state during display of SOT

93 UIT invalid state updating history attempts/injections

94

95 UIT invalid state displaying event history

4-8 Ipump Pain Management System Service Manual 07-19-A8-092

UIT invalid state displaying history total given

Page 35

96 UIT invalid state displaying held key info

97 UIT invalid state displaying system errors list

98 UIT invalid state while setting modes

99 UIT invalid state while setting units

9A UIT invalid state while attempting to send replication data

9B UIT invalid state at end of replication

9C UIT invalid state found in auxil table

9D invalid field requested in get_hist()

9E invalid field requested in get_hist_time()

9F history checksum failure, data corrupted

9G invalid field requested in write_history()

9H error in getting rx data units for printing

9J 0 concentration in rx data for printing

9K error in getting rx data units for printing

4 - Troubleshooting

9L configuration checksum failure, data corrupt at startup

9M configuration checksum failure, data corrupt in get_cf()

9N configuration checksum failure, data corrupt in get_cf_string()

9P rx checksum failure, data corrupted at get_rx_units()

9Q rx checksum failure, data corrupted at get_rx_mode()

9R rx checksum failure, data corrupted at get_rx()

9S invalid field requested in argument to get_rx()

9T invalid field requested in argument to set_rx()

9U rx checksum failure, data corrupted at get_rx_all()

9V cur_state is corrupt

9W branch_state is corrupt

9X sw_status is corrupt at soft_status()

9Y sw_status is corrupt at set_soft_status()

9Z pump_status is corrupt at check_status()

M0 pump_status is corrupt at set_status()

M1 pump_status is corrupt at clear_status()

M2 tot_entry list too long in add_entry()

M3 tot_entry list too long in rem_entry()

M4 tot_entry list too long in upd_totals()

M5 invalid address passed to calc_checksum()

M6 LCD line 1 string length too long

M7 LCD line 2 string length too long

M8 EEPROM read after write error in reset_event_log()

07-19-A8-092 Ipump Pain Management System Service Manual 4-9

Page 36

4 - Troubleshooting

M9 EEPROM read after write error in reset_event_log()

N0 EEPROM read after write error in log_event()

N1 EEPROM read after write error in log_event()

N2 EEPROM read after write error in reset_syserr_log()

N3 EEPROM read after write error in reset_syserr_log()

N4 EEPROM read after write error in log_syserr()

N5 EEPROM read after write error in log_syserr()

N6 checksum error on get_next_event()

N8 checksum error on log_syserr()

N9 checksum error on get_next_syserr()

P0 checksum error on get_prev_syserr()

P2 checksum error on event log only in start_logs()

P2 checksum error on syserr log only in start_logs()

P3 checksum error on both logs in start_logs()

Range A0 - J1 -- Processing Errors

Failures specific to abnormal processing conditions encountered during operation variable out of range.

Code Cause

A0 invalid type passed to checkpump()

A1 invalid state in f329_init()

A2 invalid date format in f135()

A3 invalid cursor position in date set, proc12()

A4 invalid cursor position in date set, proc12()

A5 invalid cursor position in date set, proc12()

A6 invalid cursor position in time set, proc24()

A7 invalid cursor position in set_dt_display()

A8 invalid cursor position in set_dt_display()

A9 invalid cursor position in set_dt_display()

B0 invalid state in f234_enter()

B1 invalid state in f303_enter()

B2 invalid state in f304_enter()

B3 invalid state in f310_enter()

B4 invalid state in f319_init()

B5 invalid state in f320_init()

4-10 Ipump Pain Management System Service Manual 07-19-A8-092

Page 37

B6 invalid state in f325_init()

B7 invalid state in f324_init()

B8 invalid state in f330_init()

B9 invalid state in f334_init()

C0 invalid state in f334_init()

C1 invalid state in f335_init()

C2 invalid state in f335_enter()

C3 invalid state in f336_init()

C4 invalid state in f336_enter()

C5 invalid state in f337_enter()

C6 invalid state in f340_init()

C7 invalid state in f345_init()

C8 invalid state in f405()

C9 invalid state in f405_io()

4 - Troubleshooting

D0 invalid reason to stop bolus

D1 illegal event f425()

D2 illegal dose limit type f615_init()

D3 illegal menu item in f730_enter()

D4 illegal menu item in f734_enter()

D5 illegal menu item in f740_enter()

D6 illegal menu item in f750_enter()

D7 illegal menu item in Build766Display()

D8 illegal menu item in f766()

D9 illegal menu item in Build770Display()

E0 illegal menu item in f770()

E1 illegal menu item in f810_enter()

E2 illegal event in proc_i()

E3 illegal event in io_proc_o()

E4 illegal event in io_proc_cur()

E5 illegal str_buf len in io_bcd_to_string()

E6 illegal str_buf len in io_bcd_to_string()

E7 illegal event in proc_menu()

E8 illegal event in proc_menu1()

E9 illegal event in proc_menu2()

F0 illegal event in proc_text()

F1 illegal unit type in get_unit_text()

F2 invalid LED request

07-19-A8-092 Ipump Pain Management System Service Manual 4-11

Page 38

4 - Troubleshooting

F3 invalid audio request

F4 negative number passed to lrtoa()

F5 invalid unit for this print request

F6 decimal point precision out of range

F7 number too big in round_value()

F8 string too long to display

F9 precision too large in sprintg()

G0 unrecognized format in sprintg()

G1 string produced by cpystr() too long for display

G2 unknown timer in process_msg()

G3 unknown key in process_msg()

G4 invalid silence until time requested

G5 invalid config item requested at get_cf()

G6 invalid config item requested at get_cf_string()

G7 invalid config item requested at cf_cond()

G8 invalid config item requested at set_cf()

G9 invalid config item requested at set_cf_string()

H0 invalid timer_id in set_timer

H1 invalid timer_id in kill_timer

H2 invalid clock register requested

H3 variable out of range in hextobcd()

H4 invalid clock register requested in rtc_rd_time()

H5 variable out of range in bcdtohex()

H6 invalid month in days_in_month()

H7 invalid alert time in check_bag_volume()

H8

H9 invalid unit for this print request

J0 invalid field width in 1toaw

J1 invalid field width in 1rtoaw

illegal menu item in restart

pm cycle

4-12 Ipump Pain Management System Service Manual 07-19-A8-092

Page 39

5 - Functional Tests

In this section Page

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Exterior Visual Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Flow Rate Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Procedure Using the Gravimetric Method . . . . . . . . . . . . . . . . . . . . . . . 5-7

Procedure Using the Volumetric Method . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Downstream Occlusion Calibration Pressure Test . . . . . . . . . . . . . . . . . . . . 5-8

Operational Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Test Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Power-On Self Test (POST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Keypad Operation Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Bag Cover Lock/Unlock Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Tubing Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Occlusion Sensor Test - Downstream. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Occlusion Sensor Test - Upstream . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Air Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

PCA Cable & Button Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

AC Adapter Test (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

History Retention Test (Backup Battery Check) . . . . . . . . . . . . . . . . . . 5-14

Printer Test (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Unintended Shutdown Circuit Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

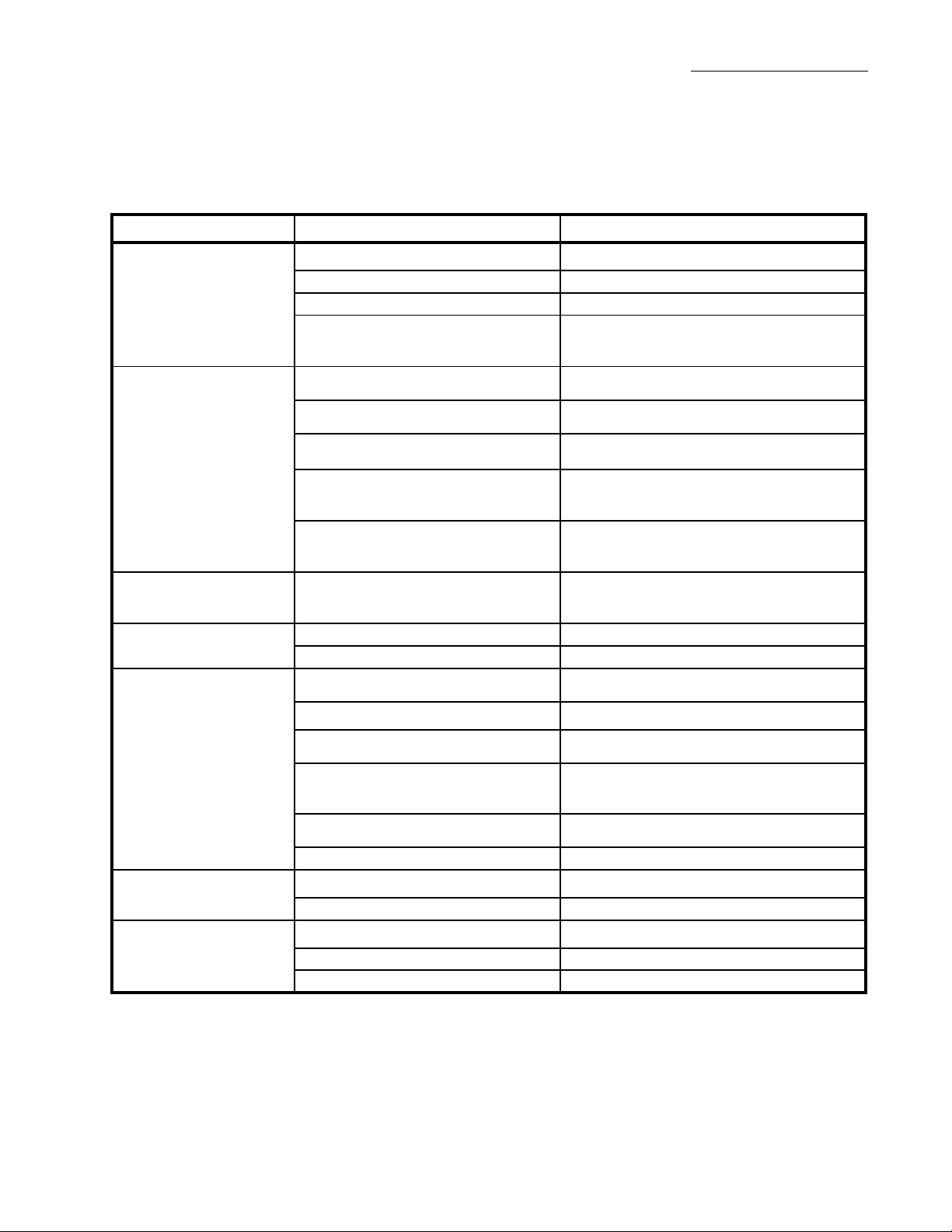

Functional Test Data Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Overview

The pump design includes extensive self-tests which continually monitor the pump’s

operation. These checks occur during normal operation of the pump. When an alarm or

fault condition is detected, the pump generates an error message, flashing LED indicators

and/or an audible alarm. These indicators warn the user of the detected fault. The pump

will stop operating until the fault condition has been corrected.

The test procedures in this chapter ensure that the pump operates properly. It is

recommended that anyone performing these functional tests become familiar with the

07-19-A8-092 Ipump Pain Management System Service Manual 5-1

Page 40

5 - Functional Tests

pump operating procedures contained in the Ipump Pain Management System Operator’s

Manual. To properly perform these tests, the pump must be reset to the specific

configuration settings provided in the procedure on page 5-4.

Pumps that fail any of the tests in this chapter are to be repaired using the information

provided in Chapter 4, "Troubleshooting" and Chapter 6, "Disassembly & Reassembly",

or returned to a Baxter Service Center for repair. Before returning the pump for repair,

record the failure mode and the pump’s setup prior to and during the failu re. Call a Baxter