Page 1

HPB SERIES

ROLL-IN PROOF BOXES

MODELS

HPB1 ML-132003

HPB2 ML-132004

HPB4 ML-132005

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 34480 (Sept. 2000)

Page 2

Model HPB1 Proof Box Model HPB2 Proof Box

© HOBART CORPORATION, 2000

Model HPB4 Proof Box

– 2 –

Page 3

Installation, Operation, and Care of

HPB SERIES PROOF BOXES

SAVE THESE INSTRUCTIONS

GENERAL

The HPB Series Roll-In Proof Boxes are one-, two-, or four-rack cabinets for proofing dough. The Proof

Box’s AirWash™ Humidification System provides ideal proofing conditions and includes accurate

controls for temperature, humidity, and time.

Interior and exterior construction is 300 series stainless steel throughout. Interior bumper guards are

provided for the left, right, and rear walls.

Glass door is an option on the single rack model only. Door hinging on the single door unit can be

reversed, if necessary, by a service technician (but a new ramp is required). Two-door units are hinged

on the side walls and open out from the middle. There is no center post. A door closer is provided above

the right hand door.

Proofers may be ordered with either the Proof Box control or with the Thaw Proofer control:

• The Proof Box control is a single-stage control which controls temperature, humidity, and time.

• Thaw Proofer control is a two-stage control that can work just like the Proof Box control; or, it can

also allow an initial Thaw stage to be automatically followed by a Proof stage. Each stage

independently controls temperature, humidity, and time.

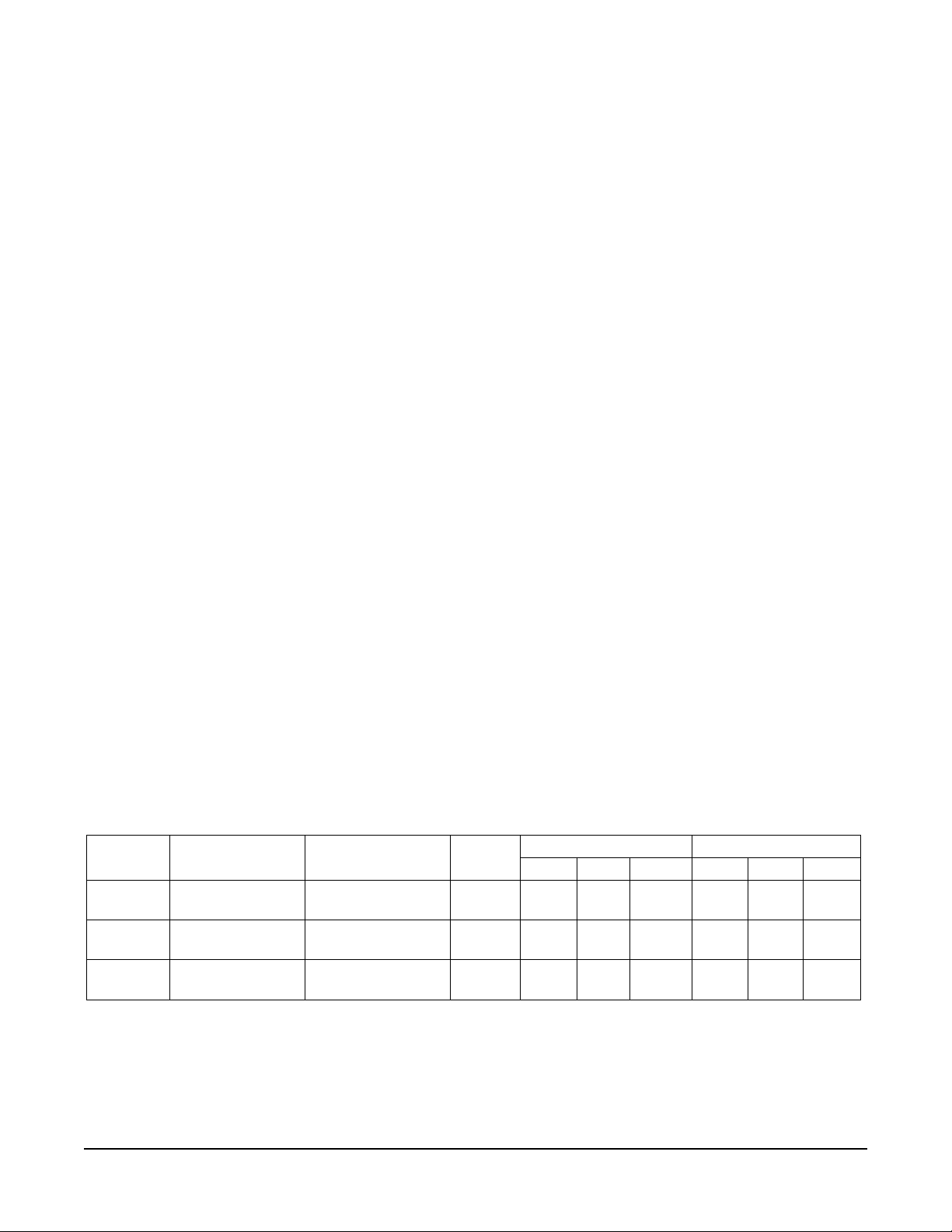

SNOISNEMIDDNA,NOITARUGIFNOC,YTICAPAC

ledoMyticapaCnoitarugifnoC)s(rooD

1BPHkcaRelgniS1

2BPHskcaRelgniS2

4BPH

roskcaRelgniS4

skcaRelbuoD2

xediWelgniS

peeDelgniS

xediWelbuoD

peeDelgniS

xediWelbuoD

peeDelbuoD

htdiWhtpeDthgieHhtdiWhtpeDthgieH

1923/8"031/2""57335/61"533/8"291/8"

3

225

225

/4"031/2"373/4""06533/8"291/8"

3

/4"461/2"373/4""06961/8"291/8"

ROIRETNIROIRETXE

– 3 –

Page 4

INSTALLATION

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the cabinet is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, test the electrical service to verify that it agrees with the data plate located in the

upper left corner inside the cabinet.

SCREWS

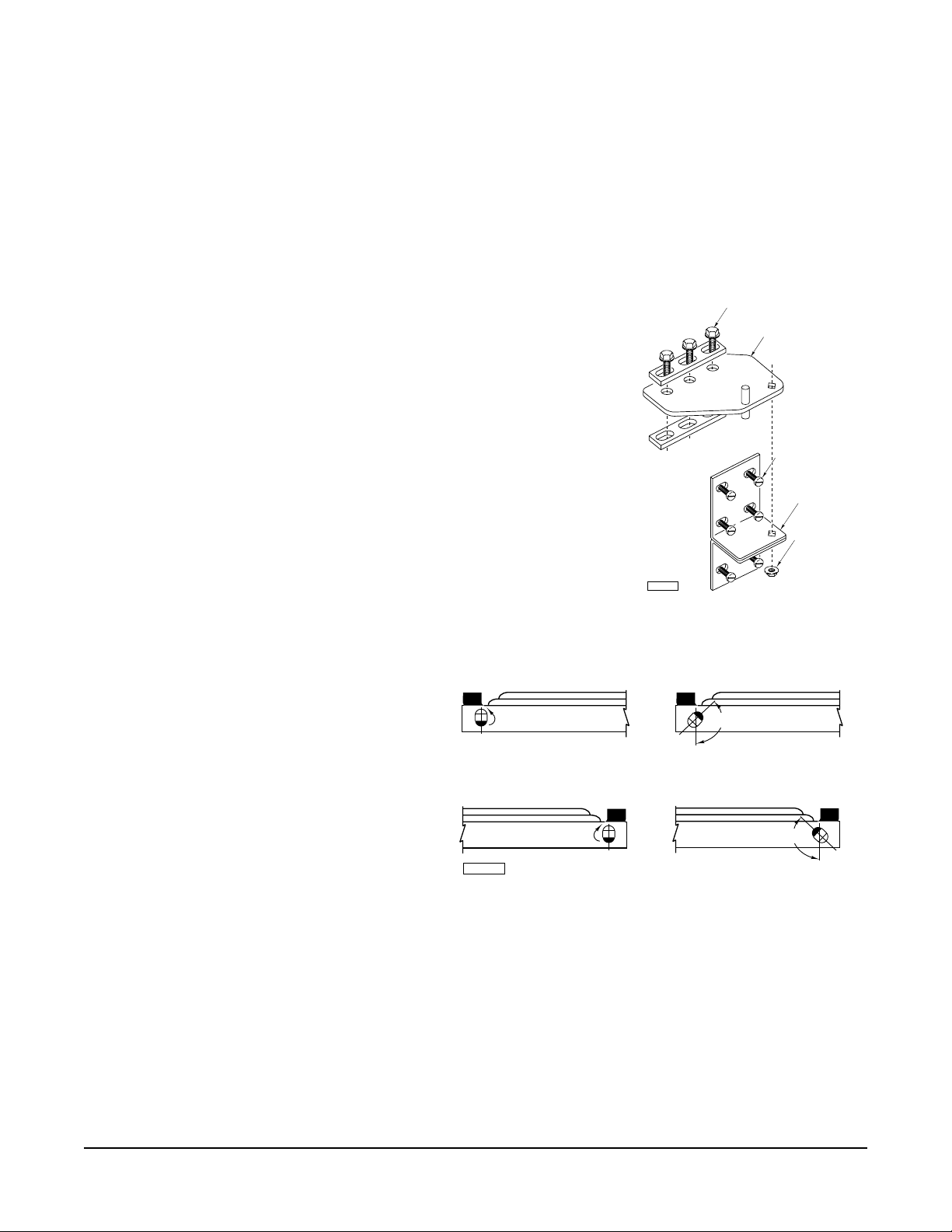

ASSEMBLY

Some components can be removed to allow the cabinet to pass

through short or narrow doorways.

Door(s) and hinges can be removed, as follows:

(3)

UPPER

HINGE

1. Lift up and remove the front trim panel.

2. Carefully lay the front trim panel on top of the cabinet — avoid

damaging the control wires.

3. Remove the three screws which secure the upper hinge plate

to the cabinet (Fig. 1). This will remove hinge tension. Remove

the nut underneath the lower hinge plate which secures the

bottom hinge. Remove the door. Remove lower hinge plate

(Fig. 1).

4. If the hinge mechanism should become

uncocked while changing the door, it

will be necessary to recock the hinge

mechanism. To do this, remove the

UNCOCKED POSITION

TURN 135º

door from the cabinet and position the

door face down on a work table. Using

5

/16" open end or adjustable wrench,

a

turn the hinge mechanism shaft 135°

UNCOCKED POSITION COCKED POSITION

– POSITION 1 – (LEFT-HAND HINGED DOOR)

(Fig. 2).

5. Replace the hinge plates and door(s)

TURN 135º

in the reverse order of disassembly.

PL-50961

– POSITION 2 – (RIGHT-HAND HINGED DOOR)

POSITION DOOR IN ONE OF THE TWO POSITIONS SHOWN.

The humidifier and control box on top of the

proof box cannot be removed to pass through

short openings.

PL-53452

Fig. 2

SCREWS

(6)

LOWER

HINGE

NUT

Fig. 1

COCKED POSITION

135º

135º

ASSEMBLY — Model HPB4

Model HPB4 is shipped in two main sections, front and rear, which must be assembled at the site.

Position the rear half (without doors) as near to the desired final location as possible. Remove eight

hex bolts at the bottom rear of the front section. Remove eight hex bolts at the bottom front of the rear

section. Apply a bead of aluminum colored RTV, provided, on the entire rear joint immediately before

joining the front section.

– 4 –

Page 5

Look at the Cam Locks which are used to join and

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

6

6

6

6

6

6

7

7

7

7

7

7

7

7

7

lock the front and rear sections together. The Cam

Locks on the left and right sides of the rear half are

positioned so that they will swing down and clamp

onto the pins located in the front section.

To lock the Cam Locks on the left side and ceiling,

5

/16" Hex Wrench (not provided) must be turned

a

counterclockwise in the Hex Openings of the Cam

Locks. To lock the Cam Locks on the right side, the

5

/16" Hex Wrench must be turned clockwise in the

Hex Openings of the Cam Locks (Fig. 3).

Move the front half of the Proof Box to its final

position so it mates with the rear half.

Lock the nine Cam Locks. Turn the three Cam

Locks on the left side and the three on top

counterclockwise. Turn the three Cam Locks on

the right side clockwise. Wipe-off any excess RTV

at the section joint. When all Cam Locks are

properly tightened and locked, insert the Plug

Buttons, provided, in the nine Cam Lock holes.

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

FOAM

STOP

CAM FAST UNLOCKED

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

HEX WRENCH

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

LOCK ASSEMBLY

ON TONGUE OF PANEL

STOP

23456789012345

23456789012345

23456789012345

CAM FAST LOCKED

Fig. 3

PANEL SKIN

LOCKING ARM

HEX OPENING

2345678901234567890123456789012123

2345678901234567890123456789012123

PIN ASSEMBLY

2345678901234567890123456789012123

2345678901234567890123456789012123

ON GROOVE OF PANEL

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

2345678901234567890123456789012123

23456789012345

2345678901234567890123456789012123

23456789012345

2345678901234567890123456789012123

23456789012345

LOCKING PIN

FOAM

LOCKING ARM

Humidifier Crossover Duct Assembly - Model HPB4

On Model HPB4, the Crossover Duct is shipped loose and must be assembled after the front and rear

sections are joined. Remove the cover on the front fan unit by removing six screws. Apply a bead of

clear RTV (provided) to all mating surfaces of the crossover duct, humidifier, and front fan unit. Make

sure the end of the crossover duct with the two plain flanges faces the humidifier section. Slide the

crossover duct (Fig. 4) into place so the flanges fit the slots in the humidifier and front fan unit. Secure

the crossover duct using nine #10-24 Phillips head screws provided. Replace the front fan unit cover

and secure it using nine #10-24 Phillips head screws.

HUMIDIFIER

REAR FAN UNIT

ELECTRICAL BOX

CONDUIT NUT

CONDUIT CABLE

23456

23456

23456

23456

23456

23456

23456

23456

23456

REAR SECTION

CROSSOVER DUCT

FRONT FAN UNIT

FRONT SECTION

Fig. 4

– 5 –

CONTROLS

Page 6

ASSEMBLY — ELECTRICAL WIRING — Model HPB4

WARNING: ELECTRICAL AND GROUNDING CONNECTS MUST COMPLY WITH THE APPLICABLE

PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL ELECTRICAL

CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT.

Remove the top panel from the electrical box located on the top of the rear section. Extend the flexible

conduit cable from the front fan unit to the mating conduit fitting on the electrical box. Insert the two

wires from the front fan unit conduit cable into the electrical box. Connect the two wires from the front

fan unit conduit cable to terminal block location J2, terminals 1 and 2 in the electrical box per the wiring

diagram. Tighten the conduit connector nut "Finger Tight" to the mating conduit fitting on the front of

the electrical box (Fig. 4). Replace the top panel on the electrical box.

Also, connect the three cables to the Controls (Fig. 4). A nine pin cable connects to the connector on

the electrical box and to another nine pin connector on the Controls. A two wire cable extends from

the electrical box and connects to a mating connector that extends from the Controls. The cable from

the humidifier requires an extension cable that is shipped with the unit. All cables have separate unique

connectors.

Assemble the Floor Plate over the Floor Joint — Model HPB4

Place the floor plate over the floor joint where the front and rear sections join. Mark the twelve holes

3

in the floor plate using the floor plate as a template. Drill twelve

/16" diameter holes through the marked

hole locations in the top-surface of the cabinet floor. Install the twelve rivets, provided, to secure the

floor plate over the joint of the cabinet floor using a rivet tool, not provided.

LEVELING

Once the cabinet is in its final position, replace any components that may have been removed and then

level the cabinet front-to-back and side-to-side using shims as required.

SEALING THE BASE

Before installing the ramp, seal between the base of the cabinet perimeter and the floor by applying

a bead of NSF-listed sealant, such as Dow Corning 732 or Devcon Silicone #17150.

INSTALLING THE RAMP

On models HPB2 and HPB4, lower the ramp in place so the notches on the ramp slide over the two

mounting brackets on either side of the center screws.

On model HPB1, back out the four screws along the front edge of the bottom. Lower the ramp in place

so the notches on the ramp slide over the 4 screw heads.

– 6 –

Page 7

PLUMBING CONNECTIONS

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY,

AND PLUMBING CODES.

Make sure the water supply has proper hardness, pH and chloride concentration. The recommended

water hardness range is 4 – 6 grains per gallon. The recommended pH range is 6.5 to 8.0. The

acceptable range for chloride concentration is 0 – 30 ppm. Consult your local water company and/or

water conditioner dealer before installing the Proof Box.

Water Connection

Model HPB1 Shown

Connect the water supply to the incoming water

connection located at the top rear (Fig. 5). The

1

/8" NPT external threaded fitting on the filter,

DRAIN CONNECTION

provided for the incoming water connection, is

plumbed to the solenoid valve and ready for the

1

ferrule fitting of

/4" copper tubing. The water line

should provide 40 – 60 psig flowing pressure.

Drain Connection

The copper pipe extending from the rear of the

humidifier (Fig. 5) must be extended to an open

1

drain. Plastic (Tygon)

/2" I.D. tubing and a

WATER CONNECTION

PL-41447-1

tubing clamp are recommended. Avoid bends

and kinks. A vented drain line (open gap-type)

Fig. 5

is recommended to avoid air lock.

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH APPLICABLE

PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL ELECTRICAL

CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT.

Refer to the wiring diagram supplied with the cabinet.

ATADLACIRTCELE

yticapmAtiucriCmuminiM

ledoMesahP/ztreH/stloV

SPMA

1BPH802--05/042--1/0602

2BPH802--05/042--1/0602

4BPH802--05/042--1/0602

.noitidetsetal,07APFN,edoClacirtcelElanoitaNehthtiwecnadroccanidelipmoC

– 7 –

eciveDevitcetorPmumixaM

Page 8

CONTROLS — Proof Box (Fig. 6)

OPERATION

ON

OFF

TEMP

F

SET VIEW

HUM

%

SET

PROOF BOX

Fig. 6

On-Off Switch Turns the Proofer Control On or Off.

ON

OFF

TEMP normally displays the Set-Point Temperature.

TEMP

F

To adjust the Set-Point Temperature, press and hold

to Increase or to Decrease.

SET VIEW

VIEW

displays the Actual Temperature.

TIMER

SET

STOP

START

SET

while using

HUM

TIMER

SET

STOP

HUM displays the Humidity Set-Point.

SET

while using

SET

%

To adjust the Humidity Set-Point, press and hold

to Increase or to Decrease.

TIMER displays the minutes remaining [zero (0) indicates not in use].

SET

while using to Increase

STOP

START

To set the Time, press and hold

or to Decrease.

START

To start the Timer, press

. The Time (minutes) displays and begins

flashing as it counts down. When the Timer reaches zero (0), a beeper

SET

sounds for 30 seconds. To stop the beeper, press

ON-OFF, TEMP, HUM, and TIMER functions described above, also apply to the THAW

PROOFER

, page 9.

STOP

.

– 8 –

Page 9

CONTROLS — Thaw Proofer (Fig. 7)

SET THAW

PROOF

AUTOMATIC

MODE

ON

OFF

TEMP

F

SET VIEW

HUM

%

SET

THAW PROOFER

Fig. 7

Press

MODE

and or to select Proof, Set Thaw, or Automatic mode.

The mode lights indicate control function

SET THAW

PROOF

AUTOMATIC

PROOF mode allows you to set Temperature, Humidity, and Time

values for manual or automatic proofing operations. To start a

manual (non-timed) proofing operation, press

Temperature, Humidity, and Time, refer to the previous page.

S

SET THAW

PROOF

AUTOMATIC

ET THAW mode allows you to set Temperature, Humidity, and Time

values for the Preheat and Thaw portions of an Automatic cycle

without disturbing an ongoing proofing operation. Thaw values are

set the same as Proofer values — refer to page 8. Control returns

to manual Proof mode if no buttons are pressed in 30 seconds. To

enter Set Thaw mode, the timer must not be running.

SET THAW

PROOF

AUTOMATIC

MODE

TIMER

SET

SET

START

STOP

STOP

:

START

. To set

SET THAW

PROOF

AUTOMATIC

UTOMATIC — displays Thaw Temperature and Thaw Humidity.

A

Thaw Temperature flashes when reached, indicating ready-to-

load. Load the product and press

START

to begin an Automatic Thaw

and Proof cycle.

UTOMATIC THAW — maintains the Thaw Temperature and Thaw

SET THAW

PROOF

AUTOMATIC

SET THAW

PROOF

AUTOMATIC

A

Humidity while the Thaw Time counts down. After the Timer counts

down to zero, the control immediately goes into Automatic Proof.

AUTOMATIC PROOF — maintains the Proof Temperature and Proof

Humidity while the Proof Time counts down. After the Timer counts

down to zero, the control beeps and the display flashes indicating

that the product is ready to be unloaded from the proofer and moved

to an oven for baking. The control returns to manual Proof mode.

During Automatic mode —

To cancel the Thaw portion of an Automatic cycle, press Timer Set/Stop and advance to the Proof portion.

To cancel the entire Automatic Thaw and Proof cycle, press the Mode button and return to manual Proof.

– 9 –

Page 10

REMOTE CONTROL — Proofer and Thaw Proofer (Fig. 8, When Equipped)

SET

TEMP

SET

HUM

SET

TIMER

Connect Remote Control

“Phone Jack” to terminal

on Electrical Box on Top

of Unit

VIEW

TEMP

MODE

START

TIMER

Fig. 8

The Remote Control is used in conjunction with either Proofer Controls or Thaw Proofer Controls

MODE

described on the previous two pages. The

key is used only on Thaw Proofer models.

PROOFING

Controlled temperature and humidity in the proofer promotes yeast fermentation which generates gas

and causes the dough to rise. Proofing takes from 45 – 60 minutes depending on the product. A

temperature setting of 95°F and humidity at 85% are typical but will vary slightly depending on the

product being proofed. Ask your dough supplier for information so you can make a chart with the

Temperature, Humidity, and Proof Times required for the products you will be baking.

– 10 –

Page 11

MAINTENANCE

WARNING: DISCONNECT ELECTRICAL POWER BEFORE CLEANING.

CLEANING

Cabinet

Clean the inside of the cabinet and the doors weekly with a warm water solution of mild household liquid

dishwashing detergent (such as Palmolive green or Ivory). Do not use anything containing grit,

abrasive materials, bleach, harsh chemicals, or chlorinated cleaners. Be cautious with new or

improved formulas; use only after being well tested. Rinse thoroughly and dry with a clean soft cloth.

Do not use steel wool to clean surfaces.

Side Ducts

The Side Duct(s) can be removed for cleaning by unscrewing the Phillips head screws (four on each

side). Replace Side Duct(s) and snug all Phillips head screws after cleaning.

Ramp

The Ramp can be removed for cleaning and reinstalled (refer to page 6).

NOTE: Failure to follow instructions may void your Hobart warranty.

Gaskets

Door gaskets should be cleaned weekly using a warm water solution of mild household liquid

dishwashing detergent (such as Palmolive green or Ivory). Never allow gaskets to contact concentrated

cleaners or disinfectants. This can cause premature failure of the gasket material.

– 11 –

Page 12

SERVICE

For additional information or to discuss a maintenance program, contact your local Hobart-authorized

service office.

FORM 34480 (Sept. 2000) PRINTED IN U.S.A.

– 12 –

Loading...

Loading...