Page 1

Operator & Installation

HYBRID CONVECTION OVEN

Manual

HCO100G ML-132510

Model Number: ___________

Serial Number: ___________

Date of Installation: ___________

Baxter Mfg, a Division of ITW FEG, LLC • 19220 State Route 162 East • Orting, WA 98360-9236

Phone: (360) 893-5554 • Fax: (360) 893-1337

www.baxterbakery.com

FORM 36722 (March 2011)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND ADJUSTMENTS

OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED FROM THE

LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS

AT MAIN SHUTOFF VALVE AND CONTACT THE LOCAL GAS

COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO

OPERATE THIS DEVICE.

KEEP AREA AROUND OVEN CLEAR OF COMBUSTIBLES. DO

NOT OBSTRUCT COMBUSTION AND VENTILATION OPENINGS

ON THE OVEN.

©BAXTER MFG, 2011

This manual has been prepared to provide information in accordance with

ANSI Z83.11-2007 for gas equipment.

– 2 –

Page 3

TABLE OF CONTENTS

GENERAL ............................................................................................................................................. 4

INSTALLATION ..................................................................................................................................... 4

Location ........................................................................................................................................... 5

Water Requirements ........................................................................................................................ 5

Installation Codes and Standards .................................................................................................... 5

Assembly ......................................................................................................................................... 6

Gas Connections ............................................................................................................................. 6

Testing the Gas Supply System ....................................................................................................... 6

Ventilation ........................................................................................................................................ 6

Elevation De-Rating ......................................................................................................................... 7

Plumbing Connections ..................................................................................................................... 7

Drain Connections ........................................................................................................................... 7

Electrical Connections ..................................................................................................................... 8

Dimensions Diagram ....................................................................................................................... 9

OPERATION .........................................................................................................................................11

Door Opening And Closing .............................................................................................................11

Controls ..........................................................................................................................................11

Setting the Clock ........................................................................................................................... 13

Setting the Bake Temperature ....................................................................................................... 13

Setting the Bake Timer .................................................................................................................. 13

Setting the Steam Timer ................................................................................................................ 14

Setting the Fan Delay .................................................................................................................... 14

Cool Down Mode ........................................................................................................................... 14

Recipe Designations ...................................................................................................................... 15

Entering Recipes ........................................................................................................................... 15

Using and Reviewing Recipes ....................................................................................................... 15

Customized Operation ................................................................................................................... 15

Basic Operation ............................................................................................................................. 18

CLEANING .......................................................................................................................................... 19

Daily Cleaning ............................................................................................................................... 19

Glass Cleaning .............................................................................................................................. 19

MAINTENANCE .................................................................................................................................. 20

Light Replacement ......................................................................................................................... 20

Service and Parts Information ....................................................................................................... 20

Schematic ...................................................................................................................................... 21

– 3 –

Page 4

INSTALLATION, OPERATION AND CARE OF

HCO HYBRID CONVECTION OVENS

SAVE THESE INSTRUCTIONS

GENERAL

HCO Series Hybrid Convection Ovens (Fig. 1) are designed for your baking needs. There is one size

available, but it is stackable to provide a bank of two independent units. They are produced with quality

workmanship and material. Proper installation, usage and maintenance of the ovens will result in years

of satisfactory performance.

It is suggested that you thoroughly read this manual and carefully follow the instructions provided.

Fig. 1

INSTALLATION

The HCO100G Hybrid Convection Oven comes pre-assembled, but requires qualifi ed personnel to install

and make connections.

UNPACKING

This oven was inspected before leaving the factory. The transportation company assumes full responsibility

for safe delivery upon acceptance of the shipment. Immediately after unpacking, check for possible shipping

damage. If the oven is found to be damaged, save the packaging material and contact the carrier within

15 days of delivery.

Carefully unpack the oven and place in a work-accessible area as near to its fi nal installed position as

possible. Remove protective covering from exterior surfaces prior to placing oven in its fi nal location.

Prior to installation, verify that the electrical and the water service agree with the specifi cations on the

oven data plate and in this manual.

– 4 –

Page 5

LOCATION

The HCO100G Hybrid Convection Oven must have the following minimum clearances to combustibles:

• Top and Sides: 0"

• Back 1" from motor

The oven must be installed on a noncombustible surface and combustibles may not be stored beneath

the mounting surface.

NOTE: Minimum 24" clearance needed for service access on the right side.

Do not obstruct the fl ow of combustion and ventilation air. Adequate clearance for air openings

into the combustion chamber must be provided. Make sure there is an adequate supply of air in the room

to replace air taken out by the ventilating system.

WATER REQUIREMENTS

As with all steam related products, water fi ltration and regular fi lter replacements, coupled with

routine deliming, are required. Your local Hobart Service offi ce can recommend a water treatment system

to meet the needs of your local water conditions. Contact your local Hobart Service representative for

water treatment offerings.

Proper water quality can improve the taste of the food prepared in the oven, reduce liming and extend

equipment life. Local water conditions vary from one location to another. The recommended proper water

treatment for effective and effi cient use of this equipment will also vary depending on the local water conditions.

Ask your municipal water supplier for details about your local water supply prior to installation.

Recommended water hardness is 2.0 to 6.0 grains of hardness per gallon with pH from 7.0 to 8.0. Chlorides

must not exceed 30 parts per million. Water hardness above 6.0 grains per gallon should be treated by

a water conditioner (water softener and/or in-line water treatment). Water hardness below 4.0 grains per

gallon may also require a water treatment system to reduce potential corrosion. Water treatment has

been shown to reduce costs associated with machine cleaning, reduce deliming and reduce corrosion of

metallic surfaces.

INSTALLATION CODES AND STANDARDS

The oven must be installed in accordance with:

In the United States:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1 (latest edition). Copies may be obtained from The American

Gas Association, Inc.; 1515 Wilson Blvd.; Arlington, VA 22209.

3. National Electrical Code, ANSI/NFPA-70 (latest edition).

In Canada:

1. Local codes.

2. CAN/CGA-B149.1 Natural Gas Installation Code (latest edition).

3. CAN/CGA-B149.1 National Fuel Gas Code (latest edition), available from The Canadian Gas

Association; 178 Rexdale Blvd.; Etobicoke, Ontario; Canada M9W 1R3.

– 5 –

Page 6

ASSEMBLY

BRACKET

The oven must be installed on a stand, proofer cabinet

or any non-combustible surface.

The oven must be sealed to the stand with an NSFapproved sealant, such as Dow Corning 732 or GE

RTV 108.

Secure the oven to the stand or proofer using the

SCREWS

provided tie down brackets, which mount on the rear

of the oven (Fig. 2).

Oven Mounted on a Stand or Proofer with Caster

Fig. 2

For an appliance equipped with casters:

1) It must be installed with casters supplied.

2) The installation shall be made with a connector that complies with the Standard for Connectors for

Movable Gas Appliances, ANSI Z21.69 or Connectors for Moveable Gas Appliances, CAN/CGA-6.16,

and a quick-disconnect device that complies with the Standard for Quick-Disconnect Devices for

Use With Gas Fuel, ANSI Z21.41, or Quick Disconnect Devices for Use with Gas Fuel, CAN1-6.9.

3) Must be installed with restraining means to guard against transmission of strain to the connector,

as specifi ed by the manufacturer. Adequate means must be provided to limit the movement of the

appliance.

GAS CONNECTIONS

Gas supply connections and any pipe joint compound must be resistant to the action of propane

gases.

The HCO100G is an indirect gas-fi red oven, consisting of a heat exchanger with three independent tubes,

each with a separate in-shot burner rated at 13,333 BTU/hr for a total input of 40,000 BTU/hr.

Prior to lighting, check all joints in the gas supply line for leaks. Use soap and water

solution. Do not use an open fl ame.

TESTING THE GAS SUPPLY SYSTEM

When gas supply pressure exceeds

1

/2 psig (3.45 kPa), the oven and its individual shutoff valve must be

disconnected from the gas supply piping system.

When gas supply pressure is

1

/2 psig (3.45 kPa) or less, the oven should be isolated from the gas supply

system by closing its individual manual shutoff valve.

VENTILATION

Information on the construction and installation of ventilating hoods may be obtained from the standard

for Vapor Removal from Cooking Equipment, NFPA No. 96 (latest edition), available from the National

Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

Indirect Vent (Under Exhaust Hood) - Standard

Locate the oven under an exhaust hood with adequate overhangs and exhaust rates to completely capture

the by-products of combustion discharged from the fl ue. From the termination of the fl ue to the fi lters of

the hood venting system, a minimum clearance of 18" (45.7 cm) must be maintained. The hood exhaust

fan can be electrically interlocked with the oven.

– 6 –

Page 7

ELEVATION DE-RATING

This unit has been tested to a higher rating to allow safe operation of the unit at 40,000 BTU/hr up to an

elevation of 5000 ft (1524 m). After 5000 ft (1524 m) elevation, the following are the corrected values.

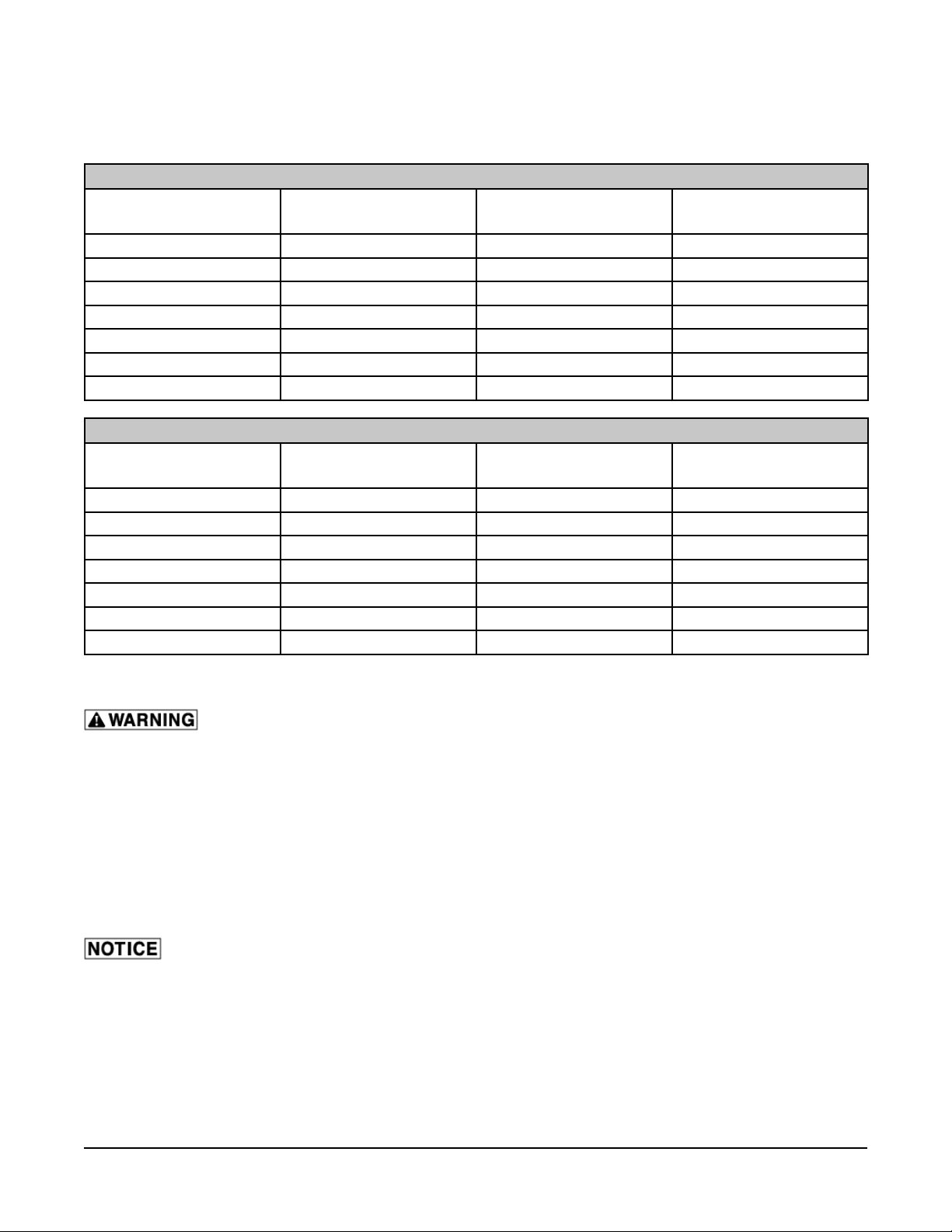

NATURAL GAS

RATING (BTU/HR) MANIFOLD

ORIFICE SIZE

PRESSURE

5000 ft (1524 m) 40,000 3.0 #50 (.070)

5500 ft (1676 m) 39,000 2.9 #50 (.070)

6000 ft (1829 m) 38,000 2.75 #50 (.070)

6500 ft (1981 m) 37,000 2.6 #50 (.070)

7000 ft (2134 m) 36,000 2.5 #50 (.070)

7500 ft (2286 m) 35,000 3.5 #52 (.0635)

8000 ft (2438 m) 34,000 3.25 #52 (.0635)

PROPANE GAS

RATING (BTU/HR) MANIFOLD

ORIFICE SIZE

PRESSURE

5000 ft (1524 m) 40,000 10.5 #58 (.042)

5500 ft (1676 m) 39,000 10.0 #58 (.042)

6000 ft (1829 m) 38,000 9.5 #58 (.042)

6500 ft (1981 m) 37,000 9.0 #58 (.042)

7000 ft (2134 m) 36,000 8.6 #58 (.042)

7500 ft (2286 m) 35,000 8.1 #58 (.042)

8000 ft (2438 m) 34,000 7.6 #58 (.042)

PLUMBING CONNECTIONS

Water and waste piping and connections shall comply with the International Plumbing

Code 2003, International Code Council (ICC), or to the Uniform Plumbing Code 2003, International

Association of Plumbing and Mechanical Offi cials (IAPMO). Plumbing connections must comply

with applicable sanitary, safety and plumbing codes and provide adequate backfl ow protection to

comply with applicable federal, state and local codes.

Connect the cold water supply to the

3

/8" NPT connection located at the rear of the oven. Water supply

should have a pressure of 20 to 80 psi. The oven is supplied with a fl ow regulator which must remain on

the oven.

DRAIN CONNECTIONS

In order to avoid any back pressure in the oven, do not connect solidly to any drain.

Route the drain line to a fl oor drain, allowing a minimum 1" air gap between the drain line outlet and fl oor

drain.

– 7 –

Page 8

ELECTRICAL CONNECTIONS

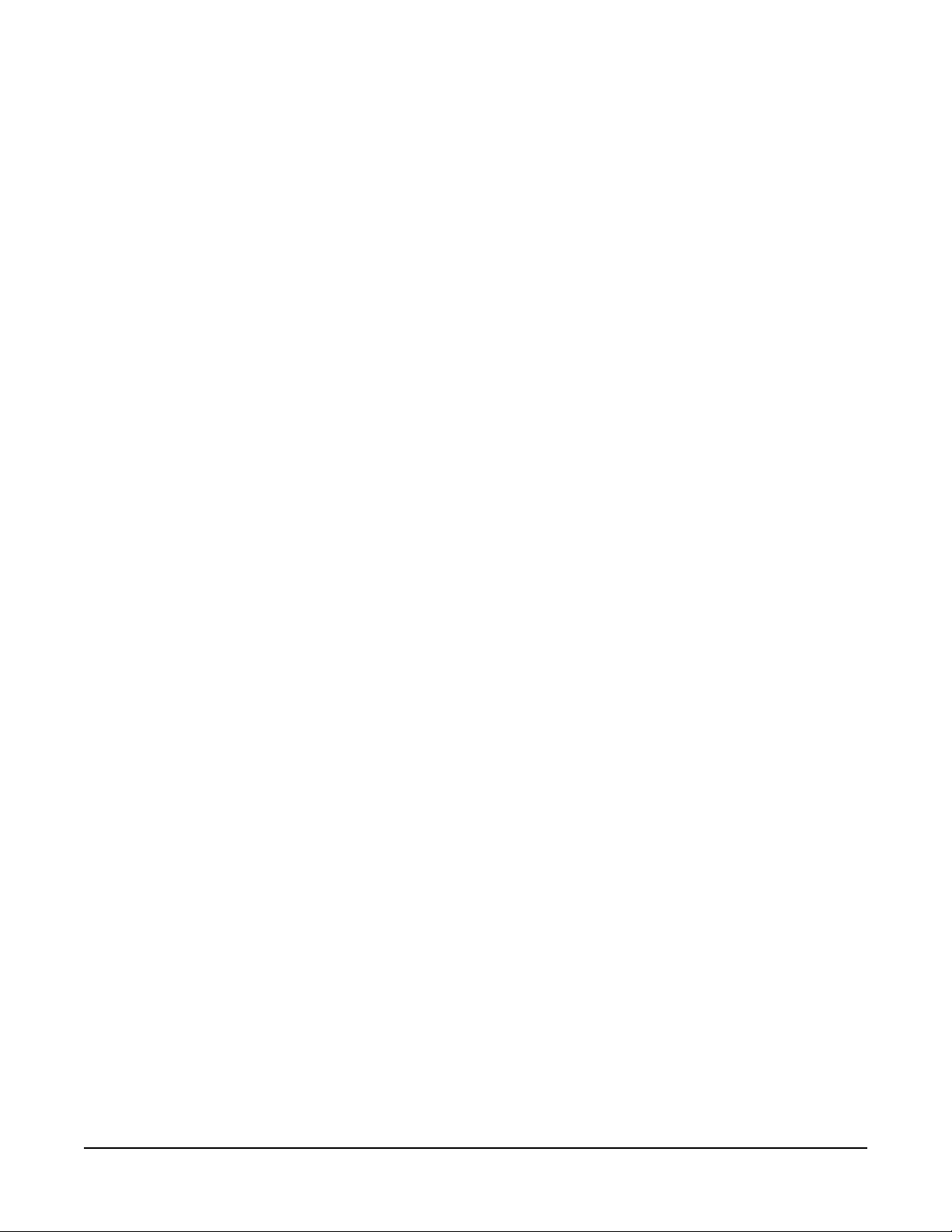

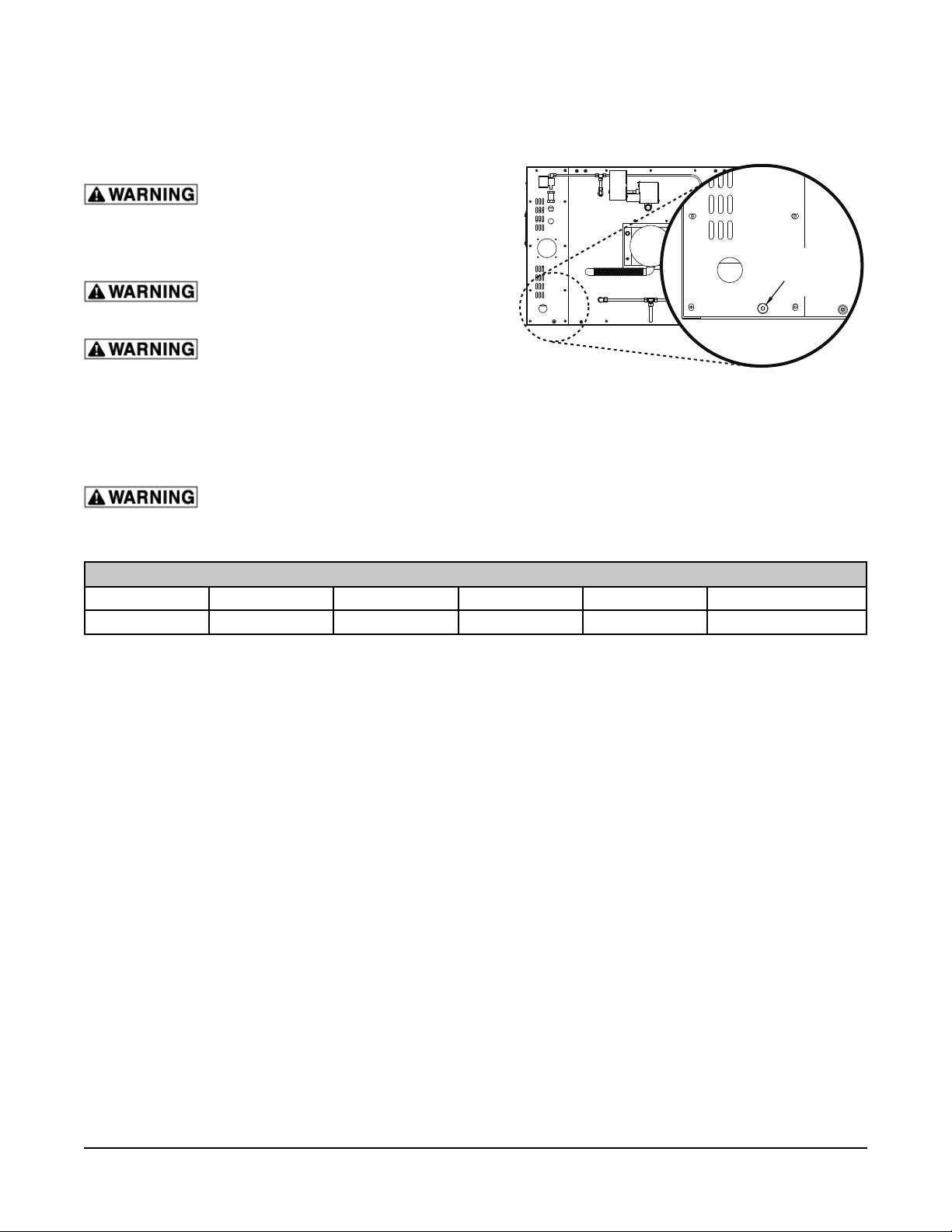

NOTE: The oven must be installed with the provided lanyard securely attached to the oven (Fig. 3) and to

the wall. Verify that all connections are long enough so that the oven can be pulled forward to the extent

of the lanyard without straining any connections.

Electrical and grounding connections

must comply with the applicable portions of the

National Electrical Code and/or other local electrical

codes.

Disconnect the electrical power to the

LANYARD

CONNECTION

POINT

unit and follow lockout / tagout procedures.

Appliances equipped with a fl exible

electric supply cord are provided with a three-prong

grounding plug. This plug must be connected into

Fig. 3

a properly grounded three-prong receptacle. If the receptacle is not the proper grounding type,

contact an electrician. Do not remove the grounding prong from this plug.

The wiring diagram is located behind the side service panel on the right side of the oven.

Do not connect the HCO100G gas model to the electrical supply until after gas

connections have been made.

ELECTRICAL DATA (Per Unit)

Model Voltage Phase Amps Motor Max Breaker Size

HCO100G 120 1 6.4

1

/2 Hp.* 15 Amp.

* 5.4 amp included in rating.

– 8 –

Page 9

DIMENSIONS DIAGRAM

STEAM VENT

WATER INLET

3

5

8

N

I

A

2

1

R

0

D

2

L

C

5

27

8

35

MUST BE MOUNTED ON STAND (OPTIONAL)

OR NON-COMBUSTIBLE SURFACE

35

1

3

4

4

3

8

7

7

2

5

8

HCO100G Without Stand Base

412

38

47

5

1

9

2

WATER IN

1

4

3

" WATER

8

CL VENT

7

6

8

15

3

8

INLET

MOTOR

5

3

8

8

6' CORD

120V, 15 A PLUG

7

49

8

5/8" DRAIN

8

6

HCO100G With Stand Base

– 9 –

5

4

3

1

38

2

Page 10

49 7/8 in

35 in

47 1/8 in

n

n

i

8

/

7

9

6

n

i

8

/

7

7

2

i

6

7

5 1/2 in

n

i

4

1

6 3/8 in

HCO100G Double Stacked With Stand Base

– 10 –

Page 11

OPERATION

The oven and its parts are hot. Use care when operating, cleaning or servicing the

oven. The baking compartment contains live steam. Stay clear when opening door.

DOOR OPENING AND CLOSING

To open the door, pull from top of handle (Fig. 4) and

open door slightly to allow steam to escape.

After the steam escapes, open the door to allow

removal of pans.

To close door, push to close.

Fig. 4

CONTROLS

Control Panel Displays

WINDOW DESCRIPTION

TEMPERATURE

DISPLAY

TIMER DISPLAY

TIMER

TIMER DOTS

STEAM TIMER

STEAM

FAN DELAY

FAN

DELAY

RECIPE DISPLAY

R

RECIPE

STEP DISPLAY

STEPS

1 2 3 4

LED in thermometer is the Heat On indicator.

Main display indicates set temperature in normal operation or

actual temperature when called for.

F or C LED indicate temperature in Fahrenheit or Celsius.

Timer dot in left window indicates timer is confi gured for MM:SS.

Timer dot in right window indicates timer is confi gured for HH:MM.

When timer is set for more the 5 minutes, timer will confi gure to

HH:MM.

Will show time of day if oven is off.

Display will show time in seconds for steam. It will count down

when steaming. When complete, it will show "00" except in Food

Service Steam mode.

In Food Service mode, display resets timer for next cycle.

Display will show time in minutes for Fan Delay. It will count down

when selected and period will fl ash. If "00" shows, fan will run if

door closed.

Display will show recipe number selected when used.

Display will show step number of recipe selected and operating if

recipes are being used.

POWER

TIMER

STEAM FAN

R

RECIPE

VENT

R

START / STOP

ENTER

LOW

STEPS

1 2 3 4

DELAY

STEPS

1 2 3 4

– 11 –

Page 12

Control Panel Buttons

BUTTON ACTION DISPLAY

POWER BUTTON

Press to turn oven on or off. Time of day will be displayed in Timer window when

oven is off.

All display widows will show values when oven is on.

PRIMARY

UP/DOWN

BUTTON

SET TEMPERATURE

BUTTON

TIMER BUTTON

STEAM BUTTON

FAN DELAY BUTTON

VENT OPEN BUTTON

LOW FAN BUTTON

START/STOP BUTTON

Press to set selected temperature,

time, steam, or fan delay.

Press to set temperature.

Press and hold for 5 seconds to see

Will change set temperature, set time, steam time,

or fan delay time.

LED is illuminated when in set temperature mode.

LED will fl ash when showing actual temperature.

actual temperature.

Press to set Bake time. LED is illuminated when in Set Timer mode.

Press to set Steam function and

LED is illuminated when in Set Steam Time mode.

time.

Press to set Fan Delay mode. LED will illuminate to show in set mode.

Press to open or close vent on oven. LED will illuminate to show vent is open.

Press to start or stop low fan

LED will illuminate if low fan is operating.

operation. Only active when oven

temperature is below 450 degrees.

Press to Start/Pause or Stop Baking

timer.

If bake time running ":" will fl ash in LED timer and

time will be counting down. If Paused, no ":" fl ash

and time is held.

SECONDARY

UP/DOWN

BUTTON

RECIPE BUTTON

R

STEP BUTTON

STEPS

1 2 3 4

ENTER BUTTON

ENTER

Press to change Recipe or Step

number.

Press to select a recipe number.

Press and hold along with the

Enter button for 5 seconds to enter

programming mode.

Will change set recipe number or step number

depending on selection.

LED will illuminate.

Press Secondary UP/DOWN button to select

program number in recipe display. LED will fl ash

when an empty recipe is displayed.

Press to select the step number. LED will illuminate. Press Secondary Up/Down

button to select step number in step display.

Press to select and enter program

number for operation. Press and hold

for 5 seconds to exit program mode.

If program mode not selected, press

to recall last manual setting before

START/STOP pressed.

– 12 –

Page 13

SETTING THE CLOCK

1. Press the Power button to turn the oven on.

2. Press and hold the Timer button for 5 seconds.

The indicator next to the button will fl ash and

the current time will be displayed in the timer

window.

POWER

TIMER

STEAM FAN

R

RECIPE

DELAY

STEPS

1 2 3 4

POWER

BUTTON

TIMER

WINDOW

TIMER

BUTTON

TIMER

STEAM FAN

R

RECIPE

DELAY

STEPS

1 2 3 4

3. Use the Primary Up/Down Arrow buttons to set

the clock. The time will save after 5 seconds of

inactivity.

NOTE: The clock can be confi gured for 12 or 24

hour display. See Setup Guide.

SETTING THE BAKE TEMPERATURE

1. Press the Temperature button. The current set

temperature will be fl ashing in the temperature

window.

2. Use the Primary Up/Down Arrow buttons to set

the temperature. After 5 seconds, the display

will stop fl ashing and the temperature is set.

The heat on indicator will illuminate.

NOTE: To view the actual oven temperature, press

and hold the Temperature button.

VENT

LOW

START / STOP

R

ENTER

POWER

TIMER

STEAM FAN

R

RECIPE

VENT

LOW

START / STOP

R

ENTER

PRIMARY

STEPS

1 2 3 4

UP/DOWN

BUTTON

HEAT ON

INDICATOR

TEMPERATURE

WINDOW

DELAY

STEPS

1 2 3 4

TEMPERATURE

BUTTON

PRIMARY

STEPS

1 2 3 4

UP/DOWN

BUTTON

VENT

TIMER

STEAM FAN

R

RECIPE

VENT

LOW

START / STOP

LOW

DELAY

STEPS

1 2 3 4

SETTING THE BAKE TIMER

1. Press the Timer button. The current set time

will be fl ashing in the timer window.

2. Use the Primary Up/Down Arrow buttons to set

the bake timer. After 5 seconds, the display will

stop fl ashing and the timer is set.

NOTE: The timer will not start running until the door

is closed and the Start/Stop button is pressed.

NOTE: The decimal point "." is an indicator between

the minutes and seconds. The colon " : " will indicate

the time between hours and minutes. The decimal

point will fl ash when time is counting down and when

time remaining is greater than 5 minutes. When time

remaining is less than 5 minutes, the timer will display

seconds and count down in seconds.

POWER

TIMER

STEAM FAN

R

RECIPE

VENT

LOW

START / STOP

R

ENTER

TIMER

WINDOW

DELAY

STEPS

1 2 3 4

TIMER

BUTTON

PRIMARY

UP/DOWN

BUTTON

STEPS

1 2 3 4

START/STOP

BUTTON

START / STOP

TIMER

STEAM FAN

R

RECIPE

VENT

LOW

START / STOP

DELAY

STEPS

1 2 3 4

– 13 –

Page 14

SETTING THE STEAM TIMER

1. Press the Steam button. The steam time will

be fl ashing in the steam window.

2. Use the Primary Up/Down Arrow buttons to set

the steam timer. After 5 seconds, the display

will stop fl ashing and the steam time is set.

POWER

TIMER

STEAM FAN

R

RECIPE

STEAM TIME

WINDOW

DELAY

STEPS

1 2 3 4

STEAM

BUTTON

TIMER

STEAM FAN

R

RECIPE

DELAY

STEPS

1 2 3 4

NOTE: The maximum set time for steam is 60

seconds. The oven will produce steam for a maximum

of 15 seconds. Any setting over 15 seconds will just

provide additional fan delay. See Setup Guide for

P6. The default is 15 but may be set to a maximum

of 20.

SETTING THE FAN DELAY

1. Press the Fan Delay button. The fan delay time

will be fl ashing in the fan delay window.

2. Use the Primary Up/Down Arrow buttons to

set the fan delay timer. After 5 seconds, the

display will stop fl ashing and the fan delay time

is set.

NOTE: The fan delay timer is set and operates in

1-minute increments.

VENT

LOW

START / STOP

R

ENTER

POWER

TIMER

STEAM FAN

R

RECIPE

VENT

LOW

START / STOP

R

ENTER

PRIMARY

UP/DOWN

BUTTON

STEPS

1 2 3 4

FAN DELAY

WINDOW

DELAY

STEPS

1 2 3 4

FAN DELAY

BUTTON

PRIMARY

UP/DOWN

BUTTON

STEPS

1 2 3 4

VENT

TIMER

STEAM FAN

R

RECIPE

VENT

LOW

START / STOP

LOW

DELAY

STEPS

1 2 3 4

COOL DOWN MODE

The oven has a cool down function which helps cool the

oven quickly to a new lower baking temperature.

1. Set the new lower temperature and open the

door.

NOTE: The new set temperature must be at least

30° lower than the current oven temperature for cool

down mode to operate.

2. Press and hold the Vent button for 3 seconds.

The display windows shut off and the timer

window displays "COOL".

The fan will continue to run until the oven temperature

is within 10° of the new temperature. The buzzer will

sound until the door is closed.

NOTE: To cancel cool down mode, press and hold

the Vent button for 3 seconds OR close the oven

door.

POWER

TIMER

STEAM FAN

R

RECIPE

VENT

LOW

START / STOP

R

ENTER

DELAY

STEPS

1 2 3 4

STEPS

1 2 3 4

TIMER

WINDOW

VENT

BUTTON

START / STOP

TIMER

STEAM FAN

R

RECIPE

VENT

LOW

START / STOP

DELAY

STEPS

1 2 3 4

– 14 –

Page 15

RECIPE DESIGNATIONS

There are two series available for recipe designations. One series is alpha-numeric and uses each letter

followed by numbers 1 to 4. The other series is numeric only which uses 1 through 40.

ENTERING RECIPES

1. Press the Power button to turn the oven on.

DELAY

STEPS

1 2 3 4

STEPS

1 2 3 4

POWER

BUTTON

STEP

WINDOW

RECIPE

WINDOW

STEP

BUTTON

TIMER

STEAM FAN

R

RECIPE

VENT

LOW

DELAY

STEPS

1 2 3 4

2. Press and hold the Recipe button and the Enter

button for 5 seconds. The indicator next to the

recipe button will fl ash.

3. Use the Secondary Up/Down Arrow buttons

to select the recipe designation. The recipe

designation will display in the recipe window.

NOTE: Unused recipe designations will fl ash. Any

used designation will not fl ash but remain solid.

NOTE: The recipe should start on step one.

POWER

TIMER

STEAM FAN

R

RECIPE

VENT

LOW

START / STOP

R

ENTER

4. Set the oven temperature, timer, steam time,

fan delay, vent position, and/or low fan.

5. Press the Enter button.

6. If additional steps are required, press the step

button.

7. Use the Secondary Up/Down Arrow buttons

ENTER

BUTTON

RECIPE

BUTTON

SECONDARY

UP/DOWN

BUTTON

START / STOP

ENTER

STEPS

1 2 3 4

R

to select the step. The step designation will

display in the step window.

8. Set the oven temperature, timer, steam time, fan delay, vent position, and/or low fan as required for

this step.

9. Repeat steps 5 through 8 for each recipe step required.

10. Once the recipe is complete, press and hold the Enter button for 5 seconds.

USING AND REVIEWING RECIPES

1. Press the Recipe button. The indicator next to the recipe button will illuminate.

2. Use the Secondary Up/Down Arrow buttons to select the recipe. If the recipe is programmed, the

recipe will display in the various windows and the various indicators will be illuminated.

3. To review the steps of the recipe, press the Step button and use the Secondary Up/Down Arrow

buttons to review each step.

4. To select a recipe for use, press the Enter button followed by the Start/Stop button.

CUSTOMIZED OPERATION

The Hybrid Convection oven controls have the capability of being customized to fi t your personal needs

using the setup mode.

Before entering the setup mode, read all the instructions to make sure you are completely clear on what

to do. If you need assistance, please call your authorized Bakery Systems service agency.

– 15 –

Page 16

Entering Setup Mode

With the oven off, press and hold the Start/Stop button and the Power button for 5 seconds. The oven is

now in Setup mode and P1 is displayed in the temperature window.

Changing Items in Setup Mode

The number in the temperature window is the setup number. The timer window displays the setup item

(the settings that can be changed).

1. To change the setup number, press the Primary Up/Down Arrow buttons.

2. To make a change in the setup item being displayed, press the Secondary Up/Down Arrow buttons.

To adjust the setting, see Setup Guide. Consult your authorized Bakery Systems service agency for

help with these features.

3. To exit the setup mode, press the Power button.

Setup Guide

SETUP

NUMBER

P1 525°F Maximum temperature set

P2 350°F Preheat temperature This is the default temperature set point when the oven is fi rst turned on. The

P3 50° Minimum temperature set

P4 0 Temperature offset This value permits an offset or correction between the temperature probe and

P5 2° Heat difference hysteresis This value adjusts the temperature difference between the on temperature and

P6 15 Maximum water injection time

P7 °F Temperature units The oven can be set to display temperature in Fahrenheit or Celsius. The values

P8 1 Bake time mode Select 0 for minutes/seconds (MM:SS). Select 1 for hours/minutes (HH:MM).

P9 0 Steam function mode In bakery mode steam system steams only once at the beginning of a bake

P10 0 Auto off timer (in minutes) Time select for oven to go into auto off mode conserving energy. Factory Default

P11 AP Clock operation This selects either 12 hour (AM/PM) or 24 hour real time display.

P12 0 Temperature set back mode Set to 0= set back time disabled. Set to 10 to 180 minutes selects the elapsed

P13 250°F Set back temperature This selects the oven set temperature that the oven will change to when the

DEFAULT

VALUE

SETUP ITEM DESCRIPTION

This is the maximum temperature at which the oven can be set. Range is 50°F

point

point

(in seconds)

to 525°F (10°C to 270°C) 5 degree increments.

preheat temperature cannot be set higher than the value in P1.

Range is 50°F to 525°F (10°C to 270°C) 5 degree increments.

This is the minimum temperature at which the oven can be set. Range is 50°F

to 200°F (10°C to 95°C) 5 degree increments.

the real baking chamber temperature. Range ± 50°F.

off temperature of the heating system from set point. Range is 1 to 20.

Time set is the maximum time (in seconds) that water solenoid is energized

during the Steam Timer operation. Range is 1 to 20.

in parameters P1, P2, & P3 are converted to the new temperature unit when

changed. Any saved recipes will be converted when new unit is selected.

step. In food service mode oven will steam a maximum of 10 seconds at the

beginning of each bake step and will steam a maximum of 10 seconds every

set interval in seconds for the duration of bake time. Select 0 for Bakery mode.

Select 300 to 990 for Food Service mode.

is 0. Must be set between 15 to 120 minutes when P14 is enabled.

AP = 12 hour mode. 24 = 24 hour mode.

time from the last time bake to when the oven goes into set back mode and

lowers the oven set temperature to the value set in P13.

Range is 10 to 180 minutes.

temperature set back time has been exceeded in P12.

Range is 225°F to 300°F (100°C to 150°C).

– 16 –

Page 17

SETUP

NUMBER

P14 0 Auto off mode This selects the auto off mode being enabled or disabled. If enabled the oven

P15 0 Clock display function 0 = Time of day displayed only with oven off. 1 = Time of day displayed with

P16 0 Recipe lockout function This selects recipe lockout function being enabled or disabled. When enabled

P17 0 Fan speed as standard This feature will select whether the oven has high or low speed for normal

DEFAULT

VALUE

SETUP ITEM DESCRIPTION

will automatically turn off after the temperature set back (P12) and auto off (P10)

times have been met. If disabled Auto off time will be inoperable.

0 = Disabled, 1 = Enabled. Time set in P10.

oven off/on, no time in bake time display, and when bake time is complete and

alarm silenced.

operator cannot change an existing recipe when running. If disabled the

operator can make temporary changes to an existing recipe and reverts to

manual operation. 0 = Lockout Disabled, 1 = Lockout Enabled.

operation. If "0" high speed operation is normal and low speed is selected as

required. If low speed operation is selected as normal "1", then low speed fan

will operate as standard for any bakes below 450° and low speed will have to

shut off if high speed operation is required. Low fan speed will not operate at set

points greater than 450°, so high fan speed will default if these set temperatures

are selected.

– 17 –

Page 18

BASIC OPERATION

Startup

When there is power to the oven and the oven is off, the time of day will display in the timer window and

the colon will be fl ashing.

With the door closed, press the Power button to turn the oven on.

• Convection fan turns on.

• Oven lights turn on.

• Heat on indicator is on after 5 seconds.

• Default temperature displayed in the temperature window.

• Timer, steam time, and fan delay display windows display "0".

• Steps window will display "1" and the step indicator will light.

For best baking performance and consistent product results, the following sequence of operation is

recommended.

DELAY

STEPS

1 2 3 4

POWER

BUTTON

TIMER

WINDOW

TIMER

STEAM FAN

R

RECIPE

DELAY

STEPS

1 2 3 4

1. Allow the oven to pre-heat for 30 minutes.

2. Set the baking parameters or use a preprogrammed recipe.

3. Open the oven door and load the product.

4. Push the Start/Stop button while the door is still

POWER

TIMER

STEAM FAN

R

RECIPE

open. The timer window will display "dOOr".

VENT

5. Close the door and the bake cycle starts.

6. When timer reaches "00:00", the display will

fl ash and the buzzer will sound.

7. Press the Start/Stop button to silence the

alarm.

LOW

START / STOP

STEPS

R

1 2 3 4

ENTER

START/STOP

VENT

LOW

BUTTON

START / STOP

NOTE: While the alarm is sounding, press the timer button to add additional time, one press for each

additional minute up to 5 minutes if required.

To clear all settings while oven is timing down, press the recipe button.

– 18 –

Page 19

CLEANING

Disconnect the electrical power to the machine and follow lockout / tagout

procedures.

The oven and its parts are hot. Use care when operating, servicing or cleaning the

oven.

DAILY CLEANING

• Allow oven to cool.

• Use care when cleaning around sensitive interior parts, such as probes and sensors.

• Using a clean cloth moistened in warm, soapy water, wash the interior of the oven cavity. Rinse

with rag moistened with clean water and dry with a clean cloth.

• Clean the door gasket with a soft, clean, damp cloth. This will ensure a long life for the gasket.

• Clean the outside daily with a clean, damp cloth.

• Do not use cleaners containing grit, abrasive materials, bleach, harsh chemicals or chlorinated

cleaners. Do not use steel wool on stainless steel surfaces. Never spray down the oven with water,

steam or power wash.

• Be cautious with new or improved cleaning formulas; use only after being well tested in an

inconspicuous place.

GLASS CLEANING

Allow the glass to cool before

cleaning. Cleaning while hot may cause the glass

to shatter.

1. Open door.

2. Loosen two thumb screws (Fig. 5).

NOTE: Thumb screws are retained to assembly.

3. Swing open inner door glass (Fig. 6).

4. Clean glass.

5. Swing inner door glass back to outer door and

tighten thumb screws (Fig 5).

Fig. 5

– 19 –

Fig. 6

Page 20

MAINTENANCE

Disconnect the electrical power to the machine and follow lockout / tagout

procedures.

The oven and its parts are hot. Use care when operating, servicing or cleaning the

oven.

LIGHT REPLACEMENT

NOTE: Do not touch the replacement bulb with your

fi ngers. Touching the replacement bulb will shorten

bulb life. Wear gloves when replacing halogen

lamps.

NOTE: Use only 5W 12V Halogen bulb.

1. Open door.

2. Remove thumb screws and lens cover from

oven (Fig. 7).

3. Pull at the top of the lens glass until it snaps

out to remove from oven (Fig. 8).

4. Remove old bulb and replace with new bulb.

5. Replace lens glass.

6. Install lens cover with thumb screws.

SERVICE AND PARTS INFORMATION

Contact your authorized service offi ce for any repairs or adjustments needed on this equipment.

Fig. 7

Fig. 8

– 20 –

Page 21

SCHEMATIC

Main Oven Harness (Sheet 1 of 2)

– 21 –

Page 22

Main Oven Harness - Ignition Wiring (Sheet 2 of 2)

– 22 –

Page 23

NOTES

– 23 –

Page 24

NOTES

FORM 36722 (March 2011) PRINTED IN U.S.A.

– 24 –

Loading...

Loading...