Page 1

Service Manual

Flo-Gard GSP

S Y R I N G E I N F U S I O N P U M P

BS036010EN-P06

Prior to servicing this pump, read this manual and the pump’s

Operator’s Manual carefully to fully understand the pump’s

functionality and to ensure safe and proper servicing.

Page 2

CONTENTS

1. INTRODUCTION………………………………………….…..4

1.1 General Information……………………………………4

1.2 General Precaution……………………………………..4

1.3 Service Contacts………………………………………..5

2. TECHNICAL DESCRIPTION………………………………..8

2.1 General…………………………………………………8

2.2 Electronic board……………………………………….10

2.3 Drive Unit board …………………………………...13

2.4 Power Supply Unit…………………………………….14

2.5 IRDA/RS232/Nurse Call Interface Specification……...14

2.6 Bootstrap Loader Unit……….………………………...15

3. USER CONFIGURATION MENU…………………………...16

4. SERVICE MENU………………………………………………16

4.1 Maintenance Menu……………………………………..16

4.2 Loading Program…………...…………………………..16

4.3 Calibration……………………………………………...17

4.4 Testing………………………………………………….20

5. RECOMMENDED ROUTINE MAINTENANCE

AND TESTING…………………………………………………22

5.1 AC/Battery Operation Check…………………………...22

5.2 General Cleaning and Inspection for Damage…………22

5.3 Battery Test……………………………………………..23

5.4 Infusion Rate Check……………………………………23

5.5 Occlusion Pressure Level Check……………………….23

6. TROUBLE-SHOOTING……………………………………….24

6.1 Safety WARNINGS…………………………………….24

6.2 Pump has been dropped or damage……………………..24

6.3 Pump has been exposed to fluids………………………..24

6.4 Trouble-shooting by fault symptom……………………..25

6.5 Trouble-shooting by failures codes……………………...28

Flo-gard GSP Service Manual

2

Page 3

7. REPAIR………………………………………………………….33

7.1 Access to the Pump……………………………………...33

7.2 Front Case and Sub-assemblies………………………….33

7.3 Rear Case and Sub-assemblies…………………………..49

7.4 Torque guide…………………………………………….40

8. ELECTRICAL SCHEMATIC DIAGRAMS, COMPONENT

LOCATION DIAGRAMS……………………………………...43

8.1. Electrical Block Diagram of the Pump…………………..43

8.2. Electrical Schematic Diagram of the Pump……………...44

8.3. Electronic Board Schematic Diagram……………………47

8.4. Electronic Board Component Location Diagram………...51

8.5. Drive Unit Board Schematic Diagram …………………..52

8.6. Drive Unit Board Component Location Diagram …….53

8.7. Power Supply Unit Schematic Diagram………………….54

8.8. Power Supply Unit Component Location Diagram………55

8.9. Battery Monitoring Unit Component Location Diagram…56

9. MECHANICAL ASSEMBLY DRAWINGS

AND PART LIST…………………………………..……………..57

9.1. Part List……………………………………………………57

9.2. Front Case Assembly………………………………………59

9.3. Rear Case Assembly……………………………………….71

9.4. Final Assembly…………………………………………….75

10. SPARE PARTS LISTING………………………………………...82

10.1 Spare Accessories…………………………………………77

10.2 Spare Labels/Publications…………………………………77

10.3 Spare Electrical Components……………………………...78

10.4 Spare Mechanical Components……………………………78

Flo-gard GSP Service Manual

3

Page 4

1. INTRODUCTION

1.1.GENERAL INFORMATION

The Flo -Gard GSP syringe pump is designed to accurately control the delivery of solution to the

patient by means of a disposable syringe.

The Flo -Gard GSP syringe pump is compatible with a wide range of standard, single-use,

disposable Luer-lock syringes, ranging from 10ml to 100ml in size.

This SERVICE MANUAL describes the theory of operation, how to check, troubleshoot and

repair Flo -Gard GSP syringe infusion pump.

Ensure that you are fully familiar with this equipment by carefully studying the Operator’s

Manual and this Service Manual prior to attempting any repairs or servicing.

1.2. GENERAL PRECAUTION

Please read the general Operating Precautions described in the Operating

Instructions carefully prior to using this pump.

This pump contains static- sensitive components. Observe strict precautions

for the protection of static sensitive components when attempting to repair and

service the pump.

An explosion hazard exists if the pump is used in the presence of

flammable materials. Exercise care to locate the pump away from any such hazardous

sources.

An electrical shock hazard exists if the pump casing is opened or removed.

Refer all servicing to qualified service personnel.

This pump is protected against the effects of high-energy radio frequency

emissions and is designed to fail-safe if extremely high levels of interference are

encountered. Should false alarm condition be encountered, either remove the source

of the interference or regulate the infusion by another appropriate means.

If the pump is dropped, subjected to excessive moisture, humidity or

high temperature, or otherwise suspected to have been damaged, remove it from

service for inspection by a qualified service engineer.

Flo-gard GSP Service Manual

4

Page 5

1.3. SERVICE CONTACTS

Baxter Technical Service Centre locations and full addresses:

Argentina

Baxter Immuno SA

Av. Olivos 4140

Tortuguitas-C.P. 1667ARGENTINA

Tel: 54-11-4463-3333

Austria

Baxter-Immuno Vertriebs GmbH

IZ-Sued Strasse 7 Obj. 58D/Tops2

2355 Wiener Neudorf

AUSTRIA

Tel: +43 (0)1 711 20 138

Fax: +43 (0)1 711 20 157

Brazil

Baxter Hospitalar Ltda

Avenida Santa Catarina 2660

04378-200

Sao Paulo, SP

BRAZIL

Tel: 55-11-541-8922 x5250

Fax: 55-11-5563-7933

Chile

Baxter de Chile, Ltda.

Avenida Mexico #715

Recoleta, Santiago

CHILE

Tel: 56-2 -6213707

Fax: 56-2 -6213708

Colombia

Laboratorios Baxter SA

Carrera 99

#46a22

Santafe’de Bogota DC

COLOMBIA

Tel: 57-1-4211820

Fax: 57-1-4210055 x234 or x233

Ecuador

Baxter Ecuador SA

Av. Naciones Unidas #1084

Esquina Amazonas

Edif. Previsora Torre B, Ofic 408

Quito

ECUADOR

Australia

Baxter Healthcare Pty. Ltd.

Baxter Drive, Old Toongabbie

New South Wales 2146

AUSTRALIA

Tel: 61-2-8845-1560

Belgium

N.V. Baxter S.A.

Boulevard R. Branquart 80

B-7860 Lessines

BELGIUM

Tel: +32 (0)68 27 30 54

Canada

Baxter Instrument Services

5055 - Unit 5, Satellite Drive

Mississauga, Ontario

L4W 5K7

CANADA

Tel: 1-877-331-9336

Fax 905-281-6730

China

Baxter Healthcare Ltd.

Rm 503 China Garments Mansion

99 Jian Guo Road

Beijing 100020,

CHINA

Tel: 8610-6581-1206

Denmark

Baxter A/S

Gydenvang 43

DK-3450

Allerod

DENMARK

Tel: +45(0)48 166 435

Fax: +45(0)48 166 464

Finland

Baxter OY

Pakkalankuja 6

PO Box 46

FIN-015111 Vantaa

Finland

Tel: +35 (0)89 862-1111

Fax: +35 (0)89 862-1211

Flo-gard GSP Service Manual

5

Page 6

France

Baxter S.A.

Avenue Louis Pasteur

Boite Postale 56

78311 Maurepas Cedex

FRANCE

Tel: +33(0)1 34 61 5566

Fax: +33(0)1 34 61 5537

Greece

Baxter (Hellas) EPE

Ethnarhou Makariou 34 & Athinodorou

GR-156341 Illioupolis

Athens

GREECE

Tel: +30 (0)1 9959 818

Fax: +30 (0)1 9959 820

Italy

Baxter S.p.a.

Via Lorenzini, 4

20139 Milano

ITALY

Tel: 39/2 89 52 71

Netherlands

Baxter BV

Koblatweg 49

3542 CE Utrecht

THE NETHERLANDS

Tel: +31(0)30 2488 771

Fax: +31(0)30 2488 795

Panama

Baxter de Panama

Calle 55 Obarrio

Edificio Plaza Obarrio

Primer Piso Suite #105

Panama

REPUBLIC OF PANAMA

Tel: 507-264-6010 or 6013

Fax: 507-264-6027

Portugal

Baxter Medico Farmaceutica Lda

Urbanizacao Industrial Cabrafiga

Estrada Nacional 249/4 Lote 3

Cabrafiga

2735 Rio De Mouro

PORTUGAL

Tel: +351 (0)1 915 8180

Fax: +351 (0)1 915 8209

Germany

Baxter Deutschland GmbH

Am Wolfsmantel 46

91058 Erlangen

GERMANY

Tel: 091 31 61 79 122

Ireland

Baxter Healthcare Limited

Unit 7, Deansgrange Industrial Estate

Blackrock Co.,Dublin

IRELAND

Tel: +353 (0)1 206 5568

Fax: +353 (0)1 206 5555

Northern Ireland

Tel: 01232 777 800

Baxter-SA de CV

Av. Javier Rojo Gomez #709

Col. Guadelupe del Moral CP

09000 MEXICO D.F.

Tel: (52) -56-94-05-20

Fax: (52) -56-94-04-53

Norway

Baxter A/S,

Box 70 Grefsen

0490 Oslo

Gjerdrumsvei 11

NORWAY

Tel: +47(0)2 258 4800

Fax: +47(0)2 258 4801

Peru

Laboratorios Baxter del Peru SA

Las Camelias 780. Segundo piso

Lima 27

PERU

Tel: (51) 1-2217170

Fax: (51) 1-4217275

Puerto Rico

Baxter Sales & Distribution

State Road 24

Rexco Industrial Park

Buchanan

Guaynabo

PUERTO RICO 00968

Tel: 787-792-5757

Flo-gard GSP Service Manual

6

Page 7

Singapore

Baxter Healthcare Asia Pte Ltd

Singapore Technical Services

159 Sin Ming Road

#02-01/02/03 Amtech Building

SINGAPORE 575625

Tel: 65-4553911

Fax: 65-4553963

Spain

Baxter S.A.

Poligno Industrial Vara de Quart

Calle Dels Gremis 7

46014 Valencia

SPAIN

Tel: +34(0)96 386 0800

Fax: +34(0)96 3702 697

Switzerland

Baxter AG

Muellerenstrasse 3

CH-8604 Volketswil

SWITZERLAND

Tel: 0041 19085050

Venezuela

Urb. Industrial Castillito

Centro Comercial Valencia II

Valencia. Edo. Carabobo,

VENEZUELA

Tel: 58-2-204-42-68

South Korea

Baxter International

4, 5/F Jinsung Bldg 996-17

Daechi-dong

Kangnam-ku, Seoul

KOREA

Tel: 82-2-5607-184

Fax: 82-2-538-0679

Sweden

Baxter Medical AB

PO Box 63

SE- 164 94 KISTA

Torshamnsgatan 35

Sverige

Tel: 46 (0)8 632 6400

UK

Baxter Healthcare Limited

UK Nat’l Distribution Centre

Salthouse Road

Brackmills Industrial Estate

Northampton

ENGLAND

NN4 0UF

Tel: 44(0) 1604 704555

Fax: 44(0) 1604 704590

Flo-gard GSP Service Manual

7

Page 8

2. TECHNICAL DESCRIPTION

2.1. GENERAL

The Block Diagram of the pump is given in the section 8.1. The Electrical Schematic Diagram is

given in the section 8.2. The pump is composed of the following elements:

- Keypads

- Stepper motor

- Stepper motor encoder

- Syringe Force sensor

- Syringe plunger grippers and pusher lever sensor

- Drive engagement sensor

- Syringe size sensor

- Pusher position sensor

- Syringe barrel sensor

- Battery unit

- Electronic board

- Drive Unit board

- Power Supply Unit

- IRDA/RS232/Nurse Call Interface

- Hard bootstrap loader

Below follows a description of these elements, refer the appropriate diagram for full

understanding of the functionality:

2.1.1. Keypads

Keypad K1 comprises of a 4 x 3 key matrix connected to the Electronic board at connector JP1.

The ON/OFF key and BATTERY & MAINS LED’s are also located on the K1 keypad connect

to the Electronic board via JP12.

Keypad K2 comprises of a 4 x 2 key matrix. It is connected to the Electronic board via connector

JP4.

2.1.2. Stepper motor

A two-phase unipolar stepper motor with 7.5º step-angle is used in the pump drive. The motor is

connected to the Drive Unit board via connector P5 and is driven in micro stepping mode. There

are 48 steps to complete one full revolution of the motor shaft. The motor is connected to the

lead screw by means of timing belt. The belt ratio is 5:1; as a result 240 motor steps move the

drive carriage by 1 mm.

2.1.3. Stepper motor encoder

Motor speed and direction is monitored by means of the encoder. It is composed of two photointerrupters D1, D2 and a 9 slot-encoding disk mounted on the stepper motor shaft. Quadrature

signals (Tax1, Tax2) are transferred to the Drive Unit board via P6 connector.

Flo-gard GSP Service Manual

8

Page 9

2.1.4. Syringe force sensor

Plunger grippers

As a syringe force sensor is used a strain gauge TZ1 mounted on a steel plate within the plunger

retaining mechanism. When this plate is deflected by applied force on the plunger mechanism, a

differential voltage is generated at gauge output. This signal, which magnitude is proportional to

the applied force, is transferred to the Drive Unit board.

2.1.5. Syringe retainer (plunger grippers and pusher lever) sensors

The plunger grippers and pusher lever sensors are composed of photo interrupters D4, D5, D6.

The LED’s of the photo interrupters are supplied with pulse-modulated current through pin 8 of

JP1 connector of the Drive Unit board.

When the syringe is loaded, the shutters controlling the photo interrupters D4 and D6 are opened.

When the pusher lever is lifted up, the shutter controlling the photo interrupter D5 is opened.

Output signals of these sensors are summed to form syringe retainer output voltage (at pin 7 of

JP1 – Drive Unit board) in accordance with the Table 1.

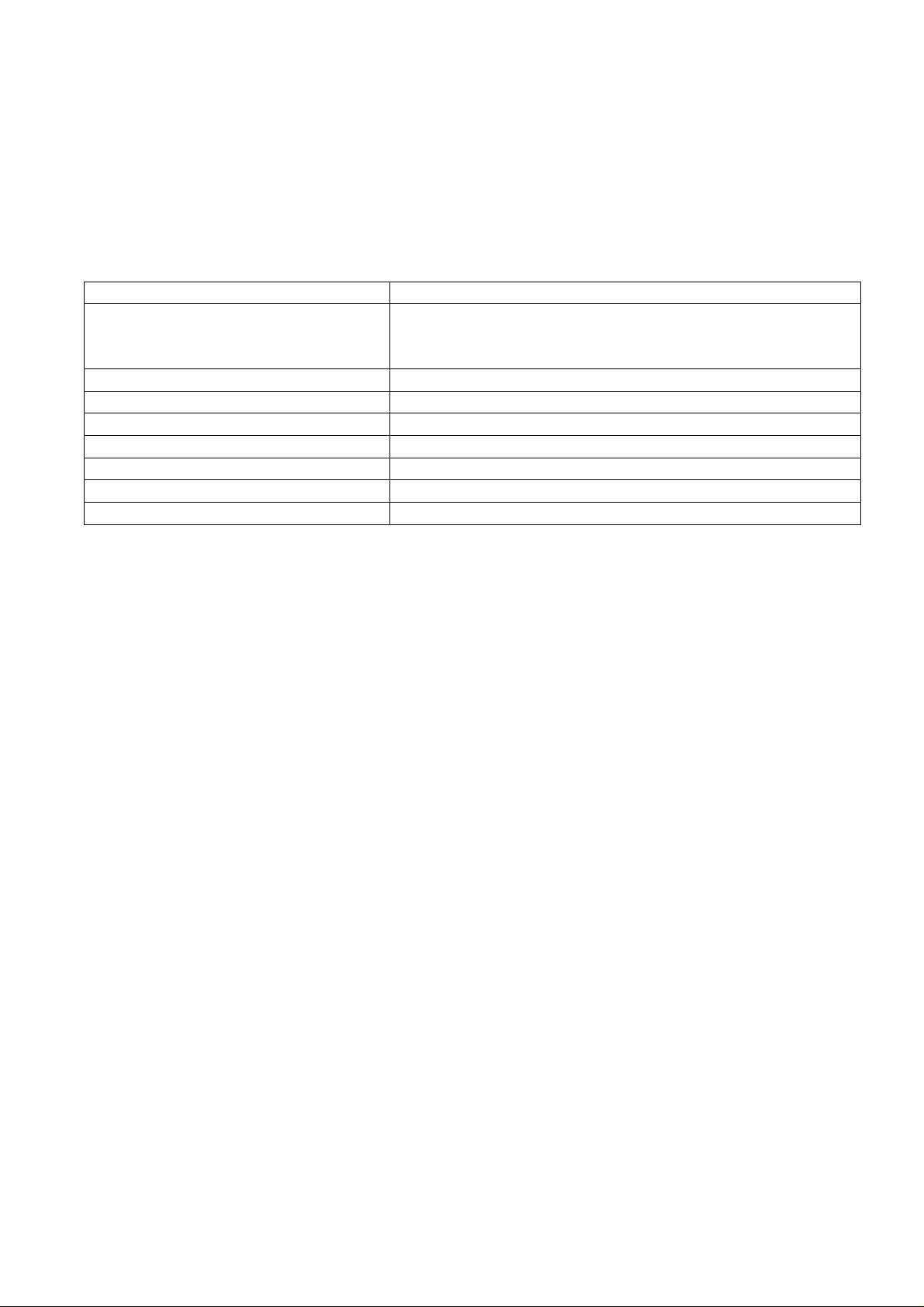

sensors (D4, D6)

Pusher lever

sensor (D5)

Syr. retainer

output voltage

Off Off <0.3V

On Off

≥0.3V;

≤0.6V

Off On >0.6V;

≤0.95V

On On >0.95V;

≤1.4V

Table 1

2.1.6. Drive engagement sensor

The drive engagement sensor is comprised of photo interrupter D3. Its LED is supplied with

pulse-modulated current. When the half-nuts of drive are closed (engaged), the shutter

controlling the photo interrupter D3 is open and electrical pulses are generated at pin 6 of the

Drive Unit’s board JP1 connector.

2.1.7. Syringe size sensor

The syringe size sensing is achieved using the linear potentiometer R1. The signal from the

potentiometer slider is applied to the Electronic board via pin 2 of JP8 connector.

2.1.8. Pusher position sensor

An optical absolute encoder of pusher position is comprised of a steel encoder ruler and photo

interrupter D7. Ruler is attached to the drive walls, and the photo interrupter is mounted on the

drive carriage and moves along ruler during infusion so that edge of the ruler is inside the gap of

photo interrupter. The edge of the ruler is punched with the slots distributed with various

intervals in certain pattern. Each slot passing the gap generates electrical pulse when the photo

interrupter is moved along the ruler. Microcontroller permanently monitors width of intervals in

Flo-gard GSP Service Manual

9

Page 10

sequence of pulses and determines pusher position basing on combination of passed intervals.

Obviously, certain number of slots should be passed after start of infusion before the pusher

position (and, correspondingly, remaining time and volume) may be determined. Maximum

delay is when the pusher is at the rightmost position (up to 9 mm of pusher travel may be

required).

2.1.9. Syringe barrel sensor

The syringe barrel sensor comprises switch S1. When the syringe is loaded, the switch S1

contacts are closed and a logic “0” is generated at pin 1 of the Electronic board’s JP5 connector.

2.1.10. Battery unit

The battery unit comprises the Ni-MH (7,2V x 2.5Ah) battery GB1 together with the battery

monitoring circuit. The integrated circuit U1 monitors battery voltage, temperature and

charge/discharge current. This data is used to calculate battery charge state and remaining

working time when pump runs on battery. Data is transferred to the microcontroller via 1-Wire

interface (pin 4 of the JP7 connector). R2 is a current sense resistor; R3 and C1 constitute a low

pass filter for the current monitoring circuit. Thermistor R1 terminates battery charging if battery

temperature exceeds the permissible value. The resettable fuse F1 protects against a short circuit

of the battery.

2.2. ELECTRONIC BOARD

The electrical diagram of the Electronic board is given in section 8.3. It comprises following

main parts:

- Microcontroller circuit

- Display unit

- Display contrast regulator

- RS232 interface

- Watch-dog circuit

- Piezotransducer drive

- Reference voltage source

- LED indicators

2.2.1. Microcontroller circuit

The 16 bit microcontroller U12 (SAB-C167CR-LM) controls and monitors major syringe pump

functions. Clock pulses are generated by the quartz oscillator Q1 at a frequency of 3.686400

MHz and multiplied x 5. Supervisor integrated circuit U9 generates a reset signal for the

microcontroller when the supply voltage changes from 0V to 5V.

Software instructions are stored in 1-Megabyte FLASH memory U10. Device constant

parameters are stored in 8-kilobyte SPI EEPROM, U14. Temporary variables are stored in 128 kilobyte SRAM U8 with real time clock and lithium battery.

Flo-gard GSP Service Manual

10

Page 11

The microcontroller functions include:

- Scanning the keypad via the port P8 and the buffers of the U2 and U4 ICs. The

keypad status information is read via other buffers of the U2 and U4 ICs to the

inputs P5.9 (pin 36), P5.10 (pin 39) and P5.11 (pin P40).

- Setting the output P2.10 (pin 59) to ‘0’on switching the pump on. This signal

maintains power supply active. In order to switch power off, the ON/OFF key

shall be kept depressed, thereby setting the P5.7 input (pin 34) to ‘1’. After 3 sec

delay micrcontroller sets the P2.10 output (pin 59) to ‘1’, which switches the

power supply off.

- Detecting pump connection to 100-240VAC mains power or 12VDC by the signal

at the P5.6 input (pin 33) (‘1’ – when connected). At this state transistor T11

opens thereby activating the MAINS indicator on the front panel. When pump is

running on internal battery, microcontroller activates the BATTERY indicator by

setting the P2.0 output (pin 47) to ‘1’.

- Obtaining information from the battery monitoring circuit on the battery voltage,

temperature and capacity via the input P7.6 (pin 25); obtaining battery fast charge

signal via the P5.14 input (pin 43) (‘0’ – fast charge in progress); disabling the

AC mains supply by setting the P7.4 output (pin 23) to ‘1’ in the battery

calibration mode.

- Activating the Nurse Call circuit located at the Supply Unit, by setting the P2.5

output (pin 52) to ‘1’.

- Receiving voltage proportional to syringe size from the syringe size sensor via the

AN0 input (pin 27). Force sensor reference voltage is applied to the AN1 input

(pin 28). Voltage directly proportional to force acting on the syringe pusher, is

applied to the AN2 input (pin 29). Force sensor reference 0 voltage is applied to

the AN3 input (30 pin). Syringe retainer output voltage (see table 1) is applied to

the input AN4 (pin 31). Voltage from piezo transducer current monitor is applied

to the input AN5 (pin 32). The P2.12 output is used for controlling force sensor’s

supply.

- Controlling (pulse modulating) the current through the LEDs of the drive

engaged, gripper and pusher lever sensors via the P2.13 output (pin 62); receiving

signal of engagement of drive half-nuts with lead screw (‘1’ pulses) via the P5.13

input (pin 42) (via the buffer U20); receiving signal that syringe barrel is fitted

(‘0’ level) via the P5.12 input (pin 41) (via the buffer U4E); receiving tachometer

pulses from the Drive Unit board via the P2.15 input (pin 64). Prior to starting

motor rotating backwards and during it microcontroller sets the P2.11 output (pin

60) to ‘0’ to disable motor direction sensor in the Drive Unit board; during normal

infusion this output is set to ‘1’.

- Generating signals for the stepper motor controller/driver which is located in the

Drive Unit board: Data A via the P2.6 output (pin 53), Data B via the P2.7 (pin

54), Strobe A,B via the P2.8 (pin 57), Clock A,B via the P2.9 (pin 58). Signal

controlling magnitude of motor winding current is generated at the POUT0 output

(pin 19) by means of PWM; AC component of this signal is suppressed by means

of the second order low-pass filter (R54, C71, R56, C73), and DC component

having range 0.4 to 2.5 V is transferred via the diode D23 and pin 4 of JP10 to the

Drive Unit board – REF/ENABLE A,B circuit. This circuit is used also for

disabling motor driver by applying +5 V to it. For this sake pin 4 of JP10 is also

connected with the P7.7 output of microcontroller (pin 26) and output of

watchdog via the D21 and D22 correspondingly; logic ‘1’ at any of these two

Flo-gard GSP Service Manual

11

Page 12

outputs sets windings current to zero (e.g. in STOP mode, during pause between

two adjacent steps or when the watchdog is activated).

- Selecting IRDA rate via the P6.4 output (pin 5). Selecting of UART connection

either with the RS232 or IRDA interface via the P6.5 output (pin 6). The P6.7

output is set to ‘1’ when RS232 selected, and ‘0’ is set when IRDA interface

selected.

- Activates Z1 buzzer by setting output P6.7 to ‘1’ when piezotransducer circuit is

interrupted;

- receiving interrupt pulses from the SRAM (U8) Real Time Clock via the T2IN

input (pin 74);

- receiving pulses from the syringe pusher position sensor via T4IN input (pin 70).

2.2.2. Display unit

A 240 x 64 dot blue negative graphic LCD display (MD1) is used in the pump. The backlight is

controlled by means of PWM, using control signal generated at the POUT2 output (pin 21) of the

microcontroller.

2.2.3. Display contrast regulator

Negative voltage adjustable within range of 7.5 to 8.5 V is utilized to control the display

contrast. The negative voltage is generated by means of the DC/DC converter U16, and voltage

regulator U17. Initial voltage value is adjusted by means of trimmer potentiometer R52. The

microcontroller U12 then controls display contrast by means of PWM signal generated at the

POUT3 output (pin 22) and applied to pin6 of the U17 via low-pass filter R50, C60 and diode

D19.

2.2.4. RS232 interface circuit

The RS232 interface circuit is isolated from the pump circuitry by means of the opto-couplers

D8, D9. This isolated part of the circuit is powered from the PC COM port using RTS (+10V)

and DTR (+10V), rectified by means of the D6, D7 diodes signals. Voltage regulator U1 is used

to provide the RS232 interface chip U3 with +5V supply (VDD).

U3 includes a DC/DC converter providing the necessary voltages of +7V and –7V. Integrated

circuit U3 hibernates when no valid receiver level and no receiver or transmitter transient is

detected for 30 seconds, and wake up when a valid receiver level or receiver or transmitter

transient is detected.

2.2.5. Watchdog circuit

The watchdog function is carried out by the uP supervisory circuits with windowed (Min/Max)

watchdog U9. The microcontroller generates clocks at the P2.4 output (pin 51) that are applied to

the WDI input (pin 3 of U9). If the clock period goes outside the permissible range, U9 generates

a short logic ‘0’ pulse at the WDP0 output (pin 5). This pulse sets ‘1’ at the Q output (pin5) of

the flip-flop U6A, which acts as follows:

1) Stops motor (via the D22),

2) Activates red alarm LED D1 (via the D4),

3) Activates the nurse call circuit located in the Supply Unit (via the D16),

Flo-gard GSP Service Manual

12

Page 13

4) Launches the buzzer Z1 (via the D10),

5) Eliminates 3 s delay when switching the pump off (via the input 5 of U11),

6) Indicates to the microcontroller U12 that watchdog is activated (via the P5.8 input – pin 35).

The watchdog circuit is also activated if the motor starts rotating backwards despite forward

rotation commands. In this case the rotation direction sensor in the Drive Unit board sets

“Backwards” circuit (pin 3 of JP9) to ‘0’ which inputs logic “0” to the watchdog (via D18) thus

activating it.

The pump carries out watchdog test each time it is powered up, and if test passes successfully

U6B trigger Q output (pin 9) is set to ‘0’, if test fails – Q output is set to ‘1’. This watchdog

signal is applied to the 67 pin of U12 microcontroller.

2.2.6. Piezotransducer drive

The audible signal is generated by means of PWM at the POUT1 output (pin 20) of the

microcontroller U12. Carrier frequency is suppressed by third order low-pass filter (R58, C75,

R60, C76, R61, C77).

In order to obtain double maximal output voltage a bridge layout of the U18 amplifier is used.

The ratio of R64 and R67 determines audio gain.

R77 monitors current applied on the piezotransducer. Signal from the R77 is amplified by the

U18A amplifier, rectified with the D21, C86 and applied to the AN5 input (pin 32) of the U12

microcontroller.

2.2.7. Reference voltage source

Voltage regulator U7 generates voltage Vref used as reference for the microcontroller’s ADC

and the syringe size sensor. U7 is switched on/off by microcontroller (via the P6.6 output).

2.2.8. LED indicators

The red LED indicator D1 flashes when an ALARM condition is detected or when the watchdog

circuit is activated. It is controlled by the microcontroller U12 via the P2.2 output (pin 49) or by

the watchdog (via the D4). The Green LED D2 flashes during infusion. It is controlled via the

P2.3 output (pin 50) of the microcontroller. The orange LED D3 flashes in ALERT condition. It

is controlled via the P2.1 output (pin 48).

2.3. DRIVE UNIT BOARD

The drive electronics is located on the separate PCB attached to drive mechanical assembly.

Controller-driver U2 is used to operate the stepper motor. It controls current through motor

windings by means of the PWM using control signals from the microcontroller: “Data A” (pin 6

of the U2), “Data B” (pin 17), “Strobe A,B” (pins 2, 13), “Clock A,B” (pins 5, 16),

“REF/ENABLE A,B” (pins 3, 14). Each step of the motor consists of 8 successive micro-steps,

which provide regulation of current through windings closely to sin/cos law, thus ensuring

smooth rotation of the motor shaft. In the case the watchdog is actuated, a high level (+5V)

signal is applied to the “REF/ENABLE A,B” inputs, which removes power from the motor

windings.

Quadrature signals from the motor encoder are processed by means of the decoder built on the

U6, U7, and U8 integrated circuits. 9 square pulses are generated at the TAX output (pin2 of

JP2) during one revolution of motor shaft. The “BACKWARDS” output is used to indicate

Flo-gard GSP Service Manual

13

Page 14

direction of motor rotation. Logic “0” is generated at this output if motor st arts rotating so as to

move syringe pusher backwards while logic “1” is applied to the FWD input (i.e. motor should

not rotate backwards). Logic “0” applied to the FWD input (pin 1 of JP2) disables the direction

sensor and ensures that logic “1” is set at the “BACKWARDS” output regardless of rotation

direction.

The operational amplifier U1 amplifies syringe force sensor’s output signal. Integrated circuit U3

produces precise supply voltage +5V both for the syringe force sensor and amplifier U1. The

trimmer potentiometer R2 is used to balance the force gauge (bridge).

U5A performs buffering of syringe retainer output signal, and U5B performs conditioning of

pusher position sensor’s signal.

2.4. POWER SUPPLY UNIT

The power supply unit includes switching power supply PS1, +5V voltage regulator U2, and

accumulator battery fast-charge controller U1 together with transistor T4. Protective circuits

built using comparators U3, U6 and thyristors D6, D7 are intended to prevent occurrence of

over-voltage and under-voltage at the +5V supply circuit in the case of failure of voltage

regulator or short circuits within pump electronics.

Voltage in the VccNS circuit is approximately +11V when pump is connected to the mains, and

approximately +7V when disconnected (powered from the internal battery). Vcc voltage is +5V

when pump is switched on, and 0 when switched off. The +5V regulator (U2) is switched on

when VccNS voltage is applied to its “ON/OFF” input (pin 2), which occurs when the operator

presses the pump’s ON/OFF key. The regulator is switched off by means of the “SHDN” signal,

which is generated by microcontroller when the operator depresses the ON/OFF key for 3

seconds.

The T8 transistor key is used for switching mains supply off in the course of the accumulator

battery test.

The controller U1 initiates fast charge of accumulator battery each time the pump is connected to

the mains. Detecting a negative battery voltage slope, which occurs when charge is completed,

normally terminates fast charge. For safety reasons termination of the fast charge is provided by

means of the thermistor within the battery pack detecting over-temperature. Additionally,

termination of fast charge is provided on elapsing of established fast charge time. After

termination of fast charge the controller switches to trickle charge mode.

A socket is located on the pump for powering from an external 12VDC source. This circuit

comprises a connector on the rear side of pump and fuses F2, F3, and filter components L1, L2,

C21, C22 mounted on the power supply unit’s PCB. Diode D10 prevents pump from damaging

in case of wrong polarity of external 12 VDC source.

2.5. IRDA/RS232/NURSE CALL INTERFACE

2.5.5. IRDA interface

Serial infrared data communication is operating in accordance with the IRDA standard using

modulator-demodulator U4 and transceiver U5 located on the power supply’s PCB.

Flo-gard GSP Service Manual

14

Page 15

The transceiver is mounted on the rear of the PCB, in front of the window at the back of the

pump. The window is covered with dark IR-transparent plastic.

2.5.6. RS232 interface

The technical specification of the RS232 Interface is listed in table 2 below:

Table 2

Connector D Type –9 Pin, female

TXD Output Voltage Range Minimum: -5V(mark), +5V(space)

Typical: -5.4V(mark), +5.4V(space) with 3kohm load to

ground

RXD Input Voltage Range -25V - +25V maximum

RXD Input Thresholds Low: 0.8V minimum/ High: 2.4V maximum

RXD Input Resistance 3 kohm minimum

Isolation Socket/pump 4 kV

Baud Rate 115 kBaud

Bit Format 1 start, 8 data, no parity, 1 stop

RS232 connections data:

1 - Not used

2 - Transmit Data (TXD) Output

3 - Received Data (RXD) Input

4 - Power Input (DTR)

5 - Ground (GND)

6 - Not used

7 - Power Input (RTS)

8 - Not used

9 - Not used

2.5.7. Nurse Call Interface

Nurse call interface is implemented using relay RL1 located on the power supply’s PCB.

Contacts are rated at 1A at 50VAC or 1 A at 30VDC. Relay contacts are accessible at the

connector on the rear of the pump.

After detecting an alarm condition the microcontroller sets a logic “1” at its P2.5 output (pin 52),

which opens transistor T3 on the power supply’s PCB and the relay is activated. If a failure of

the microcontroller is detected an output signal from the watchdog circuits activated the relay.

2.6. BOOTSTRAP LOADER UNIT

A bootstrap loader unit is used for downloading bootstrap into the Flash memory U10 on the

Electronic board, utilizing microcontroller’s U12 internal bootstrap loader, when the Flash

memory’s software does not contain bootstrap or it does not work. Bootstrap loader unit is

connected to the JP6 connector of the Electronic board. It allows launching the U12

microcontroller by means of manual reset signal, maintains Power Supply Unit active,

commutates UART via the RS232 interface and configures the microcontroller so as to launch its

internal bootstrap lo ader.

Flo-gard GSP Service Manual

15

Page 16

3. USER CONFIGURATION MENU

Depressed the key and turn the pump on. Enter code 237 using the numerical keypad.

Press OK to confirm the code. The User Configuration Menu will be displayed. Use the

softkeys to select the required parameter (see Operator’s Manual).

4. SERVICE MENU

While keeping pressed the key turn the pump on. Enter code 751 using the numerical

keypad. Press OK to confirm the code. The Service Menu will be displayed. Use the

softkeys to select the required parameter.

4.1. MAINTENANCE MENU

Select the MAINTENANCE MENU from the Service menu and press the OK softkey. Use the

softkeys to select the required parameter. Press the OK softkey:

- to modify the NEXT SERVICE DATE

- to view the selected LOG (event, use, key or service)

- to set TIME FORMAT (24h or 12h)

- to set DATE FORMAT (dd-MM-yyyy or MM-dd-yyyy)

- to set DEFAULT PARAMETERS

- to set ALARM PITCH

- to set ALERT PITCH

- to view serial number

- to select INTERFACE type (RS232 or IRDA). (Only one of these interfaces may

be active at a time.)

Press the QUIT softkey to return to Service menu.

4.2. LOADING PROGRAM

4.2.1. Loading program

In order to check the program version, keep the key depressed while turning the pump on.

To perform a programming operation, the following is required:

- Flo -Gard GSP Firmware Upload Utility must be installed and configured on the computer that

is being used.

- Either RS232 extension cable must be connected between the COM port of the computer and

the 9-way ‘D’ connector in the rear of the pump.

Select the LOADING PROGRAM and press the OK softkey. The pump is ready for loading the

program.

Note. When the ERROR: PR02 message (incorrect program CRC) is displayed, the pump also is

ready for loading the program.

Flo-gard GSP Service Manual

16

Page 17

Programming sequence:

Start Flo -Gard GSP Firmware Upload Utility application by clicking on the appropriate icon.

Select which COM port is going to be used.

Click on (Load configuration Set) in order to load program.

Click on Firmware key to start the programming operation.

Note. When the ERROR: OTH01 message is displayed set DEFAULT PARAMETERS.

Having loaded new program it is necessary to execute full testing (see Section 4.4.1).

4.2.2. Loading Bootstrap

In order to perform a programming operation, the following should be in place:

- Flo -Gard GSP Firmware Upload Utility should be installed and configured on the computer

that is being used.

- Having opened the pump housing, Bootstrap Loader Unit should be connected to the Electronic

board connector JP6 (Bootstrap Loader Unit switch should be in ON position).

- RS232 extension cable connected between the COM port of the computer and the 9-way ‘D’

connector in the rear of the pump.

Switch on the pump. Press the Reset key on the Bootstrap Loader Unit. The pump is now ready

to download a Bootstrap.

Programming sequence:

Start Flo -Gard GSP Firmware Upload Utility application by clicking on the appropriate icon.

Select which COM port is going to be used.

Click on (Load configuration Set) in order to load Bootstrap.

Click on Bootloader key to start the programming operation.

After Bootstrap downloading process is completed, it is necessary to switch Bootstrap Loader

Unit switch into OFF position and to press the Reset key.

4.3. CALIBRATION

Select the CALIBRATION from the Service menu and press the OK softkey. Select item to be

calibrated using the softkeys and press the OK softkey.

4.3.1. Syringe size sensor calibration

The syringe size detection system stores the characteristics of the syr inge clamp assembly,

including the travel of the linear potentiometer in non-volatile memory.

Equipment:

Flo-gard GSP Service Manual

17

Page 18

- Spacer (gauge) SP1 (B8640037-01) or old (B8640022-01);

- Spacer (gauge) SP2 (B8640037-02) or old (B8640022-02);

- Spacer (gauge) SP3 (B8640037-03) or old (B8640022-03);

- Spacer (gauge) SP4 (B8640023).

Select the Syringe size sensor from calibration menu and press the OK softkey. With the

syringe clamp at the lowermost position press the OK softkey. One after another insert spacers

from 1 to 4, each time closing the syringe clamp and pressing the OK softkey to acknowledge.

Finally fix the syringe clamp at the uppermost position and again press the OK softkey.

4.3.2. Pusher position sensor calibration

Equipment:

- Calibration spacer (gauge) SP1 (B8640037-01) or old (B8640022-01).

Select the Pusher position sensor from calibration menu and press the OK softkey. When

display reads the message Insert spacer SP1, insert the spacer SP1 and slide the drive pusher to

the spacer SP1. Press the OK softkey. Syringe pusher moves backwards and afterwards returns

to the spacer SP1. Following question will be indicated on display:

Is pusher contacting the spacer?

If pusher is not contacting the spacer, press the NO softkey and repeat the calibration. If pusher

is contacting the spacer, press the YES softkey. Following message will be indicated on display:

Offset XX mm,

where XX value shall be (10-13) mm. Press the QUIT softkey to exit.

4.3.3. Force sensor calibration

Equipment:

- Digitron pressure meter, model: 2022P (0-1500 mmHg);

- 50 ml BD PLASTIPAK or 60 ml BD syringe with extension line.

Select the Force sensor from calibration menu and press the OK softkey. The “0 cm Hg

>XXXmV<” message should appear on the screen.

First step is to be performed without loading syringe. Make sure that plunger retainer lever is

released and plunger grippers are in idle position, and pushing surface of the retainer is not in

contact with any part of pump or extraneous object. Leave the pump at rest for at least 15 min,

then press and release the retainer lever a few times. Make sure that actual output value of the

force sensor displayed on the pump screen is (1100±400) mV; if necessary, adjust it by means of

the R2 potentiometer on the Drive Unit board. Press the OK softkey, and the “Insert 60 ml BD

or 50 ml BD PLASTIPAK” message should appear.

Fill syringe with 10-20 ml of water, and fit it to the pump. Connect syringe to the pressure meter

by means of the extension line. Locate the pressure meter at the same height as the syringe. Press

the RUN softkey and keep it depressed, allowing the transmission to run until the pressure meter

reads (148±1.5) cmHg. When approaching the target value, it is recommended to run

transmission in short steps, since if you fail to stop transmission timely and target value is

Flo-gard GSP Service Manual

18

Page 19

overridden, calibration procedure must be repeated from the beginning. When pressure is

adjusted as required, press the OK softkey, then press retainer lever and move the retainer away

from the plunger.

Leave the pump at rest for at least 15 min, then press and release the retainer lever a few times

and check the values displayed on the pump screen to make sure the following:

− difference between actual output value and V1 value is not greater than ±10 mV,

otherwise this calibration procedure shall be repeated from the beginning (a few

times, if necessary),

− difference between V2 and V1 values is within range of 1500-2900 mV. Wrong

readings may indicate malfunction of the force sensor or the Drive Unit.

Press the QUIT softkey to exit.

4.3.4. Battery calibration

Battery calibration cycles the battery through a charge, discharge, re-charge sequence during

which the fuel gauge within Battery Unit will be updated with a measurement of the current

capacity of the cells.

This calibration allows the fuel gauge to monitor accurately the charge in the pack. Over time the

estimate of capacity may drift from the actual cell capacity, which generally decreases with time.

Recalibration will update the fuel gauge with the measured capacity of the cells.

Remove the battery pack lid to ensure a stable pack environment during calibration. It is

recommended that the pack is removed from the battery compartment and placed behind the

pump.

Connect the pump to the mains.

Extend the plunger drive arm to the maximum as it will automatically move during the discharge

phase. Select the Battery from calibration menu and press the OK softkey. Leave pump in

calibration mode for up to 14 hours. The cycle should run passing automatically three phases one

by one:

• Initial charge phase – 0 to 3 hours

• Measured discharge phase. Pack is discharged using typical load down to 1.1 V per cell

to determine how much charge is available from the pack – up to 10 hours

• Final charge phase. Pack is fully recharged ready for use. Early in this phase the

measured discharge value is transferred to the pack gas gauge to be stored as the new

capacity (mAh).

While the calibration cycle is active the battery related information is displayed on the pump

screen. At the end of the cycle the screen should show CALIBRATION COMPLETED. Press

the QUIT softkey to exit.

Flo-gard GSP Service Manual

19

Page 20

4.4. TESTING

Select the TESTING from the Service menu and press the OK softkey. Select the item to be

tested using the softkeys and press the OK softkey.

4.4.1. Full testing

This section provides a complete pump test procedure. During test it is possible to review and

modify following parameters: language, date, time, next service date. Follow each stage test and

follow the instructions on the display use the QUIT softkey to move to the other test.

4.4.2. Program testing

This test is intended to calculate program and bootstrap CRC. Select the Program from testing

menu and press the OK softkey. Software version, bootstrap version and calculated CRC values

are indicated in the display. Press the QUIT softkey to return to TESTING menu.

4.4.3. Drive sensors test

This test enables checking of the following sensors: syringe barrel, plunger grippers, push lever

and drive disengaged.

Select Drive Sensors from the testing menu and press the OK softkey. Loading and removing

the syringe will cause the sensors status to changes indicated on the pump display.

Drive engagement sensor can not be activated if nut and lead screw threads come “tooth on

tooth”. In such case slide the syringe pusher to another position and repeat the checking.

Once complete press the QUIT softkey to return to TESTING menu.

4.4.4. Syringe size sensor test

This test is enables checking the operation of syringe size sensor.

Select Syringe size sensor from the testing menu and press the OK softkey. Slowly lift the

syringe clamp. Check if syringe size sensor value changes (mV and mm). Having finished

testing press the QUIT softkey to return to TESTING menu.

4.4.5. Pusher position sensor test

This test is enables checking the operation of pusher position sensor. Select Pusher position

sensor from the testing menu and press the OK softkey. Insert the spacer SP1and slide the drive

pusher to the spacer SP1. Press the OK key. Syringe pusher moves backwards and afterwards

returns to the spacer SP1. Pusher position distance (22 ± 0.5)mm should be indicated on the

display. Having finished testing press the QUIT softkey to return to TESTING menu.

4.4.6. Motor test

This test enables checking of the motor operation. During test no syringe should be installed.

Select Motor from the testing menu and press the OK softkey. Having finished testing press the

QUIT softkey to return to TESTING menu.

Flo-gard GSP Service Manual

20

Page 21

4.4.7. Display test

This test checks that all of the display pixels (240x64) illuminate. Select Display from testing

menu and press the OK softkey. Observe “chess- board” structure fields that appear in the

display. All the rectangles should be same shaped and evenly filled. Having finished testing

press the QUIT softkey to return to TESTING menu.

4.4.8. Nurse call test

Equipment:

- Nurse call cable (B6650012);

- Ohmmeter.

This test checks the nurse call circuit operation. Select Nurse call from testing menu and

press the OK softkey. Using a meter check the circuit between the Nurse call contact 3 (com)

and contacts 1 (NO), 5 (NC). The contacts should toggle each time the CHANGE softkey is

pressed, as indicated on the display. Press the QUIT softkey to return to TESTING menu.

4.4.9. Piezotransducer (speaker)/buzzer test

This test checks the piezotransducer (speaker) and buzzer operation. Select Speaker/buzzer

from the testing menu and press the OK softkey. Check for the alternating volume and pitches

sound from the speaker. Check for the sound from the buzzer. Press the QUIT softkey to return

to TESTING menu.

4.4.10. Keyboard test

This test enables checking the keypad operation. Select Keyboard from the testing menu and

press the OK softkey. You will be prompted to press keys on the display (flashing) in sequence.

4.4.11. LEDs test

This test is intended to check the LED operation. Select LEDs from testing menu and press the

OK softkey. The following LEDs should activate one after another: ALARM, ALERT, INFUS.

and BATTERY. In order to check the operation of BATTERY LED it is necessary to connect the

power cable. In order to check the operation of MAINS LED it is necessary to remove and

reconnect the power cable. Press the QUIT softkey to return to TESTING menu.

4.4.12. Watch-dog test

This test enables checking of the watch-dog circuit operation. Select Watch-Dog from testing

menu and press the OK softkey. Initially the watch-dog circuit is applied with an over frequency

signal and later with an under frequency signal. When test completed switch off the pump using

the OFF key.

Flo-gard GSP Service Manual

21

Page 22

5. RECOMMENDED ROUTINE MAINTENANCE AND TESTING

It is recommended that routine maintenance be carried out at least once a year. This should

include:

- AC Mains / Battery operational checks (section 5.1).

- General cleaning and inspection for damage (section 5.2).

- Battery test (section 5.3).

- Infusion rate check (section 5.4).

- Occlusion pressure level check (section 5.5).

- Full test (sections 4.4.1-4.4.12).

5.1. AC MAINS / BATTERY OPERATION CHECK

Switch the pump on and plug pump into the mains. Observe that the MAINS indication LED

becomes illuminated. Remover the mains supply and observe that the MAINS LED switches off.

Observe that the battery indication LED becomes illuminated as the mains supply is removed.

5.2. GENERAL CLEANING AND INSPECTION FOR DAMAGE

To ensure that this pump remains in good operating condition, it is important to keep it clean and

carry out the routine procedures described below. Servicing should be performed only by a

qualified service engineer, with reference to this manual. The following routine maintenance

procedures should be carried out as required but at least once per year:

Thoroughly clean external surfaces of the pump before and after prolonged periods

of storages by wiping a lint- free cloth lightly dampened with warm water and standard

disinfectant/detergent solution.

Disinfectants known to be corrosive to metals and plastics must not be used.

Before cleaning always switch OFF and disconnect from the AC power supply.

Never allow liquid to enter the casing and avoid excessive fluid build up on the pump.

Do not use aggressive cleaning agents as these may damage the exterior surface of the pump.

Do not steam autoclave, ethylene oxide sterilize or immerse this pump in any fluid.

Check Labels should be flat and legible. Replace as required

Case components must be checked for damage that may affect function, present fluid ingress

routes and present a user hazard must be replaced as necessary.

Check the operation of the pole clamp screw. Check it is not loose and that the threads are not

damaged. Check that it folds away correctly.

Inspect the AC power supply inlet and cable for sings of damage.

Flo-gard GSP Service Manual

22

Page 23

5.3. BATTERY TEST

Perform battery calibration in accordance with 4.3.4. When calibration is completed and the

battery is fully charged (at least 2 hours 30 minutes on charge) disconnect the pump from the

mains. Load 50 ml BD Plastipak or 60ml BD syringe with the plunger at 60.0 ml position on the

syringe barrel scale.

Set the 5.0 ml/h rate and start infusion (see the Operator’s Manual for further information on

starting the pump).

Normally pump should be able to work on battery for about 10 hours. If this time is significantly

less battery should be replaced.

After completion of the test the pump should be recharged for a minimum of 2 hours 30 minutes.

5.4. INFUSION RATE CHECK

Equipment:

- stop-watch;

- graduated glass test-tube (one point equals to 0.1 ml, volume 60ml or more).

Take the BD Plastipak 50 ml or 60 ml BD syringe with extension set and fill it with distilled

water up to point of 60ml. Program the following infusion parameters:

- VTBI 50 ml;

- Rate 50 ml/h.

Insert the free end of extension set into the test -tube and start the infusion. Measure infusion time

with the stop-watch and read the volume of water delivered into the test-tube. Calculate the

infusion rate. It shall be 50ml/h ±1ml/h (±2%).

5.5.OCCLUSION PRESSURE LEVEL CHECK

Equipment:

- Digitron pressure meter, model: 2022P (0-1500mmHg).

Fill the 50 ml BD Plastipak or 60 ml BD syringe with 20-30 ml of the distilled water and connect

it to the pressure meter using the extension set. Switch on the pressure meter and set the ma x/min

pressure recording mode.

Set pump occlusion alarm level to L-5 and launch infusion at 5 ml/hr rate (for pump operation

details refer to the Operator’s Manual).

When pump will stop and indicate OCCLUSION read the maximum pressure recorded by

pressure meter. Readings shall be within (63 - 107) cmHg range.

If recorded value is outside this range, re-calibrate the force sensor in accordance with 4.3.3 and

repeat this test.

Flo-gard GSP Service Manual

23

Page 24

6. TROUBLE-SHOOTING

6.1.SAFETY WARNINGS

- Use extreme caution when pump whilst it is connected to the AC mains.

Hazardous voltages are present at the mains inlet and on the power supply even the pump is

switched off.

- Disconnect the battery and AC power whenever removing or inserting PCBs or

other connectors.

- This pump contains static-sensitive components. Wherever the ESD

symbol appears observe strict precaution for the protection of static-sensitive components when

attempting to service and repair the pump.

- Always visually inspect the pump, power cord and plug for damage. If the power

cord or plug is damaged they should be replaced.

- Should further technical assistance be required call your local BAXTER Service

Centre.

6.2. PUMP HAS BEEN DROPPED OR DAMAGED

If the pump is dropped or damaged, the damaged parts should be identified and replaced before

any further troubleshooting is carried out.

During inspection, careful attention should be paid to the front and rear case halves, for signs of

drop damage. Also check the pump drive, syringe pusher, syringe pusher drive, syringe size

sensor.

6.3. PUMP HAS BEEN EXPOSED TO FLUIDS

Excessive fluid spills can lead to fluid ingress into the pump. Even if the fluid dries out, deposits

can be left which cause the pump to fail.

If fluid ingress is suspected the pump should be inspected internally.

Clean and dry out the pump.

Take care to ensure dried deposits do not remain on the PCBs or other electrical components.

Replace any damaged PCBs or components.

Flo-gard GSP Service Manual

24

Page 25

6.4. TROUBLE-SHOOTING BY FAULT SYMPTOM

SYMPTOM CHECK CORRECTIVE ACTION

MAINS LED does not light

when plugged into a known

good AC outlet. BATTERY

Check mains cord

Check switching power

supply

LED lights, when pump is

powered up. MAINS LED

lights when powered from

12VDC.

MAINS LED does not light

when plugged into a known

good AC or 12VDC outlet.

BATTERY LED lights when

pump is powered up.

Check the MAINS LED of

the keypad K1 and keypad

connection with the

Electronic board connector

JP12.

Check Electronic board.

MAINS LED is light. Pump

does not switch on.

Pump is unplugged.

BATTERY LED does not

light when pump is powered

up.

Check fuse F1 in the Supply

Unit.

Check the BATTERY LED

of the keypad K1 and keypad

connection with the

Electronic board connector

JP12.

One or more keypad key

Perform keypad test. Replace keypad if necessary.

presses are not accepted.

Too high or too low contrast

level.

Check contrast setting.

Check the voltage of the

Electronics Board test point

TP9. The value should be

(-8,0±0,1)V, when contrast is

set to level 6.

Backlight does not operate

when pump is powered on.

Check backlight setting.

Check backlight circuit

interconnection on Electronic

board

Check Display Unit and its

connection with the

Electronic board connector

JP13.

Replace mains cord.

Replace switching power

supply if necessary.

Replace keypad K1 if

necessary.

Replace Electronic board if

necessary.

Replace fuse F1 with

identical one.

Replace keypad K1 if

necessary.

Adjust the contrast as

described in Operator’s

Manual.

Adjust voltage by means of

R52, if the problem persists –

replace the Electronic board.

Adjust the backlight as

described in Operator’s

Manual.

If necessary replace

Electronic board.

If necessary replace Display

Unit.

Flo-gard GSP Service Manual

25

Page 26

Red alarm LED does not

light when alarm occurs.

Yellow alert LED does not

light when alert occurs.

Green infusion LED does not

light while pump is running.

Second (long) audible alarm

does not sound after power

on.

After power up the pump

display empty or horizontal

lines illuminated only, no

backlight and watchdog

activated.

Syringe gripper sensor does

not activate when syringe is

loaded.

Pusher lever sensor does not

activate when syringe is

loaded.

Syringe barrel sensor does

not activate when syringe is

loaded.

Drive engaged sensor does

not activate when syringe is

loaded.

Syringe size sensor does not

determine syringe size.

Pusher position sensor

calculates time to end of

infusion (syringe)

incorrectly.

Stepper motor is not rotating

when it should.

Check red alarm LED (D1)

in the Electronic board.

Check yellow alert LED (D3)

in the Electronic board.

Check green infusion LED

(D2) in the Electronic board.

Check buzzer (Z1) in the

Electronic board.

Check for the presence of

VCC of +5V on Electronic

board. Check if reset

duration is (TP4) > 100ms.

Check if quartz oscillator

(Q1) is working.

Check syringe gripper

(retainer) sensor signal (see

section 2.1.5).

Check pusher lever (retainer)

sensor signal (see section

2.1.5).

Check syringe barrel sensor

and its connection on the

Electronic board.

Check drive engaged sensor

and its connection with Drive

Unit board. Check the circuit

starting from drive engaged

sensor to the Electronic

board.

Calibrate syringe size sensor

(see section 4.3.1). If the

problem persists - check

syringe size sensor.

Calibrate pusher position

sensor (see section 4.3.2). If

the problem persists - check

pusher position sensor.

Check encoder unit.

Check stepper motor.

Check Drive Unit board.

Check motor belt.

Replace faulty red alarm

LED (D1).

Replace faulty yellow alert

LED (D3).

Replace faulty green infusion

LED (D2).

Replace faulty buzzer (Z1).

If necessary load bootstrap

and afterwards lo ad program.

If necessary replace syringe

pusher with syringe gripper

sensor.

If necessary replace syringe

pusher with pusher lever

sensor.

If necessary replace syringe

barrel sensor.

If necessary replace drive

with drive engaged sensor.

If necessary replace syringe

size sensor.

If necessary replace encoder

ruler.

If necessary replace sensors

unit B6660032.

If necessary replace encoder

unit.

If necessary replace stepper

motor.

If necessary replace Drive

Unit board.

If necessary replace motor

belt.

Flo-gard GSP Service Manual

26

Page 27

Occlusion pressure level

incorrect.

Calibrate syringe force

sensor (see section 4.3.3) If

the problem persists - check

syringe force sensor.

Check syringe force sensor

amplifier circuit.

Too short operation time on

battery.

Pump does not operate from

external 12 VDC (MAINS

LED does not operate).

Pump operates from the AC

power supply.

Calibrate battery unit (see

section 4.3.4).

Check 12VDC & Nurse call

connector unit.

Check fuses F2, F3 in Supply

Unit.

Nurse Call does not operate. Perform Nurse Call test.

Check nurse call circuit

interconnection on Supply

Unit.

RS232 interface does not

operate (communication via

the RS232 interface enabled

in maintenance menu).

Check RS232 connector unit.

Check RS232 cable.

Check RS232 circuit

interconnection on Electronic

board.

IRDA interface does not

operate (communication via

the IRDA interface enabled

in maintenance menu).

Check IRDA circuit

interconnection on Supply

Unit.

Check Supply Unit

connection with the

Electronic board connector

JP3.

Check IRDA circuit

interconnection on Electronic

board.

Versatile clamp does not fix

Check versatile clamp. If necessary replace versatile

to the pump.

If necessary replace syringe

pusher with syringe force

sensor.

If necessary replace Drive

Unit board.

If necessary replace battery

unit.

If necessary replace 12VDC

& Nurse call connector unit.

If necessary replace fuses F2,

F3 wit h identical ones.

If necessary replace 12VDC

& Nurse call connector unit.

If necessary replace Supply

Unit.

If necessary replace RS232

connector unit.

If necessary replace RS232

cable.

If necessary replace

Electronic board.

If necessary replace Supply

Unit.

If necessary replace Supply

Unit.

If necessary replace

Electronic board.

clamp.

Flo-gard GSP Service Manual

27

Page 28

6.5 TROUBLE-SHOOTING BY FAILURE CODES

CODE DESCRIPTION CORRECTIVE ACTION

BT01 Communications with the battery fuel gauge

has failed.

Inspect cables between Battery

Monitoring, Drive Unit board and

Electronic board.

BT02 The battery cell voltage is low (less than

1.05V per cell).

BT03 The battery cell voltage is high (greater than

1.75V per cell).

Charge battery, if failure code recurs,

replace Battery Unit.

Check battery charge circuit and

replace power supply unit if

necessary.

BT04 The battery temperature is high (greater than

60°C).

Check battery charge circuit and

replace power supply unit if

necessary.

BT05 The battery charging current is high (greater

than 1.5A).

Check battery charge circuit and

replace power supply unit if

necessary.

BT06 The battery discharging current is high

(greater than 1.5A).

Disconnect one by one all the

connectors, find current leakage place

and replace faulty unit.

BT07 The battery charging current is low (less

than 50mA)

Inspect cables between battery

Monitoring and Power Supply Unit.

Check battery charge circuit and

replace Power Supply Unit if

necessary.

BT08 The battery fast charge time is longer then 3

hours 30 minutes

Check battery charge circuit and

replace Power Supply Unit if

necessary.

BT09 The battery is discharging whilst the pump is

on the mains.

Inspect cables between battery

Monitoring and Power Supply Unit.

Check battery charge circuit and

replace Power Supply Unit if

necessary.

BT10 The battery monitor software module has

failed.

Power off then on. If failure code

recurs, replace software.

BT11 Incorrect CRC of the battery capacity Calibrate the battery

RT01 Accuracy of the real time clock or

microcontroller quartz clock is out of spec.

(±1%).

Replace SRAM on the Electronic

board.

Replace Electronic board.

RT02 Real time clock software module has failed. Power off then on. If failure code

recurs, replace software.

RT03 Incorrect date and time settings. Set date and time.

KY01 Keypad key has been depressed for 5

Replace keypad.

minutes.

KY02 Keypad monitor software module has failed. Power off then on. If failure code

recurs, replace software.

WD01 W-D circuit failed Replace Electronic board

WD02 W-D circuit failed Replace Electronic board

WD03 W-D cir cuit failed Replace Electronic board or Drive

Flo-gard GSP Service Manual

28

Page 29

Unit board

WD04 W-D circuit failed Replace Electronic board or Drive

Unit board

WD05 W-D circuit failed Power off then on. If failure code

recurs, replace Electronic board

WD06 W-D circuit failed Power off then on. If failure code

recurs, replace Electronic board

WD07 Watch-Dog circuit activated Power off then on. If failure code

recurs, replace software or Electronic

board.

WD08 Watch-Dog circuit activated Power off then on. If failure code

recurs, replace software.

WD09 Watch-Dog circuit activated Power off then on. If failure code

recurs, replace software.

EE01 Cannot read data from external EEPROM Replace Electronic board.

EE02 Cannot write data to external EEPROM Replace Electronic board.

EE03 External EEPROM software module has

failed.

Power off then on. If failure code

recurs, replace software.

PR01 Incorrect soft Bootstrap CRC Power off then on. If failure code

recurs, replace Bootstrap software.

PR02 Incorrect program CRC Power off then on. If failure code

recurs, replace software.

PR03 A certain program task not responding Power off then on. If failure code

recurs, replace software.

BSxx Internal soft Bootstrap errors Power off then on. If failure code

recurs, replace Bootstrap software.

SM01 Stepper motor software module has failed. Power off then on. If failure code

recurs, replace software.

SM02 Momentarily stepper motor rotation speed is

high in comparison of inputs steps and

encoder.

Check Encoder Unit and replace it if

necessary.

Check Drive Unit board and replace it

if necessary.

SM03 Momentarily stepper motor rotation speed is

low in comparison of input steps and

encoder, or is not rotating when it should.

Check Encoder Unit and replace it if

necessary.

Check Drive Unit board and replace it

if necessary.

Check Stepper Motor and replace it if

necessary.

Check Motor Belt and replace it if

necessary.

SM04 Accumulated stepper motor rotation speed is

low or high in comparison of input steps and

encoder.

Check Encoder Unit and replace it if

necessary.

Check Drive Unit board and replace it

if necessary.

Check Stepper Motor and replace it if

necessary.

Check Motor Belt and replace it if

necessary.

BAR01 Barrel sensor is damaged. Check barrel sensor and replace it if

necessary.

Flo-gard GSP Service Manual

29

Page 30

AB01 During antibolus motor has exceeded the

step count limit.

Power off then on. If failure code

recurs, replace software. If the

problem persists, replace Electronic

board if necessary.

AB02 During antibolus pusher position travel has

exceeded the limit.

Power off then on. If failure code

recurs, replace software. If the

problem persists, replace Electronic

board if necessary.

AB03 Antibolus duration has exceeded the limit. Power off then on. If failure code

recurs, replace software. If the

problem persists, replace Electronic

board if necessary.

PS02 Pusher drive travel deviated from expected

position based upon motor control.

Check pusher position sensor and

replace encoder ruler or sensors unit

B6660032 if necessary.

PS03 Incorrect CRC of the pusher position table. Calibrate pusher position sensor.

PS04 Pusher position sensor readings out of range

for the inserted syringe.

Calibrate pusher position and syringe

size sensors. If the problem persists,

check and replace encoder ruler,

sensors unit B6660032 or syringe size

sensor if necessary.

PS05 Pusher position sensor has failed. Check pusher position sensor and

replace encoder ruler or sensors unit

B6660032 if necessary.

PS06 Invalid pusher position codes. Check pusher position sensor and

replace encoder ruler or sensors unit

B6660032 if necessary.

IO01 Input-output software module has failed. Power off then on. If failure code

recurs, replace software.

SS01 Syringe size sensor readings out of range. Calibrate syringe size sensor. If the

problem persists, check syringe size

sensor and replace it if necessary.

SS02 Incorrect CRC of the syringe table in

Calibrate syringe size sensor.

EEPROM

SS03 Incorrect CRC of the syringe table in SRAM Power off then on. If failure code

recurs, replace SRAM.

SRE01 Syringe gripper and push lever (retainer)

sensors readings out of range (>1.4V).

Check syringe gripper and push lever

sensors and replace syringe pusher if

necessary.

SRE02 Pusher lever or drive engaged sensors are

damaged.

Check push lever sensor and drive

engaged sensor. Replace syringe

pusher or drive if necessary.

SRE03 Syringe retainer (pusher lever, syringe

gripper) or drive engaged sensors are

damaged.

Check push lever sensor, syringe

gripper sensor and drive engaged

sensor. Replace syringe pusher or

drive if necessary.

SF01 Syringe force sensor reading out of range. Calibrate syringe force sensor. If the

problem persists:

Check syringe force sensor and

replace syringe pusher with syringe

Flo-gard GSP Service Manual

30

Page 31

force sensor if necessary.

Check syringe force sensor amplifier

circuit and replace Drive Unit board if

necessary.

SF02 Syringe force test reading out of range. Calibrate syringe force sensor. If the

problem persists:

Check syringe force sensor and

replace syringe pusher with syringe

force sensor if necessary.

Check syr inge force sensor amplifier

circuit and replace Drive Unit board if

necessary.

SF03 Syringe force 0 reference reading out of

range.

Calibrate syringe force sensor. If the

problem persists:

Check syringe force sensor and

replace syringe pusher with syringe

force sensor if necessary.

Check syringe force sensor amplifier

circuit and replace Drive Unit board if

necessary.

SF04 Incorrect CRC of the force (pressure) table. Calibrate syringe force sensor.

SF05 Syringe force sensor reading not change Clean syringe pusher, check syringe

force sensor and replace syringe

pusher if necessary

SF06 Syringe force reference voltage drift Calibrate syringe force sensor. If the

problem persists:

Check syringe force sensor Uref and

replace Drive Unit board if necessary.

SF07 Incorrect occlusion pressure level value in

EEPROM.

Power off then on. Set the default

occlusion pressure level. If failure

code recurs, replace Electronic board

if necessary.

SR01 SRAM test failed. Power off then on. If failure code

recurs, replace Electronic board.

SC01 Interrupted piezotransducer circuit. Check piezotransducer unit and

replace it if necessary.

Check piezotransducer drive circuit

and replace Electronic board if

necessary.

SC02 Shorted piezotransducer circuit. Check piezotransducer unit and

replace it if necessary.

Check piezotransducer drive circuit

and replace Electronic board if

necessary.

SC03 Sound control software module has failed. Power off then on. If failure code

recurs, replace software.

LED01 LEDs control software module has failed. Power off then on. If failure code

recurs, replace software.

AL01 Alarm manager software module has failed. Power off then on. If failure code

Flo-gard GSP Service Manual

31

Page 32

recurs, replace software.

OFF1 Software OFF module has failed. Replace software.

LOG1 Software Log module has failed. Power off then on. If failure code

recurs, replace software.

LOG2 Cannot read log (from flash). Replace Electronic board.

LOG3 Cannot write log (to flash). Replace Electronic board.

EV01 Software Event module has failed. Power off then on. If failure code

recurs, replace software.

LCD01 LCD display software module has failed Power off then on. If failure code

recurs, replace software.

LCD02 Software graph plotting on display module

has failed.

Power off then on. If failure code

recurs, replace software.

EOI01 Incorrect x ml near EOI settings. Set x ml near EOI value.

EOI02 Incorrect x min near EOI settings. Set x min near EOI value.

BR01 Incorrect basal rate limit. Set basal rate limit.

KOR01 Incorrect KVO rate. Set KVO rate.

MOD01 Incorrect infusion mode settings. Select infusion mode.

RES01 Incorrect residual volume. Set residual volume.

OCL01 Incorrect restart count of after occlusion. Set restart count after occlusion.

PUR01 Incorrect purge volume limit. Set purge volume limit.

PUR02 Incorrect purge rate for 10 ml syringe. Set purge rate for 10 ml syringe.

PUR03 Incorrect purge rate for 20 ml syringe. Set purge rate for 20 ml syringe.

PUR04 Incorrect purge rate for 30 ml syringe. Set purge rate for 30 ml syringe.

PUR05 Incorrect purge rate for 50 ml syringe. Set purge rate for 50 ml syringe.

PUR06 Incorrect purge rate for 100 ml syringe. Set purge rate for 100 ml syringe.

PUR07 Incorrect purge rate for 5 ml syringe. Set purge rate for 5 ml syringe.

BOL01 Incorrect bolus volume limit. Set bolus volume limit.

BOL02 Incorrect max bolus rate for 10 ml syringe. Set max bolus rate for 10 ml syringe.

BOL03 Incorrect max bolus rate for 20 ml syringe. Set max bolus rate for 20 ml syringe.

BOL04 Incorrect max bolus rate for 30 ml syringe. Set max bolus rate for 30 ml syringe.

BOL05 Incorrect max bolus rate for 50 ml syringe. Set max bolus rate for 50 ml syringe.

BOL06 Incorrect max bolus rate for 100 ml syringe. Set max bolus rate for 100 ml syringe.

BOL07 Incorrect max bolus rate for 5 ml syringe. Set max bolus rate for 5 ml syringe.

TR01 Internal microcontroller TRAP activated Power off then on. If failure code

recurs, replace software.

TR02 Internal microcontroller TRAP activated Power off then on. If failure code

recurs, replace software.

TR03 Internal microcontroller TRAP activated Power off then on. If failure code

recurs, replace software.

TR04 Internal microcontroller TRAP activated Power off then on. If failure code

recurs, replace software.

ID01 Incorrect drug name or pump ID in

EEPROM.

Power off then on. Set default

parameters. If failure code recurs,

replace Electronic board if necessary.

IF01 Pump software not compatible with

Replace software

hardware revision

OTH01 Other failures Check log, if necessary replace

software

Flo-gard GSP Service Manual

32

Page 33

7. REPAIR

Ensure the unit is disconnected from AC power supply and switched off before attempting to

service the pump.

The pump contains static-sensitive components. Wherever the ESD symbol appears

observe strict precautions for the protection of static-sensitive components when attempting to

service and repair the pump.

Refer to section 7.4 for torque guidelines. Components may fail or be damaged if not tightened

to correct torque level.

During servicing components found to be damaged will require replacement. Follow the

instructions below together with the assembly drawings in section 9 for further information.

Battery should be disposed of as outlined by the local country regulation. Do not send back to

the manufacturer.

For additional technical assistance, contact your local BAXTER Service Centre.

7.1 ACCESS TO THE PUMP

In order to replace any label (85, 87, 88, 90, 91, 93, 95), the clip (84) or the leg (83) there is no

need to disassemble the pump. Carefully using knife peel the old label, the old clip (84) or the

old leg (83). Using isopropyl alcohol clean the case where the label, the clip or the leg will be

positioned ensuring all old adhesive residue is removed. Stick the label (85, 87, 88, 90, 91, 93,

95) by pressing it firmly with a soft cloth. Stick the clip (84) by pressing it. Stick the leg (83) by

pressing it.

Place the pump on an anti-static grounded surface. Remove the versatile clamp (44). Remove the

2 battery covers screws (61), remove the battery compartment lid (43), disconnect the battery

unit cable and withdraw the battery unit (42). Remove the six case retaining screws (60) located

on the back of the pump.

Turn the pump upside-down. Carefully separate the front and rear case halves and disconnect the

power supply to the Electronic board cable, the piezotransducer cable, the RS232 cable and IrDA

cable. It may be necessary to remove some of the connectors by applying gentle force to the

cable.

Reassemble the pump in the reverse order. When reassembling ensure that the seal (45) under

the battery compartment lid (43) and the seal (45) between the front and rear cases are correctly

positioned.

7.2 FRONT CASE AND SUB-ASSEMBLIES

7.2.1 Removal instructions

7.2.1.1 Syringe barrel sensor cover removal

It is not necessary to disassemble the pump in order to replace syringe barrel sensor cover (28).

Use a knife to find the edge of the syringe barrel sensor cover (28) and carefully peel it back.

7.2.1.2 Keypads removal

Detach the flexi-cables of the keypad K1(25), K2(26) from the Electronic board (23). Carefully

access the edge of the keypad, peel it back.

Flo-gard GSP Service Manual

33

Page 34

7.2.1.3 SRAM removal