Page 1

157-1232-999 March 2003

OPERATOR’S MANUAL

ExtraPure Reverse Osmosis System

Page 2

WARNINGS AND CAUTIONS

As used in this manual, the term WARNING is used to indicate a condition that could

cause injury to a person. The term CAUTION indicates a condition that could cause

damage to the machine.

WARNINGS

After installation, the ExtraPure RO System must be sanitized and rinsed before using it

to supply water for dialysis.

Do not operate the ExtraPure RO System with the water quality needle in the red zone.

With a regular dialysis regimen, sanitize the ExtraPure RO System at least once a

week, or as your physician recommends.

Whenever the ExtraPure RO System will not be used for seven days or more, it should

be stored with formaldehyde disinfectant solution in the fluid path. Follow the steps for

"Sanitizing" in the Operator's Manual. Always rinse the ExtraPure RO System and test

for disinfectant before using it to supply dialysis water.

The disinfectant port cover must be securely in place before turning on the ExtraPure

RO System to guard against backsplash. Remember to replace the cover after

injecting the sanitizing agent.

CAUTIONS

If the ExtraPure RO System is operated with the water off, the pump will shut down.

The filter should be changed whenever the product water is below AMMI Standards, the

difference between the front panel pressure gauges is greater than 10 psi, after 65

hours of operation, or as recommended by your dialysis clinic.

Page 3

CONTENTS

INTRODUCTION............................................................................................... 1

Operation Overview................................................................................ 1

Water Quality Chart ................................................................................ 3

Operator's Controls................................................................................. 5

Flow Diagram Component Identification................................................. 7

Specification ........................................................................................... 8

STARTUP ......................................................................................................... 9

Water Supply.......................................................................................... 9

Unpacking............................................................................................... 9

Installing ................................................................................................. 10

Initial Rinse ............................................................................................. 11

Normal Operation ................................................................................... 13

Cleaning the Membrane ........................................................................ 14

Filter Replacement ................................................................................. 14

SANITIZATION AND STORAGE PROCEDURE............................................... 16

Sanitizing a Hydrogen Peroxide / Peroxyacetic Acid Disinfectant

Compatible RO ....................................................................................... 17

Rinsing ................................................................................................... 19

MAINTENANCE ................................................................................................ 20

Recommended Tools to Maintain One ExtraPure RO ............................ 20

Inspection for Leaks ............................................................................... 20

External Cleaning ................................................................................... 20

TROUBLESHOOTING ...................................................................................... 21

Alarms .................................................................................................... 21

Electrical................................................................................................. 21

Flow........................................................................................................ 22

Pressure ................................................................................................. 23

Water Quality.......................................................................................... 23

Calibration of Electronics........................................................................ 25

Replacing the RO TFC Membrane ......................................................... 25

Pressure Adjustments for Hydrogen Peroxide / Peroxyacetic Acid

Compatible System ................................................................................ 27

Pressure Adjustments for Formalin™ Compatible System..................... 28

Conductivity Cell Connections ................................................................ 29

DIAGRAMS AND SCHEMATICS ...................................................................... 30

Page 4

Page 5

INTRODUCTION

The ExtraPure Reverse Osmosis (RO) System supplies high-quality dialysis water to

hemodialysis machines. Impurities in dialysis water could diffuse into the blood inside

an artificial kidney, so water used to make dialysate must be as pure as possible. The

reverse osmosis membrane is designed to allow water molecules across and leave

impurities behind.

Operation Overview

As illustrated in Figure 1 on page 2, the ExtraPure RO system uses an incoming water

filter, a heat exchanger, a reverse osmosis membrane, and two recirculating water

loops.

The filter removes solid particles and chlorine from the feed water before it

reaches the RO membrane.

The heat exchanger warms the incoming water, which increases pure water

production and reduces energy use.

The reverse osmosis membrane removes bacteria, inorganics, and pyrogens.

The product water loop feeds surplus pure water back to the RO membrane.

The high-volume loop keeps the RO membrane flushed.

The ExtraPure RO System can produce more pure water than is needed for singlepatient dialysis. Instead of wasting surplus pure water down the drain, recirculation

saves this water and recycles it to improve the quality of the water feeding the RO

membrane.

The ExtraPure System monitors water quality and regulates water pressures and drain

flows. Constant adjustments are not necessary, and the operator can devote full

attention to dialysis.

1

Page 6

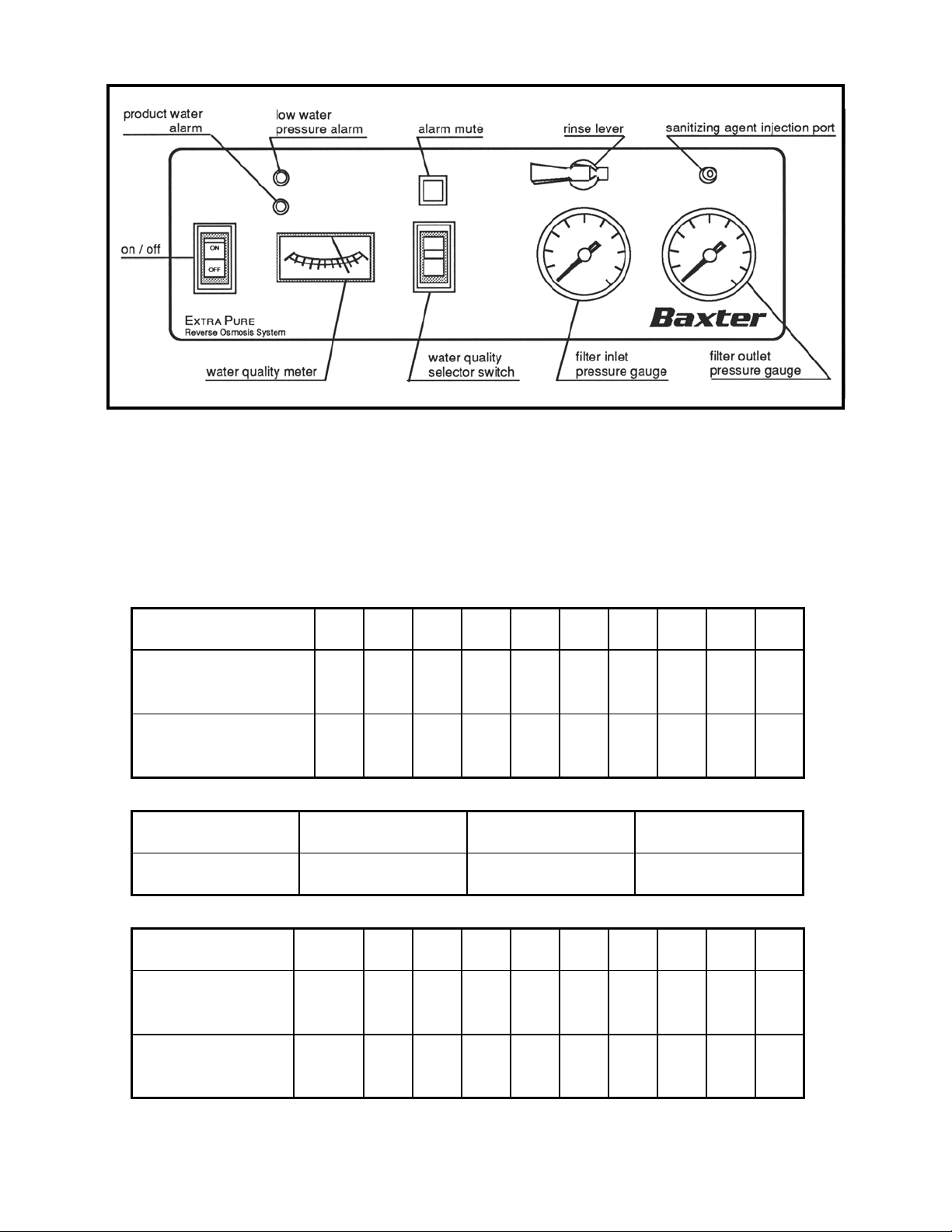

Figure 1: ExtraPure RO System overview

2

Page 7

Water Quality Chart

Move the selector switch and read the water quality meter. Find the chart column

closest to the actual meter reading and read down for the conductivity in microsiemens

(µS/cm) and approximate total dissolved solids (TDS) in parts per million (ppm) or for

percent rejection.

PRODUCT WATER

meter 2 2.5 3 4 5 6 7 8 9 10

conductivity

(µS/cm)

approximate

TDS (ppm)

meter red yellow green

% rejection below 80% 80%-89% 90% and greater

meter 1.5 2 3 4 5 6 7 8 9 10

conductivity

(µS/cm)

approximate

TDS (ppm)

126 49 31 17 12 9 8 6 6 5

85 33 21 12 8 6 5 4 4 3

% REJECTION

RECIRCULATION WATER

1451 871 484 335 256 207 174 150 132 118

980 588 327 226 173 140 117 101 89 79

3

Page 8

Figure 2: Rear view of RO unit

4

Page 9

Operator's Controls

The filter inlet and filter outlet pressure gauges monitor the water pressure on both sides

of the incoming water filter. The pressure difference between the two gauges should

always be less than 10 psi. If the pressure difference is greater than 10 psi, the filter

must be changed.

The water quality meter monitors the quality of the water on the inlet and outlet side of

the reverse osmosis membrane and thus monitors the integrity of the RO membrane.

The green zone of the meter indicates that at least 90% of all dissolved solids are being

rejected by the RO membrane. The yellow zone shows 80 to 89% rejection. Less than

80% rejection (red zone) indicates that the reverse osmosis membrane needs to be

replaced.

WARNING:

Never operate the ExtraPure RO System with the needle in the red zone.

The three-position selector switch allows the meter to display the water quality of either

the recirculating water or the product water. Consult the water quality chart to

determine conductivity in microsiemens (µS/cm) and total dissolved solids in parts per

million (ppm).

The low water pressure alarm will activate when the incoming water pressure drops

below 5 psi. The product water alarm indicates that the output water to the dialysis

system has a conductivity of more than 118 µS/cm. The percent rejection alarm (needle

in the red zone) indicates that the RO membrane rejection is less than 80% and the RO

membrane may need replacement. Audible alarms can be silenced with the alarm mute

button. Also on the operator's control panel are the ON/OFF switch, the rinse lever, and

the sanitizing agent injection port.

5

Page 10

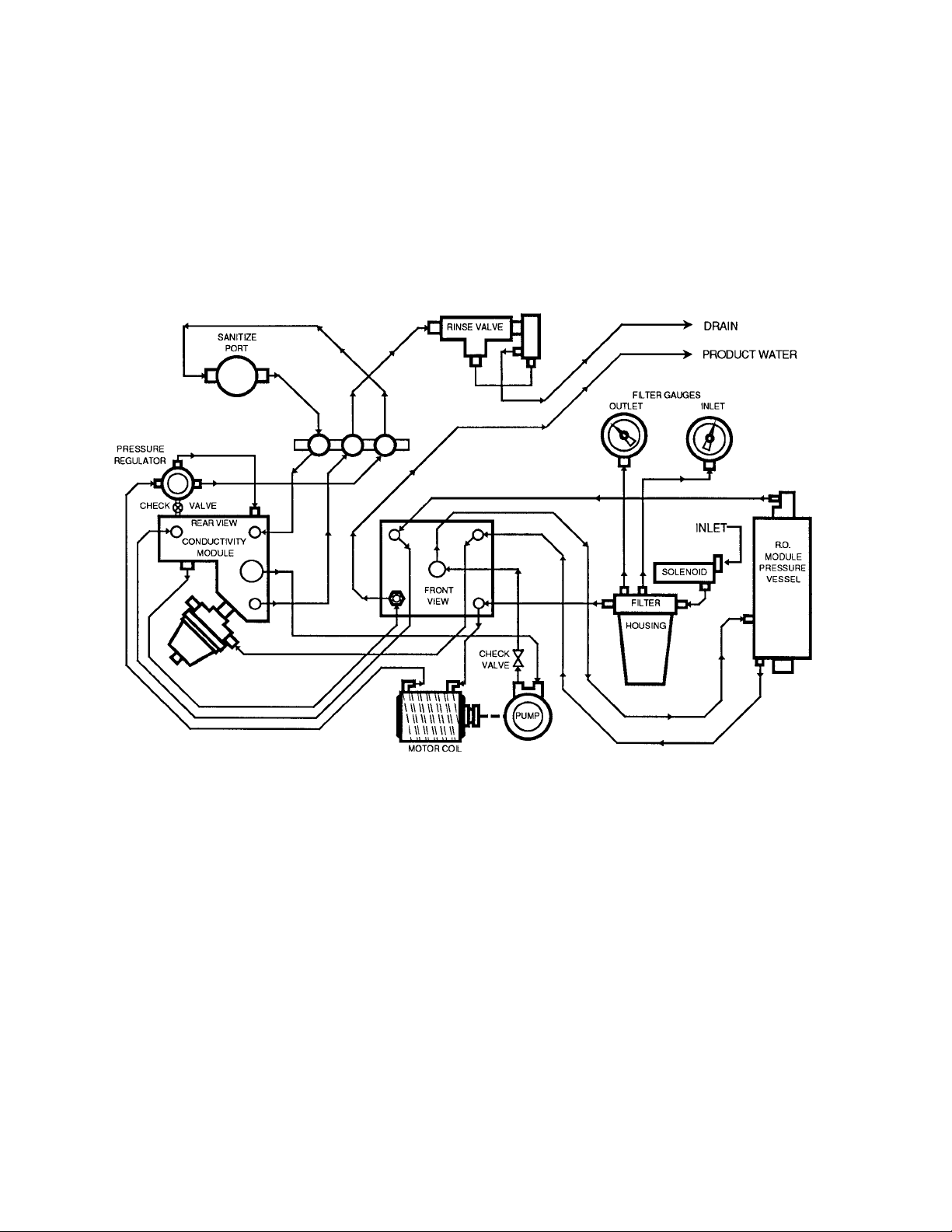

Figure 3: RO Flow Diagram

6

Page 11

Flow Diagram Component Identification

Component Purpose

Solenoid valve Opens to allow water to enter the RO. Closes when the unit is turned

off. It ensures that the disinfectant used in disinfecting the unit remains

inside the instrument until it is turned on again.

Water pressure

gauges

Filter Contains both a fiber material (5-10 micron) and activated carbon. The

Heat exchanger Tubing around the pump motor to cool the motor and warm the water.

Water pressure

regulator (20 psi)

Sanitize Luer port Used to inject disinfectant into the RO for sanitizing the machine.

Sanitize check valve Prevents back up of water or disinfectant through the sanitize Luer port.

Water pressure

switch

Thermistor Used to monitor the water temperature. This information is used in

Conductivity cells Used to measure the conductance of the recirculating and product

Procon pump Pump used in RO to push the water across the membrane. The pump

RO module Contains the thin film composite (TFC) membrane, which is the heart of

Test points Plugged holes in the system's flow block, which can be used by service

Pressure regulator

(200 psi)

Flow regulator A restrictor used to limit the flow of water to the drain during normal

Fast rinse valve Opened to create a high flow to drain when rinsing disinfectant from the

Check valve

(product line)

Located before and after the water filter. When the difference between

the two gauge readings is greater than 10 psi, the filter should be

changed.

carbon is sufficient for 13 treatments (for the home, about one month) if

the incoming water contains less than 3 ppm chloride ions. For higher

chloride levels and chloramines, additional activated carbon may

be needed.

This is done so the motor can be enclosed in insulation without

overheating and warmer water assists the membrane in producing

quality water.

Regulates the water pressure to the Procon pump at 20 psi.

Set at about 6 psi. Should the incoming pressure drop below this

amount, the Procon pump will be shut off and an alarm will sound.

conjunction with the two conductivity cells to determine the total ion

concentration of the recirculating and product water.

water. This information is combined to yield the display of percent

rejection on the front panel.

can produce pressures much higher than the 200 psi which is

necessary in the RO.

the system.

personnel to test pressures and set the pressure regulators.

Provides the backpressure necessary for the Procon pump to create

the 200 psi required to push water across the membrane.

function. The drain flow is about 1000mL/min.

system. This reduces the waiting time before the unit can be used.

Used to prevent incoming or recirculating water from entering the

product line. Because this valve is 1 psi, the output water pressure will

be 21 psi to the dialysis machine.

7

Page 12

Specifications

Name ExtraPure Reverse Osmosis System

Electrical supply 117 VAC 60/50 Hz or 230 VAC 60/50 Hz,

580 W, 6.5 A/3.3 A

Incoming water supply pressure 20-100 psi (138-690 kPa)

Filter 5-micron carbon filter (P/N 407-8502-014)

Maximum water hardness without

softening

Membrane configuration Spiral wound

Membrane material Thin film composite -- polyamide

Membrane pH tolerance of input water 3.0- 10.0

Operating temperature, minimum output

of 500 mL/min

Rated output at 25ºC (77ºF) input water

temperature

Rated output at 5ºC (41ºF) input water

temperature

Size unit Depth - 406 mm (16")

Weight 27 kg (60 lb)

RO membrane operating pressure 200 psi (1,380 kPa)

Depends on pH of feed water

5ºC to 35ºC (41ºF to 95ºF)

500 - 1,100 mL/min minimum

525 mL/min minimum

Width - 406 mm (16")

Height - 710 mm (28")

Membrane integrity/conductivity monitors Dual cell conductivity temperature

compensated, show % rejection and

absolute conductivity in microsiemens

Low water pressure alarm 5 psi (35 kPa)

Rejection of dissolved salts 90-98%

Rejection of organism (mol wt. greater

than 300), bacteria, pyrogens

Output pure water pressure 21 psi (145 kPa)

Disinfectant 37% aqueous formaldehyde or Hydrogen

Greater than 99%

Peroxide / Peroxyacetic Acid

depending on model.

8

disinfectant

Page 13

STARTUP

Water Supply

Every water supply is different and should be tested to determine the water treatment

required. Always have your water supply tested before connecting the ExtraPure RO

System. In some areas, water softening or other pre-treatment may be required.

Water Supply Requirements

Water supply: 7.5 liters per minute (2.2 gallons per minute) minimum

Pressure between 20 and 100 psi

Water temperature between 5ºC and 35ºC (41ºF and 95ºF)

Water pH between 3.0 and 10.0

Drain capability of 3 liters per minute (0.78 gallons per minute)

Negative test for scaling (Langlier saturation index)

Unpacking

After inspecting the shipping container for damage, open the box, remove all packing

materials, and inspect for damage. Report all damage promptly to the shipping

company and make a claim for compensation. Damage caused in shipment is not

covered by the equipment warranty. Save the shipping carton and packing material for

inspection and verification of your claim.

Inspect the ExtraPure RO System for leaks after unpacking. The ExtraPure RO System

is shipped with a new membrane, an input hose, a drain hose, a sanitize hose and a

new water filter.

The ExtraPure RO System must be disinfected prior to use. Follow procedures on page

16 and page 17 or according to your clinic’s recommendation.

9

Page 14

Installing

The ExtraPure RO System's hoses are shipped with caps on them.

Remove these caps before connecting the hoses.

1. Connect the input hose to the water supply. The

connection is a 3/4" female garden hose connection.

Use rubber washers on all connections.

2. Place the drain hose in the drain.

3. Connect the sanitize hose to the ExtraPure RO System

product water fitting (3/4" male garden hose) and place

the open end in the drain.

4. Check for proper voltage and then plug in the unit.

10

Page 15

Initial Rinse

1. Turn on the water supply. Check for

leaks. You should not hear water

running through the unit until it is

turned on.

2. Lift the rinse lever and turn on the

ExtraPure RO System with the

ON/OFF switch on the control panel.

Look for water flowing through the

drain line and sanitize hose.

3. Run the ExtraPure RO System for 15

minutes to rinse the fluid path.

RINSE!

After 15 minutes, turn off the unit to

install the filter in its blue housing.

Unscrew the housing counterclockwise and carefully remove it.

There will be water in the housing.

Empty the housing completely and

refill partially with fresh water. Then

slide the new filter into place and

reinstall the housing. The fresh water

in the housing prevents excessive air

in the fluid path.

After startup, never operate the

ExtraPure RO System without the

filter. Do not use any filter other than

the specified Baxter 5-micron carbon

filter (P/N 407-8502-014 or 5M1315).

4. Rinse the ExtraPure RO System by

lifting the rinse lever on the control

panel and letting the unit run for 15

minutes.

11

Page 16

5. Lower the rinse lever. After a few

minutes, water quality should be

normal and the water quality meter on

the control panel should read in the

green zone (above 90% rejection).

Product ____________

% Rejection _________

Recirculation ________

6. Use the three-position selector switch

on the control panel to determine the

values of the product and the

recirculation water. Write these down

for future reference. If the needle goes

off the right side of the scale, refer to

the Troubleshooting section of this

manual.

12

Page 17

Normal Operation

1. Rinse and then test for residual disinfectant according to your clinic's

recommendation before connecting the ExtraPure RO System to the dialysis

machine.

2. Turn on the water and turn on the ExtraPure RO System.

3. Note the filter pressure readings at the beginning of use. The difference between

filter/inlet pressure and filter/outlet pressure should always be less than 10 psi with

no water pressure alarm.

CAUTION:

The filter should be changed whenever the product water is below AMMI

Standards, the filter inlet/outlet pressure difference is greater than 10 psi, after 65

hours of operation, or as recommended by your clinic.

13

Page 18

Cleaning the Membrane

Note: This is not a sanitizing procedure. Follow procedures on page 16 or 17 to

sanitize the system.

1. Disconnect the product water line from the RO and install the sanitize hose. Place

the open end of this hose in the drain.

2. Inject 200-300 ml of white vinegar into the sanitization port. Turn the RO on, let the

machine run for 1 minute, then turn the machine off and let it stand overnight.

3. After allowing the vinegar to dwell overnight, turn the RO on and lift the rinse lever to

the rinse position. Rinse the machine for 15 minutes.

4. Check pH to verify all the vinegar has been flushed out of the RO. If pH is not in the

acceptable range continue the rinse until the pH is within limits.

5. Lower the rinse lever to the operating position and check the water quality meter to

ensure the needle is in the green zone. (If not the membrane will need to be

replaced.)

6. Turn the RO off.

7. Disconnect the sanitize hose from the RO and reconnect the product water line to

the RO.

8. Place the rinse lever in the run position.

The RO is now ready to be put back in service or to Sanitize as outlined on page 16 thru

19.

Filter Replacement

The ExtraPure RO System uses a disposable cartridge filter as illustrated in Figure 4.

The filter should be replaced if the product water is below AMMI Standards, if the

inlet/outlet pressure difference is more than 10 psi, or if the filter has been used more

than 65 hours (13 dialysis treatments).

1. Turn off the water to the unit.

2. Unplug the ExtraPure RO System.

3. To relieve the water pressure inside the unit, disconnect the water line to the dialysis

machine and place it in a clean bucket to avoid contamination.

4. Unscrew the blue filter housing (rear compartment of unit) by turning it

counterclockwise. The housing will have water in it. Pour off the water and set the

housing aside.

5. Remove and discard the old filter.

6. Replace with a new Baxter 5-micron carbon filter (P/N 407-8502-014 or 5M1315).

DO NOT USE ANY FILTER OTHER THAN THE FILTER SPECIFIED. Partially fill

the housing with fresh water to prevent excessive air in the fluid path. Then slide the

filter into place and carefully reinstall the housing.

7. Turn on the water supply and plug in the ExtraPure RO System. Run the unit for 15

minutes with the rinse lever on the control panel in the rinse position. After rinsing,

return the rinse lever to the normal operating position.

14

Page 19

Figure 4: Filter assembly

15

Page 20

SANITIZATION

Sanitizing a Formaldehyde RO and Storage Procedure

WARNING: Store all Disinfectants out of reach of children

1. The ExtraPure RO System should be sanitized at least once a week with regular

use, or follow your clinic's recommendation, to prevent bacteria building up in the

water path. Use only 37% aqueous formaldehyde solution (Formalin™).

2. With the unit off, disconnect the water line connecting the ExtraPure RO System to

the dialysis machine. In its place, connect the sanitize hose. Place the end of the

sanitize hose in the drain. Ensure the drain hose is in the drain.

3. Carefully inject 100 cc Formalin™ into the disinfectant port. Slowly inject the

Formalin™ into the disinfectant port on the control panel. Then inject 50 cc water

and reinstall the sanitize cap.

4. Turn on the unit and let it run for 30 - 45 seconds with the rinse lever in the operating

position. (If storage time will be more than three days, remove filter and housing,

and allow to air-dry.

5. Turn off the ExtraPure RO System and turn off the feed water. Let the RO unit stand

with the Formalin™ disinfectant in it until rinsing, according to your dialysis regimen

and your clinic's recommendation. (If storage time will be more than three days,

remove filter and housing, and allow to air-dry.)

6. Rinse the Formalin™ solution from the RO for at least 15 minutes with the rinse

lever in the up position. Rinse until output water tests negative for Formalin™

residuals according to your clinic's procedures. See page 19.

7. Turn off the ExtraPure and the feed water. Disconnect the sanitize hose and

reconnect the product water line to the dialysis machine.

NOTE

In a 7-day period, a typical dialysis regimen will have one

interval between treatments longer than the other interval(s).

For convenience, this longer interval can incorporate the

sanitization of the ExtraPure RO System. For example, in

the dialysis schedule shown, with treatments on Monday,

Wednesday, and Friday, sanitize the ExtraPure RO System

after dialysis on Friday and rinse the unit before dialysis on

Monday.

S

6

13

20

27

M

7

14

21

28

T

1

8

15

22

29

W

2

9

16

23

30

T

F

3

4

10

11

17

18

24

25

31

S

5

12

19

26

16

Page 21

Sanitizing a Hydrogen Peroxide/ Peroxyacetic Acid

Disinfectant Compatible Reverse Osmosis System

CAUTION:

Make sure the device you will be using is model 5M5509 or FM4644. Use of

Hydrogen Peroxide and Peroxyacetic Acid in a non-compatible machine will

cause premature deterioration of components. The ExtraPure RO System should

be disinfected with Formaldehyde if the system will sit idle for more than seven

days. Refer to page 16 "Sanitizing a Formaldehyde RO and Storage Procedure."

The ExtraPure RO System should be sanitized at least twice a week with regular

use, or follow your clinic’s recommendation, to prevent bacteria building up in the

water path. Use 100% disinfectant that is made with 22% Hydrogen Peroxide and

4.5% Peroxyacetic Acid.

Minntech® manufactures a product called Minncare® for this purpose.

WARNING: Store all Disinfectants out of reach of children.

1. With the unit off, disconnect the water line connecting the ExtraPure RO System to

the dialysis machine. In its place, connect the sanitize hose. Collect at least 50 cc of

product water from the sanitizing hose. This product water will be used in step 2.

Then place the end of the sanitize hose in the drain. Ensure the drain hose is in the

drain.

2. Carefully inject 60 cc of Hydrogen Peroxide/ Peroxyacetic Acid into the disinfectant

port on the control panel, and then inject 50 cc of the product water collected in step

1. Reinstall cap on sanitize port.

3. Verify the rinse lever is in the operating position. Turn on the unit and let it run for 30

to 45 seconds.

17

Page 22

4. Turn off the ExtraPure RO System and turn off the feed water. Let the RO unit stand

idle until rinsing, according to your clinic’s recommendation. The disinfectant must

dwell in the system for two hours.

Notice: Damage to the system may result if the dwell time is longer than two

hours and the membrane is fouled by one of the following conditions: 1. Heavy

metals in the water source such as iron 2. Inorganic matter in the water source 3.

The pH level is higher than 5.

5. Rinse the Hydrogen Peroxide/ Peroxyacetic Acid solution from the RO for at least 15

minutes with the rinse lever up. Rinse until output water tests negative for Hydrogen

Peroxide/ Peroxyacetic Acid residuals according to your clinic’s recommendation. See

the next page.

CAUTION: The Hydrogen Peroxide / Peroxyactic Acid should never dwell in the

system longer than twelve hours. For long-term storage follow the procedure

using Formaldehyde.

18

Page 23

Rinsing

WARNING:

After sanitizing, you must rinse the ExtraPure RO System before using it to

supply dialysis water.

1. Turn on the feed water.

• Lift the rinse lever on the control panel to the RINSE position.

• Turn on the ExtraPure RO System.

• Let the ExtraPure run for at least 15 minutes.

2. After 15 minutes rinsing, test the product water (sanitize hose) for residual

disinfectant according to your clinic's recommendation. Continue rinsing until the

test is negative.

3. When the test for disinfectant is negative, place the rinse lever in the OPERATE

position. The ExtraPure RO System is ready for operation when the water quality

meter reads in the yellow or green zones.

4. Turn off the ExtraPure RO System and the feed water.

5. Remove the sanitize hose and reconnect the product water line to the dialysis

machine.

19

Page 24

MAINTENANCE

Required periodic maintenance includes inspections for leaks, cleaning, sanitation, and

filter replacement.

Recommended Tools to Maintain One ExtraPure RO

Tool Part Number

Hach Water Test Kit 413-0001-026

Myron L Total Dissolved Solids Meter 499-4000-032

0-30 psi gauge 403-8500-004

0-400 psi gauge 403-8500-009

Filter Wrench 413-0001-013

Recommended Spare Parts to Maintain One ExtraPure RO for

One Year

Catalog

Page #

1 3 407-8502-014 Charcoal Filter, 5 micron As needed

3 35 908-5000-176 RO Filter Element 1

4 7 157-1232-255 Sanitizing Port Cap 1

4 23 402-9862-132 Sanitizing Port Female Luer-Lok 1

Item Part Number Description Quantity

Inspection for Leaks

Before each dialysis treatment, check for leaks at the hose connections, filter housing,

and cabinet assembly. If leaks cannot be corrected, call Baxter Instrument Services

1-800-553-6898.

External Cleaning

Clean the outside of the ExtraPure RO System cabinet with a solution of water and a

mild detergent. If additional cleaning is needed, use a solution of half water and half

household bleach.

20

Page 25

TROUBLESHOOTING

Basic troubleshooting procedures are given below. If these procedures do not correct

the problem, call Baxter Instrument Services at 1-800-553-6898.

Alarms

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Product alarm High product TDS caused by a

torn membrane.

High product TDS caused by

an occluded drain orifice. (No

flow at drain when rinse valve

is down.)

Low pressure alarm Water not turned on.

The filter needs to be changed.

20 psi regulator is not properly

adjusted

Water pressure switch is

broken

Change the membrane.

Clean the drain orifice or

change the flow controller

assembly.

Turn on the water.

Check filter gauges.

Change filter if necessary.

Install a gauge in the proper

port; adjust the regulator.

Replace the switch.

Electrical

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Motor does not run ON/OFF reset switch in back of

the machine set at OFF.

Fails electrical

leakage test

Unable to adjust +12

Volts to +

Unable to adjust -12

Volts to + 0.1 VDC

0.1 VDC

Power supply, power cord,

pump/motor, and wiring.

Power supply Replace or call Baxter

Power supply Replace or call Baxter

Switch to ON.

Replace or call Baxter

Instrument Services.

Instrument Services.

Instrument Services.

21

Page 26

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Moisture around

conductivity cell

electrodes

With water off, no

alarms & pump runs,

or mute inoperative

Meter indication or

logic inaccurate

RO recirculation cell is

< 10 X RO product

cell

Electrodes Replace or call Baxter

Instrument Services.

PCB, pressure switch, wiring,

alarm mute switch, inlet.

Meter, PCB, thermistor, wiring,

3 position switch, product water

LED, Sonalert alarm,

conductivity cells

Meter, PCB, power supply,

electrodes, thermistor, RO

module or vessel, filter, wiring

Replace or call Baxter

Instrument Services.

Clean, calibrate or replace

as necessary, or call Baxter

Instrument Services.

Clean, calibrate or replace

as necessary, or call Baxter

Instrument Services.

Flow

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Proper input water

pressure, but no

output

Unable to regulate

product flow to 500

mL/min

Unusual noise coming

from the pump

Water running out of

the cabinet

Drain flow < 800

mL/min

Product flow <1100

mL/min

Drain flow w/fast rinse

switch up <1500

mL/min

Pump motor not running, motor

overload protector stopping

motor.

PCB, power supply, pressure

switch, power cord, relay,

pump/motor, RO

module/vessel, low pressure

regulator, wiring, inlet water

solenoid, on/off SW/CRT

breaker

Filter partly clogged and not

supplying enough water.

Pump pressure to RO

membrane low.

Leak inside the unit. Look for loose connections.

Pump or motor, RO module or

vessel

Pump or motor, RO module or

vessel, Inlet water temperature

is below 25º C.

Pump or motor, RO module or

vessel. Fast rinse switch block

Verify that the conductivity

cell connection is secure.

Check motor connections.

Calibrate or replace as

necessary, or call Baxter

Instrument Services.

Change the filter.

Replace pump head or call

Baxter Instrument Services.

Tighten or repair with Teflon

tape or silicon RTV. If

unable to repair, call Baxter

Instrument Services.

Replace or call Baxter

Instrument Services.

Replace or call Baxter

Instrument Services.

Replace or call Baxter

Instrument Services.

22

Page 27

Pressure

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Output water pressure

low

Water pressure

gauges vibrate

Difference between

water inlet/outlet

gauges > 10 psi

Reverse Osmosis membrane

aged, capacity has fallen below

specification due to use and

scaling.

Pump pressure to RO

membrane low.

Incoming water pressure is too

high.

Filter, pressure gauges Replace filter/gauges or call

RO membrane will need to

be cleaned or replaced.

Call Baxter Instrument

Services.

Replace pump head or call

Baxter Instrument Services.

Install an incoming water

pressure regulator.

Baxter Instrument Services.

Water Quality

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Water quality as

indicated on the water

quality meter is in the

red zone (below 80%

rejection)

Water quality not in

green, but quality is

good

Water quality meter

reads off the right side

of the scale

This condition can be caused

by a number of related

conditions:

1. Failure of the RO

membrane.

2. Degradation of the RO

membrane but not a membrane

leak.

3. Flow and pressure

conditions within the unit have

changed so that the % yield

has increased significantly.

Meter, PCB, power supply,

electrodes, thermistor, RO

module/vessel, filter, wiring

Open electrical connection in

conductivity circuit.

Do not operate with water

quality meter in the red

zone. Call Baxter

Instrument Services.

Check conductivity reading

with the three-position

switch.

Call Baxter Instrument

Services

Clean, calibrate or replace

as necessary, or call Baxter

Instrument Services.

Call Baxter Instrument

Services.

23

Page 28

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

% rejection indicator is

in the red zone,

audible alarm.

% rejection indicator is

in the red zone but

there is no audible

alarm.

Product water chlorine

exceeds AMMI

Standards

Incoming TDS is less than 150

ppm (calculated % rejection is

less than 80%).

Membrane is scaling.

Internal water pressure

regulators are not set properly.

Drain orifice is occluded.

Meter is not calibrated.

% rejection offset is not

calibrated.

Filter may be saturated with

chlorine.

Install a 5K resistor in

parallel with the

recirculation conductivity

cell.

Inject 200-300 ml white

vinegar into the sanitization

port, let the unit run for 1

minute, then let it stand

overnight.

Install gauges in the ports

provided, then set the

product and recirculation

regulators at 20 psi and 200

psi, respectively.

Clean the drain orifice or

replace the flow controller

assembly.

Calibrate the meter.

Calibrate the % rejection

offset.

Change the carbon filter.

24

Page 29

Calibration of Electronics

CAUTION: The following procedure should only be performed by a qualified

technician. Call Baxter Instrument Service at 1-800-553-6898.

% Rejection Meter Adjustment R55: For the recirculation cell, substitute a 4K resistor

(10% or better). For the product cell, substitute a 20K resistor. Adjust R55 so that the

meter rests on the red-yellow border.

% Rejection Meter Adjustment R56: With the same resistors in place, connect the

voltmeter to TP2. Adjust R56 for the point at which the voltage changes from low to

high. You will not be able to use the LED as a reference due to the delay.

Product Alarm Adjustment R44:

1. Short out the recirculation cell.

2. Substitute 11.2K resistor for product cell.

3. Hook voltmeter to TP1.

4. Adjust R44 for point at which voltage changes from low to high.

NOTE

This adjustment is sensitive to ambient thermistor temperature.

You will not be able to use the LED as a reference due to the delay.

Monitor Check: With the 4K and 20K resistors in place as in the first calibration, you

should be able to get the following readings on the water quality meter.

Product 1.5 - 3.5

Recirculation 4.0 - 6.0

% Rejection on red-yellow border

This will confirm conductivity PCB operation. If meter readings do not agree with

laboratory analysis, check the thermistor (10K resistance) and the cells.

Replacing the RO Membrane

CAUTION: The following procedure should only be performed by a qualified

technician. Call Baxter Instrument Service at 1-800-553-6898.

1. Turn off the RO and disconnect it from the water source and electrical outlet.

2. From the back of the unit, open the straps at the top and bottom of the vessel.

3. Once the pressure vessel is loose, lift it out of the bracket and lay it on its side on

something (such as a wastebasket) to catch the water that will be draining out of the

vessel.

4. Remove the compression fitting on the input water line located about 4" from the

bottom of the vessel. Remove this fitting slowly. There still may be pressure in the

line.

25

Page 30

5. Using a flat blade screwdriver, remove the top snap-ring holding the top cap in

place. Slowly pull the cap out of the top of the vessel using a rocking motion.

6. Remove the bottom snap-ring and end cap as in previous step. (This step is not

necessary if you are able to remove the membrane through the top without

difficulty.)

7. Remove the old membrane by pushing from the bottom or pulling from the top of

the vessel.

8. Unpack and inspect the new membrane. The end with the U cup brine seal is the

bottom of the membrane. Make sure the open side of the U cup brine seal faces

upward toward the top.

9. Insert the new membrane into the vessel from the top. The U cup brine seal will

allow the membrane to be inserted only in one direction. The bottom of the

membrane inserts into the top of the vessel. If the membrane is difficult to insert,

inspect the U cup brine seal to be sure it is oriented properly.

10. Replaced the two o-rings on the top and bottom end caps. (The part numbers for

the o-rings are 408-8500-005 for the small o-ring and 408-8500-004 for the large oring.) After installing the o-rings, apply a light coat of high vacuum grease (part

number 594-0001-019) to the o-rings.

11. Reinstall the top and bottom end caps and snap-rings, being careful not to damage

the 0-rings. Make sure the snap-rings are set in their respective grooves in the

vessel.

12. Reinstall the vessel into the straps.

13. Connect the input water supply line to the vessel.

14. Turn on the unit long enough to let the vessel pressurize. You will notice the end

caps move when the pressure builds up.

WARNING: Do not stand directly above the RO while turning it on. If the snaprings are not seated correctly, the end cap may fly off.

15. Check for leaks.

16. Return equipment to operation after sanitizing and rinsing.

17. Confirm the water quality prior to use.

26

Page 31

A

AA

B

BB

Pressure Adjustments for Hydrogen Peroxide/Peroxyacetic Acid

Compatible System

CAUTION: The following procedure should only be performed by a qualified

technician. Call Baxter Instrument Service at 1-800-553-6898.

1. Remove hole plugs in the conductivity cell block while the RO unit is off.

2. Install:

"AA" 0-30 psi gauge in the below recirculation cell.

"BB" 0-400 psi gauge in the hole on the high pressure regulator.

3. Turn the RO unit on and restrict product water flow to 500 cc/min.

"A" verify recirculation pressure is 21 to 24 psi. If not, adjust the low pressure

regulator located above the block.

"B" verify RO module pressure is 200 psi. If not, adjust pressure using the

high pressure regulator.

4. Remove gauges and replace the hole plugs.

27

Page 32

AAA

BB

B

Pressure Adjustments for Formalin™ Compatible System

CAUTION: The following procedure should only be performed by a qualified

technician. Call Baxter Instrument Service at 1-800-553-6898.

1. Remove hole plugs in the conductivity cell block while the RO unit is off.

2. Install:

"AA" 0-30 psi gauge in the below recirculation cell.

"BB" 0-400 psi gauge in the hole on the high pressure regulator.

3. Turn the RO unit on and restrict product water flow to 500 cc/min.

4. At point "A" verify recirculation pressure is 21 to 24 psi. If not, adjust the low

pressure regulator located above the block.

At point "B" verify RO module pressure is 200 psi. If not, adjust pressure using the

high pressure regulator.

5. Remove gauges and replace the hole plugs.

28

Page 33

Conductivity Cell Connections

Damage or loosening of these connections could render the conductivity cell useless

and result in erroneous water quality readings. The following are results obtained by

simulating conductivity cell failure.

Conditions % Rejection Product Recirculation

Product cell open pegged right pegged right normal

Recirculation cell

open

Both cells open lower, still in green

pegged left slightly high, still in

green scale

pegged right pegged left

scale

pegged right

29

Page 34

DIAGRAMS AND SCHEMATICS

The following diagrams and schematics are contained in this section:

ExtraPure RO Wiring Diagram, 157-1232-996

ExtraPure RO System Schematic Diagram, 157-1232-997

Logic-Conductivity Circuit, 157-1232-994

30

Page 35

31

Page 36

32

Page 37

33 34

Page 38

Page 39

Loading...

Loading...