Page 1

E

C

X

E

X

C

Operator’s Manual

E

C

X

E

X

C

.

E

C

X

E

X

C

C

O

L

L

E

A

G

U

E

G

U

A

R

D

I

A

N

PRODUCT CODES: 2M91617 and 2M91637

A

E

G

L

U

L

E

O

C

G

N

U

A

A

I

R

D

.

E

X

C

C

X

E

Prior to using this pump, read this manual carefully to fully understand

the pump’s functionality and to ensure safe and proper operation.

071960491

Page 2

!

WARNING

!

There are risks associated with using anything other than the recommended sets with this

device. Sets designated for use with this device are identified in “Recommended Administration

Sets,” 4-15. Baxter’s warranty on this device will be null and void and Baxter will assume no

responsibility for incidents which may occur if the product is not used in accordance with

product labeling.

Computer Software Copyrights

©Copyright 1996 – 2010, Baxter Healthcare Corporation. All rights reserved.

For use only by Baxter Healthcare Corporation. The software contains proprietary information belonging to Baxter

Healthcare Corporation. The software must not be reproduced or disclosed to others without prior written approval.

Any unauthorized use of this information may subject the user to substantial liability.

Documentation Copyrights

Duplication or distribution of this manual and any information contained within is strictly prohibited without the

express written permission of Baxter. This manual and any information contained within, may not be reproduced,

distributed, or transmitted in any form, or by any means, for any purpose, without the express written permission of

Baxter. To order additional copies of this manual, or other related manuals, contact your local Baxter Service Center.

Disclaimer

The information in this document has been carefully examined and is believed to be entirely reliable. However, no

responsibility is assumed for inaccuracies. Furthermore, Baxter reserves the right to make changes to any products

herein to improve readability, function, or design. Baxter does not assume any liability arising out of the application

or use of any product or circuit described herein; neither does it cover any license under its patent rights nor the rights

of others.

Trademark Information

Baxter, Buretrol, Colleague, Colleague Guardian, Continu-Flo, and Personality are trademarks of Baxter International

Inc. Other trademarks/products appearing herein are the property of their respective owners.

Patent Information

This device is protected under one of more of the following U.S. and foreign patents: United States: 5151019,

5764034, 5779207, 5782805, 5842841, 6013057, 6123524, D390654, RE37074E, 2004/0193325A1; Australia:

130693, 706187, 710286, 712859, 713132, 721076, 740655; Austria: E248618, E255925; Belgium: EP0833674,

EP0836492, EP0837708, EP0891784; Canada: 2223838, 2223841, 2223897, 80218; Denmark: 165/97,

EP0833674, EP0836492, EP0837708, EP0891784; European Patent Convention: EP0833674; Finland:

EP0836492, EP0891784; France: EP0426273, EP0833674, EP0836492, EP0837708, EP0891784, EPO931555;

Germany: 69013289.1, 69720637.8, 69724600.0, 69726089.5, 69726683.4, 69731650.5, M9608875.3; Greece:

20030404616, 20040400581; Hong Kong: 1002288, 1002294, 1026249, 1026250, HK1002291, HK1002353;

Ireland: EP0836492, EP0891784; Italy: 20471BE2004, 22304BE/04, 34797BE2003, 36769BE2003, 72121; Japan:

1002447, 3473958; Korea: 10-344041, 10-376076, 207012, 428607; Liechtenstein: EP0836492, EP0891784;

Luxembourg: EP0836492, EP0891784, EP0836492, EP0891784; New Zealand: 28022, 329316, 329318, 329319,

33087, 333092; Singapore: 47250, 47257, 48670, 51196, 83736, DU2001/267G; Spain: 2206830T3, 2212092T3;

Sweden: 61479, EP0833674, EP0836492, EP0837708, EP0891784; Switzerland: EP0836492, EP0891784; Taiwan:

058282, 090525, 092501, 096216, 098653; United Kingdom: 2225065, 2059861, 2312022B, 2312049B, 2312055,

2312234, 2338753, 2338758B. Other U.S. and foreign patents pending.

071960491

Page 3

Table of Contents

Material Specifications ........................................................................................... ix

Meaning of the CE Mark Symbol............................................................................. x

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

User Assistance Information................................................................................. 1-1

Overview............................................................................................................... 1-1

Safety Summary.................................................................................................... 1-3

Warnings and Cautions......................................................................................... 1-6

North America ........................................................................................... 1-1

Outside North America.............................................................................. 1-1

Standards.................................................................................................... 1-3

Labeling Symbol Definitions..................................................................... 1-4

Definitions ................................................................................................. 1-6

Warnings.................................................................................................... 1-7

Cautions ..................................................................................................... 1-9

Notes ................................................................................................................... 1-10

Indications for Use.............................................................................................. 1-10

Chapter 2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Overview............................................................................................................... 2-1

Description of Controls and Indicators................................................................. 2-2

Front Panel Features .................................................................................. 2-2

Pump Module Features .............................................................................. 2-6

Rear Panel Features ................................................................................... 2-8

Color Reference Guide .............................................................................. 2-9

0719 60491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL i

Page 4

Table of Contents

Display Reference Guide ...................................................................................... 2-9

Main Display Screen................................................................................ 2-10

Programming Screens .............................................................................. 2-12

Pop-up Windows ............................................................................. 2-13

Menus .............................................................................................. 2-13

Main Display Icons.................................................................................. 2-13

Label Location .................................................................................................... 2-16

Pump Software Features ..................................................................................... 2-18

PERSONALITY Feature Sets ................................................................. 2-18

Label Library ........................................................................................... 2-19

Infusion Modes ................................................................................................... 2-19

Rate-Volume Infusions ............................................................................ 2-20

Volume-Time Infusions........................................................................... 2-20

COLLEAGUE GUARDIAN Feature ...................................................... 2-20

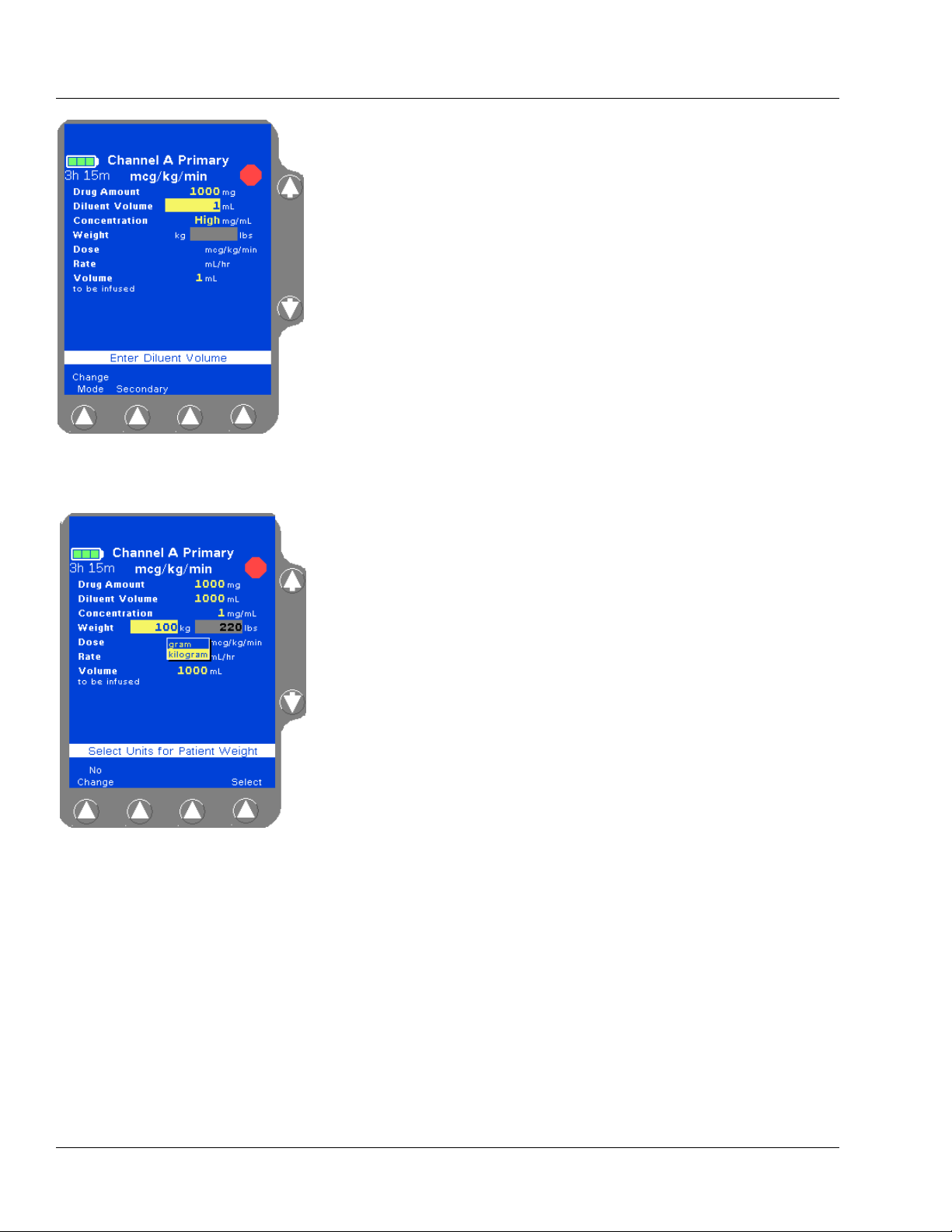

Dose Modes ............................................................................................. 2-23

How Concentration is Determined .................................................. 2-23

How Doses and Rates are Calculated.............................................. 2-23

Changing a Parameter After All Parameters Have Been Entered ... 2-24

Changing Units of Measure............................................................. 2-24

Primary Delay Start Mode ....................................................................... 2-25

Chapter 3 Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Environmental Conditions .................................................................................... 3-1

Setup Instructions ................................................................................................. 3-1

Initial Installation....................................................................................... 3-1

Mounting the Pump on an IV Pole ............................................................ 3-2

Mounting the Pump on a Headboard (Single Channel Pumps Only) ........ 3-2

Changing the Mounting Bracket Orientation (Single Channel Pumps

Only) .......................................................................................................... 3-3

Check-out.............................................................................................................. 3-3

ii COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 5

Table of Contents

Chapter 4 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Starting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Powering On Using AC Power............................................................................. 4-1

Selecting a Pump PERSONALITY Feature Set ................................................... 4-5

Viewing PERSONALITY Feature Settings at Power-Up ......................... 4-5

Adjusting the Audible Volume ............................................................................. 4-6

Adjusting the Display Contrast............................................................................. 4-6

Powering On Using Battery Power....................................................................... 4-6

Full/Partial Battery Charge ........................................................................ 4-6

Low Battery Condition .............................................................................. 4-7

Depleted Battery Condition ....................................................................... 4-7

Operating on Battery Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Battery Charge Icon Descriptions......................................................................... 4-8

Battery Charge Alerts and Alarms...................................................................... 4-10

Battery Charge Progress Indicator Alert............................................................. 4-12

Damaged Battery Alert and Alarm ..................................................................... 4-13

Preparing for an Infusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Preparing the Primary Infusion Container and Set ............................................. 4-13

Replacing the Primary Infusion Container (Using the Same Administration

Set) .................................................................................................................... 4-15

Recommended Administration Sets.................................................................... 4-15

Loading the Administration Set.......................................................................... 4-16

Using the Optional Prime Function .................................................................... 4-18

Overview.................................................................................................. 4-18

Priming the Administration Set ............................................................... 4-18

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL iii

Page 6

Table of Contents

Programming an Infusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Primary Infusions................................................................................................ 4-21

Programming a Primary Rate-Volume Infusion...................................... 4-21

Selecting a Label...................................................................................... 4-23

Programming a Primary Volume-Time Infusion..................................... 4-25

Programming a Primary COLLEAGUE GUARDIAN Infusion

(Rate-Volume) ......................................................................................... 4-26

Programming a Primary COLLEAGUE GUARDIAN Infusion

(Non-Weight-Based)................................................................................ 4-29

Programming a Primary COLLEAGUE GUARDIAN Infusion

(Weight-Based)........................................................................................ 4-32

Programming a Primary Dose Mode Infusion (Non-Weight Based) ...... 4-36

Programming a Primary Dose Mode Infusion (Weight-Based) .............. 4-40

Secondary Infusions............................................................................................ 4-45

Preparing a Secondary Infusion Set......................................................... 4-46

Programming a Secondary Rate-Volume Infusion.................................. 4-46

Programming a Secondary Volume-Time Infusion................................. 4-49

Enabling the Secondary Callback Alert Option....................................... 4-50

Standby Mode ..................................................................................................... 4-50

Standby Activation (Single Channel Pumps) .......................................... 4-51

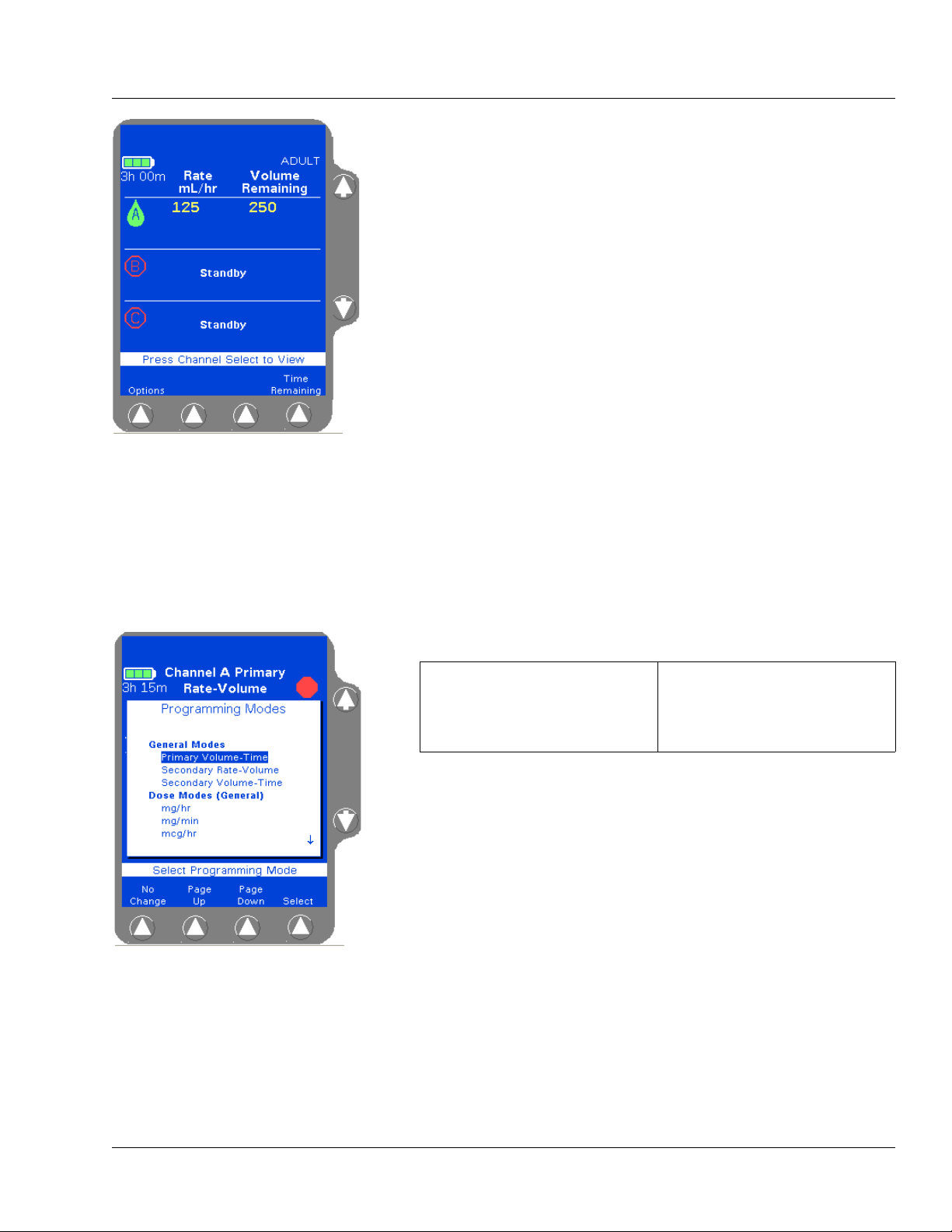

Standby Activation (Triple Channel Pumps)........................................... 4-52

Standby Deactivation............................................................................... 4-54

Programming a Delay Start Infusion .................................................................. 4-54

Viewing Delay Start Settings Prior to the Start of Infusion .................... 4-56

Exiting Delay Start Mode................................................................ 4-57

Powering On with Delay Start Infusions......................................... 4-58

While the Infusion is Running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

Managing Volume History ................................................................................. 4-59

Changing the Primary Flow Rate During an Infusion ........................................ 4-60

Changing the Dose During an Infusion .............................................................. 4-61

Changing Volume, Weight or Concentration During an Infusion...................... 4-61

Adding or Changing a Label Line During an Infusion....................................... 4-63

iv COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 7

Table of Contents

Viewing COLLEAGUE GUARDIAN Limits During an Infusion .................... 4-63

Changing the Secondary Flow Rate During an Infusion .................................... 4-65

Panel Lockout ..................................................................................................... 4-66

Activating/Deactivating Panel Lockout................................................... 4-66

Auto Lock ............................................................................................... 4-67

Completing an Infusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

Stopping a Primary Infusion Before Completion ............................................... 4-67

Stopping a Secondary Infusion Before Completion ........................................... 4-68

Infusion Complete (Switch to KVO) .................................................................. 4-69

Unloading the Administration Set ...................................................................... 4-70

Automatic Unloading............................................................................... 4-70

Using the Manual Tube Release .............................................................. 4-71

Resetting the Manual Tube Release ................................................ 4-72

Powering Off the Pump ...................................................................................... 4-73

Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-74

Overview............................................................................................................. 4-74

Managing Occlusion Settings ............................................................................. 4-75

Auto Restart ............................................................................................. 4-76

Viewing PERSONALITY Settings .................................................................... 4-77

Using Flow Check Display ................................................................................. 4-77

Using the Configuration/Service Function ......................................................... 4-78

Chapter 5 Optional Pump Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Syringe Adapter .................................................................................................... 5-1

COLLEAGUE GUARDIAN Configuration Tool ................................................ 5-2

COLLEAGUE DL2 Event History Download Application ................................. 5-2

Chapter 6 Configurable Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Overview............................................................................................................... 6-1

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL v

Page 8

Table of Contents

Chapter 7 Maintenance and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

General Pump Options.......................................................................................... 6-2

COLLEAGUE GUARDIAN Feature Options ..................................................... 6-3

Options Specific to PERSONALITY Feature Sets............................................... 6-4

Label Library ........................................................................................................ 6-7

Predefined Labels ...................................................................................... 6-7

Application Labels..................................................................................... 6-9

Custom Labels ......................................................................................... 6-10

Cleaning ................................................................................................................ 7-1

Maintenance.......................................................................................................... 7-2

Preventive Maintenance............................................................................. 7-2

Battery Care ............................................................................................... 7-3

Battery Service Life........................................................................... 7-4

Optimizing Battery Service Life ....................................................... 7-5

Charging the Batteries ....................................................................... 7-5

Disposing of Used Batteries .............................................................. 7-6

Storage .................................................................................................................. 7-6

Chapter 8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Alert, Alarm, and Failure Messages ..................................................................... 8-1

Troubleshooting Failures ...................................................................................... 8-2

Overview.................................................................................................... 8-2

Device Failure............................................................................................ 8-2

Channel Failures (Single Channel Pumps) ................................................ 8-3

Channel Failures (Triple Channel Pump) .................................................. 8-5

Troubleshooting Alarms ....................................................................................... 8-7

Overview.................................................................................................... 8-7

About the Damaged Battery Alarm ........................................................... 8-8

Troubleshooting Air Detected Alarms....................................................... 8-9

Troubleshooting Other Alarms ................................................................ 8-12

Troubleshooting Alerts ....................................................................................... 8-16

vi COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 9

Table of Contents

Chapter 9 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Pump Specifications ............................................................................................. 9-1

Interfaces............................................................................................................... 9-4

Configuration Transfer Cable .................................................................... 9-4

COLLEAGUE Communication Cable ...................................................... 9-5

External Monitoring................................................................................... 9-5

Recommended Practices ....................................................................................... 9-5

Volumetric Accuracy of the System..................................................................... 9-6

Startup Graph Description .................................................................................... 9-7

How Trumpet Curve Graphs are Interpreted ........................................................ 9-8

How Trumpet Curve Graphs are Created ............................................................. 9-8

How Trumpet Curves can be Used ....................................................................... 9-9

Accuracy Tests...................................................................................................... 9-9

Tested at 1 mL/hr....................................................................................... 9-9

Tested at 25 mL/hr................................................................................... 9-11

Electromagnetic Compatibility Statement .......................................................... 9-14

Chapter 10 Warranty and Service Information . . . . . . . . . . . . . . . . . . 10-1

Warranty ............................................................................................................. 10-1

Service Information ............................................................................................ 10-2

Authorized Service Centers ................................................................................ 10-2

Chapter 11 Quick Reference Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

User Assistance Information............................................................................... 11-1

North America ......................................................................................... 11-1

Outside North America............................................................................ 11-1

Warnings and Cautions....................................................................................... 11-2

Warnings.................................................................................................. 11-2

Cautions ................................................................................................... 11-2

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL vii

Page 10

Table of Contents

Power On and PERSONALITY Feature Set Selection ...................................... 11-3

Power Off............................................................................................................ 11-4

Loading the Administration Set.......................................................................... 11-4

Programming a Primary Rate-Volume Infusion................................................. 11-6

Selecting a Label................................................................................................. 11-7

Programming a Primary Volume-Time Infusion................................................ 11-8

Programming a COLLEAGUE GUARDIAN Infusion (Rate-Volume)............. 11-8

Programming a COLLEAGUE GUARDIAN Dose Mode Infusion ................ 11-10

Programming a Dose Mode Infusion................................................................ 11-13

Programming a Secondary Rate-Volume Infusion........................................... 11-14

Programming a Secondary Volume-Time Infusion.......................................... 11-15

Standby Mode ................................................................................................... 11-15

Unloading the Administration Set .................................................................... 11-17

Automatic Unloading............................................................................. 11-17

Using the Manual Tube Release (MTR)................................................ 11-17

Resetting the Manual Tube Release .............................................. 11-18

Troubleshooting Failures .................................................................................. 11-20

Device Failure........................................................................................ 11-20

Channel Failures .................................................................................... 11-20

Troubleshooting Alarms ................................................................................... 11-21

Troubleshooting Alerts ..................................................................................... 11-23

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

viii COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 11

Material Specifications

The pump contains the plastics and alloys listed below.

Note: No natural latex was used in the manufacture of this pump or its power cord and plug.

Acrylonitrile Butadiene Styrene (ABS)

Acetal 25% Glass Fiber (GF) Reinforced

Acetal + Polytetrafluoroethylene (PTFE)

Acrylic

Aluminum A380.0

13% GF Nylon

30% GF Nylon

33% GF Nylon

30% GF Reinforced Polybutylene Terephthalate (PBT)

30% GF PBT + PTFE

Table of Contents

40% GF Polyphenylene Sulfide (PPS)

Nylon

PBT

Polycarbonate (PC)

PC/ABS

PC/Polyethylene Terephthalate (PET)

Polyetheretherketone (PEEK)

PET Glycol (PETG)

Polyester PBT

Polyimide

Polypropylene

Poron Urethane Foam

Silicone with silver coated glass beads

Thermoplastic Synthetic Rubber

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL ix

Page 12

Table of Contents

0123

Meaning of the CE Mark Symbol

This symbol represents adherence to Council Directive 93/42/EEC (14 June 1993) of the European Communities

concerning medical devices.

The electromagnetic compatibility (EMC) requirements are part of the essential

requirements of the Medical Device Directive.

Device: COLLEAGUE CXE

Volumetric Infusion Pump

Catalogue Number: 2M91617 2M91637

Manufacturer: Baxter Healthcare SA

8010 Zurich

Switzerland

Baxter Healthcare Corporation

Deerfield, IL 60015 USA

Made in Singapore

COLLEAGUE 3 CXE

Volumetric Infusion Pump

x COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 13

User Assistance Information

North America

For technical service of the COLLEAGUE pump call

1-800-THE-PUMP

For product usage information or clinical questions, call Baxter

Medication Delivery Product Information Center at 1-800-933-0303.

Chapter 1

Chapter 1 Introduction

Outside North America

Overview

Visit www.baxter.com/baxter_worldwide.html for contact information

or call your Baxter customer service representative to locate the nearest

service center.

Note: All information contained in this manual is applicable to the

COLLEAGUE CXE (single channel pump) and COLLEAGUE 3

CXE (triple channel pump) unless otherwise noted.

The COLLEAGUE CXE and COLLEAGUE 3 CXE pump features

include:

Three independent pump channels for infusions (triple channel

pump only)

Basic delivery programming

Micro and Macro rate range

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 1-1

Page 14

1 Overview

Adding secondary medications/solutions with configurable

Callback option

Special programming functions for dosing

Configurable PERSONALITY feature sets

Uses Baxter standard administration sets equipped with keyed

slide clamps. See “Recommended Administration Sets,” 4-15.

Automatic tube loading with misloading detection

A label library displaying the medication/solution being

administered. There are 64 predefined labels in the library; up to

436 additional custom labels can be programmed if desired.

The COLLEAGUE GUARDIAN feature, which is a clinical

decision support tool that allows the clinician to compare pump

programming with facility-defined guidelines at the point of care.

If the clinician programs any values outside of the rule sets

established by the facility, an out of limits warning occurs. The

COLLEAGUE GUARDIAN feature is a configurable option that

is available for both rate/volume and dose mode programming.

Programmable air sensor with detection sensitivity ranging from

25 to 150 microliters

Programmable downstream occlusion detection settings ranging

from 2 psig to 15 psig (103 mmHg to 775 mmHg)

Automatic restart if downstream occlusions are corrected within

60 seconds after pump detects them

A flow check graphic displaying downstream in-line resistance to

flow

Compatibility with a variety of source containers

A panel lockout function that helps minimize the potential for

tampering or inadvertent removal of the administration set

A battery charge level indicator to indicate the battery charge

level for transport applications

A Delay Start feature that allows infusions to be programmed in

advance, then started at the programmed start time

Mounting clamp (single channel pump includes headboard

mounting provisions)

Communications port

Diagnostic functions

1-2 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 15

Introduction Safety Summary

The pump has a flexible graphical interface that can be used to configure

the available features. As many as eight custom PERSONALITY feature

sets can be created by selecting the operating functions which are

needed to meet the needs of an individual care area or for specific

therapies. This flexible platform allows the pump to be used for simple

infusions and/or therapies requiring complex dose calculations. See

“Technical Specifications,” 9-1 for configurable features and default

settings.

Although the pump has been designed and manufactured to exacting

specifications, it is not intended to replace trained personnel in the

monitoring of infusions.

Safety Summary

Standards

In accordance with UL 60601-1 and CAN/CSA C22.2 No. 601.1, this

pump is classified as:

Class 1

Type CF

Drip-proof (IPX1)

Not suitable for use with flammable anesthetic mixtures with air,

oxygen or nitrous oxide

Continuous operation

This manual has been developed with consideration to the requirements

in the International Standard, IEC 60601-2-24: 1998, Medical Electrical

Equipment — Part 2-24: Particular Requirements for Safety of Infusion

Pumps and Controllers. Data presented in the Technical Specifications

reflect specific test conditions defined in this standard. Other external

factors such as varying back pressure, temperature, head height, set

usage, fluid restrictions, solution viscosity, or combinations of these

factors, may result in deviations from the performance data enclosed.

When disposing of this device, its batteries, or the administration sets

designed for use with the device, follow local regulations and

guidelines.

Note: Outside the U.S., read document DIN VDE 0753-5, Rules of

application for parallel infusion; conceivable methods for use,

when performing parallel infusions.

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 1-3

Page 16

1 Safety Summary

SN

Labeling Symbol Definitions

Labeling symbol definitions (device and packaging):

IPX1 Drip-proof equipment: enclosed equipment protected

against dripping fluids in accordance with IEC 60529.

~

Alternating current or equipment intended to be connected

to an alternating current (AC) source.

Fuse.

Attention, consult accompanying documents.

Type CF equipment in accordance with UL 60601-1. The

Type CF Applied Part symbol indicates the level of electric

shock protection for the patient contacting parts such as the

IV set. UL/IEC/EN 60601-1 defines CF as providing

greater protection than Type B or Type BF.

Manufacturer.

Recyclable, dispose of properly.

S

I

F

S

I

A

E

L

D

C

5R78

MEDICAL EQUIPMENT

UL 60601-1

CAN/CSA C22.2 No. 601.1

OCP 0011

For products where this mark is present, the device is

classified by Underwriters Laboratories Inc. with respect to

electric shock, fire, and mechanical hazards only in

accordance with UL 60601-1 and CAN/CSA C22.2 No.

601.1.

Brazil certification to:

• INMETRO - National Institute of Metrology,

Standardization and Industrial Quality.

• USP-IEE - University of São Paulo Institute of

Electrotechnics and Energy.

Catalog number.

Serial number.

Symbol (WEEE 2002/96/EC)

For product disposal, ensure the following:

• Do not dispose of this product as unsorted municipal

waste.

• Collect this product separately.

• Use collection and return systems available to you.

Bar below bin: Product distributed after August 13, 2005.

For more information on return, recovery or recycling of

this product, please contact your local Baxter

representative.

1-4 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 17

Introduction Safety Summary

Pb

Nonspillable Battery

38°C

15°C

40°C

-15°C

57°C

-29°C

10

6

For product disposal, ensure the following:

• Do not dispose of this product as unsorted municipal

waste.

• Collect this product separately.

• Use collection and return systems available to you.

• Battery must be recycled.

Bar below bin: Product distributed after August 13, 2005.

Battery: Nonspillable lead acid sealed battery.

For more information on return, recovery or recycling of

this product, please contact your local Baxter

representative.

Fragile; handle with care.

Keep dry.

20%

50kPa

%

85%

106kPa

Operating temperature limits.

Storage temperature limits.

Transport temperature limits.

Transport humidity limits.

Transport atmospheric pressure limits.

Carton stacking limit (single channel pump).

Carton stacking limit (triple channel pump).

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 1-5

Page 18

1 Warnings and Cautions

SN

15040362DL

Sequential

Number

Single Channel COLLEAGUE

CXE Pump

Year of Manufacture

(15 = 2005)

Month of

Manufacture

15060362UL

Sequential

Number

Triple Channel COLLEAGUE 3

CXE Pump

Year of Manufacture

(15 = 2005)

Month of

Manufacture

Labeling abbreviations:

COMM. PORT

VOL.

CONT.

Serial Number Format:

Communications Port

Vo l u m e

Contrast

SN

Warnings and Cautions

Definitions

Examples:

15061234UL manufactured June 2005

17122456DL manufactured December 2007

General Warnings and Cautions are included here. Additional Warnings

and Cautions appear throughout the manual.

Warning messages indicate a possible hazard which, if not avoided,

could result in severe personal injury or death.

Caution messages indicate a problem or unsafe practice which, if not

avoided, could result in minor or moderate personal injury, product or

property damage.

Note messages provide supplemental information to the accompanying

text.

1-6 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 19

Introduction Warnings and Cautions

!

WARNING

!

!

WARNING

!

!

WARNING

!

!

WARNING

!

!

WARNING

!

!

WARNING

!

!

WARNING

!

!

WARNING

!

Warnings

General Warnings:

The COLLEAGUE 3 CXE pump is intended for use in delivering multiple infusions

to a single patient. Never use the pump to deliver infusions to more than one

patient simultaneously.

Do not use this pump in Linear Accelerator Radiation Therapy suites or Magnetic

Resonance Imaging Suites.

The pump has not been evaluated for use in hyperbaric chambers. Use in these

areas may result in operation that is not within the constraints and parameters of

the device.

The pump has not been evaluated for compatibility with Extracorporeal Membrane

Oxygenation (ECMO) systems.

Epidural administration of drugs other than those indicated for epidural use could

result in serious injury to the patient.

• Epidural administration of anesthetics is limited to short term infusion (not to

• Epidural administration of analgesics is limited to use with indwelling

• To prevent infusion of drugs not indicated for epidural use, do not use

• Clearly distinguish pumps used for epidural drug delivery from pumps used

This device should be repaired only by Baxter authorized service personnel or

Baxter-trained hospital biomedical engineering personnel, using only Baxter

recommended parts. There are risks associated with using anything other than

Baxter recommended parts. Baxter will assume no responsibility for incidents

which may occur if the product was not repaired in accordance with procedures

authorized by Baxter.

Procedural Warnings:

If the pump has been dropped or appears to be damaged, it should be taken out of

service and inspected by Baxter-trained, qualified personnel only.

Clinicians are advised to verify the proper route of delivery and that the infusion

site is patent. When using this pump, periodic patient monitoring must be

performed to ensure that the infusion is proceeding as expected. The pump is

capable of developing positive fluid pressures to overcome widely varying

resistances to flow such as resistance imposed by small-gauge catheters, filters,

or intra-arterial infusions. Although the pump is designed to stop fluid flow when

an alarm occurs, it is neither designed nor intended to detect infiltrations and will

not alarm under infiltration conditions.

exceed 96 hours) with indwelling catheters specifically indicated for short

term anesthetic epidural drug delivery.

catheters specifically indicated for either short term or long term analgesic

epidural drug delivery.

administration sets incorporating injection sites during epidural delivery.

for other routes of administration.

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 1-7

Page 20

1 Warnings and Cautions

!

WARNING

!

!

WARNING

!

!

WARNING

!

Use only Baxter standard administration sets equipped with keyed slide clamps

that are labeled as being COLLEAGUE pump compatible or denoted with an “s” in

the product code. If you have questions about administration set compatibility,

contact the Baxter Product Information Center at the number shown on the

administration set labeling. Using anything other than the recommended

administration sets with this pump will result in operation that is not within the

constraints and parameters of the device.

Severe injury or death may result from using sets other than those approved by

Baxter Healthcare Corporation for use with COLLEAGUE pumps. Always read and

follow the instructions in the Operator’s Manual and those accompanying the set

and source container.

Use only CONTINU-FLO standard administration sets equipped with keyed slide

clamps and labeled as COLLEAGUE pump compatible or denoted with an “s” in

the product code as the primary fluid line when administering a secondary

medication/solution. See “Recommended Administration Sets,” 4-15. Carefully

follow the directions on the primary and secondary administration set labels.

When using the secondary infusion feature ensure:

• the medication/solution in the secondary source container is

compatible with the medication/solution in the primary source

container.

• the secondary administration set is connected to the appropriate

injection site on the CONTINU-FLO administration set.

• the interruption of the primary infusion is clinically appropriate for

the duration of the secondary infusion.

• the infusion runs from a secondary source container and not from a

primary container.

Pulling or tugging on the administration set tubing between the pump channel

and the patient may cause false Air Detected alarms, which will cause the pump to

stop infusing. In order to reduce the potential for this situation to occur:

• First, select an appropriate length administration set.

• Before loading the set into the pump, position the keyed slide clamp

at an appropriate location along the tube segment to ensure that

there is adequate length of tubing between the patient and the pump

to reduce tugging on the set.

• Lastly, ensure there is sufficient slack in the tubing between the

distal end of the tubing channel and the patient to prevent tube

tugging during activities such as moving the patient from one bed to

another, or transportation of the patient from one facility location to

another.

In order to avoid false alarms, the pump should never be placed on the bed

alongside the patient.

1-8 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 21

Introduction Warnings and Cautions

!

WARNING

!

!

WARNING

!

!

WARNING

!

!

WARNING

!

!

WARNING

!

CAUTION

CAUTION

The pump may not detect an upstream occlusion if one or more of the following

conditions exist:

• All air removed from the source container

• Incomplete insertion of the spike into the source container

• Improper venting of a rigid (glass bottle) or semi-rigid (plastic)

container, including BURETROL sets

If using rigid non-vented containers, refer to the appropriate

administration set instructions to determine the correct venting

procedure.

• The air vent above the burette chamber is not open

To help prevent upstream occlusions that may not be detected by the pump:

• Do not use a source container that has had all air removed.

• When using a BURETROL set, do not invert BURETROL and squeeze

fluid into the primary container, which may wet out the vent filter and

obstruct airflow.

Do not allow fluid to enter the tubing channel or load wet tubing into the pump.

Contact your Baxter Service Center for assistance immediately if fluid enters the

tubing channel. The tubing channel should be cleaned as soon as possible by

Baxter-trained, qualified personnel to minimize potential difficulties caused by

fluid pooling and drying on the mechanism. Fluid in the tubing channel can also

cause false Air In Line alarms. See “Authorized Service Centers,” 10-2.

Cautions

There may be periods of no flow for flow rates less than or equal to 1mL/hr.

Do not enter a Volume to be infused greater than the amount of fluid available in

the container.

COLLEAGUE pumps do not support same-bag loading dose or bolus as it may

lead to an over-infusion, under-infusion, or interruption of therapy.

General Cautions:

In the U.S., use of device is restricted by Federal Law (USA) to sale or use by,

on the order of, or under the supervision of a physician or other licensed

healthcare professional.

Follow the cleaning schedule and methods defined under “Cleaning,” 7-1 to

ensure proper maintenance of the device.

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 1-9

Page 22

1 Notes

Notes

Note: Baxter requests that parties acquiring this device:

• Promptly report the receipt of this device to the manufacturer;

• Report the device’s purchases, receipt in trade, return after

sale, loss, destruction, or retirement.

• If this is an initial purchase from the manufacturer, you may

return a signed copy of the packing list to the manufacturer in

order to comply with these requirements. Call

1-800-THE-PUMP or Baxter’s local sales office for additional

information.

Indications for Use

The COLLEAGUE CXE and COLLEAGUE 3 CXE Volumetric

Infusion Pumps are capable of delivering medications, solutions,

parenteral nutrition, lipids, blood and blood components.

The COLLEAGUE CXE and COLLEAGUE 3 CXE pumps are capable

of infusing from semi-rigid containers, rigid containers, flexible IV

bags, and vented syringes.

The COLLEAGUE CXE and COLLEAGUE 3 CXE pumps are

designed to deliver infusion therapies via clinically acceptable routes of

administration, including intravenous, intra-arterial, epidural, and

subcutaneous routes.

The COLLEAGUE CXE and COLLEAGUE 3 CXE pumps are intended

for use in a wide variety of patient care environments for adult,

pediatric, and neonatal patients. The COLLEAGUE CXE and

COLLEAGUE 3 CXE pumps facilitate the delivery of routine and

critical infusion therapies via continuous and intermittent delivery using

primary and secondary infusion modes.

1-10 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 23

Introduction Indications for Use

The COLLEAGUE CXE and COLLEAGUE 3 CXE pumps can be used

in the following care areas:

General Floor of the

Hospital

Critical/Intensive Care

Neonatal Intensive Care

Pediatric Care

Labor/Delivery/Postpartum

Hospice Facility

Outpatient/Subacute

Facilities

Nursing Facilities

Long Term Care/

Rehabilitation

Facilities

Operating Room/Anesthesia

Post Anesthesia/Recovery

Cardiac Catheterization Lab

Emergency Room

Ground Ambulance

Note: The COLLEAGUE CXE and COLLEAGUE 3 CXE pumps have

not been evaluated for use in care areas other than those listed

above.

Diagnostic Nuclear

Medicine

Oncology Floor

Burn Unit/Trauma

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 1-11

Page 24

1 Indications for Use

1-12 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 25

Overview

Chapter 2

Chapter 2 Description

This chapter describes the controls, indicators, and displays on the

pump, and provides a brief functional description of the pump’s features

and infusion modes. The following information is provided in this

chapter:

“Description of Controls and Indicators” on page 2-2

“Display Reference Guide” on page 2-9

“Label Location” on page 2-16

“Pump Software Features” on page 2-18

“Infusion Modes” on page 2-19

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 2-1

Page 26

2 Description of Controls and Indicators

.

E

C

X

E

X

C

C

O

L

L

E

A

G

U

E

G

U

A

R

D

I

A

N

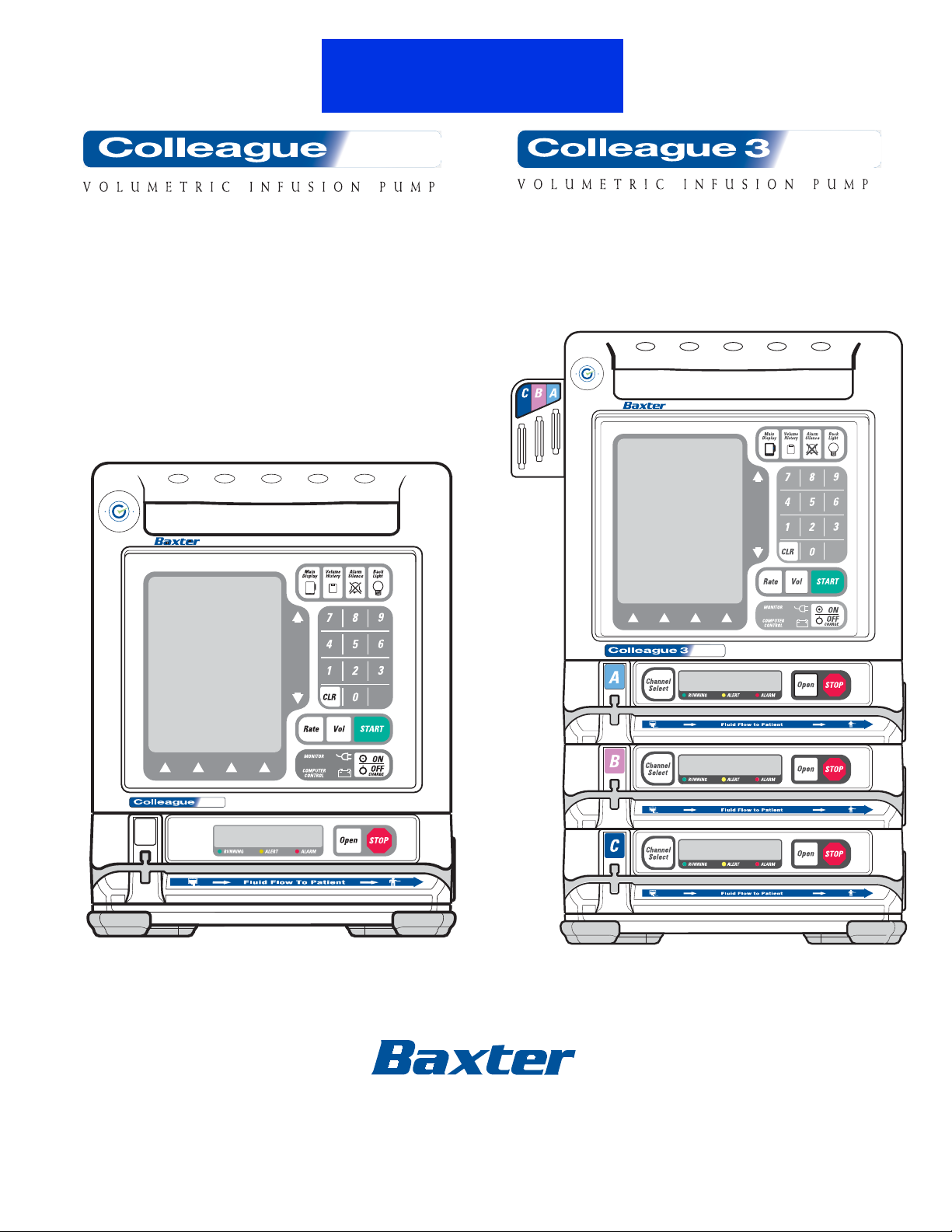

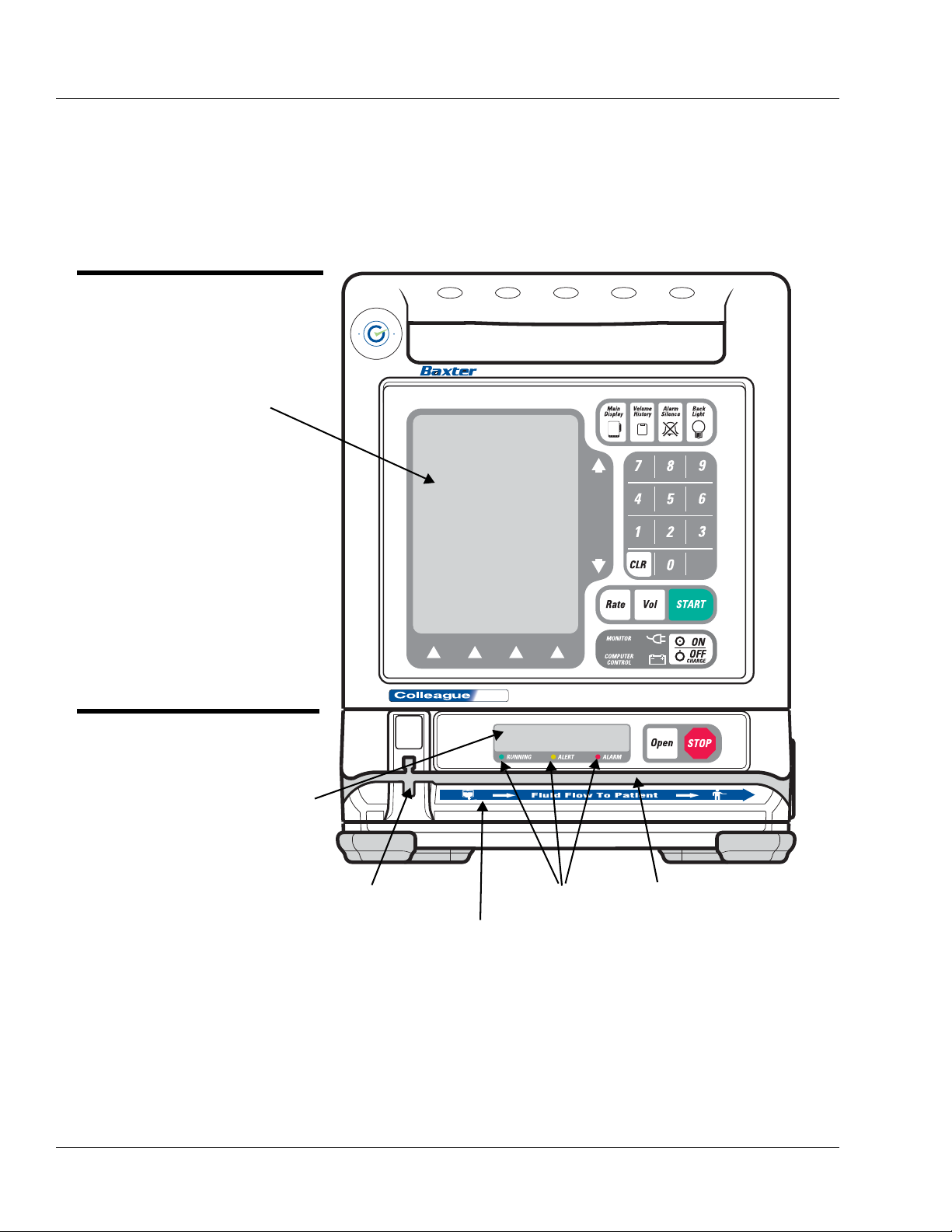

Figure 2-1 Front View, Single Channel Pump

MAIN BODY

See Table 2-1

PUMP MODULE

See Table 2-2

MAIN DISPLAY

PUMP MODULE DISPLAY

SLOT FOR KEYED SLIDE CLAMP STATUS LEDS TUBING CHANNEL

FLUID FLOW DIRECTION LABEL

Description of Controls and Indicators

Front Panel Features

Figure 2-1 is the front view of the single channel pump.

2-2 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 27

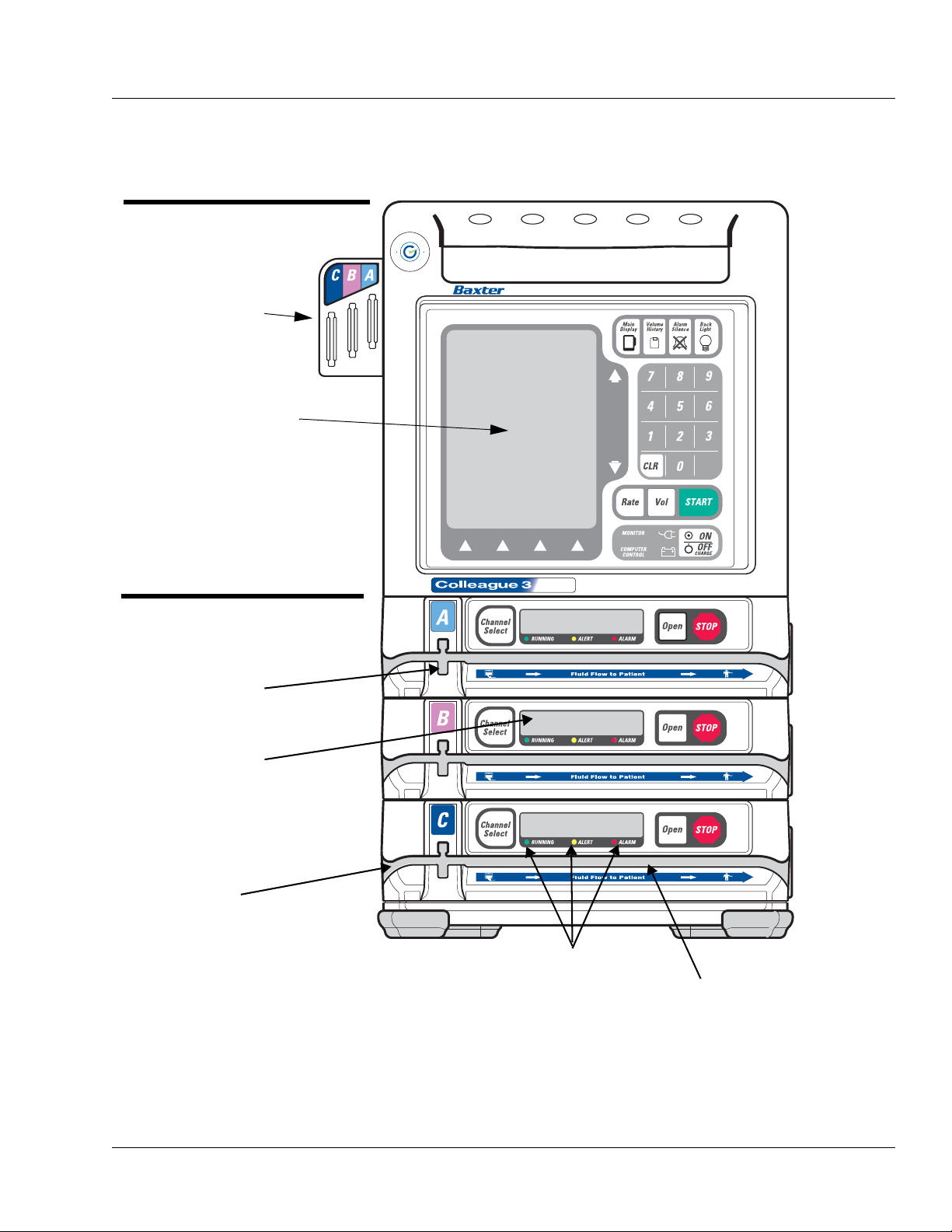

Figure 2-2 Front View, Triple Channel Pump

CHANNEL A

CHANNEL C

CHANNEL B

MAIN DISPLAY

MAIN BODY

See Table 2-1

PUMP MODULES

See Table 2-2

PUMP MODULE

DISPLAY

SLOT FOR KEYED

SLIDE CLAMP

STATUS LEDS

TUBING CHANNEL

TUBING CHANNEL

TUBING GUIDE

Description Description of Controls and Indicators

Figure 2-2 is the front view of the triple channel pump. Table 2-1

describes the controls and indicators on the main body of the pump.

A

E

G

L

U

L

E

O

C

G

N

U

A

A

I

R

D

.

E

X

C

C

X

E

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 2-3

Page 28

2 Description of Controls and Indicators

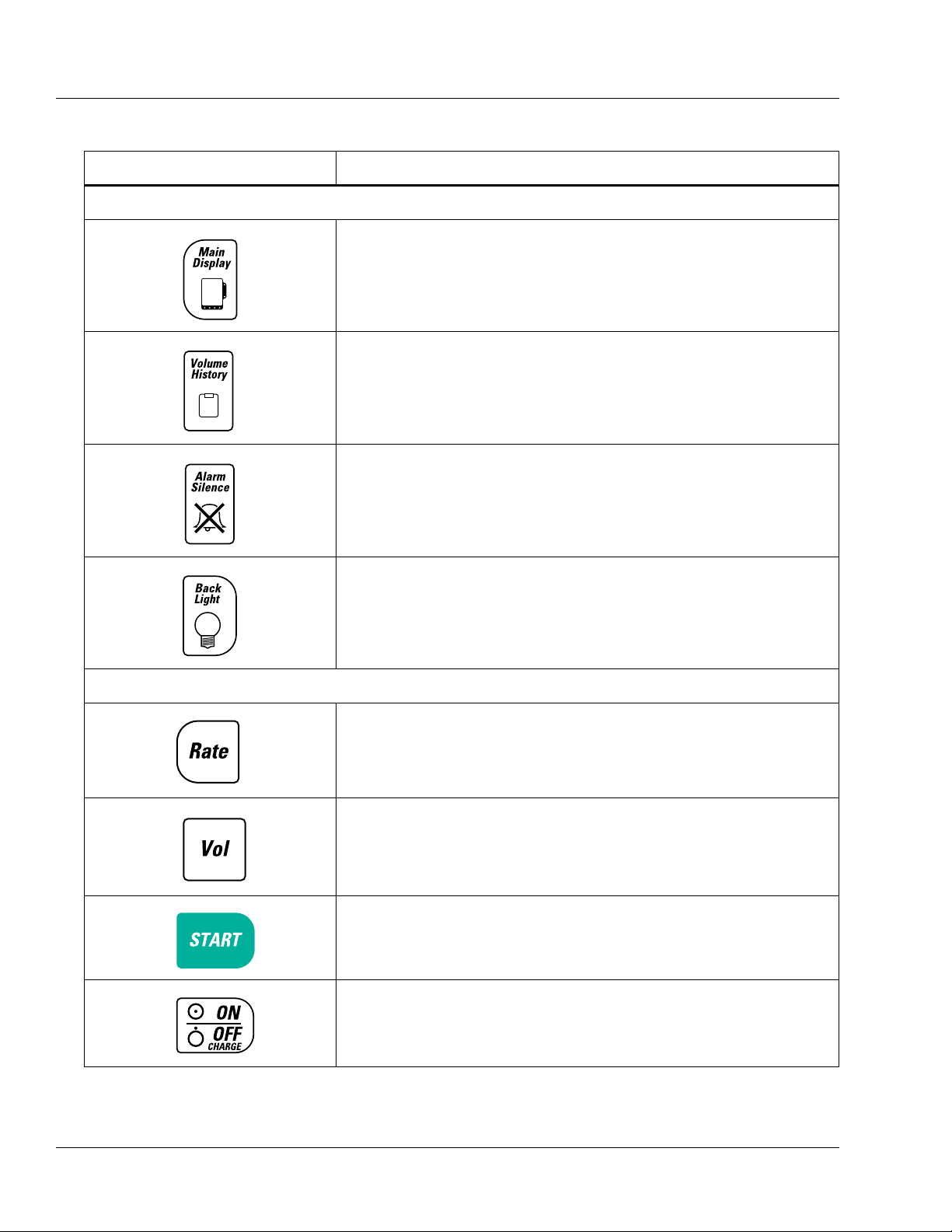

Table 2-1 Main Body Controls and Indicators

Item Description

Function Keys

This key accesses the Main Display screen from all other operating screens,

except screens with pop-up windows or passcode service functions.

This key accesses the Volume History screen, allowing the user to view a

history of volume delivered. For triple channel pumps, the volume history

screen presents information for all three channels.

This key silences alarms and alerts for two minutes.

This key turns the back lights for the main display and the pump module

display(s) on and off. During battery-powered operation, this key illuminates

the back lights for 60 seconds following the last key press.

Action Keys

This key selects the Rate field.

This key selects the Vol (Volume to be infused) field.

This key initiates the infusion from any programming screen if all the

required programming values have been entered.

This key powers the pump on or off. If the pump is on, pressing this key once

causes the pump to display the Power Off pop-up, which requests

confirmation that the user intends to turn the pump off.

2-4 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 29

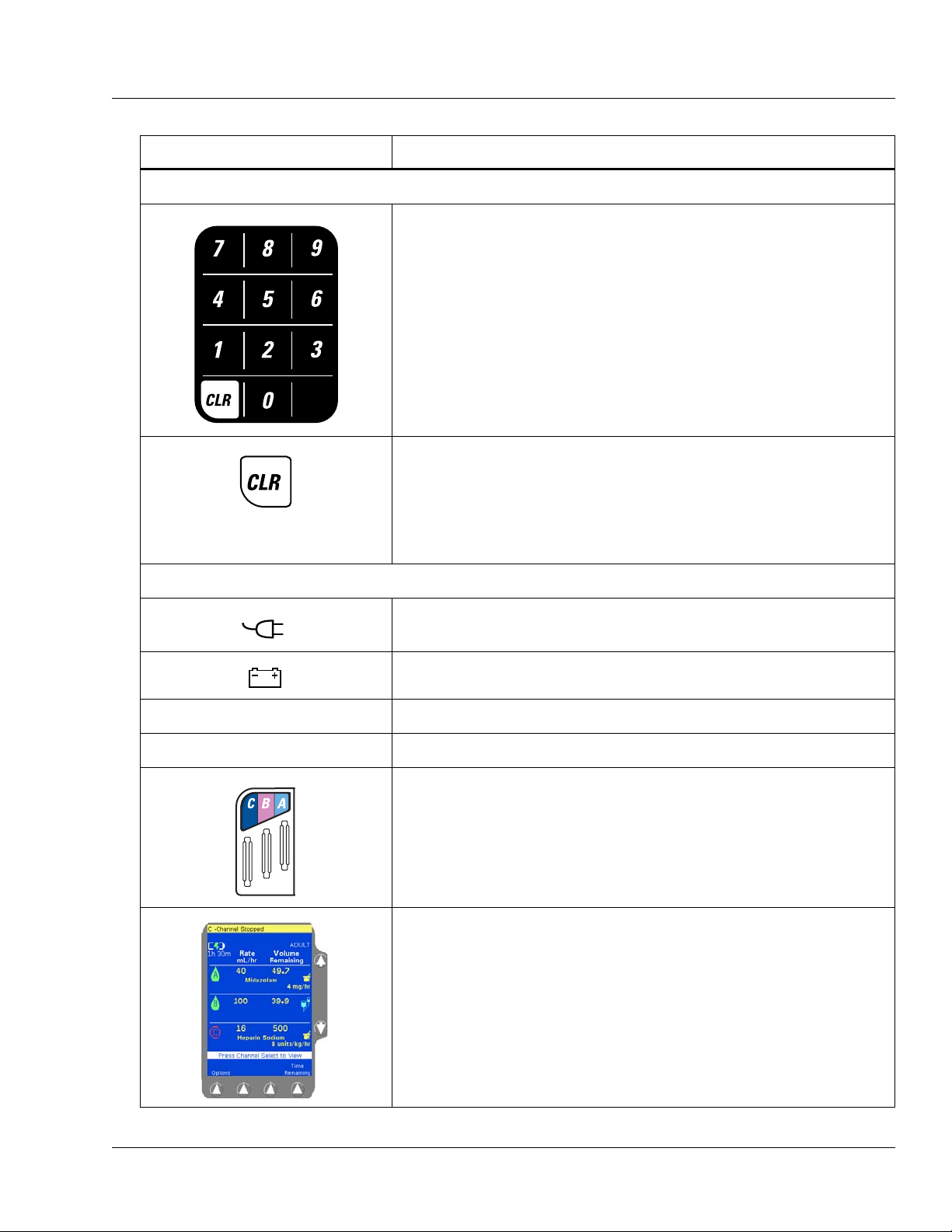

Description Description of Controls and Indicators

.

Table 2-1 Main Body Controls and Indicators — continued

Item Description

Numeric Keypad

The numeric keys and decimal point key are used to enter programming

values.

The CLR (Clear) key clears the values from the field highlighted on the

display. Pressing the key a second time restores the last value saved. If

multiple fields were cleared, the pump attempts to restore values whenever

possible.

The CLR key can also be used to clear a label if the label field is highlighted

and the infusion is stopped.

Icons

This green icon is lit whenever the pump is plugged into AC power.

Illumination of this icon also indicates the battery is being charged.

This yellow icon is lit only when the pump is operating on battery power.

MONITOR For Baxter diagnostic purposes only.

COMPUTER CONTROL FOR FUTURE USE.

Triple channel pumps only. The color-coded tubing guide on the left side of

triple channel pumps assists the clinician in identifying lines during a

multi-channel infusion. The tubing for each channel should be placed in the

corresponding tubing guide slot (A, B, C).

The pump’s Main Display is capable of displaying 10 different colors and

includes information for all three channels of a triple channel pump.

Note: For optimum viewability, view the display from a position

directly in front of the screen.

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 2-5

Page 30

2 Description of Controls and Indicators

Pump Module Features

The Pump Module(s) are located below the Main Body. Triple channel

pumps have three pump modules. See Figure 2-1 and Figure 2-2 for

illustrations of the pump modules. The pump module controls and

indicators are described in Table 2-2.

.

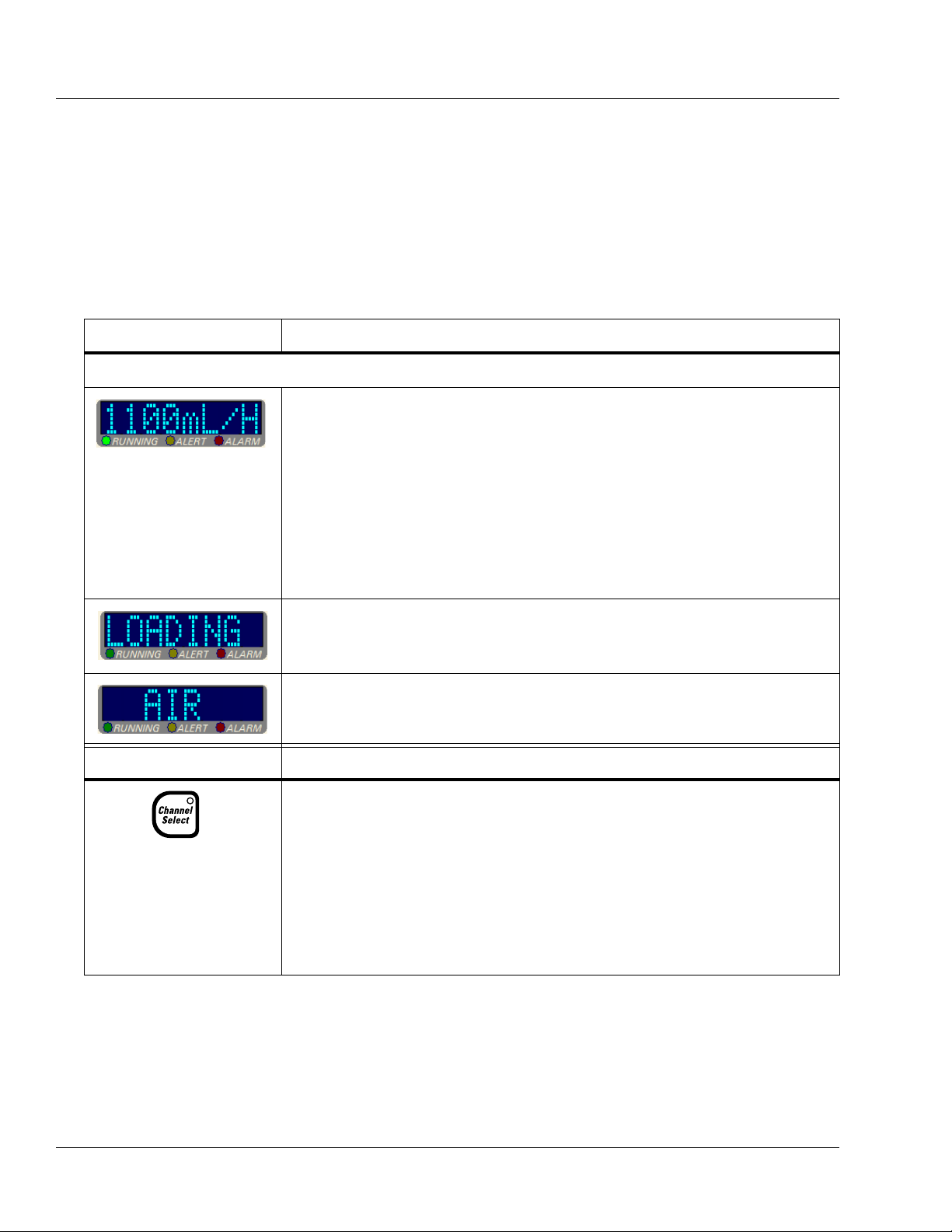

Table 2-2 Pump Module Controls and Indicators

Message Display

Key Description

Description

Pump Module Display

Note: If the pump is running on battery power, the pump module display is

blank to conserve battery power.

During infusions, the eight-character display on each channel shows one of the

following four message options:

•Rate

• Time Remaining

• Volume Infused

• Label

The message displayed depends upon the specific options selected by the care site.

Specific operations, such as tube loading, are also indicated on the pump module

display.

The pump module display also provides brief alarm and alert messages.

Triple channel pumps only.

• When pressed once, this key selects or deselects a particular pump channel for use.

The LED on the key lights and the selected channel’s programming screen appears

on the Main Display.

• Pressing this key when the channel is selected (LED is on), with no alerts or alarms

present and the channel stopped, opens the Standby pop-up for the selected channel,

allowing the user to place the channel in Standby.

• When the pump channel is in Standby, pressing this key takes the channel off

Standby and displays the channel’s programming screen.

2-6 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 31

Description Description of Controls and Indicators

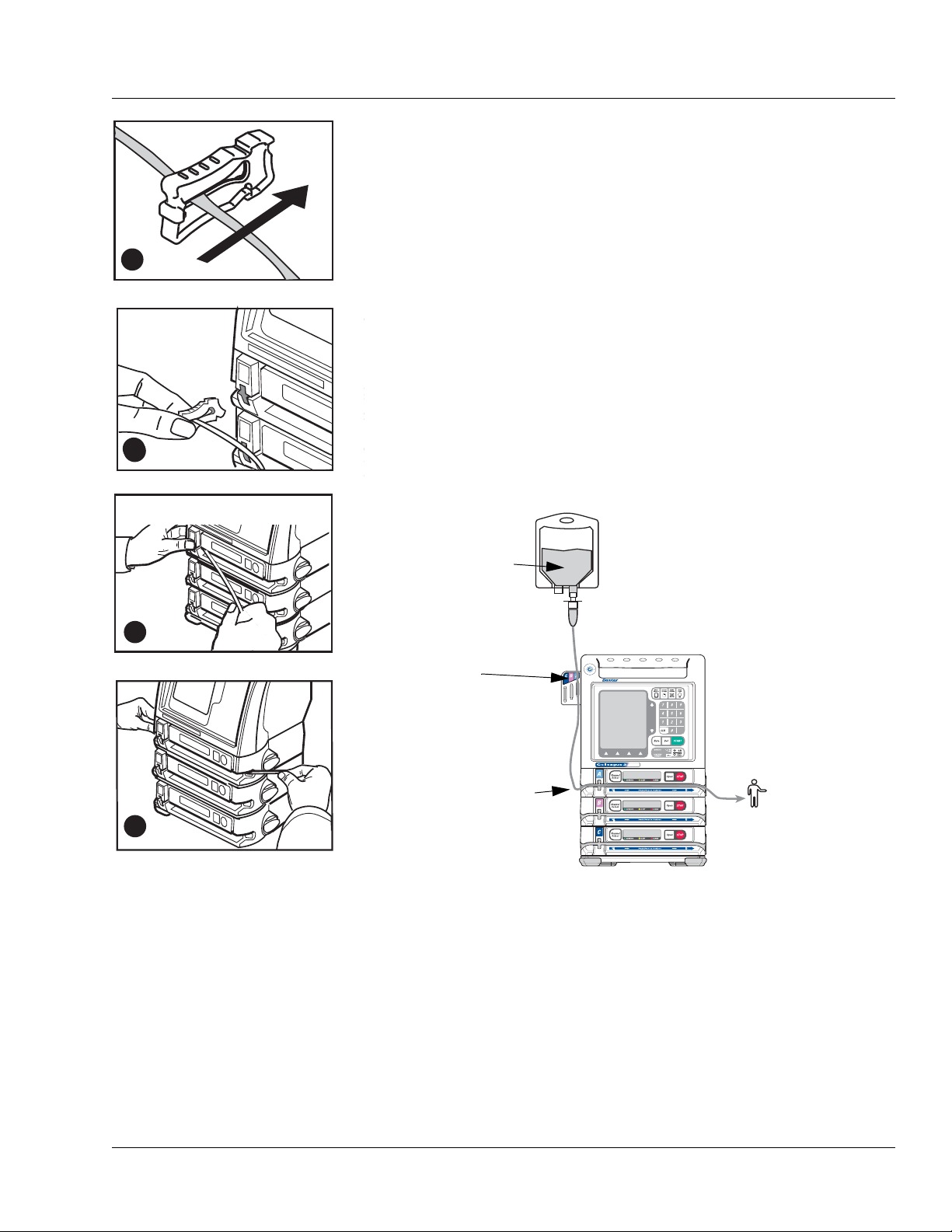

Fluid Flow to Patient

Table 2-2 Pump Module Controls and Indicators — continued

• When there is no administration set in the pump, pressing this key opens the loading

mechanism so that the administration set can be loaded.

• When there is an administration set in the pump, pressing this key opens the loading

mechanism so that the administration set can be removed.

When the pump channel is running, pressing the STOP key for that channel stops the

infusion.

Fluid Flow Symbol Description

This fluid container symbol located below the left side of the tubing channel indicates

the upstream side of the pump. When loading the administration set, always ensure

that the tubing from the container enters the left side of the pump.

This patient symbol below the right side of the tubing channel indicates the

downstream side of the pump. When loading the administration set, always ensure that

the tubing from the pump to the patient exits right side of the pump.

These arrows indicate the direction of fluid flow while the pump is running.

LEDs Description

RUNNING LED

This green LED remains on continuously during an infusion.

ALERT LED

This yellow LED remains on continuously during an alert condition, if there are no

active alarms.

ALARM LED

This red LED flashes on and off during an alarm condition and remains on

continuously during a failure condition.

CHANNEL SELECT LED

Triple channel pumps only. This LED is lit when the associated pump channel is

selected.

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 2-7

Page 32

2 Description of Controls and Indicators

MANUAL TUBE

RELEASE

(only one on single

channel pump)

MOUNTING

CLAMP KNOB

PANEL LOCKOUT

BUTTON

COMMUNICATION

PORT

MOUNTING CLAMP

RELEASE LATCH

MAIN DISPLAY

CONTRAST CONTROL

POWER CORD

NOTE: THE CORD

MAY DIFFER FROM

THAT SHOWN.

AUDIO SPEAKER

VOLUME CONTROL

FUSE HOLDERS

BACKUP BEEPER GRILL

AUDIO SPEAKER

GRILL

Rear Panel Features

See Figure 2-3 for the rear view of a triple channel pump. Table 2-3

describes the rear panel features.

Table 2-3 Rear Panel Features

Communication port An RS232 interface enables optional communication functions. For service use only.

Fuse holders The pump’s fuses are located inside.

Volume and Contrast

Controls

Figure 2-3 Rear View, Triple Channel Pump

Item Description

Thumbwheels for increasing and decreasing the audio volume and display contrast

settings.

2-8 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 33

Description Display Reference Guide

Table 2-3 Rear Panel Features — continued

Item Description

Audio speaker and beeper Generate alert and alarm tones.

Mounting clamp and knob Secures the pump to a pole.

Manual tube release Flip-out knob for manual tube unloading.

PANEL LOCKOUT button

The Panel Lockout button disables all the front panel keys except the Main

Display

Back Light

, Volume History, Channel Select (for triple channel pumps only), and

keys, and the Options, Primary, and Secondary soft keys for

viewing.

Color Reference Guide

Table 2-4 describes the meaning of the colors used on the device and

displays.

Table 2-4 Pump and Display Colors

Color Description

Yellow Yellow is used to call attention to a condition. Infusion program information is yellow. Yellow is

used in the display status line to indicate an alert condition. The ALERT LED on the pump head

module is yellow.

Red Red is used to indicate a serious condition or stop. Red is used in the display status line to indicate an

alarm or failure condition. The red stop sign icon indicates that an infusion is stopped. The ALARM

LED and the STOP key on the pump head module are red.

Green Green is used to indicate normal operation or start. The green drop icon indicates that an infusion is

running. The RUNNING LED on the pump head module and the START key on the pump are green.

White White is used for all basic information on the programming and main display screens, and as a

background color for the prompt line and some pop-ups. Also used for the Lock icon and the Flow

Check icon.

Dark blue Dark blue is used as the background color for all programming and main display screens.

Light blue Light blue is used for the secondary icon.

Black Black text is used on a yellow background to describe alert conditions.

Display Reference Guide

The Main Display provides two types of screens: the main display

screen and programming screens.

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 2-9

Page 34

2 Display Reference Guide

Main Display Screen

The main display screen provides information about the current or most

recent infusion. Information which may appear on main display screens

is described in the following table. Examples of main display screens are

shown in and described in Table 2-5.

Table 2-5 Main Display Screen Areas

Area Function

Battery charge icon/status A battery charge icon with the estimated battery time displayed in hours and minutes.

Status line This highlighted area at the top of the display shows alert, alarm, and failure messages.

For triple channel pumps, it also identifies the channel to which these conditions apply

(A, B, or C). Alert messages appear against a yellow background and alarm or failure

messages appear against a red background.

PERSONALITY feature

set

Operating state icons Animated green drop: indicates infusion is running

Infusion parameters The programmed values for the current or most recent infusion, including rate, time

Dose mode identifier If the current infusion was programmed using a dose mode, the mode is displayed below

Prompt Line The single line of highlighted type just below the body provides prompts for user action.

Pop-up Window This message box is used to provide additional information that may or may not require

Label (Optional) A label identifying the current infusion, if configured and selected, is displayed just

The name of the currently selected PERSONALITY feature set is displayed near the top

left corner of the display.

Red stop sign: indicates infusion is stopped.

Light blue IV container: indicates that the current infusion is a secondary.

Yellow mortar and pestle: indicates that the current infusion is using a label for which

COLLEAGUE GUARDIAN feature limits have been configured.

Stopwatch: indicates a Delay Start infusion has been programmed.

remaining, and volume remaining.

the program values line.

user response.

below the infusion parameters. If the label has been configured with limits using the

COLLEAGUE GUARDIAN feature, then the mortar and pestle icon is also displayed

on the screen.

×Ø (Up and Down)

Arrow Keys

Soft Keys The four keys located below the display screen are referred to as soft keys.

Soft Key Identifiers Only the key identifiers applicable to the current activity are displayed above the soft

2-10 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

These keys are used to select programming fields or to perform actions.

keys.

Page 35

Description Display Reference Guide

Infusion parameters

Label

Prompt line

PERSONALITY Feature Set

Operating State Icon

(Running)

Status line with

channel

identifier

Soft key identifiers

Soft keys

COLLEAGUE GUARDIAN

feature icon

(mortar and pestle)

Up and down arrow keys

Dose mode identifier

Triple Channel Pump

Single Channel Pump

Infusion parameters

Label

Prompt line

Battery Charge Icon

(blinking)

Operating State Icon

(Running)

Status line

(no message present)

Soft key identifiers

Soft keys

COLLEAGUE GUARDIAN

feature icon

(mortar and pestle)

Up and down arrow keys

Dose mode identifier

PERSONALITY Feature Set

Secondary infusion icon

Battery Charge Icon

(blinking)

Battery Charge Icon

(blinking)

Figure 2-4 Main Display Screen Information—Examples

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 2-11

Page 36

2 Display Reference Guide

Figure 2-5 Programming Screen Information — Examples

Pop-up window

Rate Field

Volume Field

Status Line

Soft key identifiers

Prompt line

Soft keys

Triple Channel Pump

Single Channel Pump

Rate Field

Volume Field

Status Line

Soft key identifiers

Prompt line

Soft keys

Pop-up window

Secondary Infusion Icon

Battery Charge Icon

(blinking)

Battery Charge Icon

(blinking)

Secondary Infusion Icon

Programming Screens

Programming screens have fields where infusion program values are

entered. The programming screens for each programming mode are

different because each mode requires that different information be

programmed. Programming screen examples are shown in Figure 2-5.

2-12 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 37

Description Display Reference Guide

Figure 2-6 Menu Example

Pop-up Windows

Pop-up windows are message boxes that appear on top of the usual

screen display. Pop-ups may require user response in order to clear them

from the display.

Menus

In some situations, a menu containing additional selections is provided

(Figure 2-6). To select a menu item, use the

desired selection, then press the

Select soft key.

×Ø keys to highlight the

Main Display Icons

Table 2-6 Main Display Icons

Icon Description

Table 2-6 describes the icons that appear on the Main Display.

This icon indicates that air has been detected by the air sensor.

This icon indicates that air has exited from the air sensor area and fluid is now

detected.

The battery charge icon is displayed at all times in the upper left part of the screen.

The number of filled areas in the battery charge icon is an approximate indication of

the battery charge level. When the battery time remaining is 80 to 100%, the icon

contains three green bars as shown at left.

As the battery charge level decreases, the battery charge icon changes. When the

battery time remaining is 60 to 80%, the icon contains two green bars as shown at left.

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 2-13

Page 38

2 Display Reference Guide

Table 2-6 Main Display Icons — continued

Icon Description

As the battery charge level continues to decrease, the battery charge icon continues to

change. When the battery time remaining is 20 to 60%, the icon contains two yellow

bars as shown at left.

When the battery time remaining is less than 20%, the battery charge icon contains

one red bar as shown at left.

When the battery time remaining is only 5 minutes, the battery charge icon appears as

an empty outline as shown at left. The icon will remain an empty outline until the

battery is depleted and pump shuts itself off.

If the pump’s batteries need replacement when the pump is first powered on, a

Damaged Battery! Service Now alarm occurs and this icon flashes on the

Power On screen. The pump cannot be used. Send the pump to service.

If the pump’s batteries need replacement during pump operation, a

Damaged Battery! Service Now alert occurs and this icon flashes instead of

the battery charge icon. Ensure the pump is plugged into AC power. Do not use the

pump for transport. Have the pump serviced as soon as possible so the batteries can be

replaced.

When the pump is plugged in, the battery charge icon alternates with the charging icon

shown at left.

When the pump is unplugged and operating on battery power, the battery charge icon

alternates with the Plug In icon shown at left, and the approximate battery operating

time is displayed below the icon. The pump should be plugged in whenever possible

to maintain battery charge.

A drop icon is displayed for each channel that is running, and beside the FLUID and

AIR icons when the pump is used to purge air from the tubing following an Air In

Line alarm.

The flow check icon indicates approximate level of downstream occlusion. The

greater the resistance to fluid flow, the greater the number of solid arrows displayed.

This icon indicates the screen is displaying secondary infusion information for a

channel.

This icon is displayed on the Programming screen when a pump channel is stopped.

This icon is displayed on the Main Display screen when a pump channel is stopped.

The appropriate channel letter is displayed inside of the stop symbol (A, B, or C).

When the keypad is locked, the Lock icon is displayed between the second and third

soft keys. The following keys remain available when the keypad is locked so that

infusion status information can be viewed: Main Display, Back Light, Volume

History, Primary, Secondary and Options.

2-14 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 39

Description Display Reference Guide

MORE

ARROW

Table 2-6 Main Display Icons — continued

Icon Description

This icon indicates a Delay Start infusion. It is displayed on the primary programming

screen when programming a delay start infusion for a channel, and on the main

display when a programmed delay start infusion is pending for a channel.

Mortar and pestle icon indicates that the programmed infusion is using a label for

which the COLLEAGUE GUARDIAN feature has been configured. Icon appears on

the programming screen when a COLLEAGUE GUARDIAN feature label has been

selected, and on the main display to the right of each channel running an infusion

utilizing a COLLEAGUE GUARDIAN label.

Yellow Triangle next to a label in the COLLEAGUE GUARDIAN label list indicates

that the label allows non-standard concentrations to be programmed by the clinician.

White triangle next to a field on the programming screen for a COLLEAGUE

GUARDIAN infusion indicates that the clinician has changed the default value.

Triangle next to the label while the infusion is running indicates that the clinician has

programmed the infusion using a non-standard concentration.

When a list contains more information than can be displayed on a single screen, an

arrow is displayed in the lower right and/or the upper right corner. Use the Page Up

and Page Down soft keys to page through the list.

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 2-15

Page 40

2 Label Location

ATT ENTI ON

MANUAL TUBE RELEASE

MOUNTING CLAMP

SIGNATURE/RATINGS

PATENTS (ON UNDERSIDE)

MAINTAIN BATTERY CHARGE (OPTIONAL)

SERIAL NUMBER

BAR CODE

COLLEAGUE

GUARDIAN

FEATURE

CE MARK

WORDMARK

COLLEAGUE CXE

FLUID FLOW

VOLUME CONTROL

FUSES EXTERNAL

(English pumps only)

ACCESSORIES

POWER CORD

WARNING

CONTRAST CONTROL

UL/cUL/WEEE

SI G NATUR E/R AT INGS

(English, for non-English

pumps only)

SIGNATURE/RATINGS

(local language, for nonEnglish pumps only)

TEMPERATURE LIMITS

Label Location

The pump’s labels provide additional information about the pump.

Figure 2-7 shows the location of the pump’s labels for single channel

pumps. Figure 2-8 shows the location of the pump’s labels for triple

channel pumps. If any labels are missing or damaged, contact your local

Baxter Service Center for replacement information.

2-16 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Figure 2-7 Location of Pump Labeling, Single Channel Pump

Page 41

COLLEAGUE 3 CXE

CHANNEL

SELECT “A”

LABEL

TUBING GUIDE

LABEL

CHANNEL

SELECT “B”

LABEL

CHANNEL

SELECT “C”

LABEL

WORDMARK

FLUID FLOW

VOLUME CONTROL

FUSES EXTERNAL

ACCESSORIES

PATENTS (ON UNDERSIDE)

CONTRAST CONTROL

MANUAL TUBE RELEASE

ATT E NTIO N

SERIAL NUMBER

BAR CODE

CE MARK

SI G NATUR E/R AT INGS

(English pumps only)

MAINTAIN BATTERY CHARGE (OPTIONAL)

COLLEAGUE

GUARDIAN

FEATURE

POWER CORD

WARNING

UL/cUL/WEEE

SIGNATURE/RATINGS

(English, for nonEnglish pumps only)

SI G NATUR E/R AT INGS

(local language, for

non-English pumps

only)

TEMPERATURE LIMITS

Description Label Location

Figure 2-8 Location of Pump Labeling, Triple Channel Pump

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 2-17

Page 42

2 Pump Software Features

Pump Software Features

In addition to basic infusion delivery capabilities, the pump has the

following features that help to enhance versatility and to help ensure

accurate infusion programming.

PERSONALITY Feature Sets

The pump provides the capability for a facility to create up to eight

different custom PERSONALITY feature sets, programmed with

infusion settings specific to a particular care area or therapy.

If PERSONALITY feature sets have been configured by the facility, the

clinician can select a different PERSONALITY feature set when the

pump is powered on. The PERSONALITY feature set can only be

changed at power on. For instructions on selecting a PERSONALITY

feature set, see “Selecting a Pump PERSONALITY Feature Set,” 4-5.

The Permanent Settings PERSONALITY feature set is the factory

default and its parameters cannot be changed, but it can be copied and

modified to create custom PERSONALITY feature sets tailored to the

needs of the facility. See “Configurable Options,” 6-1, for the default

settings.

PERSONALITY feature sets should be created only by

facility-authorized personnel, and the settings should be based upon

clinical protocols. An access code is required to program

PERSONALITY feature sets. See the COLLEAGUE Pump

Configuration Manual or the COLLEAGUE GUARDIAN

Configuration Tool documentation for more information.

2-18 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 071960491

Page 43

Description Infusion Modes

Figure 2-9 Programming Screen

with Label

Figure 2-10 Main Display with

Label

Label Library

This configurable feature allows the user to select informational labels

for display on the Programming screen (Figure 2-9) and Main Display

screen (Figure 2-10), and an eight-character abbreviation of the label on

the Pump Module display. For information on selecting a label during

programming, see “Selecting a Label,” 4-23.

Labels are chosen from a list of predefined or custom labels. When the

Label Library feature is enabled, the user can select from the list of

available labels. For a list of predefined labels, see “Predefined Labels”

on page 6-7.

When the label library is viewed, the application labels are listed first,

followed by the medication/solution labels. For a list of application

labels, see “Application Labels,” 6-9.

Infusion Modes

071960491 COLLEAGUE CXE VOLUMETRIC INFUSION PUMP OPERATOR’S MANUAL 2-19

The infusion modes and programming functions available on the pump

depend on the facility-authorized configuration.

Page 44

2 Infusion Modes

Rate-Volume Infusions