Baxi Solo WM 30/4 PF, Solo WM 50/4 PF, Solo WM 70/4 PF, Solo WM 40/4 PF User Manual

BS 5258BS 6332

Safety & Performance

Baxi heating is one of the leading manufacturers of

.tdomestic heating products in the U.K

Our first priority is to give a high quality service to

our customers. Quality is built into every Baxi

, product - products which fulfil the demands

and needs of modern consumers, offering

choice, efficiency and reliability.

To keep ahead of changing trends, we have

made a commitment to develop new ideas using

the latest technology - with the aim to continue

making the products that customers want to buy.

Baxi is also the largest manufacturing partnership

•

in the country. Everyone who works at the

company has a commitment to quality because, as

•

shareholders, we know that satisfied customers

- mean continued success.

We hope you get a satisfactory service from

Baxi. If not, please let us know.

BS 5750 Company

1:91.(e-

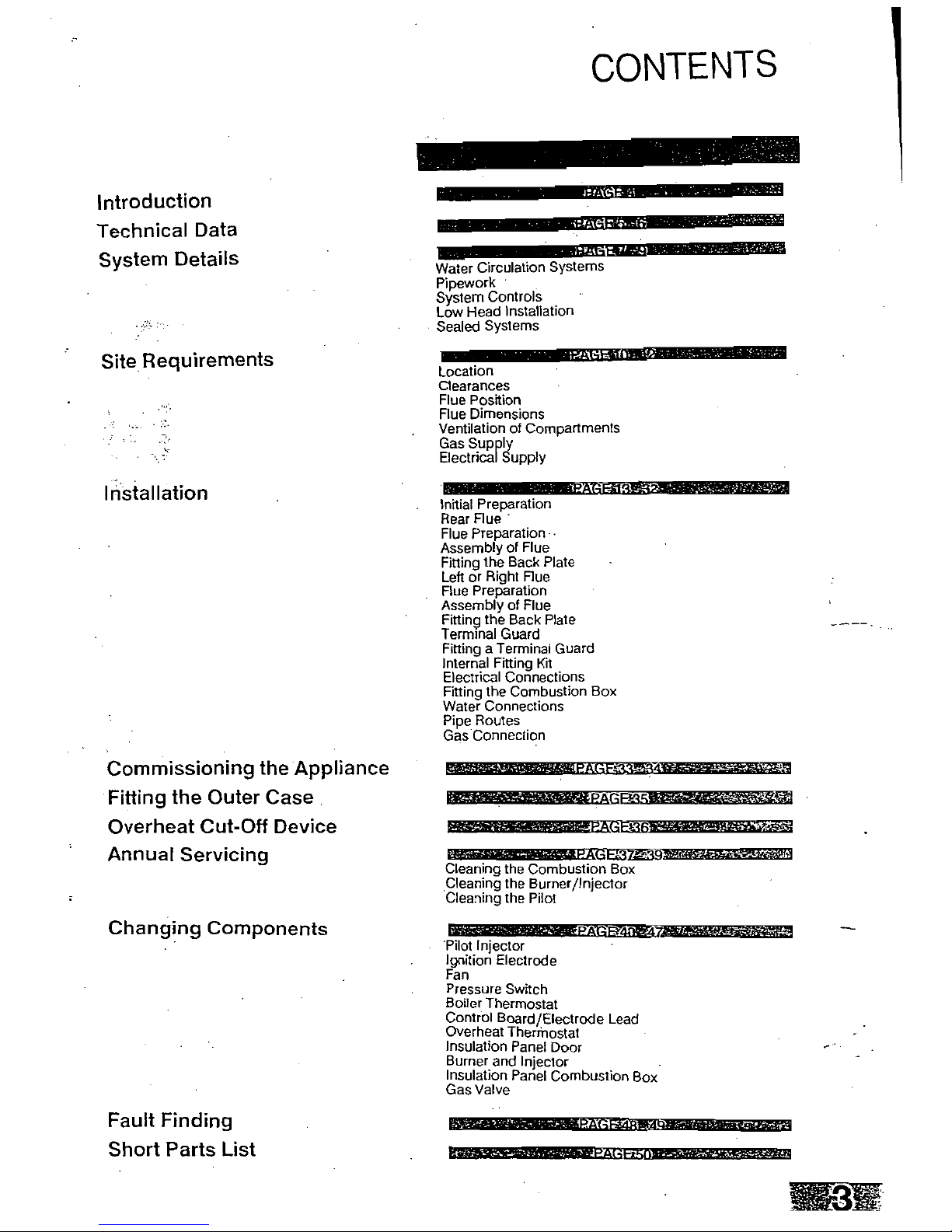

CONTENTS

Introduction

Technical Data

System Details

Site Requirements

Installation

Water Circulation Systems

Pipework

System Controls

Low Head Installation

Sealed Systems

Location

Clearances

Flue Position

Rue Dimensions

Ventilation

of

Compartments

Gas Supply

Electrical Supply

Initial PreparationPreparation

Rear Flue

Flue Preparation

Assembly

of

Flue

Fitting the Back Plate

Left or Right Flue

Flue Preparation

Assembly

of

Flue

Fitting the Back Plate

Terminal Guard

Fining a Terminal Guard

Internal Fitting Kit

Electrical Connections

Fining the Combustion Box

Water Connections

Pipe Routes

Gas Connection

Commissioning the Appliance

Fitting the Outer Case

Overheat Cut-Off Device

Annual Servicing

Changing Components

^<1-t..

4

1;14

g ,-trreiirgsivircitalemtro

Cleaning the Combustion Box

Cleaning the Burner/Injector

Cleaning the Pilot

AIEBEEIZZIEZZE

Pilot Injector

Ignition Electrode

Fan

Pressure Switch

Boiler Thermostat

Control Board/Electrode Lead

Overheat Thermostat

Insulation Panel Door

Burner and Injector

Insulation Panel Combustion Box

Gas Valve

Fault Finding

Short Parts List

7

,1

4

‘

z

le

4--I.W.7:41-

4

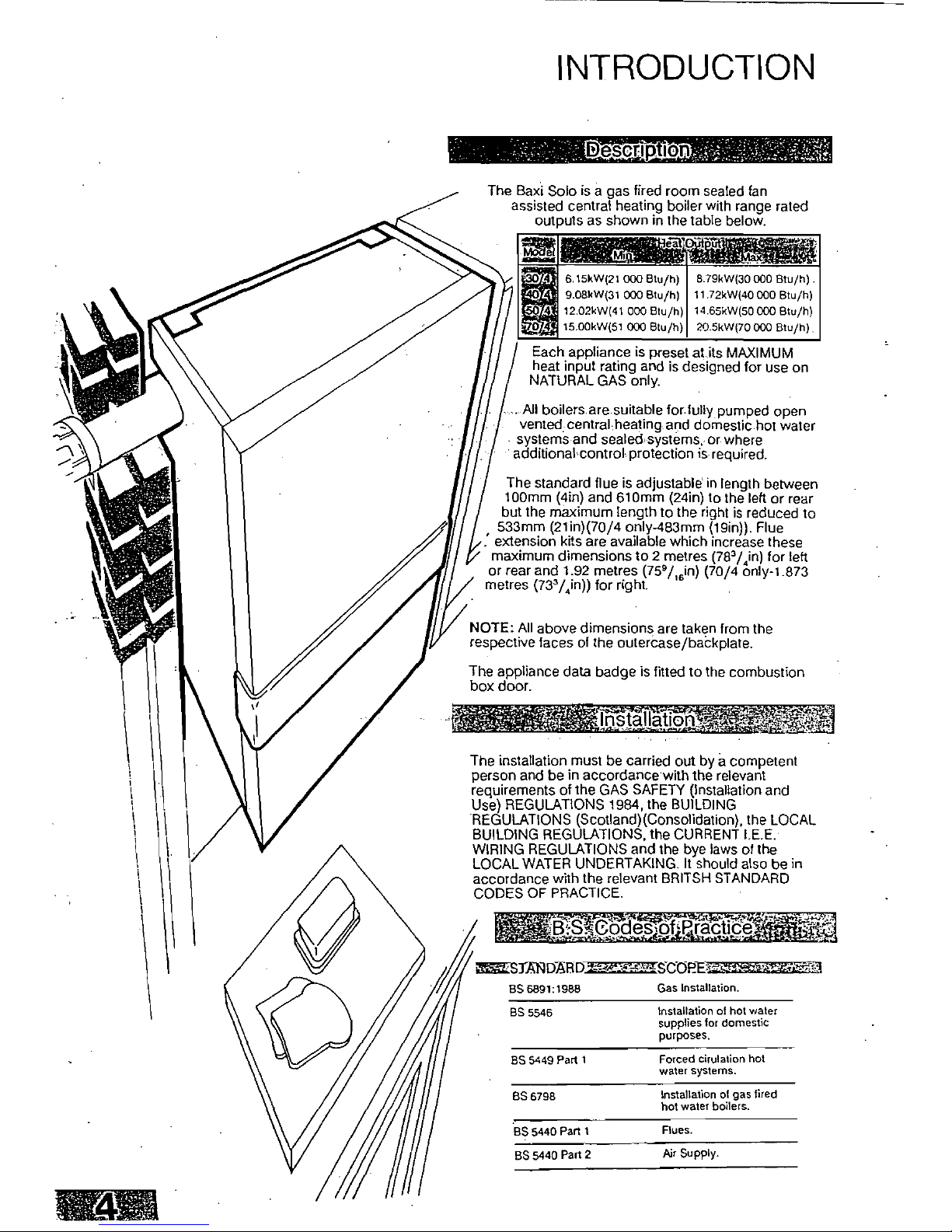

INTRODUCTION

The Baxi Solo is a gas fired room sealed fan

assisted central heating boiler with range rated

outputs as shown in the table below.

L

.:.:7.,

.i:1,3saTtlir

^g"?.M

-;-..-1•.•,,a

• -

..

i,

,

..

VA

r.,..?,15::41]lfrrii.;.;.,:).,t1.,

6.15kW(21 000 Btu/h)

8 79kW(30 000 Btu/h)

-:

II

0

9.08kW(31 000 Btu/h)

11.72kW(40 000 Btu/h)

..ca-

.

12.02kW(41 000 Btu/h)

14.65kW(50 000 Btu/h)

15.00kW(51 000 Btu/h)

20.5kW(70 000 Btu/h)

Each appliance is prese at its MAXIMUM

hea input rating and is designed for use on

NATURAL GAS only.

...AB boilers are suitable for fully pumped open

vented central heating and domestic hot water

•

systems and sealed, systems, or where

additional control protection

is

required.

The standard flue is adjustable in length between

100mm (4in) and 610mm (24in) to the left or rear

but the maximum length to the right is reduced to

533mm (21in)(70/4 only-483mm (19in)). Flue

extension kits are available which increase these

maximum dimensions to 2 metres (78

3/4

in) for left

or rear and 1.92 metres (759/16in) (70/4 only-1.873

metres (733/4in)) for right.

NOTE: All above dimensions are taken from the

respective faces of the outercase/backplate.

The appliance data badge is fitted to the combustion

box door.

:Inpitallation;

.4 • A,

The installation must be carried out by a competent

person and be in accordance with the relevant

requirements of the GAS SAFETY (Installation and

Use) REGULATIONS 1984, the BUILDING

REGULATIONS (Scotland)(Consolidation), the LOCAL

BUILDING REGULATIONS, the CURRENT I.E.E.

WIRING REGULATIONS and the bye laws of the

LOCAL WATER UNDERTAKING. It should also be in

accordance with the relevant BRITSH STANDARD

CODES OF PRACTICE.

13;Sfiebeles,of,Praadtid:e

STANDARDaSCOPai

85 6891:1988

Gas Installation.

BS 5546

Installation of hot water

supplies for domestic

purposes.

88 5449 Part 1

Forced cirulation hot

water systems.

BS 6798

Installation of gas fired

hot water boilers.

BS 5440 Part 1

Rues.

855440 Part 2

Air Supply.

Internal Fuse

F2A 250V to BS 4256

situated on control board

(spare fuse also located

on control board)

Connections

2 x 22mm

compression adaptors

Gas Rate

(after 10 mins)

Outerease

Dimensions

1.08m3/h

(38.05113/h)

Height600mm

Width

400mm

Depth

300mm

Flue Terminal

Dimensions

Diameter 100mm

Depth

65mm

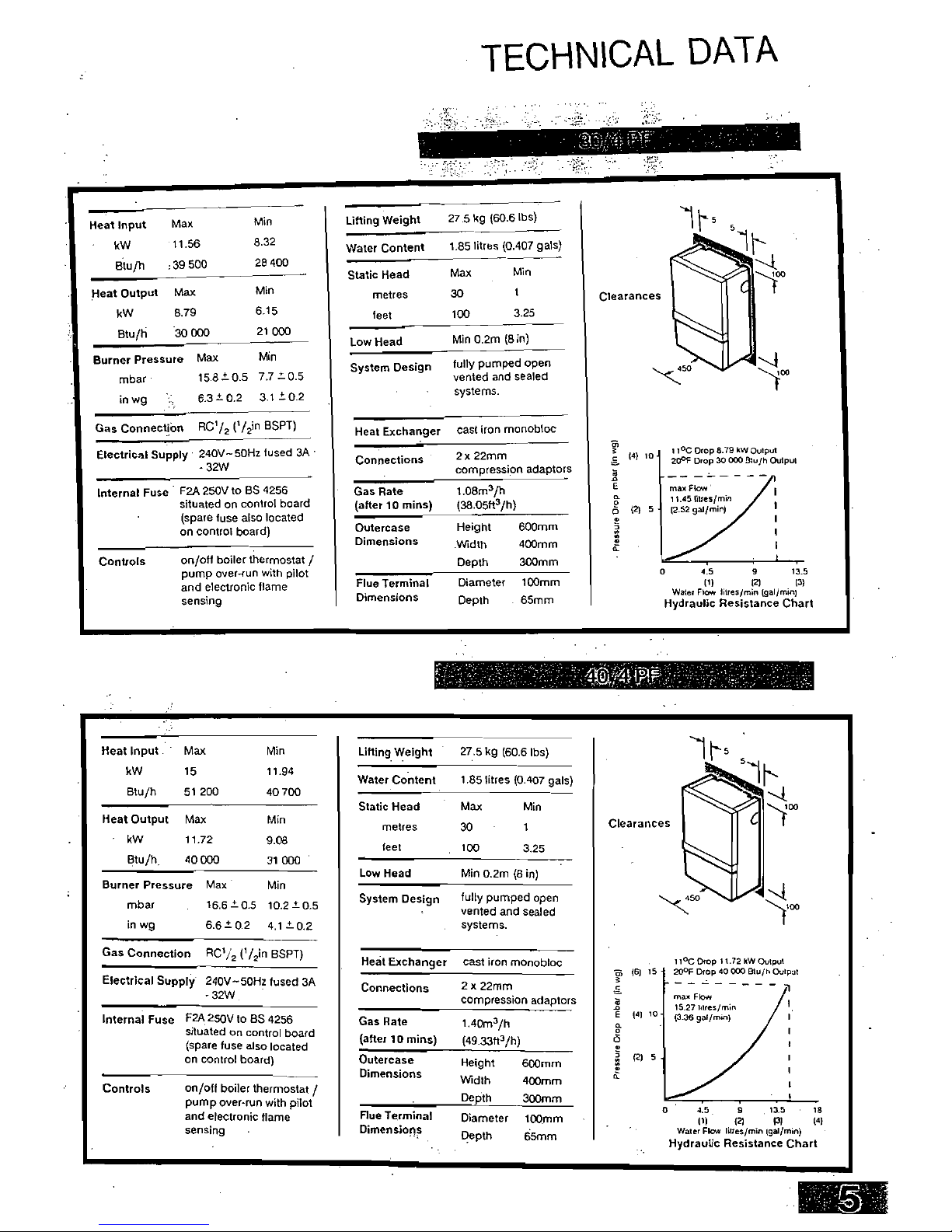

Heat Input

Max

Min

Lifting Weight

•

kW

11.56

8.32

Water Content

Btu/h

39500

28 400

Static Head

Heat Output

Max

Min

metres

kW

8.79

6.15

feet

Btuth

SO 000

21 000

Low Head

Burner Pressure

Max

Min

System Design

mbar

15.8±0.5

7.7 ±0.5

in wg

6.3

=

0.2

3.1 =0.2

Gas Connection

RC72

('/in BSPT)

Electrical Supply 240V-50H2 fused 3A

- 32W

Controls

on/off boiler thermostat /

pump over-run with pilot

and electronic flame

sensing

Heat Exchanger cast iron monobloc

I 1

0

C Drop 8.79 kW Output

c

rn-

(4)

ID

20°F Drop 30 000 131u/h Output

max Flow

11.45 litres/mm

2

(2) 5

12.52 gal/min)

C.

o

4.5

9

13.5

(1)

RI

131

Water Flow litres/mm

n (gal/min)

Hydraulic Resistance Chart

27.5 kg (60.6 lbs)

1.85 litres (0.407 gals)

Max

Min

30

1

100

3.25

Min 0.2m (8 in)

fully pumped open

vented and sealed

systems.

Max

15

51 200

Min

11.94

40 700

Heat Input

kW

Btu/h

Max

11.72

40 000

Min

9.08

31 000

Heat Output

kW

Btu/h

Min

10.2 =0.5

4.10.2

Burner Pressure Max

mbar

.

16.6 ± 0.6

in wg

6.6 0.2

Internal Fuse

F2A 250V to BS

4256

situated

on control board

(spare fuse also located

on control board)

Gas Connection

RC'/2 (I/

2

in BSPT)

Electrical Supply 240V-50Hz fused 3A

- 32W

Controls on/off boiler thermostat /

pump over-run with pilot

and electronic flame

sensing

•

Connections

Gas Rate

(after

10

mins)

Flue Terminal

Dimensions

2 x 22mm

compression

1.40m3/h

(49.33t13/h)

Height

Width

Depth

Diameter

Depth

adaptors

-1

max Flow

a

(4)

10

15.27 Mres/rnin

(3.36 gal/min)

2

0

600mm

(2)

5

400mm

300mm

o4.59

13.5

•

18

.

.

100mm

(1)

(2)

PI

(4)

65mm

Water Flow litres/min tgailmin)

Hydraulic Resistance Chart

-

Outerease

Dimensions

Lifting Weight

27.5 kg (60.6 lbs)

Water Content1.85 litres (0.407 gals)

Static Head

Max

Min

metres

30

1

Clearances

feet

100

3.25

System Design

fully pumped open

vented and sealed

systems.

X50

Heat Exchanger cast iron monobloc

11

0

0 Drop 11.72 kW Output

ggoc Drop 40 000 BW/h Output

rth (6) 15

Low Head

MM 0.2m (8 in)

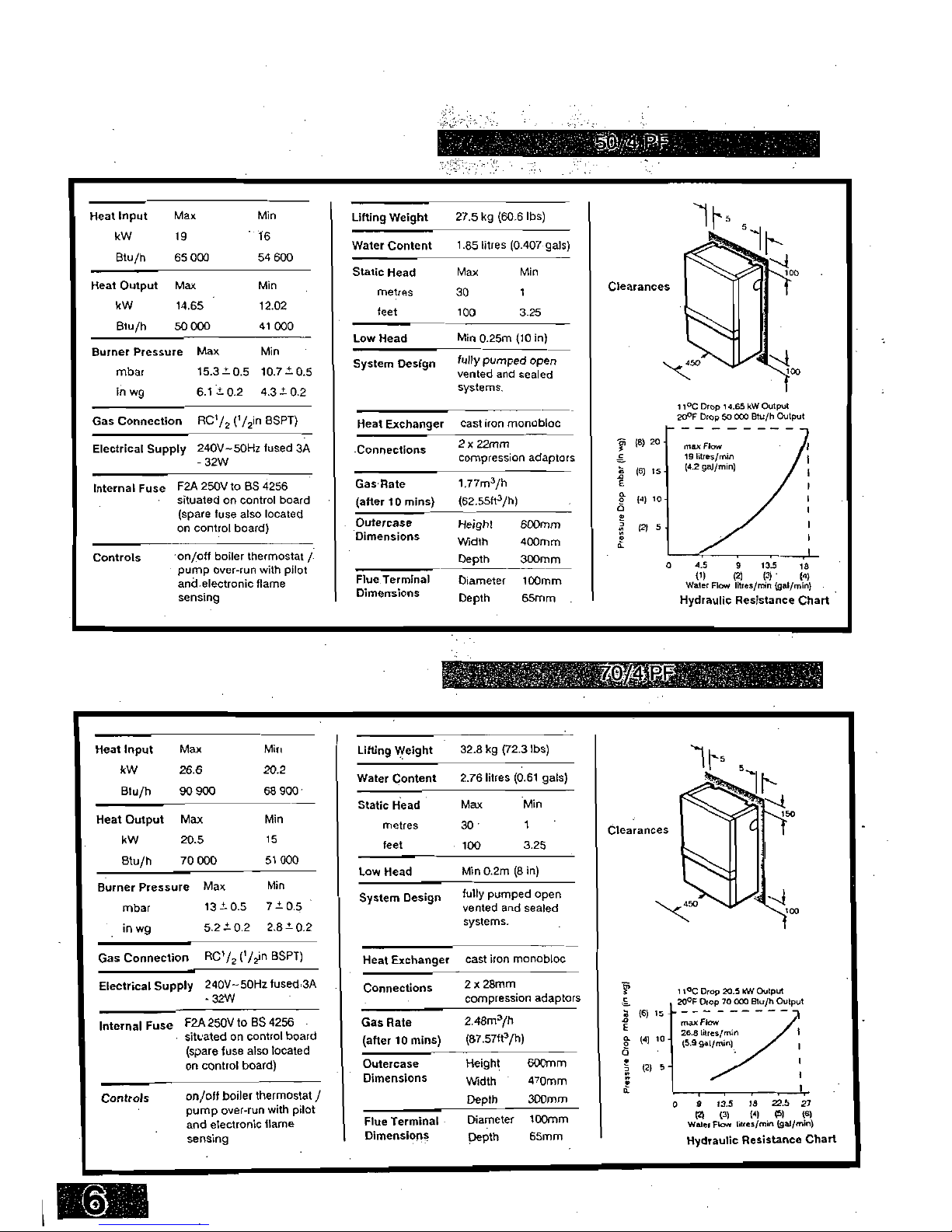

TECHNICAL DATA

P9):V4

(4)

10

(2) 5

Lifting Weight

27.5 kg (60.6 lbs)

Water Content

1.85 litres (0.407 gals)

Static Head

metres

MM 0.25m (10 in)

fully pumped open

vented and sealed

systems.

Heat Exchanger cast iron monobloc

2

x

22mm

compression adaptors

1.77m3/h

(62.5583/h)

Height600mm

Width

400mm

Depth300mm

Flue Terminal

Diameter 100mm

Dimensions

Depth

65mm

Clearances

11

0

0 Drop 14.65 kW Output

20°F Drop 50 CO0 Btuth Output

max

Flow

19 litres/min

(4.2 gal/min)

04.5

913.518

(1)

(2)(3)(4)

Water Flow litres/min (gal/mln)

Hydraulic Resistance Chart

Max

30

Min

1

Low Head

System Design

Connections

Gas Rate

(after

10

mins)

Outercase

Dimensions

feet

100

3.25

Max

26.6

90 900

Min

20.2

68 900:

Heat Input

kW

Btu/h

Lifting Weight

32.8 kg (72.3 lbs)

MM 0.2m (8 in)

Low Head

Diameter

Depth

Flue Terminal

Dimensions

Internal Fuse

F2A 250V to BS 4256

situated on control board

(spare fuse also located

on control board)

Controls

on/off boiler thermostat /

pump over-run with pilot

and electronic flame

sensing

Height

Width

Depth

600mm

470mm

300mm

100mm

65mm

Static Head

Max

Min

Max

Min

Heat Output

kW

Blu/h

metres

30

1

Clearances

20.5

15

feet

100

3.25

70 000

51 000

Burner Pressure

mbar

in wg

Max

13 = 0.5

5.2 = 0.2

Min

7-±a5 •

2.8 = 0.2

System Design

fully pumped open

vented and sealed

systems.

Gas Connection RC

1

/

2

('/

2

in BSPT)

Electrical Supply 240V-50Hz fused 3A

- 32W

2 x 28mm

compression adaptors

2.48m3/h

(87.5783/h)

11°C Drop 20.5 kW Output

20°F Drop 70 000 Btu/h Output

r,

(6) l5

a

(4) 10-

0

(2) 5 -

max Flow

26.8 litres/min

(5.9 gal/min),

1

0

9 13.5

18

22.5 27

(2)(3)

99(5)

(8)

Water Flow litres/min (gal/min)

Hydraulic Resistance Chart

Water Content

2.76 litres (0.61 gals)

Heat Exchanger cast iron monobloc

Connections

Gas Rate

(after 10 mins)

Outercase

Dimensions

Heat Input

Max

Min

kW

19

Btu/h

65 000

54 600

Heat Output Max

Min

kW

14E5

12.02

Btu/h50 000

41 000

Burner Pressure Max

Min

mbar

15.3 = 0.5 107

in wg

6.1 = 0.2 4.3 = 0.2

Gas Connection RC'/2 (

I

/2in BSPT)

Electrical Supply 240V-50Hz fused 3A

- 32W

Internal Fuse F2A 250V to BS 4256

situated on control board

(spare fuse also located

on control board)

Controls on/off boiler thermostat /

pump over-run with pilot

and electronic flame

sensing

k

fk

te

i

t

i

r

treS6Y9N

t

System Drains at

All Low Points

15mm By-pass

if required

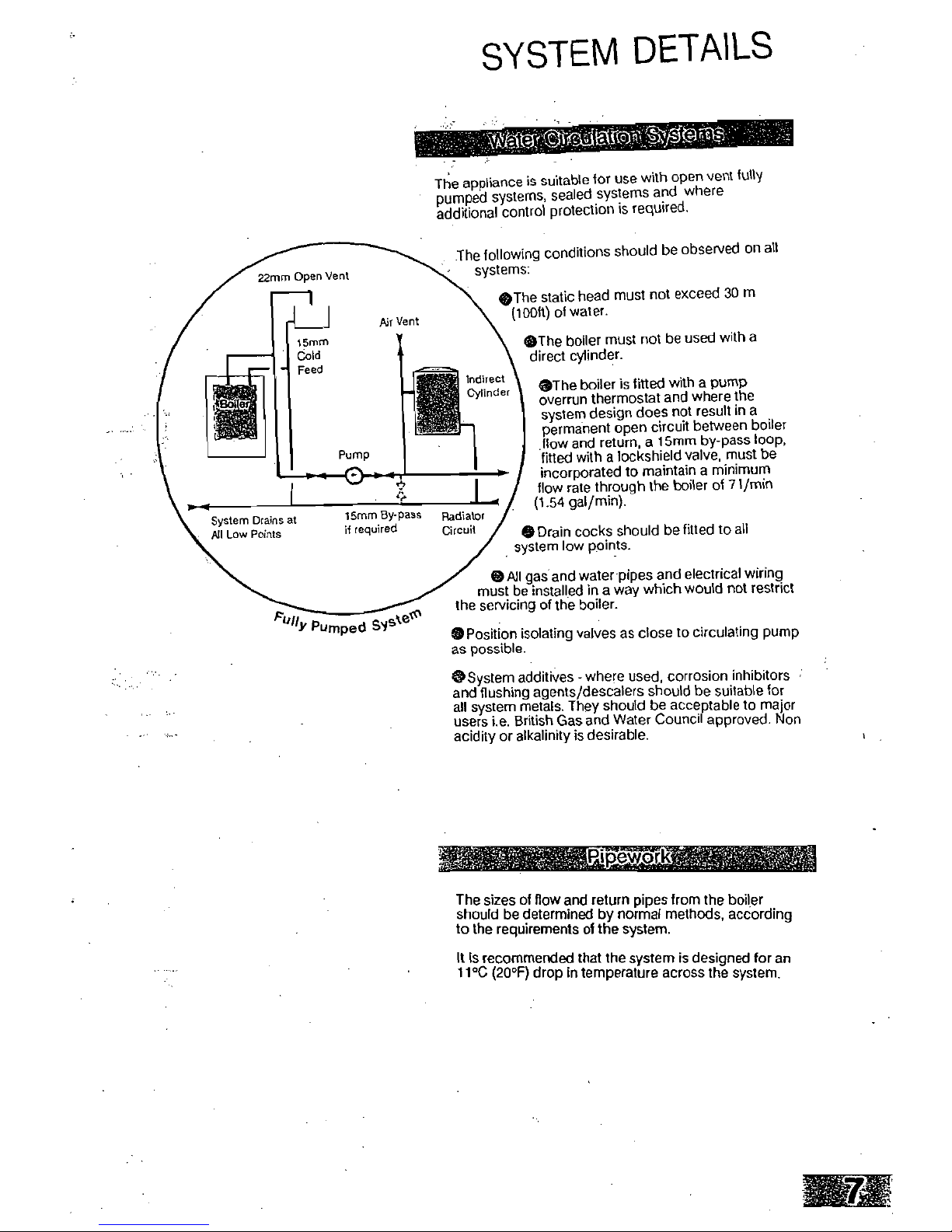

SYSTEM DETAILS

The appliance is suitable for use with open vent fully

pumped systems, sealed systems and where

additional control protection is required.

•

The following conditions should be observed on all

systems:

()The static head must not exceed 30 m

(100ft) of water.

•The boiler must not be used with a

direct cylinder.

0The boiler is fitted with a pump

overrun thermostat and where the

system design does not result in a

permanent open circuit between boiler

flow and return, a 15mm by-pass loop,

fitted with a lockshield valve, must be

incorporated to maintain a minimum

flow rate through the boiler of

7

1/min

(1.54 gal/min).

•

Drain cocks should be fitted to all

system low points.

Ptp,

cteta

"Y

Pumped SI-

OPosition isolating valves as close to circulating pump

as possible.

S

System additives - where used, corrosion inhibitors

and flushing agents/descalers should be suitable for

all system metals. They should be acceptable to major

users i.e. British Gas and Water Council approved. Non

acidity or alkalinity is desirable.

The sizes of flow and return pipes from the boiler

should be determined by normal methods, according

to the requirements of the system.

It Is recommended that the system is designed for an

11°C (20°F) drop in temperature across the system.

22mm Open Vent

15mm

Cold

Feed

Air Vent

-gt

Radiator

Circuit

0 All gas and water pipes and electrical wiring

must be installed in a way which would not restrict

the servicing of the boiler.

Indirect

Cylinder

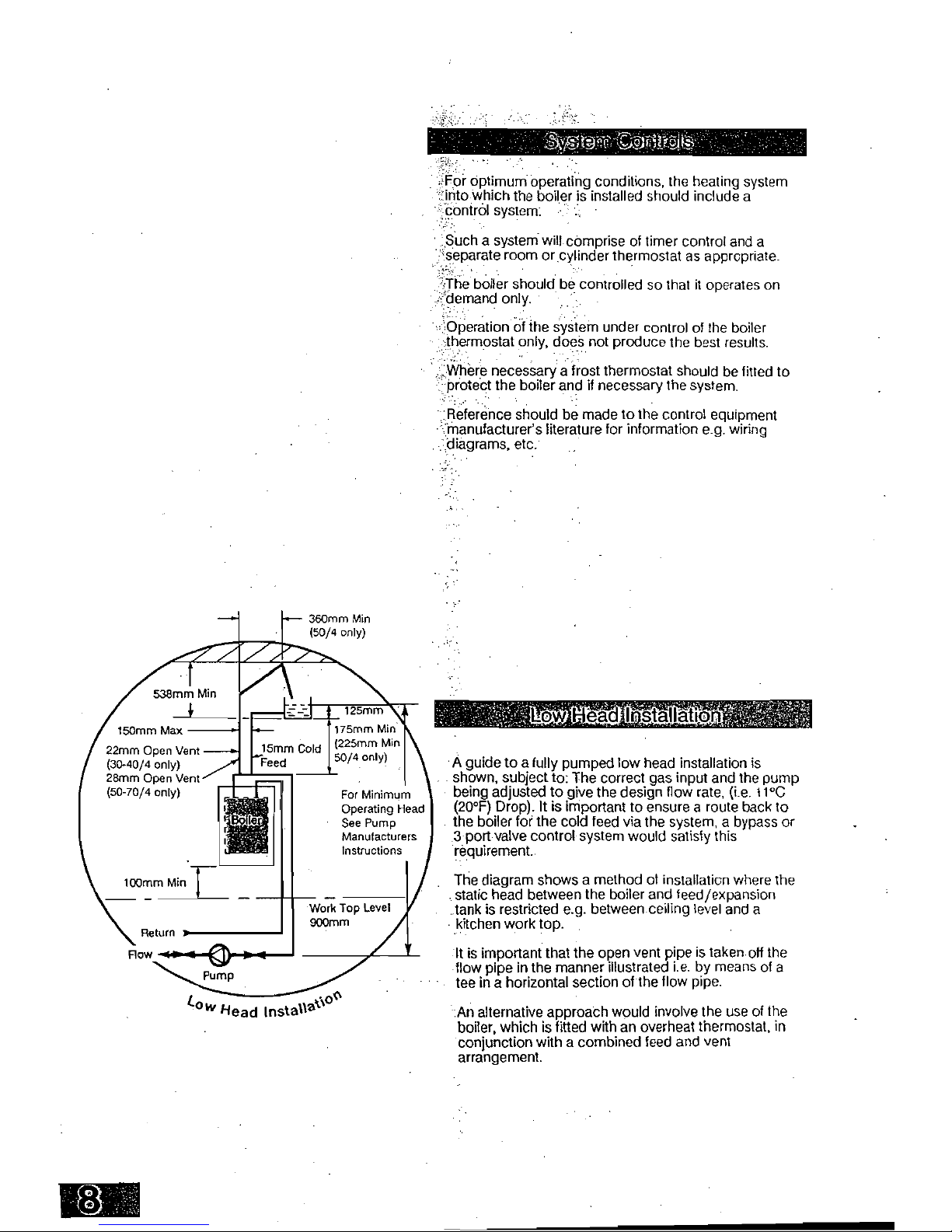

360mm Min

(50/4 only)

125mm

xk

r

kt

ri').

;;;;

O

Viltgl

ks

For optimum operating conditions, the heating system

'into which the boiler is installed should include a

-

control system.

Such a system will comprise of timer control and a

'

,

separate room or cylinder thermostat as appropriate.

The boiler should be controlled so that it operates on

demand only.

Operation of the system under control of the boiler

thermostat only, does not produce the best results.

Where necessary a frost thermostat should be fitted to

protect the boiler and if necessary the system.

Reference should be made to the control equipment

manufacturer's literature for information e.g. wiring

•

diagrams, etc.

175mrn Min

(225mm Min

50/4 only)

For Minimum

Operating Head

See Pump

Manufacturers

Instructions

538mm Min

150mm Max

22mm Open Vent

(30-40/4 only)

28mm Open Vent

(50-70/4 only)

100mm Min

I

Return

Row '1 I

CD

C

to

0(t

Iv

Head Insta

%

lla

•

A guide to a fully pumped low head installation is

shown, subject to: The correct gas input and the pump

being adjusted to give the design flow rate, (i.e. 11°C

(20°F) Drop). It is important to ensure a route back to

the boiler for the cold feed via the system, a bypass or

3 port valve control system would satisfy this

requirement.

The diagram shows a method of installation where the

static head between the boiler and feed/expansion

tank is restricted e.g. between ceiling level and a

•

kitchen work top.

It is important that the open vent pipe is taken off the

flow pipe in the manner illustrated i.e. by means of a

tee in a horizontal section of the flow pipe.

An alternative approach would involve the use of the

boiler, which is fitted with an overheat thermostat, in

conjunction with a combined feed and vent

arrangement.

Pressure

Gauge

Filling

Point

Pump

0

V I

Expansion

Vessel

Radiator

Circuit

Safety

Valve

Al

Vent

3 Litre

Top Up Bottle

(If Required)

A safety valve complying with the requirements of

BS 6750 Part 1 must be fitted close to the boiler on the

flow pipe by means of a horizontal or vertically upward

connection with no intervening valve or restrictions and

should be positioned to facilitate testing. The valve

should be pre-set and non-adjustable to operate at a

pressure of 3 bar (45 lbf/In9. It must be arranged to

discharge any water or steam through a pipe to a

safe outlet position.

,

--

IUSERMIESEMBEEMES

A pressure gauge of minimum range 0-4 bar

(0-60 lbf/In

2

) with a fill pressure indicator

must be fitted to the system, preferably at the

same point as the expansion vessel in an

easily visible position.

An expansion vessel complying with the

requirements of BS 4814 must be fitted to the

system by means of a connection close to the

inlet side of the circulating pump in accordance

with the manufacturers instructions, the

connecting pipe being unrestricted and not less

than 15mm

(

V

2

in) nominal size. The volume of the

vessel should be suitable for the system water content

and the nitrogen or air charge pressure should not be

less than the system static head. Further details of

sealed system design can be obtained from BS 5449:

Part 1 and the British Gas publication entitled

'Specifications for Domestic Wet Central Heating

Systems'.

I*4111.101W4.13/4.

-

System Drains

at Low Points

Max Boiler Flow

Temp = 82°C

Pr

cot

miciiii

el

*volytiikurn

_

c,

• ;C

oll- 4

5

-"icsin

"

4713a4 %-f-9--r-e-44

.7-

-it2-9,,terP

'co..

,

0

7 --Pe;

ko

.4115.09'ie

404.-k

4'

I--

Vessel Charge

Pressure (Bar)

1

Initial System

Pressure (Bar)

Multiply Total

Water Content

Of System by

(Litres)

0.5 -'

'0.5

1.0

1.5

2.0

0.067

0.112

0.207

0.441

1.0

1.5

2.0

0.087

0.152

0.330

1.5

2.0

0.125

0.265

Vetherohardtplessure

nitialljjlein-preicute

5

Ekpans

yatem_volume

0' 5

raire

/

rot

-t

e n

,

41,6

'Op Oa

Pe

NOTE

w

of the calce‘

a

e27

0

-1

0‘

e

-9

e,

ta

ble

se

siz

e

e

then the neXt

-nould be used.

- 0 10,i-

A filling point and an approved stop valve to BS 1010

must be fitted at low level and the method used for

fillingthe system should be approved by the local

Water undertaking. For further details see BS 6798.

afAXEMEISYSIEMEMENZEMES

A method of replacin9 water lost from the system

should be provided either by means of a make up

vessel of not more than 3 litres (5 pints) capacity,

mounted above the highest point of the system, or by

pre-pressurisation of the system.

A method of venting the system during filling and

commissioning must be provided by fitting automatic

air vents or by venting manually.

-Worn

,

Am; .

0

tom

The hot water storage vessel must be of the indirect

coil type. All components used in the system must be

suitable for operation at 110°C (230°F) and at the

pressure allowed by the safety valve.

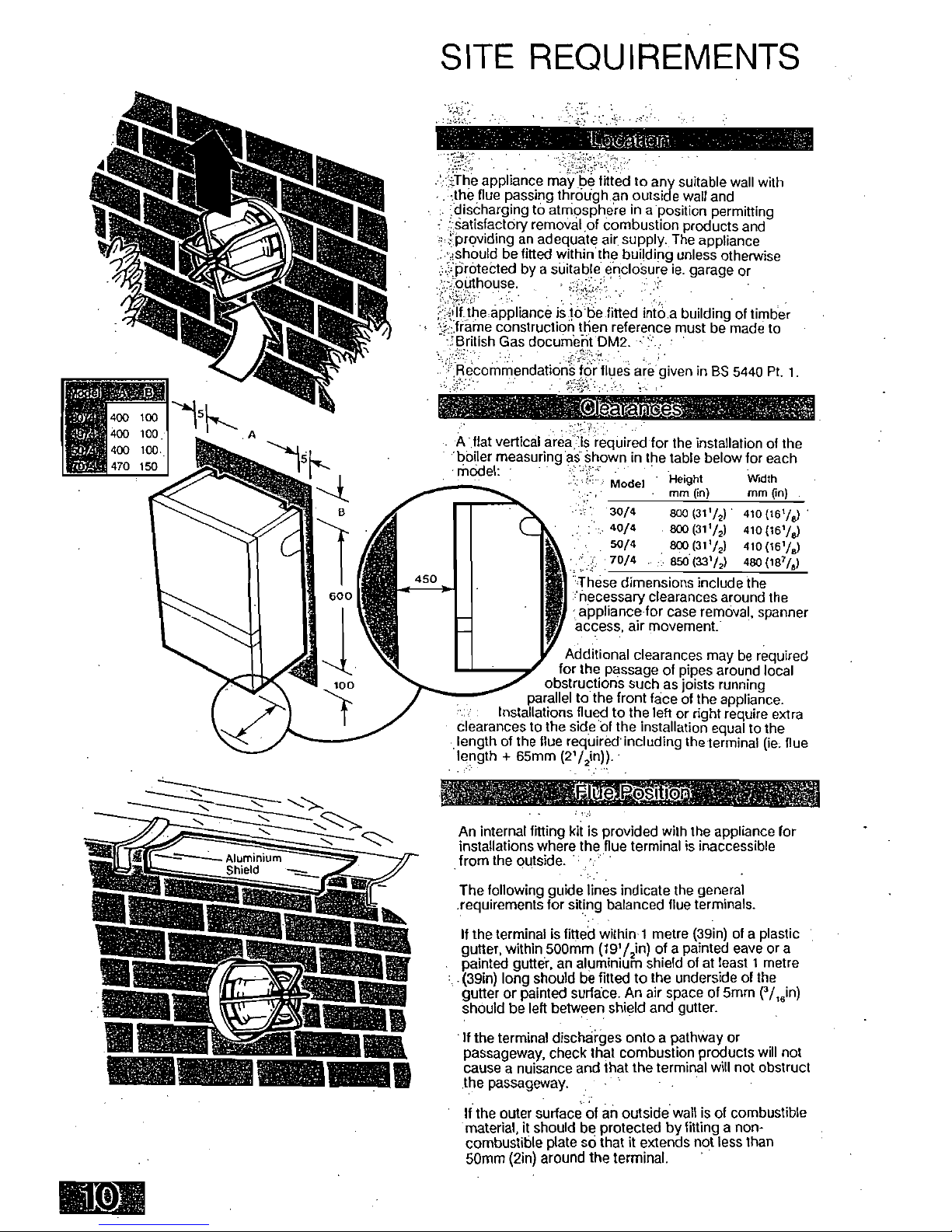

SITE REQUIREMENTS

.0-he appliance maY be fitted to any suitable wall with

the flue passing through .an outside wall and

.discharging to atmosphere in a position permitting

7 "[Satisfactory removal of combustion products and

.:

.

fProviding an adequate air

.

supply. The appliance

:.should be fitted within the building unless otherwise

::protected by a suitable enclosure ie. garage or

'.:.cauthouse.

lithe appliance is to be fitted into a building of timber

::frarne construction then reference must be made to

.:British Gas document DM2.

RecornmendatiOnS for flues are given in BS 5440 Pt. 1.

'SS

.

A flat vertical area

le

required for the installation of the

'boiler measuring aS shown in the table below for each

Height

Width

Model

mm (in) mm (in)

30/4

800 (31

1/2

)

410 (161/)

40/4

800(311/2)

410 (161/8)

50/4

800(3172)

410(15h/)

70/4

850 (3372)

480 (1874)

obstructions such as joists running

parallel to the front face of the appliance.

clearances to the side of the installation equal to the

length of the flue reqUired including the terminal (ie flue

length + 65mm (2V2in)).

Model:

These dimensions include the

'necessary clearances around the

appliance for case removal, spanner

access, air movement:

Additional clearances may be required

for the passage of pipes around local

Installations flued to the left or right require extra

(SNP

An internal fitting kit is provided with the appliance for

installations where the flue terminal is inaccessible

from the outside.

The following guide lines indicate the general

.requirements for siting balanced flue terminals.

If the terminal is fitted within-1 metre (39in) of a plastic

gutter, within 500mm (1972in) of a painted eave or a

painted gutter, an aluminium shield of at least 1 metre

(39in) long should be fitted to the underside of the

gutter or painted surface. An air space of 5mm (116in)

should be left between shield and gutter.

If the terminal discharges onto a pathway or

passageway, check that combustion products will not

cause a nuisance and that the terminal will not obstruct

the passageway.

If the outer surface of an outside wall is of combustible

material, it should be protected by fitting a non-

combustible plate so that it extends not less than

50mm (2in) around the terminal.

-

• "ft.3;

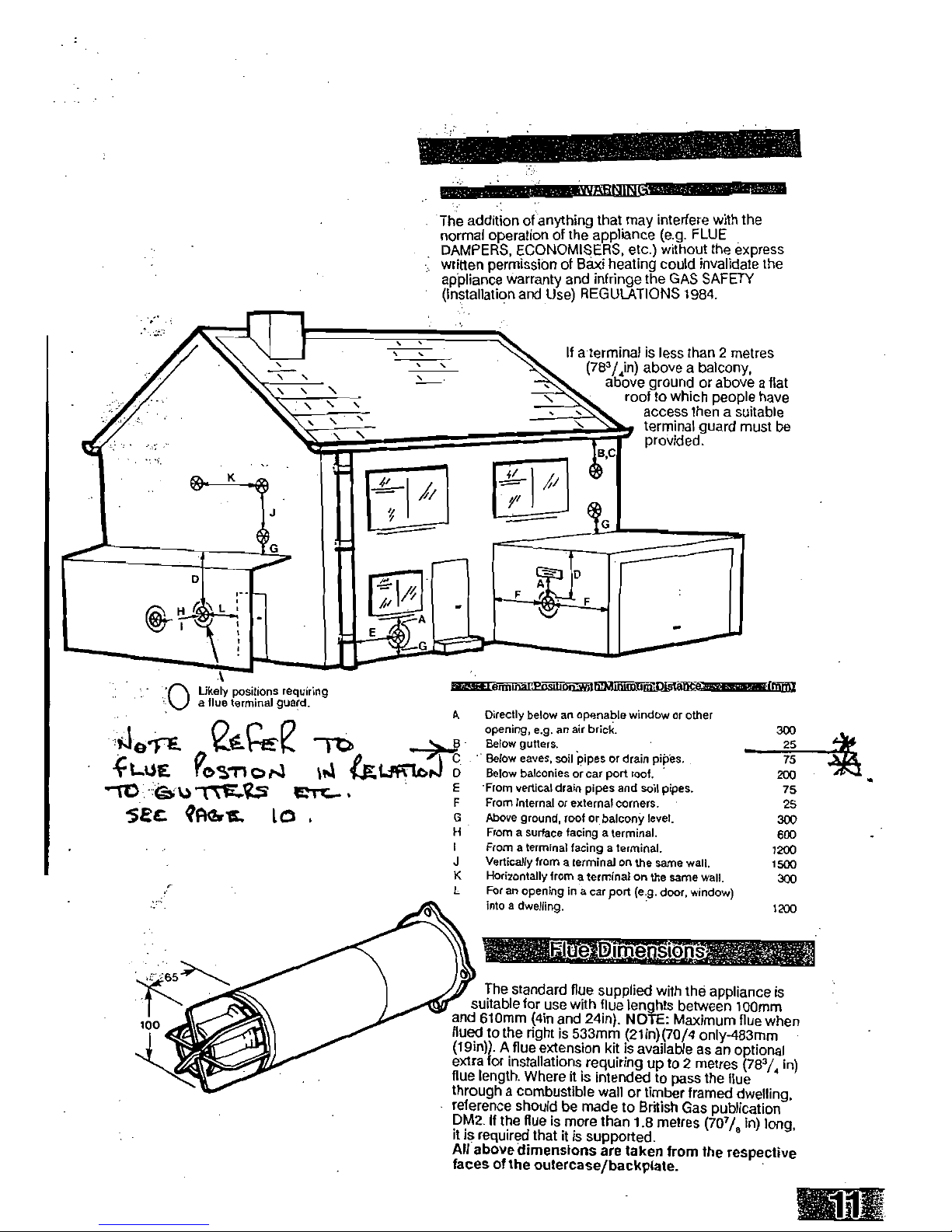

If a terminal is less than 2 metres

(78

3

/4in) above a balcony,

above ground or above a flat

roof to which people have

access then a suitable

terminal guard must be

provided.

The addition of anything that may interfere with the

normal operation of the appliance (e.g. FLUE

DAMPERS, ECONOMISERS, etc.) without the express

written permission of Baxi heating could invalidate the

appliance warranty and infringe the GAS SAFETY

(Installation and Use) REGULATIONS 1984.

Likely positions requiring

a flue terminal guard.

•

.

41

0

1-€. sag-ce

41-0E 9os-ri ()NI

CELiriend

D

--ro .t.)-rW...?..s

5Et.

VIGIL 10

em

r

—

VMIEMMElliThAffumilolDiatitilir

w

r

icnry

' 11

The standard flue supplied with the appliance is

suitable for use with flue lenghts between 100mm

and 610mm (4in and 24in). NOTE: Maximum flue when

flued to the nght is 533mm (21in)(70/4 only-483mm

(Win)). A flue extension kit is available as an optional

extra for installations requiring up to 2 metres (78

3/4

in)

flue length. Where it is intended to pass the flue

through a combustible wall or timber framed dwelling,

reference should be made to British Gas publication

DM2. If the flue is more than 1.8 metres (70

7

/, in) long,

it is required that it is supported.

All above dimensions are taken from the respective

faces of the outercase/backplate.

A

Directly below an openable window or other

opening, e.g. an air brick.

Below gutters.

Below eaves, soil Pipes or drain pipes.

Below balconies or car port roof.

From vertical drain pipes and soil pipes.

From internal or external corners.

Above ground, roof or balconY level.

From a surface facing a terminal.

From a terminal facing a terminal.

Vertically from a terminal on the same wall.

K

Horizontally from a terminal on the same wall.

L

For an opening in a car port (e.g. door, window)

into a dwelling.

300

25

75

200

75

25

300

600

1200

1500

300

1200

Ai5lists?

Where the appliance is installed in a cupboard or

compartment, air vents are required (for cooling

purposes) in the cupboard or compartment at

high and low level which may communicate

with a room or direct to outside air.

Detailed recommendations for air supply are

given in BS 5440: Part 2.

An existing cupboard or compartment may be

used, provided that it is modified for the

purpose. Recommendations for air supplies

and details of essential cupboard

compartment design are given in BS 5440:

Part 2.

NOTE: Both air vents must communicate with

the same room or both be on the same wall to

outside air.

104

,n2

52cm2

(I5.84,

2

)

FREE AREA

osin2) FREE AREA

I35cm

2

67.5cm2

(20,481n;

FREE AREA

(10.24in2)

FREE

AREA

17Icm

2

85.5cm2

/26in2) FREE AREA

113,n2) FREE AREA

240cm

2

120cm2

(36,46

2) FREE AREA

(I

Eigin21

FREE AREA

The gas installation should be in accordance with

85 6891:1988.

The connection of the appliance is

RC'/

2

(1/?in

BSPT internal) located at the

bottom right hand side.

Ensure that the pipework from the meter to

the appliance is of adequate size. Do not

use pipes of a smaller diameter than the

appliance gas connection.

Electrica Supply

External wiring must be correctly earthed, polarised

and in accordance with CURRENT I.E.E. WIRING

REGULATIONS.

The mains supply required is 240V — 50Hz fused at 3A.

NOTE: The method of connection to the electricity

supply must facilitate complete electrical isolation of

the appliance, preferably by the use of a fused three

pin plug and unswitched shuttered socket outlet, both

complying with the requirements of BS 1363.

Alternatively, connection may be made via a fused

double-pole isolater with a contact separation of at

least 3mm in all poles and serving the appliance and

system controls only.

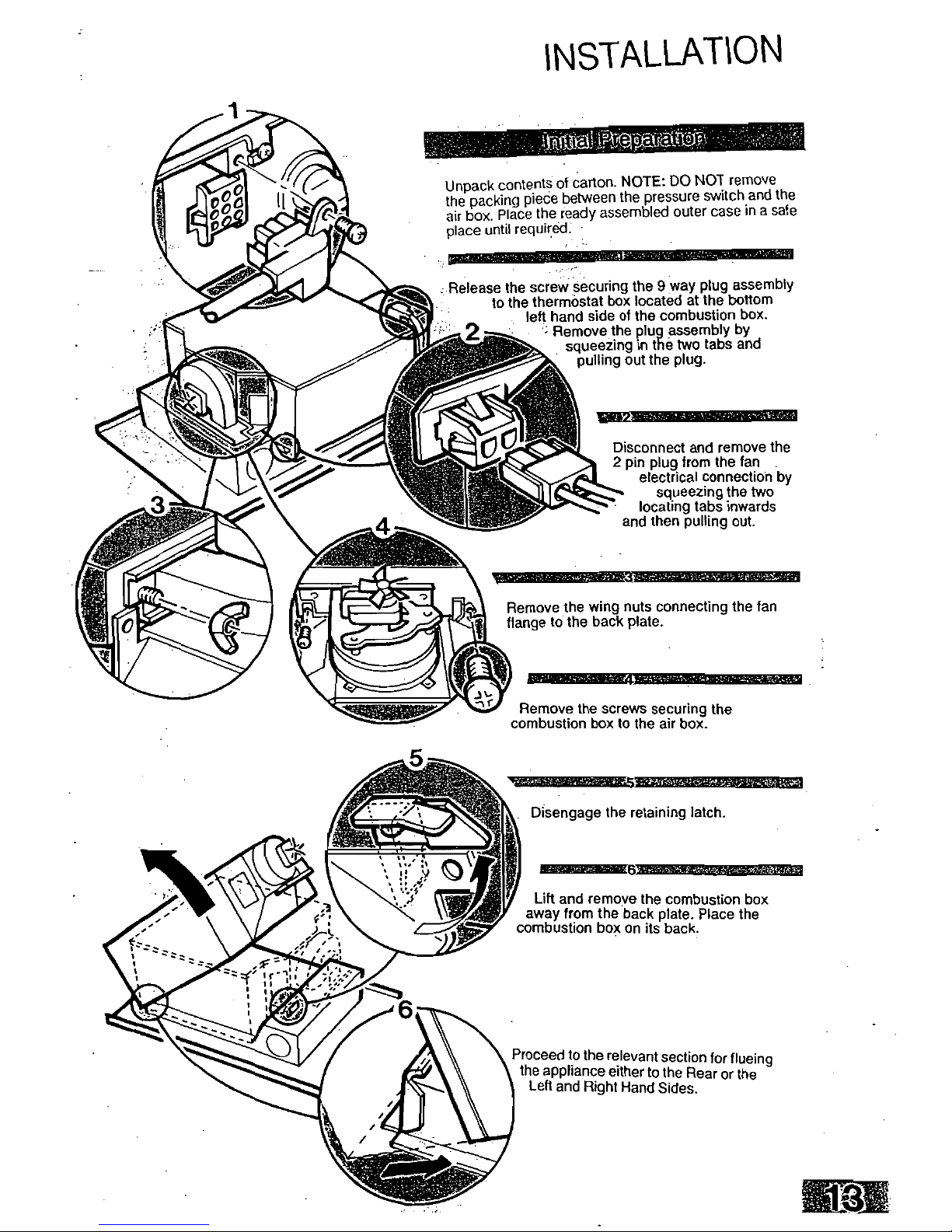

Unpack contents of carton. NOTE: DO NOT remove

the packing piece between the pressure switch and the

air box. Place the ready assembled outer case in a safe

place until required.

Release the screw securing the 9 way plug assembly

to the thermostat box located at the bottom

left hand side of the combustion box.

2

Remove the plug assembly by

squeezing in the two tabs and

pulling out the plug.

Disconnect and remove the

2 pin plug from the fan

electrical connection by

squeezing the two

locating tabs inwards

and then pulling out.

ISSIESIESSZEIMMEIBBEZIEEMBIEBEESES

Remove the wing nuts connecting the fan

flange to the back plate.

Remove the screws securing the

combustion box to the air box.

NEESZESIEMESIIMMEMEUESSMEEME8

Disengage the retaining latch.

MAIMIIITIZEKOZEMEESEZICIER

Lift and remove the combustion box

away from the back plate. Place the

combustion box on its back.

Proceed to the relevant section for flueing

the appliance either to the Rear or the

Left and Right Hand Sides.

INSTALLATION

100

(150-70/4 only)

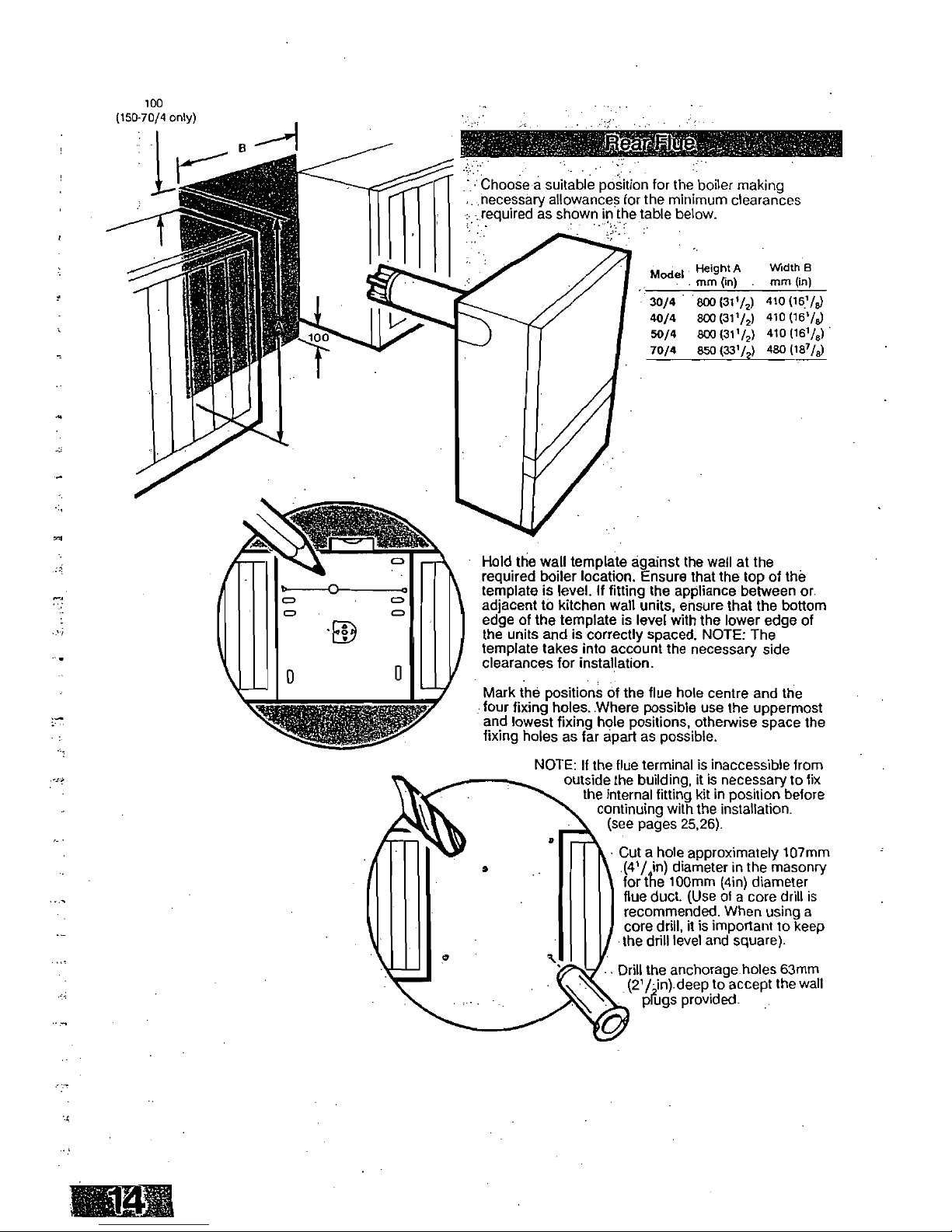

Choose a suitable position for the boiler making

necessary allowances for the minimum clearances

required as shown in the table below.

Model

Height A

mm On).

Width B

mm (in)

30/9

800 (31i/2)

410

(181/8)

40/4

8C0(31'/2)

410

(151/8)

50/4

800 (311/2)

410

(161/8)

70/4

850 (331/2)

480

(187/8)

Hold the wall template against the wall at the

required boiler location. Ensure that the top of the

template is level. If fitting the appliance between or.

adjacent to kitchen wall units, ensure that the bottom

edge of the template is level with the lower edge of

the units and is correctly spaced. NOTE: The

template takes into account the necessary side

clearances for installation.

Mark the positions of the flue hole centre and the

four fixing holes. Where possible use the uppermost

and lowest fixing hole positions, otherwise space the

fixing holes as far apart as possible.

NOTE: If the flue terminal is inaccessible from

outside the building, it is necessary to fix

the internal fitting kit in position before

continuing with the installation.

(see pages 25,26).

• Cut a hole approximately 107mm

(41/ in) diameter in the masonry

for the 100mm (4in) diameter

flue duct. (Use of a core drill is

recommended. When using a

core drill, it is important to keep

the drill level and square).

Drill the anchorage holes 63mm

(2

1

/,in) deep to accept the wall

plugs provided.

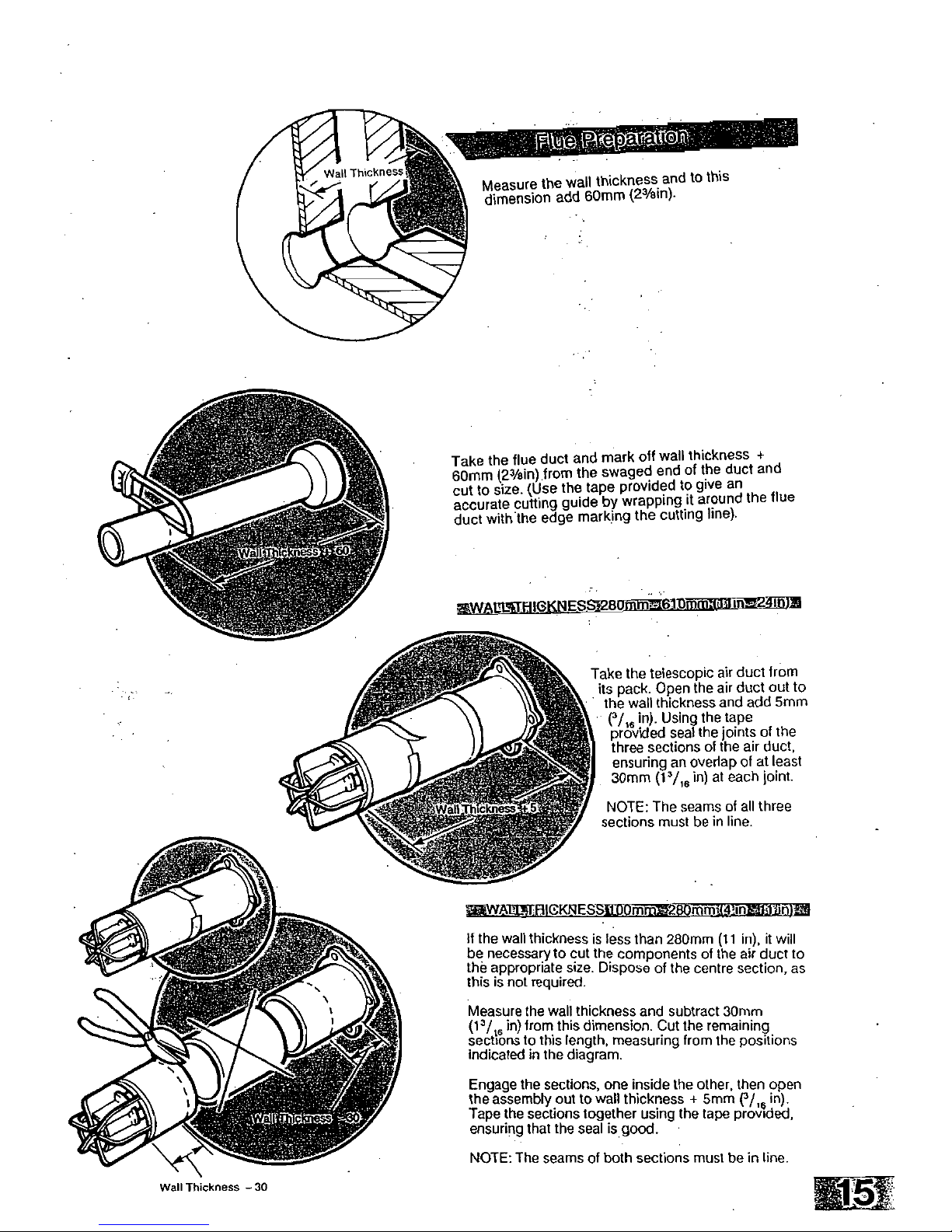

Measure the wall thickness and to this

dimension add 60mm (23/8in).

Take the flue duct and mark off wall thickness +

60mm (2

3

/ein) from the swaged end of the duct and

cut to size. (Use the tape provided to give an

accurate cutting guide by wrapping it around the flue

duct with the edge marking the cutting line).

.

2

WA

le ES -

9

80

il

--iftv

•

• tii)-'+'

lluie

Take the telescopic air duct from

its pack. Open the air duct out to

the wall thickness and add 5mm

(9,

6 in). Using the tape

provided seal the joints of the

three sections of the air duct,

ensuring an overlap of at least

30mm (1

3/,6

in) at each joint

NOTE: The seams of all three

sections must be in line.

tv_WA U " OKNESS

smth-Th-o.

tie an

etrimonak-;:

If the wall thickness is less than 280mm (11 in), it will

be necessary to cut the components of the air duct to

the appropriate size. Dispose of the centre section, as

this is not required.

Measure the wall thickness and subtract 30mm

(

13

/

16

in) from this dimension. Cut the remaining

sections to this length, measuring from the positions

indicated in the diagram.

Engage the sections, one inside the other, then open

the assembly out to wall thickness + 5mm

(915

in).

Tape the sections together using the tape provided,

ensuring that the seal is good.

NOTE: The seams of both sections must be in line.

Wall Thickness —30

4w-40ov A

i.:4111;1

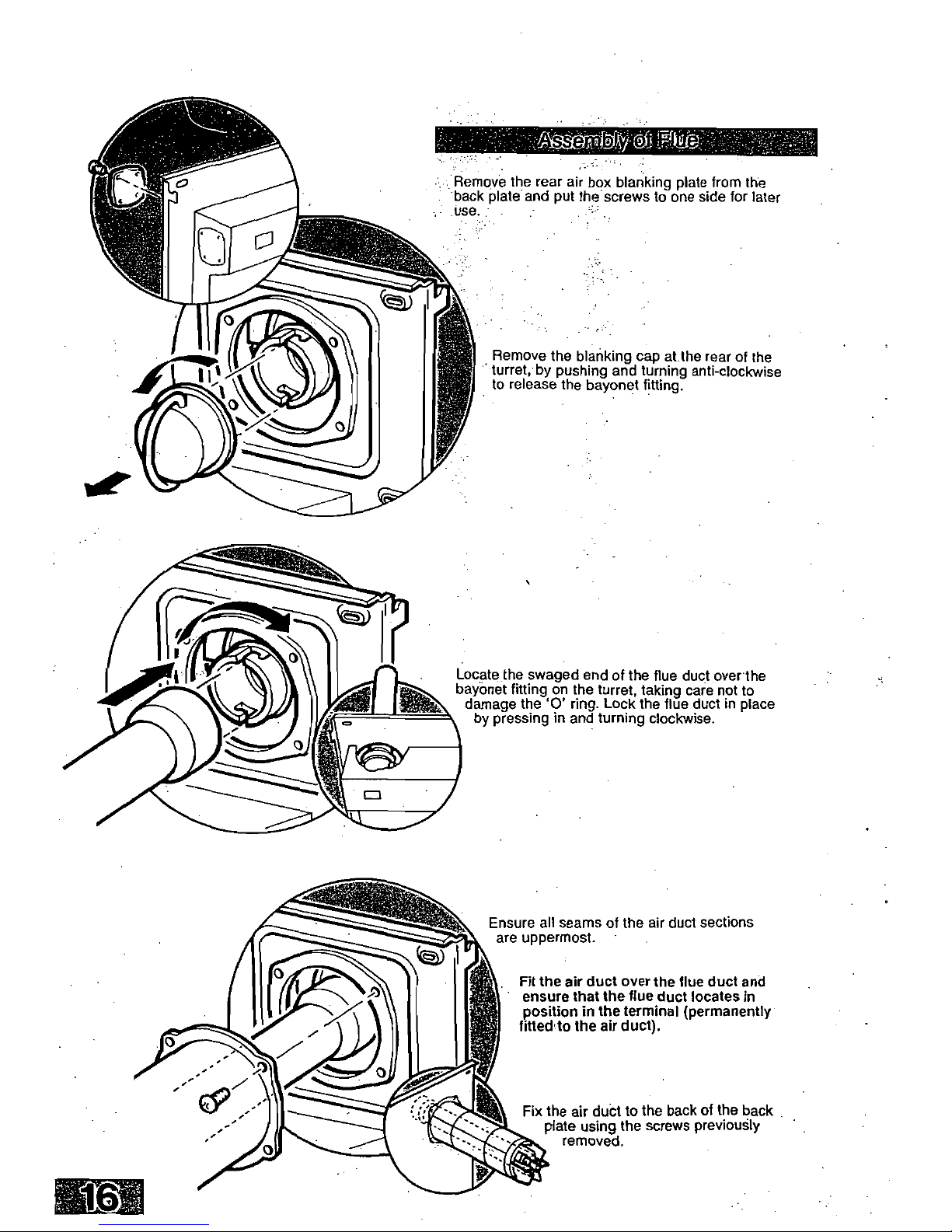

Remove the rear air box blanking plate from the

•

back plate and put the screws to one side for later

Remove the blanking cap at the rear of the

turret, by pushing and turning anti-clockwise

to release the bayonet fitting.

Locate the swaged end of the flue duct over the

bayonet fitting on the turret, taking care not to

damage the '0' ring. Lock the flue duct in place

by pressing in and turning clockwise.

Ensure all seams of the air duct sections

are uppermost.

Fit the air duct over the flue duct and

ensure that the flue duct locates in

position in the terminal (permanently

fitted to the air duct).

Fix the air duct to the back of the back

plate using the screws previously

removed.

Loading...

Loading...