Baxi Solo 2 RS Quick Start Manual

Please leave these Instructions with the User.

Baxi Solo 2 RS Range

Wall Mounted Room Sealed

Gas Fired Central Heating Boilers

Installation and

Servicing Instructions

2

Natural Gas

Baxi Solo 2 60 RS

G.C.No. 41 077 79

Baxi Solo 2 50 RS

G.C.No. 41 077 78

Baxi Solo 2 40 RS

G.C.No. 41 077 77

Baxi Solo 2 30 RS

G.C.No. 41 077 76

Baxi UK Limited is one of the leading manufacturers of

domestic heating products in the U.K.

Our first priority is to give a high quality service to our

customers. Quality is built into every Baxi product products which fulfil the demands and needs of

customers, offering choice, efficiency and reliability.

To keep ahead of changing trends, we have made a

commitment to develop new ideas using the latest

technology - with the aim of continuing to make the

products that customers want to buy.

Baxi is also the largest manufacturing partnership in the

country. Everyone who works at the company has a

commitment to quality because, as shareholders, we

know that satisfied customers mean continued success.

We hope you get a satisfactory service from Baxi. If

not, please let us know.

3

Baxi is a BS-EN ISO 9001

Accredited Company

CONTENTS

Introduction

Technical Data

System Details

(and By-pass Requirements)

Site Requirement

Installation

Commissioning the Appliance

Fitting the Outer Case

Overheat Cut-Off Device

Annual Servicing

Changing Components

Fault Finding

Short Parts List

PAGE 5

PAGE 6 - 7

PAGE 8 - 11

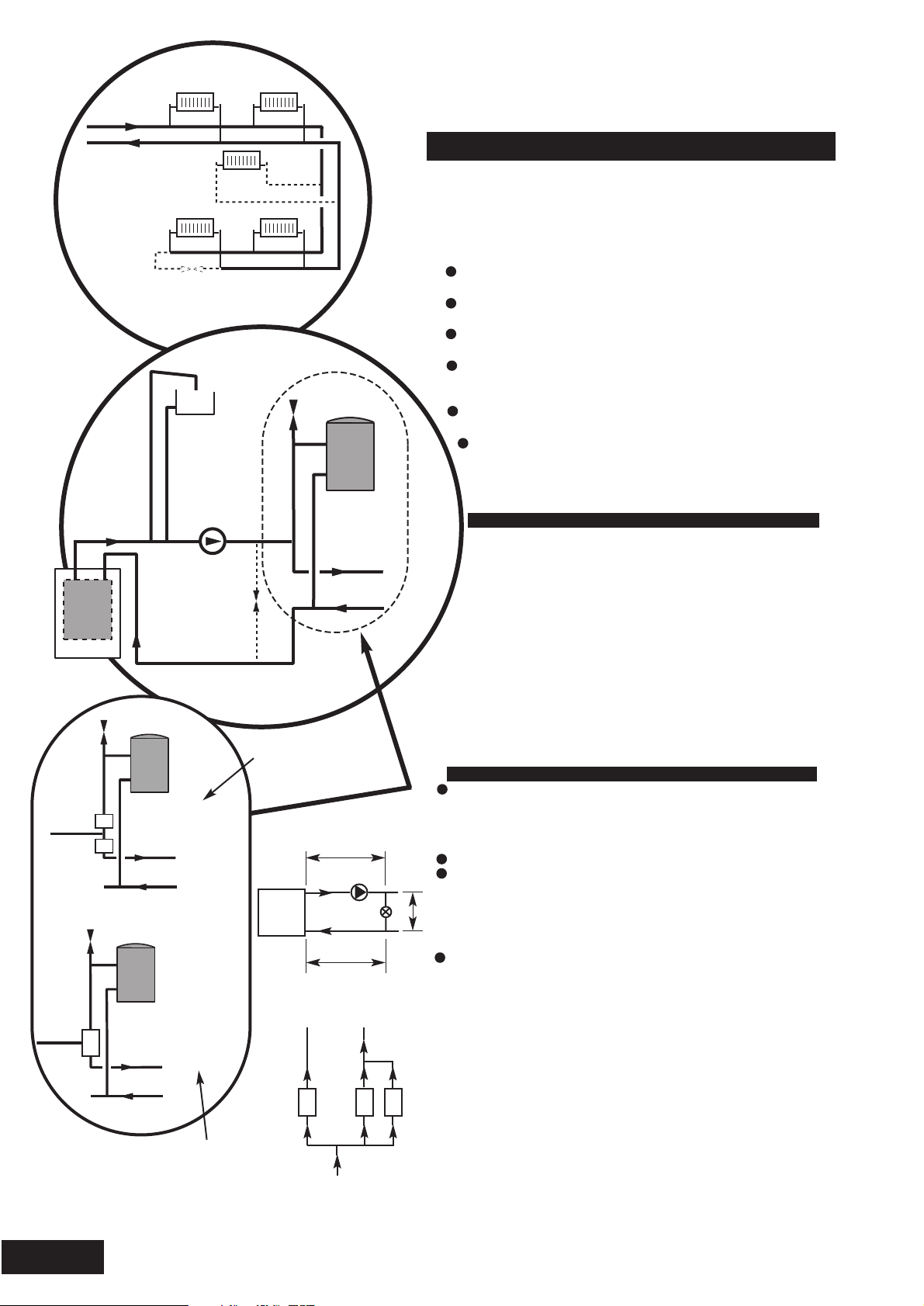

Water Circulating Systems

System Controls

Pipework

Fully Pumped, Open Vented Systems

Low Head Installation

Sealed Systems

Gravity Systems

Hydraulic Charts

PAGE 12 - 14

Location

Clearances

Flue Position

Flue Dimensions

Ventilation of Compartments

Gas Supply

Electrical Supply

PAGE 15 - 25

Initial Preparation

Flue Preparation

Fitting the Wall Mounting Plate

Fitting the Flue Duct

Terminal Guard

Fitting a Terminal Guard

Fitting the Boiler

Water Connections

Pipe Routes

Fully Pumped System

Sealed System

Gravity Hot Water System

Gas Connection

Electrical Supply

PAGE 26 - 27

PAGE 28

PAGE 29

PAGE 30 - 32

Dismantling the Boiler

Cleaning the Burner/Injectors

Cleaning the Combustion Box

PAGE 33 - 40

Eco Interrupter Leads

Piezo Igniter

Solenoid Operator

Thermocouple

Spark Electrode & Lead

Pilot Injector

Pilot Bracket & Gasket

Overheat Thermostat

Main Thermostat

Pump Overrun Timer

Removal of Combustion Chamber Door

Burner and Injectors

Gas Valve

Insulation Panels

PAGE 41

PAGE 42

4

INTRODUCTION

Description

The Baxi Solo 2 RS is a wall mounted gas

fired room sealed natural draught central

heating boiler with range rated outputs as

shown in the table below.

Each appliance is preset at its MAXIMUM

heat input rating and is designed for use on

NATURAL GAS only. They are suitable for

gravity domestic hot water with pumped

central heating, fully pumped open vented

central heating and domestic hot water and

sealed systems.

The standard flue assembly supplied is suitable

for wall thicknesses between 100mm (4in) and

356mm (14in). An optional flue extension kit is

available for walls of 356mm (14in) and 610mm (24in)

thickness.

The appliance data badge is fitted to the combustion

chamber door above the gas valve.

Installation

The installation must be carried out by a CORGI

Registered Installer and be in accordance with the

relevant requirements of GAS SAFETY (Installation

and Use) REGULATIONS, the BUILDING

REGULATIONS (Scotland) (Consolidation), the

LOCAL BUILDING REGULATIONS, the current I.E.E.

WIRING REGULATIONS and the bye laws of the

LOCAL WATER UNDERTAKING. (Where no specific

instruction is given reference should be made to the

relevant BRITISH STANDARD CODES OF

PRACTICE.)

Important Information

This product contains Refractory Ceramic Fibres (R.C.F.) which are

man-made vitreous silicate fibres. Excessive exposure to these

materials may cause temporary irritation to eyes, skin and respiratory

tract. Care must be taken when handling these articles to ensure the

release of dust or fibres is kept to a minimum. To ensure that the

release of fibres from these articles is kept to a minimum, during

installation and servicing it is recommended that a H.E.P.A. filtered

vacuum is used to remove any dust, soot or other debris

accumulated in and around the appliance. This should be performed

before and after working on the installation. It is recommended that

any replaced item(s) are not broken up but sealed within heavy duty

polythene bags and clearly labelled “R.C.F. waste”. This is not

classified as “hazardous waste” and may be disposed of at a tipping

site licensed for the disposal of industrial waste. Protective clothing is

not required when handling these articles but it is recommended that

gloves are worn and the normal hygiene rules of not smoking, eating

or drinking in the work area are followed and always wash hands

before eating or drinking.

HEAT OUTPUT

Model Min Max

30 6.15kW (21,000 Btu/h) 8.79kW (30,000 Btu/h)

40 9.09kW (31,000 Btu/h) 11.72kW (40,000 Btu/h)

50 12.02kW (41,000 Btu/h) 14.65kW (50,000 Btu/h)

60 14.95kW (51,000 Btu/h) 17.58kW (60,000 Btu/h)

5

B.S. Codes of Practice

STANDARD SCOPE

BS 6891 Gas Installation.

BS 5546 Installation of hot water supplies

for domestic purposes.

BS 5449 Part 1 Forced circulation hot water

systems.

BS 6798 Installation of gas fired hot water

boilers.

BS 5440 Part 1 Flues.

BS 5440 Part 2 Air Supply.

WARNING

The addition of anything that may interfere with the

normal operation of the appliance (e.g. FLUE

DAMPERS,ECONOMISERS etc) without the express

written permission of BAXI could invalidate the

appliance warranty and infringe the GAS SAFETY

(Installation and Use) REGULATIONS.

“Benchmark” Log Book

As part of the industry-wide “Benchmark” initiative

all Baxi boilers now include an Installation,

Commissioning and Service Record Log Book.

Please read the Log Book carefully and complete

all sections relevant to the appliance and

installation. These include sections on the type of

controls employed, flushing the system, burner

operating pressure etc. The details of the Log

Book will be required in the event of any warranty

work. Also, there is a section to be completed at

each subsequent regular service visit.

TECHNICAL DATA

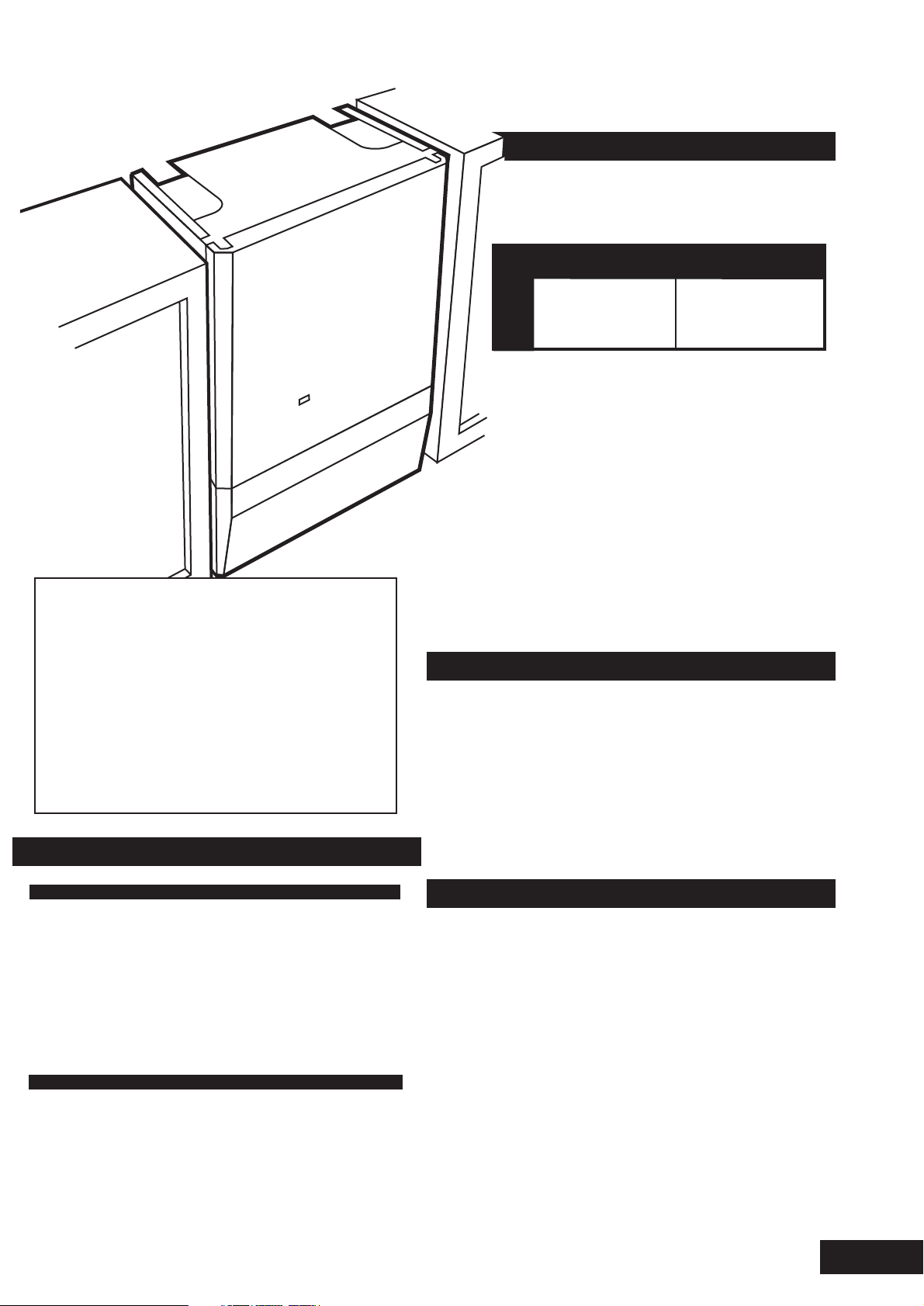

30 RS

40 RS

Heat Input Max Min

kW 11.00 7.69

Btu/h 37,500 26,250

Heat Output Max Min

kW 8.79 6.15

Btu/h 30,000 21,000

Burner Pressure Max Min

mbar 15.4

+

0.5 8.0 +0.5

in wg 6.2 +0.2 3.2 +0.2

Gas Connection RC1/2(1/2in BSPT)

Electrical Supply 230V~50Hz

fused 3A

Controls on/off boiler thermostat

with pilot/thermocouple cut

out/overheat

thermostat on fully

pumped applications only

Heat Exchanger cast iron monobloc

Lifting Weight 37.3 kg (82.1 lbs)

Water Content 2.1 litres (0.46 gals)

Static Head Max Min

metres 30 1

feet 100 3.25

Low Head Min 0.15m (6in)

System Design gravity hot water fully

pumped open vented

and sealed systems

Connections 2 x 22mm and a kit for

gravity

Gas Rate

(after 10 mins) 1.05m

3

/h (37.0ft3/h)

Outercase Height 600mm

Dimensions

Width 420mm

Depth 287mm

Flue Terminal Height 208mm

Dimensions

Width 293mm

Depth 173mm

Heat Input Max Min

kW 14.65 11.36

Btu/h 50,000 38,750

Heat Output Max Min

kW 11.72 9.09

Btu/h 40,000 31,000

Burner Pressure Max Min

mbar 16.3

+

0.5 10.3 +0.5

in wg 6.5 +0.2 4.1 +0.2

Gas Connection RC

1

/2(1/2in BSPT)

Electrical Supply 230V~50Hz

fused 3A

Controls on/off boiler thermostat

with pilot/thermocouple cut

out/overheat

thermostat on fully

pumped applications only

Heat Exchanger cast iron monobloc

Lifting Weight 37.3 kg (82.1 lbs)

Water Content 2.1 litres (0.46 gals)

Static Head Max Min

metres 30 1

feet 100 3.25

Low Head Min 0.15m (6in)

System Design gravity hot water fully

pumped open vented

and sealed systems

Connections 2 x 22mm and a kit for

gravity

Gas Rate

(after 10 mins) 1.40m

3

/h (49.3ft3/h)

Outercase Height 600mm

Dimensions

Width 420mm

Depth 287mm

Flue Terminal Height 208mm

Dimensions

Width 293mm

Depth 173mm

50

50

5

5

300

80

for

ravity

for

servicing

5

inside

cupboard

Clearances

50

50

5

5

300

80

for

ravity

for

servicing

5

inside

cupboard

Clearances

NOTE: On gravity applications a clearance

of 80mm (31/8in) is required from the top

panel

NOTE: On gravity applications a clearance

of 80mm (3

1

/8in) is required from the top

panel

6

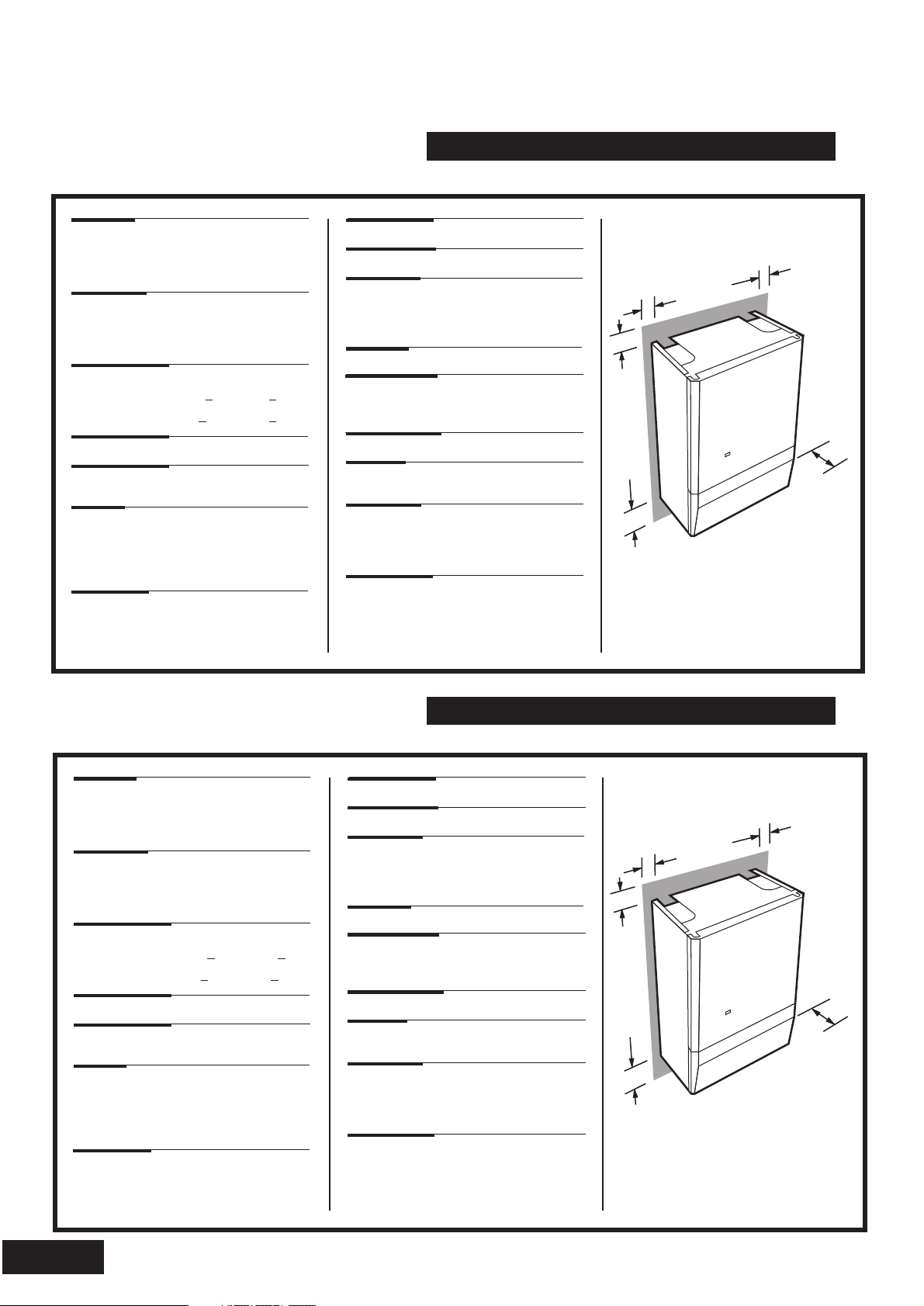

50 RS

60 RS

Heat Input Max Min

kW 18.32 15.02

Btu/h 62,500 51,250

Heat Output Max Min

kW 14.65 12.02

Btu/h 50,000 41,000

Burner Pressure Max Min

mbar 16.3

+

0.5 11.2 +0.5

in wg 6.5 +0.2 4.5 +0.2

Gas Connection RC1/2(1/2in BSPT)

Electrical Supply 230V~50Hz

fused 3A

Controls on/off boiler thermostat

with pilot/thermocouple cut

out/overheat

thermostat on fully

pumped applications only

Heat Exchanger cast iron monobloc

Lifting Weight 37.3 kg (82.1 lbs)

Water Content 2.1 litres (0.46 gals)

Static Head Max Min

metres 30 1

feet 100 3.25

Low Head Min 0.15m (6in)

System Design gravity hot water fully

pumped open vented

and sealed systems

Connections 2 x 22mm and a kit for

gravity

Gas Rate

(after 10 mins) 1.75m

3

/h (61.6ft3/h)

Outercase Height 600mm

Dimensions

Width 420mm

Depth 287mm

Flue Terminal Height 208mm

Dimensions

Width 293mm

Depth 173mm

Heat Input Max Min

kW 21.98 18.68

Btu/h 75,000 63,750

Heat Output Max Min

kW 17.58 14.95

Btu/h 60,000 51,000

Burner Pressure Max Min

mbar 16.0

+

0.5 12.0 +0.5

in wg 6.4

+

0.2 4.8 +0.2

Gas Connection RC

1

/2(1/2in BSPT)

Electrical Supply 230V~50Hz

fused 3A

Controls on/off boiler thermostat

with pilot/thermocouple cut

out/overheat

thermostat on fully

pumped applications only

Heat Exchanger cast iron monobloc

Lifting Weight 37.3 kg (82.1 lbs)

Water Content 2.1 litres (0.46 gals)

Static Head Max Min

metres 30 1

feet 100 3.25

Low Head Min 0.15m (6in)

System Design gravity hot water fully

pumped open vented

and sealed systems

Connections 2 x 22mm and a kit for

gravity

Gas Rate

(after 10 mins) 2.09m

3

/h (74.0ft3/h)

Outercase Height 600mm

Dimensions

Width 420mm

Depth 287mm

Flue Terminal Height 208mm

Dimensions

Width 293mm

Depth 173mm

50

50

5

5

300

80

for

ravity

for

servicing

5

inside

cupboard

Clearances

50

50

5

5

300

80

for

ravity

for

servicing

5

inside

cupboard

Clearances

NOTE: On gravity applications a clearance

of 80mm (31/8in) is required from the top

panel

NOTE: On gravity applications a clearance

of 80mm (3

1

/8in) is required from the top

panel

7

This system is unlikely to

require a By-pass unless all

radiators are thermostatically

controlled

Water Circulating Systems

The appliance is suitable for use with fully pumped

open vented systems (small bore and micro-bore),

gravity domestic hot water with pumped central heating

systems and sealed systems.

The following conditions should be observed on all

systems:

The static head must not exceed 30m (100ft) of

water.

The boiler must only be used with an indirect

cylinder.

Drain points should be fitted to the lowest points in

the system.

All electrical wiring, gas and water pipes must be

installed in a way which would not restrict the servicing

of the boiler.

Position isolating valves as close to circulating pump

as practicable.

For fuel economy and best boiler performance, the

system should be designed so that gravity circulation

does not take place in the heating system when the

pump is not running.

Treatment of Water Circulating Systems

For optimum performance after installation, this boiler and its

associated central heating system must be flushed in

accordance with the guidelines given in BS7593:1992

“Treatment of water in domestic hot water central heating

systems”.

This must involve the use of a proprietry cleanser, such as

BetzDearborn’s Sentinel X300 or X400, or Fernox’s Superfloc. Full

instructions are supplied with the products but for immediate

information please contact BetzDearborn on 0151 420 9563, or

Fernox on 01799 550811.

For long term protection against corrosion and scale, after flushing it

is recommended that an inhibitor such as BetzDearborn’s Sentinel

X100, or Fernox’s MB-1 or Copal is dosed in accordance with the

guidelines given in BS7593:1992.

Failure to flush and add inhibitor to the system may

invalidate the appliance warranty.

BYPASS REQUIREMENTS

The boiler is fitted with a pump overrun device which allows the

removal of residual heat from the boiler. NOTE: The pump overrun

will operate for approximately 3 minutes. The system design must

therefore always provide an open circuit for water to circulate

between the boiler flow and return.

If a system has an open circuit a bypass is not required.

A system using a 3 port diverter valve does not normally require a

bypass and therefore this system is recommended. The exception to

this is where all radiators in the system are fitted with thermostatic

valves, in which case a bypass would be required. However, if one

radiator in such a system was fitted with 2 lockshield valves a bypass

would not be required.

A system controlled by non-electrical valves e.g. mechanical

thermostatic control valves both on the radiators and the hot water

circuit and systems using twin zone valves (e.g. Honeywell 'S' Plan)

will require a bypass.

The bypass circuit can be:A) A minimum of 9 metres of 22mm pipe (measured between the

boiler flow and return connections). It should be fitted with a

lockshield valve opened at least 1 full turn to give a minimum flow rate

of 8 litres/min (1.8 gal/min).

B) A radiator fitted with lockshield valves. The radiator output should

be a minimum of 800 watts (2,700 Btu/h). Typically a convector type

radiator with an area of 3750 cm2(4ft2) is adequate.

C) By including an automatic bypass valve in the system (see

diagram).

D) Any circuit that provides the same operating conditions as option A

or option B.

Radiator Circuit

Examples of

Open Circuits

By-pass

Loops

SYSTEM DETAILS

(and By-pass Requirements)

Air Vent

8

A By-pass is

required with

this system

Typical Systems Arrangement

B

F

R

B

C

C

A

A

Flow from boiler

Boiler

Pump

Valve

A = D. H. W. Zone valve

B = C. H. Zone valve

C = Automatic Bypass valve

Bypass length = A + B + C

Bypass Incorporating

Automatic Valve

Bypass Length

Pump

Boiler

Optional

Bypass

Fully Pumped System

Air

Vent

Twin Zone

Valve System

Radiator

Circuit

Air

Vent

3 Port Diverter

Valve System

Radiator

Circuit

Radiator

Circuit

Typical Low Head Installation

Alternative Layout

Alternative Low Head Installation

9

System Controls

For optimum operating conditions, the heating system

into which the boiler is installed should include a

control system.

Such a system will comprise of timer control and a

separate room or cylinder thermostat as appropriate.

The boiler should be controlled so that it operates on

demand only.

Operation of the system under control of the boiler

thermostat only, does not produce the best results.

Pipework

The sizes of flow and return pipes from the boiler

should be determined by normal methods, according to

the requirements of the system.

It is recommended that the system is designed for an

11 °C (20°F) drop in temperature across the

system.

In systems using non-metallic pipework it is necessary

to use copper pipe for the boiler Flow and Return. The

copper must extend at least 1 metre from the boiler

and include any branches. The copper pipe must not

be insulated.

Fully Pumped, Open Vented Systems

Low Head Installation

Using a close couple arrangement the minimum head

is as shown in the diagram, subject to the following

conditions:

1) The correct heat input.

2) The pump being adjusted to give an 11oC drop

across the boiler.

3) The pump must be fitted on the flow.

4) The pump must be fitted in accordance with the

pump manufacturer's instructions.

5) The open vent pipe must be taken up from a tee

in a horizontal section of the flow pipe.

Alternative Low Head Installation for all Solo 2 RS

If less height is available then a combined vent and

feed pipe may be connected. This must be a minimum

of 22mm diameter. It is recommended that an air

separator is fitted when using a combined feed and

vent pipe.

Boiler

Flow

Return

Copper

0.5m

Copper

1m

Copper

0.5m

Copper Pipe In Non-Metallic System

Boiler

Automatic

Air

Vent

500mm

45

1000mm

Min

150mm

Max

Return

o

15mm

Cold

Feed

22mm

Open Vent

400mm

Min Head

Pump

Flow

500mm

45

1000mm

Min

o

15mm

Cold

Feed

22mm

Open Vent

400mm

Min Head

150mm

Max

Boiler

200mm

Min

Boiler

22mm

Feed & Vent

Pipe

Air

Separator

Pump

Return

Return

Flow

Pump

Flow

Initial System

Pressure (Bar)

Vessel Charge

Pressure (Bar)

Multiply Total

Water Content Of

System By (Litres

0.067

0.112

0.207

0.441

0.087

0.152

0.330

0.125

0.265

0.5

1.0

1.5

2.0

1.0

1.5

2.0

1.5

2.0

0.5

1.0

1.5

Example :-

Then :-

System Volume = 75 litres

Vessel Charge Pressure = 1.0 bar

Initial System Pressure = 1.5 bar

75 x 0.152 = 11.4 litres

Expansion Vessel Volume

Method of determining minimum

value of expansion vessel volume for

sealed systems using Baxi Boilers

NOTE

Where a vessel of the calculated size is not

then the next available larger size should

Sealed Systems

SAFETY VALVE

A safety valve complying with the requirements of BS

6750 Part 1 must be fitted close to the boiler on the

flow pipe by means of a horizontal or vertically upward

connection with no intervening valve or restrictions and

should be positioned to facilitate testing. The valve

should be pre-set and non-adjustable to operate at a

pressure of 3 bar (45 Ibf/in2). It must be arranged to

discharge any water or steam through a pipe to a safe

outlet position.

PRESSURE GAUGE

A pressure gauge of minimum range 0-4 bar (0-

60 Ibf/in2) with a fill pressure indicator must be

fitted to the system, preferably at the same point

as the expansion vessel in an easily visible

position.

EXPANSION VESSEL

An expansion vessel complying with the

requirements of BS 4814 must be fitted to the

system by means of a connection close to the inlet

side of the circulating pump in accordance with the

manufacturers instructions, the connecting pipe

being unrestricted and not less than 15mm (1/2in)

nominal size. The volume of the vessel should be

suitable for the system water content and the nitrogen

or air charge pressure should not be less than the

system static head.

Further details of sealed system design can be

obtained from BS 5449: Part 1 and the British Gas

publication entitled 'Specifications for Domestic Wet

Central Heating Systems'.

FILLING POINT

A filling point and an approved stop valve to BS 1010

must be fitted at low level and the method used for

filling the system should be approved by the local

water undertaking. For further details see BS 6798.

MAKE UP SYSTEM

A method of replacing water lost from the system

should be provided either by means of a make up

vessel of not more than 3 litres (5 pints) capacity,

mounted above the highest point of the system, or by

pre-pressurisation of the system.

VENTING

A method of venting the system during filling and

commissioning must be provided by fitting automatic

air vents or by venting manually.

HOT WATER STORAGE

The hot water storage vessel must be of the indirect

coil type. All components used in the system must be

suitable for operation at 110OC (230OF) and at the

pressure allowed by the safety valve.

Boiler

Safety

Valve

System Drains

at Low Point

Expansion

Vessel

Pump

Pressure

Gauge

Filling

Point

Air

Vent

3 Litre

Top Up Bottle

(If Required)

Radiator

Circuit

Max Boiler Flow

Temp = 82OC

10

n

e

Gravity Systems

When the boiler is to be installed to an existing or new

gravity domestic hot water and pumped central heating

system, the following considerations should be given

to the design of the gravity domestic hot water flow

and return pipes.

The minimum circulating head should not be less

than 1m (3ft) with a maximum horizontal run of

3m (10ft) when using 28mm pipes. Smaller pipe

sizes and longer horizontal runs are acceptable

with suitably increased circulating heads.

The system must be designed to prevent

reverse circulation.

Pipes should be laid to maximum fall avoiding

points of possible air lock.

If the domestic hot water temperature is controlled by a

cylinder thermostat and zone valve, it is recommended

that a bypass is installed in the gravity circuit. One

method is to install a bathroom radiator, fitted with two

lock shield valves. Mechanical valves which allow the

boiler to operate when the valve is closed should not

be used.

Note: If the above conditions cannot be met, then

pumped primaries must be used.

See page 25 for wiring of boiler when installed with

gravity hot water.

Hydraulic Charts

Boiler

Bathroom Radiator used

as Gravity Circuit Bypass

when a Zone Valve is used

m

11

Hydraulic Resistance Chart

For Gravity Systems - with injector wash

60 RS

(20)50

(16)40

(12)30

(8)20

(4)10

50 RS

40 RS

30 RS

Pressure Drop mbar (in wg)

0

4.5 9.0 13.5 18.0 22.5

(1) (2) (3) (4) (5)

Water Flow litres/min (gal/mi

(12)30

(8)20

(4)10

Pressure Drop

mbar (in wg)

Hydraulic Resistance Chart

(For Fully Pumped Systems)

60 RS

50 RS

40 RS

30 RS

0

4.5 9.0 13.5 18.0 22.5

(1) (2) (3) (4) (5)

Water Flow litres/min (gal/

SITE REQUIREMENTS

Location

The appliance may be fitted to any suitable wall with

the flue passing through an outside wall and

discharging to atmosphere in a position permitting

satisfactory removal of combustion products and

providing an adequate air supply. The appliance should

be fitted within the building unless other-wise protected

by a suitable enclosure ie. garage or outhouse. The

appliance may be fitted inside a cupboard provided that

ventilation requirements and combustible material

standards are adhered to.

If the appliance is fitted in a room containing a bath or

shower reference must be made to the Current I.E.E.

Wiring Regulations and Building Regulations.

If the appliance is to be fitted into a building of timber

frame construction then reference must be made to the

current edition of Institute of British Gas Engineers

Publication IGE/UP/7 (Gas Installations in Timber

Framed Housing).

Recommendations for flues are given in BS 5440 Pt1.

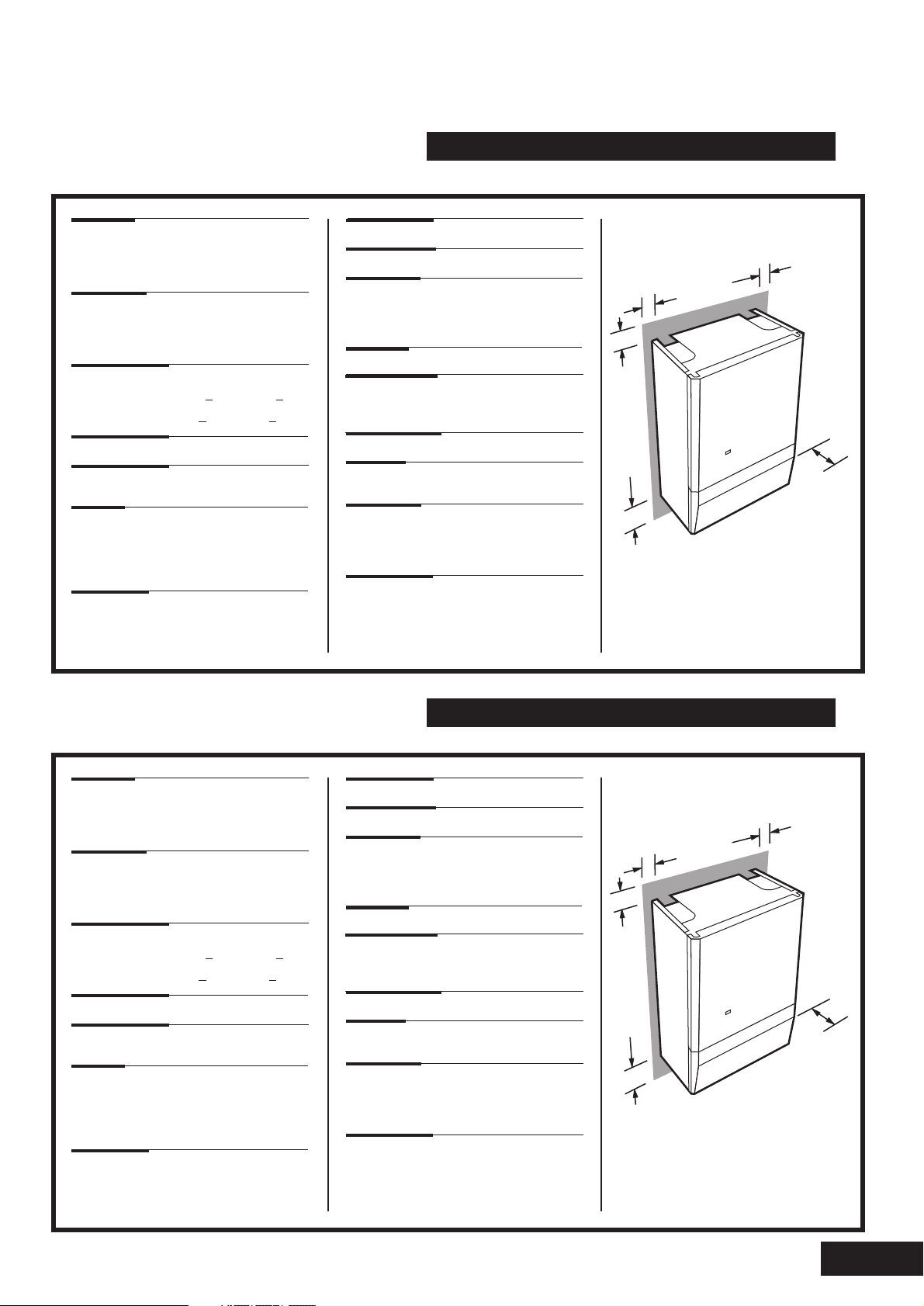

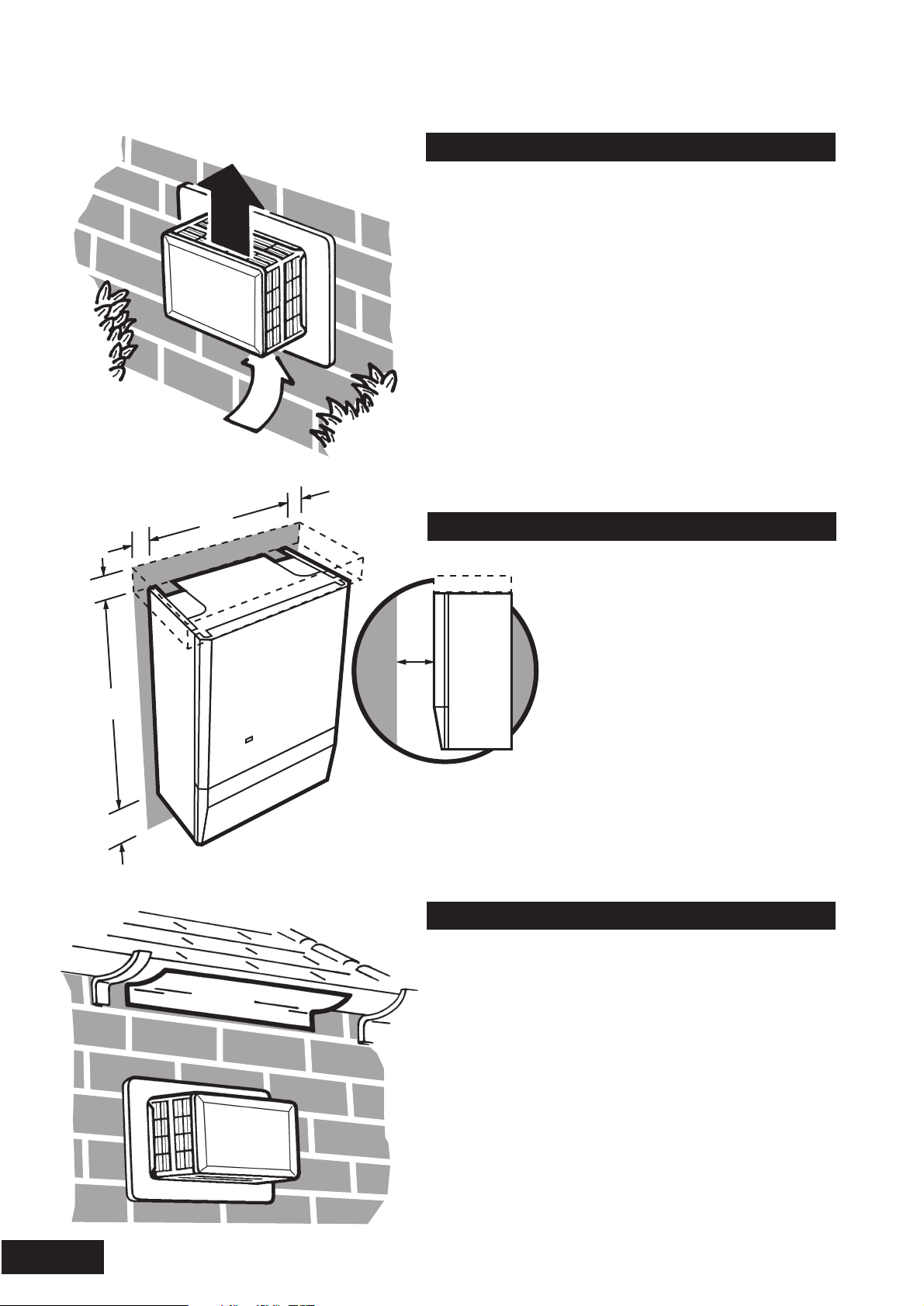

Clearances

A flat vertical area is required for the installation of the

boiler measuring as shown. A space above

the boiler should also be left clear as

indicated by the dotted lines.

These dimensions include the necessary

clearances around the appliance for

case removal, spanner access and air

movement. Additional clearances may

be required for the passage of pipes

around local obstructions such as joists

running parallel to the front face of the

appliance.

If fitted inside a cupboard the clearance of 300mm

shown is only necessary when the cupboard door is

open. A clearance of 5mm (3/16in) is required from the

front of the casing when the door is closed.

NOTE: On gravity applications a clearance of 80mm

(31/8 in) is required from the top panel.

Flue Position

The following guide lines indicate the general

requirements for siting balanced flue terminals.

If the terminal is fitted within 1 metre (39in) of a plastic

gutter, within 500mm (191/2in) of a painted eave or a

painted gutter, an aluminium shield of at least 1 metre

(39in) long should be fitted to the underside of the

gutter or painted surface. An air space of 5mm (3/16in)

should be left between shield and gutter.

If the terminal discharges onto a pathway or

passageway, check that combustion products will not

cause a nuisance and that the terminal will not obstruct

the passageway.

If the outer surface of an outside wall is of combustible

material, it should be protected by fitting a noncombustible plate so that it extends not less than 50mm

(2in) around the terminal.

Aluminium

Shield

600

420

50

50

5

5

300

12

Terminal Position with Minimum Distance (mm)

A Directly below an openable window or other

opening, e.g. an air brick. 300

B Below gutters, soil pipes or drain pipes. 300

C Below eaves. 300

D Below balconies or car port roof 600

E From vertical drain pipes and soil pipes. 75

F From internal or external corners. 600

G Above ground, roof or balcony level. 300

H From a surface facing a terminal. 600

I From a terminal facing a terminal. 600

J Vertically from a terminal on the same wall. 1500

K Horizontally from a terminal on the same wall. 300

L For an opening in a car port (e.g. door, window)

into a dwelling. 1200

WARNING

If a terminal is less than 2 metres (783/4in) above a

balcony, above ground or above a flat roof to which

people have access then a suitable

terminal guard must be provided.

Flue Dimensions

Recommendations for flues are given in BS 5440:1.

The standard flue terminal supplied with the appliance

is suitable for use with wall thickness between 100mm

(4in) and 356mm (14in).

A flue terminal extension kit is available as an optional

extra for wall thickness between 356mm (14in) and

610mm (24in) from the manufacturer. Quote appliance

Model Nowhen ordering.

293

208

173

13

H,I

K

J

G

D

L

Likely positions requiring

a flue terminal guard

D

E

B,C

G

A

F

A

G

D

F

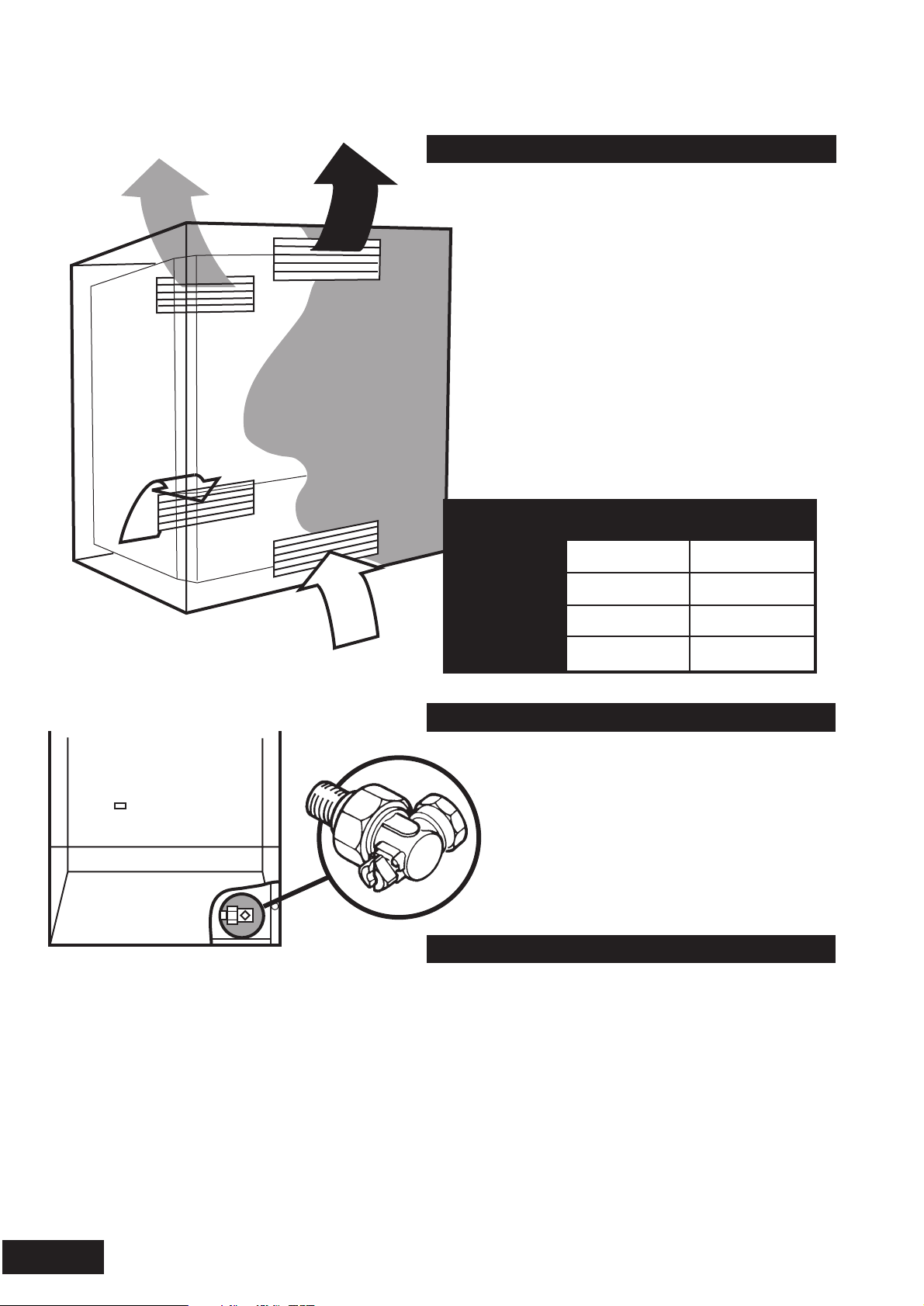

Ventilation of Compartments

Where the appliance is installed in a cupboard or

compartment, air vents are required (for cooling

purposes) in the cupboard or compartment at high

and low level which may communicate with a room

or direct to outside air.

Detailed recommendations for air supply are given

in BS 5440: Part 2.

An existing cupboard or compartment may be used,

provided that it is modified for the purpose.

Recommendations for air supplies and details of

essential cupboard compartment design are given in

BS 5440: Part 2.

NOTE: Both air vents must communicate with the

same room or both be on the same wall to outside

air.

MINIMUM AIR VENT FREE AREA

Gas Supply

The gas installation should be in accordance with

BS 6891.

The connection on the appliance is RC1/

2

(1/2in BSPT internal) located at the bottom right

hand side of the appliance.

Ensure that the pipework from the meter to the

appliance is of adequate size. Do not use pipes

of a smaller diameter than the appliance gas

connection.

Electrical Supply

External wiring must be correcty earthed, polarized

and in accordance with CURRENT I.E.E. WIRING

REGULATIONS.

The mains supply is 230V ~ 50Hz fused at 3A. NOTE:

The method of connection to the electricity supply

must facilitate complete electrical isolation of the

appliance, preferably by the use of a fused three pin

plug and unswitched shuttered socket outlet, both

complying with the requirements of BS 1363.

Alternatively, connection may be made via a fused

double-pole isolator with a contact separation of a

least 3mm in all poles and serving the appliance and

system controls only.

Model

Position of Air from Air direct

Air Vent Room from Outside

30

HIGH AND 99.0cm2FREE AREA 49.5cm2FREE AREA

LOW LEVEL (15.35in2) (7.68in2)

40

HIGH AND 131.9cm2FREE AREA 66.0cm2FREE AREA

LOW LEVEL (20.44in2) (10.22in2)

50

HIGH AND 164.9cm2FREE AREA 82.5cm2FREE AREA

LOW LEVEL (25.56in2) (12.78in2)

60

HIGH AND 197.9cm2FREE AREA 99.0cm2FREE AREA

LOW LEVEL (30.67in2) (15.34in2)

14

Loading...

Loading...