Baxi LUNA 310 Fi Troubleshooting Manual

Marathon

1815 Sismet Road phone: 800-461-4657

Mississauga, Ontario

L4W 1P9 CANADA

fax: 905-602-7422

International

BAXI LUNA 310 Fi Troubleshooting Guide

Before getting started, remember………..

All BAXI LUNA boilers are tested during manufacture for correct operation and are

shipped to you factory tested for correct operation.

Most of the faults experienced on start up are field issues associated with items

external to the boiler. These are mostly simple problems, such as:

• Venting installed incorrectly

• Air in the system (system must be fully purged)

• Air in the gas line

• Undersized gas line

• System not flushed (cold flush then hot flush)

• Incorrect connection of external equipment

• Leaks in the Heating system and pipe-work

When commissioning the boiler, only a few items need to be checked:

• Inlet gas pressure (static and working inlet pressure of boiler running at

maximum output)

• Maximum and minimum burner pressures

• Power supply for polarity and ground

When troubleshooting BAXI LUNA boilers avoid changing parts prematurely,

assuming that the boiler component is defective. In our experience, items such as the

control PCB are changed incorrectly, when it is another component supplying false

information to it. Likewise, the pump is changed because it has stopped operating.

This is normally due to contamination from a dirty hydronic system. The pump can be

removed and cleaned; after which the heating system must be flushed and cleaned.

Get all the information before going to the job site……………

Get as much information from your customer before you go to the boiler. Model of

boiler, type of venting, type of system and layout connected to the boiler, how long has

the system been installed and is this an isolated breakdown or are they repeatedly

resetting the boiler.

Don’t be afraid to ask the obvious questions! Do they know how to reset the boiler?

Just unplugging the lead and replacing it or turning the boiler off and on again will

not reset the logic board. They have to turn the switch to the “R” to restart the boiler.

Is there any water in the system? Where is the needle on the pressure gauge? This

may save an unnecessary trip to the job site.

April 2004

BAXI LUNA 310 Fi troubleshooting guide

e

s

Page 1

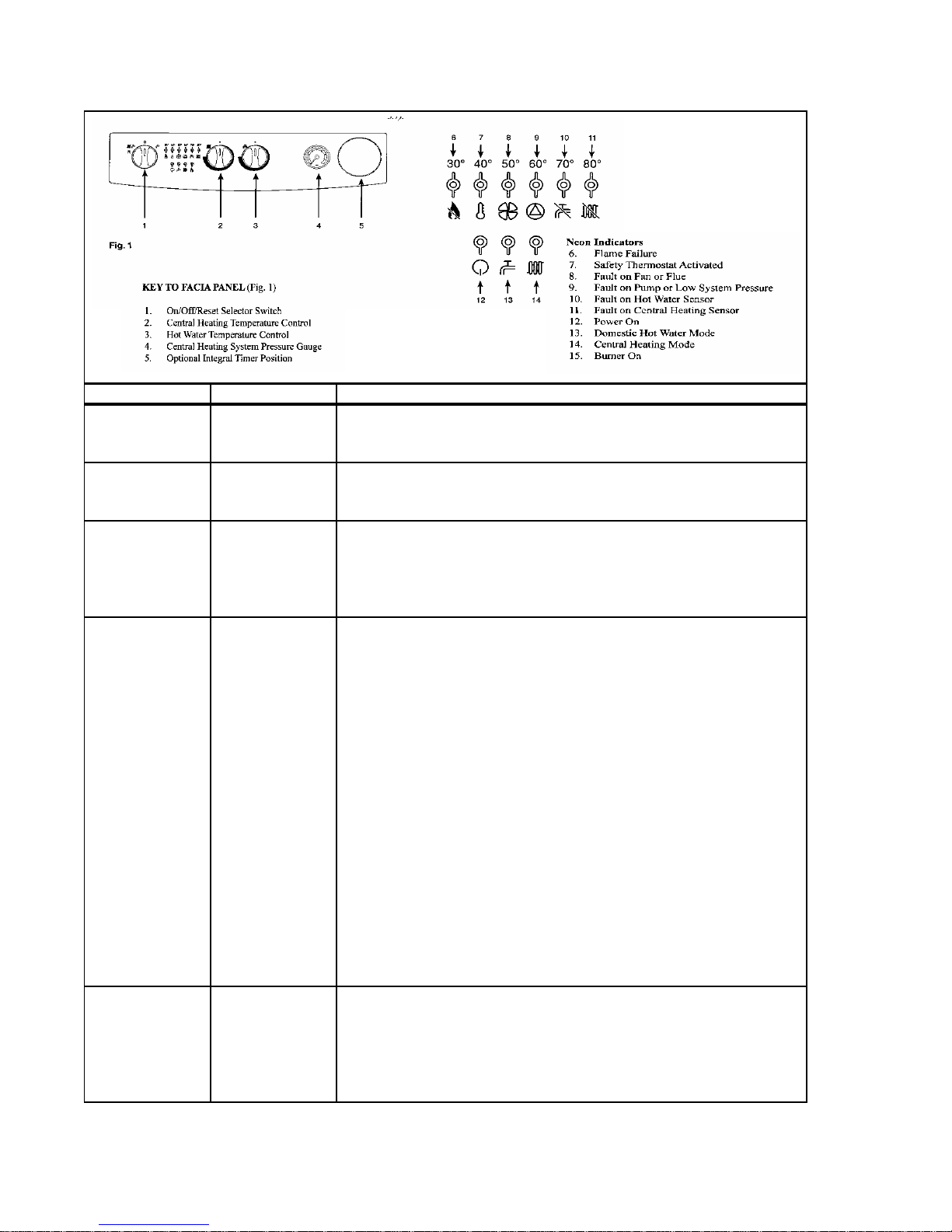

Fault Caus

Boiler does not start No power at the

no LED's lit. boiler

Boiler does not start #14 LED not lit

but #12 LED is lit. (call for heat) 1&2 at terminal strip and jumper it. If boiler starts replace switching relay.

Boiler does not start #13 LED not lit

but #12 LED is lit. (call for DHW)

Boiler does not start Low water pressure

but #12 and #13 or on gauge. Check for and repair leaks in heating system.

#14 LED's are lit.

Primary/DHW sensor

faulty.

Pump not operating

Suggested Solution

▪ Check 120 Vac at power cord outlet.

▪ Check if main 3.15 amp boiler fuse has blown.

▪ No signal from external control. Remove wires from thermostat connections

▪ Open DHW tap fully, has pin moved out from DHW differential assembly to

close micro switch (green wires)? No; DHW flow valve diaphragm damaged

replace. If diaphragm OK clean and lubricate DHW valve rod. Yes; check

continuity across DHW micro switch, replace if faulty.

▪ Re-pressurize heating system till pressure gauge reads between 1-2 Bar

▪ Check DHW/ Primary temperature sensors for cold resistance of approx

11 K Ω (resistance reduces with increase in temp), replace if faulty.

▪ Check for 120 V at pump, if no power and sensors OK, replace main PCB.

▪ 120 V at pump, but pump not turning. Release jammed pump by removing

vent cap on front of pump and turning shaft counter-clockwise. If pump will not

turn. Drain boiler, remove pump head release and clean pump cartridge.

Air in system

▪ If pump is running but the flow switch has not closed, or is "bouncing" up

and down, purge air from the pump and heating system.

Flow switch faulty

Pump running, flow Air switch not

switch closed fan operating sealed door on boiler and pull suction tube from fan venturi. Gently suck on

not running the end of the sensing tube, you should hear the air switch operating. Re-

▪ If pump is running but flow switch has not closed; has pin moved out from

diverter valve to close micro switch? No; flow switch diaphragm damaged,

replace. If diaphragm Ok clean and lubricate flow switch rod. Yes; check

continuity across primary flow micro switch, replace if faulty.

▪ Check air switch has not stuck in the open position. To check, remove room

connect the sensing tube and retry lighting boiler, (signal from PCB to fan on

start is via the NC terminals on the air switch). If air switch OK replace PCB.

Loading...

Loading...