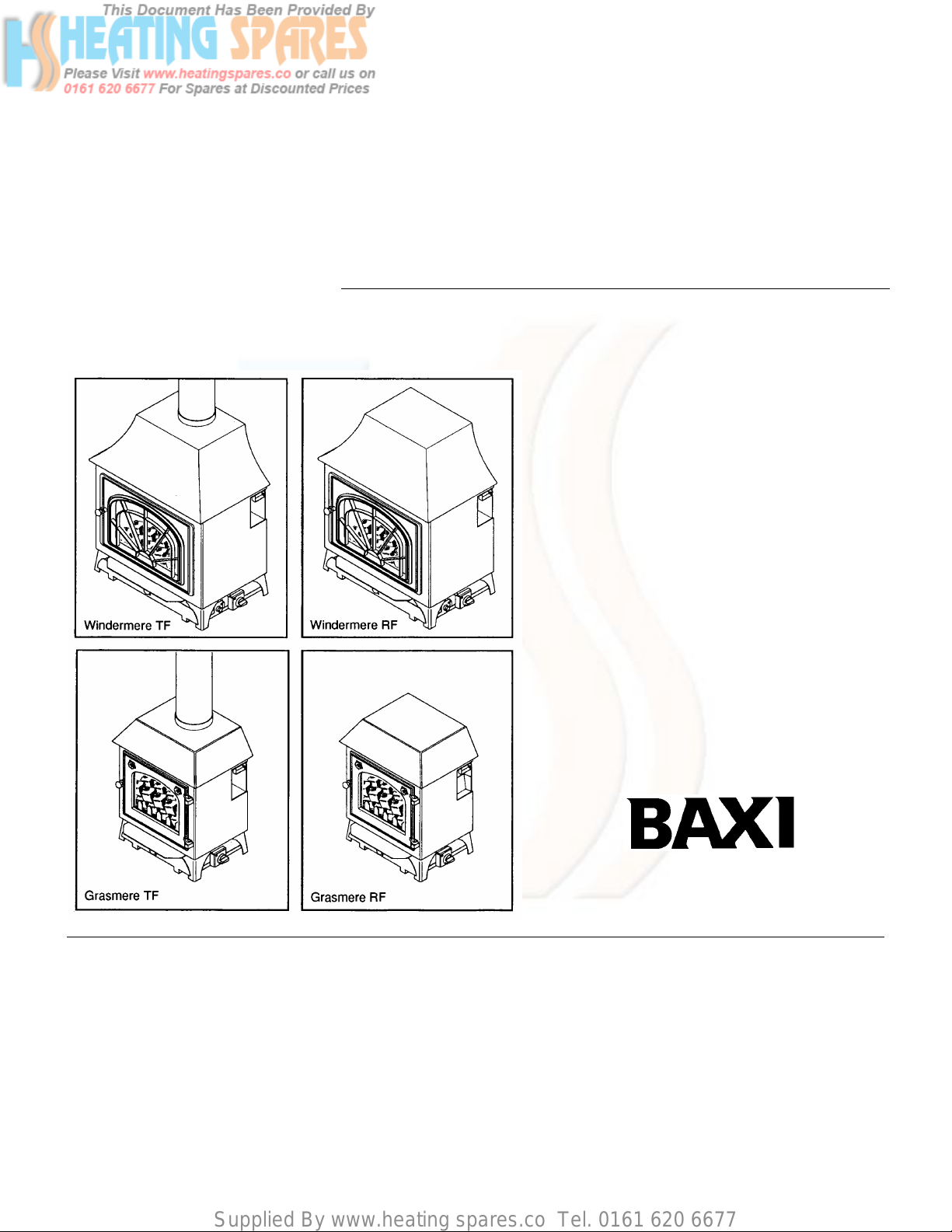

Baxi windermere TF, windermere RF, grasmere RF, grasmere TF Installation And Servicing Instrucnions

Page 1

Supplied By www.heating spares.co Tel. 0161 620 6677

Please leave these Instructions with the user.

Baxi Windermere

Baxi Grasmere

Gas Stoves

Comp No 242300 - Iss 5 - 5/00

Installation and

Servicing Instructions

Page 2

Supplied By www.heating spares.co Tel. 0161 620 6677

Natural Gas Propane Gas

Baxi Windermere RF

G.C.No 32 075 26

Baxi Windermere TF

G.C.No 32 075 27

Baxi Grasmere RF

G.C.No 32 075 24

Baxi Grasmere TF

G.C.No 32 075 25

Baxi UK Limited is one of the leading

manufacturers of domestic heating products in

the UK.

Our first priority is to give a high quality service to

our customers. Quality is built into every Baxi

product -products which fulfil the demands and

needs of customers, offering choice, efficiency

and reliability.

To keep ahead of changing trends, we have

made a commitment to develop new ideas using

the latest technology - with the aim of continuing

to make the products that customers want to buy.

Baxi Windermere RF

G.C.No 32 075 28

Baxi Windermere TF

G.C.No 32 075 29

Baxi is also the largest manufacturing partnership

in the country. Everyone who works at the

company has a commitment to quality because,

as shareholders, we know that satisfied

customers mean continued success.

We hope you get a satisfactory service from Baxi.

If not, please let us know.

Baxi is a BS-EN ISO 9001

Accredited Company

Page 3

Supplied By www.heating spares.co Tel. 0161 620 6677

Contents – Page 3

Section

Page

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

11.0

12.0

13.0

Introduction

Technical Data

Site Requirements

Installation

Arranging the Coals

Commissioning the Stove

Checking for Spillage

Completion

Annual Servicing

Changing Components

Fault Finding

Short Parts List

Propane Models

4

5

6

9

11

13

14

15

16

20

23

24

25

The following items are packed with the appliance:-

Literature

Controls Cover

Coal Pieces (Windermere 2 types)

(Grasmere 3 types)

Ceramic

Closure Plate (All RF models)

Coal Guard (Grasmere only)

Page 4

Supplied By www.heating spares.co Tel. 0161 620 6677

1.0 Introduction – Page 4

Notice

Discolouration of wall surfaces

Most heating appliances generate warm air convection currents

and transfer heat to any wall surface against which they are

situated.

Some soft furnishings (such as blown vinyl wallpapers) may not

be suitable for use where they are subject to temperatures

above normal room levels and the manufacturer’s advice should

be sought before using this type of wall covering adjacent to any

heating appliance.

The likelihood of wall staining from convected air currents will be

increased in environments where high levels of tobacco smoke

or other contaminants exist.

1.1 Description

1. The Baxi Windermere RF and TF and Grasmere RF and

TF are gas fired stove - style appliances with heat inputs of

8.17 kW (27,876 Btu/h) and 6.5 kW (22,178 Btu/h)

respectively at maximum setting. They are designed to be

used on Natural Gas only at a setting pressure of 20mbar

on an installation with a governed meter. The appliances

are intended for heating and decorative purposes.

2. For details of Propane appliances see section 13.0

Propane Models.

3. They incorporate a safety feature in the form of a spillage

monitoring system which must not be adjusted or

bypassed.

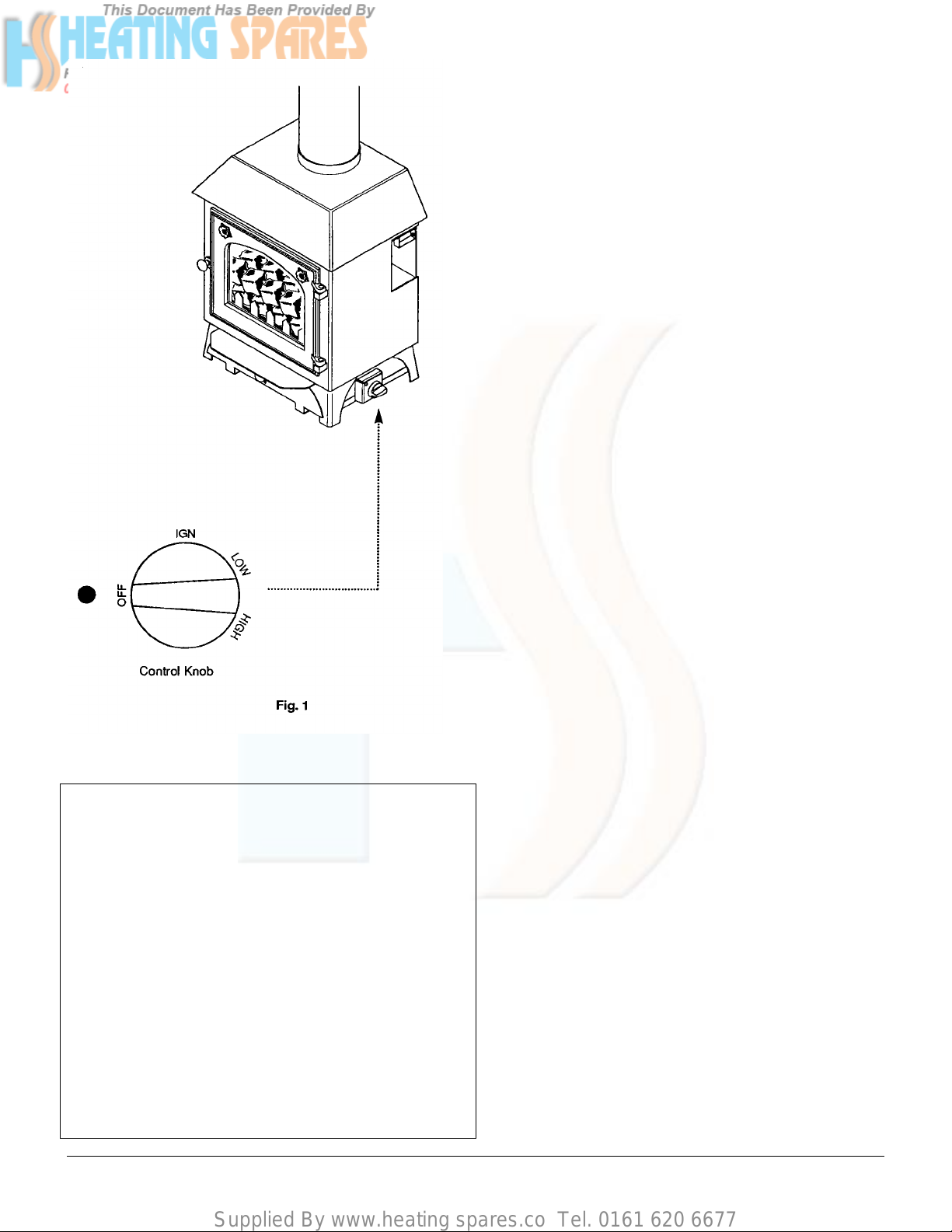

4. The stove is controlled by a knob which is positioned at the

lower right hand side of the appliance (Fig1). The knob has

four positions:

OFF IGN LOW HIGH

5. The pilot will be lit at IGN.

1.2 Installation

1. Prior to installation, ensure that the local distribution

condition (identification of the type of gas and pressure)

and the adjustment of the appliance are compatible.

2. The appliance is suitable for installation only in GB. and

I.E. and should be installed in accordance with the rules in

force. For Ireland install in accordance with l.S.813

“INSTALLATION OF GAS APPLIANCES”. The

installation must be carried out by a CORGI Registered

Installer or other competent person and be in accordance

with the relevant requirements of the current GAS

SAFETY (Installation and Use) REGULATIONS (as

amended), the BUILDING REGULATIONS issued by the

Department of the Environment, BUILDING STANDARDS

(Scotland) (Consolidation) REGULATIONS issued by the

Scottish Development Department and the LOCAL

BUILDING REGULATIONS. Where no specific

instructions are given, reference should be made to the

relevant BRITISH STANDARD CODES OF PRACTICE.

2. This appliance must be installed in accordance with

the manufacturers instructions and the rules in force

and only used in a suitably ventilated location.

3. Read the instructions before installing or using this

appliance.

1.3 Important Information

This product contains Refractory Ceramic Fibres (R.C.F.) which

are man-made vitreous silicate fibres. Excessive exposure to

these materials may cause temporary irritation to eyes, skin and

respiratory tract. Care must be taken when handling these

articles to ensure the release of dust or fibres is kept to a

minimum.

To ensure that the release of fibres from these articles is kept to

a minimum, during installation and servicing it is recommended

that a H.E.P.A. filtered vacuum is used to remove any dust, soot

or other debris accumulated in and around the appliance. This

should be performed before and after working on the

installation.

It is recommended that any replaced item(s) are not broken up

but sealed within heavy duty polythene bags and clearly labelled

“R.C.F. waste”. This is not classified as ‘hazardous waste” and

may be disposed of at a tipping site licensed for the disposal of

industrial waste.

Protective clothing is not required when handling these articles

but it is recommended that gloves are worn and the normal

hygiene rules of not smoking, eating or drinking in the work area

are followed and always wash hands before eating or drinking.

Page 5

Supplied By www.heating spares.co Tel. 0161 620 6677

2.0 Technical Data – Page 5

Grasmere Windermere

Category of Appliance I

2H

The stove is set for Gas Type G20 at 20mbar.

Category of Appliance I

2H

The stove is set for Gas Type G20 at 20mbar.

Heat Input High Low Heat Input High Low

kW 6.5 5 kW 8.17 5.6

Btu/h 22,178 17,060 Btu/h 27,876 19,107

Heat Output High Heat Output High

kW 4.96 kW 6.14

Btu/h 16,922 Btu/h 20,962

Inlet Setting Pressure Cold Inlet Setting Pressure Cold

mbar 9 ± 0.5 mbar 6.5 ± 0.5

in wg 3.6 ± 0.2 in wg 2.6 ± 0.2

Gas Connection 8mm OD tube, rigid or semi

rigid and 8mm compression

fitting at appliance inlet

Controls &

Safety system

Rotary gas tap with piezo

ignition to pilot.

Spillage monitoring system

Gas

Connection

Controls &

Safety system

8mm OD tube, rigid or semi rigid

and 8mm compression fitting at

appliance inlet

Rotary gas tap with piezo ignition

to pilot.

Spillage monitoring system

Gas Rate 0.63m3/h Gas Rate 0.80m3/h

(22.241 ft3/h) (24.01 ft3/h)

Lifting Weight RF TF Lifting Weight RF TF

38.2 kg 36.4 kg 54.1 kg 51.6 kg

Dimensions Height 555mm (RF) Dimensions Height 730mm (RF)

Height 580mm (TF) Height 758mm (TF)

Width 450mm Width 600mm

Depth 345mm Depth 410mm

Injector 82/600 Injector 82/850

B.S. Codes of Practice

STANDARD SCOPE

B.S. 5440: Pts 1 & 2 Flues & Air Supply.

B.S. 1251 Open Fireplace Components

B.S. 5871: Pt 2 & 3 Installation of inset live fuel effect &

B.S. 715 Specification for metal flue pipes,

B.S. 6391 Gas Installation.

B.S. 1289: Pts 1 & 2 Specification for precast & clay flues

decorative fuel effect appliances.

fittings etc.

and terminals.

Page 6

Supplied By www.heating spares.co Tel. 0161 620 6677

3.0 Site Requirements – Page 6

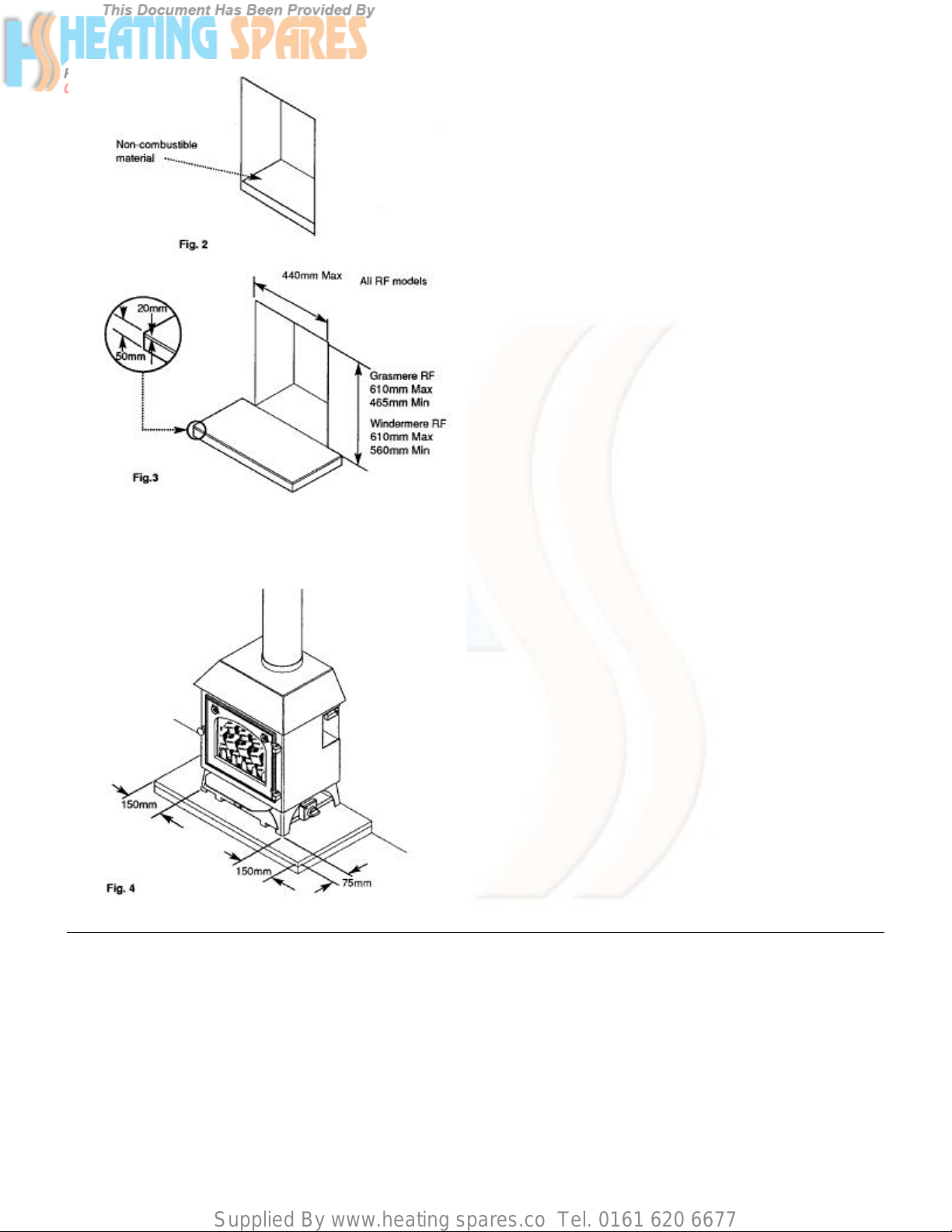

3.1 Fireplace Surround and Hearth

1. A hearth of non-combustible material must be provided

within the fireplace opening on which material the stove

stands (where applicable) (Fig. 2).

2. A non-combustible hearth must also be provided in

front of the fireplace opening. This must be a minimum

of 20mm thick, the top surface of the hearth should be

a minimum of 50mm above floor level (Fig. 3).

3. The hearth should extend at least 75mm in front of the

stove legs and 150mm either side of the stove (Fig. 4).

4. If a fire surround is to be used, it must have a minimum

rating of 300o C. Any gaps between the wall and

surround must be sealed.

5. On no account should the stove be fitted directly

onto a combustible floor or carpet.

3.2 Ventilation

Grasmere

1. No purpose provided ventilation is required for the

appliance, normal adventitious room ventilation being

sufficient.

Windermere

1. A permanent air vent of 100cm2 minimum is required.

The permanent vent may be directly into the room in

which the appliance is installed, or to an adjacent room

which has a vent to outside of at least the same area.

Page 7

Supplied By www.heating spares.co Tel. 0161 620 6677

3.0 Site Requirements – Page 7

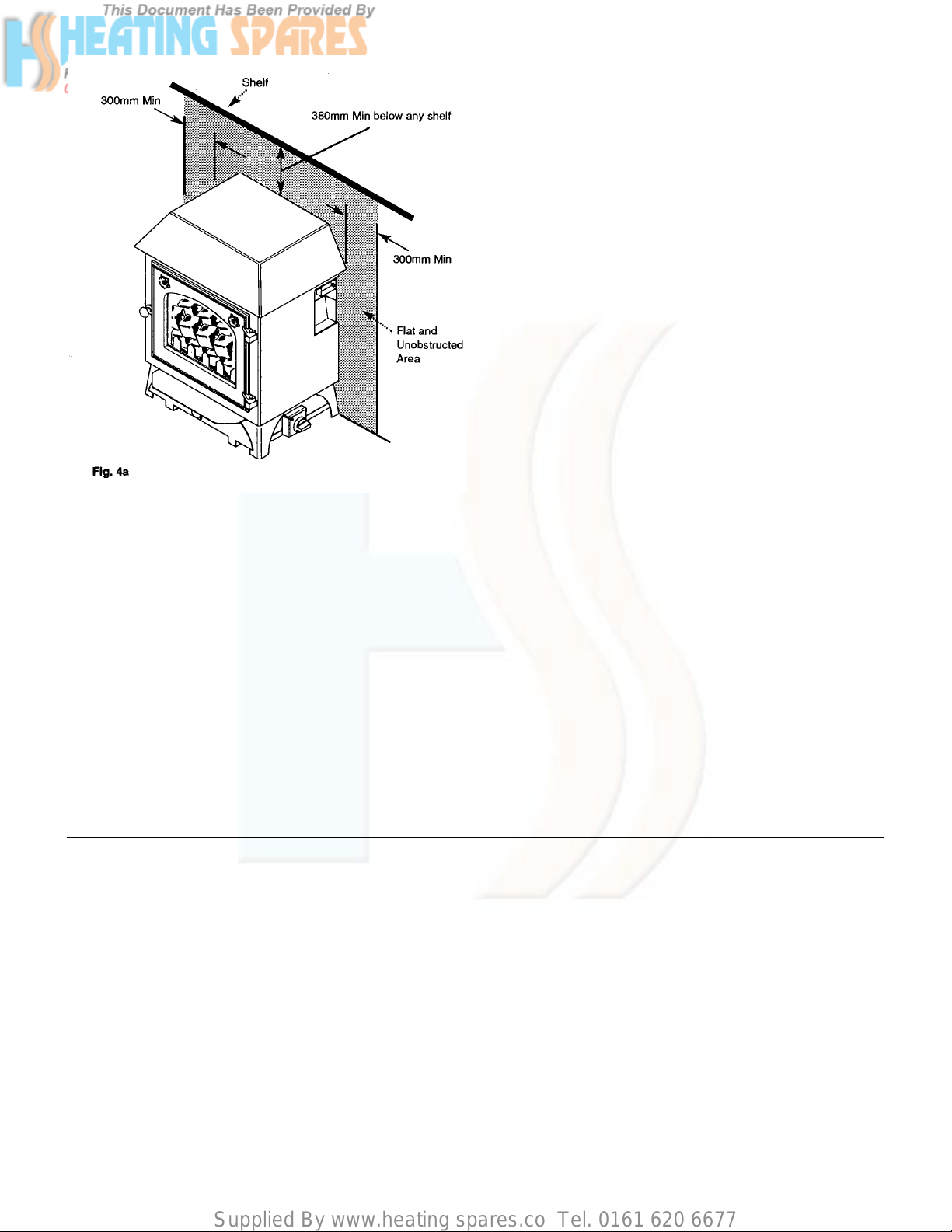

3.3 Clearances (Fig. 4a)

1. Any combustible material must be at least 300mm

away from the stove or flue pipe.

2. The wall or surround to each side of the stove must be

flat and unobstructed for at least 300mm.

3. Any shelf above the stove must be at least 300mm

away from the stove or flue pipe.

4. No curtains should be within 380mm of the stove or flue

pipe when they are in any position.

3.4 Flues

1. The chimney or flue system must be suitable for a

Class 1 or Class 2 appliance, as defined by the Building

Regulations.

2. It must have an internal diameter of minimum 125mm

or equivalent.

3. Generally brick or block built chimneys, pre-cast flues

or fabricated flues will meet these requirements.

4. The flue must be a minimum of 4m high, measured

from the hearth to the point of termination. The flue

must befitted with a suitable pot or cowl with an internal

diameter not less than 125mm.

5. Any obstructions, damper plates or flue restrictors must

be removed before installation.

6. If the flue is not sound or in good condition a liner of not

less than 125mm internal diameter and conforming to

BS 715 must be fitted.

7. The flue must be swept before installation and any

underfloor air supply beneath the stove sealed off.

8. It is essential that there is a positive pull up the flue or

chimney. If there is not, DO NOT fit the stove. Seek

expert advice before continuing with the installation.

Page 8

Supplied By www.heating spares.co Tel. 0161 620 6677

3.0 Site Requirements – Page 8

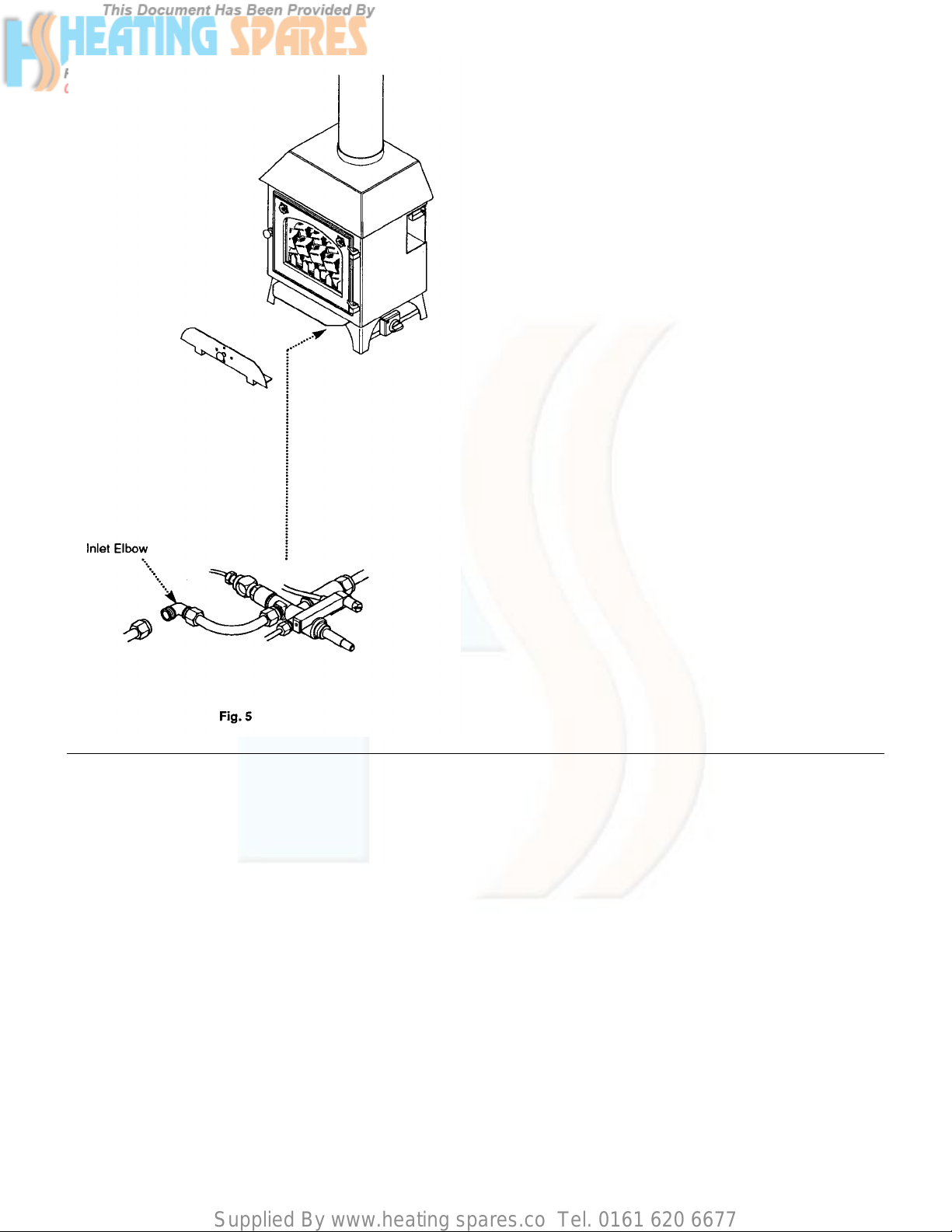

3.5 Gas Supply & Connection

1. Determine where the gas supply is to be connected to

the appliance. This may be done from either the left or

right side, from the front, or a concealed fitting from the

rear.

Turn off any appliances that are fed by the meter and

isolate the gas supply by turning off at the meter.

2. The inlet elbow of the stove will accept 8mm OD tubing

(Fig. 5).

3. A suitable isolating cock and disconnecting union

should be always be fitted in the supply feed to the fire

to facilitate servicing.

Page 9

Supplied By www.heating spares.co Tel. 0161 620 6677

4.0 Installation – Page 9

4.1 Initial Preparation

1. After unpacking the appliance, carefully remove all

items from inside the stove.

2. Care must be exercised when handling the appliance to

prevent damage to the paint finish. Avoid touching the

appliance with greasy or dirty hands

4.2 Top Flue Outlet Stoves

1. These models must be connected to the flue or

chimney with a suitable length of 125mm diameter

vitreous enamelled flue pipe fitted inside the spigot on

top of the stove.

2. The flue pipe must be fitted through a register plate of

fireproof material. All joints must be sealed.

4.3 Rear Flue Outlet Stoves (Fig. 6)

1. These models may be fitted to a builders opening, class

2 starter block or flue starter box, using the closure

plate supplied.

2. The closure plate must be sealed along all edges. No

air relief vent is necessary.

3. If necessary the closure plate can be cut down

providing the fireplace opening is fully covered.

4. A minimum clearance of 50mm is required between the

end of the flue spigot and rear face of the flue or

opening.

5. The rear of the stove must not touch the closure plate,

a gap of at least 15mm being required. The flue spigot

collar ensures this dimension.

Page 10

Supplied By www.heating spares.co Tel. 0161 620 6677

4.0 Installation – Page 10

4.4 Fitting the Stove

1. Position the stove in the installation, and in the case of

top flue outlet models, connect the flue pipe.

2. When positioning the stove, care must be exercised not

to mark the hearth.

3. Purge the gas supply and connect it to the stove inlet

elbow (Fig. 7). Check for gas soundness with leak

detection fluid (to BS 6891).

Page 11

Supplied By www.heating spares.co Tel. 0161 620 6677

5.0 Arranging the Coals – Page 11

5.1 Arranging the Coals

It is important that all the coals are used and arranged

as shown in order to achieve the desired flame picture.

CAUTION: The coals are extremely fragile and must be

handled accordingly. To avoid soiling ones hands,

gloves should be worn and any inhalation of the dust

should be avoided. Keep the coals away from children at

all times. Never use coals other than those supplied or

Genuine Baxi Spare Parts. Never put additional coals on

the stove. Please read section 1.3 Important Information.

5.2 Grasmere

1. Remove the coal guard (Fig. 8).

2. Carefully unpack the ceramic base (Fig. 9). Locate this

in the stove, resting on the two supports (Fig. 10 & 13).

3. Replace the coal guard (Fig. 10).

4. Three types of coal are supplied with the Grasmere, 13

small coals with location holes, 14 standard small coals

and 2 large coals.

5. Take the 13 small coals and locate them on the pegs

on the ceramic base (Fig. 11).

6. The two large coals should be placed between the

outer two coals on the back row and the ceramic

sidecheeks (Fig. 12).

7. Place the remaining 14 standard coals over the gaps

between the other small coals (Fig. 13).

8. Close the appliance door and secure it with the brass

knob (Fig. 14).

Page 12

Supplied By www.heating spares.co Tel. 0161 620 6677

5.0 Arranging the Coals – Page 12

5.3 Windermere

1. Carefully unpack the ceramic base and place it

centrally over the burner (Fig. 15).

2. Two types of coal are supplied with the Windermere, 24

small coals with location holes, 18 large coals.

3. Take the 24 small coals and locate them on the pegs

on the ceramic base (Fig. 16).

4. Place six of the large coals between the middle row and

back row and a further six between the middle and front

row (Fig. 17).

5. The final six large coals should be placed between the

door of the stove and the ceramic base (Fig. 18).

6. Close the appliance door and secure it with the brass

knob (Fig. 19).

5.4 Cleaning

1. Carefully clean the stove with a soft lint free duster or

cloth. DO NOT USE any abrasive cleaning agents,

solvents or similar when cleaning.

2. Clean any debris from around and underneath the

stove.

Page 13

Supplied By www.heating spares.co Tel. 0161 620 6677

6.0 Commissioning the Stove – Page 13

6.1 Checking Gas Soundness

1. Turn on the gas supply and check for gas soundness

with leak detection fluid (to BS 6891).

6.2 Checking Operation of the Stove

1. Remove the screw from the pressure test point on the

gas tap (adjacent to the control knob) and fit a pressure

gauge (Fig. 20).

2. Purge the air from the appliance by pushing in the

control knob and rotating to the ignition position (Fig.

21). Allow the air in the pipework to be purged, and

then rotate the knob further to operate the piezo igniter.

The pilot should light.

3. Once the pilot is established push the control knob in

and turn to the HIGH setting. Check the setting

pressure. (Setting pressure detail found in Section 2.0

Technical Data.)

4. Turn the control knob to the OFF position, disconnect

the pressure gauge and refit the pressure test point

sealing screw.

6.3 Spillage Monitoring Device (Fig. 22)

1 The stove incorporates a spillage monitoring device.

This will cut off the gas supply in the event of spillage of

combustion products into the room.

2. In the event of this occuring there is a reset procedure.

Wait for 10 minutes before trying to reset the stove.

3. Unscrew the cap off the reset device and press in the

red button with a small screwdriver or similar

instrument.

4. Relight the stove as previously described. If this is not

possible, wait a further 5 minutes before pressing the

red button. If this fails, wait until the stove is completely

cool and reset it.

5. If the stove cannot be re-set or the spillage monitoring

device is frequently activated the flue condition must be

investigated.

WARNING: The spillage monitoring device must not be

adjusted in any way. The spillage monitoring device

must not be altered so that it will not operate or be

bypassed in any way. Only use genuine Baxi spare

parts.

Page 14

Supplied By www.heating spares.co Tel. 0161 620 6677

7.0 Checking for Spillage – Page 14

7.1 Checking for Spillage

CAUTION - Whilst checking for spillage care must be

taken to avoid touching hot panels.

1. Before starting the test, close all doors and windows.

2. Operate the stove from cold at maximum input.

3. After approximately 5 minutes check for spillage.

4. Insert a lighted smoke match in the draught diverter at

the left hand side. The match should be positioned

35mm from the top edge of the diverter (Fig. 23). All the

smoke should be drawn into the diverter. If not, wait a

further 5 minutes and repeat the test.

5. If the test is successful repeat with any extractor fan on.

If a connected room has an extractor fan, the test

should be repeated with this fan on and any connecting

doors open.

6. If spillage occurs and the problem cannot be rectified

the stove must be isolated until the problem is resolved.

7.2 Possible causes of Spillage

1. The smoke match may have been positioned

incorrectly, resulting in the smoke being picked up by

hot convected air currents.

2. The flue installation may be unsound.

3. Down draughts may be present.

4. Flue blockages.

5. Rear flue - closure plate not sealed, stove not close

enough to closure plate.

6. Top flue – flue pipe not sealed to stove spigot.

Page 15

Supplied By www.heating spares.co Tel. 0161 620 6677

8.0 Completion – Page 15

8.1 Completion

1. Unpack the controls cover and place it centrally

underneath the stove (Fig. 24).

2. These instructions and the users instructions should be

handed to the customer. At the same time the customer

should be shown how to operate the stove safely and

efficiently.

3. The need for annual servicing should be emphasised

and the returning of the guarantee card advised.

Page 16

Supplied By www.heating spares.co Tel. 0161 620 6677

9.0 Annual Servicing – page 16

9.1 Maintenance

IMPORTANT: It is possible that some soot may be

deposited on the coals after use. This is acceptable

providing it is not allowed to accumulate.

CAUTION: The coals are extremely fragile and must be

handled accordingly. To avoid soiling ones hands,

gloves should be worn and any inhalation of the dust

should be avoided. Keep the coals away from children at

all times. Never use coals other than those supplied or

Genuine Baxi Spare Parts. Never put additional coals on

the stove. Please read section 1.3 Important Information.

1. Servicing should be carried out regularly by a

competent person in accordance with the relevant

regulations, to ensure the safe and correct operation of

the appliance.

2. Before commencing any service or replacement of

parts, turn off the gas supply to the stove and ensure

that the stove is cold.

3. After servicing, check for gas soundness.

4. When ordering spare parts please quote appliance

name and serial number. These can be found on the

data badge which is located by removing the controls

cover (Fig. 25). The badge is behind the cover and

fixed to the burner.

5. At least once a year check for debris in the catchment

area behind the stove (RF models) and in the flueway.

6. If soot has accumulated in the flue or catchment area,

check to establish the cause. Rectify and clean flue or

chimney accordingly.

7. The coals may be removed for cleaning. The coals are

delicate and should be handled carefully. Gently brush

with a soft brush to remove dust or deposits.

8. Examine the coals for signs of cracking and replace if

necessary.

IMPORTANT: See coal layout procedure

(Section 5.0 Arranging the Coals) before attempting to

replace coals.

9. Do not clean pilot jet or injectors using pins or wire.

Page 17

Supplied By www.heating spares.co Tel. 0161 620 6677

9.0 Annual Servicing – Page 17

9.2 Preparation

1. For reasons of safety and economy it is important to

service the stove annually.

WARNING: Isolate the gas supply to the appliance

before servicing.

2. For Grasmere models see section 9.3 Grasmere.

3. For Windermere models see section 9.4 Windermere.

9.3 Grasmere

1. Unscrew the brass door knob and open the door (Fig.

26).

2. Remove the coal guard (Fig. 27) and remove all the

coals.

3. Manoeuvre the ceramic base (Fig. 28) out of the stove

and place carefully to one side.

4. Remove the two sidecheeks, noting their orientation

(Fig. 29).

5. Undo the screw and nut retaining the pilot shield

bracket and remove the bracket (Fig. 30).

6. Undo the disconnecting union on the gas supply.

7. Pull the control knob off the tap and undo the screw

retaining the plate (Fig. 31).

8. Undo the brass locknut holding the tap to the mounting

bracket (Fig. 31).

9. Undo the screw and remove the data badge plate (Fig.

32).

10. Disconnect the two leads from the spillage monitoring

device (Fig. 33).

11. Carefully manoeuvre the burner/controls assembly out

of the stove (Fig. 32).

Page 18

Supplied By www.heating spares.co Tel. 0161 620 6677

9.0 Annual Servicing – Page 18

9.4 Windermere

1. Unscrew the brass knob and open the door (Fig. 34).

2. Remove all the coals and manoeuvre the ceramic base

out of the stove and place carefully to one side (Fig. 35

& 36).

3. Undo the disconnecting union on the gas supply.

4. Pull the control knob off the tap and undo the screw

retaining the plate (Fig. 38).

5. Undo the brass locknut holding the tap to the mounting

bracket (Fig. 38).

6. Disconnect the two leads from the spillage monitoring

device (Fig. 39).

7. Carefully manoeuvre the burner/controls assembly out

of the stove (Fig. 40).

Page 19

Supplied By www.heating spares.co Tel. 0161 620 6677

9.0 Annual Servicing – Page 19

9.5 Cleaning the Pilot (Fig. 41)

1. Undo the feed pipe from the pilot injector and pull the

lead off the ignition electrode.

2. Undo the two screws holding the pilot assembly

retaining plate. Remove the plate and withdraw the

electrode and pilot burner. Note the orientation of the

pilot burner outlet ports.

3. Pull the pilot injector from the burner and clean

carefully. Do not use pins or wires

4. Clean the pilot burner and electrode.

9.6 Cleaning the Burner and Injector

(Fig. 42)

1. Undo the screw retaining the injector cover to the

injector mounting plate and remove the cover. Undo the

nut on the injector feed pipe at the injector.

2. Remove the two screws securing the injector mounting

plate to the burner and undo the locknut retaining the

injector to the plate.

3. Carefully clean the injector with a soft brush.

4. Carefully brush the burner and ceramic inlays. Care

must be taken not to damage the inlays.

9.7 Completing Servicing

1. Examine the thermocouple and replace if necessary

(Fig. 41).

2. Clean any dirt and debris from the combustion box,

builders opening and the hearth under the stove.

Please read section 1.3 Important Information.

3. Reassemble the stove in reverse order of dismantling.

On RF models reseal the closure plate and reposition

the stove at least 15mm away from the plate.

4. Recommission the stove as described in section 6.0

Commissioning the Stove.

Page 20

Supplied By www.heating spares.co Tel. 0161 620 6677

10.0 Changing Components – Page 20

10.1 Changing Components

WARNING: Before changing any components, ensure

that the stove is cool and that the gas supply is isolated.

10.2 Spillage Monitoring Device

(Figs. 43 & 44)

1. Undo the nut and screw holding the monitoring device

sensor bracket to the draught diverter.

2. Withdraw the sensor from the bracket.

3. Pull the two wires off the sensor body and undo the

screws holding the body to the appliance.

4. Remove the spillage monitoring device from the

appliance.

5. Refit the new device in reverse order, carefully routing

the capillary so as it does not touch any hot panels.

WARNING: The spillage monitoring device must not be

adjusted in any way. The spillage monitoring device

must not be altered so that it will not operate or be

bypassed in any way. Always use a Genuine Baxi Spare

Part.

TO CHANGE ANY GAS CONTROL COMPONENTS. IT IS

NECESSARY TO REMOVE THE COMPLETE CONTROLS

ASSEMBLY. SEE SUB-SECTION 9.2 PREPARATION OF

9.0 ANNUAL SERVICING

Page 21

Supplied By www.heating spares.co Tel. 0161 620 6677

10.0 Changing Components – Page 21

10.3 Gas Tap, Igniter and FFD

NOTE: The tap incorporates a flow setting device on its

outlet connection. This is factory set and must not be

adjusted.

1. Pull the electrode lead off the electrode (Fig. 45).

2. Undo the thermocouple nut from the interrupter unit and

pull off the two leads (Fig. 46).

3. Undo the pilot feed nut and the gas inlet and outlet nuts

from the tap assembly (Fig. 46).

4. Note the orientation of all the pipes and remove them.

5. Remove the gas tap (Fig. 46).

6. Remove the interrupter unit from the gas tap (Fig. 46).

7. Refit in reverse order of dismantling, ensuring that the

thermocouple nut is done up tight in the interrupter unit.

10.4 Injector (Fig. 47)

1. Undo the screw retaining the injector cover to the

injector mounting plate and remove the cover.

2. Undo the nut on the injector feed pipe at the injector.

3. Remove the two screws securing the injector mounting

plate to the burner and undo the locknut retaining the

injector to the plate.

4. Fit the new component and reassemble in reverse

order of dismantling.

Page 22

Supplied By www.heating spares.co Tel. 0161 620 6677

10.0 Changing Components – Page 22

10.5 Electrode (Fig. 48)

1. Pull the lead off the electrode and undo the two screws

holding the pilot retaining plate.

2. Note the orientation of the electrode, withdraw it and

refit the new component in reverse order of dismantling.

10.6 Thermocouple (Figs. 48 & 49)

1. Undo the thermocouple nut from the interrupter unit and

remove the two screws holding the pilot retaining plate.

2. Remove the thermocouple and shape the new one in a

similar manner to the original.

3. Fit the new component in reverse order of dismantling.

10.7 Pilot Burner and Injector (Fig. 48)

1. Undo the pilot feed pipe nut from the pilot injector.

2. Undo the two screws holding the pilot assembly

retaining plate, noting the orientation of the pilot burner

outlet ports.

3. Withdraw the pilot injector and burner. The injector can

now be removed from the burner.

4. Replace either or both components as required and

reassembly in reverse order of dismantling.

10.8 Burner (Fig. 50)

1. Remove all other control components as described in

sections 10.3 through to 10.7.

2. Fit all the previously removed control components to

the new burner.

3. Reassemble all components in reverse order and

recommission the appliance.

Page 23

Supplied By www.heating spares.co Tel. 0161 620 6677

11.0 Fault Finding – Page 23

11.1 Fault Finding

Page 24

Supplied By www.heating spares.co Tel. 0161 620 6677

12.0 Short Parts List – Page 24

12.1 Short Parts List

Key

No.

G.C. No

Description

Manuf ’s

Part No.

19a

16

39

35

20/23

28

22

25/29

47

42

45

41

46

44

3

2

9

10

39/43

E37 444

E39 307

E37 468

E39 314

E37 448

E37 452

E39 310

E37 450

E37 475

E39 327

E37 473

E39 326

E37 474

E37 472

E37 425

E37 424

E37 433

E39 300

E37 471

Main Burner - Grasmere

Main Burner – Windermere

Gas Tap-inc. Lead – Grasmere

Gas Tap-inc. Lead - Windermere

Pilot Burner Kit

Main Injector - Grasmere

Main Injector – Windermere

Spillage Monitoring Device

Burner Inlays - Grasmere

Burner Inlays - Windermere

Base - Grasmere

Base - Windermere

Kit- Coals - Grasmere

Side Cheeks - Grasmere

Rear Ceramic - Grasmere

Top Ceramic - Grasmere

Door Glass Kit - Grasmere

Door Glass Kit - Windermere

Control Knob

242675

242676

242677

242678

242679

242681

242682

242683

242684

242685

242686

242687

242690

242691

242692

242693

242694

242695

242696

4/7

19/22

18/21

40

E37 431

E37 447

E37 445

E39 324

Brass Door Knob

Thermocouple - Stove

Electrode - Stove

Kit -Loose Coals - Windermere

242697

242698

242699

242700

Page 25

Supplied By www.heating spares.co Tel. 0161 620 6677

13.0 Propane Models – Page 25

13.1 Windermere Propane Models

1. Most aspects of the Propane Models are the same

as Natural Gas, with the exception of the following:

The gas type is G31 (Propane)

The supply pressure is 37mbar

(Max) Heat Input 7.5kW (25,590 Btu/h)

(Min) Heat Input 5.2kw (17,742 Btu/h)

(Max) Heat Output 5.6kw (19,116 Btu/h)

Burner Pressure 28.5mbar (11.4 in wg)

2. The following spares components differ from natural

gas models:

Injector 242704

Ceramic burner inlay 242705

Burner 242706

Pilot Injector 242707

3. This appliance is designed for use on Propane

and must not be used with any other gas.

Click here for Helplines

Loading...

Loading...