Page 1

Supplied By www.heating spares.co Tel. 0161 620 6677

Please leave these Instructions with the User

Baxi Genesis

Gas Fired Wall Mounted Combination Boiler

Natural Gas, Propane & Butane

Comp No. 236463 - 10/96

Baxi Genesis 80 – G.C.No 47 077 01

Baxi Genesis 96 – G.C.No 47 077 02

Installation

and

Servicing

Instructions

Page 2

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Baxi Heating Ltd is one of the leading manufacturers of

domestic heating products in the U.K.

Our first priority is to give a high quality service to our

customers. Quality is built into every Baxi product -products

which fulfil the demands and needs of consumers, offering

choice, efficiency and reliability.

To keep ahead of changing trends, we have made a

commitment to develop new ideas using the latest

technology - with the aim of continuing to make the products

that customers want to buy.

Baxi is also the largest manufacturing partnership in the

country. Everyone who works at the company has a

commitment to quality because, as shareholders, we know

that satisfied customers mean continued success.

We hope you get a satisfactory service from Baxi. If not,

please let us know

Baxi is a BS-EN ISO 9002 Accredited Company

Page 3

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Contents – Page 3

Introduction

General Layout

Appliance Operation

Technical Data

General Dimensions & Fixings

System Details

Site Requirements

Installation

PAGE 4

PAGE 5

PAGE 6

PAGE 7-8

PAGE 9

PAGE 10-12

Central Heating circuit

Bypass

System Control

System Filling & Pressurising

Pressure Vessel

Pressure Relief Valve

Domestic Hot Water Circuit

Showers

Hard Water Areas

PAGE 13-16

B.S. Codes of Practice

Clearances

Location

Ventilation of Compartments

Gas Supply

Electrical Supply

Flue

Terminal Guard

PAGE 17-24

Initial Preparation

Flushing

Preparing the Boiler

Fitting the Boiler

Fitting the Flue

Making the Electrical Connections

Commissioning the Appliance

Servicing The Appliance

Changing Components

Fault Finding

Short Parts List

PAGE 26

PAGE 27

PAGE 28-41

Pressure Switch

Fan

Gas Valve Solenoids

Domestic Hot Water Heat Exchanger

Heat Exchanger

Pump

PCB & Spark Generator

Thermistors

Safety Thermostat

Expansion Vessel

Pressure Relief Valve

Pressure Gauge

Flow Switches

Flame Sensing Probe

Spark Electrode

Injector Manifold

3-Way Valve

Water Filters

Automatic Air Vent

Flow Regulator

PAGE 42-50

PAGE 51

Page 4

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Introduction – Page 4

Description

The Baxi Genesis is a fully automatic gas fired wall mounted

combination boiler. It is room sealed and fan assisted, and

will serve central heating and mains fed domestic hot water.

Genesis 80

The boiler is preset to give a maximum output of 23.25 kW

(79,347 Btu/hr) for both hot water and central heating

modes.

Genesis 96

The boiler is preset to give a maximum output of 28.0 kW

(95,555 Btu/hr) for both hot water and central heating

modes.

It is designed for use on natural gas (G20). Using the

conversion kit it can be used on LPG (Propane G31 or

Butane G30).

The boiler is suitable for use only on fully pumped sealed

heating systems. Priority is given to domestic hot water.

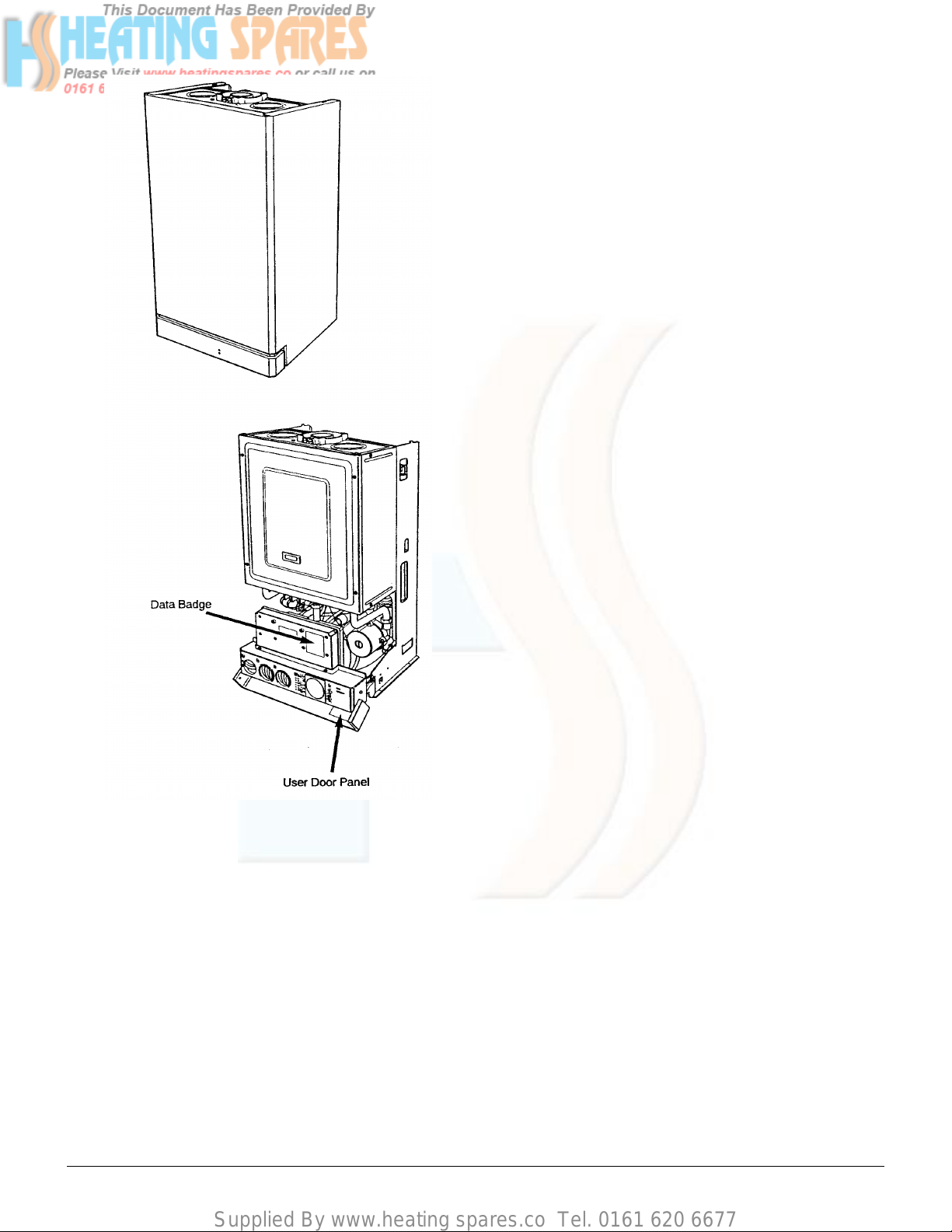

The appliance data badge is positioned on the electrical box

behind the outer case.

A label on the user door panel gives details of the model,

serial number and Gas Council number.

Optional Extras

KIT PART No

Flue extension 1 M (Use two kits for 2M etc.) 236439

Flue Extension 0.25M 238605

Flue Extension 0.5M 238604

DHW Expansion Vessel Kit 238395

Wall liner/internal fixing 236441

Programmable room thermostat 24 hr. 236254

Programmable room thermostat 7 day 238326

Integral 7 day Electronic Timer Kit 238399

Integral 12 hr. AM/PM 8ectro-Mechanical

Timer Kit 238398

80 LPG Conversion - Propane & Butane 235983

96 LPG Conversion - Propane & Butane 237474

Flue bend - 45º 236467

Flue bend - 90º 236466

Vertical Flue Equipment See Installer’s Guide or Notes For Guidance

Page 5

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

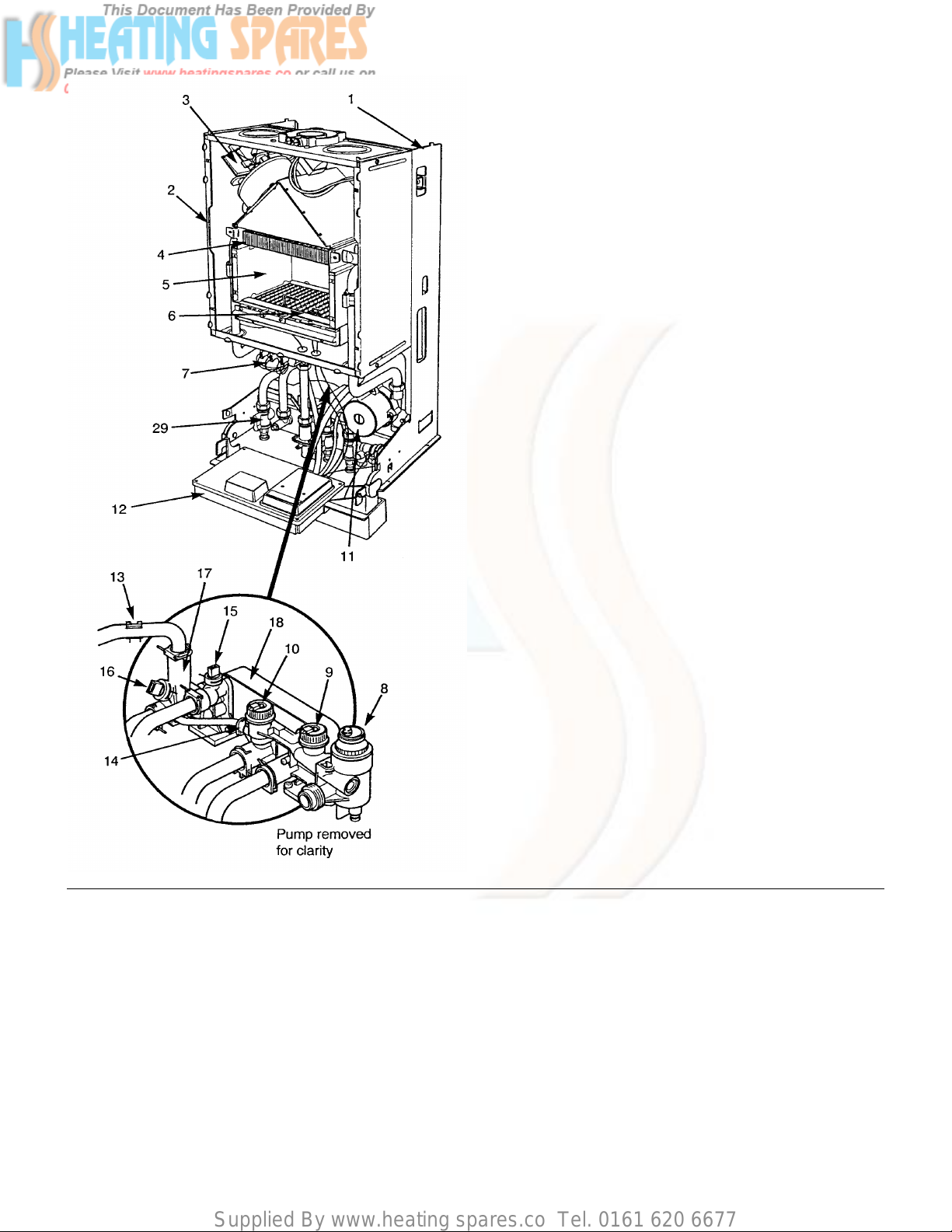

General Layout – Page 5

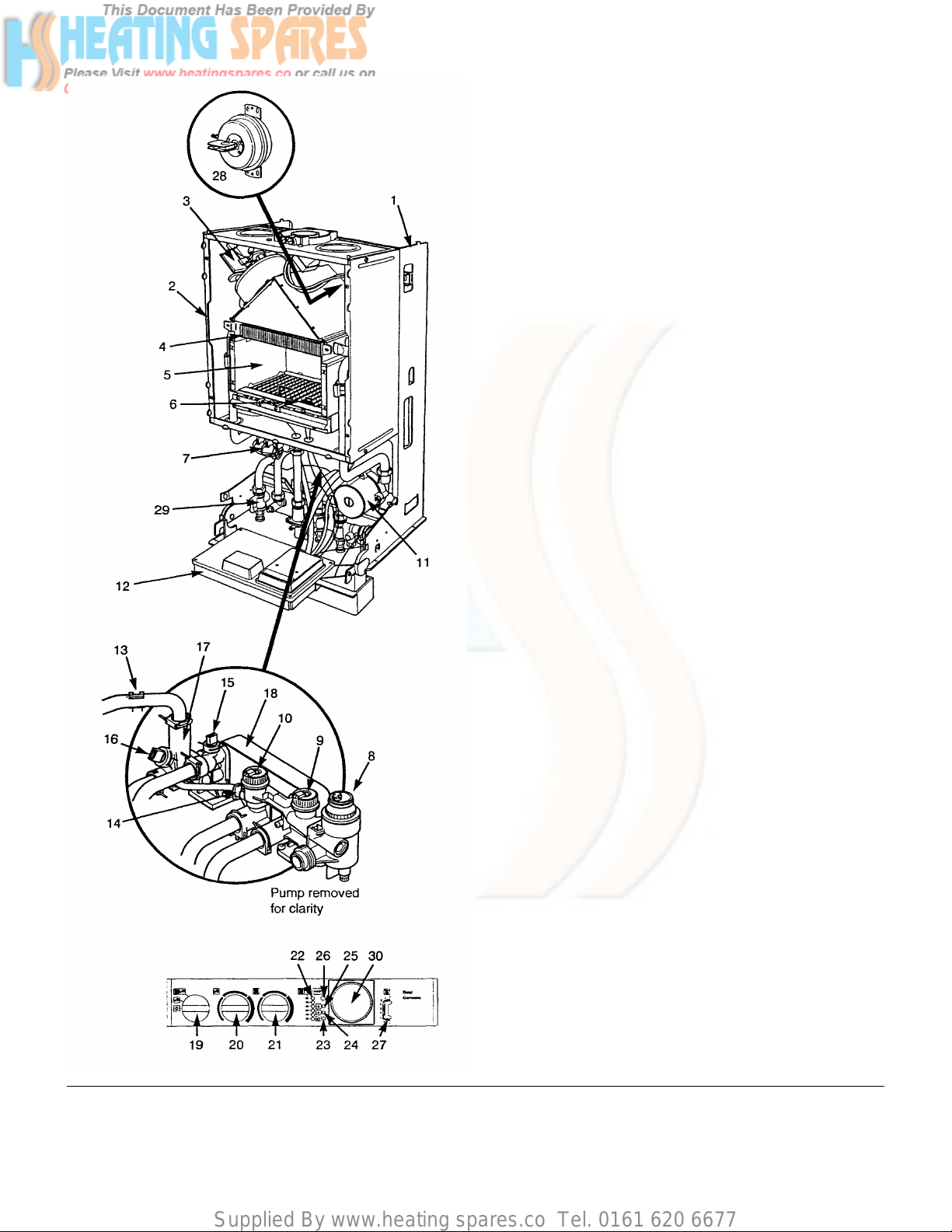

1 Chassis with Expansion Vessel

2 Combustion Box

3 Fan Assembly

4 Primary Heat Exchanger

5 Combustion Chamber

6 Burner Assembly and Electrodes

7 Gas Valve Assembly

8 Automatic Air Seperator and Vent

9 Flow Switch Heating Circuit

10 Flow Switch DHW Circuit

11 Circulation Pump

12 Electrical Box

13 Safety Thermostat

14 By-Pass Valve

15 DHW Thermostat Sensor

16 CH Thermostat Sensor

17 Three Way Valve

18 DHW Plate Heat Exchanger

19 Selector Switch On-Off

20 DHW Temperature Adjustment

21 Heating Temperature Adjustment

22 Heating Temperature Indicator

23 Green Light - Power On

24 Orange Light - Boiler On

25 Red Light - Flame Failure

26 Flame Failure Reset Button

27 Pressure Gauge

28 Pressure Switch

29 Isolating Valves

30 Optional Integral Timers

Page 6

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

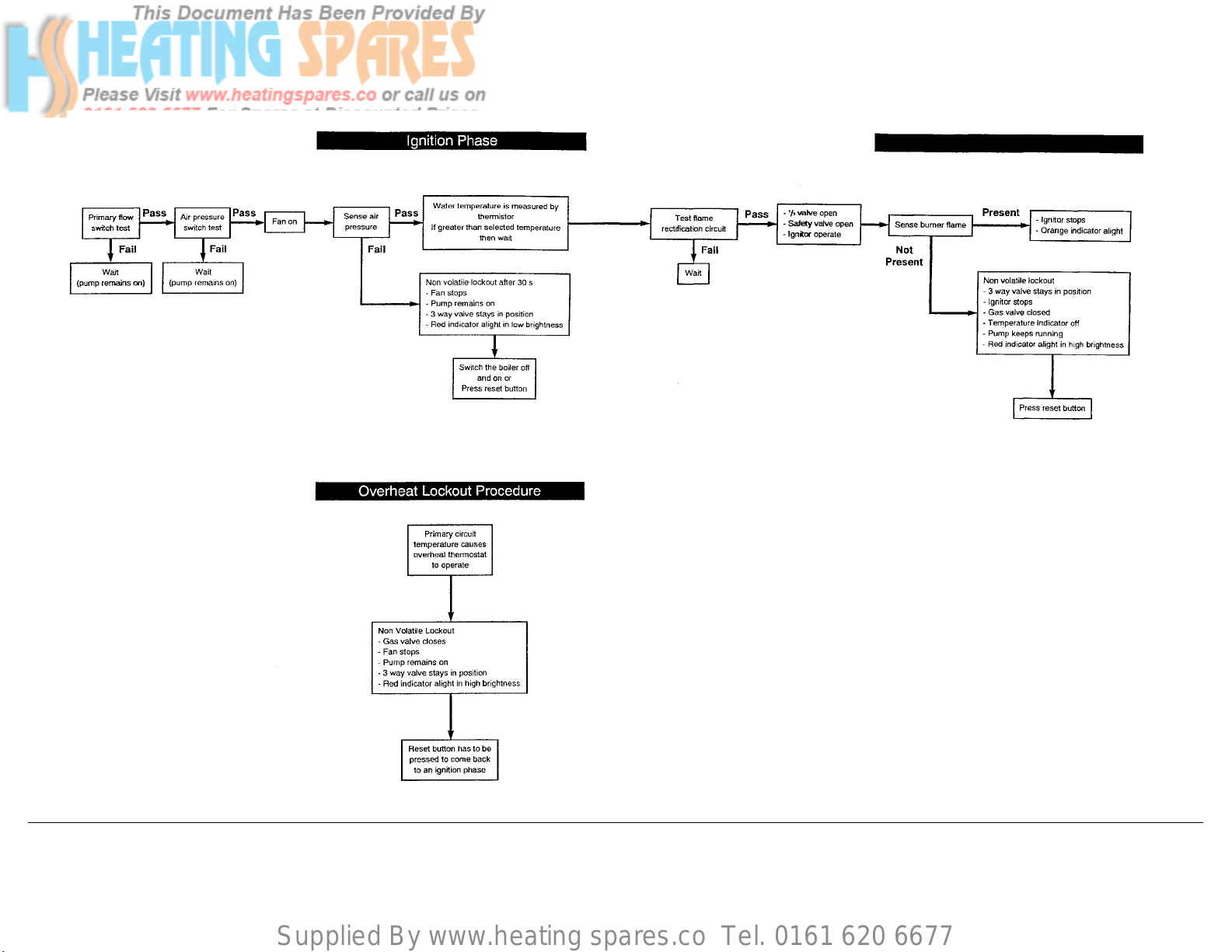

Appliance Operation – Page 6

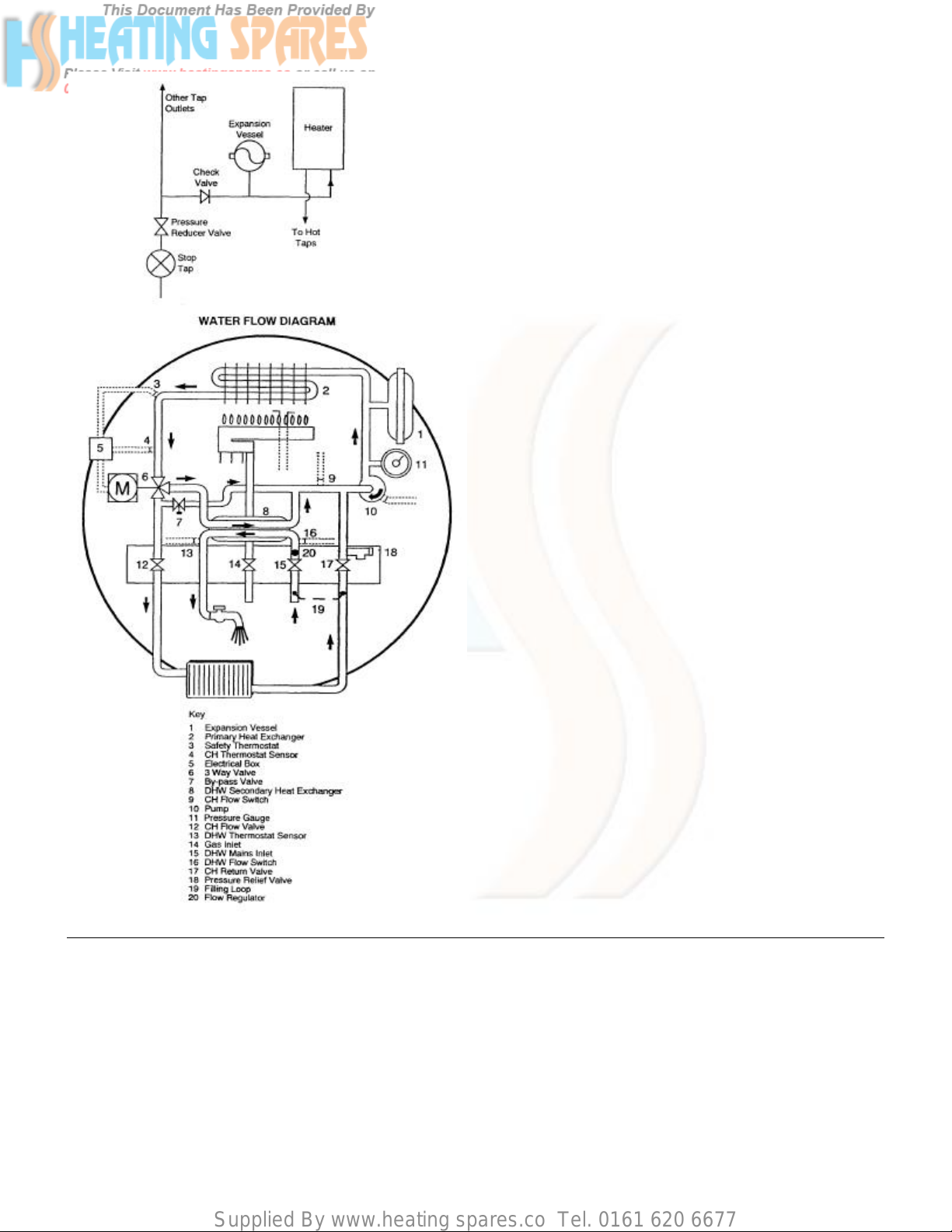

CENTRAL HEATING MODE

With a demand for heating the pump (11) circulates water

through the primary circuit. At a flow rate of approximately

250 I/hr the central heating flow switch (9) operates,

commencing the ignition sequence.

The main burner (6) ignites at 1/3 rate then switches to full

gas rate. The gas valve (7) controls the gas rate “HIGH LOW” to maintain the heating temperature measured by the

thermostat sensor (16).

When demand is satisfied the burner is extinguished, the

pump continues to run. The duration of each OFF cycle is 3

minutes before re-lighting automatically. Each ON cycle

commences with a 45 second duration at third gas rate

before switching to full rate if necessary.

On completion of a heating period the pump will continue to

run for a period of 3 minutes (PUMP OVERRUN).

DOMESTIC HOT WATER MODE

Priority is given to hot water supply. A demand at a tap or

shower will override any central heating requirement.

The flow of cold water will operate the DHW flow switch (10)

which requests the 3 way valve (17) to change position to

allow the pump (11) to circulate the primary water through

the secondary DHW heat exchanger (18).

The appliance-will light automatically and the temperature of

the domestic water is controlled by the thermostat sensor

(15).

When the hot water demand ceases the burner will

extinguish and for a period of 3 minutes the appliance

remains ready in the DHW mode before returning to the

central heating mode.

Page 7

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

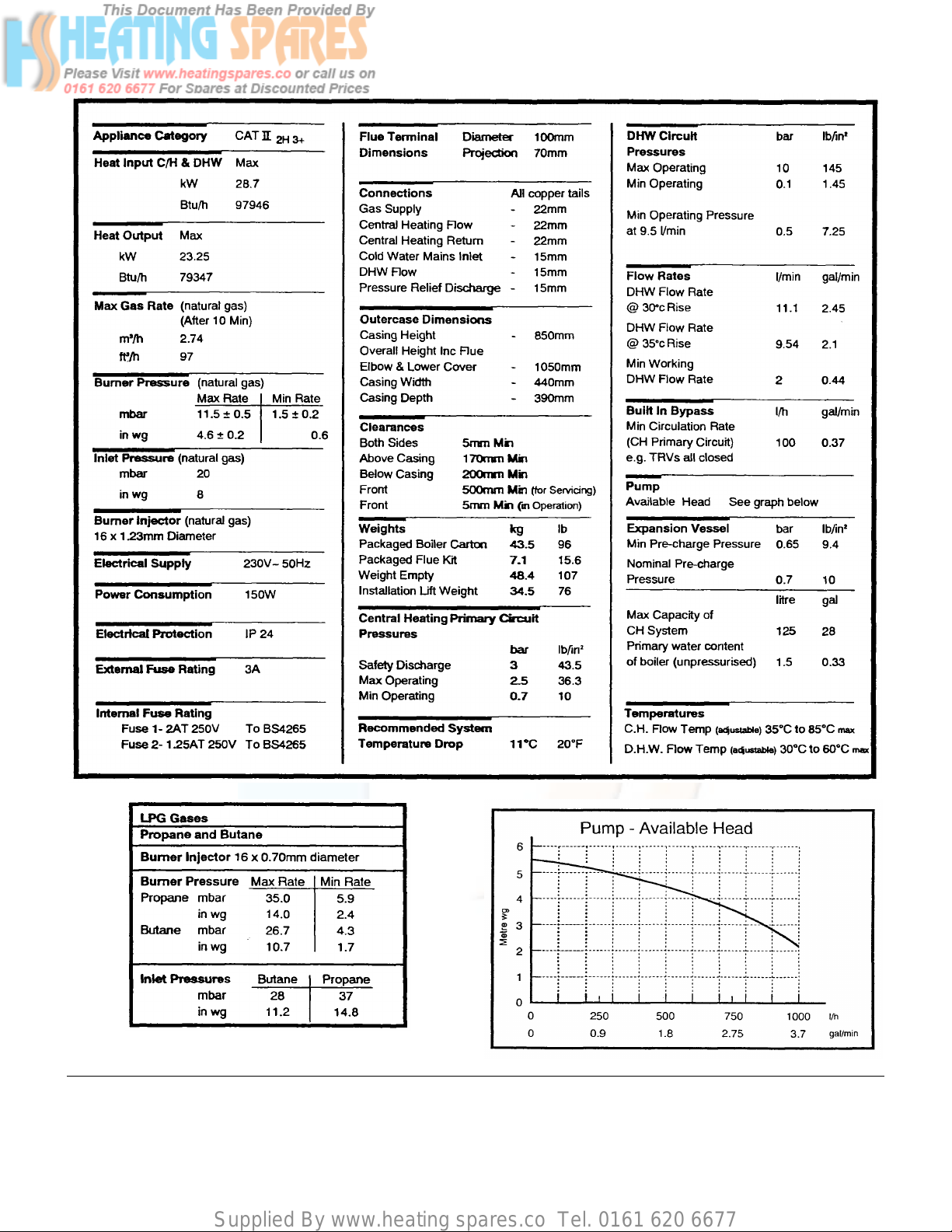

Technical Data – Page 7

GENESIS 80

Page 8

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

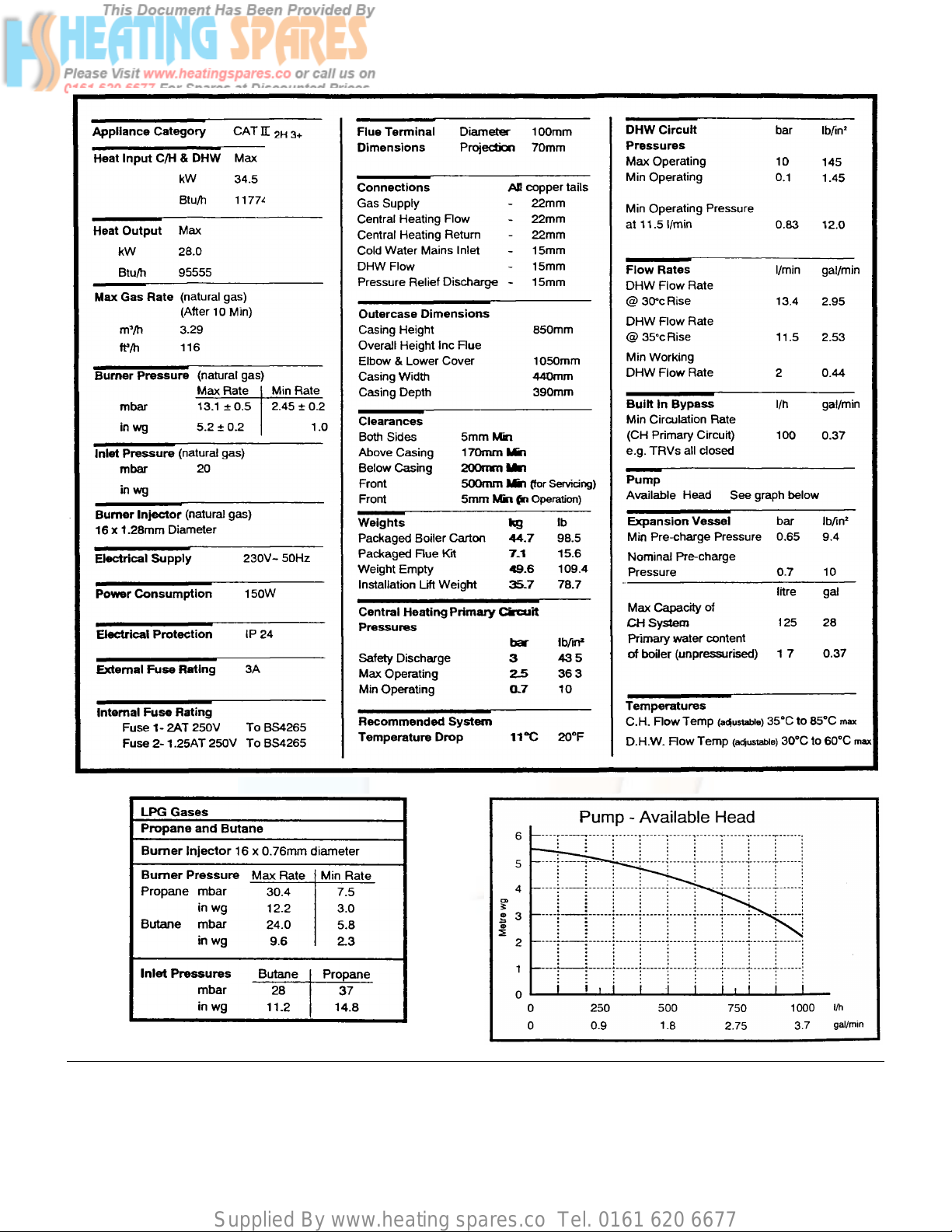

Technical Data – Page 8

GENESIS 96

Page 9

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

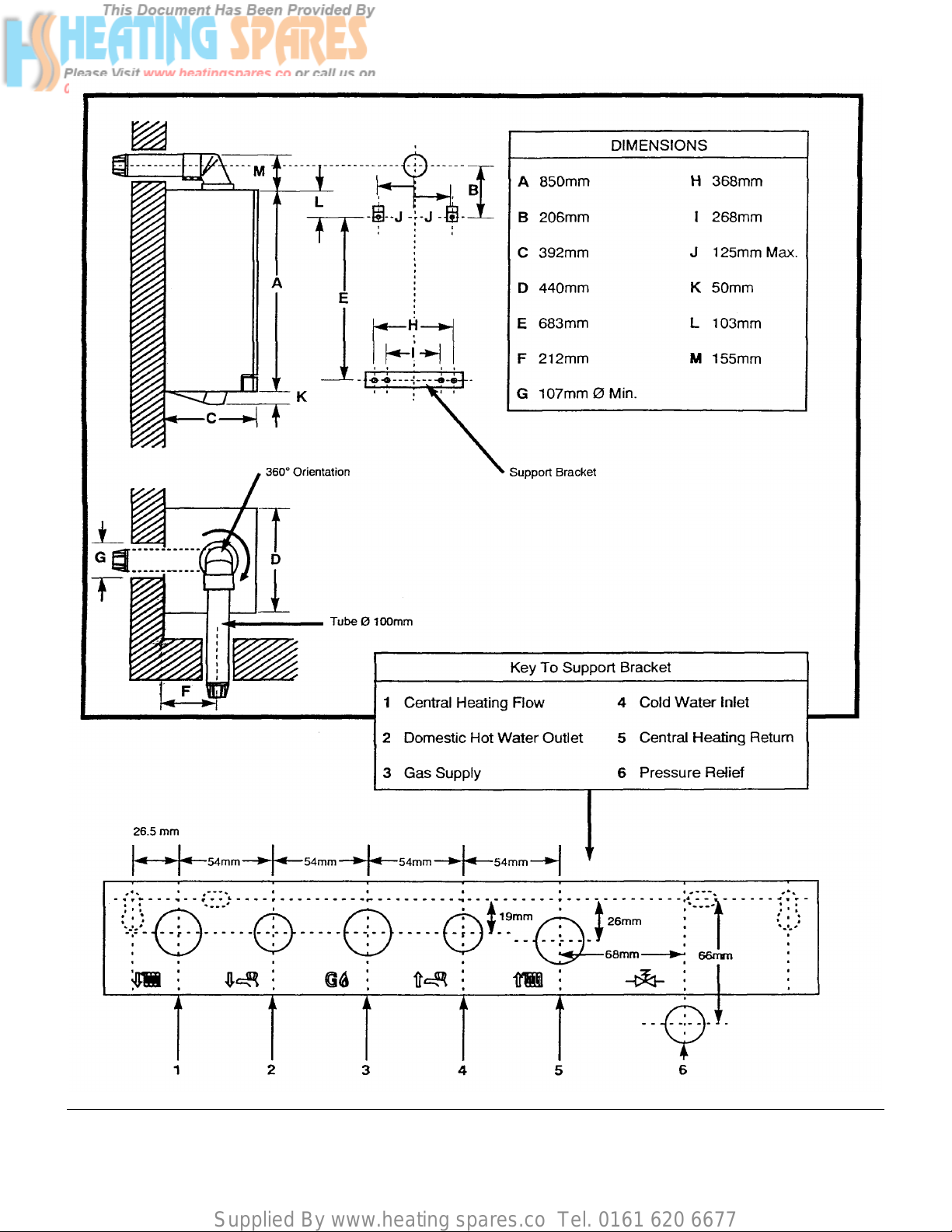

General Dimensions and Fixings – Page 9

Page 10

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

System Details – Page 10

The Genesis Combination Boiler is a ‘Water Byelaws

Scheme - Approved Product’.

To comply with the Water Byelaws your attention is

drawn to the following installation requirements and

notes (IRN).

1) IRN 001 - See text of entry for installation requirements

and notes.

2) IRN 116- Byelaw 90 and 91.

3) IAN 302 - Byelaw 14.

Reference to the WRc publications, ‘Water fittings and

materials directory’ and ‘Water supply byelaws guide’ give

full details of byelaws and the IRNs.

Central Heating Circuit

The appliance is suitable for fully pumped SEALED

SYSTEMS ONLY.

All systems should be thoroughly flushed prior to

connection of the appliance. If the installation is on an

existing sealed system, or a modified open system, it is

particularly important to flush preferably using an

appropriate descaling/flushing agent.

Where used, corrosion inhibitors, flushing agents/descalers

should be approved and suitable for all system metals.

BYPASS

The appliance has an integral pre-set bypass, therefore no

external bypass on the system is required. TRV’s can be used on all radiators.

SYSTEM CONTROL

Operation of the system under control of the boiler

thermostat only does not produce the best results. The

heating system should include a control system. This should

comprise of at least a single channel timer.

Integral Single Channel Timer Kits are available as optional

extras.

For optimum operating conditions and best economy the

fitting of a programmable thermostat is recommended.

Programmable thermostats - the ‘Baxi Genesis

Controllers’ are available as an optional extra.

Page 11

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

SYSTEM DETAILS – Page 11

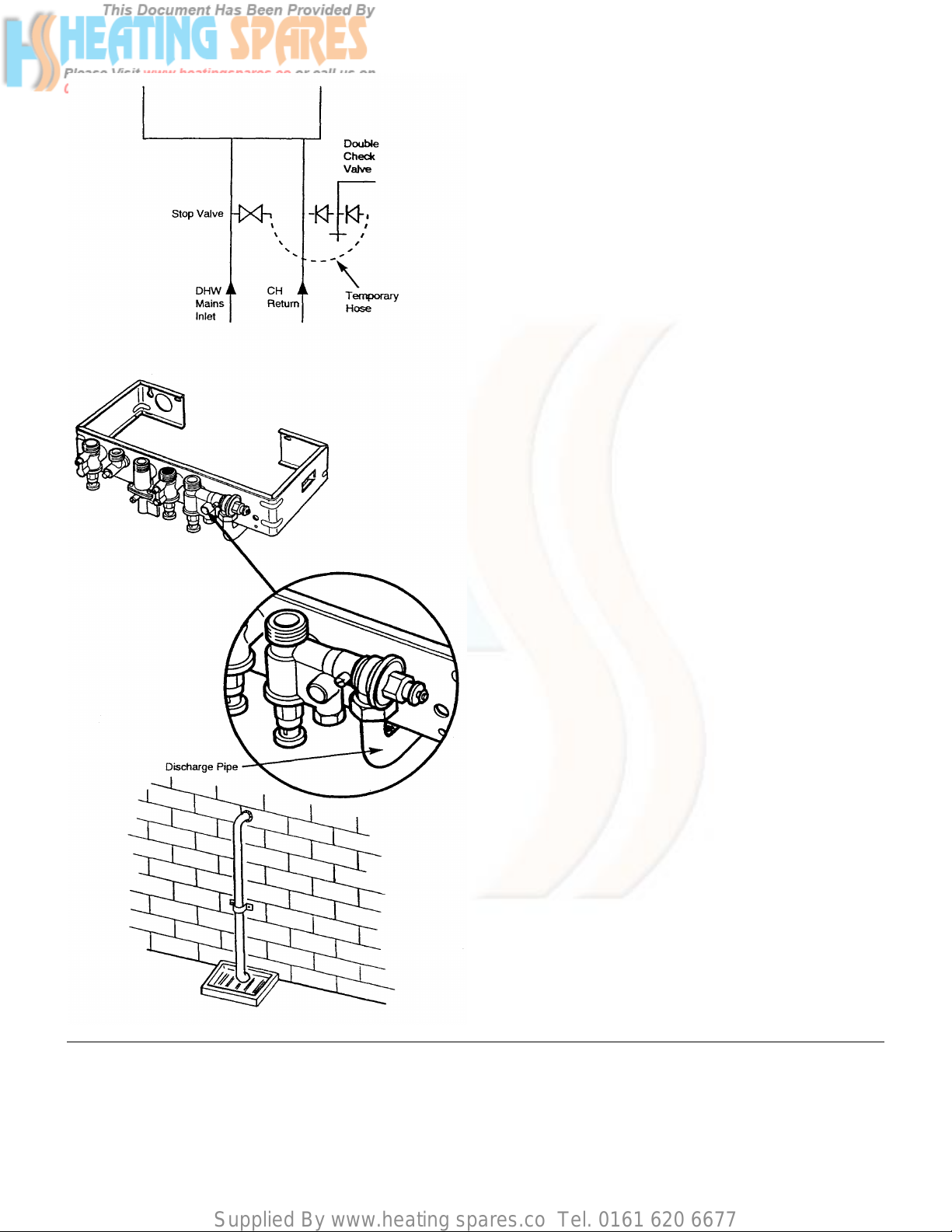

A filling point connection on the central heating return

pipework must be provided to facilitate initial filling and

pressurising and also any subsequent water loss

replacement/refilling.

The filling method adopted must be in accordance with

all relevant water supply byelaws using approved

equipment.

Your attention is drawn to: IRN 302 and Byelaw 14.

Unvented primary circuits may be filled or replenished by

means of a temporary connection between the circuit and a

supply pipe provided a ‘Listed’ double check valve or some

other no less effective backflow prevention device is

permanently connected at the inlet to the circuit and the

temporary connection is removed after use.

PRESSURE VESSEL

The appliance expansion vessel is pre-charged to 0.7 bar

(10 lb/in2). Therefore, the minimum cold fill pressure is 0.7

bar. The vessel is suitable for correct operation for system

capacities up to 125 litres (27.5gal). For greater system

capacities an additional expansion vessel must be fitted refer to BS 7074 Pt 1.

PRESSURE RELIEF VALVE

The pressure relief valve is set at 3 bar, therefore all

pipework, fittings etc should be suitable for pressures in

excess of 3 bar.

The pressure relief discharge pipe should be not less than

15mm, run continuously downward, and discharge outside

the building, preferably over a drain, and in such a manner

that no hazard occurs to occupants or cause damage to

wiring or electrical components.

The end of the pipe should terminate facing down and

towards the wall.

THE DISCHARGE MUST NOT BE ABOVE A WINDOW,

ENTRANCE OR OTHER PUBLIC ACCESS.

CONSIDERATION MUST BE GIVEN TO THE POSSIBIUTY

THAT BOILING WATER /STEAM COULD DISCHARGE

FROM THE PIPE.

Page 12

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

SYSTEM DETAILS – Page 12

Domestic Hot Water Circuit

All DHW circuits, connections, fittings etc should be

fully in accordance with relevant standards and water

supply bye-laws.

Your attention is drawn to: IRN 116 and Byelaw 90 and 91.

Sealed primary circuits and / or secondary hot water

systems shall incorporate a means for accommodating the

thermal expansion of water to prevent any discharge from

the circuit and / or system except in an emergency situation.

When the system includes any device which prevents water

expanding back towards the supply (check valve, loose

jumpered stopcock; water meter, water treatment device),

then an expansion vessel must be fitted e.g. (Zilmet 160ml,

R ½ 15bar).

To comply with Byelaw 91,a check valve must also be fitted

on the supply as shown, to ensure efficient operation and

also to prevent the reverse flow of hot water into the supply

pipe.

IF THE HOT WATER EXPANSION IS NOT PROVIDED

FOR, THEN HIGH PRESSURES CAN DEVELOP WHICH

MAY RESULT IN DAMAGE TO FITTINGS AND DEVICES

ON THE SYSTEM.

The appliance maximum working mains pressure is 10 bar

(150 lb/in2), therefore all pipework, connections, fittings etc

should be suitable for pressures in excess of 10 bar: A

pressure reducing valve must be fitted for pressures in any

outlet fittings, such as a shower excess of 10 bar: The

manufacturer of valve, may require a lower maximum

pressure. The pressure reduction must take account of all

fittings connected to the DHW system.

SHOWERS

If a shower control is supplied from the appliance it should

be of the thermostatic or pressure balanced type.

Thermostatic type shower valves provide the best comfort

and guard against water at too high a temperature. Existing

controls may not be suitable - refer to the shower

manufacturers.

HARD WATER AREAS

If the area of the installation is recognised as a HARD

WATER AREA then a suitable device should be fitted to

treat the mains water supply to the appliance.

Page 13

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Site Requirements – Page 13

The installation must be carried out by a CORGI Registered

Installer or other competent person and be in accordance

with the relevant requirements of GAS SAFETY (Installation

and Use) REGULATIONS, the BUILDING REGULATIONS

(Scotland) (Consolidation), the LOCAL BUILDING

REGULATIONS, the current I.E.E. WIRING REGULATIONS

and the bye laws of the LOCAL WATER UNDERTAKING.

(Where no specific instruction is given reference should be

made to the relevant British Standard Codes of Practice.)

B.S. Codes of Practice

Standard Scope

BS 6891 Gas Installation.

BS 5546 Installation of hot water supplies for

domestic purposes.

BS 5449 Part 1 Forced circulation hot water systems.

BS 6798 Installation of gas fired hot water

boilers.

BS 5440 Part 1 Flues.

BS 5440 Part 2 Air supply

BS 7074 Expansion vessels and ancillary

equipment for sealed water systems.

WARNING

The addition of anything that may interfere with the

normal operation of the appliance without the express

written permission of Baxi Heating could invalidate the

appliance warranty and infringe the GAS SAFETY

(Installation and Use) REGULATIONS.

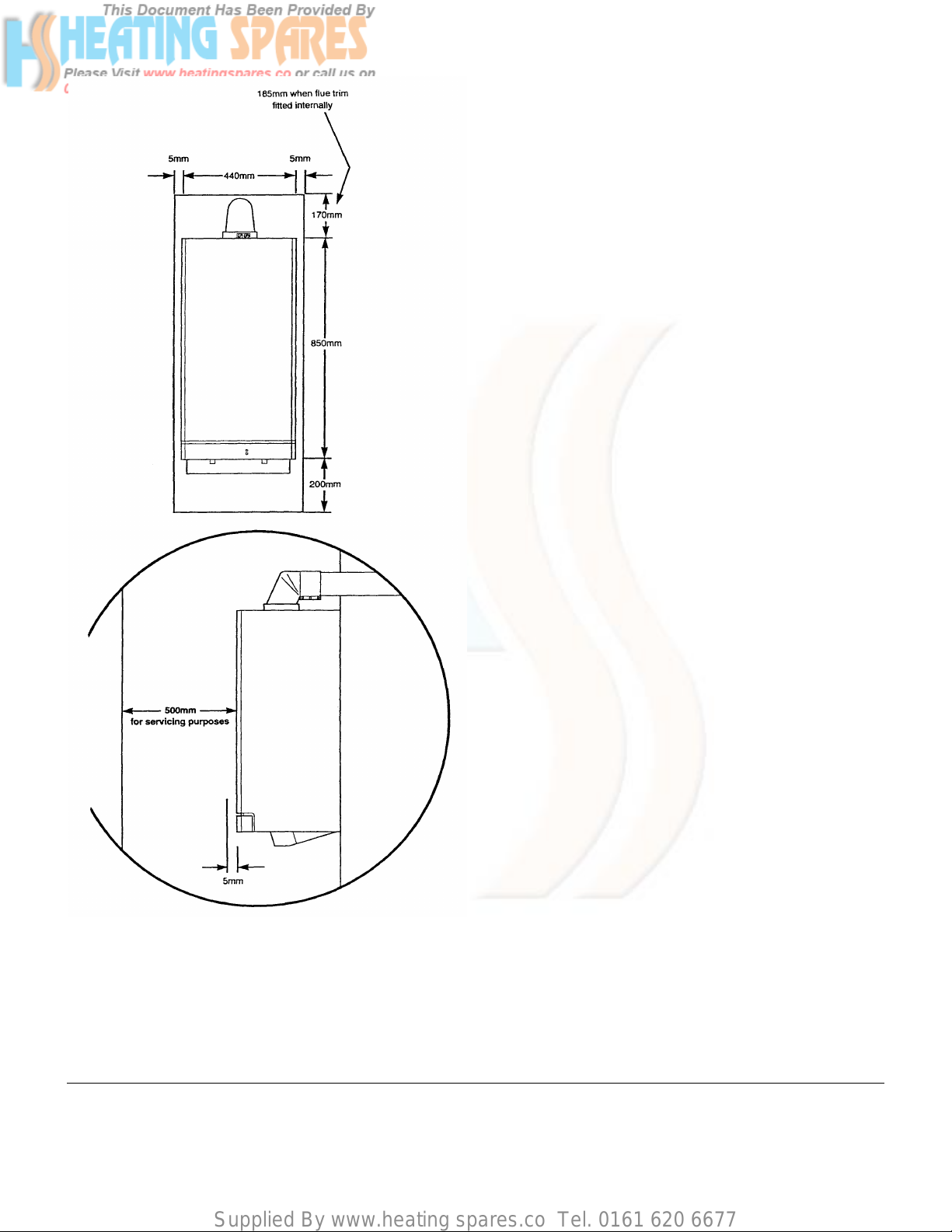

Clearances

A flat vertical area is required for the installation of the boiler.

These dimensions include the necessary clearances around

the appliance for case removal, spanner access and air

movement. Additional clearances may be required for the

passage of pipes around local obstructions such as joists

running parallel to the front face of the appliance.

Location

The appliance may be fitted to any suitable wall with the flue

passing through an outside wall and discharging to

atmosphere in a position permitting satisfactory removal of

combustion products and providing an adequate air supply.

The appliance should be fitted within the building unless

otherwise protected by a suitable enclosure ie. garage or

outhouse. (The appliance may be fitted inside a cupboard see page 14).

If the appliance is fitted in a room containing a bath or

shower reference must be made to the Current I.E.E. Wiring

Regulations and Building Regulations. If the appliance is to

be fitted into a building of timber frame construction then

reference must be made to British Gas document DM2.

Page 14

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

SITE REQUIREMENTS – Page 14

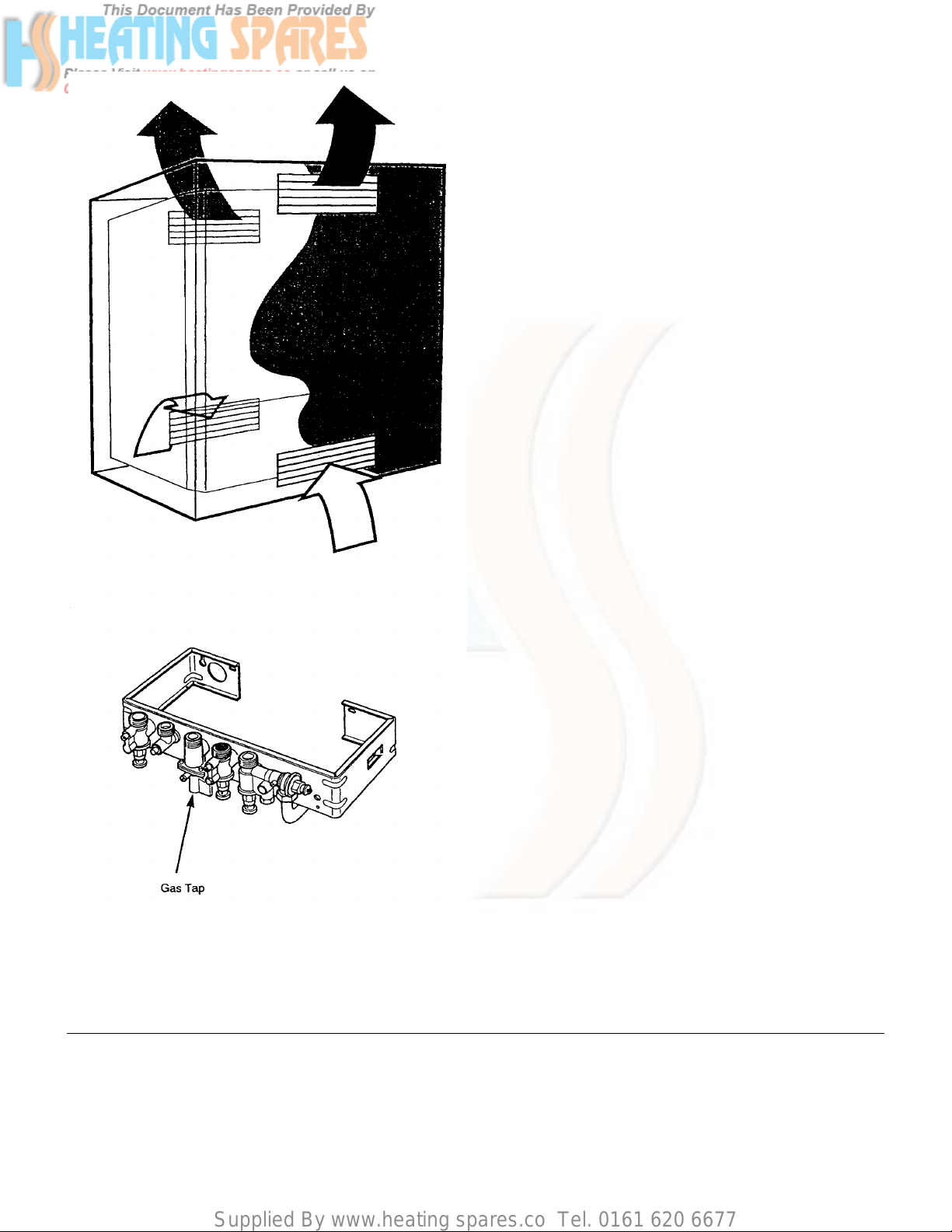

Ventilation of Compartments

Where the appliance is installed in a cupboard or

compartment, air vents are required (for cooling purposes) in

the cupboard or compartment at high and low level which

may communicate with a room or direct to outside air.

Detailed recommendations for air supply are given

in BS 5440: Part 2.

An existing cupboard or compartment may be used,

provided that it is modified for the purpose.

Recommendations for air supplies and details of -essential

cupboard compartment design are given In BS 5440:Part2.

NOTE:-Both air vents must communicate with the same

room or both be on the same wall to outside air.

Genesis 80

Position of Air from Air direct

Air Vent Room from Outside

High 257cm2 (39in2) 128cm2 (19.5in2)

Low 257cm2 (39in2) 128cm2 (19.5in2)

Genesis 96

Position of Air from Air direct

Air Vent Room from Outside

High 311cm2 (48.2 in2) 156cm2 (24.1 in2)

Low 311cm2 (48.2 in2) 156cm2 (24.1 in2)

Gas Supply

The-gas installation should be in accordance with BS 6891.

The connection to the appliance is a 22mm copper tail

located at the rear of the gas cock.

Ensure that the pipework from the meter to the appliance is

of adequate size. Do not use pipes of a smaller diameter

than the appliance gas connection.

Electrical Supply

External wiring must be correctly earthed, polarized and in

accordance with current I.E.E. Wiring Regulations.

The mains supply is 230V - 50Hz fused at 3A.

NOTE:-The method of connection to the electricity

supply must facilitate complete electrical isolation of the

appliance.

Connection may be via a fused double-pole isolator with a

contact separation of at least 3mm in all poles and servicing

the appliance and system controls only.

Page 15

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

SITE REQUIREMENTS – Page 15

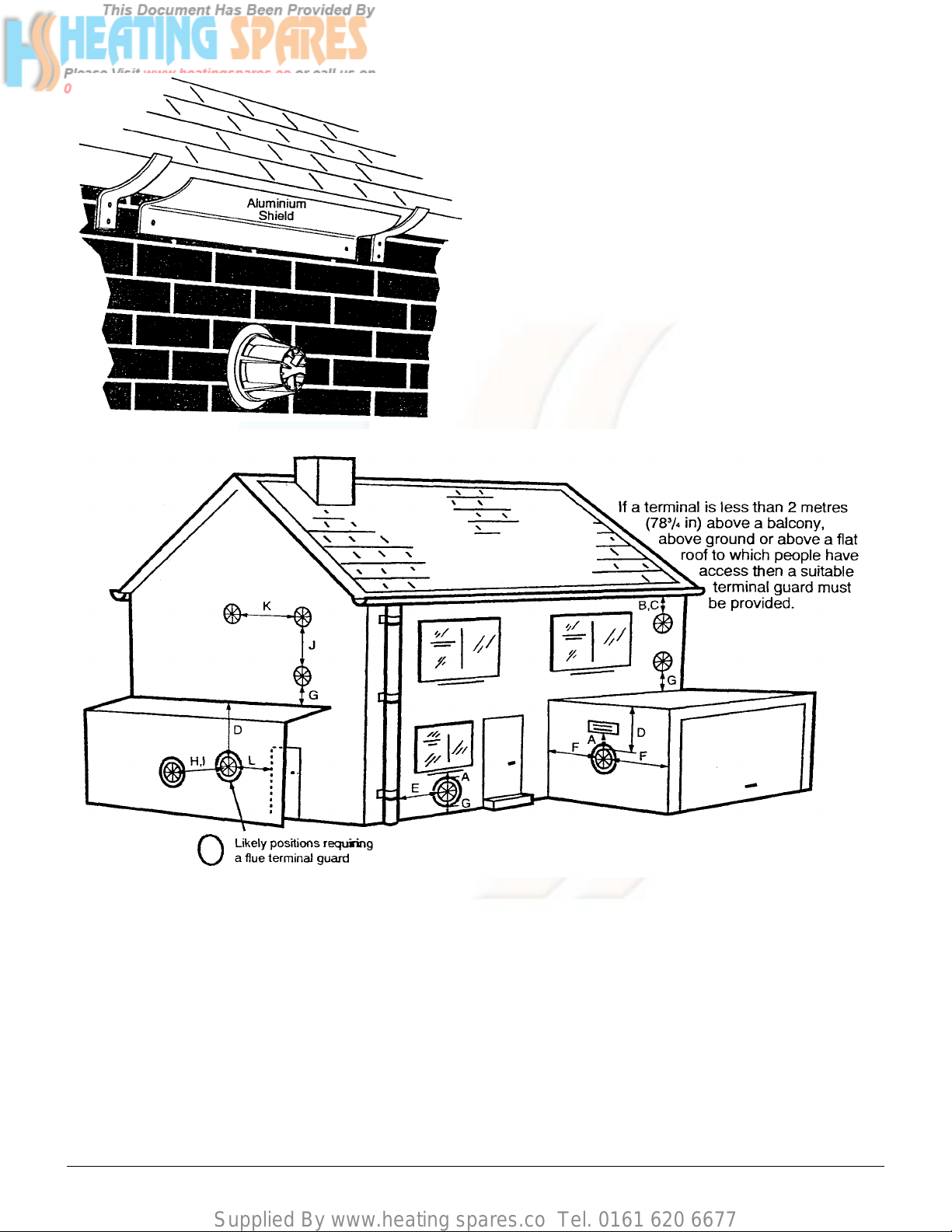

Flue

An internal fitting kit is available for installations where the

flue terminal is inaccessible from the outside. -(Part No

236441). This is available from merchants or direct from Baxi

free of charge.

The following guidelines indicate the general requirements

for siting balanced flue terminals. Recommendations for

flues are given in BS 5440 Pt.1.

If the terminal is fitted within 1 metre (39 in) of a plastic

gutter, within 500mm (19 ½ in) of a painted eave or a

painted gutter, an aluminium shield of at least 1 metre (39 in)

long should be fitted to the underside of the gutter or painted

surface. An air space of 5mm (3/16 in) should be left

between shield and gutter.

If the terminal discharges onto a pathway or passageway,

check that combustion products will not cause a nuisance

and that the terminal will not obstruct the passageway.

Terminal Position with Minimum Distance (mm)

A Directly below an openable window or other

opening. e.g. an air brick. 300

B Below gutters. 25

C Below eaves, soil pipes or drain pipes. 75

D Below balconies or car port roof 200

E From vertical drain pipes and soil pipes. 75

F From internal or external corners. 25

G Above ground, roof or balcony level. 300

H From a surface facing a terminal. 600

I From a terminal facing a terminal. 1200

J Vertically from a terminal on the same wall. 1500

K Horizontally from a terminal on the same wall. 300

L For an opening in a car port (e.g. door, window)

into a dwelling. 1200

Page 16

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

SITE REQUIREMENTS – Page 16

Flue Dimensions

The standard flue supplied with the appliance is suitable for

use with flue lengths between 220mm (8 21/32in) and

610mm (24in).

TOTAL FLUE LENGTH PERMISSIBLE IS:

3 METRES MAX.

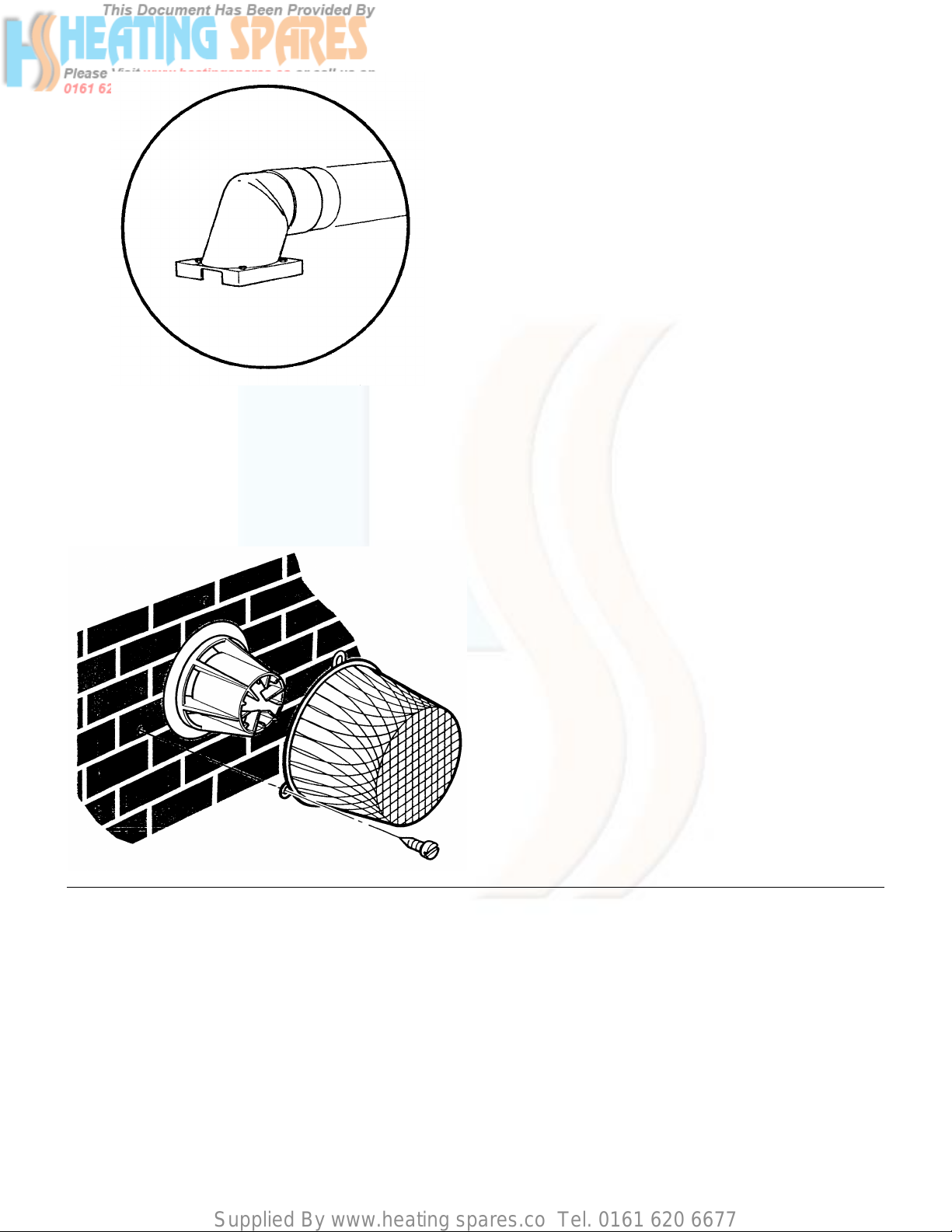

Terminal Guard

When codes of practice dictate the use of terminal guards,

they can be obtained from most Plumbers and Builders

Merchants nationwide.

When ordering a terminal guard, quote the appliance model

number.

The guard manufacturers listed below can be contacted for

terminal sizes and guard model numbers.

Tower Flue Components Ltd.,

Tower House,

Vale Rise,

Tonbridge,

Kent.

Tel: 01732 351555.

Quinnell, Barrett & Quinnell,

884 Old Kent Road,

London, SE15 1NL

Tel: 0171 639 1357.

FIXING

The flue terminal guard should be positioned centrally over

the terminal and fixed as illustrated.

Page 17

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Installation – Page 17

Initial Preparation

Remove the fixing template from the small carton.

After considering the site requirements (see page 13)

position the template on the wall.

Mark the position of the fixing holes for the two hooks. Use

the upper two holes where possible.

Mark the centre of the flue hole (rear exit). For side exit,

mark as shown. If required, mark the position of the gas and

water pipes. Remove the template.

Cut the hole for the flue (minimum diameter 107mm).

Drill and plug the wall as previously marked. Secure the two

hooks to the wall.

Insert the two outer support bracket fixing screws, leaving

them sufficiently proud to engage in the keyhole slots.

GENESIS 96 ONLY

Before fixing the support bracket to the wall remove the blue

regulator unit from the inlet connection of the cold water

isolating valve. Replace with the red regulator supplied in

the contents kit (See page 41).

Attach the support bracket and ensuring it is level, secure to

the wall.

Insert the two inner screws.

Connect the gas and water pipes to the valves on the

support bracket using the copper tails supplied. Ensure the

sealing washers are fitted correctly. (The rubber washer is

for use on the gas connection only. The fibre washers

are for the water circuit connections.)

Connect a pressure relief discharge pipe to the safety valve

tail routed to discharge safely outside the property.

The symbols for each connection are embossed on the

support bracket.

Flushing

Flush thoroughly (see system notes). There is a plastic tube

in the contents kit to aid flushing.

Insert in to valve outlet as shown.

Fit the water filter supplied in the kit to the cold water inlet

valve.

Page 18

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

INSTALLATION – Page 18

Preparing The Boiler

Follow the sequence depicted on the carton to unpack the

boiler.

Remove the lower cover poly bag assembly and contents kit

before laying the boiler on its back supported by the

polystyrene block.

Hinge down the lower door panel and spring off.

Remove the four securing screws, slide and lift away the

outer case.

Remove the sealing plugs from the copper bends.

Stand the boiler on its base on the carton sleeve.

Note: A small amount of water may drain from the boiler

in the upright position.

Page 19

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

INSTALLATION – Page 19

Fitting The Boiler

Lift the boiler using the lower edge of the combustion box

and the hand holds in the chassis.

Place boiler on the support bracket, slide back then lift to

engage on top hooks.

Hinge down the electrical box to gain access to the

connections between boiler and valves.

At both sides push in the two tabs - hinge box down by

rotating.

Check the inlet water filter is fitted (F).

Make the gas connection first (G). This will centralise the

boiler.

Insert the sealing washers between the valve outlet face and

the flange on the copper bends. The rubber washer is for

use on the gas connection only. The fibre washers are

for the water circuit connections.

Tighten the connections.

Page 20

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Fitting The Flue – Page 20

HORIZONTAL FLUE

The standard flue supplied with the appliance is suitable for

lengths 220mm minimum to 610mm maximum.

Rear flue: maximum wall thickness - 490mm.

Side flue,

(left or right): maximum wall thickness - 477mm.

If fitting the optional Intel fitting kit, flue extension kit or

elbows refer to the instructions provided with the kits.

Place the flue elbow on to the flue connection, with the

outlets facing the wall opening.

Measure the distance from the outside wall face to the

elbow. This is to be dimension (X)

Mark dimension (X) on the plastic air duct measuring from

the flue terminal as shown.

Measure the length of waste material from the air duct.

Take the aluminium flue duct and mark off this length. from

the plain end. Do not cut the flared end.

The required dimension of the flue duct is (X)+55mm.

IMPORTANT:

Check your measurements before cutting.

Cut the ducts to size.

Page 21

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Fitting The Flue – Page 21

Slide the rubber seal and clip over the air duct.

Engage the flared end of the flue duct onto the flue elbow.

Insert the flue duct into the air duct and engage it in the

terminal.

Slide the rubber sleeve over the joint between the air duct

and elbow.

Align the clip over the rubber seal. For neatness the screws

on the clip flange should be below the air duct if possible,

providing they remain accessible.

Secure the clip.

Place the flue gasket on the boiler flue connection.

Slide the flue ducts through the hole in the wall.

Engage the elbow flange and collar on to the flue connection

on top of the boiler. Align the cut-out in the collar with the

two sampling points. Secure with the four screws.

Make good between the wall and air duct outside the

building.

Fit the circular flue trim outside if required. Fit a terminal

guard if necessary (see page 16).

VERTICAL FLUE

Only a flue approved with the Baxi Genesis can be used.

For information on vertical flues consult the Genesis Installer

Guide or Notes for Guidance supplied with the vertical flue

pack.

Page 22

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Making The Electrical Connections – page 22

The electrical connections are on the right hand side of the

unit.

Undo the screws securing the small cover and remove the

cover.

Undo the screw securing the right hand cable clamp and

hinge up.

If fitting an integral timer kit please refer to kit

instructions at this stage, paying particular attention to

voltage requirements.

Route the incoming electrical cable/s over the top edge of

the support bracket. This will prevent damage to the

cables.

Lay the cable/s through the cable clamp to gauge the length

of cable required when the plug is connected.

Connect the (L) and (N) wires to the multipin plug, and the

earth wire to the grounding strip earth point.

The incoming cable/s can be routed through the cable clip at

the right hand side of the support bracket.

Check the electrical installation for earth continuity,

short-circuits, resistance to earth-correct polarity and

fuse failure.

CONNECTING AN EXTERNAL DEVICE

If a Baxi Genesis Controller (programmable thermostat)

is fitted refer to the instructions supplied with it.

To connect an external timer or room thermostat, remove the

link wire between terminals 1 & 2.

This connection delivers a low voltage switching signal to the

external controls, therefore only devices having voltage-free

switch contacts can be connected.

IMPORTANT: DO NOT CONNECT MAINS 230V TO

TERMINALS 1,2 OR 3- DAMAGE TO THE P.C.B. WILL

OCCUR.

Page 23

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Making The Electrical Connections – page 23

Fitting a Room Thermostat

A 2-wire or 3-wire low voltage thermostat can be fitted to

the Genesis plug.

To fit a 2-wire thermostat, remove link, and wire the

thermostat switch between positions 1 & 2.

To fit a 3-wire thermostat, remove link, and wire the

thermostat switch between positions 1 & 2. The anticipator

should be wired to position 3, as this provides a continuous

24V supply.

FITTING AN EXTERNAL TIMER

The external timer must have voltage-free switch contacts.

The timer switch must be connected between positions 1 &

2.

FITTING A FROST THERMOSTAT

The frost thermostat must have voltage-free switch

contacts.

If room and frost Thermostats, and an external timer are to

be incorporated in the control system they should be wired

as shown.

Connect the multipin plug into the socket on the

power board.

Secure the incoming cable/s with the cable damp and

replace the cover.

Page 24

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Schematic Wiring Diagram – Page 24

Page 25

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Illustrated Wiring Diagram – Page 25

Page 26

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Commissioning The Appliance – Page 26

Reference should be made to BS 5449 Section 5 when

commissioning the appliance.

Open the cold feed to the appliance.

Open all hot water taps to purge the DHW system.

Ensure that the filling loop is connected, and open the

heating flow and return valves on the appliance.

Open the automatic air vent. To help purge the primary

circuit turn the pump on & off several times by using the ONOFF selector switch.

Pressurise the system to 1.0 bar and disconnect the filling

loop.

Turn the gas supply on and purge the system according to

BS 6891.

Test for gas soundness.

Run the system and check the appliance for correct

operation. Check that there is an adequate gas supply

pressure at the gas tap (preferred minimum pressure is

19.5mbar).

Fitting The Outer Case

Locate lower cover below support bracket with isolating

valve spindles protruding through the slot.

Locate rear tabs through slots in support bracket -flange and

secure with the four-screws.

Fit lower hinged door by sliding the tabs into the cut-outs.

Hinge up, locating the two front tabs into the slots.

Remove the protective film from the outercase.

Position outercase on the chassis, ensuring that the two

slots in the top flange align with the tabs on the chassis.

Insert the four fixing screws into the base of the

chassis.

Replace the lower door panel by springing both ends on to

the pivots.

Hinge up to close.

Instruct the user in the operation of the appliance and

system, explaining the operational sequence.

Hand over these instructions and the users guide.

Emphasise the need for regular maintenance and returning

of the guarantee card.

Page 27

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Servicing The Appliance – Page 27

Annual Servicing

For reasons of safety and economy, it is recommended that

the appliance is serviced annually.

To measure the Co% and (Co2% content of the flue

products, remove the LH sample screw and insert a suitable

sampling probe.

Ensure that the appliance is cool.

Ensure that both the gas and electrical supplies to the

appliance are isolated.

Remove the outer case and lower door panel

(See Installation, p18).

Remove the screws securing the door panel.

Remove the door by lifting its lower edge forwards and

upwards, and disengage the lugs on the top corners.

Remove the screws securing the combustion box door.

Remove the door by lifting the lower edge forwards and

upwards through 90º.

Draw the door forwards.

Remove the two screws securing the injector manifold to gas

inlet pipe.

Remove the remaining four screws securing the manifold to

the burner.

Brush any deposits from the injectors. Do not use a pin or

wire to clean them.

Carefully brush the heat exchanger fins.

Brush the burner blades and venturis and combustion box

clean.

Reassemble in reverse order of dismantling and

recommission.

Page 28

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Changing Components – Page 28

Ensure that both the gas and electrical supplies to the

appliance are isolated.

Remove the outer case and door panel as described under

“Servicing the Appliance”.

Isolate the water circuits and drain as necessary.

There are five drain points:

1. Central heating flow valve.

2. Domestic hot water outlet elbow.

3. Domestic cold water inlet valve.

4. Under three way valve.

5. Under automatic air vent.

Place tube on drain point to-drain water away from

electrics. Turn anticlockwise to open.

NOTE: When reassembling ‘O’ ring joints always place

the ‘O’ ring on the spigot

Where appropriate, after changing a component, recommission the appliance.

Pressure Switch

Remove the screw holding the pressure switch to the air box

back panel.

Draw the switch forwards, and noting the position of the

electrical connections and pressure pipes, remove them.

Reassemble. in reverse order. of dismantling, and in

accordance with the label on reverse of door panel.

Fan

Slacken the screw securing the fan and elbow seal.

Remove the screws holding the fan sealing plate to the

hood, and disengage the fan from the seal.

Draw the fan assembly forwards, and remove the electrical

connections. Note the position of the earth wire.

Remove the screws holding the sealing plate to the fan, and

remove the plate.

Fit the plate to the new fan, and reassemble in reverse order

of dismantling.

Page 29

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

CHANGING COMPONENTS – Page 29

Gas Valve Solenoids

All three solenoids are permanently fixed to the valve cover

plate.

Remove the electrical connections, having noted their

positions. The wires are colour coded to each solenoid.

Remove the screws holding the plate to the valve body.

Remove the plate and gasket carefully to avoid losing the

three valves and springs.

Always fit a new gasket.

Reassemble in reverse order of dismantling.

Domestic Hot Water Heat Exchanger

Hinge down the electrical box.

Undo the screws holding the heat exchanger to the

manifolds.

Draw the heat exchanger carefully over the manifolds,

ensuring no wires are caught or damaged.

Remove and inspect the four lip seals, replace if necessary.

Replace in reverse order of dismantling, and re-commission,

ensuring that the off set location peg on the heat exchanger

is to the right.

Page 30

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

CHANGING COMPONENTS – Page 30

Heat Exchanger

Remove the combustion box door as described under

“Servicing the Appliance”.

Undo the nut on the return pipe at the pump.

Remove the “R” clip on the flow pipe at the manifold.

Remove the clips securing the flow and return pipes to the

heat exchanger.

Ease the flow and .return pipes from the heat exchanger by

gently pulling downwards.

Pull the heat exchanger forwards and remove.

Reassemble in reverse order of dismantling, and re-

commission.

Pump

For ease of replacement fit a new pump head to the existing

housing.

A standard Grundfos UPS 15-50 pumphead is

interchangeable.

This must be switched to setting 3.

Page 31

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

CHANGING COMPONENTS – Page 31

Pump (Head Only)

Hinge down the electrical box.

Remove the screw retaining the pump electrical cover and

remove the cover.

Disconnect the wires (L,N,E) and slide out the grommet

assembly.

Remove the four socket head screws securing the pump

head, and seperate from the housing.

Switch the new pump head to setting No3.

Remove electrical cover and discard.

Assemble new head with electrical box at 10 ‘o’Clock to

housing.

Rewire using existing harness and box cover.

CHECK THAT THE PUMP HAS BEEN SWITCHED TO

SETTING No 3.

Pump (Complete)

Hinge down the electrical box.

Remove the screw retaining the pump electrical cover, and

remove the cover.

Disconnect the wires (L,N,E) and slide out the grommet

assembly.

Undo the return pipe nut from the pump body, retain the ‘O’

ring.

From the rear of the pump housing pull up the “U” shaped

retaining clip to disengage.

Pull the pump forwards off the manifold spigot and retain the

‘O’ ring.

Reassemble in reverse order of dismantling and re-

commission.

Page 32

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

CHANGING COMPONENTS – Page 32

PCB and Spark Generator

Hinge down the electrical box.

Remove the screws and small cover.

Remove the three screws to release the cable clamp.

Unplug the multipin connections to the two P.C.B.s as

follows:-

1. Mains input plug- (C).

2. Pressure switch & fan - (D).

3. Safety thermostat & sensing electrode - (E).

4. Pump - (F).

Unplug the-two spark electrode leads from the generator -

(G).

Remove single screw securing the grounding strip to the

large plastic cover -(H).

Disconnect the earth tag going to the power P.C.B.

Unplug multipin connector (18 wire) from the control P.C.B.

at (A).

Remove the four screws and large cover panel to expose

P.C.B.s.

Page 33

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

CHANGING COMPONENTS – Page 33

Spark Generator

Disconnect generator lead at connection on power board

(K).

Lift power board partially from locating pegs to allow the

release of the generator from its locating pins.

Disconnect terminals to L, N & Earth.

Replace spark generator or wiring as necessary.

Reassemble in reverse order.

POWER BOARD

Disconnect spark generator lead at connection (K) on power

board.

Unplug the link plug connecting the two P.C.B.s at (B).

Lift power board from locating pegs.

Reassemble in reverse order.

CONTROL BOARD

Unplug the link plug connecting the two P.C.B.s at (B).

Remove the three control knobs by pulling off from the

spindles.

Lift the control board from the locating pegs.

Replace the new P.C.B. in reverse order of dismantling

ensuring the correct location on the pegs.

Ensure the slide switch is in the left hand position.

NOTE: One of the control knobs has a longer locating

spindle, this is used on the ‘On/Off’ selector switch.

Page 34

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

CHANGING COMPONENTS – Page 34

Thermistors

The procedure is the same for both domestic hot water and

central heating thermistors.

Remove the electrical connection from the thermistor.

Remove the spring clip retaining it to the manifold.

Withdraw the thermistor.

Reassemble in reverse order.

Safety Thermostat

Remove the electrical connections from the sensor.

Remove the retaining clip from the flow pipe.

Remove the sensor from the clip.

Apply heat transfer paste and reassemble in reverse order.

Page 35

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

CHANGING COMPONENTS – Page 35

Expansion Vessel

Hinge down the electrical box.

Turn off gas tap and close all water valves.

Drain as necessary.

Undo all unions between the boiler and isolating valves,

retaining the sealing washers.

Remove the electrical cover, and unplug the input lead.

Remove the earth connection from the grounding strip.

Release the input cables from the cable clamp.

Remove the screws holding the flue elbow to the boiler.

Slacken the screws on the flue clip, and slide the clip along

the air duct.

Slide the rubber seal off the elbow and onto the air duct.

Ease the elbow upwards.

Remove elbow and securing collar.

Page 36

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

CHANGING COMPONENTS – Page 36

Remove the boiler from the wall by lifting to unhook then

remove from the lower support bracket.

Stand the boiler on its base and undo the two screws holding

the vessel retaining bracket to the chassis.

Remove the clip retaining the braided expansion tube to the

manifold.

Lift the vessel away from the boiler.

Undo the screw holding the retaining bracket to the

expansion vessel.

Reassemble in reverse order, ensuring that the vessel flange

sits in the slot in the chassis.

RE-PRESSURISING EXPANSION VESSEL

The charge pressure = 0.7 bar.

Close central heating flow and return isolating valves.

Drain down the boiler.

The ‘Schraeder’ valve is positioned on the top retaining

bracket.

Pressurise to 0.7 bar.

Open isolating valves and re-charge the system to 1.0 bar.

Vent system as necessary.

Page 37

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

CHANGING COMPONENTS – Page 37

Pressure Relief Valve

Close all water valves and drain as necessary.

Disconnect the union between the valve and the discharge

pipe. Slacken the grub screw retaining the valve.

Pull the valve sideways to disengage it.

Reassemble in reverse order.

Pressure Gauge

Hinge down the electrical box.

Remove the spring fork clip retaining the gauge to the facia,

and withdraw the gauge.

Remove the clip retaining the capillary to the manifold.

Reassemble in reverse order.

Flow Switches

The procedure for changing both flow switches is the same

They are interchangeable.

Remove the electrical connection.

Unscrew the switch cap assembly, and remove the “O’ ring.

The cap is hand tight so no tool is necessary.

Reassemble in reverse order.

Page 38

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

CHANGING COMPONENTS – Page 38

Flame Sensing Probe

Remove combustion box door, and hinge down electrical

box.

Disconnect the sensor lead from the main wiring loom (in

line amp tag).

Pull the lead through the grommet in the combustion box

lower panel.

Slacken the screws holding the burner flange, and remove

the flange.

Remove the screw securing the probe to the burner.

Remove assembly from the burner by rotating forwards.

Lift out and thread lead between burner blades.

Reassemble in reverse order.

Spark Electrode

Remove the combustion box door and hinge down the

electrical box.

Slacken the screws holding the burner flange, and remove

the flange.

Remove the screw securing the electrode to the burner.

Remove the screws and small electrical cover.

Release the cable clamp.

Disconnect both leads from the spark generator and feed

through the cable clamp and cable tie on the main harness.

Untwist the two leads.

Remove the grommet in the combustion box lower panel,

slide the two leads and connections through the grommet.

Remove assembly from the burner by rotating forwards.

Lift out and thread the leads between burner blades.

Reassemble in reverse order.

It is important that the two leads are twisted together a

minimum of 8 times before feeding through the cable tie

and clamp.

This requirement is to ensure that compatibility with the

electromagnetic directive is maintained.

Page 39

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

CHANGING COMPONENTS – Page 39

lnjector Manifold

Remove the combustion box door.

Remove the six screws holding the manifold to the burner

and inlet pipe.

Remove the burner flange and draw the manifold forwards.

Reassemble in reverse order.

3 - Way Valve

Close central heating isolating valves and drain down.

Release union nut and remove ‘R’ clip on central heating

outlet pipe.

Pull forward to disengage pipe spigot.

Remove ‘R’ clip securing the by pass pipe to the valve.

Pull out the spring clip and unplug the thermistor and

electrical connection.

Remove the clip securing the flow pipe to the heat

exchanger and the ‘R’ clip holding it to the valve.

Disengage the flow pipe at the heat exchanger end by

easing down, so that the lower end of the pipe slides further

into the valve spigot

Pull pipe upwards to disengage from valve spigot.

Rotate the front end of the valve upwards by ¼ turn to

disengage the bayonet fitting.

Ease the assembly to the left to separate the spigot from the

manifold.

Bring the valve assembly forward and unplug the electrical

connection.

Reassemble in reverse order ensuring all ‘O’ rings are on the

spigots before assembly.

Page 40

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

CHANGING COMPONENTS – Page 40

Domestic Hot Water Filter

Undo the nut on the DHW inlet bend.

Swivel the bend to gain access to the flat filter.

AUTOMATIC AIR VENT

Unscrew the air separator head assembly.

Replace unit in reverse order.

Central Heating Filter

Undo the nut on the central heating return bend.

Remove the ’R’ clip on the connection at the manifold and

remove the filter.

Clean or replace filter/s as necessary.

Reassemble in reverse order.

Page 41

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

CHANGING COMPONENTS – Page 41

Flow Regulator

To remove the flow regulator use a small screwdriver to

lever the plastic housing out of the valve inlet.

Fit the replacement regulator ensuring it is inserted in the

direction shown.

Page 42

Supplied By www.heating spares.co Tel. 0161 620 6677

Page 43

Supplied By www.heating spares.co Tel. 0161 620 6677

Baxi Heating Ltd.

Page 44

Supplied By www.heating spares.co Tel. 0161 620 6677

Baxi Heating Ltd.

Page 45

Supplied By www.heating spares.co Tel. 0161 620 6677

Page 46

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Fault Finding – Page 46

Page 47

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

FAULT FINDING – Page 47

Page 48

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

FAULT FINDING – Page 48

Page 49

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

FAULT FINDING – Page 49

Page 50

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Electronic Board Detail – Page 50

Page 51

Supplied By www.heating spares.co Tel. 0161 620 6677

Genesis Baxi Heating Ltd.

Short Parts List – Page 51

Key

206

572

615

505

616

607

117

117

111

811

810

216

510

411

110

104

206

117

117

Description

Fan Assembly (80)

Pump

Power Board

3-Way Valve

control Board

Spark Generator

Injector Manifold - NG (80)

Injector Manifold - LPG (80)

Flame Sensing Electrode

control Knob,

control Knob - Extended

Pressure Switch

Thermistor

SoIenoid Valve Assembly

Ignition Electrode Assembly

Safety Thermostat

Fan Assembly (96)

Injector Manifold - NG(96)

Injector Manifold - LPG (96)

G.C.

No

277 804

277 862

277 880

277 833

277 881

379 075

277 795

277 794

277 789

277 896

277 899

277 808

277 834

277 812

277 788

277 78.3

170 621

170 619

170 620

Manuf’rs

Part No

235799

235878

235907

235838

235908

235899

235791

235790

235785

235920

236462

235804

235840

235831

235784

235779

237465

237467

237468

Click here for Helplines

Loading...

Loading...