Page 1

© Baxi Heating U.K. Limited 2007.

5122664/01

INSTALLER GUIDE

INSTALLER: Please leave this guide with the owner

THIS APPLIANCE IS FOR USE WITH NATURAL GAS (G20).

WHEN CONVERTED USING CONVERSION KIT NO. 0591011

THIS APPLIANCE

IS FOR USE WITH PROPANE GAS (G31).

THIS APPLIANCE IS SUITABLE ONLY FOR INSTALLATION IN THE UNITED

KINGDOM (GB) AND THE REPUBLIC OF IRELAND (IE).

Firefox 5

Model 910

CAST-IRON GAS STOVE

Fitted with a Ceramic Coal fuel effect.

(GC No. 32-264-24)

For technical advice firstly contact your retailer.

If further advice is required then call 01204 868550.

Page 2

© Baxi Heating U.K. Limited 2007.

All rights reserved. No part of this publication may be reproduced in any material form

(including photocopying), stored in any medium by electronic means (including in any

retrieval system or database) or transmitted, in any form or by any means, whether

electronic, mechanical, recording or otherwise, without the prior written permission of

the copyright owner.

Applications for the copyright owner's permission to reproduce any part of this

publication should be made, giving details of the proposed use, to the following

address: The Company Secretary, Baxi Heating UK Limited, The Wyvern Business

Park, Stanier Way, Derby, DE21 6BF.

Warning: Any person who does any unauthorised act in relation to a copyright work

may be liable to criminal prosecution and civil claims for damages.

Valor Fires, Erdington, Birmingham B24 9QP

Because our policy is one of constant development and improvement, details may vary slightly from

those given in this publication

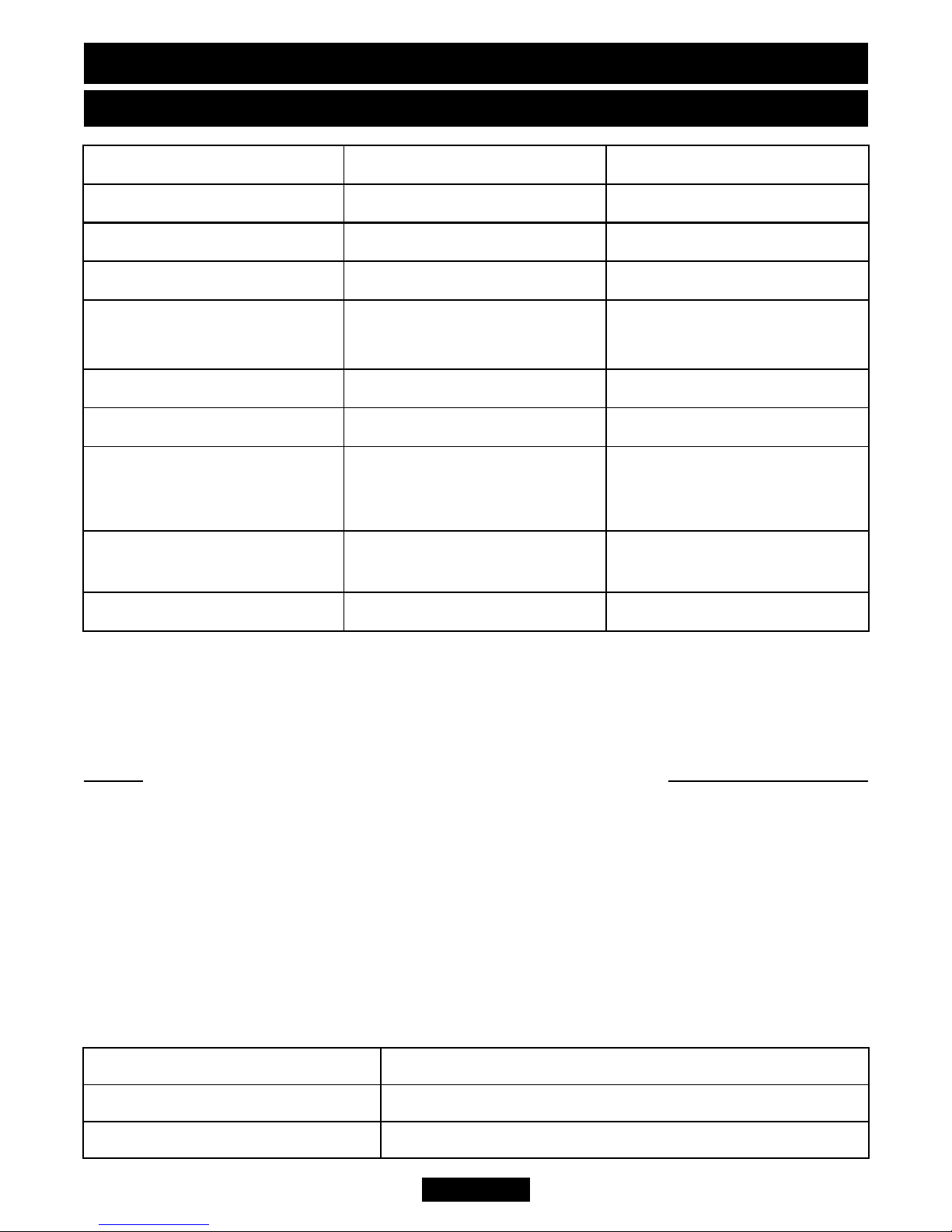

LIST OF CONTENTS

Heading Page

1. SAFETY 3

2. APPLIANCE DATA 4

3. UNPACKING 5

4. STOVE SET UP 6

5. GENERAL INSTALLATION REQUIREMENTS 9

6. OPERATING THE STOVE 12

7. FINAL REVIEW AND SERVICING 14

Page 2

INSTALLER GUIDE

© Baxi Heating U.K. Limited 2007.

Page 3

Page 3

INSTALLER GUIDE

1. SAFETY

Installer

Firefox stoves are efficient appliances giving off convected, conducted and radiated

heat. All the surfaces of the stove - except the controls - are working surfaces and

become hot in use. They must not be touched or have any combustible objects or

materials placed on or near them. A fire guard complying with BS 8423 should be

fitted for the protection of young children, the elderly, the infirm or pet animals.

The appliance is fitted with a flue safety device. If the appliance closes down after a

period of operation for no apparent reason, the consumer should be informed to stop

using the appliance until the installation and appliance have been thoroughly

checked. Under no circumstances should the flue safety device be altered or

bypassed in any way. Only a genuine manufacturers replacement part should be

fitted.

Before continuing any further with the installation of this appliance please read the

following guide to manual handling:

! The lifting weight of this appliance is 55 kg. We therefore recommend that two

people should be sufficient to lift the stove. If fitting or moving the stove alone we

recommend the use of suitable lifting apparatus.

! When lifting always keep your back straight. Bend your legs and not your back.

! Avoid twisting at the waist. It is better to reposition your feet.

! Avoid upper body/top heavy bending. Do not lean forward or sideways whilst

handling the stove.

!

Always grip with the palm of the hand. Do not use the tips of fingers for support.

! Always keep the stove as close to the body as possible. This will minimise the

cantilever action.

! Use gloves to provide additional grip.

! Always use assistance if required.

© Baxi Heating U.K. Limited 2007.

Page 4

Page 4

INSTALLER GUIDE

© Baxi Heating U.K. Limited 2007.

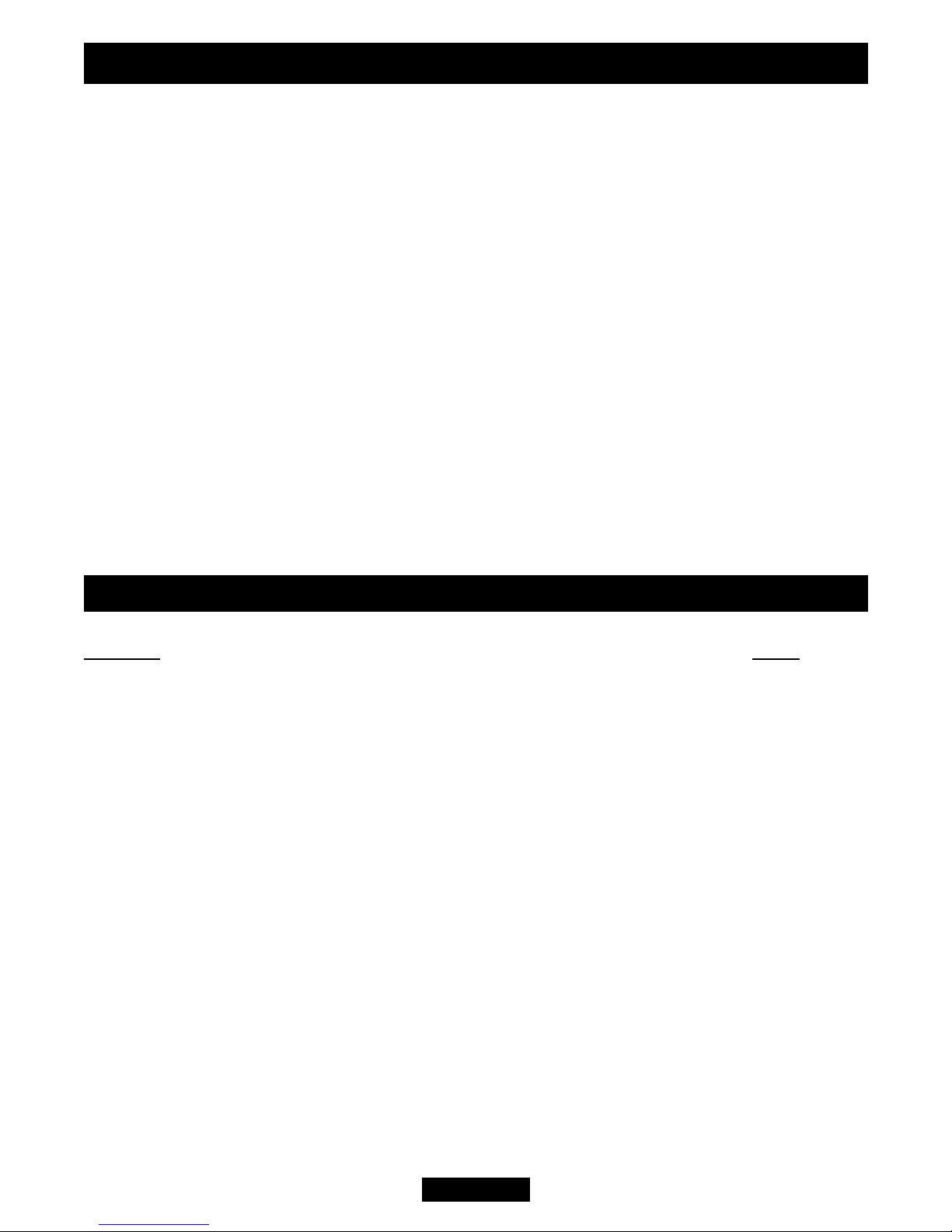

2. APPLIANCE DATA

*When converted using kit 0591011.

The appliance information label is located on a plate at the base of the stove.

The efficiency of this appliance has been measured as specified in BS EN 613 and

the result is as below :

Model

Efficiency % (Gross)

910 73.1

910 when converted to LPG. 73.1

The gross calorific value of the fuel has been used for this efficiency calculation. The

test data from which it has been calculated has been certified by Advantica

Certification services (0087). The efficiency value may be used in the UK

Government's Standard Assessment Procedure (SAP) for energy rating of dwellings.

The conversion of net efficiency to gross was achieved by multiplying the net

efficiency by the following conversion factor from Table E3 of SAP 2005, rounding

down to the nearest whole number.

Gas Conversion factor from net to gross efficiency

Natural Gas 0.901

LPG 0.921

Gas Natural (G20) Propane (G31) *

Inlet Pressure 20mbar 37mbar

Input - Max. (Gross) 5.50kW (18,766Btu/h) 5.4kW (18,425Btu/h)

Input - Min. (Gross) 2.3kW (7,850 Btu/h) 3.8kW (12,965Btu/h)

Inlet Test Pressure (Cold)

20.0 ± 1.0mbar (8.0 ± 0.4in

w.g.)

37.0 ± 1.0 mbar (14.85 ±

0.4in w.g.)

Gas Connection 8mm pipe 8mm pipe

Burner Injector Cat 82 - 065 Size 116

Pilot

Copreci Ref. O.D.S

21500/212

Copreci Ref. O.D.S

21500/212 Fitted with RBM

180 -02 injector

Ignition

Piezo Electric. Integral with

Gas Tap

Piezo Electric. Integral with

Gas Tap

Aeration See section 7.1 Non-adjustable

Page 5

This product uses fuel effect pieces containing Refractory Ceramic Fibres

(RCF), which are man-made vitreous silicate fibres. Excessive exposure to

these materials may cause irritation to eyes, skin and respiratory tract.

Consequently, it is important to take care when handling these articles to

ensure that the release of dust is kept to a minimum. To ensure that the release

of fibres from these RCF articles is kept to a minimum, during installation and

servicing we recommend that you use a HEPA filtered vacuum to remove any

dust and soot accumulated in and around the stove before and after working on

the stove. When replacing these articles we recommend that the replaced items

are not broken up, but are sealed within a heavy duty polythene bag, clearly

labelled as RCF waste. RCF waste is classed as a stable, non-reactive

hazardous waste and may be disposed at a landfill licensed to accept such

waste. Protective clothing is not required when handling these articles, but we

recommend you follow the normal hygiene rules of not smoking, eating or

drinking in the work area and always wash your hands before eating or

drinking. This appliance does not contain any component manufactured from

asbestos or asbestos related products.

3. UNPACKING

Before installation, check that the following components, where required, have been

delivered.

Box 1 - Containg the following loose parts:

4 feet.

1 Lower casting cover.

4 securing bolts (For feet / lower casting cover).

4 flat washers (For feet / lower casting cover).

4 locking washers (For feet / lower casting cover).

2 wall plugs (For securing feet to floor).

2 wood screws (For securing feet to floor).

1 Small nut and bolt (For vent switch).

2 bolts with washers (For the diverter box).

3 self tapping screws (For burner).

1 Flue spigot.

1 Flue restrictor.

2 small machine screws (For flue spigot and flue restrictor).

Box 2 - Ceramic fuel effect.

Page 5

INSTALLER GUIDE

© Baxi Heating U.K. Limited 2007.

Page 6

Stove body

The stove is supplied with a locked door. Using a suitable sized spanner, turn the

locking bolt on the front of the door in a counter clockwise direction. Carefully remove

and unpack the contents of the stove.

The stove body contains the following:

1 Burner module.

1 Inlet ‘T’ connector with nut and olive.

1 Vent switch and mounting bracket assembly.

1 Diverter box.

1 Down draught diverter.

1 Control knob assembly.

4. STOVE SET UP

Legs and lower casting cover.

(See figure 1).

1. Locate the four legs to the underside of

the casting body. There are two feet with

holes in the base. We recommend that

these be placed at the rear of the stove.

2. Place the front cover casting on top of

the front legs.

3. Secure the legs and front cover casting

to the underside of the casting body using

the bolts and washers supplied.The bolts

should have the locking washer added first

followed by the flat washer.

4. This appliance is supplied with a flue

restrictor for use where the flue draught is

excessive. Fit the restrictor as in point 1

below. There may however, be certain

circumstances where fitting the restrictor

causes the fire to fail the spillage test. In

such cases the restrictor will have to be

removed. After removal conduct the

spillage check again.

Page 6

INSTALLER GUIDE

© Baxi Heating U.K. Limited 2007.

Figure 1.

Page 7

Flue collar, down draught diverter, diverter box, flue spigot and flue restrictor

plate.

These should be assembled to the stove as in figure 2. The flue spigot is screwed to

the cast collar and clamps the flue restrictor plate in place (See figure 2).

5. The down draught diverter is secured in place using the front bolt and nut that

secure the cast collar to the outside of the cast body. Unscrew and remove the nut

and washer from inside the top of the casting body. Position the down draught

diverter as in figure 3. It MUST be sealed against the top of the stove casting. It is

important that it sits on top and between the raised cast areas on the rear of the stove

body (See figure 3). Secure in

place using the nut and washer

removed previously.

Page 7

INSTALLER GUIDE

© Baxi Heating U.K. Limited 2007.

Figure 3.

Figure 2.

Page 8

6.

The Thermal Switch should be fitted to the inside of the Diverter Box as in figure 4.

Secure using the nut and bolt supplied. Never modify the fixing bracket and always

ensure that the switch is fitted correctly. NEVER USE THE STOVE IF THE THERMAL

SAFETY SWITCH HAS BEEN REMOVED OR IF IT IS DAMAGED IN ANY WAY.

7. Locate the diveter box to the rear of the

stove body and secure in place using the

bolts and washers supplied.

8. Offer the burner module into the stove

and connect the thermal switch leads to the

tags mid way along the thermocouple.

9. Locate the burner assembly inside the

stove body as in figure 5 (The outer front of

the stove is not shown for clarity). The rear

leg of the burner should sit on the rear of

the casting. Secure using the three screws

supplied The screw locations are shown ion

figure 5).

10. Secure the control knob assembly to the

gas valve, the screw tail should secure onto

the flat on the gas valve spindle.

Page 8

INSTALLER GUIDE

© Baxi Heating U.K. Limited 2007.

Figure 5.

Figure 4.

Page 9

5. GENERAL INSTALLATION REQUIREMENTS

The installation must be in accordance with these instructions.

For the user’s protection, in the United Kingdom it is the law that all gas appliances

are installed by competent persons in accordance with the current edition of the Gas

Safety (Installation and Use) Regulations. Failure to install the appliance correctly

could lead to prosecution. CORGI requires its members to work to recognised

standards.

In the United Kingdom the installation must also be in accordance with all the relevant

parts of local regulations.

BS 5440 Part 1

BS 5440 Part 2

BS 4543 Part 2

BS 5871 Part 1

BS 6891

BS 8303

In England and Wales, the current edition of the Building Regulations issued by the

Department of the Environment and the Welsh Office

In Scotland, the current edition of the Building Standards (Scotland) Regulations

issued by the Scottish Executive.

In Northern Ireland, the current edition of the Building regulations (Northern Ireland)

issued by the Department of the Environment for Northern Ireland.

In the republic of Ireland the installation must be carried out by a competent person

and also conform to the relevant parts of:

a) The current edition of IS 813 “Domestic Gas Installations”

b) All relevant national and local rules in force.

Where no specific instructions are given, reference should be made to the relevant

British Standard Code of Practice.

The Hearth.

!

The appliance must be mounted on a non-combustible hearth (N.B. conglomerate

marble hearths are considered as non-combustible). The hearth material must be at

least 12mm thick. The hearth must protrude at least 150mm (6”) in front of the stove

body. In most buildings with solid concrete floors this requirement will be met by the

floor itself.

Page 9

INSTALLER GUIDE

© Baxi Heating U.K. Limited 2007.

Page 10

© Baxi Heating U.K. Limited 2007.

INSTALLER GUIDE

Page 10

Clearances

Clearances from combustible and non-combustible materials must be at least those

shown in figure 6.

Flue / Chimney.

! The stove is approved for use with 102mm (4

inch) diameter insulated Selkirk

insta - lock gas vent.

! The spigot is designed to be compatible with a

selkirk 4 SIL - DH draft hood connector. The inner

sleeve will require reducing in length so that it

prodrudes 25mm below the outer sleeve (See figure

7).

! Before you install the stove make sure the

chimney flue outlet is correctly positioned to align

with the flue outlet on the stove and that the

chimney is in good condition. If not, a chimney liner

must be installed or a suitable class 2 gas flue

used. A draught is necessary to ensure the products of combustion are fully

evacuated. Connect and seal the the stove flue collar to the chimney using full depth

of collar. The flue must have a minimum effective height of 3 metres (10ft), however

to, to ensure optimum performance we recommend 3.66 metres (12ft) or higher. The

flue must be free of obstruction and any dampers must be fixed in a permanently

open position. Ensure that the chimney is not closed and that it has been swept prior

Figure 6. Dimensions and Clearances

Figure 7.

Page 11

© Baxi Heating U.K. Limited 2007.

INSTALLER GUIDE

Page 11

to the stove being installed. Make sure that rain, birds or any foreign bodies cannot

get into the chimney and cause blockage or damage. This problem can normally be

overcome by fitting an approved Gas Cowl. It is essential to the effective running of

your stove that the chimney draws properly and allows the products of combustion to

escape.

Ventilation.

! Normal adventitious ventilation is usually sufficient to satisfy the ventilation

requirements of this appliance. In GB reference should be made to BS5871 Part 1

and in IE reference should be made to the current edition of IS 813 “ Domestic gas

installations” which make clear the conditions that must be met to demonstrate that

sufficient ventilation is available.

!

An extractor fan may only be used in the same room as this appliance, or in any

area from which ventilation for the appliance is taken, if it does not affect the safe

performance of the appliance. Note the spillage test requirements detailed further on

in this manual. If the fan is likely to affect the appliance, the appliance must not be

installed unless the fan is permanently disconnected.

Location.

! This appliance must not be installed in a private garage or any room, which

contains a bath, or shower or where steam is regularly present.

Propane gas

!

Propane gas appliances must not be installed in a cellar, basement or other room

which is built entirely below ground level

(See Gas Safety (Installation and use) Regulations).

Gas connection.

!

A nut and olive are provided for an 8mm pipe inlet connection to the elbow at the

bottom front of the appliance. The elbow can be rotated to allow a connection from

any direction. The elbow includes a valve for isolating the gas supply.

! The supply pipe must be rigid material. Flexible pipe must not be used.

!

Note: Prior to connecting the gas supply it is advisable to blow out the gas

supply so that any dirt which may be present in the pipe is cleared and cannot

enter the gas valve or pilot burner and so cause a blockage

! With the supply connected pressure check the installation pipework for gas

soundness. In the United Kingdom check in accordance with the current edition of

BS6891. In the Republic of Ireland check in accordance with the rules in force.

Securing the stove.

The stove is supplied with two wood screws and wall plugs. Secure the stove in place

through the holes in the rear feet.

Page 12

Fitting the ceramic fuel effect.

The installer and owner guide for the ceramic fuel effect is supplied with the ceramic

fuel effect. It is important that the installer guide for the ceramic fuel effect be placed

inside or attached to this guide and handed to the customer following completion of

the ‘Final review’ section.

6. OPERATING THE STOVE

Pre-lighting checks.

1. Ensure all the building work and flue sealing is complete.

2. Ensure the down draught diverter plate is fitted correctly.

3. Ensure all the ceramic fuel effect pieces are correctly placed.

4. Ensure that the stove door is closed and secured. Lock the stove door with the

locking bolt.

5. Ensure that the stove door is completely sealed.

Lighting the burner.

1. If closed, open the isolating valve at the

inlet elbow.

2. Depress the control knob and rotate it

anticlockwise to the pilot ignition position. A

'click' will be heard as the integral piezo

operates.

3. Turn the control knob clockwise to the 'Off'

position. Repeat this operation until a flame

appears at the pilot. The pilot can be seen by

looking through the space in the left hand front

of the fuel effect (See figure 8). There may be

a delay before the pilot lights due to air being

purged from the system. When a flame

appears at the pilot keep the control knob

depressed and hold the pilot ignition position

for five seconds. When the control knob is

released the pilot flame should remain lit.

Operating the burner.

1. When the pilot burner is operating properly, gradually turn the control knob anti-

clockwise to 'HIGH' (Depress the knob slightly to get past the pilot ignition position).

The main burner should now light. Depress the control knob slightly to release from

the 'HIGH' position and turn back (clockwise) to 'LOW'. While turning, the burner

flames should gradually become lower but remain alight. Depress the control knob

slightly to release from the 'LOW' position and turn back (clockwise) to the ‘Pilot

ignition’ position. The main burner should extinguish but the pilot should remain

alight. Depress the control knob slightly and turn back (clockwise) to turn OFF.

Page 12

INSTALLER GUIDE

© Baxi Heating U.K. Limited 2007.

Figure 8.

Page 13

This will extinguish the pilot.

Inlet pressure check.

The appliance is pre-set to give the correct heat input at the inlet pressure shown in

section 2 of this manual. No adjustment is necessary.

1.

Check the inlet pressure by fitting a pressure gauge at the test point. The test point

is on the inlet ‘T’ connector (See

figure 9). Check the pressure with

the appliance alight and set at

maximum output.

2. After checking, turn off the

appliance. Remove the pressure

gauge and replace the test point

sealing screw.

3. Relight the appliance. Turn to the

maximum output position and test

around the sealing screw for gas

soundness with a suitable leak

detection fluid.

Check for spillage.

1. Close all doors and windows in the room containing the appliance.

2. Light the appliance and turn the control knob to the ‘HIGH’ position.

3. Leave the appliance on for five minutes.

4.

A smoke match should be placed close to base of the diverter box. The installation

is satisfactory if the smoke is drawn into the appliance/ flue way. Do not use a lighted

match or a naked flame.

If the smoke is not drawn into the appliance leave the appliance alight at the

maximum setting for a further ten minutes and then repeat the test. If the flue

restrictor is fitted (See page 6 - point 4) then remove the restrictor and repeat the

above test. If the smoke is still not drawn into the appliance then disconnect the

appliance and seek expert advice.

5.

If the above test is satisfactory open all internal connecting doors, hatches, etc. in

the room. Keep all doors and windows that open to the outside of the building closed.

Recheck for spillage as above. If an extractor fan is installed in the same room as the

appliance or a connecting room, check that spillage does not occur with the fan

operating and all doors and other openings between the fan and the appliance open.

If the smoke is drawn into the appliance, continue with the installation. If the test is

not satisfactory

disconnect the appliance and advise the customer of the cause

of failure.

Flame supervision and spillage monitoring system.

The pilot unit incorporates a system that will automatically shut off the gas supply if

the pilot flame goes out. Check that the system operates properly as follows;

Page 13

INSTALLER GUIDE

© Baxi Heating U.K. Limited 2007.

Figure 9.

Page 14

! Light the appliance. Set at the “HIGH” position and leave for one minute.

! Turn back to “OFF” to extinguish the pilot. Note the time when the pilot goes

out. Listen for a snap sound at the gas tap. Note the time when the sound is

heard.

This sound is caused by an electromagnetic valve shutting off the gas supply

through the tap. The valve is located in the body of the tap. The valve should operate

within 60 seconds of the pilot going out.

If the valve does not operate within this

time limit do not allow the appliance to be used until the fault has been corrected.

This monitoring system must not be adjusted, bypassed or put out of

operation.

This monitoring system, or any of its parts, must only be exchanged using

Valor Fires authorised parts.

7. FINAL REVIEW AND SERVICING

Final Review.

! Hand the literature pack with this guide to the customer.

! Visually inspect the appliance. Clean off any marks incurred during installation.

! Advise the customer how to operate the appliance. Point out that lighting

instruction details are on the metal plate attached to the burner at the bottom of the

appliance.

w

Explain to the customer that the appliance has a flame failure & spillage monitoring

system. Point out the explanation of this system shown in the owner guide under

“Operating your stove”. Advise that if the stove goes out for any reason, wait at least

ten minutes before relighting. Stress that if the monitoring system repeatedly shuts off

the stove, the appliance should be switched off and a specialist should be consulted.

!

Advise the customer that they should read their owner guide before operating the

stove and always follow the advice in the section headed “Cleaning your stove”.

! Stress that no extra ceramic fuel effect pieces must be added over and

above those supplied with the appliance and that any replacements must only

be the authorised spares. Warn that ignoring this advice could cause

incomplete clearance of the products of combustion with consequent health

hazards.

!

Advise the customer that the appliance will operate to its maximum potential if the

flue is primed during the first 20 – 30 minutes of use. To do this, simply turn the

control knob to its highest setting. This will also burn off any carbon deposits that may

have formed during previous use.

If using the appliance for long periods it is beneficial to change between settings. This

will also help to remove any carbon deposits that may form during use.

! Recommend that the appliance should be serviced by a competent person at

least annually.

!

If the appliance is in premises in the United Kingdom occupied by a tenant, point

out that by law a landlord must have any gas appliance, flue and pipework which is

situated in a tenant’s premises checked for safety at least every 12 months.

! Explain to the customer that when operating the stove for the first time, some

Page 14

INSTALLER GUIDE

© Baxi Heating U.K. Limited 2007.

Page 15

vapours may be given off which may cause a slight odour and could possibly set off

any smoke alarms in the immediate vicinity. These vapours are quite normal with new

appliances. They are totally harmless and will disappear after approximately twelve

hours use.

! Inform the customer that the Serial number for the appliance is located on

the metal plate attached to the burner at the bottom of the appliance

underneath the burner module.

Servicing

!

Always turn off the gas supply and allow to cool completely before commencing

any servicing.

This product uses fuel effect pieces containing Refractory Ceramic Fibres

(RCF), which are man-made vitreous silicate fibres. Excessive exposure to

these materials may cause irritation to eyes, skin and respiratory tract.

Consequently, it is important to take care when handling these articles to

ensure that the release of dust is kept to a minimum. To ensure that the release

of fibres from these RCF articles is kept to a minimum, during installation and

servicing we recommend that you use a HEPA filtered vacuum to remove any

dust and soot accumulated in and around the stove before and after working on

the stove. When replacing these articles we recommend that the replaced items

are not broken up, but are sealed within a heavy duty polythene bag, clearly

labelled as RCF waste. RCF waste is classed as a stable, non-reactive

hazardous waste and may be disposed at a landfill licensed to accept such

waste. Protective clothing is not required when handling these articles, but we

recommend you follow the normal hygiene rules of not smoking, eating or

drinking in the work area and always wash your hands before eating or

drinking. This appliance does not contain any component manufactured from

asbestos or asbestos related products.

!

Check that the thermal switch is correctly located in the diverter box (See figure 4

on page 8).

!

Check that the appliance is clean and that no matter is blocking the burner or pilot

which may cause imperfect flames or prevent a correct electrode spark.

! After servicing, make sure that the ceramic fuel effect pieces are replaced

correctly as described in the installer and owner guide supplied with the ceramic

fuel effect. The ceramic fuel effect guide may have been placed inside or attached

to this guide.

! Always test for gas soundness and spillage after servicing the appliance.

Page 15

INSTALLER GUIDE

© Baxi Heating U.K. Limited 2007.

Page 16

7.1 Checking the aeration setting of the burner.

(For LPG models refer to the conversion guide).

1. The aeration shutter is factory set. It is important to ensure

that the aeration setting is correct. Check the aeration shutter

setting (See figure 10).

2. To adjust the aeration setting, loosen the two aeration

shutter screws, slide the aeration shutter to the position shown

in figure 9 and tighten the fixing screws.

Page 16

INSTALLER GUIDE

© Baxi Heating U.K. Limited 2007.

Figure 10. Aeration

shutter setting

Loading...

Loading...