Page 1

Please keep these instructions in a safe place.

If you move house please hand them over to the next occupier.

United Kingdom

en

User Guide

High Efficiency Wall Hung Condensing Gas Boiler

Baxi Combi

224 – 228 – 424 — 428

Page 2

Dear Customer,

Thank you very much for buying this appliance.

Please read through the manual carefully before using the product, and keep it in a safe place for later reference. In order to

ensure continued safe and efficient operation we recommend that the product is serviced regularly. Our service and customer

service organisation can assist with this.

We hope you enjoy years of problem-free operation with the product.

Page 3

Contents

7661618 - 1 - 04072016 3

Contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.1 The Benchmark Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.2 Benchmark Commissioning Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Liabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3.1 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.3.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.3 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Additional documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.1 Symbols used in the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Abbreviations/glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.1 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.2.1 Technical information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.2.2 Dimensions and connections/clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Description of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.2 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.1 In operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Control panel description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3.1 Description of the keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3.2 Description of the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.4 Accessories and options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4.1 Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5.1 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1.1 Operation checking procedure and basic fault identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Use of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.1 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1 List of parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1.1 Reading out operating parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2 Setting the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2.1 Setting the central heating water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.2.2 Setting the domestic hot water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2 Maintenance instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2.1 Re-pressurising the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.3 Venting the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.4 Draining the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

8.1 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.2 Fault finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

9 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.1 Decommissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

10 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Page 4

Contents

4 7661618 - 1 - 04072016

10.1 Disposal and recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11.1 Energy saving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11.2 Room thermostats and settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

12.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

12.2 Standard warranty terms and conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

13 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

13.1 Product fiche - Combination boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

13.2 Package fiche - boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

13.3 Package fiche - Combination heaters (boiler or heat pumps) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Page 5

1 Safety

PN-0000263

A

B

7661618 - 1 - 04072016 5

1.1 General safety instructions

1 Safety

Danger

This boiler can be used by children aged 8 years and above and

by persons with reduced physical, sensory or mental capabilities

or lack of experience and knowledge when they have been given

supervision or instruction concerning the safe use of the device

and understand the resulting risks. Children must not be allowed

to play with the appliance. Cleaning and user maintenance must

not be carried out by children without supervision.

Danger

If you smell gas:

1. Turn off the gas supply at the meter.

2. Open windows and doors in the hazardous area.

3. Do not operate light switches.

4. Do not operate any electrical equipment.

5. Do not use a telephone in the hazardous area.

6. Extinguish any naked flame and do not smoke.

7. Warn any other occupants and vacate the premises.

8. Telephone the National Gas Emergency Service on:- 0800

111 999.

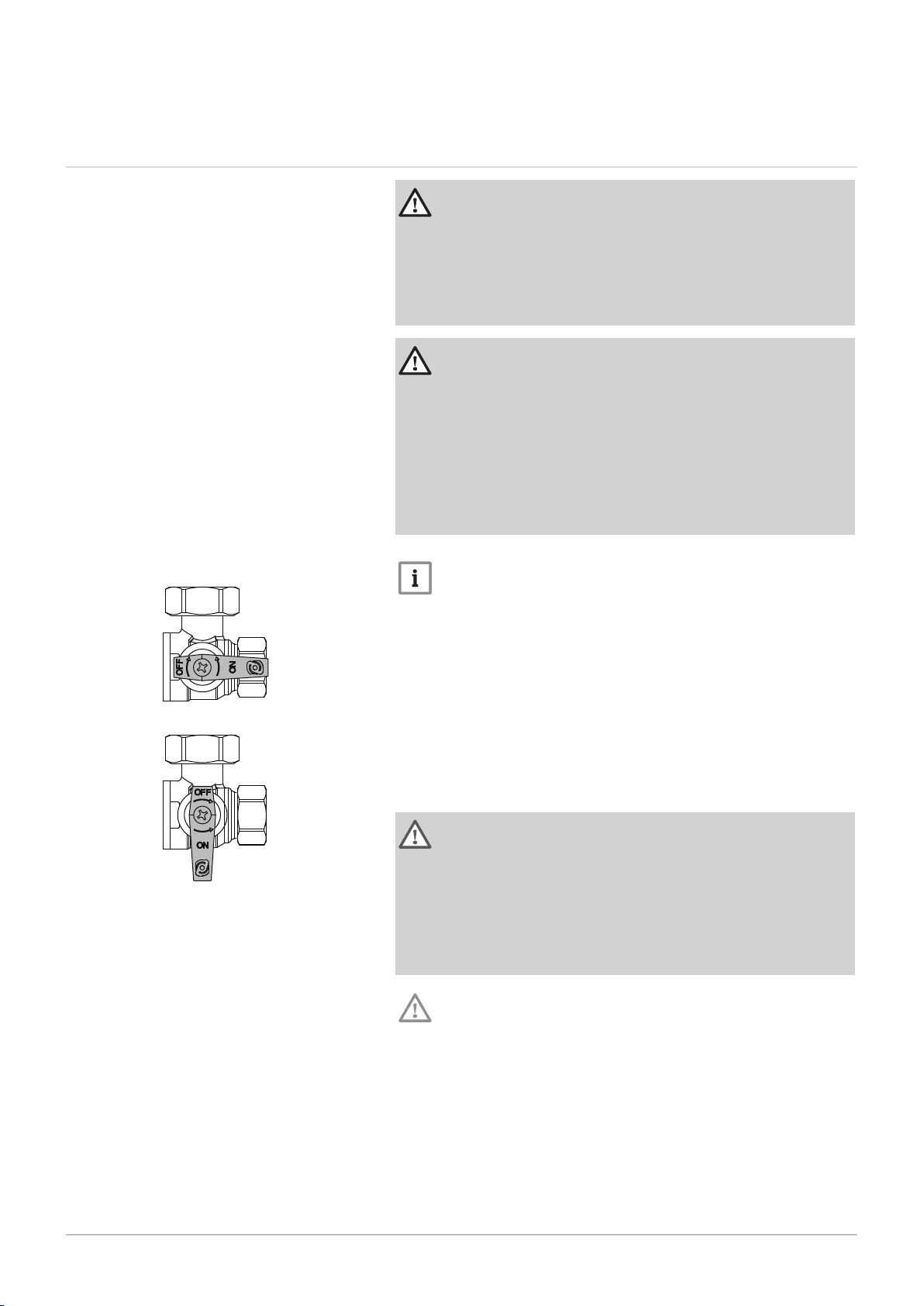

Fig.1 Taps ON and OFF

Note

If a water or gas leak occurs or is suspected, the boiler can be iso

lated at the inlet valves by turning their taps through 90° (1/4 turn)

downwards.

A ON

B OFF

For advice please contact your Installer, Annual Service Provider

or Baxi Customer Support - The Service Division of Baxi. You can

contact Baxi Customer Support on telephone number 0344 871

1545.

When contacting Baxi Customer Support it will be useful to have

the "Benchmark Checklist " at the back of the Installation & Serv

ice Manual to hand as it includes details relevant to the boiler and

installation.

Warning

Do not touch flue/chimney pipes. Depending on the settings of the

appliance, the temperature of flue/chimney pipes may exceed 60

°C.

Do not touch radiators for long periods. Depending on the settings

of the appliance, the temperature of radiators may reach 85 °C.

Take precautions with domestic hot water. Depending on the set

tings of the appliance, domestic hot water temperature may reach

65 °C.

Caution

Do not neglect to service the appliance. Contact a qualified pro

fessional or take out a maintenance contract for the annual servic

ing of the appliance.

Page 6

1 Safety

6 7661618 - 1 - 04072016

1.2 Recommendations

Caution

Only qualified professionals are authorised to work on the boiler

and the installation.

The appliance has an integral frost protection mode as long as

there is power to the boiler.

Note

Regularly check the water pressure in the system (recommended

pressure is 1.5 bar).

Keep the appliance accessible at all times.

Do not remove or cover the user information and serial number la

bels affixed to the boiler control flap. They must remain legible

throughout the lifetime of the boiler.

1.2.1

Baxi Heating UK Ltd is a licensed member of the Benchmark Scheme

which aims to improve the standards of installation and commissioning of

domestic heating and hot water systems in the UK and to encourage regu

lar servicing to optimise safety, efficiency and performance.

Benchmark is managed and promoted by Heating and Hotwater Industry

Council. For more information visit www.centralheating.co.uk

1.2.2

Please ensure that the installer has fully completed the Benchmark Check

list on the inside back pages of the installation instructions supplied with

the product and that you have signed it to say that you have received a full

and clear explanation of its operation. The installer is legally required to

complete a commissioning checklist as a means of complying with the ap

propriate Building Regulations (England and Wales).

All installations must be notified, by the installer, to Local Area Building

Control either directly or through a Competent Persons Scheme. A Build

ing Regulations Compliance Certificate will then be issued to the customer

who should, on receipt, write the Notification Number on the Benchmark

Checklist.

This product should be serviced annually to optimise its safety, efficiency

and performance. The service engineer should complete the relevant sec

tion of the Benchmark Service Record in the Installation & Service manual

after each service.

The completed Benchmark Checklist & proof of annual servicing (where

applicable) will be required in the event of any warranty work.

The Benchmark Scheme

Benchmark Commissioning Checklist

1.3

Liabilities

1.3.1 User's liability

To guarantee optimum operation of the system, you must abide by the fol

lowing instructions:

Read and follow the instructions given in the manuals provided with the

appliance.

Call on a qualified professional to carry out installation and initial com

missioning.

Get your installer to explain your installation to you.

Have the required inspections and maintenance carried out by a quali

fied installer.

Keep the instruction manuals in good condition close to the appliance.

Page 7

1 Safety

7661618 - 1 - 04072016 7

1.3.2 Installer's liability

The installer is responsible for the installation and initial commissioning of

the appliance. The installer must abide by the following instructions:

Read and follow the instructions given in the manuals provided with the

appliance.

Install the appliance in compliance with prevailing legislation and stand

ards.

Carry out initial commissioning and any checks necessary.

Explain the installation to the user.

If maintenance is necessary, warn the user of the obligation to check the

appliance and keep it in good working order.

Give all the instruction manuals to the user.

1.3.3 Manufacturer's liability

Our products are manufactured in compliance with the requirements of the

various Directives applicable. They are therefore delivered with the

marking and any documents necessary. In the interests of the quality of

our products, we strive constantly to improve them. We therefore reserve

the right to modify the specifications given in this document.

Our liability as manufacturer may not be invoked in the following cases:

Failure to abide by the instructions on installing the appliance.

Failure to abide by the instructions on using the appliance.

Faulty or insufficient maintenance of the appliance.

Page 8

2 About this manual

8 7661618 - 1 - 04072016

2 About this manual

2.1 General

Warning

Installation, repair and maintenance must only be carried out only

by a competent person.

All Gas Safe registered engineers carry an ID card with their licence num

ber and a photograph. You can check your engineer is registered by tele

phoning 0800 408 5500 or online at www.gassaferegister.co.uk

This manual is intended for the user of the Baxi Combi boiler. If the appli

ance is sold or transferred, or if the owner moves leaving the appliance

behind you should ensure that the manual is kept with the appliance for

consultation by the new owner and their installer.

The appliance is designed as a boiler for use in residential domestic envi

ronments on a governed meter supply only. The selection of this boiler is

entirely at the owner’s risk. If the appliance is used for purposes other than

or in excess of these specifications, the manufacturer will not accept any

liability for resulting loss, damage or injury.

The manufacturer will not accept any liability whatsoever for loss, damage

or injury arising as a result of failure to observe the instructions for use,

maintenance and installation of the appliance.

2.2 Additional documentation

2.3 Symbols used

Various timers, external controls, etc. are available as optional extras. Full

details are contained in the relevant sales literature.

2.3.1 Symbols used in the manual

This manual uses various danger levels to draw attention to special in

structions. We do this to improve user safety, to prevent problems and to

guarantee correct operation of the appliance.

Danger

Risk of dangerous situations that may result in serious personal

injury.

Danger of electric shock

Risk of electric shock.

Warning

Risk of dangerous situations that may result in minor personal in

jury.

Caution

Risk of material damage.

Note

Please note: important information.

See

Reference to other manuals or pages in this manual.

2.4

Abbreviations/glossary

CH Central heating

Page 9

DHW Domestic hot water

7661618 - 1 - 04072016 9

PCU PCB for managing burner operation

Pnc Condensing output

SU Safety PCB

2 About this manual

Page 10

3 Technical specifications

10 7661618 - 1 - 04072016

3 Technical specifications

3.1 Homologations

3.1.1 Certifications

Tab.1 Certifications

CE certificate number 0085CQ0192

NOx class 5 (EN 15502)

Boiler type C13, C

33

3.2

Tab.2 General

Tab.3 Heating circuit specifications

Tab.4 Domestic water circuit specifications

Technical data

3.2.1

Baxi Combi 224 228 424 428

Gas council numbers 47–077–21 47–077–22 47–077–23 47–077–24

Baxi Combi 224 228 424 428

Maximum pressure bar 3 3 3 3

Minimum pressure bar 0.5 0.5 0.5 0.5

Heating circuit temperature °C 25/80 ± 5° 25/80 ± 5° 25/80 ± 5° 25/80 ± 5°

Baxi Combi 224 228 424 428

Maximum pressure bar 8.0 8.0 8.0 8.0

Dynamic minimum pressure bar 0.15 0.15 0.15 0.15

Minimum water flow l/min 2.0 2.0 2.0 2.0

Domestic water circuit tempera

ture

Specific flow rate (D) l/min 11.5 13.4 11.5 13.4

°C 35/60 ± 5° 35/60 ± 5° 35/60 ± 5° 35/60 ± 5°

Technical information

Note

Where low flow taps or fittings are intended to be used in the DHW system connected to the boiler,

it is strongly recommended that the DHW flow rate DOES NOT fall below 2.5 l/min. This will ensure

reliable operation of the DHW function.

Tab.5 Electrical specifications

Baxi Combi 224 228 424 428

Electrical power supply voltage V 230 230 230 230

Electrical power supply fre

quency

Nominal electrical power W 84 94 84 94

External fuse rating Amp 3A 3A 3A 3A

Hz 50 50 50 50

Page 11

1

2

3

4

5 6 7

8

700

279

395

PN-0000264

A

*

5.0

6

B*

285

700

3

95

PN-0000205

5.0

178

3 Technical specifications

7661618 - 1 - 04072016 11

Tab.6 Other specifications

Baxi Combi 224 228 424 428

Degree of protection against humidi

IP IPX5D IPX5D IPX5D IPX5D

ty (EN 60529)

Net weight when empty/water load kg 26/28 26/28 26/28 26/28

Dimensions (height/width/depth) mm 700/395/279 700/395/279 700/395/279 700/395/279

Clearances (above/below casing)

front (for servicing)/(in operation)

side (left hand/right hand)

mm

mm

mm

178/250*

1000*/6

5/5

178/250*

1000*/6

5/5

178/250*

1000*/6

5/5

178/250*

1000*/6

5/5

* These are recommended dimensions. See fig. 3 for Minimum allowable clearances

Note

All data in this section are nominal values and subject to normal

production tolerances.

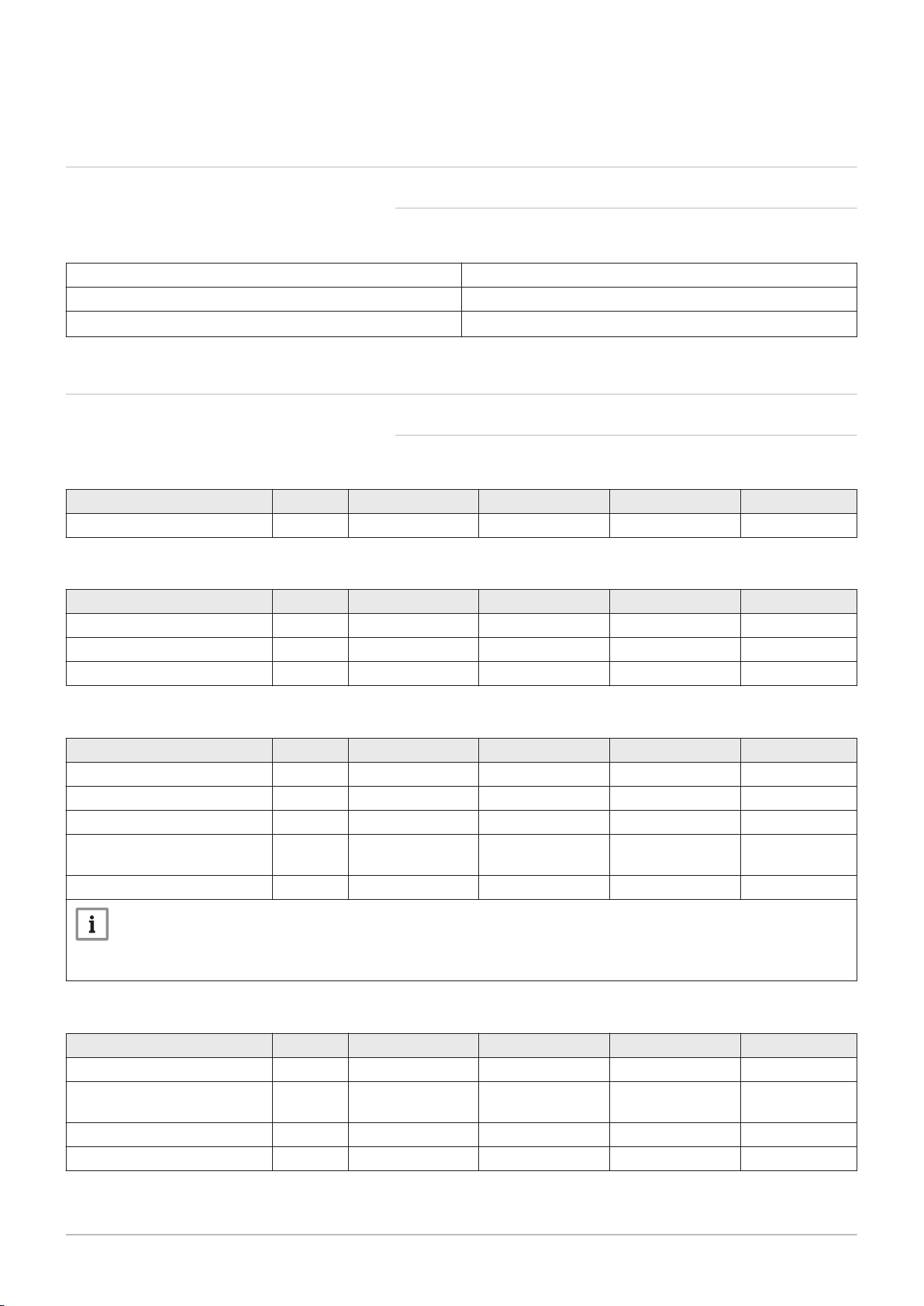

Fig.2

Fig.3

Dimensions and connections

Clearances

3.2.2

1

2

3

4

5

6

7

8

Dimensions and connections/clearances

Safety valve

Heating circuit water flow

Condensates discharge

Heating system/boiler drain tap

Domestic hot water outlet

Gas inlet

Mains cold water inlet

Heating circuit water return

A* Clearances below — 200mm minimum, 250mm recommended

B* Clearances in front — 450mm minimum, 1000mm recommended

The clearances shown in the diagram are minimum requirements to allow

for case removal, spanner access and air movement. These should be ob

served at all times and kept clear of obstructions.

Page 12

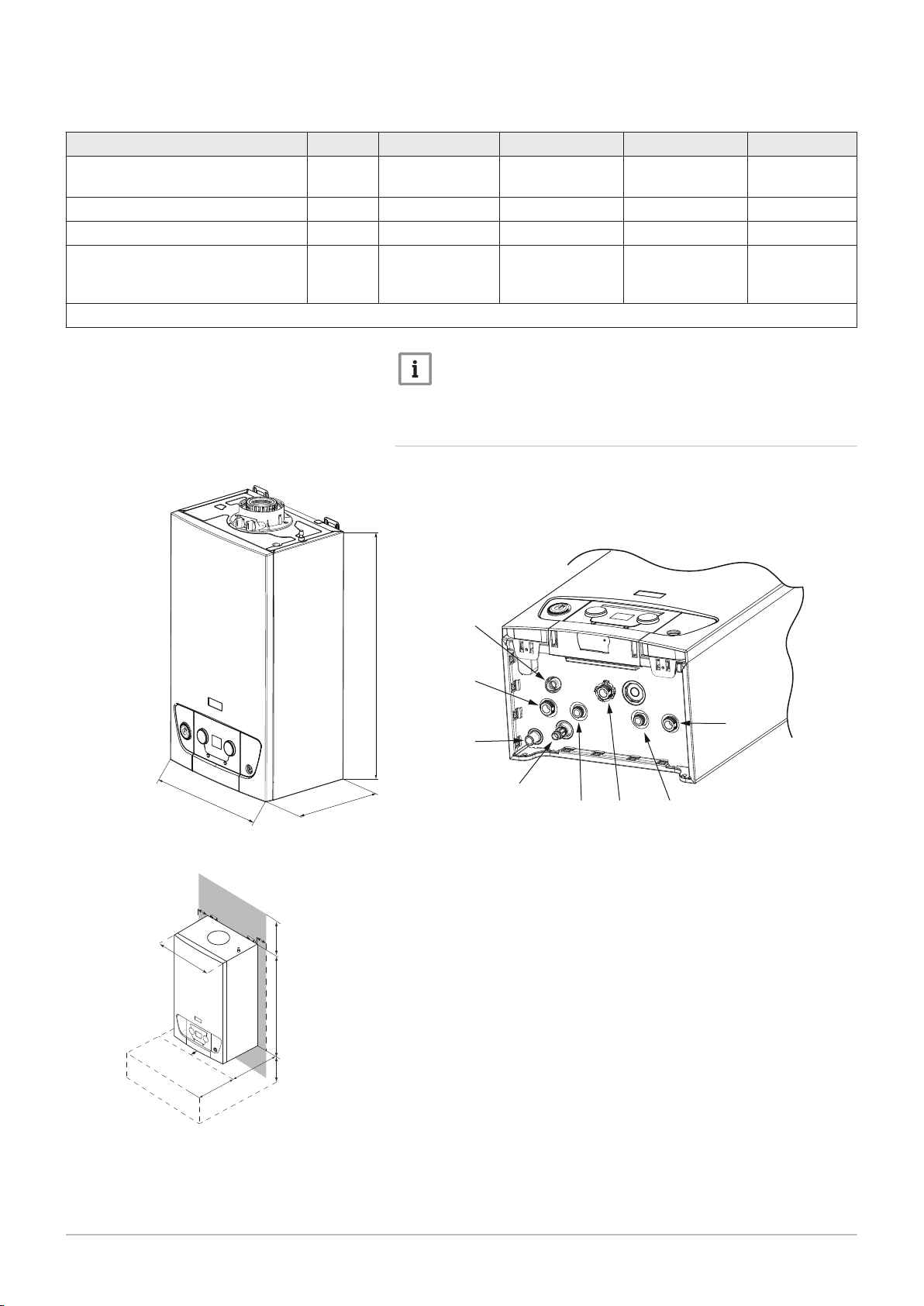

PN- 000 02 65

A

PN-0000266

PN-0000267

4 Description of the product

12 7661618 - 1 - 04072016

4 Description of the product

4.1 General description

Fig.4

Information label location

4.2 Operating principle

The Baxi Combi range of fully automatic gas fired wall hung condensing

combination boilers are room sealed and fan assisted, and will serve cen

tral heating and mains fed domestic hot water.

Tab.7 The boiler is set to give a maximum output of :-

24 model 24 kW DHW

21.8 kW CH Pnc (Condensing)

28 model 28 kW DHW

26.1 kW CH Pnc (Condensing)

The boiler is factory set for use only on Natural Gas (G20).

Priority is given to domestic hot water.

The boiler model, serial number and Gas Council number are also shown

on the information label. This is for user reference.

A

Information label

4.2.1 In operation

Whilst the boiler is in operation cooled flue gases are discharged through

the flue gas discharge pipe. This may appear as a cloud of steam which is

normal.

Condensed water is discharged from the boiler heat exchanger into a pipe

(the condensate drain). This pipe must never be altered or re-routed ex

cept by a qualified professional.

4.3

Fig.5 Control panel

Fig.6 Display screen

Control panel description

4.3.1

Description of the keys

Heating temperature control knob

Level access button: Information, Installer or Chimney Sweep

Manual reset button

Domestic hot water temperature control knob

4.3.2 Description of the display

Hour run meter

Malfunction

Maintenance

Reset necessary

Burner status

Heating mode

Outside temperature sensor

Domestic hot water mode

Page 13

4.4 Accessories and options

7661618 - 1 - 04072016 13

4 Description of the product

4.4.1 Optional accessories

The table below shows the accessories available for this boiler range.

Tab.8 Optional accessories

Part number Accessory

7658276 Baxi plug-in 24 hr mechanical timer combi - RH

7658523 Baxi plug-in 7 day digital timer combi - RH

7658781 Baxi plug-in receiver 24 hr RF programmable mech room

thermostat-combi

7658789 Baxi plug-in receiver 7 day RF digital programmable room

thermostat-combi

7212438 Baxi single channel wired programmable room thermostat

7212444 Baxi single channel wired timer

720971601 Baxi room thermostat

720330001 Baxi wired weather sensor

720648301 Multifit condensate & PRV combined pump

720644401 Multifit 1m condensate drain pipe 'trace heating' element

720664101 Multifit 2m Condensate drain pipe 'trace heating' element

720664201 Multifit 3m condensate drain pipe 'trace Heating' element

720664401 Multifit 5m condensate drain pipe 'trace heating' element

7659335 Baxi 200-400 stand off kit

5121379 Multifit remote secondary PRV kit

248221 Multifit filling loop (Not required for 424 and 428 models)

For Flue Accessories (elbows, extensions, clamps etc.) refer to the Flue

Installation Guide supplied in the literature pack.

Any of the above MUST be fitted ONLY by a qualified competent person.

Further details can be found in the relevant sales literature and at

www.baxi.co.uk

Page 14

START

Make sure the gas

supply is turned ON

and check if other

gas appliances are

operating (e.g. fire,

cooker). If the

property has a

prepayment meter

ensure it has

sufficient credit.

NO

If no gas, consult

your supplier.

Is there electricity to the

boiler ? Is the display lit ?

Check electrical supply to

boiler is switched on.

NO

YES

Is the Burner Flame

showing.

Burner Flame

(Indicates burner

is on)

Boiler operating

satisfactorily.

NO

YES

YES

YES YES

YES

If it does

not reset

CONTACT YOUR

INSTALLER OR

SERVICE ENGINEER.

Press the RESET button on the

controller to restart the boiler

Are reset and triangle symbols

illuminated or flashing?

Is the telephone symbol

illuminated or flashing?

OR

PN-0000229

5 Operation

14 7661618 - 1 - 04072016

5 Operation

5.1 Start-up

Fig.7 Start-up and checking

5.1.1 Operation checking procedure and basic fault identification

Page 15

Fig.8 Start up and checking (continued)

IMPORTANT: Where Low Flow Taps or Fittings are

intended to be used in the DHW system connected

to the boiler it is strongly recommended that the

DHW flow rate DOES NOT fall below 2.5 l/min.

This will ensure reliable operation of the DHW function.

Is the Timer ON and

calling for heat ?

Is the Room Thermostat

(if fitted) set high enough ?

12

1

2

3

4

5

6

7

8

9

10

11

Typical

examples

of external

timer

Ensure timer is set for

Central Heating ON (see

any instructions supplied

with timer)

NO

YES

YES

NO

15

10

5

20

25

15

10

5

20

25

Turn Room Thermostat

to maximum setting

(typical example shown)

CH ON

CH OFF

bar

0

1

2

3

4

Is the Central Heating

System Pressure

between 1.0 and 2.5 bar ?

Repressurise the system to

between 1.0 and 1.5 bar.

NO

YES

R

Error Code flashing between

E.02 and .07 indicating system

pressure below 0.5 bar.

YES

If you don’t know what you need to do

to get the boiler to light, or need help with

the system and controls, contact your

installer as soon as possible

R

PN-0000230

7661618 - 1 - 04072016 15

5 Operation

Page 16

1 2

3

PN-0000289

5 Operation

16 7661618 - 1 - 04072016

5.2 Use of the control panel

5.2.1 Control

Fig.9 Operating the controls

5.3

Shutdown

1. The controls are operated by the buttons and knobs shown.

1 Central heating water temperature control

2 Domestic Hot Water temperature control

3 Reset button

Isolate the mains power supply at the fused spur unit.

Isolate the gas supply at the boiler valve.

Protect the boiler from frost.

Note

The boiler is not protected against frost once it has been shut

down.

Note

If it is anticipated that the boiler will not be used for a long period

or the property is to be unoccupied it is recommended that the

system be drained if the electricity and gas supplies are to be

turned off. Your installer will be able to offer advice.

5.4

Frost protection

Where possible, draining the system should be avoided. If the system is to

be unused during winter months several precautions must be taken:

Any parts of the system that are in unheated areas of the dwelling fitted

with a device such as a pipe thermostat or frost thermostat.

Power must remain supplied to the boiler and controls.

Gas must remain supplied to the boiler.

The boiler pump will operate if the system temperature drops below 7°C. If

the temperature falls to 4°C the burner will ignite and remain lit until the

temperature reaches 10°C. At this temperature the burner will extinguish

but the pump will continue to operate for 15 minutes. This feature will pro

tect the boiler and to some extent adjacent parts of the system but addi

tional devices must be incorporated to guarantee frost protection.

Page 17

6 Settings

PN-0000291

PN-0000292

7661618 - 1 - 04072016 17

6.1 List of parameters

6 Settings

6.1.1 Reading out operating parameters

Pressing the button enables you to view information about how the boil

er is working.

1. Press this button for one second to view the operating mode (e.g. "t.

17" = purging in progress).

2. Press this button for one second again to view the operating substatus or the corresponding function that is active (e.g. "u.00" = boil

er in standby mode).

3. Press this button for one second again to view the operating temper

ature in the heating system: The symbol followed by the temper

ature in °C will flash.

4. Press this button for one second again to view the operating temper

ature in the domestic water system: The symbol followed by the

temperature in °C will flash.

5. Press this button for one second again to view the power level from

0 to 100: The symbol and the number relating to the level of oper

ating power will flash.

Press and hold the button for more than three seconds to exit this

menu.

6.2 Setting the parameters

Fig.10

Fig.11 Setting the domestic hot water tem

Setting the central heating

perature

6.2.1 Setting the central heating water temperature

Turn the central heating temperature setting button to adjust the central

heating water temperature. See Fig. 10.

Note

If the central heating water temperature set point is lower than

16°C without an outside temperature sensor, the heating is switch

ed off automatically. The heating starts up again only to ensure

frost protection if the outside temperature sensor shows a value of

less than 3°C.

6.2.2 Setting the domestic hot water temperature

Turn the domestic hot water temperature setting button to adjust the tem

perature. See Fig. 11.

Page 18

bar

0

1

2

3

4

bar

0

1

2

3

4

PN-0000259

7 Maintenance

18 7661618 - 1 - 04072016

7 Maintenance

7.1 General

The boiler does not require any special maintenance. However, the boiler

must be serviced annually in accordance with the Installation and Service

Manual and the relevant section of the Benchmark Service Record com

pleted in order to maintain the warranty.

Note

Taking out a maintenance contract is recommended.

Caution

Maintenance operations must be performed by a qualified compe

tent person.

Use only BAXI genuine spare parts.

The painted panels should be wiped with a damp cloth and then dried

completely. DO NOT USE ABRASIVE CLEANING AGENTS.

7.2

Maintenance instructions

Fig.12 Water pressure

The central heating system should be checked regularly. Proceed as fol

lows:

1. Check the water pressure in the central heating system.

Note

If the water pressure is lower than 0.7 bar, the system must be

topped up.

See

Re-pressurising the system.

Note

If the water pressure drops below 0.5 bar the boiler will not work.

2. Check radiators for leaks and (especially in damp areas) for rust.

3. Open and close the radiator valves several times a year to ensure

they can still be rotated.

Caution

Only a qualified installer may clean the inside of the boiler.

7.2.1 Re-pressurising the system

If the water pressure is too low, the system must be re-pressurised.

The normal operating water pressure is between 1 and 2 bar. If the pres

sure exceeds 3 bar the safety pressure valve will operate and a fault is in

dicated. Ensure that the temporary filling loop is disconnected. Contact

your installer.

It may be necessary to repressurise the system occasionally (when the

water pressure falls below 0.7). A filling device (the filling loop) will be fitted

on the system. This will be on the boiler itself, or on pipework near to the

boiler.

Page 19

PN-0000260

7 Maintenance

7661618 - 1 - 04072016 19

Fig.13 Filling loop (400 series only)

400 series boilers are supplied with a temporary filling loop as shown.

For 200 series boilers seek advice from your installer.

Note

If the water pressure requires regular re-pressurising a fault or

leak is indicated. Seek advice from your installer.

The temporary filling loop consists of two isolating taps and a separate fill

ing pipe with connection fittings.

Only when repressurising should the filling pipe be connected between the

two taps. Ensure that the nuts on the pipe ends are tightened onto the

taps.

1. Fully open one of the taps first, and then while watching the pres

sure gauge, carefully open the second tap.

Note

The system pressure is shown at all times on the pressure gauge

and can be viewed on the display when there is power to the boil

er.

2. When the figures on the display or needle on the pressure gauge in

dicate between 1 and 1.5 bar turn both taps off.

3. Disconnect the filling pipe from the taps (a small amount of water

may be present) and remove it. Keep the pipe in a safe place for fu

ture use.

4. If blanking caps are available fit them to the taps.

Note

Go to the "How to videos" section of the "Advice" page at

www.baxi.co.uk for further details.

5. When the correct pressure is restored the boiler will reset automati

cally.

Page 20

76

A

C

B

5

4

3

2

1

2

3

4

1

10

PN-0000225

7 Maintenance

20 7661618 - 1 - 04072016

7.3 Venting the installation

Fig.14 Venting the radiators

If any air is present in the appliance or system it must be removed in order

to prevent nuisance noises that may occur during heating or when drawing

off hot water. Proceed as follows:

1. Open the valves of all the radiators connected to the system.

2. Set the room thermostat to the highest possible temperature and

any timers to ‘ON’.

3. Wait until the radiators are warm.

4. Switch off the boiler.

5. Vent the radiators. Work from the lowest radiator in the property.

6. Open the bleed vent with the key, keeping a cloth pressed against

the vent.

7. Wait until water comes out of the bleed vent and then close.

Warning

The CH water in the radiators will still be hot.

8. Switch the boiler on.

9. After venting, check that the water pressure in the system is still ad

equate.

Note

If the air is difficult to remove, it is possible to manually de-aerate

the boiler and system using the control panel. Press and hold the

RESET button for approximately 5 seconds and release to start

the process. The display will show dAF briefly and then t.17 to in

dicate that the process has started. The de-aeration will last for

approximately 5 minutes then the control panel will revert to its

normal display.

Note

If the water pressure is lower than 0.7 bar, the water must be top

ped up. If necessary repressurise the system (recommended

pressure between 1 and 1.5 bar when cold).

10. Reset the room thermostat to the desired temperature.

Page 21

7.4 Draining the installation

AD-3000730-01

5

3

2

1

2

3

4

1

4

7661618 - 1 - 04072016 21

7 Maintenance

Fig.15 Draining the installation

It may be necessary to drain the central heating system if radiators need

to be replaced, if there is a major water leak or if there is a risk of freezing.

Proceed as follows:

1. Open the valves of all the radiators connected to the system.

2. Switch off the boiler's electrical connection.

3. Wait approximately ten minutes, until the radiators feel cold.

4. Connect a drain hose to the lowest draining point. Place the end of

the hose in a drain or at a place where drained pipe water will not

cause any damage.

5. Open the central heating system fill/drain valve. Drain the installa

tion.

Warning

The water may still be hot.

6. Close the drain valve when no more water comes from the draining

point.

Note

After draining the system, the concentration of corrosion inhibitor

and antifreeze agent may be extremely diluted - check with your

installer.

Page 22

PN-0000271

1

2

3

4

5

8 Troubleshooting

22 7661618 - 1 - 04072016

8 Troubleshooting

8.1 Error codes

Fig.16 Display errors

1

2

3

4

5

In the unlikely event of an error occurring the display will show either a

flashing triangle, or a flashing triangle with RESET. The display will also

flash and show the error code (see Error Code tables).

A warning triangle indicates a temporary fault. (3)

A warning triangle with RESET indicates a permanent fault. (4)

A temporary fault is indicated by an ‘H’ followed by a two-digit code num

ber (e.g. .02). This code flashes and alternates with a second two-digit

code (e.g. .06) to indicate the specific fault. (3)

A temporary fault prevents the boiler operating but will automatically reset

once the cause of the fault has been resolved.

Tab.9 Temporary error code descriptions

Control panel

Main display icons

Example of temporary error code (Low water pressure)

Example of permanent error code (Low water pressure)

Example of typical display after a successful RESET

Error code Description of fault

H01 00 Temporary loss of communication between the gas valve

and boiler PCB

H01 05 Maximum difference between flow and return temperature

reached

H01 08 Flow temperature increasing too quickly in heating mode

H01 14 Maximum flow temperature value reached

H01 18 No circulation of water in the system

H02 06 Low water pressure in the heating circuit

H03 02 Temporary loss of flame

A permanent fault ‘Lock out’ is indicated by an ‘E’ followed by a two-digit

code number (e.g. .02). This code flashes and alternates with a second

two-digit code (e.g. .07) to indicate the specific fault (4)

A permanent fault prevents the boiler operating and will not automatically

reset. Once the fault condition has been rectified the RESET button must

be pressed for at least 3 seconds to restart the boiler.

If the error cannot be reset, or it frequently re-occurs, please contact your

Installer, Annual Service Provider or Baxi Customer Support . You can

contact Baxi Customer Support on 0344 871 1545.

When contacting Baxi Customer Support it will be useful to have the

‘Benchmark Checklist’ at the back of the Installation & Service Manual to

hand as it includes details relevant to the boiler and installation.

Tab.10 Permanent error code descriptions

Error code Description of fault

E04 01

E04 02

E00 04

E00 05

E04 04

E04 05

E01 11

E04 13

E02 07 Low water pressure

Flow temperature sensor fault

Return temperature sensor fault

Flue temperature sensor fault

Fan fault

Page 23

8 Troubleshooting

7661618 - 1 - 04072016 23

Error code Description of fault

E01 17 No water circulation

E04 10 Ignition failure after 5 attempts

E01 04 Loss of flame detected 5 times in 24 hours

E04 00

E04 17

E04 08 Maximum safety temperature reached

E02 47 Connection with external device failed

E02 48 Configuration with external device failed

Note

If a different error code from those described in the error code ta

ble appears on the display contact Baxi Customer Support on

0344 871 1545.

Gas valve fault

8.2

Tab.11 Problems and solutions

Fault finding

Problem Possible causes Solution

Check that the boiler is being supplied with power.

Check fuses and the switches.

Check whether the gas isolation cock is properly

open.

If the property has a prepayment meter ensure it

has sufficient credit.

Increase the value with the CH temperature knob

or if a room thermostat is connected, increase the

temperature on the room thermostat.

system.

Check fuses and switches.

Check whether the gas isolation cock is properly

open.

If the property has a prepayment meter ensure it

has sufficient credit.

There is no domestic hot wa

ter.

The radiators are cold.

The boiler is not working.

The DHW function is switched off. Activate the DHW mode.

The water pressure is too low (< 0.5 bar). Re-pressurise the system.

Insufficient flow. Flow must be at least 2.5 litres per minute.

The temperature set point for the heating

is too low.

The heating mode is deactivated. Activate the heating mode.

The radiator valves are not open. Open the valves of all radiators connected to the

The boiler is not working. Check that the boiler is being supplied with power.

The water pressure is too low (< 0.5 bar). Re-pressurise the system.

Page 24

8 Troubleshooting

24 7661618 - 1 - 04072016

Problem Possible causes Solution

The temperature set point for the heating

is too low.

Increase the value with the CH temperature knob

or if a room thermostat is connected, increase the

temperature on the room thermostat.

No demand for heating. Ensure that timers & thermostats are calling for

heat.

No power supply. Check that the boiler is being supplied with power.

Check the fuses and switches.

The boiler is not working.

The water pressure is too low (< 0.5 bar). Re-pressurise the system.

The boiler is indicating an error. Press the Reset button.

Correct the error, if possible.

The gas pressure is too low. Check whether the gas isolation cock is fully open.

Open the gas isolation cock.

Condensate drain blocked. Check drain, especially any external runs in freez

ing temperatures.

If the boiler is not working also check section "Operation checking proce

dure and basic fault identification" or contact your Installer.

Page 25

9 Decommissioning

7661618 - 1 - 04072016 25

9.1 Decommissioning procedure

9 Decommissioning

Caution

Only qualified persons are authorised to work on the appliance

and system to decommission.

If your boiler needs to be decommissioned either temporarily or perma

nently the following should be performed:

1. Switch off the boiler.

2. Switch off the boiler’s electrical connection.

3. Close the gas isolation tap.

4. Drain the central heating system.

Seek the advice of your installer.

Page 26

10 Disposal

26 7661618 - 1 - 04072016

10 Disposal

10.1 Disposal and recycling

Caution

Removal and disposal of the boiler must be carried out by a quali

fied person in accordance with local and national regulations.

Page 27

11 Environmental

7661618 - 1 - 04072016 27

11.1 Energy saving

11 Environmental

Tips on saving energy:

Do not cover radiators. Do not hang curtains in front of radiators.

Install reflective panels behind the radiators to prevent heat loss.

Insulate the pipes in rooms that are not heated (cellars and lofts).

Install loft insulation & double glazing.

Use draught excluders where necessary.

Upgrade any older boiler external controls.

Turn down room thermostats by 1°.

Turn off radiators in rooms not in use.

Do not run hot (or cold) water pointlessly.

Fit a water-saving shower head to save up to 40 % energy.

Take showers rather than baths. A bath consumes twice as much water

and energy.

11.2

Room thermostats and settings

Various models of room thermostat are available. The thermostat type and

setting affect the total energy consumption.

A few tips:

A modulating thermostat in combination with thermostatic radiator valves

saves energy and offers considerable comfort. This combination gives

you flexibility with the temperatures. Do not fit thermostatic radiator

valves in the room in which the room thermostat is installed.

Completely closing and opening thermostatic valve radiators causes un

desirable temperature fluctuations. Open and close thermostatic valves

in small steps.

Lower the thermostat to around 20°C. This reduces heating costs and

energy consumption.

Lower the room thermostat temperature temporarily if opening windows

to air the rooms.

If you are using an ON/OFF type thermostat, reduce the water tempera

ture value in summer (e.g. 60°C in summer and 80°C in winter).

When setting an hourly programmable thermostat, consider days when

you are absent or on holiday. Electricity production and energy savings

reach their optimum level with a programmed and activated timer pro

gramme.

Page 28

12 Warranty

28 7661618 - 1 - 04072016

12 Warranty

12.1 General

To make sure your boiler warranty is activated and maintained, it is essen

tial that the:

1. Benchmark checklist is completed by your installer

2. Warranty is registered within 30 days

3. Boiler has an annual service

Please note that failure to adhere to terms and conditions will invalidate

your warranty.

12.2

Standard warranty terms and conditions

Warranty registration, service & repair

For full terms and conditions, visit www.baxi.co.uk/terms.

Benchmark checklist

The Benchmark Checklist will be completed by your installer and records

that the boiler has been installed and commissioned correctly. It can be

found at the back of the installation and service manual and should be

kept in a safe place for the life of the boiler. We will check that the Bench

mark Checklist has been completed on an in-warranty visit.

Ways to register your warranty

If your boiler is eligible for an extended warranty, your installer may regis

ter the product on your behalf and provide you with the relevant documen

tation. Please check with your installer.

Should this not be the case, you can register your warranty online at

www.baxi.co.uk/registration

To activate a standard two year warranty, please use one of the following

methods:

Freephone 0800 013 7989 or

Visit the website www.baxi.co.uk and go to Warranty Registration.

Annual service

A service must be completed every 12 months from the date of installation

to maintain your warranty.

This service must be completed by one of the following:

A Gas Safe registered installer/engineer

Baxi Customer Support; call us 0344 871 1545

Please make sure that your engineer has logged the service information at

the back of the installation and service manual. You will be asked for your

service history on any in-warranty repair visit.

If you experience a problem with your boiler

For any in or out of warranty repair, Baxi Customer Support is on hand to

help you. Call our award-winning team to arrange for one of our nation

wide team of Gas Safe registered engineers to visit.

If your product is in warranty, everything is free of charge, subject to our

warranty terms and conditions. If it is out of warranty, we can still help and

offer a range of options you can choose from to suit your needs.

Contact Baxi Customer Support 0344 871 1545

Opening hours

Monday - Friday, 8.00am - 6.00pm

Weekends and Bank Holidays, 8.30am - 2.00pm

Please note calls may be recorded for training and monitoring purposes.

When contacting Baxi Customer Support, please have the following infor

mation to hand:

Page 29

12 Warranty

7661618 - 1 - 04072016 29

Boiler serial number.

See

Section 4.1 for details.

Proof of purchase if you do not have the boiler serial

Please note that for in-warranty repairs, our engineers will ask to see your

service history record, completed Benchmark Checklist and details of your

installer. These can all be found in the Installation and Service manual.

Page 30

AAA

A

AAA

A

13 Appendix

30 7661618 - 1 - 04072016

13 Appendix

13.1 Product fiche - Combination boilers

Tab.12 Product fiche for combination boilers

Baxi Combi 224 228 424 428

Space heating - Temperature application Medium Medium Medium Medium

Water heating - Declared load profile XL XL XL XL

Seasonal space heating energy efficiency class

Water heating energy efficiency class

Rated heat output

Space heating - Annual energy consumption GJ 62 74 62 74

Water heating - Annual energy consumption

Seasonal space heating energy efficiency % 93 93 93 93

Water heating energy efficiency % 86 85 86 85

Sound power level LWA indoors dB 48 50 48 50

(1) Electricity

(2) Fuel

(Prated or Psup)

kW 20 24 20 24

kWh

GJ

(1)

(2)

33

17

33

17

33

17

33

17

See

For specific precautions about assembling, installing and main

taining: Safety, page 5

Page 31

13.2 Package fiche - boilers

AD-3000743-01

%

1

‘I’

2

%+

3

%( - ‘I’ ) x 0.1 = ±

4

%(‘III’ x + ‘IV’ x ) x 0.9 x ( /100) x = +

(1)

A* = 0.95, A = 0.91,

B = 0.86, C = 0.83,

D - G = 0.81

5

%( - ‘I’ ) x ‘II’ = +

6

%0.5 x 0.5 x = -

54

<30%

G F E D C B A A

+

A

++

A

+++

%+ (50 x ‘II’) =

7

7

%

from fi che of solar device

Solar contribution AND Supplementary heat pump

Solar contribution

The energy effi ciency of the package of products provided for in this fi che may not correspond to its actual energy effi ciency once installed

in a building, as this effi ciency is infl uenced by further factors such as heat loss in the distribution system and the dimensioning of the

products in relation to building size and characteristics.

Boiler and supplementary heat pump installed with low temperature heat emitters at 35°C ?

Seasonal space heating energy effi ciency class of package

Seasonal space heating energy effi ciency of package

OR

Seasonal space heating energy effi ciency (in %)

Supplementary heat pump

Tank rating

Collector effi ciency (in

%)

Tank volume (in m³) Collector size (in m²)

Seasonal space heating energy effi ciency (in %)

Supplementary boiler

Class I = 1%, Class II = 2%, Class III = 1.5%,

Class IV = 2%, Class V = 3%, Class VI = 4%,

Class VII = 3.5%, Class VIII = 5%

Temperature control

Seasonal space heating energy effi ciency of boiler

(1) If tank rating is above A, use 0.95

select smaller value

from fi che of heat pump

from fi che of heat pump

from fi che of boiler

from fi che of temperature control

7661618 - 1 - 04072016 31

Fig.17 Package fiche for boilers indicating the space heating energy efficiency of the package

13 Appendix

I The value of the seasonal space heating energy efficiency of the

preferential space heater, expressed in %.

Page 32

13 Appendix

32 7661618 - 1 - 04072016

II The factor for weighting the heat output of preferential and supple

mentary heaters of a package as set out in the following table.

III The value of the mathematical expression: 294/(11 · Prated),

whereby ‘Prated’ is related to the preferential space heater.

IV The value of the mathematical expression 115/(11 · Prated),

whereby ‘Prated’ is related to the preferential space heater.

Tab.13 Weighting of boilers

Psup / (Prated + Psup)

(1)(2)

II, package without hot water storage tank II, package with hot water storage tank

0 0 0

0.1 0.3 0.37

0.2 0.55 0.70

0.3 0.75 0.85

0.4 0.85 0.94

0.5 0.95 0.98

0.6 0.98 1.00

≥ 0.7 1.00 1.00

(1) The intermediate values are calculated by linear interpolation between the two adjacent values.

(2) Prated is related to the preferential space heater or combination heater.

Tab.14 Package efficiency

Baxi Combi 224 228 424 428

Temperature control X %

Temperature control Y %

Page 33

AD-3000747-01

%

1

‘I’

2

%(1.1 x ‘I’ - 10%) x ‘II’ - - ‘I’ = +

‘III’

<28%

XXL

XL

L

M

G F E D C B A A

+

A

++

A

+++

3

%

%+ 0.4 x =

23

%- 0.2 x =

23

The energy effi ciency of the package of products provided for in this fi che may not correspond to its actual energy effi ciency once installed

in a building, as this effi ciency is infl uenced by further factors such as heat loss in the distribution system and the dimensioning of the

products in relation to building size and characteristics.

Water heating energy effi ciency class of package under average climate

Water heating energy effi ciency of package under average climate

Auxiliary electricity

Solar contribution

Water heating energy effi ciency of combination heater

from fi che of solar device

Colder:

Warmer:

Water heating energy effi ciency under colder and warmer climate conditions

Declared load profi le:

13 Appendix

7661618 - 1 - 04072016 33

13.3 Package fiche - Combination heaters (boiler or heat pumps)

Fig.18 Package fiche for combination heaters (boilers or heat pumps) indicating the water heating energy efficiency of the

package

I The value of the water heating energy efficiency of the combination

heater, expressed in %.

II The value of the mathematical expression (220 · Q

where Q

15 and Q

is taken from Regulation EU 811/2013, Annex VII Table

ref

nonsol

clared load profile M, L, XL or XXL of the combination heater.

III The value of the mathematical expression (Q

expressed in %, where Q

solar device and Q

ble 15 for the declared load profile M, L, XL or XXL.

from the product fiche of the solar device for the de

is taken from the product fiche of the

aux

from Regulation EU 811/2013, Annex VII Ta

ref

)/Q

ref

· 2,5)/(220 · Q

aux

nonsol

,

),

ref

Page 34

13 Appendix

34 7661618 - 1 - 04072016

Page 35

© Copyright

All technical and technological information contained in these technical instructions, as well as any drawings and technical de

scriptions supplied, remain our property and shall not be multiplied without our prior consent in writing. Subject to alterations.

Page 36

Baxi Customer Support

0344 871 1545

Opening hours

Monday - Friday, 8.00am-6.00pm

Weekends and Bank Holidays, 8.30am-2.00pm

Please note calls may be recorded for training and monitoring purposes

baxi.co.uk

Register now to activate your warranty:

www.baxi.co.uk/registration

For the warranty to be maintained, please make sure...

Benchmark checklist is completed

Warranty is registered within 30 days

The boiler has an annual service

1

2

3

For full terms and conditions, visit www.baxi.co.uk/terms. Failure to adhere to

terms and conditions will void your manufacturer’s warranty.

Baxi

Brooks House,

Coventry Road,

Warwick, CV34 4LL

Please ensure the boiler is installed in accordance with these installation

instructions and that you adhere to the Building Regulations.

e&oe

All descriptions and illustrations provided in this document have been

carefully prepared but we reserve the right to make changes and

improvements in our products which may affect the accuracy of the

information contained in this leaflet. All goods are sold subject to our

standard Conditions of Sale which are available on request.

7661618 - 1 - 04072016

Loading...

Loading...