Page 1

TE1/TE2 - Pt100 Temperature System

Safety instructions

This instrument is built and tested according to the current EU-directives and packed in technically safe condition. In order to maintain this

condition and to ensure safe operation, the user must follow the hints

and warnings given in this instruction.

During the installation the valid national rules have to be observed.

Ignoring the warnings may lead to severe personal injury or substantial damage to property.

The product must be operated by trained staff. Correct and safe operation of this equipment is dependent on proper transport, storage,

installation and operation.

All electrical wiring must conform to local standards. In order to

prevent stray electrical radiation, we recommend twisted and shielded

input cables, as also to keep power supply cables separated from the

input cables. The connection must be made according to the connecting diagrams.

Before switching on the power supply take care that other equipment

is not affected. Ensure that the supply voltage and the conditions in

the environment comply with the specification of the device.

Before switching off the supply voltage check the possible effects on

other equipment and the processing system.

WARNING

This product contains no replaceable parts.

In case of malfunction the product must be shipped to Baumer for

repair.

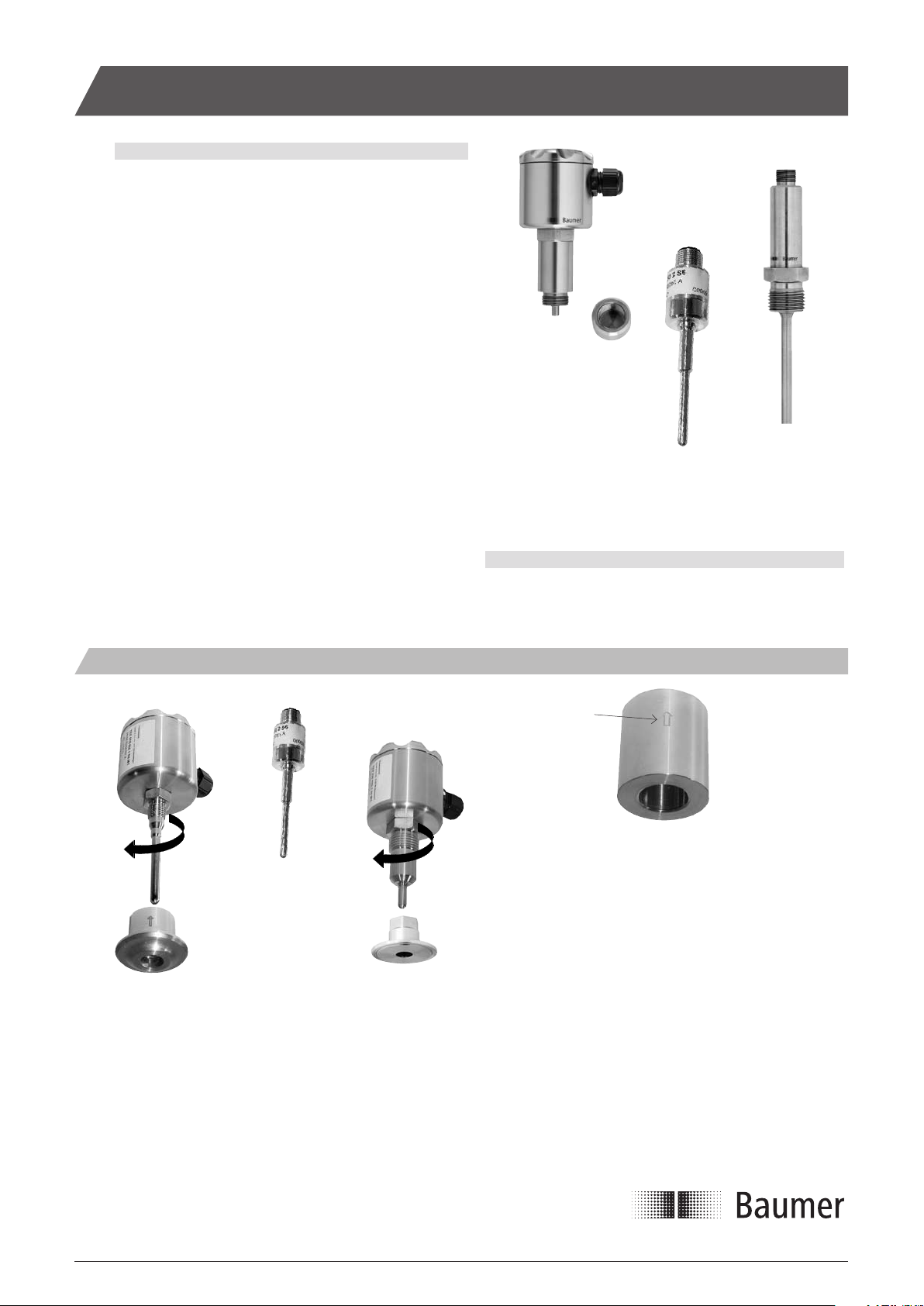

TE1

temperature-

sensor or

transmitter

TE2

temperature

sensor

TE2

temperature

transmitter

Mechanical Installation - Mounting Examples Mounting a Welding Part

M12 connection No thread G1/2A hygienic

Mark

The hygienic welding parts are easy to weld into tank walls and pipes.

10...20 Nm.

10...20 Nm.

PM031 CAM020

Use only the recommended sleeves or adapters. If other systems are

used, there is a severe risk of system malfunction or untight process

connections.

Do not use Teflon, elastomere or other types of gaskets for the

hygienic process connection featuring a conical seal.

The tightening torque is 10...20 Nm.

The mark or hole on the welding part indicates the final position of the

cable gland or M12 connector for a TE1/TE2 sensor.

We recommend to position the gland or plug downwards in order to

avoid water intrusion.

Check the tightness of the process connection. Make sure that the

cable gland or the M12 plug connector is properly screwed in.

Installation Manualwww.baumer.com/process

Page 1 Design and specifications subject to change without notice

Page 2

Page 2

Design and specifications subject to change without notice

Installation Manual

www.baumer.com/process

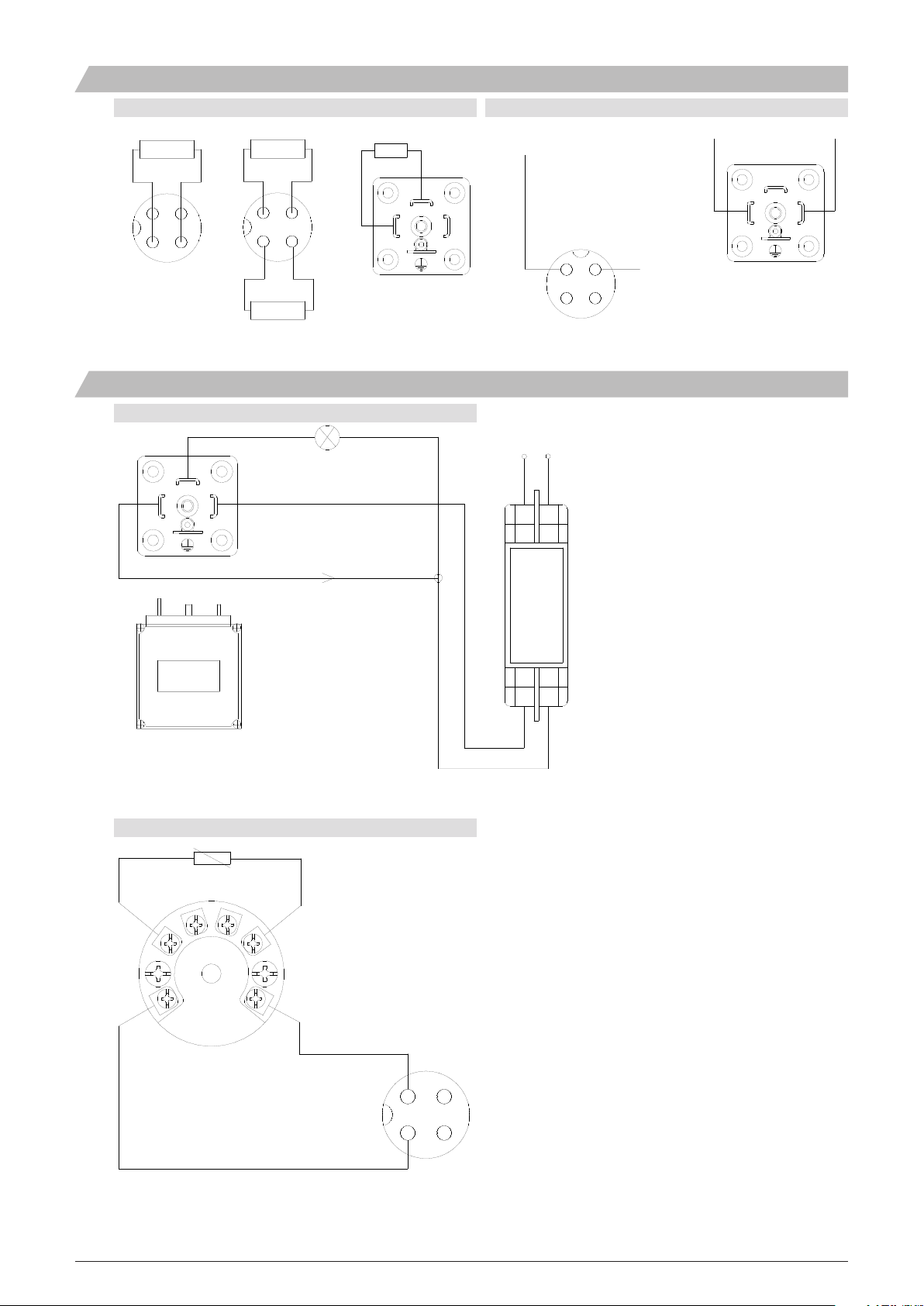

Electrical Installation

TE1/TE2 Temperature Sensor

Pt100

1 4

2 3

M12 Plug

Pt100

1 4

2 3

Pt100

Application Examples

TE2 with Integrated Transmitter and ZED601

3

1

2

Lamp

Pt100

2

Plug

DIN 43650-A

TE2 - Integrated Temperature Transmitter

- +

4...20 mA

3

1

230 Vac

3

Male plug

2

M12 Plug

4

1

Note:

The lamp is controlled by the open collector

output (PNP) from the ZED601 (optional).

4...20 mA

- +

3

2

Plug

DIN 43650-A

1

ZED601 display

mounted on a TE2

temperature transmitter

8888

TE1 with FlexTop Transmitter

RTD

4...20 mA

2

1

+ -

24 Vdc

Mounting example of a FlexTop 2201 temperature transmitter

Please refer to the relevant FlexTop manual in case a transmitter is

mounted.

2 1

4...20 mA (+)

4...20 mA (-)

1

2

Page 3

Page 3 Design and specifications subject to change without notice

Installation Manualwww.baumer.com/process

Configuration with FlexProgrammer

Note:

Disconnect loop supply before

connecting the FlexProgrammer

to the transmitter.

1

2

1

TE2 with integrated

transmitter

FlexTop

transmitter

2

2

FlexProgrammer 9701

Red clip

1

2

Black clip

2

Note: Ambient temperature range 0...50°C

1

Brown

1

1

Adapter cable for TE2 with integrated transmitter

White

2

In the following description the TE2 with an integrated transmitter and

the TE1 with a FlexTop temperature transmitter will be referred to as

“transmitter”.

The transmitter can be configured, using the 4...20 mA cable. The

maximum distance depends on the cable type, resistance and capacity. We recommend to use screened cables.

To be able to configure the transmitter with the FlexProgrammer the

dedicated software, FlexProgram, must be loaded on the PC.

The Flex-program has help menus for all functions.

Samples of Product Types

G1/2A (hygienic with a dedicated welding part)

During the configuration the new data are, by means of the FlexPro-

grammer, transferred from the PC to the transmitter, in which they are

stored in the internal memory.

The indication for a correct configuration sequence is:

TE1: The LED on the FlexTop lights up constantly.

TE2: The transmitter has no indication.

Note: During the first power-up after a configuration the power-on time

increases to approx. 10 sec.

M12 (hygienic with a dedicated welding part)

TE1x-4

TE2x-4 TE1x-5 TE2x-6TE2x-5

Page 4

Samples of Accessories

In case the TE1 is equipped with a FlexTop in-head transmitter or the

TE2 is with internal transmiiter the Flexprogrammer will be needed.

The FlexProgrammer 9701 is a dedicated tool to configure all

Baumer configurable products.

Type No. 9701-0001 complies:

FlexProgrammer interface unit

CD with the FlexProgram software and product drivers (DTM)

USB cable

Cable with 2 alligator clips

Mounting of 3A Approved Products

Max. ± 85°

1)

A full range of accessories for TE1 and TE2 can be found in the data

sheet ”Accessories”

4)

5)

2)

3)

Installation of 3A approved products:

1) Use only a 3A approved counter part.

2) The inspection hole should be visible and drained.

3) Mount the instrument in a self drained position.

4) Level the inner surface of the pipe with the counter part.

5) Weldings should be grinded to Ra= 0.8

Max. ± 175°

Refer to the data sheet “Accessories” for O-rings, gaskets and other

accessories.

The TE1x-7/8/9/A versions are approved by 3A providing it is installed

according to the guidelines given in the installation manual.

The 3A approved products fulfill the FDA demands and follow the

EHEDG guidelines regarding design, materials and finishing.

5850-006_EN/2011-10-10 This data sheet may only be reproduced in full.

www.baumer.com/process

Design and specifications subject to change without notice

Installation Manual

Page 4

Loading...

Loading...