Page 1

Operating Instructions

Smart Reflect

FNDH 14G6901/IO

FNDH 14G6901/KS34A/IO

FNDR 14G6901/S14/IO

FNDK 14G6904/IO

FNDK 14G6904/S35A/IO

FNDK 14G6904/S14/IO

Background suppression

FHDH 14G6901/IO

FHDH 14G6901/KS34A/IO

FHDR 14G6901/S14/IO

Page 2

Operating Instructions for Series 14 Hygienic and Washdown

Design with IO-Link

Contents

1

1.1

1.2

2

2.1

2.2

2.3

3

4

4.1

4.1.1

4.2

4.2.1

4.2.2

4.2.3

4.2.4

General information ..................................................................................................................... 3

Concerning the contents of this document ..................................................................................... 3

General information ........................................................................................................................ 3

IO-Link introduction ..................................................................................................................... 4

SIO mode ........................................................................................................................................ 4

IO-Link communication mode ......................................................................................................... 4

IODD (IO-Link device description) .................................................................................................. 5

Sensor in SIO mode ..................................................................................................................... 5

Sensor in IO-Link communication mode ................................................................................... 5

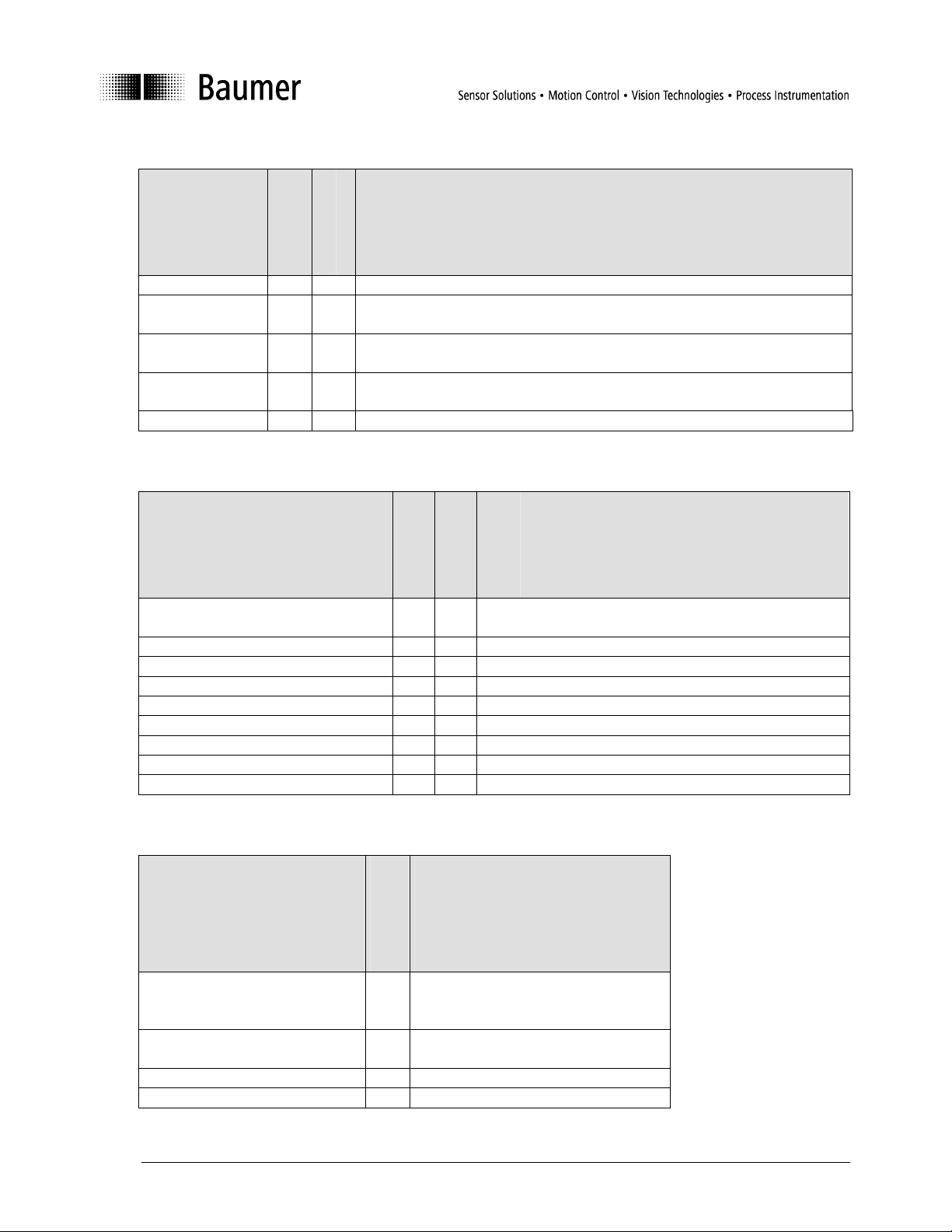

Process data ................................................................................................................................... 5

Process data structure .................................................................................................................... 5

Parameters and commands ........................................................................................................... 6

Product data ................................................................................................................................... 6

Parameters ..................................................................................................................................... 6

Commands ..................................................................................................................................... 6

Saving changes .............................................................................................................................. 6

5

5.1

5.1.1

5.1.2

5.1.3

5.1.4

5.1.5

5.2

5.2.1

5.2.2

6

6.1

6.2

6.3

6.4

6.5

Explanation of sensor configuration .......................................................................................... 7

Teach-in of a user-specific switching point ..................................................................................... 7

Parameters ..................................................................................................................................... 7

Commands ..................................................................................................................................... 7

Description ...................................................................................................................................... 7

Hysteresis ..................................................................................................................................... 10

Error correction ............................................................................................................................. 10

Dirt indicator .................................................................................................................................. 10

Parameters ................................................................................................................................... 10

Description .................................................................................................................................... 10

Configuration .............................................................................................................................. 12

Table of general parameters ......................................................................................................... 12

Table of work parameters ............................................................................................................. 12

Table of system commands .......................................................................................................... 13

Table of error codes ...................................................................................................................... 13

Table of factory settings ................................................................................................................ 13

en_BA_FNDx14_FHDx14_IO.doc 2/14 Baumer Electric AG

12.04.2013/hem Frauenfeld, Switzerland

Page 3

1 General information

1.1 Concerning the contents of this document

This manual contains information regarding the commissioning and communication of Baumer series 14

photoelectric diffuse sensors with SmartReflect and background suppression with the IO-Link interface. It is a

supplement to the mounting instructions supplied with each sensor.

This manual applies to the following sensor types:

Diffuse sensors with SmartReflect technology

FNDH 14G6901/IO

FNDH 14G6901/KS34A/IO

FNDR 14G6901/S14/IO

FNDK 14G6904/IO

FNDK 14G6904/S35A/IO

FNDK 14G6904/S14/IO

Diffuse sensors with background suppression

FHDH 14G6901/IO

FHDH 14G6901/KS34A/IO

FHDR 14G6901/S14/IO

1.2 General information

Intended

use

Commissioning Installation, mounting and adjustment of this product may be performed only by a

Mounting For mounting, use only the mechanical mountings and mechanical mounting

en_BA_FNDx14_FHDx14_IO.doc 3/14 Baumer Electric AG

12.04.2013/hem Frauenfeld, Switzerland

This product is a precision device and is used for object detection and the

preparation and/or provision of values as electrical quantities for a subsequent

system.

Unless this product is specially labeled, it may not be used for operation in

potentially explosive environments.

qualified person.

accessories intended for this product.

Unused outputs must not be wired. In cable versions with unused cores, these cores

must be insulated. Do not exceed admissible cable bending radii. Prior to electrical

connection of the product, the system must be disconnected from the power supply.

In areas where screened cables are mandatory, they must be used as protection

against electromagnetic disturbances. If plug connections to screened cables are

made by the customer, an EMC version of the connectors should be used, and the

screen must be connected to the connector housing across a large area.

Page 4

2 IO-Link introduction

These operating instructions contain a description of the most important aspects of the IO-Link interface

which are required for understanding the configuration options. For detailed information about IO-Link and all

specifications, go to www.io-link.com .

IO-Link is a standard interface for sensors and actuators. The device (sensor, actuator) and IO-Link master

are interconnected as a point-to-point connection. Communication between master and device takes place

bi-directionally via the device connecting line. Via this interface values can be read out and it is possible to

configure the sensor via IO-Link. The sensor can be operated in two modes: standard input/output mode

(SIO mode) and IO-Link communication mode.

The master switches the sensor to IO-Link communication mode. In this mode, process data are

continuously sent from the sensor to the master and demand data (parameters, commands) are written to

the device or read off it.

2.1 SIO mode

After start-up the sensor is in SIO mode. In this mode the sensor functions as a normally switching sensor.

On the master side the IO-Link port is switched as a normal digital input. The sensor can be used like a

standard sensor without IO-Link. Diverse functions can, however, only be controlled via IO-Link.

2.2 IO-Link communication mode

With a so-called "wake-up" the sensor is switched by the master into "communication mode". In the process

the master attempts to find a connected device through a defined signal on the switching line. If the sensor

responds, communication parameters are exchanged and afterwards cyclical transmission of process data is

initiated.

In IO-Link communication mode:

• Process data can be read.

• Parameters can be read off the sensor.

• Parameters can be written to the sensor.

• Commands can be sent to the sensor (e.g. teaching the switching point, restoring to factory setting,

etc.).

In the process data cyclical data such as outputs or quality data are transmitted to the superordinate control.

The master can leave the IO-Link communication mode again with a "fall back", and the sensor continues to

operate in SIO mode until a new "wake up".

In IO-Link communication mode, sensor behavior can be adjusted in SIO mode so that the sensor can easily

be parameterized according to requirements and then operate as a "normal" sensor without the IO-Link

master. Alternatively, the sensor can also be operated in IO-Link communication mode, enabling use of the

full range of functions via process data.

en_BA_FNDx14_FHDx14_IO.doc 4/14 Baumer Electric AG

12.04.2013/hem Frauenfeld, Switzerland

Page 5

2.3 IODD (IO-Link device description)

The IODD describes the IO-Link device and can be downloaded at www.baumer.com. It consists of a set of

XML and PNG files. An engineering tool or diagnosis tool reads the IODD of a sensor and therefore knows

its:

• Identification (manufacturer, designation, article number, etc.)

• Communication characteristics (communication speed, frame type, etc.)

• Parameters and commands

• Process data

• Diagnosis data (events)

Sensor data that can be viewed and changed is defined by the IODD. The manner of data representation

and manipulation is defined by the control manufacturer and is therefore sensor-independent.

3 Sensor in SIO mode

In SIO mode the sensor operates according to the factory settings or the settings adjusted by the user via

IO-Link. The range of functions in SIO mode is sensor-specific.

4 Sensor in IO-Link communication mode

4.1 Process data

If the sensor is in IO-Link communication mode, data are periodically exchanged between the IO-Link master

and the device. These data consist of process data and possible commands and parameters to the sensor.

In the process data the current measuring value and status bits like output, quality data, etc. are transmitted

to the master. The process data do not have to be explicitly queried by the master.

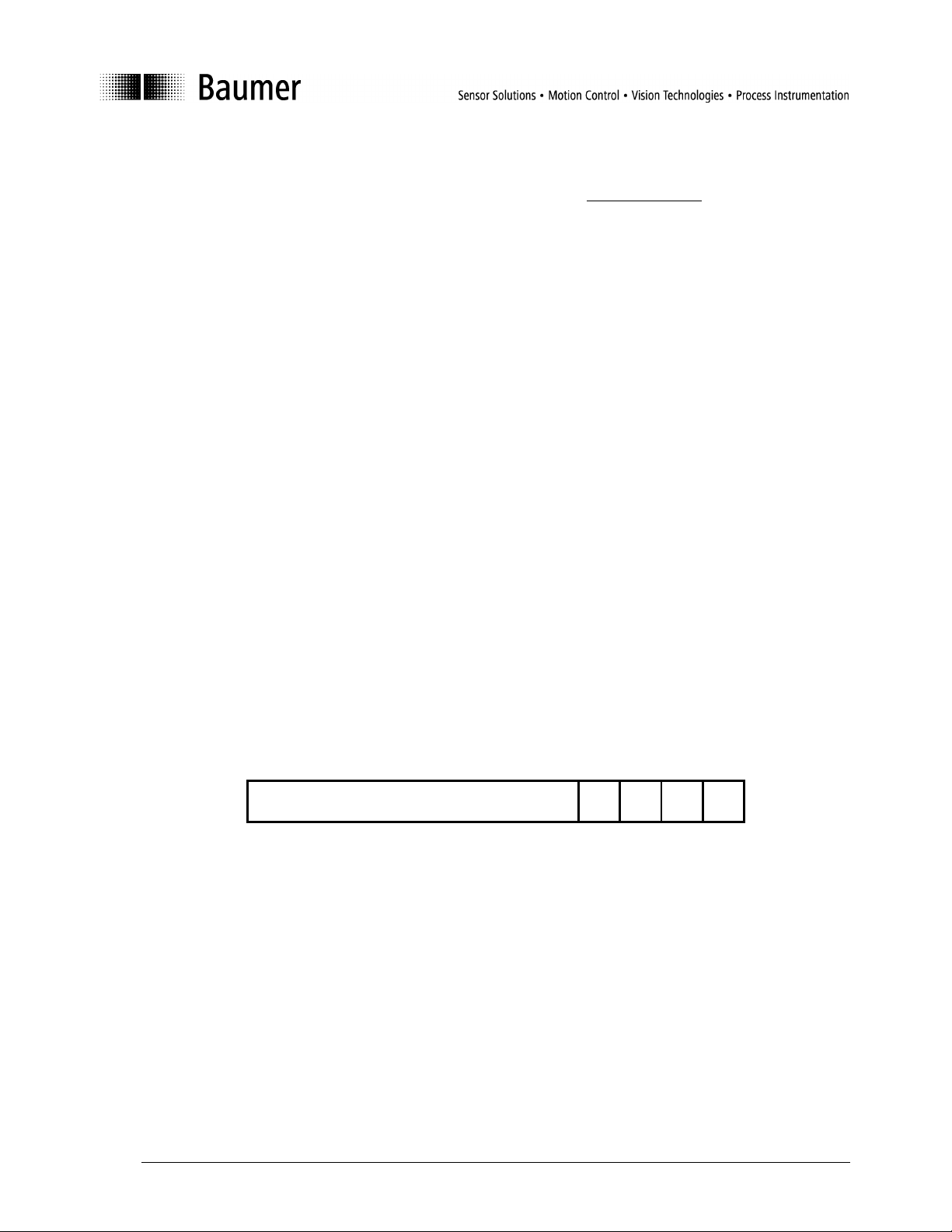

4.1.1 Process data structure

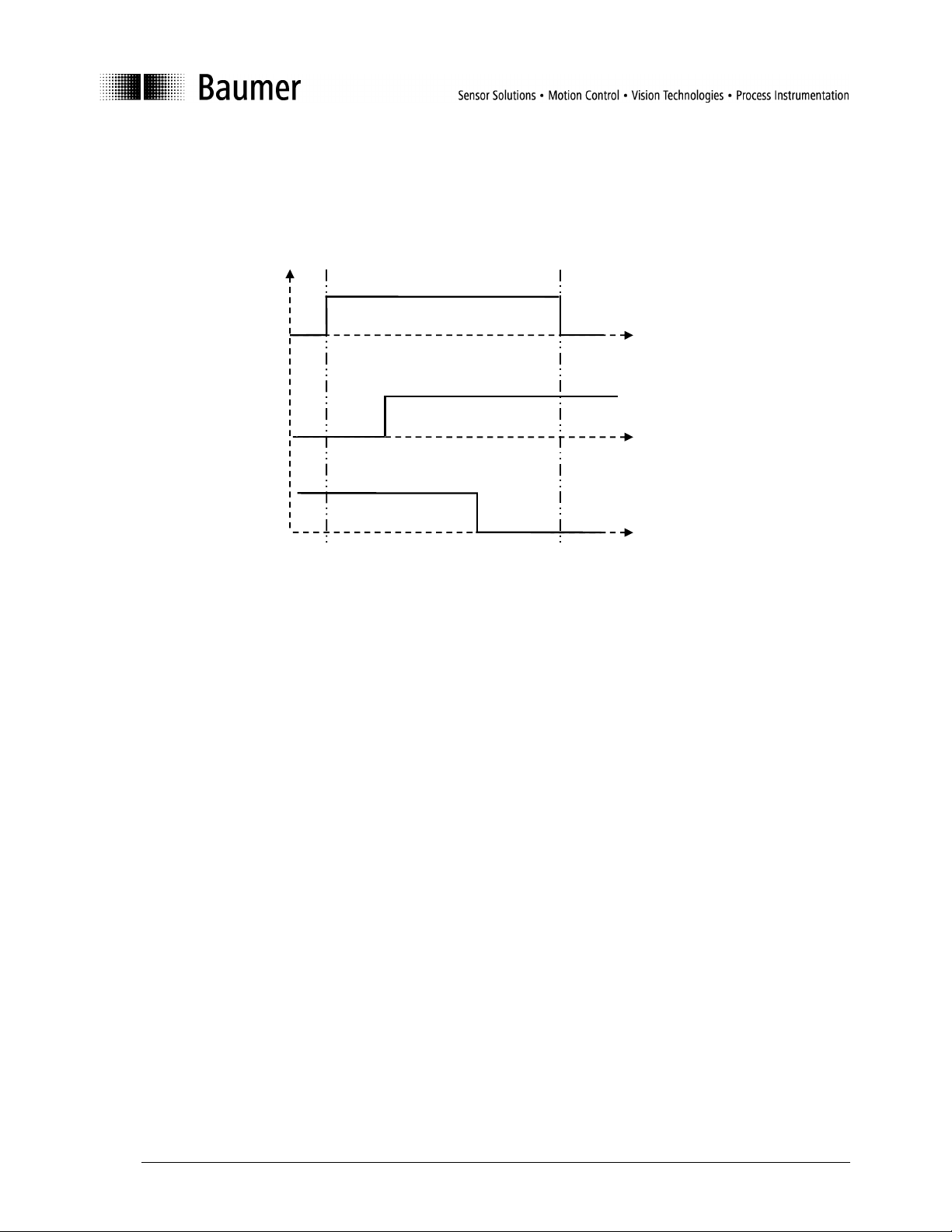

Figure 1 shows the process data structure. A brief description of the individual data is provided in the

following.

4.1.1.1 Back-up

Bit4…Bit15 serve solely as a back-up and are reserved with the value 0.

4.1.1.2 Meaning of status information

Bit 0: Alarm

The alarm bit indicates whether an object is in the defined scanning range (e.g. 50 to 400 mm)

Bit0 = 0 → There is an object is in the scanning range

Bit0 = 1

→ There is no object in the scanning range

Bit4…Bit15

Figure 1: Process data

Bit3

Bit2

Bit1 Bit0

en_BA_FNDx14_FHDx14_IO.doc 5/14 Baumer Electric AG

12.04.2013/hem Frauenfeld, Switzerland

Page 6

Bit 1: Switching bit

The switching bit assumes the function of the switching output in IO-Link communication mode

Bit1 = 0

Bit0 = 1

→ There is no object in th

e switching range

→ There is an object in the switching range

Bit 2: Quality

This bit provides information about the quantity of light reflected by the object (dust indicator).

Bit2 = 0

→ reflected light above the threshold (sufficient signal)

Bit2 = 1 → reflected light below the threshold (weak signal)

Bit3: Not used

4.2 Parameters and commands

Parameters and commands are written to the device or read off the device via indices. The read and write

function of indices is provided by the IO-Link master. The user can write a value into an index or read a value

off an index.

4.2.1 Product data

Some parameters contain product information like manufacturer's name, product name, and number, plus

room for a user-specific designation of the sensor (see: 6.1 Table of general parameters).

4.2.2 Parameters

For a description of the parameters, see 6.2 Table of work parameters.

The following settings are possible via parameters:

• Setting the switching point (numerical or manual teach-in)

• Defining the output state (light or dark switching)

• Selecting a teach-in function

• Setting a delay function at the switching output. Value range from 1 to 1000 ms

• Defining the threshold for the dust indicator

4.2.3 Commands

Commands are written to index 0x02 (system command). For a description of the commands, see 6.3 Table

of system commands.

The following settings can be made via commands:

• Teach-in and application of the switching point

• Save changed parameters

• Restore to factory settings

4.2.4 Saving changes

If parameter changes are made by directly writing parameters or by a command (also restoring to factory

settings), the settings must be permanently saved by the command Save parameters. Otherwise the

changes are lost after the sensor is restarted, and the last saved entries are reactivated.

en_BA_FNDx14_FHDx14_IO.doc 6/14 Baumer Electric AG

12.04.2013/hem Frauenfeld, Switzerland

Page 7

5 Explanation of sensor configuration

The functionality of the sensor can be configured with the parameters and the commands. In the following

sections, the individual configuration options are explained in detail.

5.1

5.1.1 Parameters

Switching points work: This parameter contains the currently used switching point and can be

Teach-in positions interim: This parameter serves as an interim register for teaching-in the switching

5.1.2 Commands

Teach-in position A: Command for teaching-in position A. The taught-in value is transferred to

Teach-in position B: Command for teaching-in position B. The taught-in value is transferred to

Transfer switching points: The positions A and B taught into the interim register Teach-in position

Teach-in of a user-specific switching point

written directly (numerical teach-in) or set automatically to an object via the

interim register during teach-in. The parameter consists of two 16-bit

parameters Switching point A and Switching point B, whereby one

switching point respectively must have the value 65535 (corresponds to

"not valid").

- Unit: 1 mm

- Factory setting: Switching point A = 50mm, Switching point B =

65535 "not valid"

point to an object (1-point teach-in) or to a reference position and an object

(2-point teach-in). The parameter consists of two 16-bit parameters Teach-

in position A interim and Teach-in position B interim.

- Unit: 1 mm

the interim register Teach-in position A interim.

the interim register Teach-in position B interim.

interim are offset against one another, transferred to the working register

Switching points work and activated.

5.1.3 Description

The switching point of the sensors described here can be adjusted by the user in two ways:

• Numerical teach-in: The switching point can be written directly into the parameter Switching points

work. The two parameters selected for the switching point must not be smaller than 50 mm and not

larger than 400 mm for sensors with background suppression (or 800 mm for SmartReflect). One

parameter respectively must be 65535 (not valid). The switching function (light/dark switching) is

defined by the selection of the switching point parameter (A/B).

• Teach into object (1-point teach-in): The switching point is taught into an object for measurement

with the command Teach-in position. The switching function (light/dark switching) is defined by the

selection of the teach-in parameter (A/B). If the object is outside of the adjustable sensing distance,

the minimum or maximum sensing range is taught in.

• Teach into reference position and object (2-point teach-in): To teach in the switching point with 2-

point teach-in, the command Teach-in position must be executed at two positions: once to a solid

reference position (background of the object or a reflecting machine part) and once to the object

en_BA_FNDx14_FHDx14_IO.doc 7/14 Baumer Electric AG

12.04.2013/hem Frauenfeld, Switzerland

Page 8

0

0

0

1

1

1

Switching bit/Switching output

A

B

A

B

50mm 400mm

itself. Both teach-in parameters must be within the adjustable sensing distance and be more than 4%

of the sensing distance apart. The switching function (light/dark switching) is defined by the order of

the teach-in parameters (A/B).

Adjustable sensing

distance

(Calibration curve 1)

Taught-in sensing range

(Calibration curve 2)

Inverted sensing range

(Calibration curve 3)

Figure 2: Possible switching curves

5.1.3.1 Sample numerical teach-in:

1) A switching point is set at 150 mm (A) (Calibration curve 2).

Point A absolute in mm: 150 mm → 0096 hex (= Switching point A)

Point B absolute in mm: not valid → FFFF hex (= Switching point B)

Parameter to be written:

Switching points work: 0096FFFF hex

Save parameters to save the values permanently!

2) The sensing range is set inversely at 200 mm (B) (Calibration curve 3).

Point A absolute in mm: not valid → FFFF hex (= Switching point A)

Point B absolute in mm: 200 → 00C8 hex (= Switching point B)

Parameter to be written:

Switching points work: FFFF00C8 hex

Save parameters to save the values permanently!

en_BA_FNDx14_FHDx14_IO.doc 8/14 Baumer Electric AG

12.04.2013/hem Frauenfeld, Switzerland

Page 9

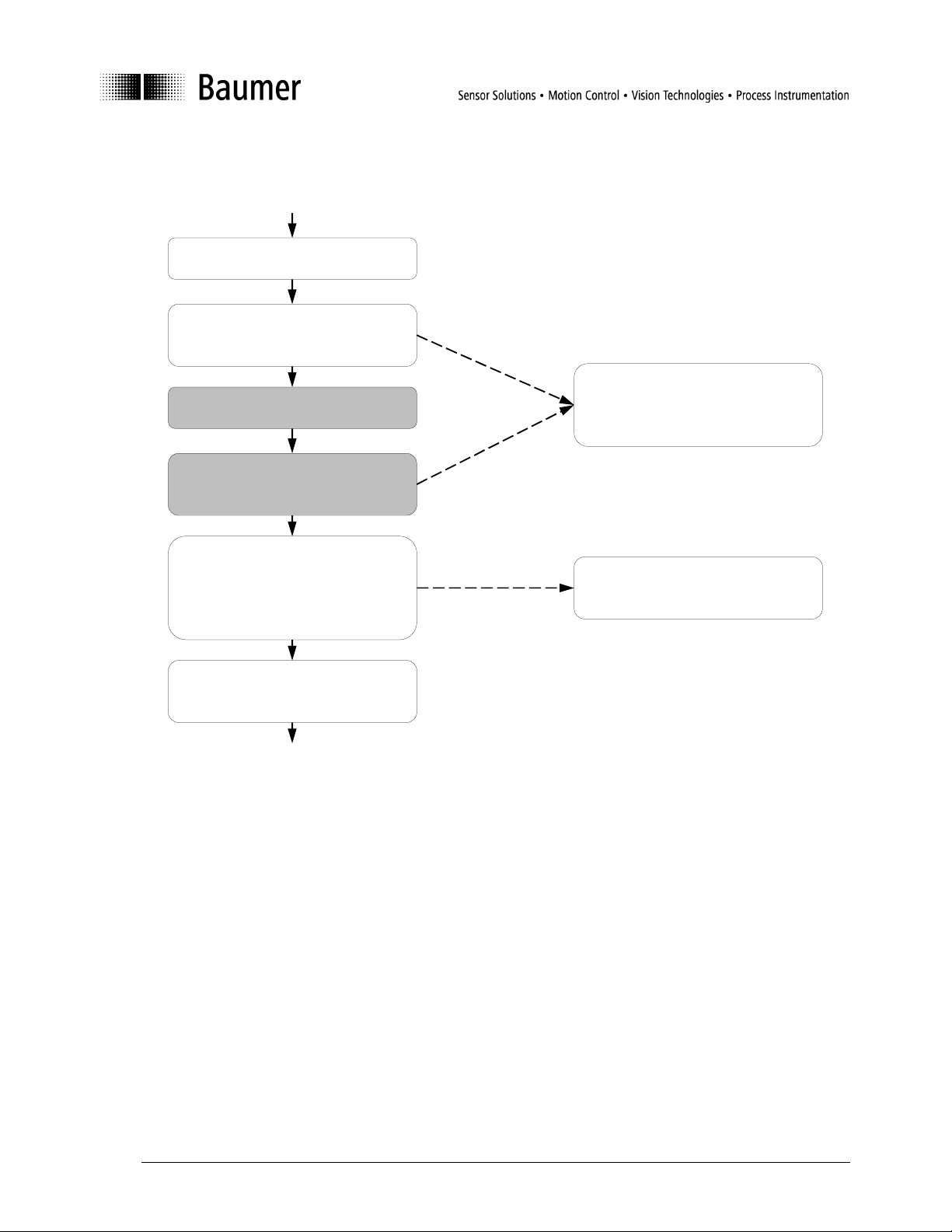

5.1.3.2 Sample teach-in to object

Teach

-

in

The sensing range is taught into an object (Calibration curve 2).

Place object at the desired

switching point

Read taught-in position into the

interim register with the command

Teach-in Position A

Align sensor to reference object

(reflector or background)

Read taught-in position into the

interim register with command

Teach-in Position B

The interim registers

positions interim can be read

out at any time, and the read-in

values can be checked

Transfer switching points from

the interim register to the working

register and activate them with

the command Transfer

After transfer into the working

register, the interim register is

reset to FFFF FFFF hex

switching points

Save the changes permanently

with the command Save

parameters

Figure 3: Teach-in switching range

Fields highlighted in gray are required only for teach-in with 2-point teach-in.

For an inverted switching range (Calibration curve 3):

• The command Teach-in Position B must be used instead of Teach-in Position A for 1-point teach-

in.

• For 2-point teach-in the distance from the sensor to Teach-in Position A must be greater than the

distance to Teach-in Position B.

en_BA_FNDx14_FHDx14_IO.doc 9/14 Baumer Electric AG

12.04.2013/hem Frauenfeld, Switzerland

Page 10

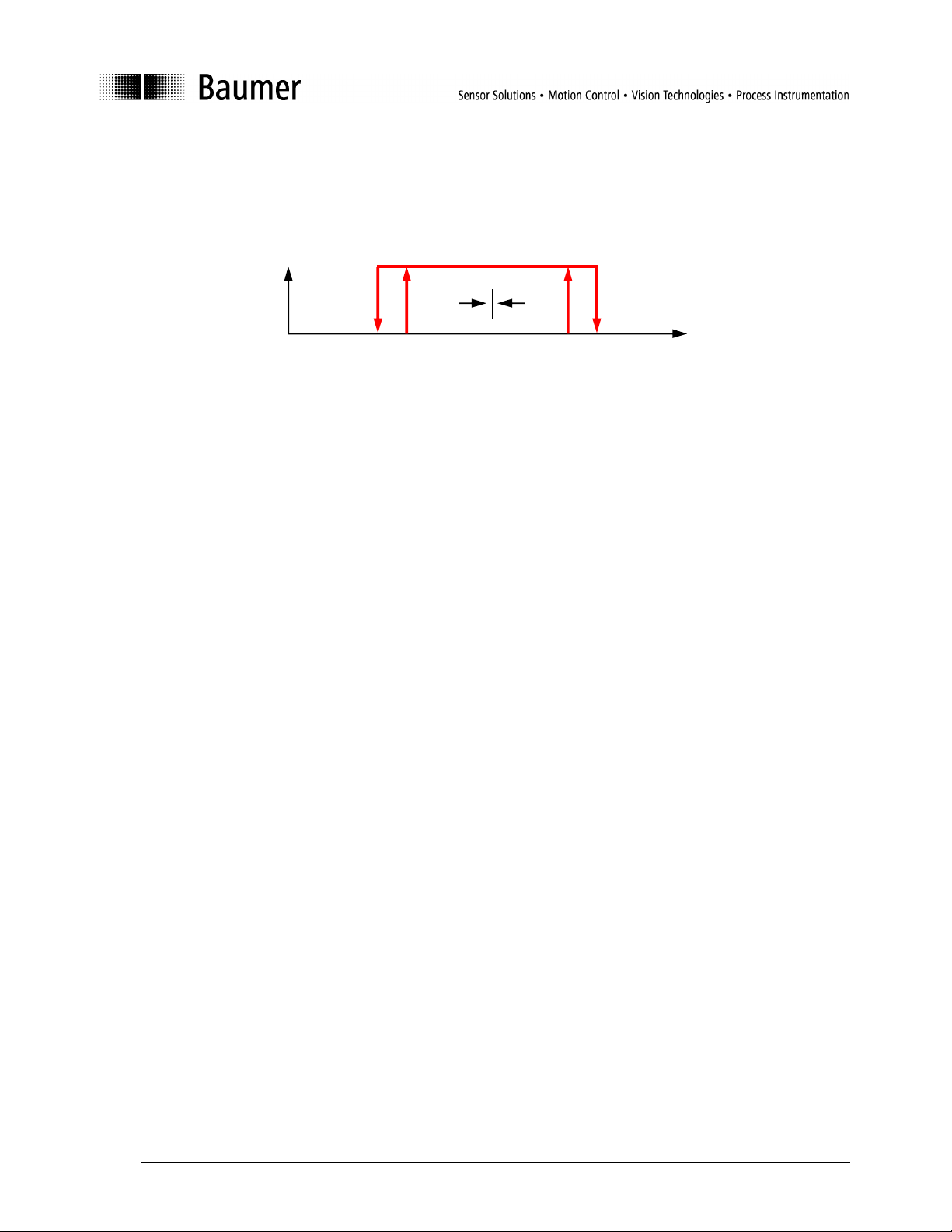

5.1.4 Hysteresis

In the direction of approach to the sensing range, the sensor actuates exactly at the taught-in switching

points. When the sensing range is re-exited, a hysteresis is added (see: Figure 4).

Switching bit/Output

1

0

Distance

A B

Figure 4: Hysteresis switching range

5.1.5 Error correction

The difference of the learning positions (distance between object and background/reflector) is too small; that

is they are closer together than 4% of the sensing range.

• Error message Interfering parameter (see: 6.4 Table of error codes)

• Interim is set to FFFF FFFF hex

• Last valid values remain activated

The taught-in switching points are outside of the scanning range (see data sheet):

• Numerical teach-in: Writing Switching points work is not possible, error message Parameter value

out of range, last valid values remain activated.

• 1-point teach-in: Error message Parameter value out of range, the sensor is adjusted to maximum

or minimum sensing distance.

• 2-point teach-in: Teach-in positions interim are not transferred, error message Parameter value

out of range, last valid values remain activated.

5.2 Dirt indicator

5.2.1 Parameters

Nominal value quality parameter: Threshold for quality evaluation of the received signal. If the received

light quantity drops below this threshold, the quality bit is set in the

process data.

- Value range: 1-8

- Factory setting: 7

Quality parameter: Actual value of reception quality.

5.2.2 Description

Via the sensor exposure control it is possible to determine whether sufficient excess gain is still available for

reliable measurement. This excess gain is represented quantitatively by the Quality parameter. If the

Quality parameter drops below the threshold specified in the Nominal value quality parameter, this is

indicated with the quality bit of the process data.

en_BA_FNDx14_FHDx14_IO.doc 10/14 Baumer Electric AG

12.04.2013/hem Frauenfeld, Switzerland

Page 11

Application example:

During application setup it is possible to take account of this by reading out the Quality parameter regularly

to determine its lowest value. Then the threshold Nominal value quality parameter can be set 1-2 levels

lower. If the Quality parameter drops below this threshold for any reason during operation, this is indicated.

At that moment the application still works properly, however the sensor should be checked some time.

Possible reasons for activation of the Quality parameter may be:

Sensor is soiled → Sensor must be cleaned

Sensor has been moved → Readjust sensor

Something in the application has changed, e.g. varying object surface finishes → Readjust

sensor (Nominal value quality parameter) if necessary.

With the aid of this function, it is possible to detect sensor failure at an early stage and take appropriate

action.

Important: The sensor still functions properly even with a Quality parameter of 1. It is not absolutely

necessary to achieve the highest possible value!

en_BA_FNDx14_FHDx14_IO.doc 11/14 Baumer Electric AG

12.04.2013/hem Frauenfeld, Switzerland

Page 12

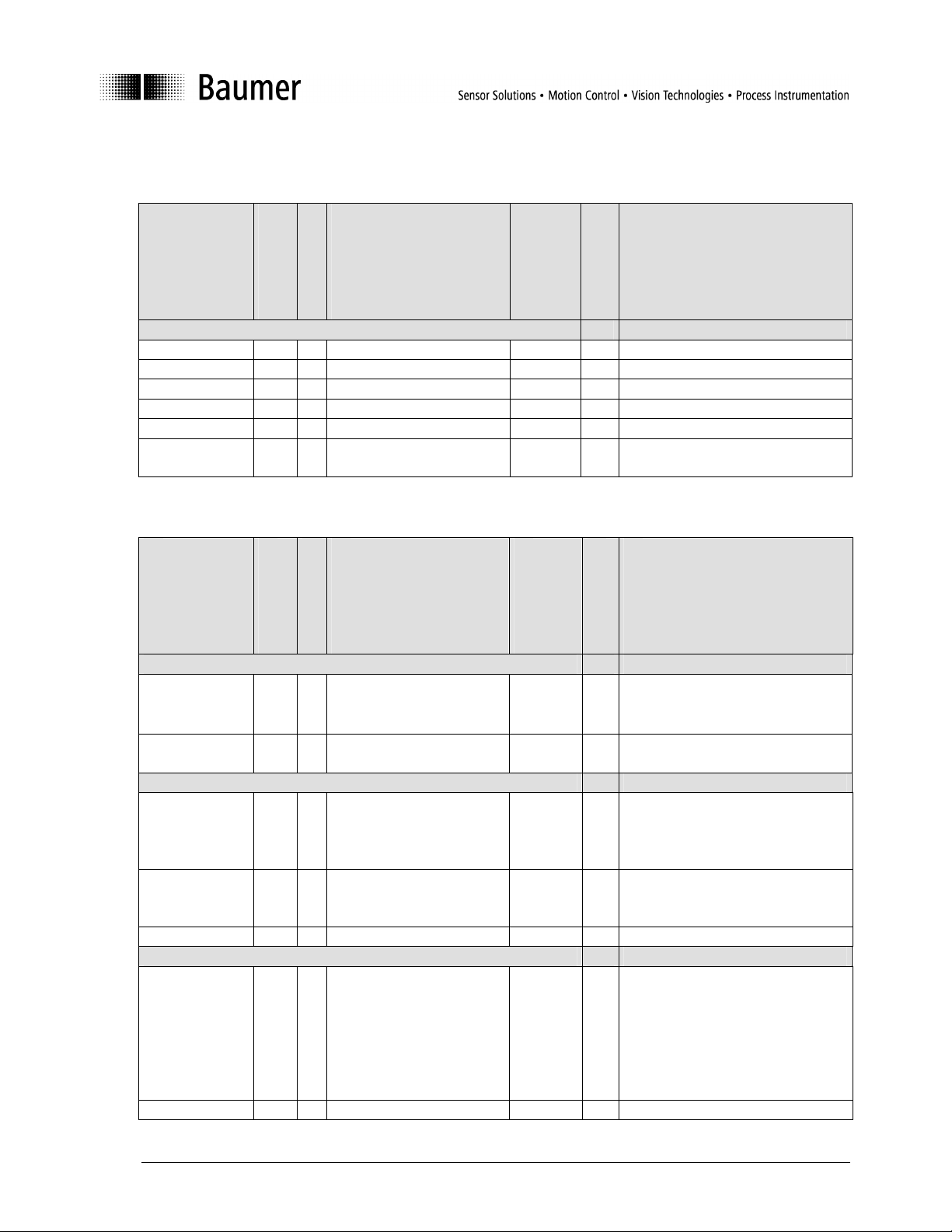

6 Configuration

6.1

General information on sensors

Vendor Name 0X10 18 String ASCII R “Baumer Electric AG“ for all sensors

Product Name 0X12 22 String ASCII R Corresponds to Baumer article description

Product ID 0X13 8 String ASCII R Corresponds to Baumer article number

Serial Number 0X15 4 String ASCII R Baumer P-Code

Firmware Revision 0X17 8 String ASCII R Baumer Firmware Revision

Application Specific

Name

Table of general parameters

SPDU name

SPDU index

Number of Bytes

0X18 8 - - R/W 8 Byte at customer disposal

Format

Range of values

R/W

Comments

6.2 Table of work parameters

SPDU name

Teach-in and switching points

Switching points

work

Teach-in positions

interim

Sensor functions

Teach function 0X60 1 0 = One point Teach-in

Nominal value

quality parameter

Quality parameter 0X66 1 1..8 or 255 R

Output functions

Output delay

function

Output delay time 0x72 2 Byte 1…2, time in 1ms 0…1000 R/W Delay time

SPDU index

Number of Bytes

Format

0X40 4 Switching point A (HB, LB)

Switching point B (HB, LB)

0X41 4 Teach-in Position A (HB, LB)

Teach-in Position B (HB, LB)

(Reference position)

2 = Two point Teach-in

(ON/OFF-position)

0X65 1 1..8 R/W Provided the internal quality parameter

0x71 1 Byte 0 (Subindex 1)

0 = no delay

1 = on delay

2 = off delay

3 = minimum pulse

4 = single shot positive edge

5 = single shot negative edge

Range of values

50…400 R/W Distance information on switching points,

50…400,

65535

0.2 R/W Selection of Teach mode

0…5 R/W Choose delay funciton

R/W

Comments

calculated from the information on Teachin position interim

R Distance information on Teach-in position

drops below this threshold the switching

output is set.

en_BA_FNDx14_FHDx14_IO.doc 12/14 Baumer Electric AG

12.04.2013/hem Frauenfeld, Switzerland

Page 13

6.3 Table of system commands

Name of

Command

Restore factory setting 0X02 0X82 Restores all original factory settings of the sensor

Teach-in position A 0X02 0XA0 Teach-in of switching point A. The measured distance is written into the interim Teach in

Teach-in position B 0X02 0XA1 Teach-in of switching point A. The measured distance is written into the interim Teach in

Transfer switching

positions

Save parameters 0X02 0XE0 Save all parameters in Flash memory

SPDU Index

CMD Value

Comments

position register.

position register.

0X02 0XA2 Transfer of the teach-in positions from the interim to the working register.

6.4 Table of error codes

Error Case

Communication error

(Checksum, …)

Length of written SPDU is wrong 0x10 0x00 Communication error, No details

Reading an unimplemented SPDU 0x80 0x11 Device error, Index not available

Writing to an unimplemented SPDU 0x80 0x11 Device error, Index not available

Reading Index 2 0x80 0x23 Device error, Access denied

Writing to a read only SPDU 0x80 0x23 Device error, Access denied

Writing an unimplemented System Command 0x80 0x23 Device error, Access denied

Distance between two taught points too small 0x80 0x40 Device error, Interfering parameter

Written parameter out of defined range 0x80 0x30 Device error, Parameter value out of range

Error Code 1

Error Code 2

Description of

Error Codes

0x10 0x00 Communication error, No details

6.5 Table of factory settings

SPDU name

Switching points work 0X40 Switching point A: 50mm

Nominal value

quality parameter

Output Delay Function 0X71 0 = No delay

Output Delay Time 0X72 1 (ms)

SPDU index

Default value

Switching point B: 65535 (corresponds to “Not

valid”)

0X65 7

en_BA_FNDx14_FHDx14_IO.doc 13/14 Baumer Electric AG

12.04.2013/hem Frauenfeld, Switzerland

Page 14

Baumer worldwide

Brazil

Canada

China

Denmark

France

Germany / Austria

India

Italy

USA

United Kingdom

Singapore

Sweden

Switzerland

Headquarters

Baumer do Brasil Ltda

BR-04726-001 São Paulo-Capital

Phone +55 11 56410204

Baumer Inc.

CA-Burlington, ON L7M 4B9

Phone +1 (1)905 335-8444

Baumer (China) Co., Ltd.

CN-201612 Shanghai

Phone +86 (0)21 6768 7095

Baumer A/S

DK-8230 Abyhoi

Phone +45 (0)8931 7611

Baumer India Private Ltd.

IN-411038 Pune

Phone +91 (0)20 2528 6833

Baumer Ltd.

GB-Watchfield, Swindon, SN6 8TZ

Phone +44 (0)1793 783 839

Baumer Electric AG

CH-8501 Frauenfeld

Phone +41 (0)52 728 1122

Baumer SAS

FR-74250 Fillinges

Phone +33 (0)450 392 466

Baumer Italia S.r.l.

IT-20090 Assago, MI

Phone +39 (0)245 70 60 65

Baumer (Singapore) Pte. Ltd.

SG-339412 Singapore

Phone +65 6396 4131

www.baumer.com/worldwide

Technische Änderungen und Irrtum vorbehalten.

Technical data has been fully checked, but accuracy of printed matter is not guaranteed.

Baumer GmbH

DE-61169 Friedberg

Phone +49 (0)6031 60 070

Baumer Ltd.

US-Southington , CT 06489

Phone +1 (1)860 621-2121

Baumer A/S

SE-56122 Huskvarna

Phone +46 (0)36 13 94 30

Baumer Electric AG

CH-8501 Frauenfeld

Phone +41 (0)52 728 1122

en_BA_FNDx14_FHDx14_IO.doc 14/14 Baumer Electric AG

12.04.2013/hem Frauenfeld, Switzerland

Loading...

Loading...