Page 1

B70.1BL 60 cm 4 Burner glass gas hob with

thermocouples

PHG602 60 cm 4 Burner glass gas hob with

thermocouples

B77TCBL 70 cm 5 Burner gas glass hob with

thermocouples.

B72BL 60 cm 4 Burner glass gas hob

B77BL 70 cm 5 Burner glass gas hob

1

Page 2

User Manual for your Baumatic

B70.1BL 60 cm 4 Burner gas glass hob

with thermocouples

PHG602 60 cm 4 burner gas glass hob

with thermocouples

B77TCBL 70 cm 5 burner gas glass hob

with thermocouples

B72BL 60 cm 4 burner gas glass hob

B77BL 70 cm 5 burner gas glass hob

NOTE: This User Instruction Manual contains important

information, including safety & installation points, which will

enable you to get the most out of your appliance. Please keep it

in a safe place so that it is easily available for future reference; for

you or any person not familiar with the operation of the appliance.

DD 19/05/09

2

Page 3

Contents

Environmental note 4

Important safety information 5 – 7

Specifications 8 – 14

B70.1BL 8

PHG602 9

B77TCBL 10

B72BL 11

B77TCBL 12

Electrical details 13

Gas details 13

Gas hob surface layout 13 - 14

Using the gas hob 15 - 16

Before first use 15

Switching the hob on 15

Automatic ignition (B72BL/B77BL) 15 - 16

Automatic ignition with flame failure safety device 16

(B70.1BL/PHG602/B77TCBL)

Energy saving tips 16 - 17

Cleaning 17 - 18

Cleaning the hob top 17

After each use 18

Cleaning the hob burners 18

Maintaining the cast iron pan stands 18

Installation 19 - 29

Positioning 20

Unpacking the appliance 21

Installing the appliance 21 - 23

Gas connection 23

Ventilation requirements 24

Gas Safety (Installation and Use) Regulations 25

Gas Adjustment (Conversion to LPG) 26 - 27

Minimum flow adjustment for hob gas taps 27

Gas tap maintenance 28

Electrical connection 29

Replacing the mains supply cable 29

My appliance isn’t working correctly 30

Contact details 31

3

Page 4

Environmental note

o The packaging materials that Baumatic uses are environmentally

friendly and can be recycled.

o Please discard

environment.

all packaging material with due regard for the

4

Page 5

Important safety information

Your safety is of the utmost importance to Baumatic.

Please make sure that you read this instruction booklet

before attempting to install or use the appliance. If yo

are unsure of any of the information contained in tu his

ooklet, please contact the Baumatic Advice Line.

b

General Information

This appliance is designed for domestic househo

the cooking and frying of domestic foodstuffs.

o IMPORTANT: The adjacent furniture and all materials used

the installation must be able to withstand a minimum

temperature of 85°C above the amb

room it is located in, whilst in use.

o Certain types of vinyl or laminate kitchen furniture are

particularly prone to heat damage or discolouratio

temperatures below the guidelines given above.

o Any damage caused by the appliance being installed in

contravention

the owner.

o Your new appliance is guaranteed against electrical or

mechanical defects, subject to certain exclusions that are noted

in Baumatic’s Conditions Of G

affect your statutory rights.

o The use of this appliance for any other purpose or in any other

environment without the express agreement o

will invalidate any warranty or liability claim.

o You shou

surface.

o No modifications to the appliance are permitted by Baumatic Ltd.

o You should not store or place flammable or highly flammable

liquids/materials on top of or near the appliance. Items made

from aluminium, plastic or plastic film should also be k

from the appliance, as they may fuse to the surface.

o Repairs may only be carried out by Baumatic

engineers or their authorised service agent.

of this temperature limit, will be the liability of

uarantee. The foregoing does not

ld not use this appliance to store items on or as a work

ient temperature of the

old use and for

n at

f Baumatic Ltd.

ept away

service

in

5

Page 6

hild Safety

C

o Baumatic strongly recommend that babies and young children

are prevented from being near to the appliance and not allowe

to touch the applianc

surfaces will be hot.

o If it is necessary for younger family members to be in the

kitchen, plea

at all times.

o Older children shou

when supervised.

eneral Safety

G

o The appliance should only b

CORGI registered installer.

o Care should be taken to ensure that the units and work su

that you bu

standards.

uring use

D

o Any film or stickers that are present on the h

is delivered should be removed before use.

o Care should be used when utilising the

there is a risk of burns being caused.

o You should not allow the electrical connection cables to com

into contact

cookware.

o If fat and oil overheats, then it can ignite extremely quickly. For

this reason, when cookin

not be left unattended.

o Make

use.

sure that all of the cooking zones are switched off after

se ensure that they are kept under close supervision

ild the appliance into, meet with the relevant

with the hob surface when it is hot or any hot

e at any time. During and after use, all

ld only be allowed to utilise the appliance

e installed and connected by a

ob surface when it

appliance, otherwise

g with fat and oil the appliance should

d

rfaces

e

6

Page 7

leaning

C

Cleaning of the hob should be carried out on a regular basis.

o

o IMPORTANT: Before attempting to clean the appl

should be disconnected from the mains and cool.

o Great care should be taken whilst

following the cleaning procedure.

using this appliance and when

iance, it

o You should not use a steam jet or any other

cleaning equipment to clean the appliance.

Installation

This appliance must be correctly installed by a

CORGI registered installer, strictly in accordan

with the manufacturer’s instructions and the

relevant British Standards. Please see the specific

ection of this booklet that refers to installation.

s

o Baumatic Ltd. declines any responsibility for injury or

damage, to person or property, as a r

use or installation of this appliance.

o If the appliance is being used in a Leisure Accommodat

Vehicle, the requirements of N 721 MUST be followed.

o Baumatic Ltd. DO NOT recommend that

installed on any type of marine vessel.

eclaration of conformity

D

This appliance complies with the following European Directives:

-73/23/EEC dated 19/02/1973 Low Voltage Directive.

-89/336/EEC dated 03/05/1989 E

Amending Directive 92/31/EEC.

-93/68/EEC dated 22/07/1993 CE Marking Directive.

-89/109/EEC dated 25/01/19

-90/396/EEC Gas Products.

N60335-1, EN60335-2, EN301-1 Safety Standards.

-E

The manufacturer declares that the hob is built using certified

materials and requires the appliance to be installed in accordance w

the standards currently in force. This applian

ained person for domestic purposes only.

tr

MC Directive inclusive of

92 Materials that can touch food.

ce must be used by a

high pressure

esult of improper

this appliance is

ce

ion

ith

7

Page 8

pecifications S

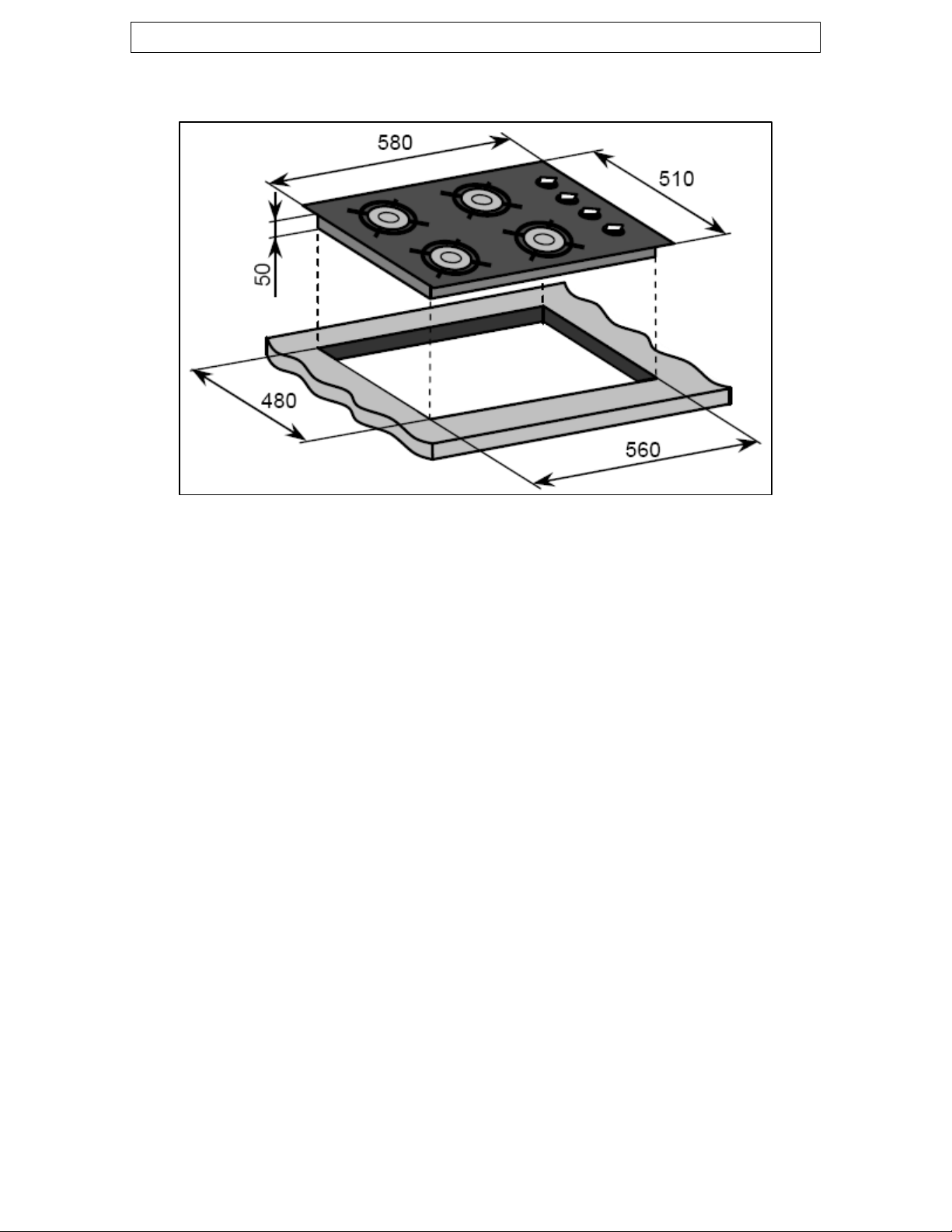

B70

.1BL

Product dimensions: Aperture dimensions:

Height: 510 mm Height: 490 mm

Width: 580 mm

Depth: 50 mm

Product specifications:

o 1 x 3.00 kW rapid burner

o 2 x 1.75 kW semi-rapid burne

o 1 x 1.00 kW auxiliary burner

o Side control operation

Automatic ignition o

o Flame failure safety device

o RANA cast iron pa

Standard accessories:

o LPG conversion jets

Width: 560 mm

rs

on each burner

n stands

8

Page 9

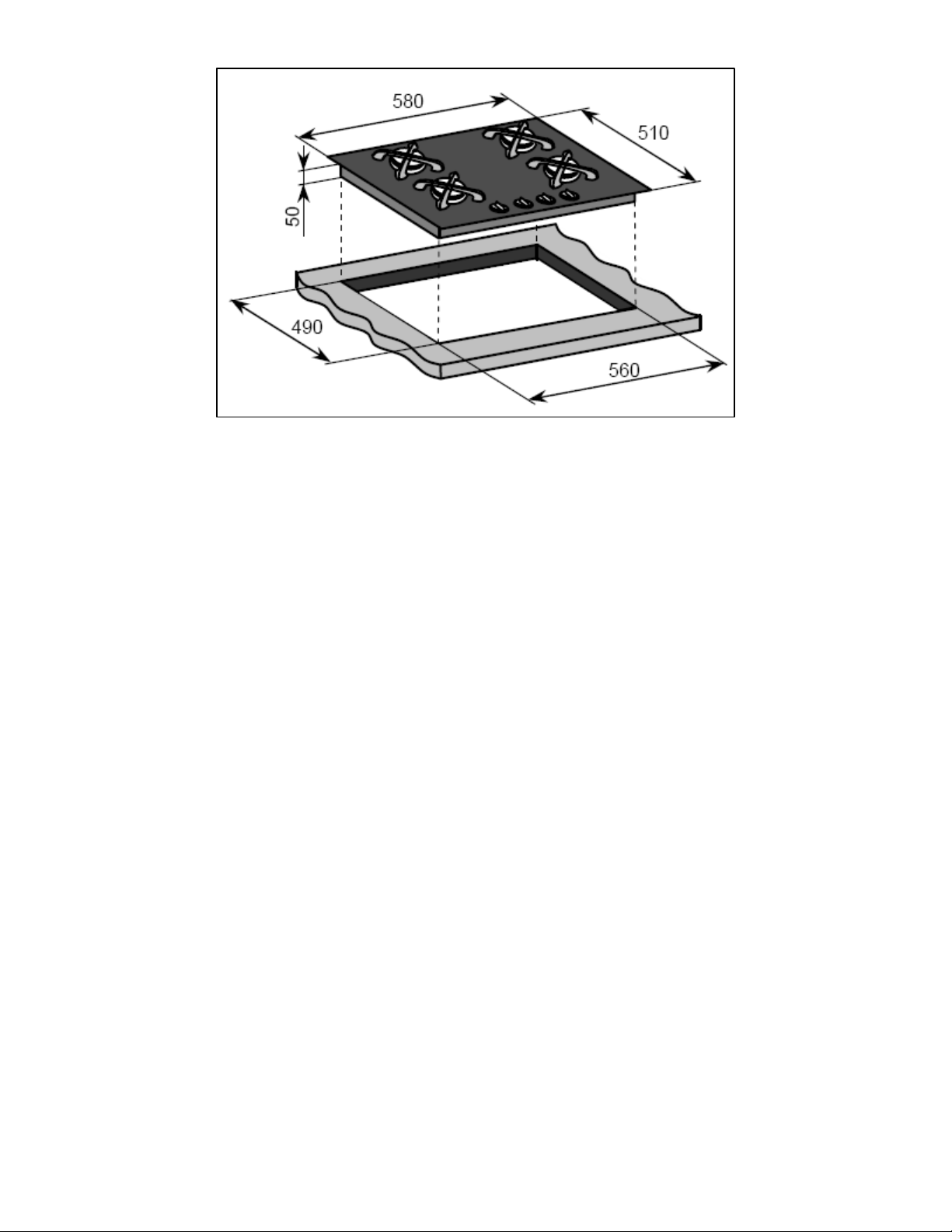

HG602

P

roduct dimensions: Aperture dimensions:

P

Height: 510 mm Height: 490 mm

Width: 580 mm

epth: 50 mm

D

roduct specifications:

P

o 1 x 3.50 kW rapid burner

o 2 x 1.75 kW semi-rapid burne

1 x 1.00 kW auxiliary burner

o

o Front control opera

o Automatic ignition

o Flame failure safety device

o RANA cast i

Frameless

o

tandard accessories:

S

o LPG conversion jets

ron pan stands

Width: 560 mm

rs

tion

on each burner

9

Page 10

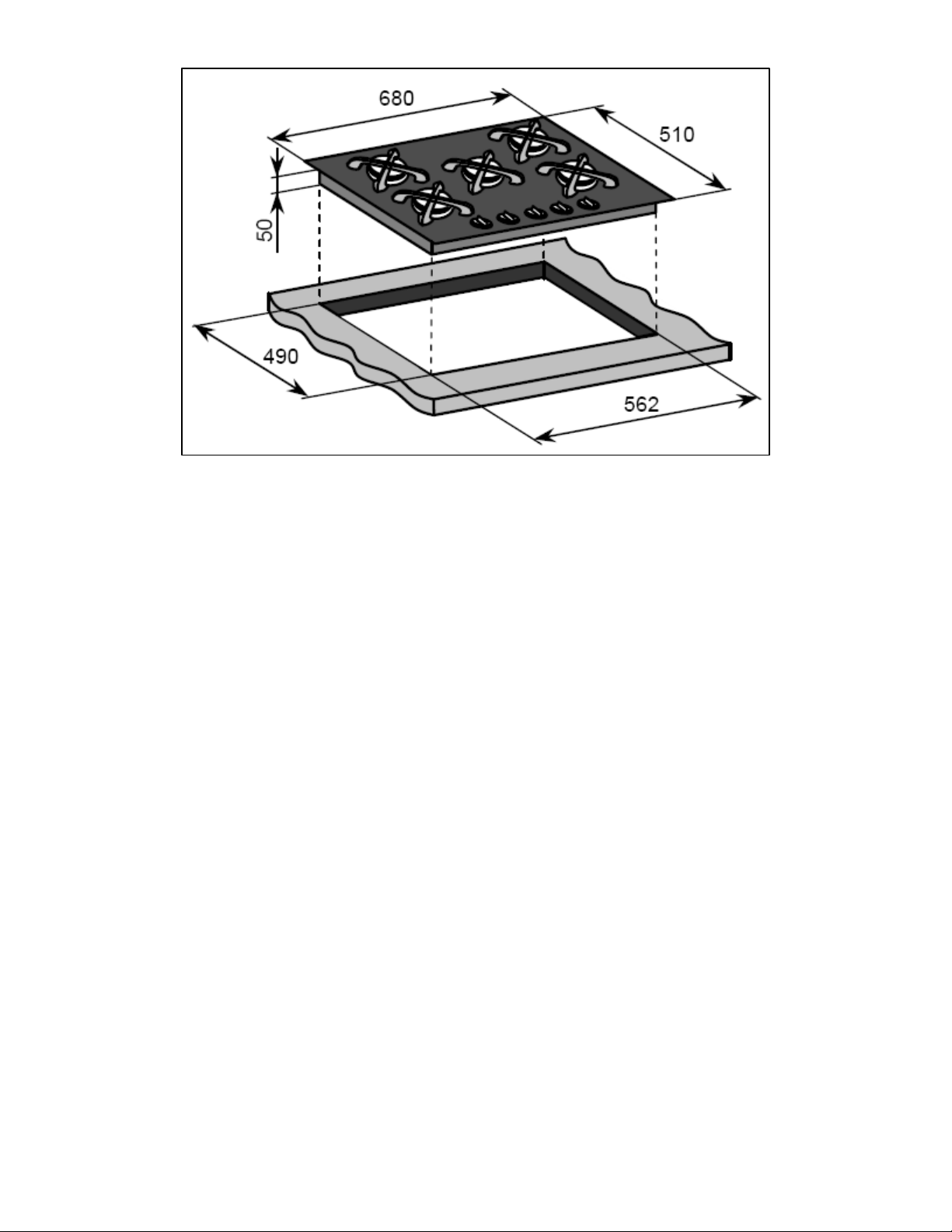

77TCBL

B

roduct dimensions: Aperture dimensions:

P

Height: 510 mm Height: 490 mm

Width: 680 mm

epth: 50 mm

D

roduct specifications:

P

o 1 x 3.50 kW wok burner

o 1 x 3.00 kW rapid burner

o 2 x 1.75 kW semi-rapid burne

1 x 1.00 kW auxiliary burner

o

o Front control opera

o Automatic ignition

o Flame failure safety device

RANA cast iron pan stands

o

tandard accessories:

S

o LPG conversion jets

Width: 562 mm

rs

tion

on each burner

10

Page 11

72BL

B

roduct dimensions: Aperture dimensions:

P

Height: 510 mm Height: 490 mm

Width: 580 mm

epth: 50 mm

D

roduct specifications:

P

o 1 x 3.00 kW rapid burner

o 2 x 1.75 kW semi-rapid burne

1 x 1.00 kW auxiliary burner

o

o Front control opera

o Automatic ignition

RANA cast iron pan stands

o

tandard accessories:

S

o LPG conversion jets

Width: 560 mm

rs

tion

11

Page 12

77BL

B

roduct dimensions: Aperture dimensions:

P

Height: 510 mm Height: 490 mm

Width: 680 mm

epth: 50 mm

D

roduct specifications:

P

o 1 x 3.50 kW wok burner

o 1 x 3.00 kW rapid burner

o 2 x 1.75 kW semi-rapid burne

1 x 1.00 kW auxiliary burner

o

o Front control opera

o Automatic ignition

RANA cast iron pan stands

o

tandard accessories:

S

o LPG conversion jets

Width: 562 mm

rs

tion

12

Page 13

lectrical details

E

Rated Voltage: 230 Vac 50 Hz

Supply Connection: itched fused outlet with

Max Rated Inputs: 0.008 to 0.02 kW (depending on model)

ains Supply Lead: 3 core x 0.75mm² (Type RR-F <HAR> marked)

M

as details

G

Connection: Rp ½ (ISO R7)

Type: Natural Gas (20.9 mbar),

Alternative LPG G30 (28-30 mbar),

For future reference please record the following information which ca

be found on the rating plate and the date of purchase which can be

found on your sales invoice. The rating plate of your hob is located on

the underneath of the appliance. Therefore it is a g

th

M

S

D

G

B

Town gas G110 – 120 (8 mbar) to order.

is information before you install your appliance.

odel Number ……………………………….

erial Number ……………………………….

ate of Purchase ……………………………….

as hob surface layout

70.1BL

3 A (double pole sw

3mm contact gap)

n

ood idea to record

13

Page 14

72BL/PHG602

B

77BL/B77TCBL

B

14

Page 15

sing the gas hob U

Before first use

IMPORTANT: You should clean the hob surface (see

Cleaning and maintenance” section).

“

Switching the hob on

The following s

control knob:

0 = gas off

arge flame: maximum setting

L

mall flame: minimum setting

S

o The minimum setting

of the control knob.

o All operation positions m

and minimum position.

o Never se

position.

o The symbol on the control panel, next

indicate which gas burner it operates.

Automatic ignition

To ignite a burner:

o Press in the control knob of the burner that you

turn it anti-clockwise to the maximum position.

o If you keep the control knob

for the burner will operate.

o Once the burner is lit, turn the control knob to your required

setting between the maximum and minimum setting symbols.

o To turn the burner of

the gas off position.

ymbols will appear on the control panel, next to each

is at the end of the anti-clockwise rotation

ust be selected between the maximum

lect a knob position between the maximum and off

to the control knob will

(B72BL/B77BL)

wish to light and

depressed, the automatic ignition

f, turn the control knob fully clockwise to

15

15

Page 16

o In case of power failure, the burners can be lit by carefully using

a match.

Automatic ignition with flame failure safety device

(B70.1BL/PHG602/B77TCBL)

The appliance is fitted with a flame failure safety device on each

burner, which is designed to stop the flow of gas to the burner head in

the event of the flame going out.

To ignite a burner:

o Press in the control knob of the burner that you wish to light and

turn it anti-clockwise to the maximum position.

o If you keep the control knob depressed, the automatic ignition

for the burner will operate.

o You should hold down the control knob for 20 seconds after the

flame on the burner has lit.

o After this 20 second interval, turn the control knob to your

required setting between the maximum and minimum setting

symbols.

o In case of power failure, the burners can be lit by carefully using

a match.

o To turn the burner off, turn the control knob fully clockwise to

the gas off position.

o In case of power failure, the burners can be lit by carefully using

a match.

Energy saving tips

BURNERS

Wok 220 mm 260 mm

Rapid 180 mm 220 mm

Semi-rapid 120 mm 200 mm

Auxiliary 80 mm 160 mm

o The diametre of the bottom of the pan should correspond to that

of the burner.

Minimum

diametre

PANS

Maximum

diametre

16

Page 17

o The burner flame must never extend beyond the diametre of the

pan.

o Use flat bottomed pans only

o When possible, keep a lid on the pan whilst cooking.

o Cook vegetables with as little water as possible, to reduce

cooking times.

IMPORTANT: Always place pans centrally over the hob burners and

position them so that the handles cannot get accidentally caught or

knocked off. You should also make sure that the handle is not over one

of the other hob burner flames.

Cleaning

Cleaning operations must only be carried out when

the hob is cool.

The appliance should be disconnected from your

mains supply before commencing any cleaning

process.

Cleaning the hob top

Any residues that are left on the hob top surface from cleaning

agents will damage it. You should remove any residues with

warm soapy water.

Abrasive cleaners or sharp objects will damage the hob surface;

you should clean it using warm soapy water.

Although it is easier to clean some deposits whilst the

hob surface is still warm. Make sure that the hob surface,

pan supports and hob burners have all cooled sufficiently

before you attempt to touch them.

17

Page 18

After each use

o Remove the pan stands and wipe the appliance over with a soft,

damp cloth that has been put into warm soapy water. The cloth

should be wrung out after being taken out of the soapy water.

o Dry the appliance by rubbing the surface with a soft, clean cloth.

Cleaning the hob burners

The hob burners should be cleaned once a week or more frequently if

they get soiled.

o IMPORTANT: Make sure that the hob surface, pan stands and

hob burners have cooled before you attempt to touch them.

o Remove the hob burners by pulling them upwards and away

from the hob top.

o Soak them for about ten minutes in hot water and a little

detergent.

o After cleaning and washing them, wipe and dry them carefully.

o Before placing the burners back on the hob top, make sure that

the gas jet is not blocked.

o IMPORTANT: Make sure that you reassemble the burners in the

original way.

Maintaining the cast iron pan stands

o IMPORTANT: Make sure that the hob surface and pan stands

have cooled before you attempt to touch them.

o Wipe the pan stands over with a soft, damp cloth that has been

put into warm soapy water. The cloth should be wrung out after

being taken out of the soapy water.

o Using a paper towel, thoroughly dry the pan stands.

o To maintain the appearance of the cast iron pan stands, we

would recommend that you rub a small amount of olive oil into

the pan stands. After you have finished cleaning them.

18

Page 19

Installation

The installation must be carried out by a CORGI

registered installer, in accordance with the current

version of the following.

o Gas Safety Regulations (Installation & Use)

o Building Regulations (issued by the Department of Environment)

o Building Standards (Issued by the Scottish Development

Department)

o IEE Wiring Regulations

o Electricity at Work Regulations BS 6172

o Installation of Domestic Gas Cooking Appliances (if necessary,

BS 5482 Installation of Domestic LPG Appliances)

o BS 5440 Installation of Flues and Ventilation for Gas Appliances

o Baumatic Ltd Installation Instructions

19

Page 20

Positioning

The adjacent furniture must be able to withstand a

minimum temperature rise of 85°C above the ambient

temperature of the room it is located in, during

periods of use.

o This appliance can be located in a kitchen, a kitchen diner or a

bed sitting room. IMPORTANT: The appliance must not be

installed in a bathroom or shower room.

This appliance is classified as Class 3 and therefore is to be built into a

kitchen unit (depending on size) or 600mm worktop, providing the

following minimum distances are allowed:

o The edges of the hob must be a minimum distance of 55 mm

from a side or rear wall.

o 700 mm between the highest point of the hob surface (including

the burners) and the underside of any horizontal surface directly

above it.

o 400 mm between the hob surface, providing that the underside

of the horizontal surface is in line with the outer edge of the hob.

If the underside of the horizontal surface is lower than 400 mm,

then it must be at least 50 mm away from the outer edges of

the hob.

20

Page 21

o 50 mm clearance around the appliance and between the hob

surface and any combustible materials.

Unpacking the appliance

When unpacking the appliance please check that the following items

are contained within the packaging:

1 x Baumatic hob

4 x Pan stands (B70.1BL/PHG602/B72BL)

5 x Pan stands (B77BL/B77TCBL)

1 x Installation and instruction manual

1 x Baumatic guarantee card

4 x Fixing screws

4 x Clamps

1 x Sealing strip

1 x LPG conversion kit

1 x Self-adhesive label for amending the Gas Category on the

appliance’s rating plate (required if the LPG conversion kit is used).

Installing the appliance

B70.1BL/PHG602/B72BL

B77BL/B77TCBL

21

Page 22

o Cut a hole in the worktop that corresponds with the drawings

shown on page 21.

o IMPORTANT: You must have a gap of at least 25 mm between

the underneath of the appliance and any surface that is below it.

o Carefully turn the hob upside down and place it on a cushioned

mat.

o Apply the sealing strip (A) provided around the edge of the

appliance.

o The protective covering must be removed from both sides.

o Do not leave a gap in the sealing agent or overlap the thickness.

o IMPORTANT: Do not use a silicon sealant to seal the appliance

against the aperture. This will make it difficult to remove the hob

from the aperture in future, particularly if it needs to be

serviced.

(A) Sealing strip

(B) Clamp

(C) Screw

22

Page 23

o Place the clamp (B) over the holes that match the size of the

screws. There are one set of screw holes in each corner of the

hob. Slightly tighten a screw (C) through the clamp (B) so that

the clamp is attached to the hob, but so that you can still adjust

the position of it.

o Carefully turn the hob back over and then gently lower it into the

aperture hole that you have cut out.

o On the underneath of the hob, adjust the clamps into a position

that is suitable for your worktop. Then fully tighten the screws

(C) to secure the hob into position.

Gas connection

This appliance must be installed by a competent

person in accordance with the current versions of

the following UK (United Kingdom) or ROI (Republic

of Ireland) Regulations and Safety Standards or

their European Norm Replaceme

Important information

o This cooker is supplied to run on natural gas only and cannot

be used on any other type of gas without modification.

o Conversion for use on LPG and other gases must only be

undertaken by a qualified person. For information on the use of

other gases, please contact the Baumatic Advice Line.

o The cooker must be installed by a qualified person, in

accordance with the current edition of the Gas Safety

(Installation and Use) (Amendment) Regulations and the

relevant building/I.E.E. Regulations.

o Failure to install the appliance correctly could invalidate

Baumatic’s guarantee and lead to prosecution under the

regulations quoted above.

o In the UK, CORGI registered installers are authorised to

undertake the installation and service work, in compliance with

the above regulations.

nts.

23

Page 24

Ventilation requirements

o The room containing the hob should have an air supply in

accordance with the current edition of BS 5440: Part 2:

o The room must have opening windows or equivalent; some

rooms may also require a permanent vent.

o If the room has a volume between 5 and 10m³, it will require an

air vent of 50cm² (effective area). Unless it has a door which

opens directly to the outside.

o If the room has a volume of less than 5m³, it will require an air

vent of 100cm² (effective area).

o If it is installed in a room with a volume that exceeds 11m³, then

no air vent is required.

o If there are any other fuel burning appliances in the same room

the current edition of BS 5440: Part 2: should be consulted to

determine air vent requirements.

o Ensure that the room containing the hob is well ventilated, keep

natural ventilation holes or install a mechanical ventilation device

(mechanical cooker hood).

o Prolonged intensive use of the appliance may call for additional

ventilation, either by the opening of a window, or by increasing

the level of the mechanical ventilation device (where present).

o This hob is not fitted with a device for discharging the products

of combustion. Ensure that the ventilation rules and regulations

are followed.

o The walls behind and near the hob should be resistant to heat,

steam and condensation.

o Remember that the quantity of air necessary for combustion

must never be less than 2m³/h for each kW of power (see total

power in kW on the appliance rating plate).

24

Page 25

Gas Safety (Installation and Use) Regulations

IMPORTANT: The appliance MUST be connected to the gas

supply by use of a ½ BSP Elbow, seal, copper pipe and an

isolation tap fitted in an easily accessible position.

o It is the law that all gas appliances are installed by competent

persons in accordance with the current edition of the Gas Safety

Installation and Use Regulations.

o It is in your interest and that of safety to ensure compliance with

the law.

o In the UK, CORGI registered installers work to safe standards of

practice. The cooker must also be installed in accordance with

the current edition of BS 6172. Failure to install the hob correctly

could invalidate the warranty, liability claims and lead to

prosecution.

o Put the gas seal into the elbow.

o Fully tighten the elbow and seal onto the gas rail.

o The elbow MUST be pointing in a downwards direction.

o Gas pressure may be checked on a semi-rapid hob burner.

Remove the appropriate injector and attach a test nipple. Light

the other burners and observe that the gas pressure complies

with the gas standards in force.

o IMPORTANT: On completion carry out a gas soundness

test.

25

Page 26

Gas adjustment (Conversion to LPG)

All work must be carried out by a CORGI registered

engineer.

IMPORTANT: Always isolate the hob from the electricity supply

before changing the injectors and/or adjusting the minimum

flow of the burners.

o Remove the pan-stands, burners and

flame spreaders (A).

o Unscrew the injector (B) and replace it

with the stipulated injector for the new gas

supply (see table below).

GENERAL INJECTORS TABLE

Burners

mm/100

Natural 135

115

97

72

L.P.G.

Butane

Propane

o Reassemble all the burners carefully; in particular you should

make sure that the flame spreader is correctly placed on the

burner.

95

85

65

50

Wok

Rapid

Semi-rapid

Auxiliary

Wok

Rapid

Semi-rapid

Auxiliary

Power (in watts) Kind of gas Nozzle

Max. Min.

3500

3000

1750

1000

3500

3000

1750

1000

1700

700

400

350

1700

700

400

350

26

Page 27

o IMPORTANT: The minimum flow adjustment process must

be completed before the appliance is next used.

Minimum flow adjustment for hob gas taps.

All work must be carried out by a CORGI registered

engineer.

IMPORTANT: Always isolate the hob from the electricity supply

before changing the injectors and/or adjusting the minimum

flow of the burners.

o Switch the burner

on and set the

knob at the

minimum

position.

o Remove the knob

from the tap and

place a small

bladed

screwdriver in the

centre of the tap

shaft.

o Unscrew the adjusting screw, in order to increase the gas flow

or tighten the adjusting screw to decrease the gas flow.

o The correct adjustment is obtained when the flame has a

length of about 3 – 4 mm.

o For butane/propane gas, the adjusting screw must be tightly

screwed in.

o Refit the control knob.

o Make sure that the flame does not go out by quickly turning

from maximum flow to minimum flow. If it does then remove

the control knob and make further adjustments to the gas

flow, testing it again once the adjustment has been made.

o Repeat this process for each one of the gas taps.

27

Page 28

Gas tap maintenance

These maintenance operations MUST ONLY be carried

out by a CORGI registered engineer.

IMPORTANT: Before carrying out any maintenance operations,

disconnect the appliance from the gas and electricity supplies.

If a gas tap becomes stiff to operate, then you should proceed as

follows:

o Remove the control knobs, pan supports, burners, hob fixing

screws and clamps.

o Remove the hob from the worktop and remove any underside

protective covers.

o Disconnect the fixings holding the tap to the fascia panel and

separate the assembly. Then clean the cone and seating, with

a cloth dampened with solvent.

o Lightly smear the cone with high temperature grease,

reassemble into position and rotate a few times.

o Remove the cone again and remove any excess grease,

making sure that the gas ducts are not obstructed with

grease.

o Carefully reassemble the components and perform a gas

soundness test.

If it becomes necessary to replace a gas tap, then you should proceed

as follows:

o Remove the control knobs, pan supports, burners, hob fixing

screws and clamps.

o Remove the hob from the worktop and remove any underside

protective covers.

o Disconnect the fixings holding the tap to the fascia panel and

separate the assembly.

o Disconnect the gas pipe from the gas tap, and then

disassemble them from the gas rail by removing the fixing

screws.

o When fitting a new tap, ensure that a new gasket is used.

28

Page 29

o Reconnect the gas tap, perform a gas soundness test and

then reassemble the hob.

Electrical connection

This appliance must be installed by a qualified

person in accordance with the latest edition of the

I.E.E. Regulations and in compliance with Baumatic’s

instructions.

Before connecting the appliance, make sure that the supply voltage

marked on the rating plate corresponds with your mains supply

voltage.

o Cable type: H05 RRF 3 core x 0.75 mm³ (Type RR-F <HAR>

marked).

o The mains supply cable is supplied with this product.

Replacing the mains supply cable

If the mains supply cable is damaged, then it must be replaced by an

appropriate replacement which can be obtained from the Baumatic

Spares Department.

The mains supply cable should be replaced in accordance with the

following instructions:

o Switch the appliance off at the control switch.

o Open the box of the supply board.

o Unscrew the clamp (A) fixing the cable.

o Replace the cable with one of the same length and in accordance

with the specification given above.

o The “green-yellow” earth wire must be connected to the terminal

marked

neutral wires.

o The “blue” neutral wire must be connected to the terminal

marked with letter (N) - the live wire must be connected to the

terminal marked with letter (L).

. It must be about 10 mm longer than the live and

29

Page 30

My appliance isn’t working correctly

IMPORTANT: If your appliance appears not to be

operating correctly, then you should disconnect it

from your mains supply and then contact

Baumatic Customer Care on telephone number

(0118) 933 6911.

DO NOT ATTEMPT TO REPAIR THE APPLIANCE

YOURSELF.

Please note that if an engineer is asked to attend whilst the product is

under guarantee and finds that the problem is not the result of an

appliance fault, then you may be liable for the cost of the call out

charge.

The appliance must be accessible for the engineer to perform

any necessary repair. If your appliance is installed in such a

way that an engineer is concerned that damage will be caused

to the appliance or your kitchen, then he will not complete a

repair.

This includes situations where appliances have been tiled in,

sealed in with sealant, have wooden obstructions placed in

front of the appliance, like plinths. Or any installation other

than the one specified by Baumatic Ltd. has been completed.

Please refer to the conditions of guarantee that appear on the

warranty card that you receive with the appliance.

30

Page 31

United Kingdom

Baumatic Ltd.,

Baumatic Buildings,

6 Bennet Road,

Reading, Berkshire

RG2 0QX

United Kingdom

Sales Telephone

(0118) 933 6900

Sales Fax

(0118) 931 0035

Customer Care Telephone

(0118) 933 6911

Customer Care Fax

(0118) 986 9124

Spares Telephone

(01235) 437244

Advice Line Telephone

(0118) 933 6933

E-mail:

sales@baumatic.co.uk

customercare@baumatic.co.uk

spares@baumatic.co.uk

technical@baumatic.co.uk

Website:

www.baumatic.co.uk

Republic of Ireland

01- 6266 798

Czech Republic

Baumatic CR spol s.r.o.

Amperova 495

46215, Librec

Czech Republic

+420 800 185 263

www.baumatic.cz

Slovak Republic

Baumatic Slovakia, s.r.o.

Skultetyho 1

831 04 Bratislava 3

Slovakia

+421 255 640 618

Germany

Baumatic Gmbh

Janderstrasse 9

Mannheim, 68199

Germany

+4962 112 9190

www.baumatic.de

Italy

Baumatic Italia S.R.L.

Via Caltana 129

Campodarsego (Padova), 35011

Italy

+3904 9920 2297

www.baumatic.it

Holland

Baumatic Benelux B.V.

Grindzuigerstraat 22

1333 MS ALMERE

The Netherlands

+3136 549 1555

www.baumatic.nl

31

Page 32

32

Loading...

Loading...