Page 1

B602.1BL/W

B604.1SS/B609.1SS

60 cm Gas fan-assisted

oven

1

Page 2

User Manual for your Baumatic

B602.1BL/W

B604.1SS

B609.1SS

60 cm Gas fan-assisted oven

NOTE: This User Instruction Manual contains important

information, including safety & installation points, which will

enable you to get the most out of your appliance. Please keep it

in a safe place so that it is easily available for future reference; for

you or any person not familiar with the operation of the appliance.

DD 23/03/09

2

Page 3

Contents

Environmental note 4

Important safety information 5 – 8

Specifications 9

Product specifications 9

Standard accessories 10

Optional extras 10

Electrical details 10

Control panel 11

Before first use 12

Setting the time of day (B609.1SS only) 12

Switching the gas oven on 13

Switching the gas grill on 14

Operation of the fan 15

Cooking guidelines 15

Warnings 16

Setting a countdown time (B609.1SS only) 17

Using the minute minder (B602.1 & B604.1 only) 18

The oven light 18

Cleaning and maintenance 19

Replacing the oven bulb 20

Removing the oven door for cleaning 21

Removing the inner door glass for cleaning 22

Installation 22

Electrical connection 22-23

Positioning 23

Installing the oven into the kitchen cabinet 24

Positioning the appliance 24

Ventilation requirements 25-26

Gas connection 27

Gas Safety (Installation and Use) Regulations 28

Gas connection 29

Gas adjustment (Conversion to LPG and gas adjustment) 30-32

My appliance isn’t working correctly 32-33

Baumatic Ltd. conditions of guarantee 34

Contact details 35

3

Page 4

Environmental note

o The packaging materials that Baumatic uses are environmentally

friendly and can be recycled.

o Please discard

environment.

all packaging material with due regard for the

4

Page 5

IMPORTANT SAFETY INFORMATION

Your safety is of the utmost importance to Baumatic.

Please make sure that you read this instruction booklet

before attempting to install or use the appliance. If yo

are unsure of any of the information contained i

booklet, pleas

Departm

eneral Information

G

ent.

e contact the Baumatic Technical

o This appliance is designed for domestic household use an

be built into a standard kitchen cabinet or housing unit.

o IMPORTANT: The adjacent furniture or housing and all

materials used in the installation must be able to withstand a

minimum temperature of 85°C above the

of the room it is located in, whilst in use.

o Certain types of vinyl or laminate kitchen furniture are

particularly prone to heat damage or discolouratio

temperatures below the guidelines given above.

o Any damage caused by the appliance being installed in

contravention of this temperature limit, or by placing adjacent

cabinet materials closer t

liability of the owner.

o For use in leisure accommodation vehicles, please refer to

the appropriate info

for this appliance.

o IMPORTANT: Baumatic Ltd. DO NOT recommend t

appliance is installed on any type of marine vessel.

o The use of this appliance for any other purpose or in any other

environment without the express agreement o

will invalidate any warranty or liability claim.

o Your new appliance is guaranteed against electrical or

mechanical defects, subject to certain exclusions that are noted

in Baumatic’s Conditions Of G

affect your statutory rights.

rmation given in the installation instructions

han 4mm to the appliance, will be the

uarantee. The foregoing does not

ambient temperature

n at

hat this

f Baumatic Ltd.

o Repairs may only be carried out by Baumatic

Engineers or their authorised service agent.

Service

u

n this

d can

5

Page 6

arning and safety instructions

W

o This appliance complies with all current European safety

legislation. Baumatic do wish to emphasise that this compl

does not remove the fact that the appliance surfaces will

become hot during use and retain heat after operation.

hild Safety

C

iance

o Baumatic strongly recommend that babies and young children

are prevented from being near to the appliance and not allowe

to touch the appliance at a

surfaces will become hot.

o If it is necessary for younger family members to be in the

kitchen, plea

at all times.

eneral Safety

G

Make sure that you understand the controls before using the

appliance.

Check that all of the controls on the appliance are turned off

after use.

when opening the oven door, this will allow

Always stand back

eat to disperse.

h

Take care when removing items from the oven, as the contents

may be hot.

Always keep the oven doors closed when the oven is not in use.

Always follow the basic principles of food handling and hygiene,

this will prevent the possibility of bacterial growth.

Always keep ventilation slots clear of obstructions.

Keep fingers away from the hinge areas when closing the door,

otherwise you may trap them.

Oven gloves should be used when placing food in the oven ca

and when removing it. Care should be taken to avo

contact with any of the elements in the appliance.

se ensure that they are kept under close supervision

ny time. During and after use, all

id direct

o DO NO

USE.

T LEAVE THE APPLIANCE UNATTENDED WHILST IN

d

vity

6

Page 7

o Do not place heavy objects on the oven door or lean on the

oven door when it is open, as this can cause damage to the oven

door hinges. Nobody should be allowed to sit or stand on any

part of the oven.

o Do not heat up unopened food containers, as pressure can build

up which may cause the container to burst.

o Do not place flammable or plastic items in the oven.

o Do not leave heated oil or fat unattended, as this is a fire risk.

o Do not allow fat or oil to build up in the oven trays, grill pan or

oven base.

o Do not place pans or baking trays directly on the base of the

oven cavity, or line it with aluminium foil.

o Do not grill food containing fat without using the grill trivet. The

grill trivet should never be covered with aluminium foil.

o Do not place hot enamel parts in water, leave them to cool first.

o Do not allow vinegar, coffee, milk, saltwater, lemon, tomato

juice or any liquid with high sugar content to remain in contact

with the enamel parts of the appliance. Spillages should be

wiped up immediately.

o Do not allow electrical fittings or cables to come into contact

with areas on the appliance that get hot.

o Do not use the appliance to heat the room it is located in or to

dry clothing. No clothing should be placed over or near to the

oven door.

o Do not install the appliance next to curtains or soft furnishings.

o Do not attempt to lift or move cooking appliances by using the

oven door or handle, as this may cause damage to the appliance

or result in injury to the person lifting the appliance.

o Do not store chemicals, food stuffs, pressurised containers in or

on the oven or in cabinets immediately above or next to the

oven.

7

Page 8

Cleaning

o Cleaning of the oven should be carried out on a regular basis.

o Great care should be taken whilst using this appliance and when

following the cleaning procedure.

o IMPORTANT: The appliance must be disconnected from the

mains before following the cleaning procedure.

Installation

This appliance must be correctly installed by a

suitably qualified person, strictly in accordance

with the manufacturer’s instructions. Please see

the specific section of this booklet that refers to

installation.

o Baumatic Ltd. declines any responsibility for injury or

damage, to person or property, as a result of improper

use or installation of this appliance.

o Heat, steam and moisture will be created during use of the

appliance, take care to avoid injury and ensure that the room is

adequately ventilated. If the appliance is going to be used for

prolonged periods of time, then additional ventilation may be

required.

o Please consult with your qualified installer if you are in any doubt

about the amount of ventilation that you will require.

Declaration of conformity

This appliance complies with the following European Directives:

-73/23/EEC regarding “low voltage”

-89/336/EEC regarding “electromagnetic disturbances”

-90/396/EEC regarding “gas appliances”

-89/109/EEC regarding “materials in contact with food”.

o The above directives comply with 93/68/EEC regarding CE

marking.

o The manufacturer declares that the oven is built using certified

materials and requires the appliance to be installed in

accordance with the standards currently in force. This appliance

must be used by a trained person for domestic purposes only.

8

Page 9

Specifications

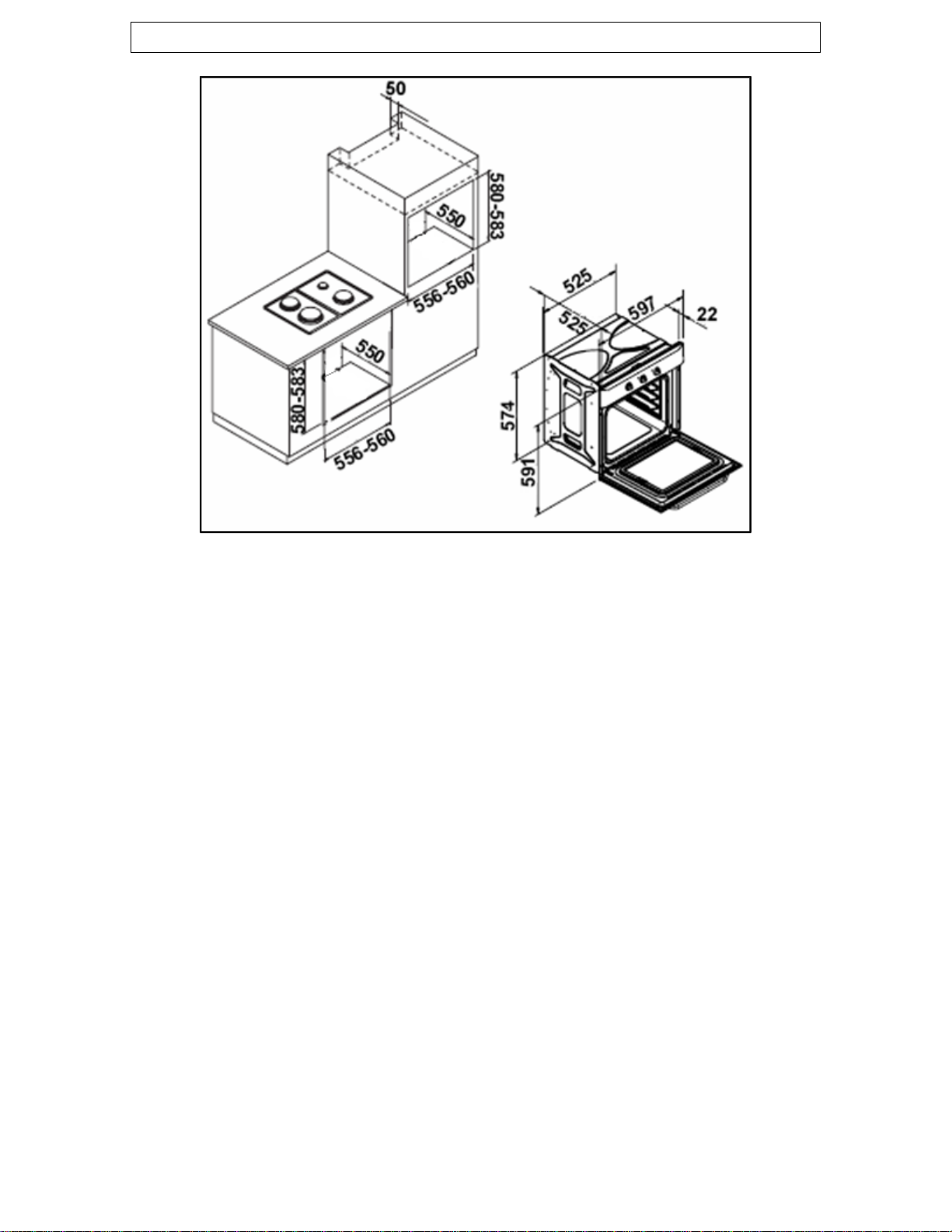

(IMPORTANT: The above drawing does not show the ventilation

requirements that are necessary for installing this appliance, please

refer to the installation instructions for this information).

Product Dimensions Aperture Dimensions

Height: 591 mm 580 mm – 583 mm

Width: 597 mm 556 mm - 560 mm

Depth: 525 mm 550 mm

Cooling fan

o A tangential cooling fan is fitted inside of this appliance, to make

the internal temperature of the oven stable and the external

surface temperature lower.

Product specifications

o Oven capacity: 47 litres

o Minute minder

o LED minute minder (B609.1SS only)

o Cooling fan

o Gas grill

o Flame failure safety device

o Auto-ignition

o Fan-assisted gas oven with lower burner

o Double-glazed removable door

9

Page 10

Standard accessories

o Removable side racks

o 2 x safety shelves

o Enamelled drip tray with handle

o Trivet

o LPG conversion jets

Optional extras

o BPS1 Pizza stone

Electrical details

Rated Voltage: 230 Vac 50 Hz

Supply Connection: 13 A (double pole switched fused

outlet with 3mm contact gap)

Fuse rating: 3 amp

Max Rated Inputs: 0.075 kW

Mains Supply Lead: 3 x 1.0 mm²

For future reference please record the following information which can

be found on the Rating Plate and the date of purchase which can be

found on your sales invoice. The rating plate for your oven can be

located by opening the oven door and looking on the right hand side of

the oven chassis.

Model Number ……………………………….

Serial Number ……………………………….

Date of Purchase ……………………………….

10

Page 11

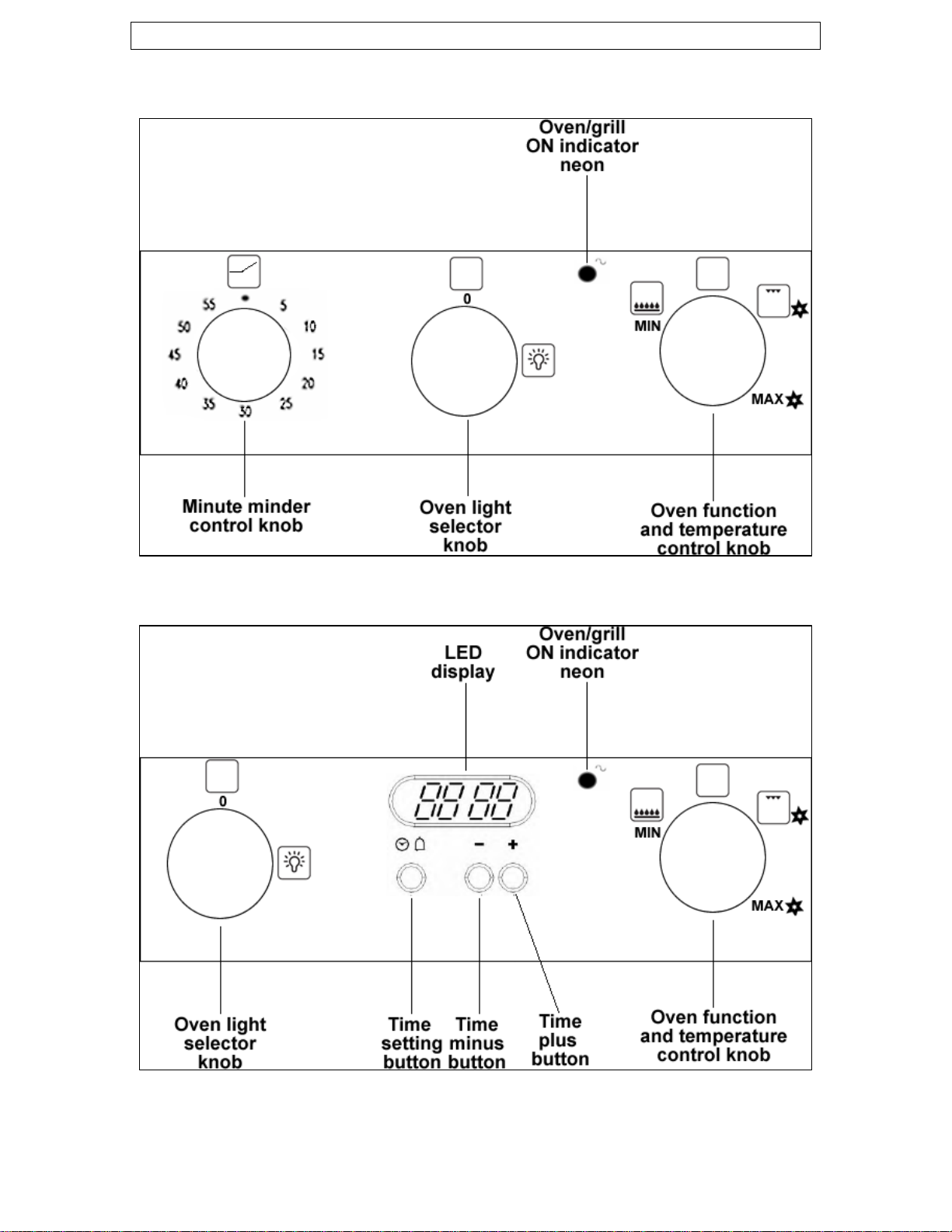

Control Panel

B602.1/B604.1

B609.1

11

Page 12

Before first use

o To remove any residue from the oven that may have been left

from the manufacturing process, you should select the gas oven

and set it to its maximum temperature setting.

o It is perfectly normal for a smell to be produced during this

process.

o You should make sure that any windows in the room are left

open during this process.

o It is advisable for you not to remain in the room whilst the

burning off process is taking place.

o You should leave the oven on maximum setting for 30 – 40

minutes.

Setting the time of day (B609.1SS only)

When the oven is switched on for the first time (or if power has been

cut to the appliance), three zeros will flash on the timer display.

o To set the time of day, hold down button (A) and then press the

(B) and (C) buttons until the current time of day is shown on

the timer display.

o The speed that the time adjusts at depends on how hard the (B)

and (C) buttons are held down.

o When the correct time of day is shown, release all of the

buttons. After a few seconds the time of day will be set on the

timer display.

12

Page 13

Switching the gas oven on

The oven has electric ignition, to light it you should do the following:-

o Open the door of the appliance.

o Push the oven function and temperature control knob down

slightly and then turn it anticlockwise to the word MAX.

o Whilst it is pointed to the MAX position, fully push down this

knob and hold it down.

o The gas oven should light within 15 seconds.

o Once the burner has lit, continue to keep the oven function and

temperature control knob held down for a further 10 seconds.

Otherwise the safety cut off will operate and block the flow of

gas.

o IMPORTANT: When you are certain that the oven burner is fully

lit, close the oven door. Then turn the oven function and

temperature control knob clockwise until it reaches the

temperature that you desire.

o DO NOT turn the control knob past the MIN position, otherwise

the burner may go out.

o If the gas oven does not light within 15 seconds, then release

the oven function and temperature control knob. IMPORTANT:

YOU MUST TURN THE CONTROL KNOB BACK TO ITS

ORIGINAL POSITION; OTHERWISE GAS WILL CONTINUE

TO BE RELEASED.

o Wait for 1 minute, before repeating the ignition procedure again.

When lighting your oven for the first time, it may take

several times until the electric ignition operates. This is

due to air being in the gas pipe.

13

Page 14

Switching the gas grill on

The grill has electric ignition, to light it you should do the following:-

o Open the door of the oven and fit the

grill defllector to the front of the

appliance.

o Push the oven function and

temperature control knob down slightly

and then turn it anticlockwise to the

grill symbol (shown above)

o Whilst it is pointed to the grill symbol, fully push down this knob

and hold it down.

o The gas grill should light within 15 seconds.

o Once the burner has lit, continue to keep the oven function and

temperature control knob held down for a further 10 seconds.

Otherwise the safety cut off will operate and block the flow of

gas.

o THE OVEN DOOR MUST BE LEFT OPEN WHILST YOU ARE

GRILLING.

o If the gas grill does not light within 15 seconds, then release the

oven function and temperature control knob. IMPORTANT: YOU

MUST TURN THE CONTROL KNOB BACK TO ITS ORIGINAL

POSITION; OTHERWISE GAS WILL CONTINUE TO BE

RELEASED.

o Wait for 1 minute, before repeating the ignition procedure again.

When lighting your grill for the first time, it may take

several times until the electric ignition operates. This is

due to air being in the gas pipe.

o IMPORTANT: You should allow the oven to cool completely

before attempting to remove the grill deflector. If you

attempt to remove the grill deflector before the oven is

cool, it will be hot.

14

Page 15

Operation of the fan

o After igniting the oven and shutting the door of the appliance,

check to make sure that the fan on the rear wall of the oven

cavity is turning.

o IMPORTANT: If there is a power cut whilst the oven is in use,

then you should immediately turn the oven off until power is

restored.

o If the cooling fan does not operate and there is still power to the

appliance, then DO NOT continue to use the appliance. Switch

the oven off and contact the Baumatic Service Department to

arrange for an engineer to attend the appliance.

If the oven is in use and the door is opened, the cooling

fan will stop operating. This is to prevent excessive heat

being blown in the direction of the user. When the door is

shut again, check to make sure that the fan restarts.

Cooking guidelines

o Please refer to the information given on food packaging for

guidance on cooking temperatures and times. Once familiar with

the performance of your appliance, temperatures and times can

be varied to suit personal preference.

o Make sure that frozen foods are thoroughly thawed before

cooking, unless the instructions on the food packaging advise

that you can “cook from frozen”.

o Before cooking, check that any unused accessories are removed

from the oven.

o Place cooking trays in the centre of the oven and leave gaps

between the trays to allow air to circulate.

o Try to open the door as little as possible to view the dishes.

15

Page 16

Warnings

o Keep the oven door open when using the grill function and make

sure that the grill deflector is fitted.

o Do not use aluminium foil to cover the grill pan or heat items

wrapped in aluminium foil under the grill. The high reflectivity of

the foil could potentially damage the grill element.

o You should also never line the base of your oven with aluminium

foil.

o During cooking, never place pans or cookware directly onto the

bottom of your oven. They should always be placed on the

shelves provided.

o The grill heating element becomes extremely hot during

operation, avoid touching it inadvertently when handling the

food which you are grilling.

o Important: Be careful when opening the door, to avoid contact

with hot parts and steam.

o The drip tray handle should only be used to reposition the drip

tray and NOT for removing it from the oven cavity. When

removing the drip tray, you should ALWAYS use an oven glove.

o The drip tray handle should not be left in position when the

appliance is switched on.

16

Page 17

Setting a countdown time (B609.1SS only)

o Press button (C) and the numbers on the timer display will begin

to advance and a symbol will illuminate.

o Use buttons (B) and (C) to adjust the time on the timer display,

until it shows the length of time that you want the oven to

countdown for.

o The maximum countdown time that can be set is 99 minutes and

59 seconds.

o Once your desired countdown time is displayed, release all of the

buttons. After 10 seconds, the countdown time will be stored and

the countdown will commence immediately.

o At the end of the cooking time a bell will ring for 7 minutes. It

can be switched off by pressing button (C) once.

o To reset a countdown before it reaches its end time, press

buttons (B) and (C) simultaneously. Then release button (C)

first, followed by button (B).

IMPORTANT: If you have the oven or grill in use

whilst the timer is counting down. When the

countdown ends, the oven will continue to heat. You

must turn off the oven/grill using the oven function

and temperature control knob.

Adjusting the audible signal (B609.1SS only)

There are 3 levels of audible signal available; to adjust it you should

do the following:

o When the time of day is shown on the timer display, press

button (B) for approximately 2 seconds. You will then hear the

current level of audible signal.

o Repeat this process until the audible signal reaches the level that

you require, and then release the button (B).

17

Page 18

Using the minute minder (B602.1 & B604.1)

The minute minder can be used independently of

an oven cooking function for a time period of up

to 60 minutes.

o To set the timer, turn the knob fully clockwise until it stops and

then turn it back anticlockwise to the required time.

o The time period that has been set will expire when the control

knob reaches zero, a brief audible signal will sound.

IMPORTANT: If you have the oven or grill in use

whilst the timer is counting down. When the

countdown ends, the oven will continue to heat. You

must turn off the oven/grill using the oven function

and temperature control knob.

The oven light

o Turn the oven light selector knob clockwise, until it reaches the

light bulb symbol.

o The oven light can be turned on, regardless of whether the

oven/grill are in use.

18

Page 19

Cleaning and maintenance

Cleaning operations must only be carried out

when the oven is cool.

The appliance should be disconnected from your

mains supply before commencing any cleaning

process.

o The oven should be thoroughly cleaned before it is operated for

the first time and after each use. This will avoid residual food

stuffs becoming baked on the oven cavity. After residues have

been baked on several times, they are far more difficult to

remove.

o Never clean the oven surfaces by steam cleaning.

o The oven cavity should only be cleaned with warm soapy water,

using either a sponge or soft cloth. No abrasive cleaners should

be used.

o Any stains that may appear on the bottom of the oven will have

originated from food splashes or spilt food, these splashes occur

during the cooking process. These could possibly be a result of

the food being cooked at an excessively high temperature or

being placed in cookware that is too small.

o You should make sure that the cooking temperature that is

selected is appropriate for the food that you are cooking. You

should also ensure that the food is placed in an adequately sized

dish and that you use the drip tray where appropriate.

o Outer parts of the oven should only be cleaned with warm soapy

water, using either a sponge or soft cloth. No abrasive cleaners

should be used.

o If you use any form of oven cleaner on your appliance, then you

must check with the manufacturer of the cleaner that it is

suitable for use on your appliance.

o Any damage that is caused to the appliance by a cleaning

product will not be fixed by Baumatic free of charge, even

if the appliance is within the guarantee period.

19

Page 20

Replacing the oven bulb

IMPORTANT: The oven must be disconnected from

your mains supply before you attempt to either

remove or replace the oven bulb.

o Remove all oven shelves and the drip tray to make it easier to

access the bulb.

o Remove the light cover by turning it anti-clockwise.

o Unscrew the bulb clockwise and remove it from its holder.

o Replace the bulb with a 25 W/300°C, screw type pigmy.

o Do not use any other type of bulb.

o Place the lamp cover back into position.

20

Page 21

Removing the oven door for cleaning

To facilitate the cleaning of the inside of the oven and the outer frame

of the oven, the door can be removed as follows:-

o The hinges (A) have two movable bolts on them (B).

o If you raise both of the movable bolts (B), then the hinges (A)

are released from the oven housing.

o You should grip the sides of the door at the centre and then

incline it slightly towards the oven cavity and then by pulling it

gently away from the oven cavity.

o IMPORTANT: You should make sure that the door is supported

at all times and that you place the door on some padded

material whilst cleaning it.

o The oven door and door glass should only be cleaned using a

damp cloth and a small amount of detergent. The cloth MUST

NOT have come into contact with any form of cleaning product

or chemical previously.

o To refit the door you should slide the hinges back into their slots

and open the door fully.

o IMPORTANT: The movable bolts (B) must be closed back into

their original positions before closing the door.

o Take care not to dislodge the hinge locking

system when removing the door, as the

hinge mechanism has a strong spring.

o Do not immerse the door in water at any

time.

21

Page 22

Removing the inner door glass for cleaning

o Do not use any abrasive cleaner that could cause damage.

o Remember that if the surface of the glass panel becomes

scratched, this could lead to a dangerous failure.

o To facilitate cleaning, the door glass can be lifted out after

removing the fixing screws and turning the metal stoppers that

hold the glass in position.

o When refitting, make sure that the glass is correctly seated in

the door recess and the correct way round, before turning the

metal stoppers back to their original position and fully tightening

the fixing screws.

Installation

The installation must be carried out by a suitably

qualified person, in accordance with the current

version of the following.

o UK Regulations and Safety Standards or their European

Norm Replacements.

o Building Regulations (issued by the Department of the

Environment).

o Building Standards (issued by the Scottish Development

Department).

o IEE Wiring Regulations.

o Electricity At Work Regulations.

o Gas Safety (Installation and Use) (Amendment)

Regulations.

WARNING: THIS APPLIANCE MUST BE EARTHED.

o This appliance should be wired into a 13 A double pole switched

fused spur outlet, having 3 mm contact separation and the fuse

rating reduced to 3 amps. This should be placed in an easily

accessible position adjacent to the appliance, preferably above

worktop level. An outlet can then be located at the rear of the

appliance for connection.

22

Page 23

o To connect the oven power cord, loosen and remove the cover

on the terminal block, in order to gain access to the contacts

inside. Make the connection, securing the cord in place with the

cable clamp provided and then immediately close the terminal

block cover again.

o If you have to change the oven power cord, the earthing

(yellow/green) conductor must always be 10 mm longer than the

line conductors.

o Care must be taken to ensure that the temperature of the mains

supply cable does not exceed 50°C.

o If the mains supply cable is damaged, then it must be replaced

by an appropriate replacement.

Positioning

The adjacent furniture and all materials used in the

installation must be able to withstand a minimum

temperature of 85°C above the ambient

temperature of the room it is located in, whilst the

appliance is in use.

o Your appliance is heavy, so you should be careful when moving

or positioning it.

o Do not try to move the cooker by pulling on either the door,

handle or control panel.

o The oven may be located in a kitchen, or a bedroom, but not in a

room containing a bath or shower. The oven must not be

installed in a bedroom of less than 20m³ in size.

o LPG models must not be installed in a room or internal space

below ground level (e.g. in a basement).

o This oven may be used for a built-in or built under installation

(see the diagrams on pages 25 - 26).

23

Page 24

Installing the oven into the kitchen cabinet

Positioning the appliance

o Ensure that the aperture that you will be fitting the oven into is

of the size given in the above diagram.

o The oven must be fitted into an oven housing with the ventilation

cut-outs shown in the “Ventilation requirements” section on the

next page.

o Ensure that the rear panel of the furniture housing unit has been

removed.

24

Page 25

Ventilation requirements

o You should remove the rear panel of the housing unit before

attempting to install the oven. A full depth shelf must be

incorporated into the housing and positioned 50 mm below the

support shelf for the appliance.

o A minimum ventilation gap of 90 mm must be allowed between

the rear of the support shelf and the rear of the housing unit.

o A 400 cm² (20 x 20 cm) ventilation cut out must be made in the

support shelf.

o A minimum ventilation area of 80 cm² must be allowed below

the appliance.

o If the appliance is to be installed in a Leisure Accommodation

Vehicle, the requirements of EN 721 must be applied.

25

Page 26

Additional built under ventilation requirements

o Remove the horizontal strengthening support at the upper front

housing unit.

o If your housing unit incorporates a domestic lower drawer, this

must be made non-functioning with a ventilated false front.

o A 5 mm ventilation gap must be allowed between the top of the

appliance and the underside of the worktop.

Additional tall housing ventilation requirements

o A 500 x 15 mm cut out must be made in the top of the housing

unit, the plinth and any other additional shelves apart from the

support shelf.

o If the unit is fitted flush with the kitchen ceiling, a 20 cm²

ventilation cut out must be made in the top front of the housing.

o For both times of

installation, ensure that the

oven has been securely fixed

into the housing unit. The

fixing of the oven into the

housing is made by using

four screws. These should be

screwed through the oven

cabinet and into the housing

unit.

26

Page 27

Gas connection

This appliance must be installed by a competent

person in accordance with the current versions of

the following UK (United Kingdom) or ROI (Republic

of Ireland) Regulations and Safety Standards or

their European Norm Replaceme

Important information

o This oven is supplied to run on natural gas only and cannot be

used on any other type of gas without modification.

o Conversion for use on LPG and other gases must only be

undertaken by a qualified person. For information on the use of

other gases, please contact the Baumatic Technical Department.

o The oven must be installed by a qualified person, in accordance

with the current edition of the Gas Safety (Installation and Use)

Regulations and the relevant building/I.E.E. Regulations.

o Failure to install the appliance correctly could invalidate

Baumatic’s guarantee and lead to prosecution under the

regulations quoted above.

o In the UK, only CORGI registered installers are authorised to

undertake the installation and service work, in compliance with

the above regulations.

Ventilation requirements

o The room containing the oven should have an air supply in

accordance with the current edition of BS 5440: Part 2:

o The room must have opening windows or equivalent; some

rooms may also require a permanent vent.

o If the room has a volume between 5 and 10m³, it will require an

air vent of 50cm² (effective area). Unless it has a door which

opens directly to the outside.

o If the room has a volume of less than 5m³, it will require an air

vent of 100cm² (effective area).

o If there are any other fuel burning appliances in the same room

the current edition of BS 5440: Part 2: should be consulted to

determine air vent requirements.

nts.

27

Page 28

o Ensure that the room containing the oven is well ventilated, keep

natural ventilation holes.

o Prolonged intensive use of the appliance may call for additional

ventilation.

o This oven is not fitted with a device for discharging the products

of combustion. Ensure that the ventilation rules and regulations

are followed.

o Your oven must stand on a flat surface so that when it is in

position the oven is level. When in position check that the oven

is level by using a spirit level.

o Remember that the quantity of air necessary for combustion

must never be less than 2m³/h for each kW of power (see total

power in kW on the appliance rating plate).

Gas Safety (Installation and Use) Regulations

o It is a legal requirement that all gas appliances are installed by

competent persons in accordance with the current edition of the

Gas Safety Installation and Use Regulations.

o For reasons of safety, it is in your best interests to ensure

compliance with the law.

o In the UK, CORGI registered installers work to safe standards of

practice. The cooker must also be installed in accordance with

the current edition of BS 6172. Failure to install the oven

correctly could invalidate the warranty, liability claims and lead

to prosecution.

28

Page 29

Gas connection

ALL INSTALLATION AND SERVICE WORK MUST BE

CARRIED OUT BY A CORGI REGISTERED ENGINEER.

o Prior to installation, ensure that the gas supply conditions

(nature of the gas and gas pressure) and the adjustment

conditions are compatible. The adjustment conditions for this

appliance are stated on the rating plate which can be found on

the back cover.

o This appliance is not designed to be connected to a combustion

product evacuation device. Particular attention should be given

to the relevant requirements regarding ventilation.

o A ½” BSP female to female gas

elbow (not supplied) should be

connected to the gas inlet at the

rear of the appliance and

pointing in a downward direc

As indicated in the diagra

opposite.

o IMPORTANT: FIBRE WASHERS MUST BE USED WHEN

CONNECTING THE GAS ELBOW (AS SHOWN IN THE ABOVE

DIAGRAM).

o Connection to the cooker should be made with an approved

appliance flexible connection to BS 669.

o If the cooker has been converted for use with LPG, then it should

be connected to the gas supply using an appropriate bayonet

type hose. The hose MUST be suitable for use with LPG gas,

these are identifiable by a red band or stripe.

o A hose length of 0.9m to 1.25m is recommended. The length of

hose chosen should be such that when the cooker is in situ, the

hose does not touch the floor.

o Care should be taken to ensure that the temperature rise of

areas at the rear of the cooker that are likely to come in contact

with the flexible hose do not exceed 70°C.

o IMPORTANT: On completion carry out a gas tightness test.

m

tion.

29

Page 30

Gas adjustment (Conversion to LPG and gas adjustment)

IMPORTANT: Your appliance must be disconnected from the

electric and gas supply before completing this process.

Power inputs

Natural Gas LPG

Oven 2.74 kW (injector size 115) 2.74 kW (injector size 80)

Grill 2.4 kW (injector size 115) 2.4 kW (injector size 80)

Gas details

Gas Connection Type: 1/2” BSP male thread

Gas Type (Natural Gas G20): 20 mbar

Primary air gap (Natural Gas G20): 1.0 mm

Gas Type (LPG G30/31): 28/37 mbar

Primary air gap (LPG G30/31): 1.0 mm

o Remove the rear wall assembly

and the oven burner assembly.

o Replace the injector with one

suitable for LPG (see power

inputs information). It is

recommended that the

appropriate thread sealant is

used; always check for gas

tightness after assembly.

o Re-fix the burner

assembly, ensuring that

the injector is within the

cut-out in the rear of the

oven. Adjust the position

of the burner to achieve

the primary air gap.

30

Page 31

o Remove the grill burner.

o Replace the injector with one

suitable for LPG (see power

inputs information). It is

recommended that the

appropriate thread sealant is

used; always check for gas

tightness after assembly.

o Re-fix the grill burner, no further adjustments are necessary.

o Remove the control

panel cover from the

top of the appliance.

o Remove the oven

control knobs and

then undo the two

fixing rings that are

exposed underneath,

by turning them anticlockwise.

o Disconnect the neon lamp at the rear of the fascia and then

remove the control panel front. Then refit the thermostat control

knob.

o Ensure that the appliance is in a safe condition, and then

reconnect it to the electric and gas supply.

o Open the oven door fully and ignite the oven burner. You should

set the oven to maximum temperature, then close the oven door

and leave the appliance for 10 – 15 minutes.

o Reduce the temperature to its minimum setting and remove the

thermostat control knob.

o DISCONNECT THE APPLIANCE FROM THE ELECTRICITY

SUPPLY.

o The bypass adjustment screw is located on the left hand side of

the valve body. Access can be made from the front of the

appliance and through the rear panel of the control panel. Turn

the screw clockwise to decrease the flow.

31

Page 32

o Adjust the bypass setting until the correct flame picture is

achieved.

o Refit the control knob, then turn it to the Max position and then

back to Min several times, checking that the flame is maintained.

o Fully open and close the oven door several times and check that

the flame is maintained.

o Turn the appliance off and disconnect it from the gas supply.

o Re-assemble the appliance (including the refitting of the rear

wall assembly), reinstall it and then carry out a full function test

(this should include a gas tightness test).

My appliance isn’t working correctly

The gas oven burner or grill burner do not light.

* Check that the oven is switched on at your mains supply.

* Check that the fuse in the spur outlet doesn’t need replacing.

* Check that there is not a problem with your gas supply

Food is cooking too quickly or too slowly.

* Check that you are cooking at an appropriate temperature and

shelf level.

The oven is not cooking evenly.

* Check that the oven is installed correctly.

* Check that you are cooking at an appropriate temperature and

shelf level.

The oven light does not work.

* Follow the “Replacing the oven bulb” section on page 20.

32

Page 33

I am getting condensation in my oven

* Steam and condensation is a natural by product of cooking any

food with high water content, such as frozen food, chicken etc.

* You may get condensation in the oven cavity and forming

between the oven door glasses. This is not necessarily a sign

that the oven is not working correctly.

* Do not leave food in the oven to cool after it has been cooked

and the oven has been switched off.

* Use a covered container, where practical, when cooking to

reduce the amount of condensation that forms.

IMPORTANT: If your appliance appears not to be

operating correctly, then you should disconnect it

from your mains supply and then contact the

Baumatic Service Department on telephone

number (0118) 933 6911.

DO NOT ATTEMPT TO REPAIR THE APPLIANCE

YOURSELF.

Please note that if an engineer is asked to attend whilst the product is

under guarantee and finds that the problem is not the result of an

appliance fault, then you may be liable for the cost of the call out

charge.

The appliance must be accessible for the engineer to perform

any necessary repair. If your appliance is installed in such a

way that an engineer is concerned that damage will be caused

to the appliance or your kitchen, then he will not complete a

repair.

This includes situations where appliances have been tiled in,

sealed in with sealant, have wooden obstructions placed in

front of the appliance, like plinths. Or any installation other

than the one specified by Baumatic Ltd. has been completed.

Please refer to the conditions of guarantee that appear on the

warranty card that you receive with the appliance.

33

Page 34

United Kingdom

Baumatic Ltd.,

Baumatic Buildings,

6 Bennet Road,

Reading, Berkshire

RG2 0QX

United Kingdom

Sales Telephone

(0118) 933 6900

Sales Fax

(0118) 931 0035

Service Telephone

(0118) 933 6911

Service Fax

(0118) 986 9124

Spares Telephone

(01235) 437244

Technical Advice Telephone

(0118) 933 6933

E-mail:

sales@baumatic.co.uk

technical@baumatic.co.uk

Website:

www.baumatic.co.uk

Republic of Ireland

01- 6266 798

Czech Republic

Baumatic CR spol s.r.o.

Amperova 495

46215, Librec

Czech Republic

+420 800 185 263

www.baumatic.cz

Slovak Republic

Baumatic Slovakia, s.r.o.

Skultetyho 1

831 04 Bratislava 3

Slovakia

+421 255 640 618

Germany

Baumatic Gmbh

Janderstrasse 9

Mannheim, 68199

Germany

+4962 112 9190

www.baumatic.de

Italy

Baumatic Italia S.R.L.

Via Caltana 129

Campodarsego (Padova), 35011

Italy

+3904 9920 2297

www.baumatic.it

Holland

Baumatic Benelux B.V.

Grindzuigerstraat 22

1333 MS ALMERE

The Netherlands

+3136 549 1555

www.baumatic.nl

34

Page 35

35

Page 36

36

Loading...

Loading...