BAUER

COMPRESSORS

Instruction Manual and Replacement Parts List

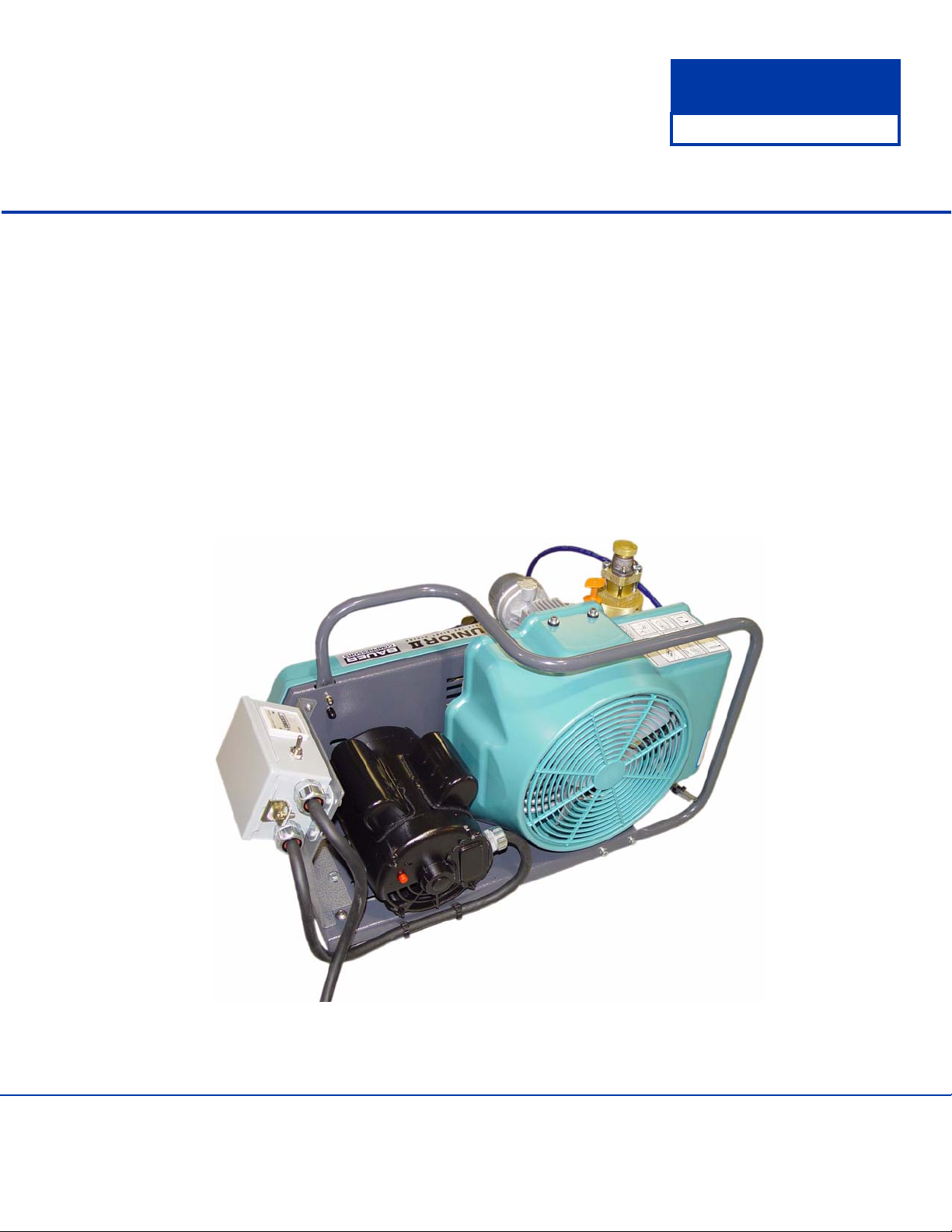

Junior II

High Pressure Air Compressor Unit

Junior II WT

April 26, 2007 1st ed. Rev 0 Chg 3 MNL-0391

© 2007 Bauer Compressors, Inc.

BAUER Compressors, Inc. Phone: (757) 855-6006

1328 Azalea Garden Road Fax: (757) 855-6224

Norfolk, Virginia 23502-1944 www.bauercomp.com

BAUER

COMPRESSORS

This information is believed to be accurate by Bauer Compressors, Inc., as of it’s date of publication,

but Bauer offers NO WARRANTY regarding the accuracy, or continuing accuracy, of the information

set forth herein. Bauer shall not be liable for inaccuracies in, or consequences resulting from, your use

of this information. All information supplied is in connection with sales of Bauer’s products, and is thus

subject to Bauer’s standard terms and conditions of sale. Bauer reserves the right to change this information and has no obligation to update these materials. This information is © 2007 Bauer Compressors,

Inc., and Bauer reserves to itself all rights to this publication. Bauer’s customers have no right to reproduce, rewrite, modify, license or permit anyone else’s use of this information, without the express written permission of Bauer Compressors, Inc.

^ WARNING ^

This Instruction Manual and Replacement Parts List contains safety information and instructions for the

Junior II WT High Pressure Air Compressor Unit.

You must read, understand and follow all safety precautions and instructions.

Junior II WT

EDITIONS, REVISIONS AND CHANGES

• An Edition is the original or a complete rewriting of the entire Manual.

• A Revision occurs whenever a complete Section or Appendix is rewritten or added.

• A Change occurs when individual pages, drawings or tables are changed.

1st Edition

Rev Chg Date Notes Auth

0 0 02/28/2005 JD

0 1 9/9/2005 Changed Intermediate Separator to P/N 081800 JD

0 2 07/11/2006 Changes to Fig 3-14 JD

0 3 04/26/2007 Updated compressor block to Parts List TJ-4/7 from BKM JD

Page i 1st ed. Rev 0 Chg 3

MNL-0391

BAUER

COMPRESSORS

TABLE OF CONTENTS

CHAPTER 1:- - - - - - - - - - - - - - - - - - - - - INTRODUCTION

1.1 HOW TO USE THIS MANUAL.........................................................................................................................................1

1.1.1 Manual Safety Notices................................................... ....................................................................................................1

1.2 HOW TO USE THE REPLACEMENT PARTS LIST....................................................................................................2

1.3 HOW TO USE THE APPENDIX.......................................................................................................................................3

1.4 DESIGN................................................................................................................................................................................4

1.5 AIR FLOW DIAGRAM......................................................................................................................................................5

1.5.1 Junior II WT.......................................................................................................................................................................6

1.5.2 Compressor Block Technical Specifications......................................................................................................................6

1.5.3 Compressor Drive Technical Specifications......................................................................................................................6

CHAPTER 2:- - - - - - - - - - - - - - - - - - - - - - - OPERATION

2.1 PREPARATION FOR OPERATION................................................................................................................................7

2.2 STARTING THE UNIT......................................................................................................................................................7

2.3 FILLING PROCEDURE.................................................................................................................................................... 7

2.3.1 General Procedures ..........................................................................................................................................................8

2.3.2 Bottle Filling Procedures....................................................................................................................................................8

2.3.3 Connecting to the Air Storage Bottle................................................................................... ... ...........................................9

2.3.4 Filling the Bottle.................................................................................................................................................................9

2.3.5 Removing the Bottle...........................................................................................................................................................9

2.4 SHUT-DOWN PROCEDURES..........................................................................................................................................9

CHAPTER 3:- - - - - - - - - - - - - - - - JUNIOR II COMPRESSOR

3.1 LUBRICATION.................................................................................................................................................................10

3.1.1 Oil Level Check ........................................................................ .......................................................................................10

3.1.2 Type of Oil ....................................................................................................................................................................10

3.1.3 Oil Changes......................................................... .............................................................................................................11

3.1.3.1 Oil Change Procedures............................................... ..................................................................................................11

3.2 INTAKE FILTER..............................................................................................................................................................11

3.2.1 Description.......................................................................................................................................................................11

3.2.2 Maintenance.....................................................................................................................................................................11

3.2.3 Telescope Intake Tube .....................................................................................................................................................12

3.2.4 Intermediate Separator .....................................................................................................................................................12

3.2.5 Maintenance.....................................................................................................................................................................13

3.3 COMPRESSOR VALVES ................................................................................................................................................13

3.3.1 Description.......................................................................................................................................................................13

3.3.2 Initial Operational Check .................................................... ............................................................................................13

3.3.3 Changing the Valves ............................. ...........................................................................................................................13

3.3.4 Changing the 1st Stage Valves.........................................................................................................................................14

3.3.5 Changing the 2nd Stage Valves .......................................................................................................................................15

3.3.6 Changing the 3rd Stage Valves........................................................................................................................................16

3.4 REPAIR AND TROUBLESHOOTING...........................................................................................................................17

3.4.1 General Repair Instructions..............................................................................................................................................17

3.4.2 Troubleshooting Tables ...................................................................................................................................................18

April 26, 2007 Page ii

BAUER

COMPRESSORS

3.4.2.1 Electric Motor...............................................................................................................................................................18

3.4.2.2 Gasoline Engine............................................................................................................................................................18

3.4.2.3 Compressor Block.........................................................................................................................................................18

3.5 REPLACEMENT PARTS LIST ......................................................................................................................................20

Junior II WT

CHAPTER 4:- - - - - - - - - - - - - - - - - - - JRII MAINTENANCE

4.1 MAINTENANCE RECORD.............................................................................................................................................33

4.2 MAINTENANCE SCHEDULE........................................................................................................................................33

4.2.1 After the First 25 Operating Hours................................................. .................................... ..............................................33

4.2.2 Every 125 Operating Hours..............................................................................................................................................34

4.2.3 Every 2000 Operating Hours or Biennially......................................................................................................................34

4.2.4 Annually or As Required..................................................................................................................................................35

4.2.5 After Repair Work............................................................................................................................................................36

4.2.6 After Storage and Preservation.........................................................................................................................................38

CHAPTER 5:- - - - - - - - - - - - - - - - -PURIFICATION SYSTEM

5.1 GENERAL..........................................................................................................................................................................39

5.1.1 General Purification System Procedures..........................................................................................................................39

5.1.2 Chamber Safety Bore .......................................................................................................................................................39

5.1.3 Manual Condensate Drainage................................................................. ..........................................................................40

5.1.4 Model, Serial Number and Part Number Identification ...................................................................................................40

5.1.4.1 Compressor Dataplate ...................................................................................................................................................40

5.1.4.2 Purification System Dataplate ......................................................................................................................................40

5.1.4.3 Cartridge Installation Dataplate....................................................................................................................................40

5.1.5 Industrial Purification System Configurations ................................................................................................................41

5.1.6 Cartridge Operating Life ..................................................................................................................................................41

5.1.6.1 Calculating the Maximum Cartridge Operating Hours.................................................................................................42

5.1.6.2 Calculating the Adjusted Cartridge Operating Hours...................................................................................................42

5.1.6.3 Purification Cartridge Operating Hours Form..............................................................................................................44

5.2 P0 PURIFICATION SYSTEM.........................................................................................................................................45

5.2.1 Description .......................................................................................................................................................................45

5.2.2 Maintenance .....................................................................................................................................................................46

5.2.2.1 Replacing the Cartridge ................................................................................................................................................46

5.2.2.2 Chamber Replacement Interval ...................................................................................................................................47

5.2.3 Replacement Parts List.....................................................................................................................................................49

CHAPTER 6:- - - - - - - - - - - - - - - - - - - - MISCELLANEOUS

6.1 SAFETY VALVES.............................................................................................................................................................51

6.1.1 Description .......................................................................................................................................................................51

6.1.2 Maintenance .....................................................................................................................................................................51

6.1.2.1 Checking Function........................................................................................................................................................51

6.1.2.2 Checking Blow Off Pressure ........................................................................................................................................51

6.2 PRESSURE GAUGE.........................................................................................................................................................51

6.2.1 Maintenance .....................................................................................................................................................................51

6.3 COMPRESSOR DRIVE SYSTEM..................................................................................................................................52

6.3.1 Description .......................................................................................................................................................................52

6.3.2 Checking the Drive Belt...................................................................................................................................................52

6.3.3 V-belt Tension Adjustment ..............................................................................................................................................52

6.3.4 Electric Maintenance........................................................................................................................................................52

Page iii 1st ed. Rev 0 Chg 3

MNL-0391

6.4 COOLING SYSTEM.........................................................................................................................................................53

6.4.1 General.............................................................................................................................................................................53

BAUER

COMPRESSORS

CHAPTER 7:- - - - - - - - - - - - - - - - - - - - - - - - APPENDIX

7.1 SAFETY..............................................................................................................................................................................54

7.1.1 General Safety Precautions ..............................................................................................................................................54

7.1.2 Safety Warning Labels.....................................................................................................................................................56

7.2 INSTALLATION...............................................................................................................................................................57

7.2.1 Corrosion Resistance........................................................................................................................................................57

7.2.2 Outdoor Location .............................................................................................................................................................57

7.2.3 Indoor Location................................................................................................................................................................57

7.2.3.1 Electrical Installation....................................................................................................................................................57

7.3 STORAGE AND PRESERVATION...............................................................................................................................58

7.3.1 Storage..............................................................................................................................................................................58

7.3.2 Preservation......................................................................................................................................................................59

7.3.2.1 Preparation for Preservation.........................................................................................................................................59

7.3.2.2 Preserving the Compressor...........................................................................................................................................59

7.3.2.3 Preserving the Motor or Engine................................................ ....................................................................................59

7.3.2.4 Preventive Maintenance During Storage......................................................................................................................59

7.3.2.5 Reactivating the Compressor Unit................................................................................................................................60

7.4 TABLES AND REFERENCE DATA ..............................................................................................................................61

7.4.1 Tightening Torque Values ............................................................................................................................................61

7.4.2 Pipe Connections (swivel nuts)......................................................................................... ...............................................61

April 26, 2007 Page iv

BAUER

COMPRESSORS

Junior II WT

LIST OF FIGURES

CHAPTER 1:- - - - - - - - - - - - - - - - - - - - - INTRODUCTION

Figure 1-1 Junior II WT ............................................................................................................................................................4

Figure 1-2 Internal Air Flow Diagram......................................................................................................................................5

CHAPTER 2:- - - - - - - - - - - - - - - - - - - - - - - OPERATION

Figure 2-1 Air Storage Bottle Valve Operating Sequence........................................................................................................8

CHAPTER 3:- - - - - - - - - - - - - - - - JUNIOR II COMPRESSOR

Figure 3-1 Oil Dipstick Markings .............................................................. .............................................................................10

Figure 3-2 Intake Filter............................................................................................................................................................11

Figure 3-3 Intermediate Separator...........................................................................................................................................12

Figure 3-4 Valve Function.......................................................................................................................................................13

Figure 3-5 1st Stage Plate Valve.............................................................................................................................................13

Figure 3-6 1st Stage Valve Head.............................................................................................................................................14

Figure 3-7 2nd Stage Valve Head ........................................ .................................... ...............................................................15

Figure 3-8 3rd Stage Valve Head...................................... ... ...................................................................................................16

Figure 3-9 Removing the 3rd Stage Valves ............................................................................................................................17

Figure 3-10 Crankcase, Driving Gear and Fanwheel................................ ..................................... ...........................................20

Figure 3-11 Pistons and Cylinders ............................................................................................................................................22

Figure 3-12 Valve Heads and Valves.......................................... ..............................................................................................24

Figure 3-13 Cooler .............................................................................................................. ......................................................26

Figure 3-14 Intake Filter and Intermediate Separator ...............................................................................................................28

Figure 3-15 Frame with Accessories.........................................................................................................................................30

Figure 3-16 Special Tools ............................................................................... ..........................................................................32

CHAPTER 4:- - - - - - - - - - - - - - - - - - - JRII MAINTENANCE

There are no Figures in this Chapter

CHAPTER 5:- - - - - - - - - - - - - - - - -PURIFICATION SYSTEM

Figure 5-1 Cartridge Safety Venting.......................................................................................................................................39

Figure 5-2 Purification System Dataplates (typical) ...............................................................................................................40

Figure 5-3 Correction Factor for Cartridge Operating Hours .................................................................................................43

Figure 5-4 Example Record of Adjusted Operating Hours.....................................................................................................43

Figure 5-5 P0 Purification Chamber........................................................................................................................................45

Figure 5-6 P0 Purification System Cross Section ...................................................................................................................46

Figure 5-7 P0 Purification System Parts List..........................................................................................................................49

CHAPTER 6:- - - - - - - - - - - - - - - - - - - - MISCELLANEOUS

Figure 6-1 Final Pressure Safety Valve...................................................................................................................................51

Figure 6-2 Gauges ............................................................................................ .......................................................................51

Figure 6-3 Checking V-belt Tension.......................................................................................................................................52

Figure 6-4 V-belt Pulley Alignment........................................................................................................................................52

CHAPTER 7:- - - - - - - - - - - - - - - - - - - - - - - - -APPENDIX

Figure 7-1 Incoming Power Wiring Label ..............................................................................................................................58

Page v 1st ed. Rev 0 Chg 3

MNL-0391

BAUER

COMPRESSORS

CHAPTER 1: INTRODUCTION

1.1 How To Use This Manual

This manual contains the operating and maintenance instructions for the Bauer Compressors, Inc. product(s) listed on the front cover.

All instructions in this manual should be observed and carried out as written to prevent damage or premature wear to the product or the equipment served by it.

If your unit is equipped with nonstandard accessories and/or options, supplemental information is normally included in other documentation; i.e. OEM Manuals or additional Bauer Manuals.

While every effort is made to ensure the accuracy of the information contained in this manual, Bauer

Compressors, Inc. will not, under any circumstances be held accountable for any inaccuracies or the

consequences thereof.

1.1.1 Manual Safety Notices

Important instructions concerning the endangerment of personnel, technical safety or operator safety

will be specially emphasized in this manual by placing the information in the following types of safety

notices.

^ DANGER ^

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. This is limited to the most extreme situations.

^ WARNING ^

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death

or injury.

^ CAUTION ^

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices.

^ NOTE ^

NOTE advise of technical requirements that require particular attention by the operator or the

maintenance technician for proper maintenance and utilization of the equipment.

April 26, 2007 Page 1

BAUER

COMPRESSORS

1.2 How to Use the Replacement Parts List

• A lozenge ◊ in the Item Number column indicates the part number for a complete assembly.

• A dagger (†) in the Qty column with or without an ellipsis (…) in the Part Number column means the

part is illustrated for assembly purposes only and is not available for sale as an individual component.

This part can be obtained by ordering the complete assembly.

• AR in the Qty column means that the item is cut or manufactured to the size which the customer specifies.

• A dash (—) in the Item Number column indicates that there is more than one part number applicable

to the preceding Item Number.

• The letter(s) in the columns labeled Kit indicate the number of operating hours when the part is to be

replaced; a = replaced every 1,000 hours, b = replaced every 2,000 hours and c= replaced every 4,000

hours.

• NS in the Item Number column indicates the part is not illustrated but is available.

When placing an order for spare parts, please provide the following information to ensure delivery of

the correct parts. The model number, date of manufacture and serial number can be found of the compressor unit identification plate on the compressor unit’s frame.

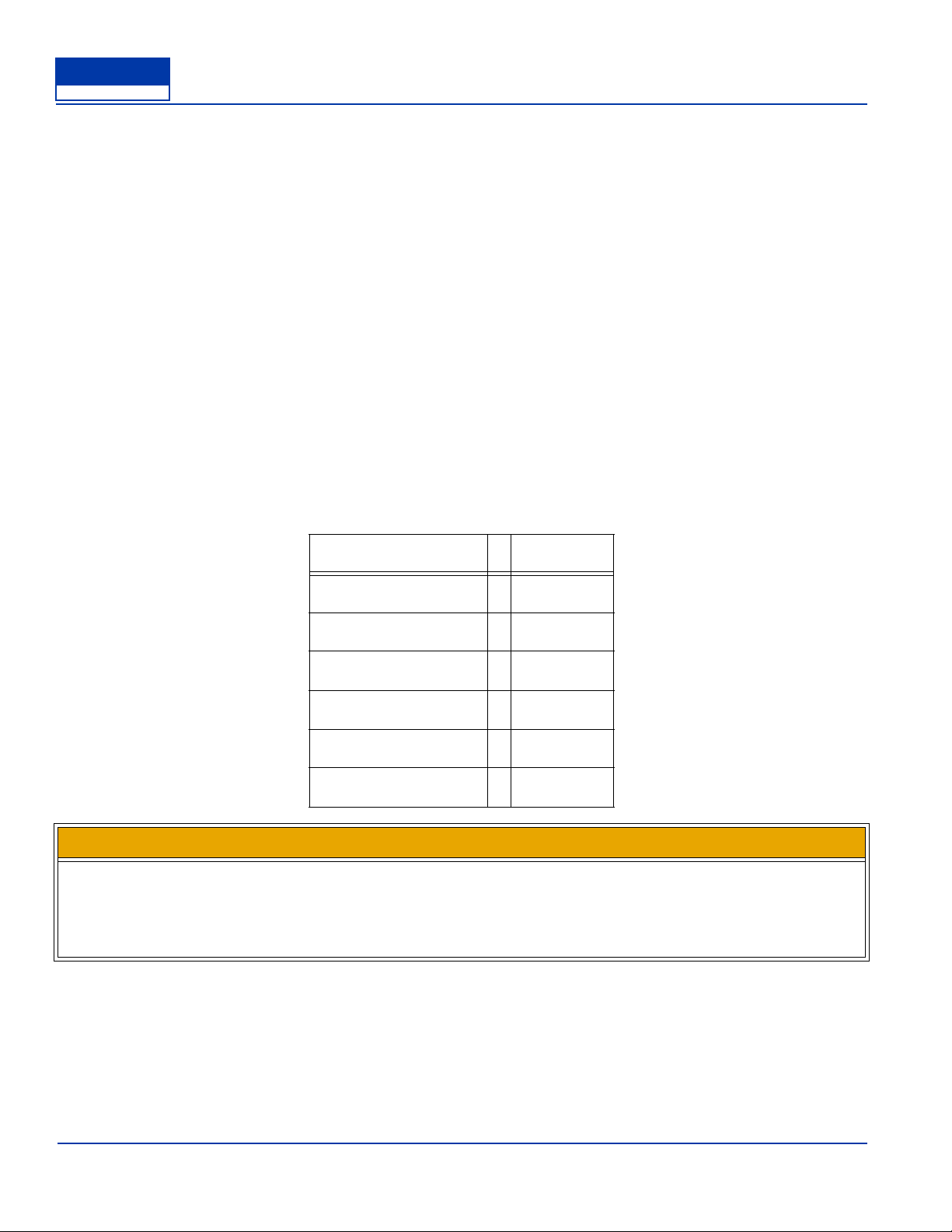

JUNIOR II WT

Information Example

Model Number TCOM25

Serial Number 32165

Date of Manufacture 02/2005

Quantity required 2

Part Number N04860

Part Description Valve

^ WARNING ^

The use of repair parts other than those included in the Bauer Replacement Parts Lists may create unsafe

conditions over which Bauer has no control. Such unsafe conditions can lead to accidents that may be lifethreatening, cause substantial bodily injury, and/or result in damage to the equipment. Therefore, BAUER

Compressors, Inc. can bear no responsibility for equipment in which unapproved repair parts are installed.

Page 2 1st ed. Rev 0 Chg 3

MNL-0391

1.3 How to Use the Appendix

Information contained in the Appendix to this manual includes the following.

• The safety instructions applicable to this product. They must be read, understood and complied with

prior to operating the product.

• The instructions for installing this product. They must be read, understood and complied with prior to

operating the product.

• The instructions for long term storage (over 90 days) of this product.

BAUER

COMPRESSORS

April 26, 2007 Page 3

BAUER

1

2

3

4

5

6

7

8

9

10

COMPRESSORS

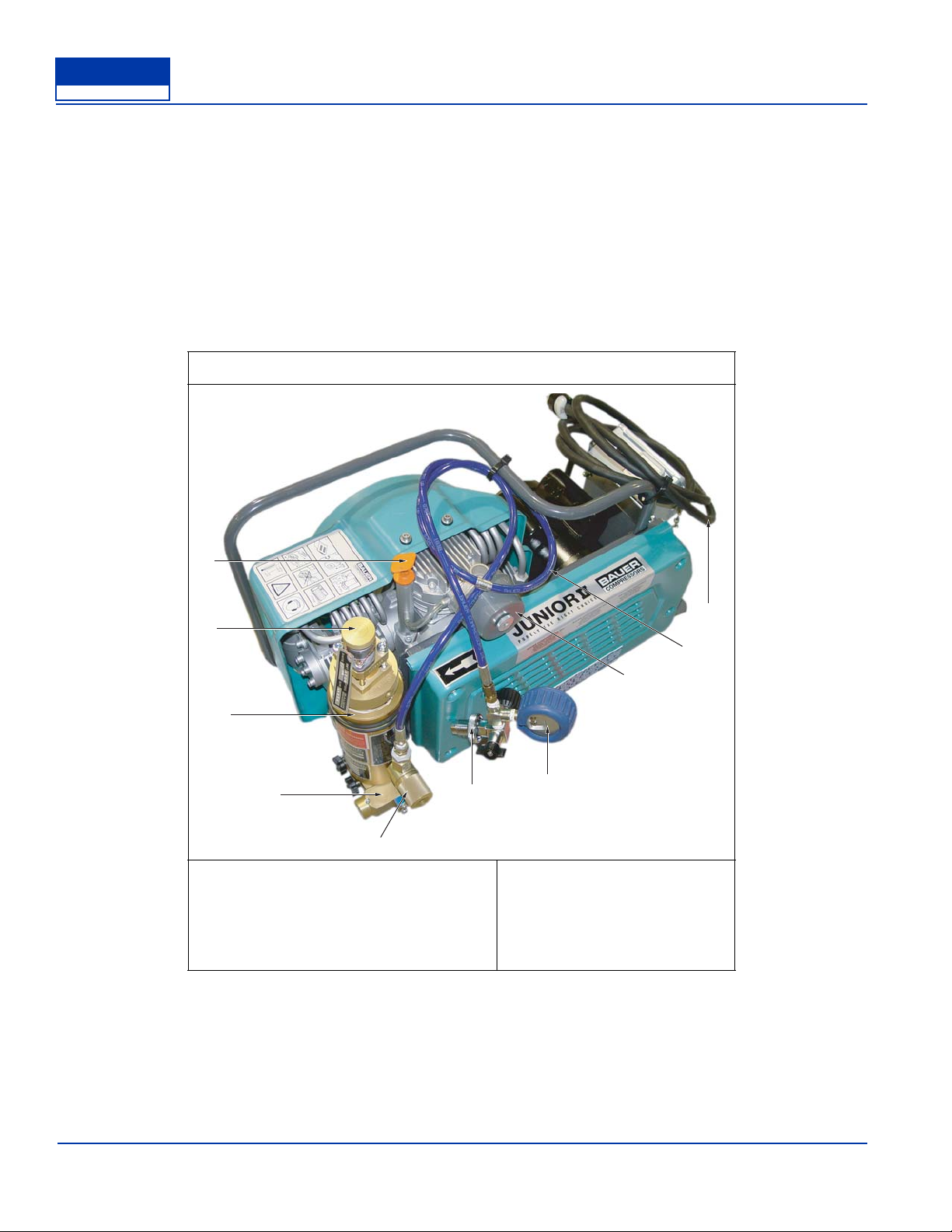

1.4 Design

The Junior II WT compressor units consists of the following major assemblies.

• Compressor Block

• Electric Motor Drive

• P0 Purification System

• Fill Hose Assembly

• Base Plate and Frame

Figure 1-1 Junior II WT

Junior II WT

1. Oil Dipstick

2. Final Pressure Valve

3. P0 Purification System

4. Pressure Maintaining Valve

5. CO and Moisture Indicator

Page 4 1st ed. Rev 0 Chg 3

6. Fill Adapter

7. Pressure Gauge

8. AIr Intake Filter

9. Fill Hose

10. Electric Cable and Plug

MNL-0391

BAUER

COMPRESSORS

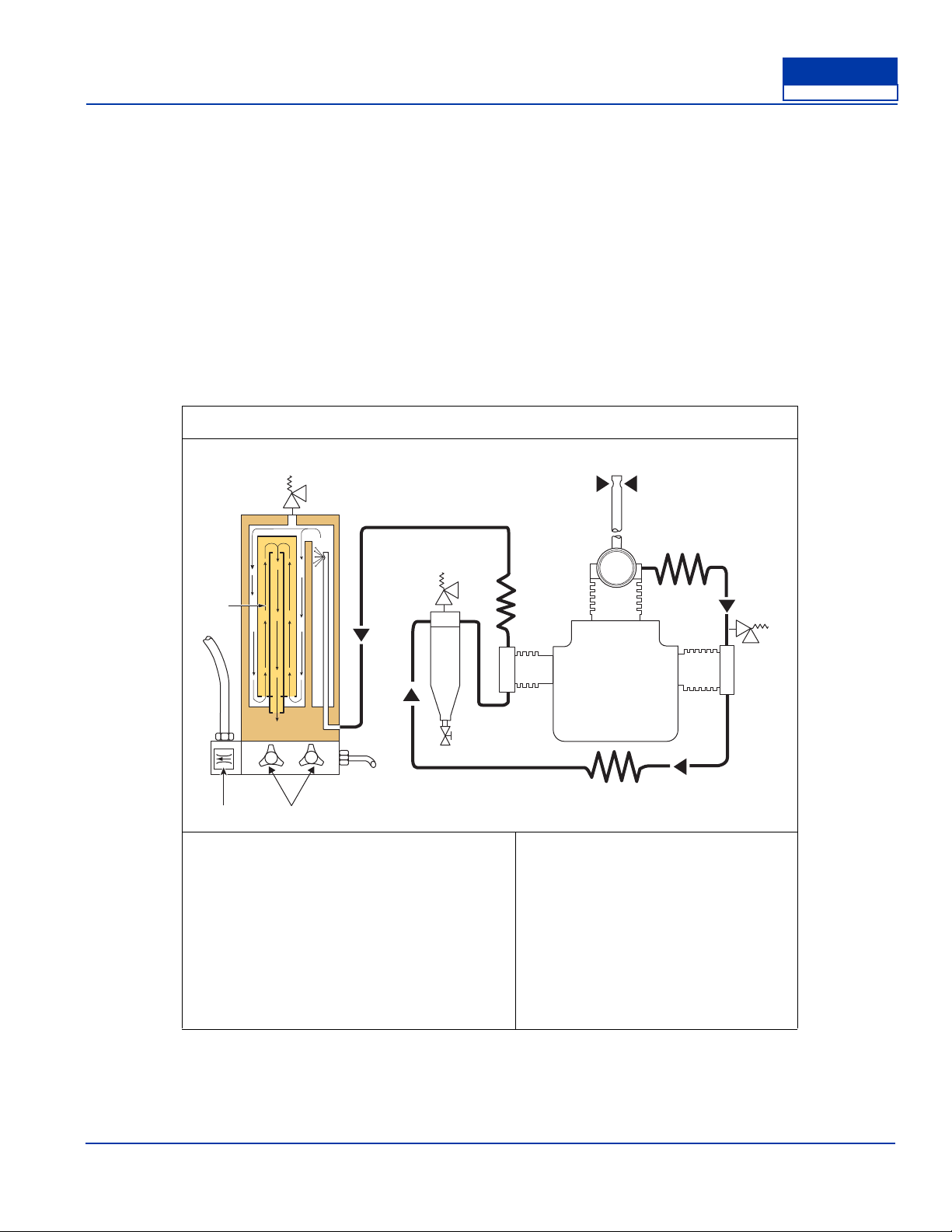

1.5 Air Flow Diagram

See Figure 1-4.

The air is drawn in through the Telescopic Tube (1) through the Intake Filter (2) and is compressed to

final pressure in the Cylinders (3, 4 and 5). It is recooled by the Intercoolers (6 and 7) and the Aftercooler (9). The pressure of the individual stages is controlled by Safety Valves (10 and 11). The compressed air is cleaned in the Intermediate Separator (8) and purified in the P0 Filter System (13). The

Intermediate Separator and P0 Filter System are drained by the Condensate Drain Valves (15). The

Pressure Maintaining Valve (16) provides a constant pressure within the P0 Filter System. The purified

compressed air then passes through the Fill Hose (17) and Fill Valve (18) to the bottles to be filled. Fill

pressure is indicated by the Final Pressure Gauge (19).The Final Safety Valve (12) is adjusted to blow

off at the pressure selected.

Figure 1-2 Internal Air Flow Diagram

12

13

11

14

17

16

15

8

15

1. Compressor Air Intake Extensions

2. Intake Filter

3. 1st Stage Cylinder

4. 2nd Stage Cylinder

5. 3rd Stage Cylinder

6. 1st/2nd Stage Intercooler

7. 2nd/3rd Stage Intercooler

8. Intermediate Separator

9. After Cooler

1

6

2

9

3

5

7

4

10. 1st Stage Safety Valve

11. 2nd Stage Safety Valve

12. Final Pressure Safety Valve

13. P0 Filter System

®

14. Triplex

Longlife Cartridge

15. Condensate Drain Valve

16. Pressure Maintaining Valve

17. Fill Hose

10

April 26, 2007 Page 5

BAUER

COMPRESSORS

1.5.1 Junior II WT

Medium Air

Intake Pressure Atmospheric

Delivery

Maximum Operating Pressure 5,000 psi (350 bar)

Final Safety Valve Pressure Setting As selected

Sound Pressure 80dB(A)

Sound (immersion) Power 100dB(A)

Weight Approximately 100 lbs (44-47 kg)

1.5.2 Compressor Block Technical Specifications

Number of stages 3

Number of cylinders 3

1st Stage Cylinder Bore 60mm

2nd Stage Cylinder Bore 28mm

3rd Stage Cylinder Bore 12mm

Intermediate Pressure 1st stage 94 psi (6.5 bar)

Intermediate Pressure 2nd stage 943 psi (65 bar)

Compressor Block Oil Capacity 12 fluid ounces (360 cc)

Maximum Ambient Temperature 41° - 113°F (5°-45° C)

Maximum Inclination of Compressor

1

2

Junior II WT

1.0 SCFM (100l/min.)

5°

1.5.3 Compressor Drive Technical Specifications

Drive Motor P/N MTR-0219

Operating Voltage 115 VAC, Single Phase, 60 Hz

Horsepower 1½HP

Speed 3600 RPM

Type ODP

1. Free air delivered at bottle filling from 0 to 5,000 psi (0-350 bar) ± 5%

2. This value is valid only if the compressor block oil in normal level position corresponds with the upper mark of the oil dipstick an d may not be exceeded.

Page 6 1st ed. Rev 0 Chg 3

MNL-0391

BAUER

COMPRESSORS

CHAPTER 2: OPERATION

2.1 Preparation for Operation

Prior to operating the unit for the first time, read this Instruction Manual carefully.

1. Make sure that all persons operating the compressor unit and associated equipment are familiar with

the function of all controls and indicators.

2. Thoroughly comply with the paragraphs titled Safety contained in the Appendix to this manual.

3. If the unit has been out of service for two years or more and uses synthetic compressor oil change

the compressor oil. If the unit uses petroleum based compressor oil change it after being out of service one year.

4. During the initial operation or prior to operation subsequent to repairs operate the unit for at least

five minutes with open outlet valve (unpressurized) to ensure proper lubrication of all parts before

pressure is built up.

5. Prior to each operation check the oil level according to Section 2 Lubrication and determine

whether maintenance is necessary in accordance with Section 13.

6. Every time the unit is started, check all systems for proper operation. If any malfunction is observed

stop the unit immediately and find the cause of the fault or call the service department.

2.2 Starting the Unit.

1. Close condensate drain valves and run the unit to the final pressure. Check final pressure safety

valve and pressure gauge.

2. As soon as the final pressure safety valve blows off, open the condensate valve and drain conden-

sate. The unit is now ready for filling operations.

2.3 Filling Procedure

^ WARNING ^

Ensure the intake air is free from noxious gas, exhaust fumes and solvent vapors.

^ WARNING ^

Never open fill valves or shut off valves when under pressure and the hose is not connected as discharging

high pressure compressed air can cause serious accidents.

^ WARNING ^

Fill hoses must be in satisfactory condition and the threads must be undamaged. Pay particular attention to

the interface from hose fitting to hose. If the rubber is scored, the hose must be discarded, otherwise water

can corrode the wire gauze causing a hose failure.

April 26, 2007 Page 7

BAUER

COMPRESSORS

2.3.1 General Procedures

1. The fill valve connection is of the manual type permitting connection to the air tank without tools.

An O-ring is provided for sealing purposes.

2. Compressed air tank fill valves for pressure in excess of 2900 psi (200 bar) are standardized and

connectors for 2900 psi (200 bar) and 4400 psi (300 bar) are different and can not be mixed up.

3. To ensure safe air tank removal after filling, the fill valve has an integral venting bore. Therefore

always close the tank valve before closing the fill valve.

4. During the fill procedure the bottles will warm up due to recompression.

5. After filling, remove and allow the bottle to cool down. When it is cool the bottle may be reconnected and topped up to its maximum filling pressure.

2.3.2 Bottle Filling Procedures

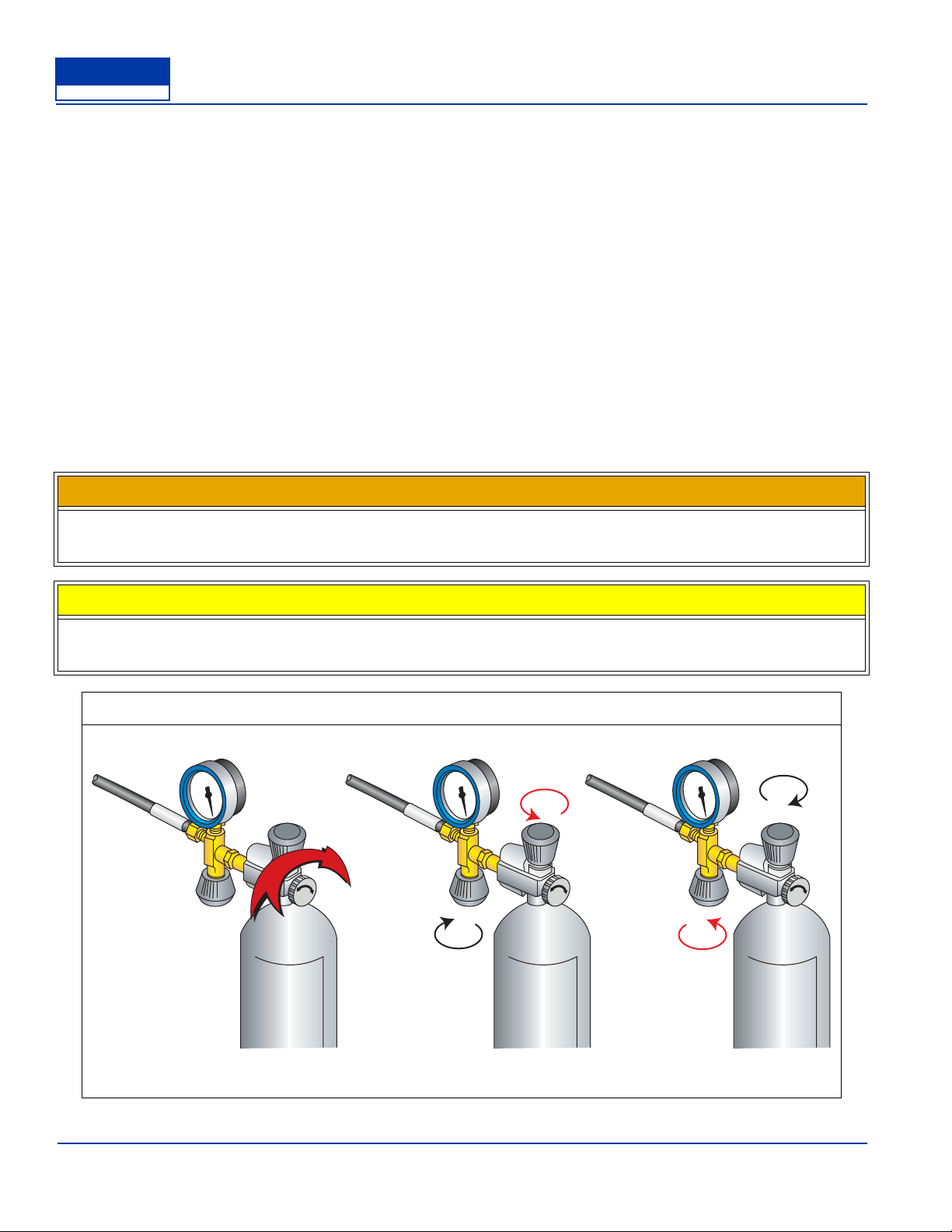

See Figure 2-1

^ WARNING ^

Never open the fill valve unless the bottle is connected to the fill hose. Whipping of an unrestrained hose

caused by high pressure air discharge can cause serious injury!

Junior II WT

^ CAUTION ^

The filling procedure should not be interrupted for more than 10 minutes to avoid increased CO2 levels in

the air filling the bottle.

Figure 2-1 Air Storage Bottle Valve Operating Sequence

1.

2.

1.

2.

Attaching the Fill Yoke

Page 8 1st ed. Rev 0 Chg 3

Opening Sequence

Closing Sequence

MNL-0391

2.3.3 Connecting to the Air Storage Bottle

1. Ensure both the fill valve and bottle valve are closed

2. Connect the air bottle to the compressor fill hose utilizing the fill yoke.

2.3.4 Filling the Bottle

1. First open fill valve. (1)

2. Open bottle valve. (2)

3. Bottle will begin filling.

4. During the filling process, monitor bottle pressure on fill valve gauge and drain condensate at the

compressor.

2.3.5 Removing the Bottle

1. First close the bottle valve. (1)

2. Close the fill valve. (2)

COMPRESSORS

BAUER

3. Remove fill yoke and store compressed air bottle.

2.4 Shut-Down Procedures

1. On all units first close the fill valve.

2. Turn off electrical power with the appropriate switch

3. Vent unit to approximately 1,150 psi (80 bar).

4. Decompress with drain valves to remove all moisture in the filter and the oil and water separator.

5. Close all drain valves again.

6. Check the oil level in the compressor and top up, if necessary.

7. Also check operating hours to see if the compressor needs servicing in accordance with the mainte-

nance schedule.

April 26, 2007 Page 9

BAUER

COMPRESSORS

CHAPTER 3: JUNIOR II COMPRESSOR

3.1 Lubrication

3.1.1 Oil Level Check

Check the oil level prior to putting compressor into operation each day

1. Remove dipstick and wipe dry.

2. Reinsert the dipstick ensuring that it is completely seated.

3. Withdraw the dipstick again and note the oil level.

The level should be between the minimum and maximum marks on the dipstick.See Figure 3-1.

Figure 3-1 Oil Dipstick Markings

Junior II WT

Max.

Min.

^ CAUTION ^

The oil level must not go down below the minimum mark but also must not exceed the maximum

mark as this will cause excessive lubrication of the compressor and result in the valves carbonizing.

3.1.2 Type of Oil

^ NOTE ^

The part number for the oil delivered in all Junior II compressor units is BAUER part number:

OIL-0024

Due to the thermal load on the compressor, only high quality oil should be used. It is recommended that

you restrict oil to BAUER P/N OIL-0024 which has a proven record of success and is specified for this

compressor.

Page 10 1st ed. Rev 0 Chg 3

MNL-0391

3.1.3 Oil Changes

The oil must be changed every 2,000 operating hours or every two years whichever is reached first.

3.1.3.1 Oil Change Procedures

1. Run the compressor until it reaches normal operating temperature.

2. Remove the oil dipstick from oil filler tube.

3. While the oil is still warm, remove oil drain plug and drain oil into an appropriate container.

4. After oil has completely drained, reinstall oil drain plug and tighten.

5. Refill with 12 Fluid Ounces (360 cc) of oil, through the oil filler tube.

6. Check oil level using the oil dipstick.

7. Oil level is correct if it is at the upper mark.See Figure 3-1

3.2 Intake Filter

3.2.1 Description

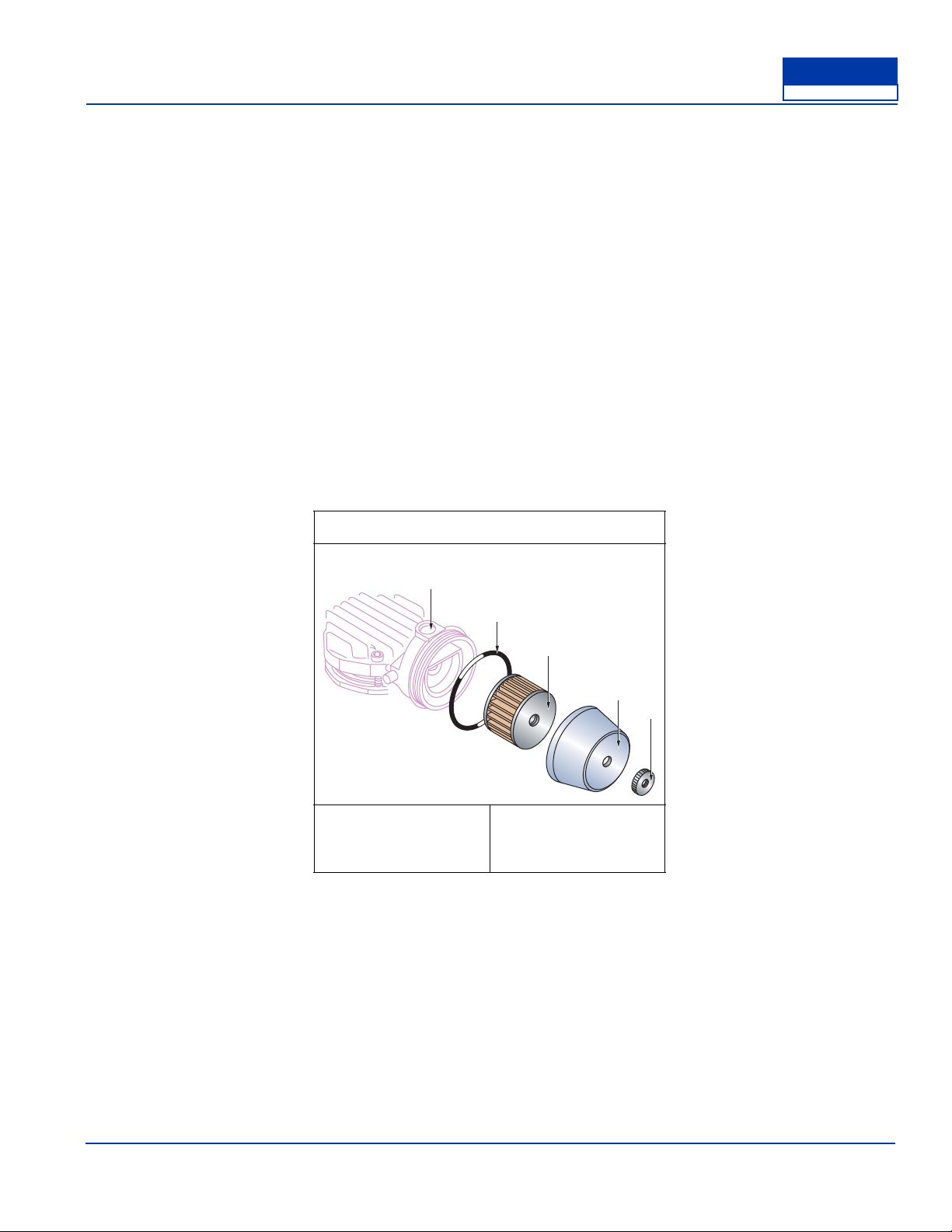

A dry micronic filter is used to filter the intake air. See Figure 3-2

BAUER

COMPRESSORS

Figure 3-2 Intake Filter

5

4

3

2

1

1. Knurled Nut

2. Plastic Cap

4. O-ring

5. Intake Opening

3. Filter Cartridge

3.2.2 Maintenance

The filter cartridge must be changed at regular intervals according to the maintenance schedule.

1. Remove knurled nut (1) and take off plastic cap (2).

2. Permanently mark filter cartridge (3) at the twelve o’clock position.

3. After cartridge has been cleaned three times (3 marks) it is dirty on all sides and must be replaced

with a new cartridge.

4. Remove filter cartridge and clean with a brush or by blowing air from the inside to the outside.

5. Clean the inside of the filter housing with a damp cloth. Take care to prevent dust from entering the

opening into the compressor.

April 26, 2007 Page 11

BAUER

COMPRESSORS

Junior II WT

6. Reinsert filter cartridge, turning it 90° so the mark made in step 2. is at the 3 o’clock position.

7. Inspect O-ring (4) and replace if damaged.

8. Replace plastic cap and tighten knurled nut

3.2.3 Telescope Intake Tube

See Figure 3-2. The telescopic intake tube is inserted in the intake opening (5). This is necessary to

ensure clean intake air on gasoline engine driven compressor units. It’s use is also recommended with

electric motor driven compressor units.

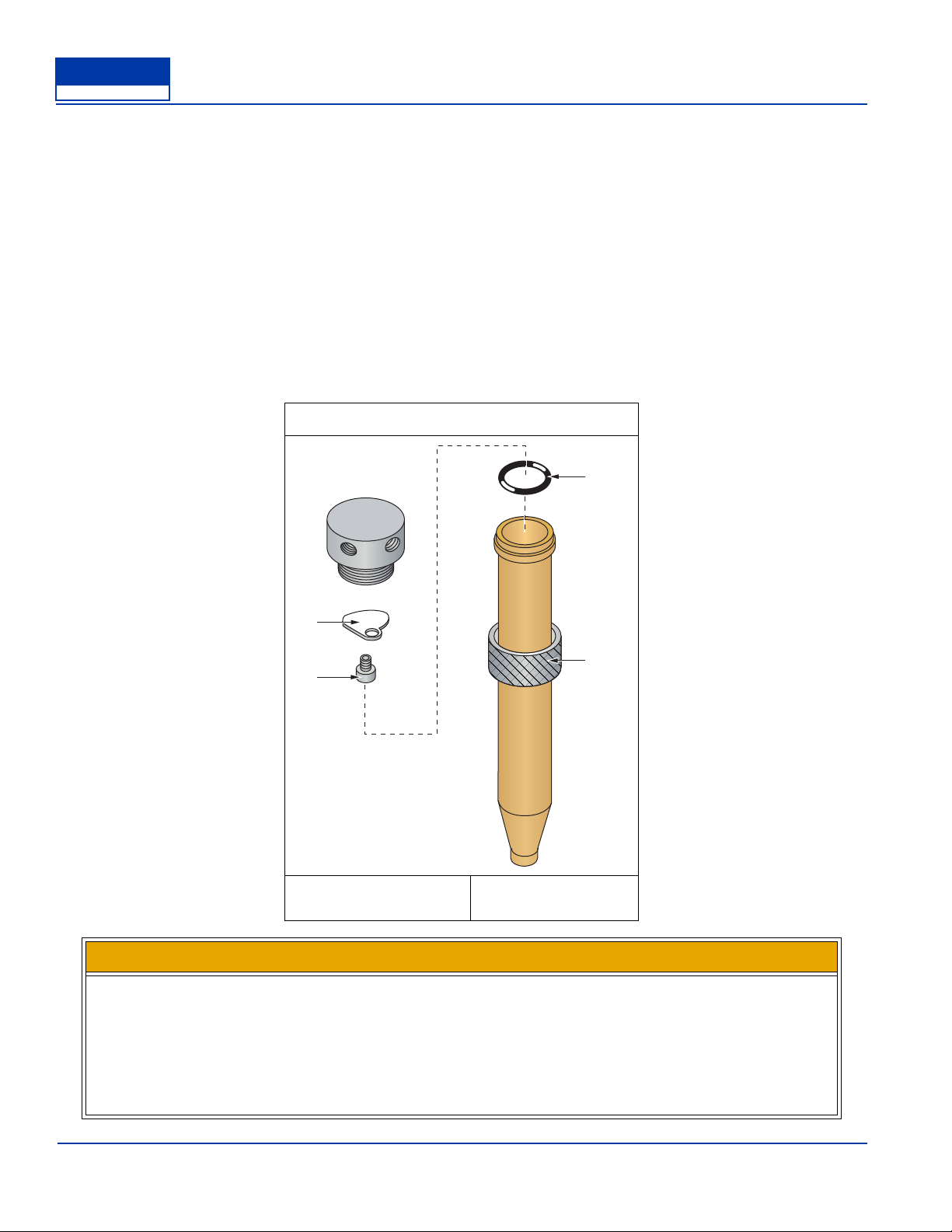

3.2.4 Intermediate Separator

An intermediate separator is mounted on the compressor block. This separator is designed to remove oil

and water which accumulates due to the cooling of the medium after the compression process. Separation

is achieved by means of centrifugal action provided by a vortex plate (1)

Figure 3-3 Intermediate Separator

3

1

4

2

1. Vortex Plate

2. Hollow Screw

3. O-ring

4. Knurled Nut

^ WARNING ^

The rapid depressurizing and repressurizing of the intermediate separator during condensate draining subjects it to metallurgical stresses. To prevent catastrophic failure with the possibility of damage, injury or death the intermediate separator must be replaced after 85,000 load cycles. A load

cycle equals one depressurization- repressurization. The Bauer recommended frequency of condensate draining is every fifteen minutes and is a balance between maximizing the life of the oil

and water separator chamber and maintaining the quality of the delivered air.

Page 12 1st ed. Rev 0 Chg 3

MNL-0391

Intake Pressure

BAUER

COMPRESSORS

3.2.5 Maintenance

The Intermediate Separator P/N 081798 requires no maintenance.

3.3 Compressor Valves

3.3.1 Description

The valve heads of the individual stages form the top part of the cylinders. The intake and pressure valves

are fitted inside the valve heads. (Note that the valves are operated by air flow. (See Figure 3-4). On the

suction stroke, the intake valve is opened and air flows into the cylinder. At the start of the compression

stroke the intake valve closes. the end of the compression stroke the compressed air forces the pressure

valve open.

The 1st Stage combines the intake and pressure valves in a plate valve. (See Figure 3-5).

Figure 3-4 Valve Function Figure 3-5 1st Stage Plate Valve

Intake

Side

S

From

Intake

Filter

To

2nd

Stage

Discharge

Side

N4860-F98

3.3.2 Initial Operational Check

After maintenance work on the valves, the valves should be checked for proper operation. Note that the

intake line to the valve heads is warm and the outlet piping should be hot. This indicates the valves are

operating correctly.

3.3.3 Changing the Valves

• Always replace the valves as a complete set.

• Observe the correct sequence when reassembling.

• Check individual components for excessive wear . If the valve seat and valve dis ks are dented, replace

the valves.

• Valve head screws must be tightened with a torque wrench.

• Check the valve space in the valve head for dirt and clean if necessary.

April 26, 2007 Page 13

BAUER

COMPRESSORS

Junior II WT

• Thirty minutes after restarting the compressor unit, stop the unit, let it cool to ambient temperature

and retighten the valve studs and cap nuts. Otherwise valves could work loose due to the setting of the

gaskets.

• After finishing all maintenance work on the valves, turn the compressor by hand using the flywheel

and check that all items have been correctly installed.

• Remove and check the valves every 1,000 operating hours.

• Replace the valves every 2,000 operating hours to avoid fatigue failure

Figure 3-6 1st Stage Valve Head

7

6

5

1

2

3

4

1. Valve Head

2. Gasket

3. Plate Valve

4. O-ring

5. Valve Head

Screw

6. Washer

7. Hex Nut

3.3.4 Changing the 1st Stage Valves

• Loosen the two cap nuts from tube connectors and remove after-cooler.

• Remove four valve head screws (5) from valve head (1). Remove valve head.

• Remove gasket (2) and plate valve (3).

• When reinstalling the plate valve, check that the mark “S” is facing upwards and towards the inlet

filter side. The cross bar of the gasket (2) provides a seal between the inlet and pressure opening of

the plate valve.

Page 14 1st ed. Rev 0 Chg 3

MNL-0391

BAUER

COMPRESSORS

Figure 3-7 2nd Stage Valve Head

1

2

3

8

7

4

6

1. Nut

2. Washer

3. Valve Cover Plate

4. Stud

5. Valve Head

6. O-rings

7. Intake Valve

8. Pressure Valve

5

3.3.5 Changing the 2nd Stage Valves

Both the intake and pressure valves can be serviced from the top of the head. See Figure 3-7.

1. Remove two captive nuts (1) and spring washers (2)

2. Remove valve cover plate (3)

3. Remove valves (7 and 8) using two screwdrivers as shown in Figure 3-9

4. Reassemble in reverse sequence. Position spring washers so the curved side is facing up. Fasten

nuts so the valve cover plate is parallel to the valve head. Torque to 7 ft-lbs (10Nm).

April 26, 2007 Page 15

BAUER

COMPRESSORS

Junior II WT

3.3.6 Changing the 3rd Stage Valves

On this valve head, the valves are arranged on the upper and lower side due to the small diameter of the

3rd Stage head. See Figure 3-8.

Figure 3-8 3rd Stage Valve Head

7

8

1

2

3

4

5

6

1. Torque Stud

2. Valve Cover

3. Pressure Valve

4. O-ring

5. Valve Head

6. Intake Valve

7. Allen Screw

8. Washer

^ CAUTION ^

Always change the intake and pressure valves of the 3rd Stage at the same time.

1. To remove or install the intake valve (6) use the special tool which is part of tool set delivered with

the unit. (See Figure 3-16.)

2. The pressure valve (3) is merely inserted into the valve head (5). It is sealed by the O-Ring (4) and

fixed to the valve head by the torque stud (1).

3. Remove pressure valve by loosening torque stud (1) a couple of turns.

Page 16 1st ed. Rev 0 Chg 3

MNL-0391

4. Remove Allen screws (7) and take off valve head cover (6).

5. To lift pressure valve out of valve head put two flat head screwdrivers into grooves of the pressure

valve body. See Figure 3-9. If necessary turn valve to loosen it, using a 13mm open end wrench on

the flat surfaces of the valve.

6. Lift out pressure valve (3) together with O-Ring (4).

7. Check O-Ring for damage and wear, replace if necessary. Put O-ring into the valve head.

8. To reinstall pressure valve Insert valve (3) and install valve head cover (6).

9. Fasten valve head cover to valve head with Allen screws and washers (8).

10. Screw in torque stud (1) and torque to 14 ft-lbs (20Nm).

Figure 3-9 Removing the 3rd Stage Valves

Pressure Valve Intake Valve

BAUER

COMPRESSORS

3.4 Repair and Troubleshooting

3.4.1 General Repair Instructions

Preventive maintenance usually involves replacing the valves, gaskets and sealing rings as well as carrying out the maintenance work.

Repair work can be carried out on the compressor block to a certain extent but a certain experience and

skill level is necessary.

It should be noted however, that

• No repair should be carried out on the crankshaft or bearings.

• Safety valves are not repaired but always replaced completely.

April 26, 2007 Page 17

BAUER

COMPRESSORS

3.4.2 Troubleshooting Tables

3.4.2.1 Electric Motor

TROUBLE CAUSE REMEDY

Check all fuses, terminal connec-

Motor will not start Electric circuitry faulty

Motor runs eccentrically V-belt worn Replace V-belt

tions, wire leads, make sure that

motor data complies with mains

supply.

Junior II WT

Insufficient voltage because of a

Motor protection switch turns

unit off

3.4.2.2 Gasoline Engine

TROUBLE CAUSE REMEDY

Engine will not start See engine instruction See engine instructions

Engine runs eccentrically V-belt worn Replace V-belt

Excessive V-belt wear

3.4.2.3 Compressor Block

TROUBLE CAUSE REMEDY

weak power supply.

Power supply cable to long or too

small in diameter

V-belt tension incorrect Retighten

Pulleys not aligned Readjust

Condensate drain valve(s) leaking

Switch off other power consuming devices.

Replace with suitable cable

Tighten and reseal.

Final pressure safety valve

defective (blows to soon)

Compressor does not attain final

pressure.

Page 18 1st ed. Rev 0 Chg 3

No cartridge in P21 Filter system. (air escaping through the

cartridge safety bore.)

Vent screw for final pressure

safety valve not in operating

position.

Replace safety valve

Replace cartridge

To vent, unscrew until completely open.

MNL-0391

BAUER

COMPRESSORS

Intake filter soiled Clean or replace filter cartridge.

Air delivery drops

Intermediate pressure safety

valve blows

Air escaping through the cartridge safety bore

Taste of oil in the air

Compressor overheats

Pipe coupling leaking Retighten couplings.

Excessive wear of the 3rd stage

piston

Intermediate pressure too high

because of defective inlet or

pressure valve of the following

stage.

Safety valve leaking Replace safety valve.

Cartridge missing Replace cartridge

Cartridge O-rings defective Check and replace O-rings

Cartridge saturated Replace cartridge

Unqualified lubricant being used Replace with approved oil.

Insufficient cooling air

Ambient temperature too high.

Replace piston and sleeve of 3rd

stage.

Check and replace inlet or pressure valve.

Inlet and pressure valve of one

stage leaking. Or direction of

rotation incorrect.

Check for a maximum ambient

temperature of 113 °F (45° C).

Direction of rotation is incorrect. Correct direction of rotation.

Inlet and pressure valve of one

stage is leaking

Check valves, clean and replace

if necessary.

April 26, 2007 Page 19

BAUER

13

12

11

9

3

2

14

3

8

10

1

2

3

4

4

5

6

3

7

24

14

15

16

17

18

19

20

21

22

23

25

26

27

28

31

29

30

COMPRESSORS

3.5 Replacement Parts List Figure 3-10 Crankcase, Driving Gear and Fanwheel

Junior II WT

# KIT Qty Part No. Description Notes

1 … 067035 Driving Gear Assembly Items 2 through 7

2 … 5 N109 Allen Screw

3 … 7 N2862 Washer

4 … 2 N4889 Key

5 … 1 59470 Thrust Washer

6 … 1 67027 V-belt Pulley

7 … 1 N61 Allen Screw

8 … 1 59397 Cover

9 … 1 N4855 O-ring

10 … 2 N3702 Roller Bearing

11 … 1 61371 Crankcase

Page 20 1st ed. Rev 0 Chg 3

MNL-0391

Figure 3-10 (cont.) Crankcase, Driving Gear and Fanwheel

# KIT Qty Part No. Description Notes

12 … 2 N2861 Shaft Seal

13 … 1 13920 Fan

14 … 1 067013 Dip-stick

15 … 1 N3951 O-ring

16 … 1 67007 Oil Filler

17 … 1 N1055 Hose

18 … 1 12560 Gasket

19 … 1 N842 Gasket

20 … 1 61973 Extension, Oil Drain

21 … 1 N3707 Plug with Plastic Gasket

22 … 1 077771 Spacer

23 … 1 N3738 Stud

24 … 1 N4051 Gasket

25 … 1 N15688 Plug

26 … 2 N158 Allen Screw

27 … 2 N3026 Split Lock Washer

28 … 2 N171 Allen Screw

29 … 1 N108 Split Lock Washer

30 … 1 N2460 Washer

BAUER

COMPRESSORS

April 26, 2007 Page 21

BAUER

1

2

3

4

5

6

7

8

9

10

11

12

12

13

13

13

13

14

15

15

14

15

16

14

15

17

18

19

20

21

COMPRESSORS

Figure 3-11 Pistons and Cylinders

Junior II WT

# KIT Qty Part No. Description Notes

1 … 1 76548 Cylinder 1st Stage 60mm

2 ..c 1 N4948 O-ring

3 … 1 069918 1st Stage Piston Assembly

4 … 1 61354 Cylinder 2nd Stage 28mm

5 ..c 1 N3157 O-ring

6 … 1 069920 2nd Stage Piston Asy

7 … 1 67096 Cylinder, 3rd Stage 12mm

8 ..c 1 N4868 O-ring

9 … 1 069927 3rd Stage Piston Asy

10 .b. 1 075310 Piston and Sleeve Assembly

11 … 1 N2507 O-ring

12 … 2 N1033 Circlip

Page 22 1st ed. Rev 0 Chg 3

MNL-0391

Figure 3-11 (cont.) Pistons and Cylinders

# KIT Qty Part No. Description Notes

13 … 4 N15294 Circlip

14 a.. 10 N1042 Hex Nut, Self Locking

15 … 12 N102 Flat Washer

16 … 4 N4615 Stud

17 … 4 N24861 Stud

18 … 4 N15691 Stud

19 … 2 67518 Hex Bushing

20 … 1 N4206 1st Stage Piston Ring Set 60mm

21 … 1 N15816 2nd Stage Piston Ring Set 28mm

BAUER

COMPRESSORS

April 26, 2007 Page 23

BAUER

1

2

3

4

5

9

10

11

6

14

15

7

8

24

23

22

21

20

18

17

19

16

12

13

COMPRESSORS

Figure 3-12 Valve Heads and Valves

Junior II WT

# KIT Qty Part No. Description Notes

1 … 1 077179 1st Stage Valve Head Assembly Items 2 through 5

2 … 1 58105 1st Stage Valve Head

3 … 1 58144 Gasket

4 .b. 1 N4860 Reed Valve

5 … 1 N3712 O-ring

6 … 1 069930 2nd Stage Valve Head Assembly Items 7 through 15

7 a.. 4 N1042 Hex Nut, Self Locking

8 … 4 N4640 Spring Washer

9 … 1 58133 2nd Stage Valve Cover

10 .b. 1 058136 Inlet Valve Assembly

11 … 2 N638 O-ring

12 … 1 58130 2nd Stage Valve Head

13 a.. 1 N4868 O-ring

14 .b. 1 058135 Discharge Valve Assembly

Page 24 1st ed. Rev 0 Chg 3

MNL-0391

Figure 3-12 (cont.) Valve Heads and Valves

Item Qty Part No. Description Notes

15 … 4 58134 Stud

16 … 1 069931 3rd Stage Valve Head Assembly Items 17 through 24

17 … 6 N1776 Allen Screw

18 … 6 N102 Flat Washer

19 … 1 59449 Plug

20 … 1 59457 Valve Head Cover

21 .b. 1 014121 Discharge Valve

22 … 1 N2789 O-ring

23 … 1 61362 3rd Stage Valve Head

24 .b. 1 81409 Intake Valve

BAUER

COMPRESSORS

April 26, 2007 Page 25

BAUER

1

2

3

4

5

6

7

10

9

11

8

20

3

3

10

13

12

3

5

14

16

19

6

5

15

13

17

5

6

18

COMPRESSORS

Figure 3-13 Cooler

Junior II WT

# KIT Qty Part No. Description Notes

1 … 1 081803 1st Stage Safety Valve

2 … 1 N20213 Male Run Tee

3 … 4 N20007 Male Elbow

4 … 1 077193 2nd Stage Inter-cooler Assembly

5 … 7 N1042 Hex Nut, Self Locking

6 … 4 N102 Flat Washer

7 … 1 61903 Inter-cooler Left Bracket

8 … 1 55579 Bracket

9 … 1 N61 Allen Screw

10 … 1 N15317 Allen Screw

11 … 3 N3313 Washer

12 … 2 55589 Bracket

13 … 2 N20153 Connector

14 … 1 077195 Tubing

15 … 1 N20172 Male Elbow

Page 26 1st ed. Rev 0 Chg 3

MNL-0391

Figure 3-13 (cont.) Cooler

# KIT Qty Part No. Description Notes

16 … 1 077197 After-cooler

17 … 1 N191 Hex Screw

18 … 2 62148 Bracket

19 … 1 N3786 Stud

20 … 1 069938 Inter-cooler, 1st-2nd Stage

21 … 2 N158 Allen Screw

22 … 2 N4640 Washer

23 … 2 14369 Clamp for Separator

BAUER

COMPRESSORS

April 26, 2007 Page 27

BAUER

COMPRESSORS

Figure 3-14 Intake Filter and Intermediate Separator

Junior II WT

10

11

14

13

16

12

9

8

7

6

5

3

15

17

2

18

19

4

1

# KIT Qty Part No. Description Notes

1 … 1 059377 Intake Filter Assembly

2 … 1 N4870 Knurled Nut

3 … 1 59433 Filter Cap

4 a.. 1 N4823 Filter Cartridge

5 … 1 N1042 Hex Nut, Self Locking

6 … 1 N2877 Hex Nut

7 … 1 N3313 Washer

8 a.. 1 N4877 O-ring

9 … 1 59434 Filter Support

Page 28 1st ed. Rev 0 Chg 3

MNL-0391

Figure 3-14 (cont.) Intake Filter and Intermediate Separator

Item Qty Part No. Description Notes

10 … 1 65985 Gasket

11 … 1 077323 Telescopic Intake Tube Assembly

12 … 1 077325 Lower Intake Tube Available only with 077323

13 … 1 077326 Upper Intake Tube Available only with 077323

14 … 1 N25393 Plug, Polyethylene Available only with 077323

15 … 1 081800 Intermediate Separator Assembly

16 … 1 81148 Plate

17 … 1 81643 Hollow Screw

18 … 1 N3556 O-ring

19 … 1 13937 Knurled Ring

20 … 1 011430 Condensate drain Tap Assembly

21 … 1 068410 Drain Valve Body

22 a.. 1 13283 Gasket

23 … 1 055888 Tommy Screw Assembly

NS … 1 012886 Safety Valve

BAUER

COMPRESSORS

April 26, 2007 Page 29

BAUER

1

2

3

4

5

6

6

7

8

9

10

11

5

12

2

13

14

14

14

15

16

17

18

18

18

19

21

6

20

22

23

Turquoise

Cyan

COMPRESSORS

Figure 3-15 Frame with Accessories

Junior II WT

Item Qty Part No. Description Notes

1 1 85148 Fanwheel Shroud Cyan

— 1 79398 Fanwheel Shroud Turquoise

2 3 N2460 Washer

3 2 N16508 Allen Screw

4 1 077285 Handle

5 6 N15769 Allen Screw

6 6 N102 Washer

7 4 N24916 Button Head Allen Screw

8 4 N25609 Vibration Isolator

9 2 N58 Washer

10 2 N370 Hex Nut

11 1 81622 Frame

12 1 N19546 Allen Screw

13 2 N25343 Washer

14 4 77248 Spacer

Page 30 1st ed. Rev 0 Chg 3

MNL-0391

Figure 3-15 (cont.) Frame with Accessories

Item Qty Part No. Description Notes

15 1 85145 V-belt Shroud Cyan

— 1 077667 V-Belt Shroud Turquoise

16 2 N15627 Grommet

17 4 N26506 Washer

18 8 N24918 Button Head Allen Screw

19 1 82494 Bracket

20 1 N16131 Rubber Isolator

21 2 N15797 Allen Screw

22 2 N15769 Allen Screw

23 1 77674 Fill Hose Holder

BAUER

COMPRESSORS

April 26, 2007 Page 31

BAUER

COMPRESSORS

Figure 3-16 Special Tools

Junior II WT

1

2

# KIT Qty Part No. Description Notes

1 … 1 004555 3rd Stage Intake Valve Removal Tool

2 … 1 077781 Triplex® Wrench

Page 32 1st ed. Rev 0 Chg 3

MNL-0391

BAUER

COMPRESSORS

CHAPTER 4: JRII MAINTENANCE

^ WARNING ^S

Always shut down and decompress the complete system prior to carrying out any work on the compressor

Never repair pressure lines by soldering or welding.

^ CAUTION ^S

Change the purifier cartridge according to the Maintenance Schedule.

The used purifier cartridge must be disposed of according to local regulations.

Use only original spare parts for maintenance or repair work.

Check the entire system for leakage by brushing all fittings with soapy water or leak test spray.

4.1 Maintenance Record

It is recommended that all maintenance work be recorded in a service record book which shows the date

and details of any maintenance work carried out. It will help avoid expensive repairs caused by missed

maintenance work. If necessary to claim against the warranty, it will help to have proof that regular

maintenance work has been carried out and the damage is not the result of insufficient maintenance.

4.2 Maintenance Schedule

As an example for the service record book the following Maintenance Schedule and Record of Operating Hours are provided. They may be reproduced as needed. The grey heading boxes on the Maintenance Schedule show the recommended maintenance interval and the Section of this manual for the

applicable maintenance procedure. Date and signature blocks are also provided

4.2.1 After the First 25 Operating Hours

Check functioning and tightness of fill valve.

Clean intake filter and intake filter cartridge.

Check V-belt tension and condition.

Check tightness of all connections and couplings

Check cooler brackets

Check zero position on final pressure gauge when the

system is depressurized.

Date Signature

Tighten all valve head bolts and studs.

April 26, 2007 Page 33

BAUER

COMPRESSORS

JUNIOR II WT

4.2.2 Every 125 Operating Hours

Change intake filter cartridge

Check V-belt and replace if necessary

Date Signature

4.2.3 Every 2000 Operating Hours or Biennially

Change synthetic based compressor oil.

Change valves

Date Signature

Page 34 1st ed. Rev 0 Chg 3

MNL-0391

BAUER

COMPRESSORS

4.2.4 Annually or As Required

Check blow-off pressure of final pressure safety valve.

Perform breathing air quality check using BAUER

AirLab IV test unit, or equivalent.

Date Signature

April 26, 2007 Page 35

BAUER

COMPRESSORS

JUNIOR II WT

4.2.5 After Repair Work

Check functioning and tightness of fill valve.

Clean intake filter and intake filter cartridge.

Check condition of O-rings

Date Signature

Check tension and condition of V-belt.

Page 36 1st ed. Rev 0 Chg 3

MNL-0391

BAUER

COMPRESSORS

4.2.5 After Repair Work

Check tightness of all connections and couplings.

Check cooler brackets

Check zero pressure position on the final pressure

gauge when depressurized

Date Signature

Tighten valve head bolts and studs

April 26, 2007 Page 37

BAUER

COMPRESSORS

JUNIOR II WT

4.2.6 After Storage and Preservation

Check functioning and tightness of filling valve

Clean intake filter and intake filter cartridge

Check condition of O-rings

Check V-belt tension and condition

Date Signature

Check tightness of all cooler pipes and couplings

Check cooler brackets

Check zero position of final pressure gauge when

depressurized

Page 38 1st ed. Rev 0 Chg 3

MNL-0391

BAUER

COMPRESSORS

CHAPTER 5: PURIFICATION SYSTEM

5.1 General

The purpose of all Bauer industrial air purification systems is to remove oil and water from the compressed air stream before final delivery. For this reason Bauer purification systems are installed immediately before the compressed air delivery point.

^ WARNING ^

Industrial Air Purification System cartridges do not remove carbon monoxide and therefore must not be

used in breathing air applications

5.1.1 General Purification System Procedures

1. Keep an accurate record of operating hours to ensure exact attention to maintenance intervals

2. Change all cartridges before reactivating a compressor unit that has been out of service more than

three months. Leave cartridges in the unit as long as it is out of service.

3. While out of service keep all condensate drain valves closed. Maintain a pressure of 700 to 1,100

psi (50 to 80 bar) within the system to prevent moisture from entering the compressor and purification system.

5.1.2 Chamber Safety Bore

The chambers in all BAUER purification systems are designed to prevent pressurization if the cartridge is

missing, not seated properly or damaged (See Figure 5-1). Without a cartridge properly in place the

safety bore is not sealed, the air escapes into the atmosphere, no pressure can be built up and thus it is

ensured that unfiltered air is not supplied to the consuming device. If air is escaping from the safety bore

remove and check cartridge. If necessary replace the cartridge or O-rings.

Figure 5-1 Cartridge Safety Venting

Safety

Vent

Safety

Vent

Cartridge Installed

No Cartridge Installed

April 26, 2007 Page 39

BAUER

CARTRIDGE FOR

CARTRIDGE NO.

LBL-

CARTRIDGE TO BE

INSTALLED

1328 Azalea Garden Road - Norfolk Virginia 23502-1944

Phone: (757) 855-6006 Fax: (757) 855-8224

MODEL NO.

MAX. PRESSURE

AIR PROCESSED

O-RING

BACK-UP RING

psig

cu. ft.

LBL-

PURIFICATION

SYSTEM

COMPRESSORS

Junior II WT

5.1.3 Manual Condensate Drainage

The condensate must be drained from the oil and water separator before changing any cartridge, before

beginning each filling procedure and in the absence of an Automatic Condensate Drain System, every fifteen minutes during the filling procedure. This is done by slowly opening the condensate drain valves.

They are opened approximately 1/3 of a turn to the left and held open until the condensate is completely

drained. The condensate drain valves close by spring pressure but if necessary may be tightened by hand

to ensure they are completely air tight.

5.1.4 Model, Serial Number and Part Number Identification

5.1.4.1 Compressor Dataplate

The model number, date of manufacture and serial number can be found on the compressor unit identification plate in the main electrical enclosure and frame.

Figure 5-2 Purification System Dataplates (typical)

Purification System Cartridge Installation

5.1.4.2 Purification System Dataplate Refer to the compressor unit purification system dataplate (See Figure 5-2) on the compressor front to determine your purification system model and specifications.

5.1.4.3 Cartridge Installation Dataplate The function performed by each chamber in the purification system is determined by the type of cartridge installed in that chamber. Refer to the cartridge installation dataplate on the chamber to determine the purpose and part number of the cartridge installed in that chamber. (See Figure 5-2)

Page 40 1st ed. Rev 0 Chg 3

MNL-0391

5.1.5 Industrial Purification System Configurations

Number and Type of Cartridges Processing Capacity

BAUER

COMPRESSORS

Purification System Dryer Purification Securus

®

cubic ft (ft)

P0 Combined 3,200

P1 … 1 … 15,000

P2 … 1 … 40,000

IP2 with Securus® … … 1 67,000

P4 1 1 … 60,000

P5 1 1 … 90,000

IP5 with Securus® 1 … 1 150,000

P10 2 1 140,000

IP10 with Securus® 2 … 1 230,000

a

IP12

IP14

a

1 1 420,000

2 1 650,000

P31 Combined 11,760

3

IP41 with Securus® … … 1 47,000

IP42 with Securus® 1 … 1 107,000

IP43 with Securus® 2 … 1 164,000

a. P12 and P14 have the Securus® Electronic Moisture Monitor System as standard equipment.

5.1.6 Cartridge Operating Life

Every BAUER Purification System is designed to process a certain volume of air before the cartridges

require replacement. By using special test equipment that measures the quality of air at the outlet any

quality reduction may be detected. However as most compressor owners do not have this test equipment

the recommended method of determining cartridge operating life is to maintain a written record of the

volume of air processed by the purification system.

Each BAUER compressor block is rated to produce a standard volume of air per minute and by using this

number and the air processing capability of the purification system it is possible to calculate the maximum operating hours before the cartridges need to be replaced. See Paragraph 5.1.6.1 for the method of

determining this figure.

The ambient air temperature and its ability to cool the compressor will effect the operating life of the cartridge. See Paragraph 5.1.6.2 for the method of calculating this adjustment factor.

April 26, 2007 Page 41

BAUER

COMPRESSORS

The optimum place to measure the temperature is at the inlet to the final separator as this best reflects the

temperature of the air as it enters the chambers. Experience has shown that this temperature is approximately 10° F above the ambient temperature. Therefore for the purpose of calculating cartridge operating

life use the Ambient Air Temperature plus 10° F.

A form titled Air Purification Cartridge Operating Hours is found in Paragraph 5.1.6.3 and in the Appendices. It is used for recording the ambient temperature, operating time and adjustment factor. It is suggested that it be copied, placed in a protective folder and kept with the unit to record the adjusted

operating hours. An example of how this form is used is shown in Figure 1-5.

5.1.6.1 Calculating the Maximum Cartridge Operating Hours

1. From the purification system dataplate (See Figure 5-2) on the purification chamber determine the

Air Processed (cu.ft.)

2. From the paragraph titled Compressor Specifications in the instruction manual for your compressor

unit determine the Charging Rate in SCFM of your compressor.

3. Divide the Air Processed by the Charging Rate to obtain the Maximum Operating Time in minutes

4. Divide the Maximum Operating Time in minutes by 60 to obtain the Maximum Operating Hours.

Junior II WT

5. Record the answer on the Air Purification Cartridge Operating Hours form.

5.1.6.2 Calculating the Adjusted Cartridge Operating Hours

1. Using the Air Purification Cartridge Operating Hours form (FORM-0018) record the Date, Operating Hours and Ambient Air Temperature plus 10° F.

2. Using either the graph or the chart in Figure 1-4 determine the Correction Factor.

3. Divide the Operating Hours by the Correction Factor and record it under the column labeled Today.

4. Add the hours recorded in Today to the previous Total and record it as the current Total.

5. When the Total approaches the Maximum Operating Hours replace the Cartridges.

Page 42 1st ed. Rev 0 Chg 3

MNL-0391

Date

Operating

Hours

Ambient Temp.

during Compression

Correction

Factor

Adjusted Cartridge Hours

Today Total

10/19/04 8 92°F 0.48 16.66 16.66

11/01/04 4 45°F 2.25 1.78 18.44

Figure 5-3 Correction Factor for Cartridge Operating Hours

3.5

3.0

2.5

2.0

1.5

Conversion Factor

1.0

0.5

0.0

0

10 20 30 40 50

Ambient Temperature in °C

BAUER

COMPRESSORS

°F°C Correction factor

50 122 0.21

40

30 86

20 68 1.00

10

0

104 0.34

50 1.81

32

Figure 5-4 Example Record of Adjusted Operating Hours

0.58

3.44

April 26, 2007 Page 43

BAUER

COMPRESSORS

5.1.6.3 Purification Cartridge Operating Hours Form

Junior II WT

Date

Operating

hours

Ambient temp.

during compression

Correction

factor

Adjusted cartridge hours

Today Total

Page 44 1st ed. Rev 0 Chg 3

MNL-0391

BAUER

COMPRESSORS

5.2 P0 Purification System

5.2.1 Description

The P0 Purification System consists of a separator and a cartridge chamber. In the separator surrounding the cartridge chamber, liquid oil a nd water particles are separated from the compressed air by a pipe

nozzle. Residual oil and water particles are then removed by the filter cartridge and the air leaving the

P0 Purification System is free of water, oil, taste and smell.

Figure 5-5 P0 Purification Chamber

8

7

1

6

2

3

4

1. Inlet Connection

2. Condensate Drain Connection

3. Condensate Drain Valve

4. Bleed Port

5

5. Bleed Valve

6. Pressure Maintaining Valve

7. Outlet Connection

8. Safety Valve

April 26, 2007 Page 45

BAUER

1

11

2

3

4

5

6

7

8

9

10

Cartridge Removal

COMPRESSORS

JUNIOR II WT

Figure 5-6 P0 Purification System Cross Section

1. Inlet

2. Cartridge

3. Jet Pipe

4. Housing

5. Plug

7. Adjustment Knob

8. Separator Chamber

9. Outlet

10. Pressure Maintaining Valve

11. Bottom

6. Final Pressure Safety Valve

5.2.2 Maintenance

5.2.2.1 Replacing the Cartridge

See Figure 5-6.

1. Depressurize system before starting any maintenance, by opening the condensate drain valve and

bleed valve.

2. Unscrew plug (5) on top of the housing (4).

3. Extract old cartridge. (2)

4. Dry inside of the housing (4) with a clean cloth. Check for corrosion. Replace if necessary.

5. Lubricate threads, O-rings and threaded portion of replacement cartridge with petrolatum.

6. Insert new cartridge and secure in place with plug (5).

Page 46 1st ed. Rev 0 Chg 3

MNL-0391

^ NOTE ^

The used filter cartridge must be disposed of in accordance with local regulations.

5.2.2.2 Chamber Replacement Interval

^ WARNING ^

The P0 Purification System is subject to dynamic loading. It is designed for a certain number of load

cycles. A load cycle equates to an abrupt pressure loss caused by draining the condensate.

The P0 Purification System must be replaced after reaching the maximum number of load cycles, otherwise the housing may fail due to material fatigue.

The maximum number of load cycles for the P0 Purification Assembly is 45,000 if operated at 5,000

psi (300 bar) or 63,000 if operated at 3,200 psi (225 bar).

If the number of load cycles of four per hour (i.e. the condensate is drained every fifteen minutes) is not

exceeded then the maximum number of operating hours before the P0 Purification System must be

replaced is 1,125 hours at 5,000 psi (300 bar). T o avoid exceeding the maximum number of load cycles

the operating hours should always be recorded.

BAUER

COMPRESSORS

April 26, 2007 Page 47

BAUER