Page 1

KOMPRESSORENKOMPRESSOREN

Fotos: Ralf Deichelmann

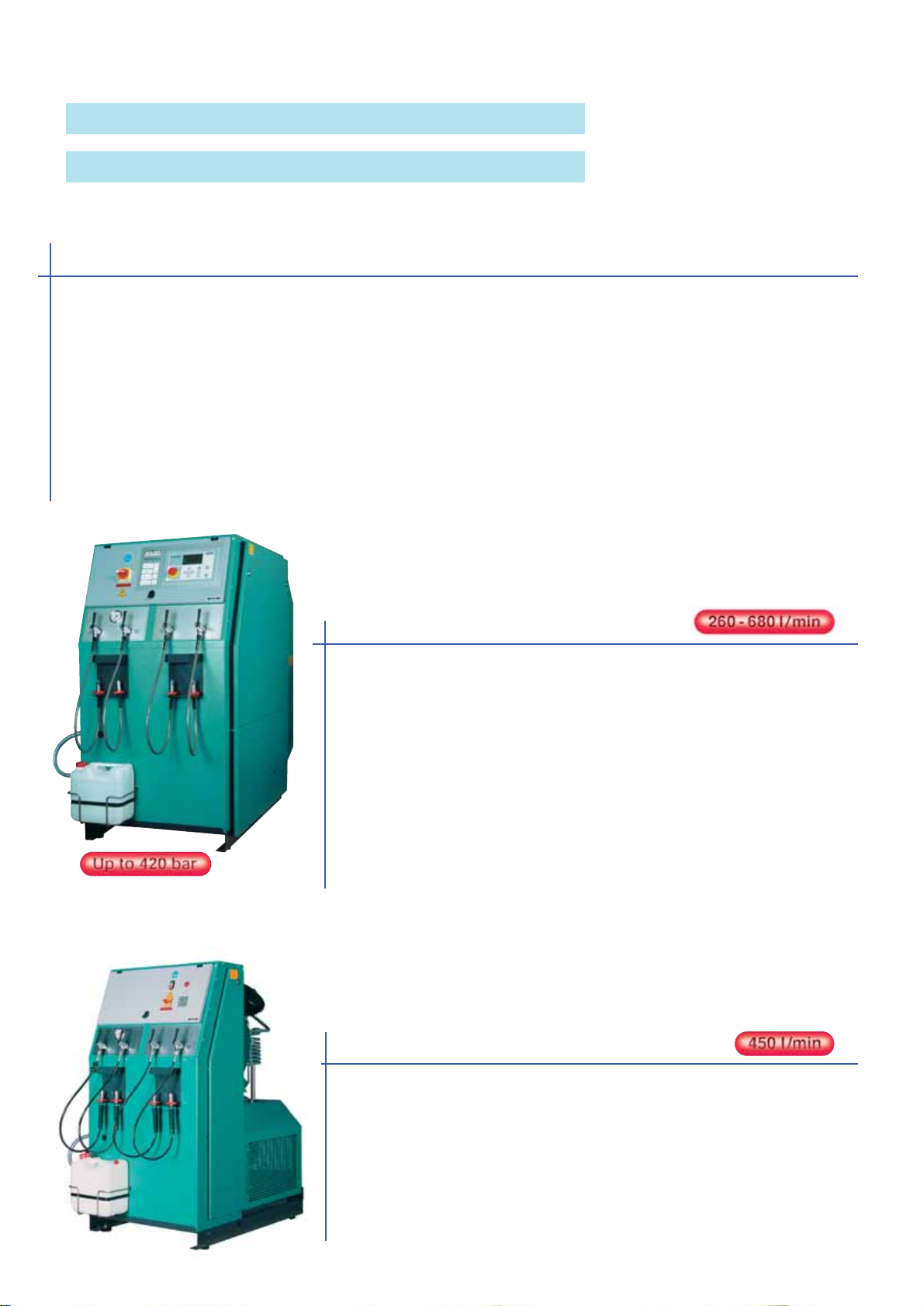

STATIONARY UNITS FOR

FIREFIGHTING

KAP- /

VERTICUS - RANGE

When firefighters are concentrating all efforts into saving

people's lives, health and possessions, then there's only

one thing that counts with

fire: an uncompromising,

reliable supply of pure breathing air.

For the past 60 years BAUER, as

their partner, has been supplying the fire brigade and disaster

prevention with breathing air

compressors that are legendary

as in regards to their reliability

and durability.

Page 2

FILLING SPECIALISTS FOR ALL PURPOSES

THE KAP- / VERTICUS RANGE

KAP- / VERTICUS - Range

Extremely compact powerful stationary filling centres.

Scope of supply: 4 filling devices and B-Control to monitor and control all important compressor functions. The

Verticus 5 - range: equipped with super silent housing.

Optional: bigger or additional filter housings, SECURUS filter monitoring, external filling panels and storage

systems. Remote control, -monitoring of one or several

units in interconnected operation via B-Messenger is possible.

KAP- / VERTICUS F - Range

High-performance open or acoustically insulated

units with the best price-performance ratio:

The new 15.1 compressor block delivers 450 litres per

minute. Otherwise technically identical to the standard

VERTICUS range, the F-unit range offers a particularly

good price-performance ratio thanks to the use of a conventional star-delta control.

The wide range of BAUER-units offers the right solution for each purpose and need

Thanks to the four-stage compr essor blocks and robust industrial bearingswith lifetime expectancies of more than 30.000 hours, the VERTICUS- and KAP- range units can be run conti-

nuously without restrictions. All coolers, filters, valves and pipes are manufactured in corrosionfree materials. High-performance axial fans and a cleverly devised cooling air supply in the sound-

proof silent units ensure an optimum supply of cooling air, a requirement necessary for a reliable application even under the most difficult external climatic conditions. The unit's design guarantees good accessibility for all routine maintenance work.

The VERTICUS range's efficient housing sound insulation permits trouble-free use even in a particularly sound-sensitive environment.

Page 3

KAP-DAH - Range

Diesel driven unit for self-sufficient use in

remote areas

Robust and low-maintenance diesel motor, particularly unsusceptible at high temperatures.

Same fuel with mobile use on diesel driven

trucks and pick-ups.

KAP-H-Range

Horizontal design for operation on heavy seas

and extreme inclinations

The low centre of gravity and the block design allow

the operation even on heavy seas.

Scope of supply similar to KAP-range, however, with

P 41 DUO filter system and without filling devices.

KOMPRESSORENKOMPRESSOREN

KAP-23 / 220 - Range

Unlimited performance for high-damage incidents

The performance of the stationary KAP-range

can meet every requirement. Designed and built

for heavy continuous operation.

We plan custom-made system solutions with

external filling panels, air purification systems and

storage solutions for you.

Page 4

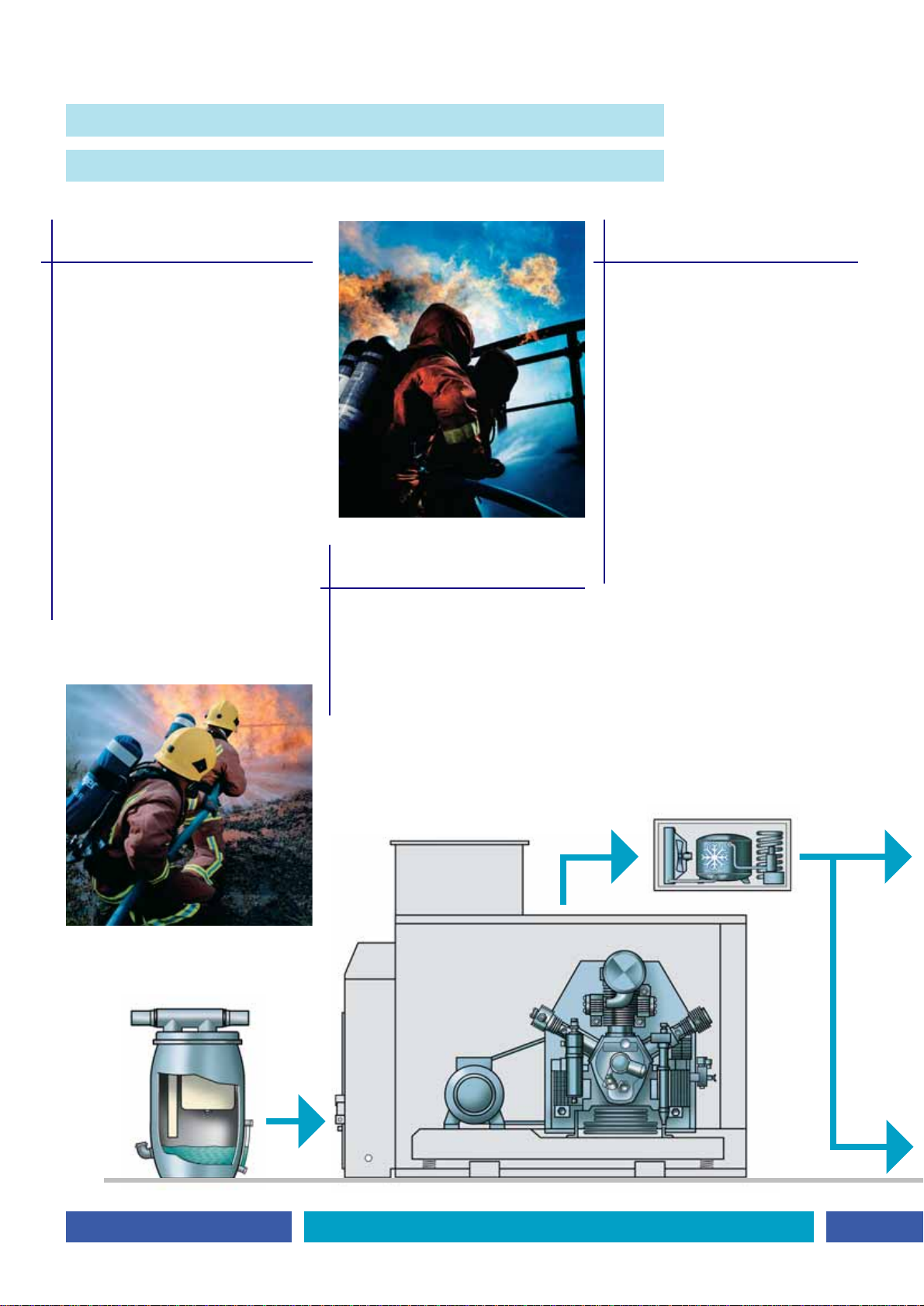

BAUER SYSTEM TECHNOLOGY

FOR A SOLUTION TAILORED TO THE CUSTOMER

BAUER'S High Pressure

System Technology

enables every fire fighting

unit to tailor a unit according

to their requirements.

This process begins at the

conceptual stage and in the

design and development of

the compressor unit. BAUER

perceives the design, deve-

lopment and evolution of its

machines as a partnership

between manufacturer and

user. This philosophy is conti-

nuous in the approach to provision of spare parts, long-

term maintenance contracts

and product support to ensure every customer a first class

service.

Systems for purification

of breathing air

AEROGUARD

Removal of CO2prior to compression at intake side.

P-FILTER SYSTEMS

Generation of breathing air

according to DIN EN12021 by

efficient removal of humidity,

oil, CO and solid particle contaminants.

SECCANT

Regenerative Dryer

Made for continuous operation

and efficient, economic purification air and gas.

Units for compression

of breathing air

Pressure range:

225 to 420 bar

F.A.D.:

260 to 1.480 l/min

Design:

Open Configuration or Super

Silent (Enclosed)

Breathing air unit

FiltersystemeCompression FiltersyPurifica

FiltersystemePurification

AIR-KOOL

AERO-GUARD

Page 5

KOMPRESSOREN

System for distribution of

breathing air

Switch over device

for maximum rate cylinder filling. Switch on of unit only for

topping up of storage cylinders.

Pressure reducing panels:

for constant regulation of outlet pressure.

Filling panels

Available in a great variety of

standard configurations to

satisfy every need with options

for switch over device to facilitate two separate pressure ranges.

Systems for storage

of high pressure air

Storages systems up to

420

bar

with 50 or 80 l* water volume

**.

Units are available as single

unit or as an extendable

modular system to provide the

required storage capacity.

Dependant upon physical limitations, various configurations

can be provided to optimize

the utilization of available

space.

*only up to 300 bar

**geometric volume

AIR-KOOL refrigeration dryer

Efficient drying of air for

increasing the filter cartridge

lifetime and effective resistance to corrosion of piping

and components.

AEROTEST SIMULTAN HP

Portable air test laboratory to

carry out testing of the breathing air quality e.g the new,

strict DIN EN 12021 standards.

P-Filter System

Pressure reducing panel

Storage bank

Filling panel

DistributionStorage

stemetion

SECCANT

Switch over device

AEROTEST

KOMPRESSOREN

Page 6

7

NO COMPROMISE REGARDING SAFETY !

FILTER SYSTEMS MADE BY BAUER

Safety starts with processing quality.

BAUER manufactures filter

housings only from costly

special aluminium alloy or

tempered high-alloy steel.

This guarantees that the filter

housings survive the highest

of pressures up to 500 bar

with tens of thousands of fil-

ling cycles.

Starting from the raw material

up to the final filter housing

the manufacturing process

is subject to perfect control

supervised by TÜV and docu-

mented with stamped material- and production numbers.

Your life is at risk with

fake cartridges!

Only original cartridges

made by BAUER guarantee

that oil, humidity or hydro-

carbons in the compressed

air are completely removed.

The limiting values of BAUER

filter systems comply with and

exceed all major national

and international standards

such as DIN EN 12021 and

medical air acc. to European

P

U

R

E

B

R

E

A

T

H

I

N

G

A

I

R

KOMPRESSOREN

F

O

R

Y

O

U

R

S

A

F

E

T

Y

Pharmacy Requirements.

Only the most appropriate

filter media of the highest

quality are used.

In the BAUER Testing- and

Research Centre the composi-

tion for the respective application is calculated, optimized

and extensively tested.

Those, who buy cheap, buy

expensive!

To achieve a germfree and

unsaturated condition, a fil-

ter cartridge can only be filled

under industrial production

conditions. The balance of

carbon and molecular sieve of

BAUER original cartridges is

adjusted perfectly.

Mechanical filling guaran-

tees exact dosing and piling

to create the perfect crossflow of the cartridge for opti-

mum air purification.

After filling the cartridges are

vaccuumized and the density is

checked.

Replacement cartridges

from uncontrolled sources

threaten your health not

only creating poor filter performance and icing of the breathing regulator, but also producing corrosion, which will

rapidly ruin the equipment.

Production- and material numbers

guarantee a perfect production control

The quality seal of an original BAUER

cartridge stands for purest breathing air

Final separator assembly at BAUER

Page 7

5

6

3

1

4

2

KOMPRESSOREN

KOMPRESSOREN

The compressed air

from the compressor block is

delivered to the final separator. The separator effectively

separates oil- and water droplets.

The condensate

The condensate from the oiland water droplets is collected

at the bottom of the filter

housing and is removed via

the condensate drain valve.

The pre-purified air

flows from the bottom of the

vessel through the molecular

sieve, which adsorbs the

remaining gaseous water. The

pores of the granules are

minute in diameter in order to

provide continuous filtration

and total removal of the water

Particle filter

holds all impurities and particles.

An activated carbon layer

for breathing air applications

removes all organic impurities

such as oil vapour and hydrocarbons.

Purest air or gas

leave the filter cartridge and

are ready for the application.

The pressure maintai-

ning valve

keeps the filter housing continuously under pressure to

increase the partial pressure on

the molecular sieve. So the

speed of the flow through the

cartridge is reduced, which

increases the purification effect

even more. Load cycles are

reduced, too - a positive effect

on the lifetime of the filter

housings and the operating

safety.

molecules.

The molecular sieve used by

BAUER matches perfectly the

granule and pore size for the

filter system. This is the only

way to comply with the strict

limiting values of breathing air

norms.

1

2

4

5

7

6

3

Page 8

THE BODYGUARD OF YOUR FILTER SYSTEM

SECURUS FILTER MONITORING

SECURUS is simple to

operate

Mobile units, and those of

the KAP/ VERTICUS-F-Range

have a control- and monitoring unit, which provides

information about the saturation status of the cartridge,

similar to a traffic light.

SECURUS protects

against damage:

All filter cartridges have a

limited life, which must be

monitored.

The patented SECURUS

system takes away from you

the important but annoying

responsibility of monitoring

the cartridge for the necessary timely replacement.

With SECURUS it is impossible to overuse the filter,

which would damage the

following system with oil

and water.

This can only be achieved

with a patented sensor technology, which is integrated

in the filter cartridge. The

integrated sensor indicates

the necessity for cartridge

change prematurely, warning in time about the

exhaustion of the cartridge

capacity and, finally switches

the compressor off.

Competitors systems, which

are available in the market,

which are fitted after the

purification system, provide

false safety!

They only warn the user

when it is too late: When

the cartridge is already

damaged and impurities

have occured.

SECURUS and B-Control:

full control - even online.

If the VERTICUS range is

equipped with the SECURUS

option, all messages are

shown on the display of

the electronic compressor

B-CONTROL.

Operators, who make use

of the new B-MESSENGER

can receive information via

SMS on their mobile telephone, via fax or even

online via email!

SECURUS helps to save

money:

The cartridge can be used

until complete saturation,

without any safety reserve.

Page 9

KOMPRESSOREN

with B-CONTROL compressor control

without B-CONTROL compressor control

GREEN

Cartridge has still sufficient

capacity.

YELLOW

Cartridge change will be required soon.

RED

The filter cartridge is saturated

and must be exchanged. In

this mode the compressor will

be automatically switched off.

SECURUS-System

Compressor units

KOMPRESSOREN

Page 10

FOR CUSTOM-MADE BREATHING AIR SUPPLY

BAUER STORAGE SYSTEMS AND FILLING PANELS

High pressure tanks ensure air is available at all times.

A perfectly designed storage solution adapted to the compressor guarantees constant

availability of breathing air, even in the case of a larger demand on short notice, inde-

pendent of whether the compressor is running.

Yet another advantage: The unit only switches on if the pressure in the tank drops below the

specified minimum value. Thanks to the low number of load cycles the durability of the

unit's components like the filter housing or final separator, are subject to pressure fluctuations, increase accordingly.

In the course of unit planning and consulting our service team will naturally calculate the

custom-made storage solution for your respective unit size and individual filling requirement.

Complete solution with storage tanks

Recommended HP Storage cylinder sizes taking into consideration 4 compressor

switch cycles per hour depending on compressor delivery and the different ON/OFF

switch differentials.

Vk (l/min = volume of flow/delivery of the

compressor in litres/min (F.A.D)

V

(l)

= storage volume in litres

(water capacity)

∆p (bar) = ON/OFF switch differential

(range of pressure fluctuation) in bar

Simplyfied formula for configuration of

high pressure storage systems taking into

consideration the compressor’s 4 switchon cycles per hour.

Free air

delivery

of compressor

[ l/min ] [ l ] Units x l [ l ] Units x l [ l ] Units x l [ l ] Units x l

For-

mulated

storage

cyl.size

Recom-

mended

storage

container

For-

mulated

storage

cyl.size

Recom-

mended

storage

container

For-

mulated

storage

cyl.size

Recom-

mended

storage

container

For-

mulated

storage

cyl.size

Recom-

mended

storage

container

referring to a pressure hysteresis of ∆p (bar)

20 bar

30 bar

40 bar

50 bar

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2500

3000

3500

4000

4500

5000

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

320

340

360

380

400

500

600

700

800

900

1000

1 x 50

1 x 50

1 x 50

2 x 50

2 x 50

3 x 50

3 x 50

3 x 50

4 x 50

4 x 50

4 x 50

5 x 50

5 x 50

6 x 50

6 x 50

6 x 50

7 x 50

7 x 50

8 x 50

8 x 50

10 x 50

12 x 50

14 x 50

16 x 50

18 x 50

20 x 50

1 x 50

1 x 50

1 x 50

1 x 50

2 x 50

2 x 50

2 x 50

2 x 50

3 x 50

3 x 50

3 x 50

3 x 50

4 x 50

4 x 50

4 x 50

4 x 50

4 x 50

5 x 50

5 x 50

5 x 50

7 x 50

8 x 50

9 x 50

11 x 50

12 x 50

13 x 50

1 x 50

1 x 50

1 x 50

1 x 50

1 x 50

1 x 50

2 x 50

2 x 50

2 x 50

2 x 50

2 x 50

3 x 50

3 x 50

3 x 50

3 x 50

3 x 50

3 x 50

4 x 50

4 x 50

4 x 50

5 x 50

6 x 50

7 x 50

8 x 50

9 x 50

10 x 50

1 x 50

1 x 50

1 x 50

1 x 50

1 x 50

1 x 50

1 x 50

1 x 50

2 x 50

2 x 50

2 x 50

2 x 50

2 x 50

2 x 50

3 x 50

3 x 50

3 x 50

3 x 50

3 x 50

3 x 50

4 x 50

5 x 50

6 x 50

6 x 50

7 x 50

8 x 50

13

27

40

53

67

80

93

107

120

133

147

160

173

187

200

213

227

240

253

267

333

400

467

533

600

667

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

250

300

350

400

450

500

8

16

24

32

40

48

56

64

72

80

88

96

104

112

120

128

136

144

152

160

200

240

280

320

360

400

Page 11

Filling panels - BAUER'S building block system for implementing the most divese

installation requirements and filling capacities

BAUER'S filling panels can be mounted on a wall, even physically apart in a separate room.

Numerous filling panels can be connected to each other in a row. In the case of a higher

filling demand, more filling panels can be mounted at a later date without any problem.

All filling panels are easy to install.

KOMPRESSORENKOMPRESSORENKOMPRESSORENKOMPRESSOREN

Example: filling panel with 10 filling hoses ( 4 x PN 200, 6 x PN 300 )

Example: filling panel with 4 filling hoses ( 2 x PN 200, 2 x PN 300 )

Our range of standard

filling panels:

4 xPN 200 connections

with 4 filling hoses or

4 direct connections.

4xPN 300 connections

with 4 filling hoses or

4 direct connections.

2xPN 200 connections +

2xPN 300 connections

with switch over

2xPN 200 connections +

2xPN 300 connections

with pressure reducer

Other equipment and versi-

ons on request!

Optional:

B-CONTROL

Operating panel for remote

compressor control.

Switch-over device

The air overflows directly

from the storage bank into

the high pressure tanks.

If the pressure needs to be

topped up, the compressor is

automatically switched on to

fill the tanks directly.

Only after having reached

the required bottle pressure

do the storage tanks get

refilled.

Page 12

KOMPRESSOREN

VERTICUS G-FW - E 5.05 3,0 St Subject to technical modifications

Weight

net

kg

4)

Dimensions

cm

L

W

H

Filter system

Motor

kW

HP

RPM

min

-1

2)

FAD

l/min

1)

Model

max.

330 bar

3)

Filling

time

min

Comp.-

stages

KAP 15.1-11-H

KAP 150-11-H

KAP 180-15-H

KAP 15.1-14-DAH

KAP 150-16-DAH

KAP 180-18-DAH

KAP 220 - 20 E

KAP 220 - 25 E

KAP 220 - 30 E

KAP 23 - 40 E

KAP 23 - 50 E

KAP 220 - 30 - 420

370

370

850

500

500

516

490

510

570

760

780

570

4

4

4

4

4

4

4

4

4

4

4

4

11

11

15

14

16

18

15

18,5

22

30

37

22

1320

1230

1400

1320

1230

1400

980

1180

1320

1200

1400

1180

450

540

680

450

540

680

650

800

950

880

15

15

20

19

22

24

20

25

30

40

50

30

KAP - DAH-Range

KAP - Range -220/23

165 78 90

165 78 90

148 83 152

V12.14-5.5-5

4)

V12.14-7.5-5

4)

V15.1-7.5-5

V15.1-11-5F

V15.1-11-5

4)

V18.1-11-5

V150-11-5

V18.1-15-5

V180-15-5

KAP 12.14-5.5-5

4)

KAP 12.14-7.5-5

4)

KAP 15.1-7.5-5

KAP 15.1-11-5F

KAP 15.1-11-5

4)

KAP18.1-11-5

KAP 150-11-5

KAP18.1-15-5

KAP 180-15-5

395

400

430

340

440

455

440

465

455

305

310

340

340

350

365

350

375

365

4

4

4

4

4

5

4

5

4

4

4

4

4

4

5

4

5

4

5,5

7,5

7,5

11

11

11

11

15

15

5,5

7,5

7,5

11

11

11

11

15

15

1185

1470

1050

1320

1320

1140

1230

1320

1400

1185

1470

1050

1320

1320

1140

1230

1320

1400

260

320

370

450

450

520

540

600

680

260

320

370

450

450

520

540

600

680

7,5

10

10

15

15

15

15

20

20

7,5

10

10

15

15

15

15

20

20

VERTICUS 5 - Range

KAP - Range

KAP H - Range

114 83 152

P61

or

P81

P41

P61

or

P81

P61

or

P81

P41

P61

or

P81

420 bar

420 bar

420 bar

1300

1480

0,44

0,37

0,29

0,44

0,37

0,29

0,31

0,25

0,21

0,15

0,14

0,25

0,77

0,63

0,54

0,44

0,44

0,38

0,37

0,33

0,29

0,77

0,63

0,54

0,44

0,44

0,38

0,37

0,33

0,29

P120

P100

P80

P80

P100-420

P61

oder

P81

P61

P61

P81

P120

214 72 132

226 87 132

214 72 132

TECHNICAL DATA

BAUER KOMPRESSOREN GmbH

P.O.BOX 710260 .D-81452 MÜNCHEN

DRYGALSKI-ALLEE 37 . D-81477 MÜNCHEN

PHONE 0049 89 78049-0

FAX 0049 89 78049-167

Internet: www.bauer-kompressoren.de

e-mail: info@bauer-kompressoren.de

1)

also available with switch over device

330 / 225 bar = HU type

2)

Cylinder filling from 0 to 200 bar

3)

Filling rate for 1 l cylinder capacity from 0 to 200 bar

4)

KAP 220/23 without filter system

Loading...

Loading...