Page 1

200MC/400MC

R

E

A

D

Y

M

O

T

O

R

C

Y

C

L

E

Rim Clamp® Tire Changer

For servicing motorcycle and ATV tire/wheel assemblies.

This is a supplement to your operating manual and covers additional

operational procedures available for this model. If you do not have your

original operating manual, please call COATS at 1-800-688-6359 to

request an additional copy.

Operation Instructions

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for ease

of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688/6359 www.ammcoats.com Manual Part No.: 85608968 00

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS® and BADA® Automotive Service Equipment and Tools. Revision: 07/13

Page 2

2 • BaseLine

Page 3

Operating Instructions

Motorcycle

ATV

Motorcycle

ATV

The unit must be properly operated and properly maintained to help avoid accidents that could damage the

unit and injure the operator or bystanders. This section

of the Operating Instructions manual review basic operations and use of controls. These instructions should be

reviewed with all employees before they are allowed to

work with the machine. Keep these instructions near

the machine for easy reference.

Tire Bead Loosening and Demounting

necessary to reinflate to 5 PSI to loosen the opposite

bead.

NOTE: Always loosen the bead on the narrow side of

the wheel’s drop center first (motorcycle wheels may

not have a narrow or long side, and some ATV wheels

may bolt together). See Figure 4 for more information

on the drop center.

REMEMBER: The clamps on the table top may extend

beyond the table top itself. To avoid damaging the

clamps, move them to their full inward position before

positioning a tire for bead loosening.

CAUTION

This machine may operate differently from

machines you have previously operated.

Practice with a regular steel wheel and tire

combination to familiarize yourself with the

machine’s operation and function.

Remember to remove all weights from both sides

of the wheel. Weights left on back side of wheel may

cause the wheel to be clamped unlevel. This may result

in the combination mount/demount tool contacting the

rim causing scratches. On alloy wheels, always rotate

the wheel one turn after setting the tool to insure proper

wheel chucking.

NOTE: Always review nicks and scratches with owners of expensive wheel and tire combinations prior to

servicing.

IMPORTANT: Review the performance wheel section

of this manual prior to servicing performance tire/wheel

combinations.

1. Deflate tire completely by removing the valve core

from the valve stem (Figure 1).

NOTE: Use extra care in positioning the bead loosener

shoe on larger wheels/tires, and on alloy wheels. Make

sure the shoe rests next to but not on the rim, and not

on the tire sidewall.

2. Pull the bead loosener shoe away from the machine

and roll wheel into position. The valve stem should be in

the 3 o’clock position. Position the bead loosener shoe

against the tire next to, but not on, the rim. Depress the

bead loosener foot pedal to actuate the shoe and loosen

the bead. It may be necessary to loosen the bead in

multiple locations around the tire (Figure 2).

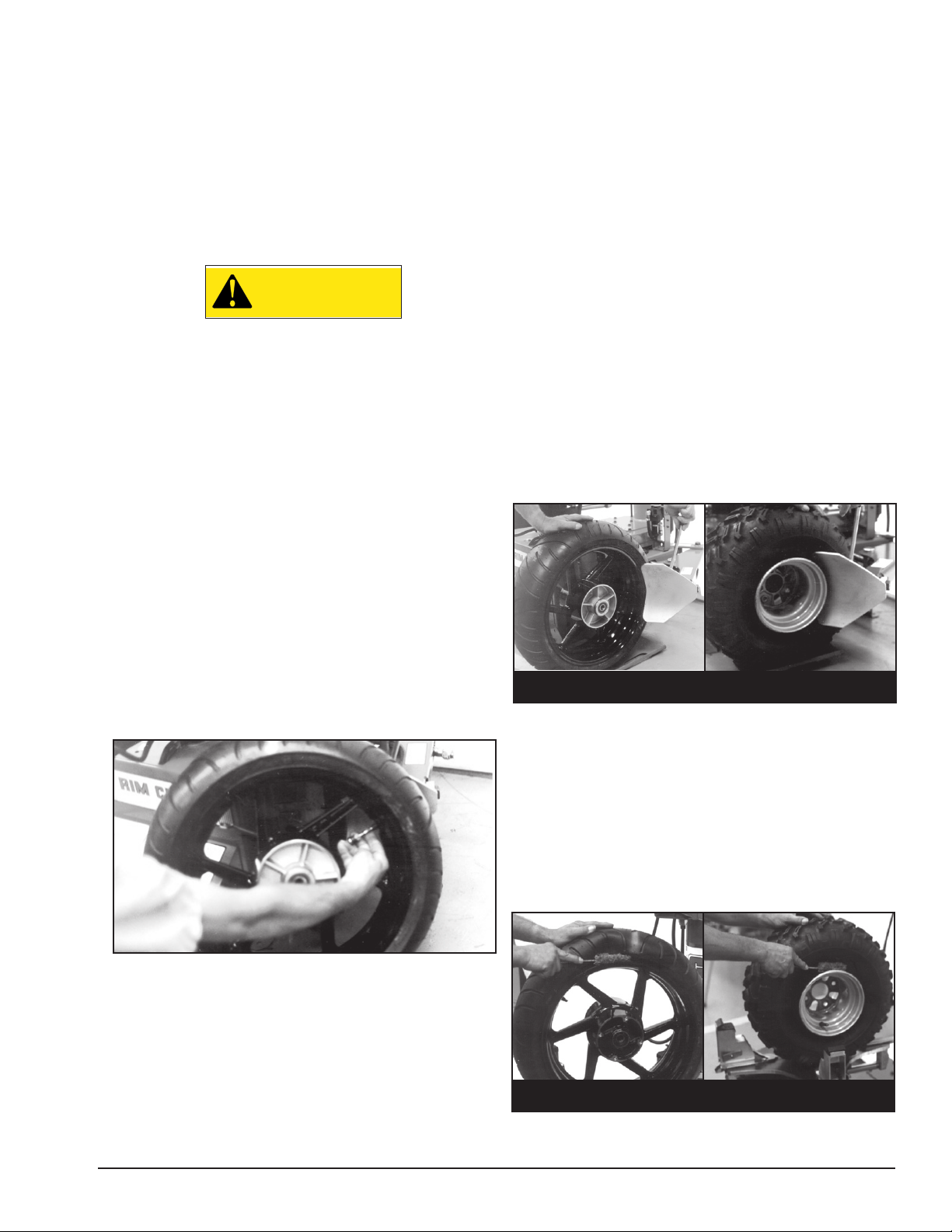

Motorcycle

Figure 2 - Position Tire and Bead Loosener Shoe

3. Turn wheel around and repeat loosening procedure

on the other side of the wheel. This should be the long

side of the drop center.

ATV

TIP: It will be easier to clamp the wheel to the table

top if the lower bead is loosened last.

4. Apply tire manufacturer’s approved rubber lubricant

liberally to entire circumference of both tire beads after

loosening.

Figure 1 - Remove Valve Core to Deflate Tire

NOTE: Loosening the beads on a fully inflated tire

is unsafe and causes excess movement and friction

against the bumper pads and excessive wear on pivots.

Deflate the tire completely to prolong the life of your

machine.

ATV NOTE: It may be necessary on ATV wheels to

leave 3-6 PSI in some of these wheels to facilitate bead

loosening. Even after loosening one bead; it may be

Motorcycle

Figure 3 - Apply Rubber Lubricant to Tire Beads

ATV

BaseLine • 3

Page 4

5a. Prior to placing the wheel on the table top to

Motorcycle

ATV

Motorcycle

ATV

clamp, observe the style and strength of the wheel

and adjust the clamp pressure as necessary using the

pressure regulator and gauge. Thin spun aluminum rims

sometimes used on ATV and motorcycle are sometimes delicate and a reduced air pressure should be

considered verses cast aluminum and steel wheels that

can support more clamping force.

5b. Next, observe the rim size from the tire, i.e. 15,

16, 17, etc. Using the clamp pedal, place the clamp valve

in the JOG IN position for prelocating the clamps to

the rim diameter. Accomplish this by moving the pedal

from the UP position to the 1/2-DOWN location. Then

JOG the pedal DOWN allowing the clamps to move

inward until the pointer on the clamps align with the rim

diameter on the table top decal. It may be necessary to

relocate the clamps on the clamp carriers. Each clamp

should be in the same position before prelocating the

clamps.

5c. Determine the mounting side of the wheel. The

mounting side is the narrow side of the drop center.

(Tire removed in Figure 4 for clarity.)

Narrow Side

Drop Center

7. Move the swing arm into position. Pull the locking handle forward to release the slide. Push down

on the top of the vertical slide to move the demount

tool into contact with the

rim edge. Push the locking handle back to lock the

slide into place. As the

slide is locked, the mount/

demount tool will move

upward approximately 1/8

inch from the rim edge.

Note: On plastic mount/

demount tool, the upward

movement should be

limited to 1/16-inch maximum.

Figure 6 - Position Mount/Demount Tool

8. The mount/demount tool roller should be in contact

with the rim edge. Turn the swing arm adjusting knob

to move the tool away from the rim 1/8 to 1/4 inch.

On expensive and polished rims, it is recommended a

plastic bootie (p/n 8183373) be used over the mount/

demount tool roller.

Long Side

Motorcycle

Figure 4 - Determining Mounting Side of Wheel

ATV

6. Place tire/wheel assembly on table top with mounting side up (Figure 5). Use the clamp control pedal to

move the clamps inwards (push pedal down) or outwards (toggle pedal up). Clamp motorcycle and ATV

wheels from the outside (clamps push inwards against

the outside rim edge). Place rim flange into rear clamp

and slowly move the other clamps inward until they

contact the rim. Observe closely to prevent tire/wheel

damage.

Figure 7 - Adjust Swing Arm to Position Tool Roller

9. Check tool positioning. Mount/demount tool should

be positioned with 1/8 to 3/16” clearance between the

top of the rim edge and the bottom of the tool (with

plastic mount/demount tool it is recommended the vertical clearance be limited to a maximum of 1/16-inch),

and 1/8 to 1/4 inch clearance between the rim edge and

the tool. This clearance will be maintained as long as the

locking handle and adjustment knob are not changed.

The operator may swing the arm out of the way and

back into place again without needing to reposition the

tool (when changing a set of the same wheels).

Motorcycle

Figure 5 - Place Tire/Wheel Assembly on Table Top

ATV

4 • BaseLine

Page 5

NOTE: Push down on the tire across from the demount

Motorcycle

ATV

Motorcycle

ATV

Motorcycle

ATV

tool during table top rotation to utilize the drop center

area of the wheel. This reduces the tensional force on

the bead during demount.

1/8" to 3/16"

1/8" to 1/4"

Figure 8 - Proper Mount/Demount Tool Position

IMPORTANT: The vertical tool clearance may change

with machine use and should be inspected often. Failure to maintain the proper clearance may result in damage to the wheel rim and/or tire.

10. Insert the smooth curved end of the bead lifting tool over the forward end of the demount tool and

below the top bead of the tire. Use your free hand to

press down on the tire opposite the tool to help with

tool insertion (Figure 9).

13. Lift and hold the tire at an angle so that the lower

bead is resting in the drop center directly across from

the demount tool, and is loose below the demount tool

(Figure 11). Insert the smooth curved end of the bead

lifting tool down over the forward end of the mount/

demount tool and below the lower bead. Lift the bead

up and over the knob on the demount tool (Figure 11).

Motorcycle

Figure 11 - Demounting Lower Bead

14. Depress the table top pedal to rotate the wheel.

The demount tool will guide the bead up and over the

edge of the wheel. Continue rotation until lower bead

is demounted.

ATV

Motorcycle

Figure 9 - Insert Bead Lifting Tool

11. Rotate the bead lifting tool down towards the

wheel to lift the tire bead up and over the knob portion

of the demount tool. The tool may be removed if desired

(Figure 10).

Motorcycle

Figure 10 - Lift Bead Over Demount Tool

12. Depress the table top pedal to rotate the wheel

clockwise. The demount tool will guide the upper bead

up and over the edge of the wheel.

ATV

ATV

NOTE: With tube-type tires, demount the upper bead

and remove the tube before demounting the lower

bead.

NOTE: Table top rotation can be stopped at any time

by removing your foot from the pedal.

NOTE: Normal table top rotation for demounting is

clockwise. Depress the table top pedal to rotate this

direction. To rotate the table top counterclockwise, lift

the pedal up with your toe.

CAUTION

At times during the mounting and demounting procedure, the bead lifting tool may

encounter resistance or come under load.

Keep one hand firmly on the tool to avoid

possible tool disconnect. Use the reversing

feature to back out or jam ups.

BaseLine • 5

Page 6

Tire Mounting

Motorcycle

ATV

Motorcycle

ATV

This information must be read and followed carefully

to prevent accidents and injuries during mounting.

WARNING

Check tire and wheel carefully before

mounting. Make sure the tire bead diameter

and wheel diameter match exactly. Consult the Rubber Manufacturer’s Association

for approved rim widths for tire sizes. Mismatched tires and wheels explode.

CAUTION

2. Inspect tire for damage, paying close attention to

the beads. Verify size match between tire and wheel

(Figure 12).

3. Lubricate tire beads liberally with tire manufacturer

approved lubricant (Figure 13).

Never Mount a tire and wheel handed to

you by anyone without checking both tire

and wheel for damage and compatibility. Be

extra cautious of persons without knowledge of tire service. Keep by-standers out of

service area.

WARNING

Never mount a damaged tire. Never mount a

tire on a rusty or damaged wheel. Damaged

tires and/or wheels may explode.

CAUTION

If you damage the tire bead during mounting, STOP!, remove the tire and mark it as

damaged. Do not mount a damaged tire.

1. Inspect the wheel closely for damage. Clean the

wheel and remove any light corrosion or rubber residue

(Figure 12). Do not attempt to service heavily corroded

wheels.

Figure 13 - Lubricate Beads

4. Place tire over wheel and move swing arm into

position. Position the tire so that the lower bead is

above the rear extension of the mount/demount tool

and below the front knob (Figure 14).

Motorcycle

Figure 14 - Position Tire Against Mount/Demount Tool

5. Depress table top pedal and rotate the wheel to

mount the lower bead. Use the drop center of the wheel

to reduce the tensional force on the bead by pressing

down on the tire directly across from the mount tool.

Rotate table top until lower bead is fully mounted.

6. For top bead, rotate the table top until the valve

stem is directly across from the mount tool. Lift the

upper bead up and over the rear of the mount tool.

With your left hand press down on the tire between the

mount tool and the valve stem to hold the tire in the

drop center. Depress the table top pedal and rotate the

tire until the bead is mounted. Continue to press down

on the tire during the remaining mounting process.

ATV

Motorcycle

Figure 12 - Inspect and Clean the Wheel

ATV

6 • BaseLine

Page 7

WARNING

Do not force the tire onto the rim. Bead damage could result making the tire unsafe and/

or creating the risk of injury.

NOTE: If table top rotation stalls, reverse the table top

momentarily until the tire bead is again loose on the

wheel. Reposition the mount tool, make sure the bead

is correctly positioned in the drop center of the wheel,

then attempt mounting again.

NOTE: For low profile or stiff sidewall tires, it may be

advantageous to use the bead lifting tool to initially hold

the upper bead down in the drop center, or use drop

center tools.

NOTE: For tube type tires, mount the lower bead first,

move swing arm out, install the tube, and then mount

the upper bead.

BaseLine • 7

Page 8

85608968 00 07/13 © Copyright 2013 Hennessy Industries and COATS All Rights Reserved

Loading...

Loading...