Page 1

1

6,000 lb. ( 2721 kg ) Portable MID RISE

READ the Manual Thoroughly Before Installing,

Operating, Servicing, or Maintaining the Lift

SAVE this MANUAL and ALL INSTRUCTIONS

Model: BLMR06

1601 J.P. Hennessy Drive

La Vergne, TN 37086

Tel. (800) 688-6359

Page 2

2

Lift Purchase Buyers Agreement

Warranty

Each product comes with a two (2) year parts warranty with five (5) years warranty on the

structure. The parts warranty is limited to defects in workmanship and material. The warranty

does not cover misuse, abuse, overloading, lack of maintenance, and inappropriate use or

“normal wear and tear”. Warranty parts must be returned to manufacturer for inspection to

qualify for warranty. Shipping costs are the owner’s responsibility.

Freight Damage

Each lifting product is carefully inspected before being loaded by our shipping department. Any

damage to the product must be noted on the shipping companies “bill of lading” and signed by

the driver. It is the owner’s responsibility to advice manufacturer within 48 business hours, of

any shipping damage.

Installation

At the purchase request, delivery and installation can be arranged by a professional contractor.

It is the owner’s responsibility to approve the completion of the work done and that the product

is working properly. If there is a dispute with the work being done the owner must advise our

office within 24 business hours.

Lift Maintenance

Every lifting product will require ongoing adjustment and maintenance. It is normal that the lifting

cables will require adjustment to ensure that the lift operates level. Periodic adjustments are the

owner’s responsibility. If the owner requires the assistance of a lift technician, a service charge

will be paid directly for a service call. The lift is manufactured with a baked on power coat finish.

It is recommended to maintain this finish that scratches are periodically touched up with

automotive style paint. All non-painted services should be kept clean and lubricated to prevent

rust or corrosion.

Service Calls

Onsite service of your lifting product can be arranged by a qualified lift service technician. The

owner will be responsible for paying the contractor directly for this service at the time the work is

completed. It is the owner’s responsibility to return any parts to manufacturer for warranty

consideration.

Page 3

3

Your new lift will provide years of dependable service if installed, operated and maintained

properly. Read and follow all safety, installation, operation, and maintenance instructions in this

manual before installing and operating the lift. In addition, read and follow all safety and other

information included on and with the lift before operating the lift. Keep this manual in a secure

place for future reference, training and service part identification.

TABLE of CONTENTS

1. Unloading Procedure & Lift Package Contents page 4

2. Important Safety Instructions page 5

3. General Requirements & Lift Specifications page 7

4. Installation And Operation Instructions page 8

5. Troubleshooting page 20

6. Lift Installation Diagrams & Parts Lists page 22

IMPORTANT: It is the shop owner's responsibility to provide a satisfactory installation area

for the lift. Lifts should only be installed indoors on level concrete floors with a minimum of 4

inches (102mm) and 3000 psi (20.7MPa) concrete that has been aged a minimum of 30 days.

Please consult a qualified individual if any doubt exists concerning proper installation and

subsequent safe operation of the lift. Do not install the lift on asphalt or outdoors.

Prior to installation, it is the shop owner's responsibility to provide constant electrical power in

the correct voltage, phase, etc., and all wiring for electrical hook-up of the lift. The shop owner

must insure that the electrical installation conforms to local building and safety codes. Where

required, the shop owner will provide an electrical isolation switch located in close proximity to

the lift. This switch will have an emergency stop capability and isolate electrical power from the

lift for servicing requirements.

Hydraulic oil cannot be shipped with the lift and will be supplied by either the shop owner or the

installer. ISO 32 hydraulic oil (10W non detergent hydraulic oil) must be used to fill the

reservoir tank before operating the lift.

It is the shop owner's responsibility to train all operators in lift

operation and safety.

Page 4

4

1. UNLOADING PROCEDURE and LIFT PACKAGE CONTENTS

For your information:

All lift components are grouped together in one package held at each end by steel frames.

Unpacking Procedure:

When the lift arrives on site:

If possible have the lift unloaded in the installation area.

Check for freight damage and report immediately to the trucking company who delivered

the lift.

Check for missing parts and report immediately to the factory.

Main Components include:

Lift Assembly – 1pc

Powerpack Assembly – 1 pc

Accessory and Hardware Box includes:

Rubber Stack Lifting Pad Assembly – 4 pc

Lifting Adapters – 4 pc

Extended Lifting Adapters – 4 pc

Hydraulic Hose w/ Fittings – 1pc

Hardware Box

Owner’s Manual

Page 5

5

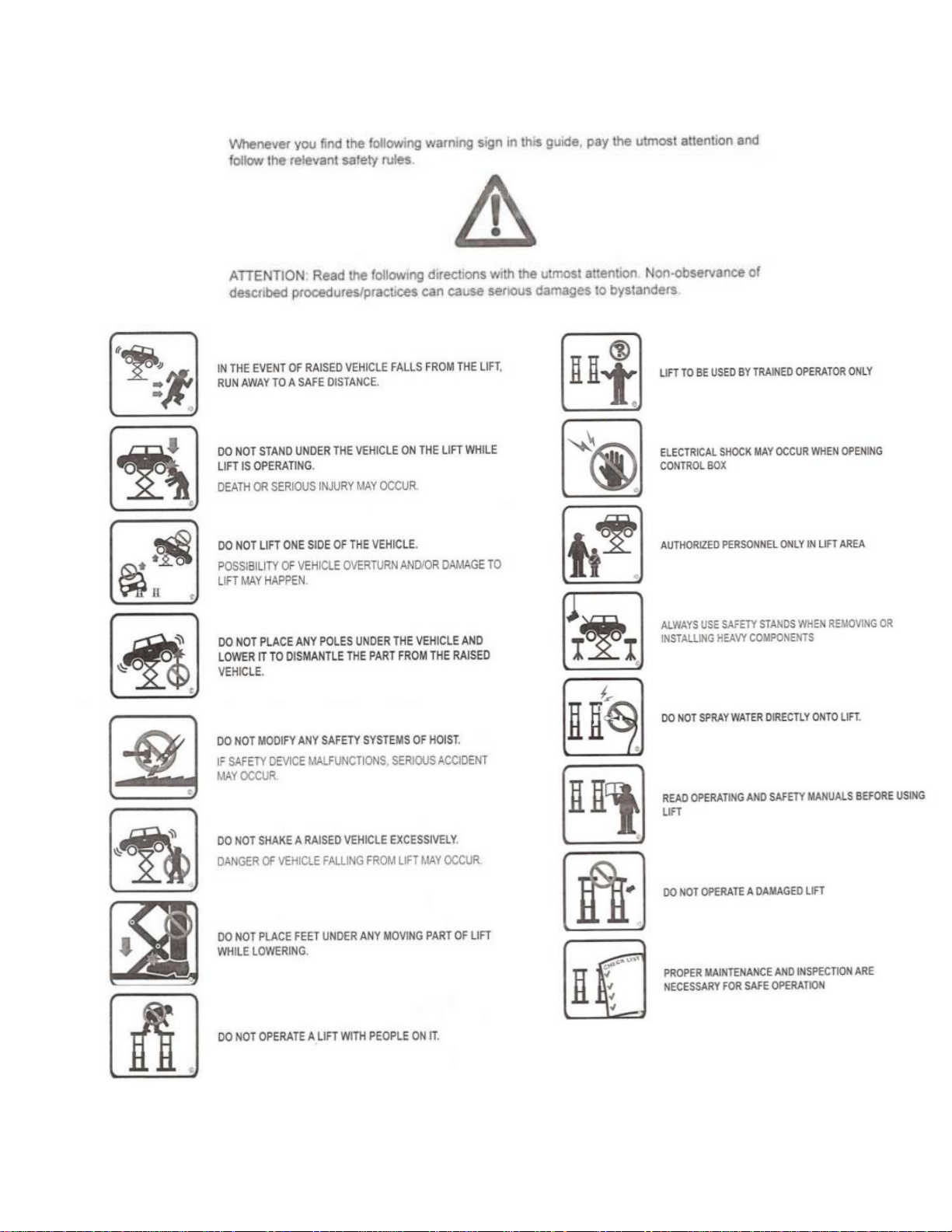

2. IMPORTANT SAFETY INSTRUCTIONS

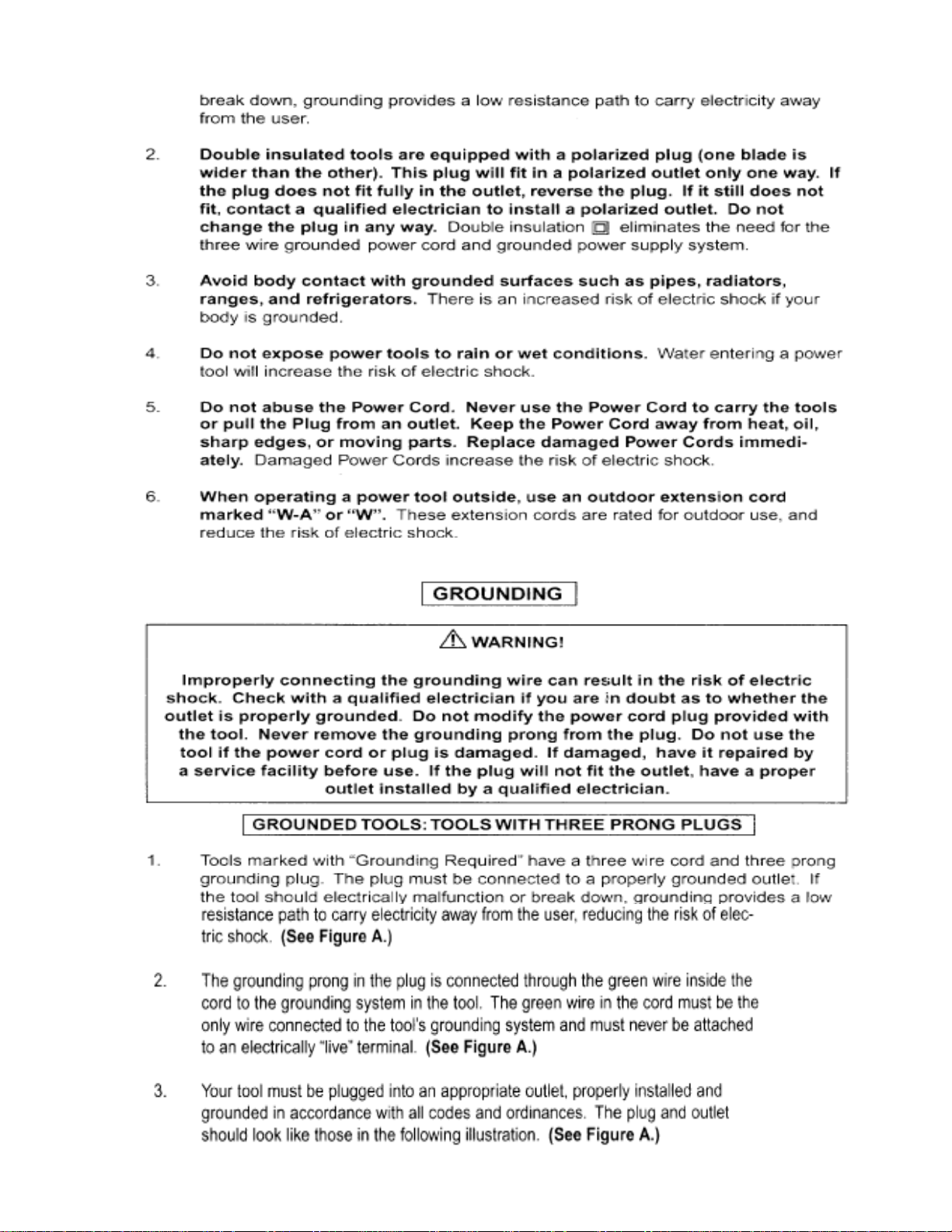

When using your garage equipment, basic safety precautions should always be followed,

including the following:

1. Read all instructions

2. Do not operate equipment with a damaged cord or if equipment has been dropped or

damaged – until it has been examined by a qualified service person

3. To reduce risk of fire, do not operate equipment in the vicinity of open containers of

flammable liquids (gasoline)

4. Adequate ventilation should be provided when working on operating internal combustion

engines

5. Keep hair, loose clothing, fingers, and all parts of body away from moving parts

6. To reduce the risk of electric shock, do not use on wet surfaces or expose to rain

7. Use only as directed in this manual. Use only manufacturer’s recommended attachments

8. ALWAYS WEAR SAFETY GLASSES. Everyday eyeglasses only have impact resistant lenses,

they are not safety glasses

Basic common sense safety precautions should always be followed when installing, operating

and maintaining the lift as a risk of fire, electric shock, injury or death may be present.

In addition:

1. Only trained and authorized personnel should position a vehicle and operate the lift.

2. Inspect the lift daily. Do not operate if potential problems have been identified or lift

malfunctions. Do not operate if lift has damaged or broken components. Never walk or

work under the lift unless all safety locks are completely engaged.

3. Never overload the lift. The hydraulic system on this lift is not designed to be a load

holding device. Mechanical safety locks must be engaged before proceeding under the lift

for vehicle servicing or lift maintenance. Never override operating controls. This is unsafe

and will void the warranty.

4. Before driving a vehicle onto the lift, insure that the lift and lift area is clear of all debris

and that all oil and grease has been cleaned from runway surfaces.

5. Always chock wheels and set parking brake before lifting vehicle.

6. When using a jack(s) to raise a vehicle, position jack lifting pads to contact vehicle

manufacturers recommended lifting points. Raise jack slowly until all pads contact the

vehicle. Confirm that the vehicle is stable on the jack(s) before raising to desired working

height.

7. Important: Removal or installation of heavier parts can change the vehicle's center of

gravity on the jack(s) resulting in a critical load shift. The vehicle may then be unstable.

Plan ahead for this possibility to insure continued safety and refer to the vehicle

manufacturer’s service manual for recommended procedures.

8. Always keep the lift area free of obstructions and debris. Grease and oil spills should be

cleaned up immediately.

9. Never raise a vehicle on the lift with passengers inside. Before lowering, check the lift

Page 6

6

and lift area and remove all obstructions. Before removing vehicle from the lift or lift

area, confirm an unobstructed exit.

10. DO NOT PERFORM ANY MAINTENANCE OR INSTALLATION OF ANY COMPONENTS WITH

OUT FIRST ENSURING THAT ELECTRICAL POWER HAS BEEN DISCONNECTED AT THE

SOURCE OR PANEL AND CANNOT BE RE-ENERGIZED UNTIL ALL MAINTENANCE AND/OR

INSTALLATION PROCEDURES ARE COMPLETED (ANSI 244.1).

SAVE THESE INSTRUCTIONS

Page 7

7

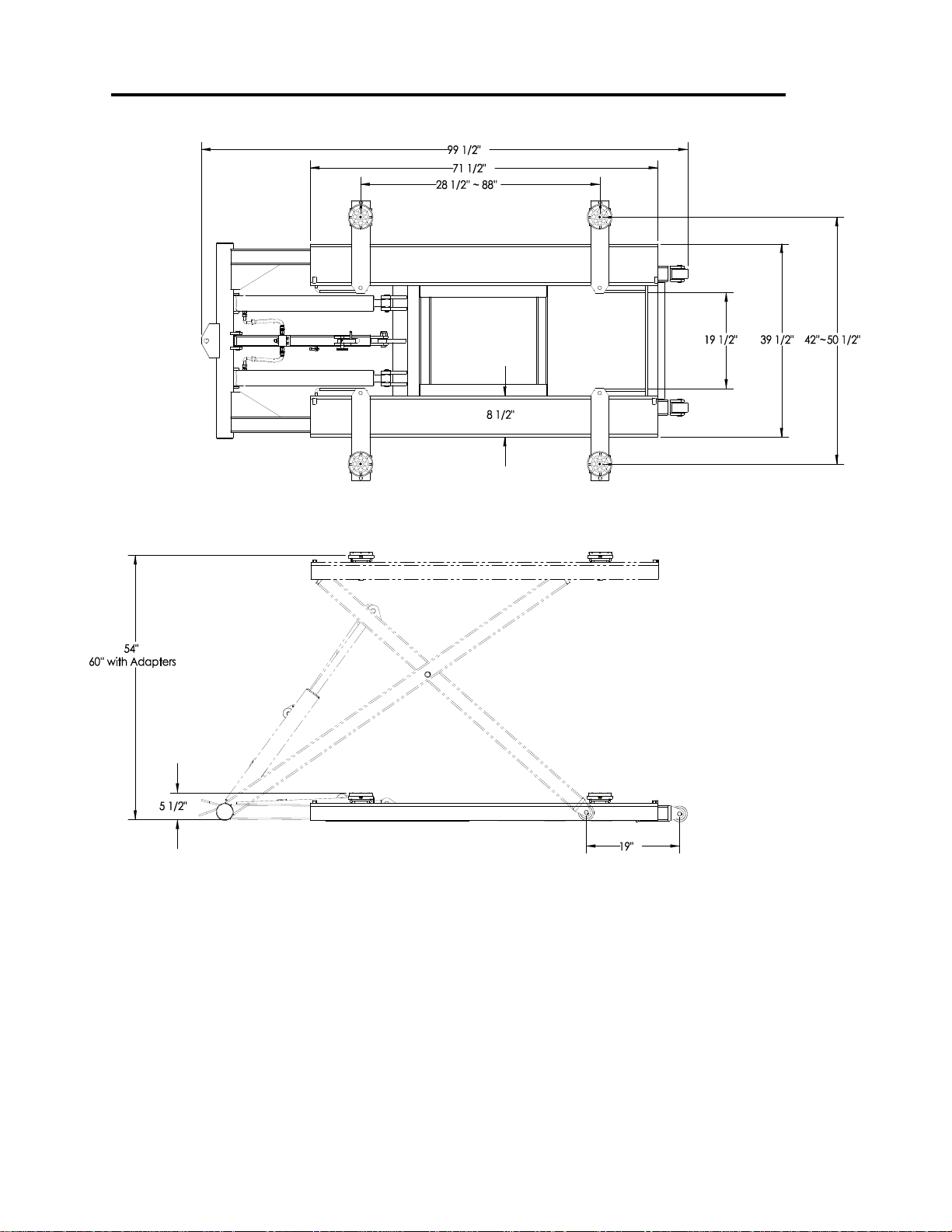

3. GENERAL REQUIREMENTS & LIFT SPECIFICATIONS

6,000 (2727 kg) Capacity – 1,500 lbs. Each Lifting Pad

Constant supply of 220V or 110V 1PH 60Hz 20A

electrical power is required for this lift.

Page 8

8

Page 9

9

Page 10

10

Page 11

11

Page 12

12

Page 13

13

Page 14

14

Page 15

15

Page 16

16

Page 17

17

Page 18

18

Page 19

19

Page 20

20

LIFT PROBLEM TROUBLESHOOTING GUIDE

Problem

Possible Causes

Solutions

Lift Will

Not Raise

or Lower

1. Blown fuse or circuit breaker

2. Incorrect voltage to motor

3. Bad wiring connections

4. "UP" switch burned out

5. Motor windings burned out

1. Replace fuse or reset/replace circuit breaker

2. Supply correct voltage to motor

3. Repair and insulate all connections

4. Replace switch

5. Replace motor

Lift Will

Not Raise

1. Air in oil or low oil level

2. Lowering Valve leaks

3. Motor runs backward

4. Pump damaged

5. Pump will not prime

6. Relief Valve leaks

7. Voltage to motor incorrect

8. Lift overloaded

1. Check fluid level, oil seal, bleed system

2. Clean valve or replace

3. Check for correct wiring

4. Repair of replace pump

5. Check fluid level and pick-up tube; replace

pump

6. Clean Relief Valve (replace if necessary)

7. Supply correct voltage to motor

8. Verify that loaded vehicle weight does not

exceed rated lift capacity

Lift Will

Not Lower

1. Mechanical locks are engaged

2. Obstruction under lift or in glide

block tracks

3. Faulty lowering valve

1. Raise unit slightly and disengage mechanical

locks

2. Carefully remove obstruction - clean glide block

tracks

3. Replace valve

Lift Will

Not Hold

Pressure

1. Contamination in system

2. Internal Cylinder leaks

3. Lowering Valve leaks

4. Check Valve leaks

5. External leaks

1. Check oil level, bleed cylinders, remove

Contamination, replace oil seal

2. Check fitting, replace cylinder

3. Contaminated fluid, handle binds, clean valves

4. Clean check valve (replace if necessary)

5. Check all fittings and repair leaks

Lift Will

Not Raise

A Vehicle

1. Low hydraulic fluid

2.Malfunction of pressure relief valve

3. Insufficient electrical voltage

4. Lift overload

5. Motor is running backwards

6. Air in hydraulic oil

7. Pump will not prime

8. Pump is damaged

9. Faulty lowering valve

1. Lower lift. Using ISO grade 32 hydraulic oil, fill

the powerpack reservoir to 1" below the top

2. Clean pressure relief valve. if problem

continues, call a service technician

3. Confirm a 208/230 volt power supply to the lift

4. Check that vehicle weight is evenly distributed

And does not exceed rated capacity.

5. Confirm proper motor rotation - rewire if

required

6. Check oil seal and bleed hydraulic system

7. Check hydraulic oil level and pick-up tube.

Replace pump if required

8. Repair or replace pump

9. Clean or replace valve

The following are some suggestions to consider if problems are encountered with the lift. Please

call a Trained Lift Service Person for further clarification and information.

Page 21

21

Problem

Possible Causes

Solutions

Slow Drift

Down

1. Mechanical safety locks not

engaged

2. Powerpack lowering valve

contamination

3. Hydraulic system leaks

1. Raise lift to engage all safety locks then lower

lift and confirm all safety locks are engaged

2. Back flush powerpack by opening manual

over-right valve. Engage "up" switch and down

lever at the same time and run approximately

10 seconds

3. Check cylinder and all fittings for any hydraulic

oil leak

Replace all worn or broken parts and components only with

manufacturer approved/supplied parts and components

Replacement parts may be purchased from your local lift supplier or the

manufacturer at 1 - 800 - 688 - 6359

Page 22

22

for installation & service part reference

SAVE this MANUAL and ALL INSTRUCTIONS

6,000 lb. ( 2721 kg ) Portable MID RISE

Model: BLMR06

1601 J.P. Hennessy Drive

La Vergne, TN 37086

Tel. (800) 688-6359

Page 23

23

Page 24

24

Loading...

Loading...