Bartscher 150.5011, 150.9511, 150.9751, 150.9701 Instruction Manual

INSTRUCTION MANUAL

ENGLISH

150.5011

150.9511

150.9701

150.9751

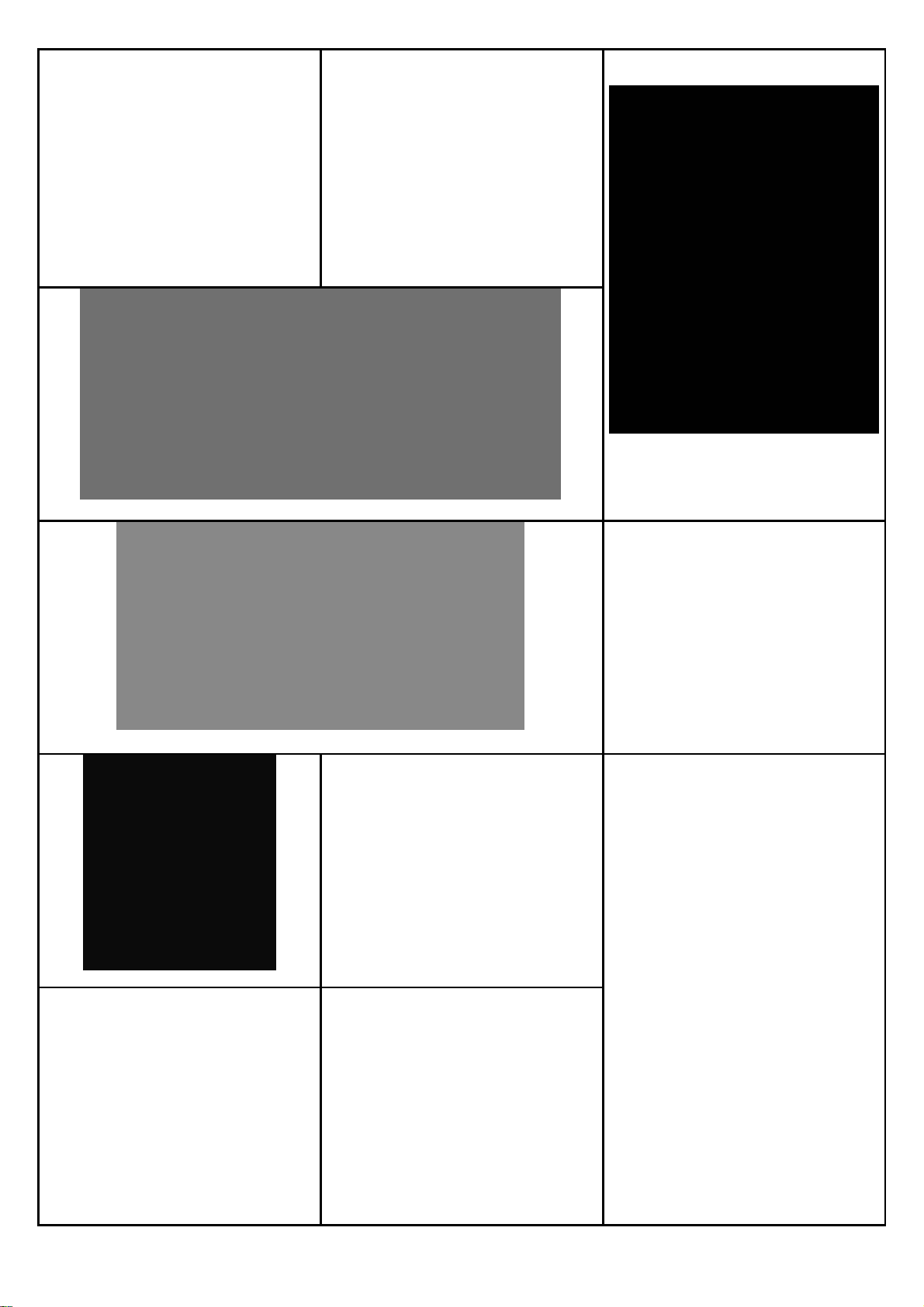

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 7

Fig. 5

Fig. 6

Fig. 8

Fig. 9

Fig. 10

- 2 -

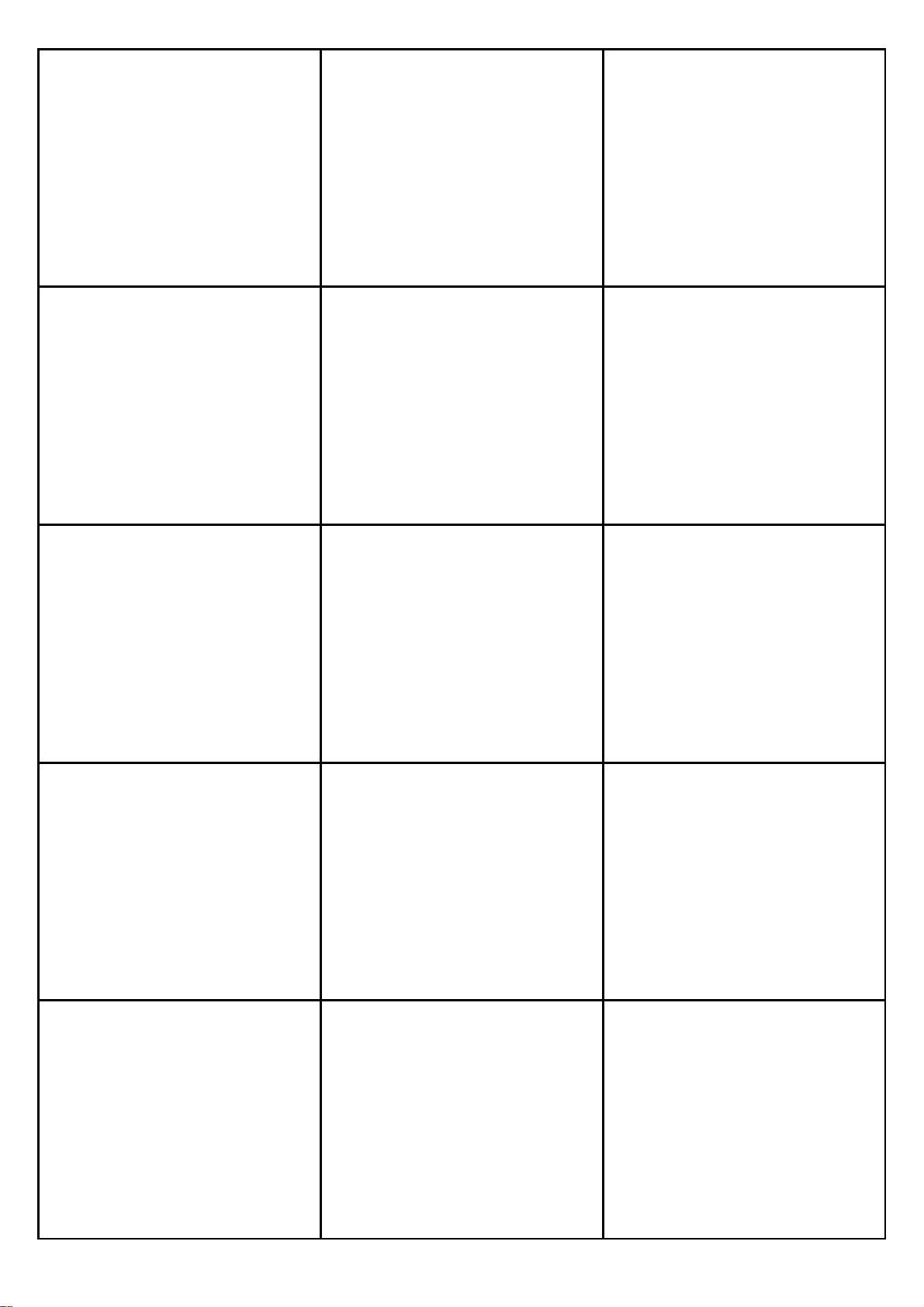

Fig. 11

Fig. 12 Fig. 13 Fig. 14

Fig. 15 Fig. 16

Fig. 18 Fig. 19

Fig. 17

Fig. 20

Fig. 21 Fig. 22 Fig. 23

Fig. 24

- 3 -

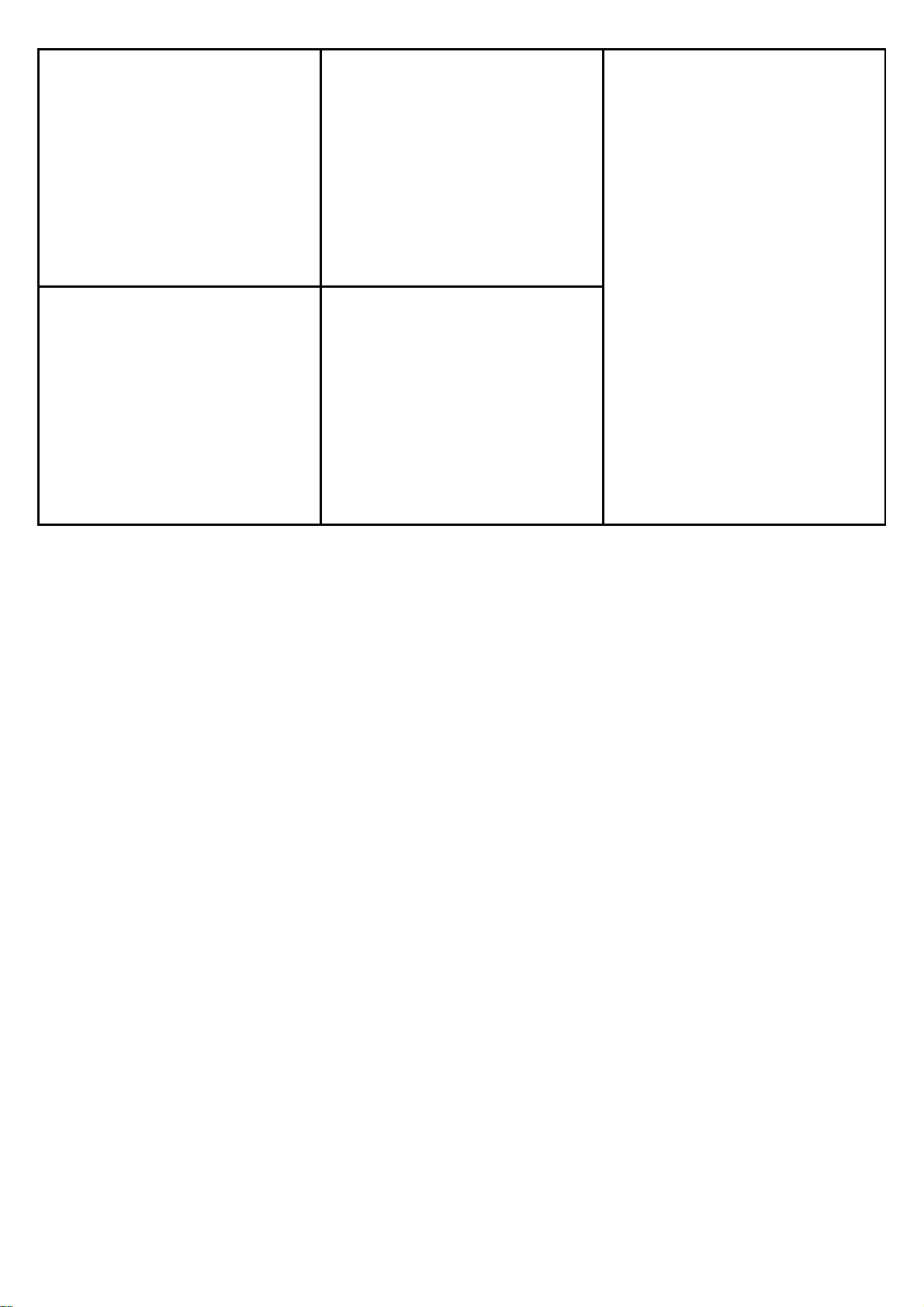

Fig. 25 Fig. 26

Fig. 27 Fig. 28

Fig. 30 Fig. 31

Fig. 29

- 4 -

IMPORTANT

CAREFULLY READ THE INSTRUCTIONS CONTAINED IN THIS HANDBOOK AS THEY PROVIDE IMPORTANT INFORMATION

CONCERNING SAFETY, USE AND MAINTENANCE OF THE APPLIANCE.

This instruction handbook is provided for various cooker models. There may be descriptions of functions or parts that do not refer to the

appliance in use.

This appliance is designed and built for domestic use. Any other use is to be considered improper and therefore dangerous. The appliance must not be used by children or unqualified persons without supervision. DO NOT USE THE APPLIANCE TO HEAT THE

ROOM. The manufacturer declines any liability for damage due to improper or incorrect use.

IN CASE OF A FAULT AND/OR MALFUNCTIONING OF THE APPLIANCE, CLOSE THE MAIN GAS COCK, DISCONNECT IT

FROM THE POWER SUPPLY, DO NOT TAMPER WITH IT, AND IMMEDIATELY CONTACT THE LOCAL AUTHORISED

ASSISTANCE CENTRE (SEE THE ATTACHED INDICATIONS).

THIS APPLIANCE COMPLIES WITH THE FOLLOWING EC DIRECTIVES AND REGULATIONS:

73/23/EEC 93/68/EEC (Low Voltage); 89/336/EEC (Electromagnetic Compatibility); 90/336/EEC (Gas); 2002/40/EC (Energy consumption of electric ovens); 2002/96/EC (EEEW),1935/2004/EC (Materials in contact with food).

The manufacturer declines any liability in case of non-compliance with what is specified in this information handbook.

The manufacturer reserves the right to modify the technical characteristics of the products, in any case respecting their safety and functionality.

INSTRUCTIONS AND NOTES ON SAFETY

Installation must be carried out by qualified personnel.

It is advisable to close the main gas cock after doing any cooking.

DOMESTIC SAFETY. During cooker use, the burners and electric hot-plates of the top, oven and grill become very hot. Do not allow

children to stand or play in the immediate vicinity.

GLASS LID (fig. 1). Do not close the glass lid when the burners or electric hot-plates are on or still hot. Always wait until they are cold.

The cooker lid must be kept open when using the oven or grill.

USING THE OVEN FOR THE FIRST TIME. Operate the oven and grill empty for at least 30 minutes in order to eliminate any grease or

impurities deriving from the production cycle. Air the room at the same time.

REMOVING PROTECTIVE FILM. Some parts of the cooker are protected with a special film. Before using the appliance remove the

film, then any sticky residues with soapy warm water.

POSITIONING OF BURNERS (fig. 2). There are several reference pins on the flame spreader. After removal for the cleaning phases,

make sure to refit every component correctly in order to avoid malfunctioning or damage.

Close the main gas cock and disconnect the appliance from the power supply before carrying out any cleaning or maintenance.

TECHNICAL INSTRUCTIONS FOR THE INSTALLER

All installation, adjustment and technical maintenance operations must only be carried out by qualified personnel. The appliance must

be installed in compliance with current regulations.

The appliance is tested and arranged to operate on the type of gas specified on the dataplate. Before installation, make sure the local

supply conditions (gas type and pressure) are compatible with those for which the appliance is arranged. The manufacturer declines

any liability for direct or indirect damage caused by non-compliance with the above-mentioned instructions. This appliance is not connected to a fume exhaust device. It must be installed and connected in conformity with the current installation rules.

ROOM VENTILATION (fig. 3). This appliance can only be installed and operate in permanently ventilated rooms as required by current

regulations. The room where the appliance is installed must ensure an adequate air inflow for regular combustion of the gas. In particular, the inflow of air necessary for correct combustion must not be less than 2 m

dataplate on the appliance). The air must be drawn directly from the outside, through permanent openings or ventilation ducts that access pollution-free areas.

ROOM AIRING (fig. 4). The appliance must exhaust the fumes into the outside air by means of a special hood connected to a chimney, flue or directly to the outside. If a hood cannot be installed it is possible to use an electric exhaust fan fitted on a window or wall

facing the outside, to be started at the same time as the appliance.

POSITIONING OF APPLIANCE (fig. 5). The appliance is class 1 and class 2/1. It can stand alone or be placed between cabinets, respecting these minimum distances: 630 mm between the appliance top and overlying horizontal surfaces; 30 mm between the sides of

the appliance and cabinets that are higher than it. If it is installed between cabinets the sides of the cabinets must be able to withstand

an overtemperature of at least 65°C.

GAS CONNECTION

CONNECTION WITH METAL FLEXIBLE TUBE (fig. 6). Connection is made with a pipe conforming to the national standard, con-

nected to the threaded union of the appliance with interposing of a seal joint. Pipe length must not exceed 2 metres.

CONNECTION WITH RUBBER HOSE. This type of connection is not allowed when the appliance is recess mounted and the entire

length of the hose cannot be inspected. The rubber hose must incorporate a bayonet connector with auto-seal in conformity with current standards.

CONNECTION WITH RIGID PIPE (fig. 8). Connection must be made preferably with a copper pipe. Connect the rigid part to the

threaded union located on the back of the appliance, interposing a seal joint conforming to current standards. Check connection tightness with a foamy solution.

3

/h for every kW of appliance rated power. (See the

- 5 -

IMPORTANT

After installation, make sure the unions are securely fixed. It is advisable to use a foamy solution, and never a flame, for the tightness

check on gas circuits.

ELECTRICAL CONNECTION. The outlet or installation must be provided with an efficient earth connection. The plug must have a 13

amp fuse (fig. 7). The yellow/green wire of the power cable must not be interrupted by switches. At the time of installation, if the con-

nection is not made with a plug located in an easily reached position, install an omnipolar circuit breaker with minimum contact opening

distance of 3 mm, adequate for the load and conforming to current standards, between the appliance and the mains. No part of the

power cable must reach a temperature above 50°C. The manufacturer declines any liability whenever the current electrical standards

are not respected and connection is not carried out in a “workmanlike way” by qualified personnel.

POWER CABLE REPLACEMENT. Disconnect the appliance from the power outlet. Remove the cooker back to access the terminal

block (fig. 9). Loosen the cable clamp fixing screws and the screws on the terminal block securing the three cable wires (fig. 10). Re-

place the cable with an HO5 RR-F type with section adequate for the appliance’s power input, connecting it to the terminal block as follows:

- blue neutral wire to terminal N;

- brown phase wire to terminal L;

- yellow/green earth wire to terminal

Fix the cable in the special cable clamp and refit the cooker back.

ADAPTATION TO DIFFERENT TYPES OF GAS

The appliance is suitable for working on different types of gas; each gas requires specific injectors and adjustments. To make possible

variations, always disconnect the appliance from the power supply and temporarily close the mains gas supply.

REPLACING COOKTOP BURNER INJECTORS (fig. 11). Manually remove the burners (no other disassembly operation is necessary)

and using a suitable spanner unscrew the injectors and replace them with ones suitable for the type of gas, listed in the technical data

table.

MINIMUM FLAME ADJUSTMENT (fig. 12). Light the burner and leave it on at max. for about 10 minutes. Turn the knob to Min. Remove the knob by pulling it off the cock stem. Using a small screwdriver adjust the minimum by turning the by-pass screw clockwise to

decrease the flame or anticlockwise to increase it. In standard cocks the adjustment screw (by-pass) is located inside the stem (fig.

13). In valve cocks the adjustment screw (by-pass) is located on the body of the cock. After any injector replacement or adjustment operation always make sure the flame has a colour tending to blue, is stable and silent, does not “float” and does not cause return when

going from max. to min.

REPLACING OVEN COMPARTMENT BURNER INJECTORS (figs. 14/15). Remove the burners, freeing them from the fixing screws,

then using a suitable spanner unscrew the injectors and replace them with ones suitable for the type of gas, listed in the technical data

table.

OVEN COMPARTMENT BURNER PRIMARY AIR ADJUSTMENT (MODELS WITH TUBE BURNER ONLY) (fig. 16). Loosen the relative screw and, operating on the metal collar located at the end of the burner, adjust the air opening (increasing or decreasing the

quantity of air) as required. After any adjustment operation always make sure the flame has a colour tending to blue, is stable and silent, does not “float” and does not cause return when going from Max. to Min.

OVEN BURNER MINIMUM FLAME ADJUSTMENT (fig. 12). Light the burner and turn the knob to max. temperature. Allow the oven

to heat for at least 10 minutes. Turn the knob to Min. Pull the knob off the thermostat stem and using a small screwdriver adjust the

minimum by turning the by-pass screw clockwise to decrease the flame or anticlockwise to increase it. The flame must be short and

stable, withstand possible air currents and oven door closing and must not cause return. The adjustment screw (by-pass) is normally

located on the thermostat body.

After any appliance component replacement or adjustment operation always carefully refit all the relative parts to restore the original

functions. Adaptation must be completed by replacing the hose union. In this case also check circuit tightness with a foamy solution

and never with a naked flame. Lastly, replace the old setting label with a new one (supplied) corresponding to the new gas used.

- 6 -

Loading...

Loading...