Page 1

Bartscher GmbH

Franz-Kleine-Str. 28 , 33154 Salzkotten

www.Bartscher.de

Operation instructions

for

Table units with

Beam Radiator

104.903, 104.904, 104.906, 104.907,

104.908, 104.909, 104.913

Page 1 of 15

Ver.1.0 Bartscher 2008 ©

Page 2

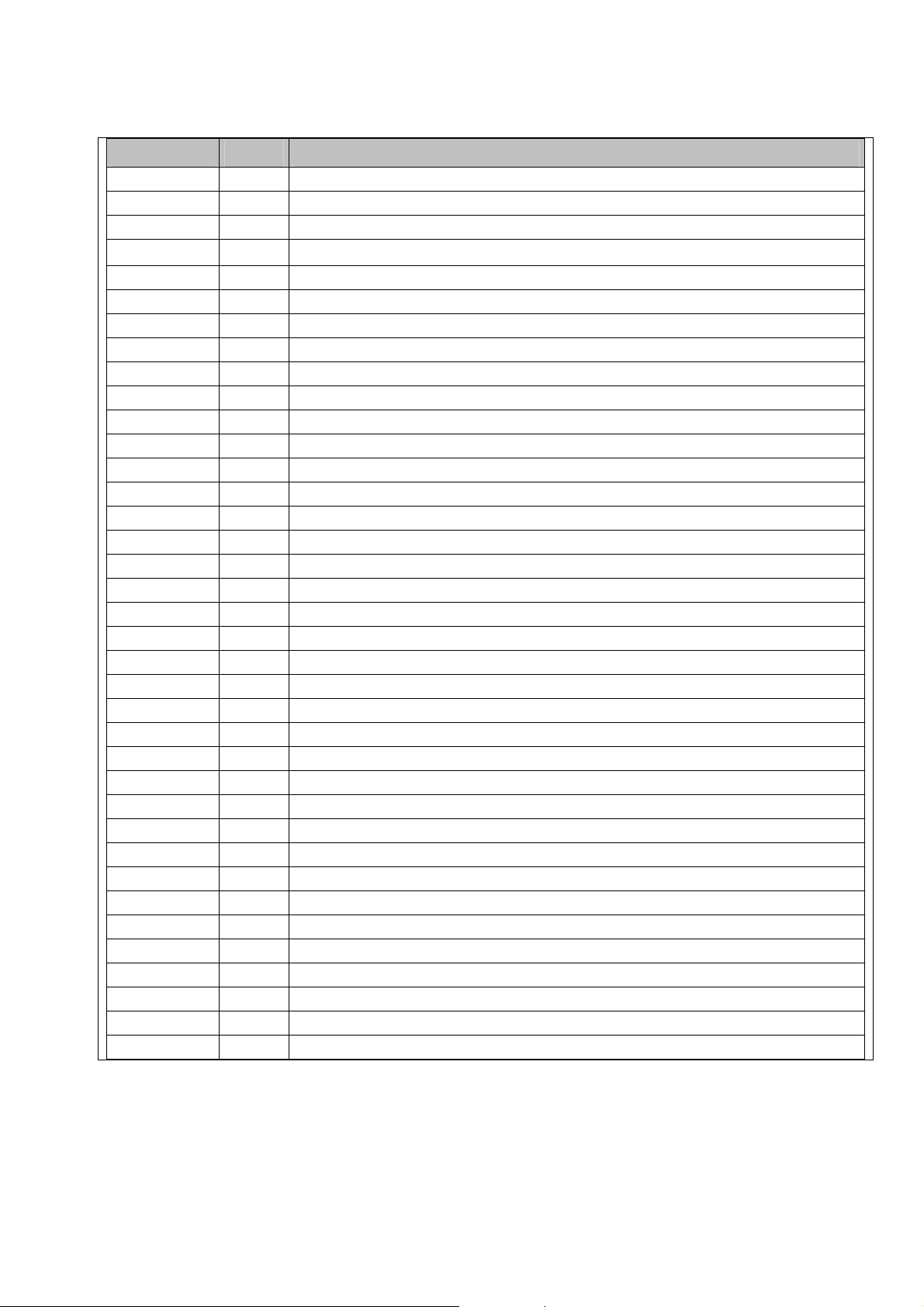

Contents list Page

1 General information 3

1.1 Area of application

2 Products description 3

2.1 Products

3

2.2 Technical Data

2.2.2. Technical data 4

2.2.3. Function conditions 4

2.2.1. Operation and Control 3

3 Installation

3.1 Electrical data of the Units

3.1.2. Unit Performance (4,6 kW, 10 kW) 4

3.1.1. Unit Performance (2,3 kW, 2,5 kW, 3,0 kW) 4

3.2 Installation requirements 5

3.3 Installation instructions

4 Taking the Unit into Service 6

4.1 Unit Assembly

5 Function test 8

6 Operation 8

6.1 Cooking

8

7 Safety instructions 9

7.1 Description of warning symbols and indicators

7.2 Dangers resulting from not observing the safety instructions

7.3 safe Application

7.4 Operator Safety Instructions

7.5 Improper operation

7.6 Modification / use of spare parts 10

8 When the unit is not in use 10

9 Troubleshooting 11

10 Cleaning 12

11 Maintenance 13

12 Disposal 13

13 Sparepartlist 14

14 Technical documentation 15-

3

3

4

5

6-7

9

9

9

10

10

Page 2 of 15

Ver.1.0 Bartscher 2008 ©

Page 3

1. General information

These operating instructions contain basic information on what needs to be

considered during installation, operation, and maintenance of the equipment. They

must be read entirely by the fitter and operators before the equipment is installed and

taken into operation. They must always be kept close to the cooking site for

reference.

1.1 Area of application

The cooking units have been designed for the preparation of meals. They can be used

for cooking, keeping food warm, as well as for flambé singing, grilling, etc.

2. Products description

2.1 Products

Model

104.903, 104.904, 104.906, 104.907, 104.908, 104.909, 104.913

- Compact module design

- Easy installation

- service-friendly

- easy operation via control knob

- compact outside dimensions

- low weight

2.2

Technical Data

2.2.1 Operation and Control

Lamp „ In use “ green

Lamp „

Lamp „

Remains warmth “ red (under glass Ceran surface)

Remains warmth “ red (in switch face plate with square beam radiator

element )

Dimensions W x D x H Ceramic glass surface

104.904 340 x 420 x 100 mm 290 x 290 mm

104.903 400 x 455 x 120 mm 350 x 350 mm

104.906 400 x 455 x 120 mm 350 x 350 mm

104.908 700 x 455 x 120 mm 650 x 350 mm

104.909 700 x 765 x 120 mm 650 x 650 mm

104.913 400 x 665 x 120 mm 350 x 560 mm

104.907 700 x 455 x 120 mm 650 x 350 mm

Page 3 of 15

Ver.1.0 Bartscher 2008 ©

Page 4

2.2.2 Technical data

Unit Voltage Performance Weight

104.904 1 x 230 V 2,3 kW 9 kg

104.903 1 x 230 V 2,3 kW 10 kg

104.906 1 x 230 V 3,0 kW 10 kg

104.908 3 x 400 V 4,6 kW 15 kg

104.909 3 x 400 V 10,0 kW 18 kg

104.913 3 x 400 V 6,0 kW 17 kg

104.907 3 x 400 V 6,0 kW 15 kg

2.2.3 Function conditions

- max. tolerance of main voltage +5%/-10%

- frequency 50 / 60 Hz

- IP Code IP 43

3 Installation

3.1 Electrical data of the Units

3.1.1. Unit Performance (2,3 kW, 2,5 kW, 3,0 kW)

Unit 1-phase (Voltage 230 Volt +5% / -10%)

Connection

Colour Frequency Fuse

Phase Black 50 Hz / 60 Hz -

N Blue

PE Yellow/Green

-

3.1.2. Unit Performance (4,6 kW, 6 kW, 10 kW )

Unit 3-phases (Voltage 400 Volt +5% / -10%)

Connection

Phase Black, Brown or 1, 2,

N Blue

PE Yellow/Green

(* = or different Colour unless gray, green or white.)

Installations-environment

- max. ambient temperature

Colour Frequency Fuse

50 Hz / 60 Hz -

3, *

-

Storage >-20°C till +70°C in Function >+5°C till +35°C

- max. relative Atmospheric humidity

Storage > 10% till 90% in Function > 30% till 90%

Page 4 of 15

Ver.1.0 Bartscher 2008 ©

Page 5

3.2 Installation requirements

The Induction-Unit has to be placed on a flat horizontal area. Don’t cover the air

supply for the air circulation. The place must be allowing a weight up to min. 40 kg.

To disconnect the Power, the user needs easy access to the power-connection.

3.3 Installation instructions

The following Points must always be observed during installation:

Make sure that the main voltage corresponds to the voltage indicated on the

nameplate of the equipment.

- All electric installations must fulfill the local building code regulations. All

regulations issued by the national electricity authorities must be observed.

- The unit is equipped with a main cable and a plug which can be plugged into a

socket.

- When using fault-current circuit breakers, they must be designed for a minimum fault

current of 30 mA.

- The personnel operating the equipment must make sure that all installation,

maintenance, and inspection work is done by specially trained and certified

personnel only.

Make sure that the plug is wired correctly:

For the electric Connection for the Unit take attention.

The Law Regulations of the Country have to be adhered!

Warning

The electrical Connection must only be

implemented by specially trained staff

Page 5 of 15

Ver.1.0 Bartscher 2008 ©

Page 6

4 Taking the Unit into Service

4.1 Unit Assembly

<Warning Electrical connections must be installed by trained staff personnel

only.>

Our units are equipped with one a main cable which must be connected with a wall

socket. If no plug has been installed at the cable, connect the plug as described in

chapter 3.

Electric installations must be carried out by registered installation companies only,

observing the specific national and local regulations. These companies are

responsible for correctly interpreting all regulations and performing the installation

in compliance with the safety instructions. Indications on warning signs and

nameplates must be strictly observed.

Make sure that the main voltage corresponds to the voltage indicated for the unit

(given on the nameplate).

The unit must always be installed on a clean, plain, and horizontal surface only

(table, cupboard, etc.). The equipment stands on non-slip rubber feet which are

permanently mounted. It must be placed so that it cannot fall down or be moved due

to a slanted position. Make sure that the requirements given in chapter 3.1

“Installation requirements” are fully met.

Turn all switches of the unit in off -position (0) before you attach the equipment to

the power supply system.

Follow the Rules like into item 3.2 described „Installation requirements“.

Page 6 of 15

Ver.1.0 Bartscher 2008 ©

Page 7

Unit On and off switch

Position OFF:

`0` points to the marker (ο)

Position ON:

Each Position, which points to the marker (ο) 1 (Minimum) - 10 (Maximum)

Before doing an operational check, the user needs to know how the equipment is

operated.

Remove all objects from the heating zone. Make sure that the heating zone is either

cracked or broken. If the heating zone is cracked or broken, stop immediately, turn

off the equipment and pull out the main plug.

Page 7 of 15

Ver.1.0 Bartscher 2008 ©

Page 8

5 Function test

After turn on the unit and turn the thermostat-knob on the heating plate get hot. The

heating can be choosed between 1 - 10 (11) steps. After the reaching the oriented

step the thermostat or Energy controller stops the heating.

The glass ceramic surface getting hot. To avoid

injuries, don't touch the heating zone.

Attention

- Place a pan in the centre of the heating zone and put in some water.

- Turn the unit on. The Operating indicator light of the equipment the (green) shine.

Turn the knob in on position (a position between 1 - 10 or 1 - 10 D). The

operation indicator light of the heating zone (green) shine, the water is heated on.

- Turn the knob in on 0 - position. The heating on stops and the operation indicator

light goes off. The remains warmth lamp shine only, if the glass ceran surface has

warmed himself.

- The shining remains warmth lamp shine (only if the unit is plugged in.), if the

glass ceran surface hot. Just when the glass ceran surface cool down to a normal

temperature the light goes off. There is no more injury danger.

Attention

this works only if the main switch is on and the main supply is not disconnected

6 Operating

6.1 Cooking

The unit can be used immediately. The green operating light next to the main switch

show the unit is turned on. The green operating light next to the thermostat or energy

controller show the cook place is turned on. The red operating light shows the remains

warmth at the ceran glass surface. Attention burning danger!

green Lamp Unit in „USE“

red Lampe ceran glass surface hot

position 1 > minimal Performance

position 10 (D) > maximum Performance

Page 8 of 15

Ver.1.0 Bartscher 2008 ©

Page 9

7 Safety instructions

Description of warning symbols and indicators

General warning signals

If you don’t follow the safety instructions, you will place

yourself in danger of injuries.

This Symbol warning from

Dangerous Voltage.

(Picture Sign 5036; IEC 60417-1)

Warning

Improper use may result in minor injuries or

Warning symbols that are located directly on the equipment must always be

observed. Their readability must be ensured at all times.

Before you connect or use the Unit,

you have to read the Operation Instructions

Warning

damages.

7.2 Dangers resulting from not observing the safety instructions

Not observing the safety instructions, may lead to danger for people, the

surroundings, and the induction unit itself. We are not liable for any damages caused

by a failure to observe the safety instructions.

Specifically, not observing the safety instructions could result in the following risks

(among others):

- Risk of personal injuries as a result of electric factors

- Risk of personal injuries because of overheated pans

- Risk of personal injuries because of overheated ceramic hob surface

7.3 Safe Application

To ensure safe use, you must observe all of the safety instructions given in this

manual, the existing national regulations for accident prevention with electrical

systems as well as any company-specific work, operation, and safety instructions.

Page 9 of 15

Ver.1.0 Bartscher 2008 ©

Page 10

7.4 Operator Safety instructions

The surface of the ceramic hob is heated by the heat of the pan. To avoid injuries

(burns), do not touch the surface of the ceramic hob.

- Attention! Place the Cookware only with whole extent on the Cooker. Ignoring

this note results to damages of the Cookware and the Equipment. Consequence

when ignoring: The warm Cookware burning the seal material and the material

get destroyed. This result humidity and grease can penetrate in the equipment and

can result in the defect of the Equipment.

- If the glass broken, the unit have to be immediately switch off and disconnected

from the power supply. Don’t touch any parts inside the unit.

- Turn off the unit if you remove the pan from the cook place. Through this you

Avoid the automatically heating on without supervised person on the stove.

- Don't use the cook area as rest!

- Do not put paper, carton, textiles, etc. between the pan and the ceramic hob – they

could catch fire.

- Because objects heat up very quickly when put in contact with the turned on

heating zone, never place objects other than pans on the unit (closed cans,

aluminum foil, cutlery, jewellery, watches, etc.).

- Prevent liquids from entering the equipment, and try not to let water or food flow

over the pan edge. Do not jet-clean the equipment.

7.5 Improper operation

The working of the induction equipment can only be guaranteed when it’s used

correctly. The equipment must always be operated within the limits given in the

technical data.

7.6 Modification / use of spare parts

Contact the manufacturer if you intend to make any modifications to the equipment.

For safety reasons, always use original parts and accessories only which have been

approved by the manufacturer. If you use anything other than the original

components, the manufacturer will not assume any liability for any costs that result.

8 When the unit is not in use

When the unit is not in use, make sure that the control knob is not turned on

inadvertently. If you do not use the unit for a longer period of time (several days),

pull the main plug from the socket or turning off the main switch. Make sure that no

liquids can get into the induction unit, and do not use excessive amounts of liquid to

clean the equipment.

Page 10 of 15

Ver.1.0 Bartscher 2008 ©

Page 11

9 Troubleshooting

The unit may only be opened by approved, specially trained service Employee.

If the heating zone (ceramic glass surface) is cracked or broken, stop working with

the equipment at once. Turn off the unit immediately and pull the main plug from the

socket. Do not touch any parts inside the unit.

Error Possible cause Error: correction by User-

Pan does not heat;

operation indictor lamp

Do not open induction unit!

Warning

High voltage!

No current supplied Control, is the unit connected to the

control knob in OFF

position

or Service staff

power (Power cable connected?), Main

Main switch is in Off Position

Turn control knob in ON position.

Insufficient heating

power

A phase is missing Control the Fuses

Heating element

no reaction regulating

the temperature

controller

Performance change

within minutes on and

off.

Units with pan detection:

no reaction regulating

temperature regulator

Heating element broken.

Contact your Dealer for the Repair

broken

temperature regulator

broken

temperature regulator

broken

Pan on cooking place,

Main switch off or

main supply

disconnected

service. Disconnect the Unit from the

Power.

Contact your Dealer for the Repair

service. Disconnect the Unit from the

Power.

Contact your Dealer for the Repair

service. Disconnect the Unit from the

Power.

Remove the pan from the cooking place

and put it back after 5 seconds.

(main switch on)

Page 11 of 15

Ver.1.0 Bartscher 2008 ©

Page 12

10 Cleaning

List of cleaning agents for specific types of dirt and stain:

Dirt / stain type Cleaning agent

Minor stains and dirt Moist cloth (Scotch cloth) with

some industrial kitchen

cleaning agent

Greasy Stains (sauces,

soups, etc.)

Lime and water stains Polychrom

Strongly shimmering,

metallic discolorations

Mechanical cleaning Razor blade

Do not use abrasive cleaning agents, steel wool, or abrasive sponges, since these may

damage the ceramic surface.

Residues of cleaning agents must be removed from the ceramic hob with a moist

cloth (Scotch cloth), since they can corrode during heating. Correct maintenance of

the induction hob includes regular cleaning, careful treatment, and service.

No liquids may enter the unit!

Polychrome

Sigolin chrom,

Inox crème

Vif Super Cleaner

Supernettoyant,

Sida,

Wiener Kalk

Pudol System Care

Sigolin chrom,

Inox crème

Vif Super- Cleaner

Supernettoyant

Polychrom

Sigolin chrom

Non-abrasive sponge

Page 12 of 15

Ver.1.0 Bartscher 2008 ©

Page 13

11 Maintenance

The users have to make sure, that all safety-relevant components always are in

perfect working condition. The unit have to be inspected at least once a year by a

specially trained technician from your supplier.

Do not open induction unit!

Warning

High voltage!

The unit must only be opened by specially trained service personnel.

12 Disposal

When the unit has reached to the end of the service life, it must be disposed of

correctly.

Avoid misuse:

The equipment can’t be used, by someone who is not qualified to do. Make sure, that

an unit you want to dispose of, can’t taken into operation again. The unit consists of

common electro-mechanic and electronic parts. No batteries are used. The user is

responsible for disposing of the induction unit correctly and safely.

Note for Waste management:

Units that for this point decide can be shipped to us. We take

only Post-paid packets

Page 13 of 15

Ver.1.0 Bartscher 2008 ©

Page 14

13 Spare part list

Item Nr. Used Name

100107 knob " Min - Max " for Heating with energy regulator

100117 knob " 1 - 6 " for Heating with thermostat

100121 knob for Main switch (red)

800100 knob " 1 - 10 " for Heating with thermostat

800101 knob front "1-10D" for Heating with energy regulator

800102 knob for Main switch

800103 knob right "1-10D" for Heating with energy regulator

800105 knob "1-10D" for Heating with energy regulator

800201 Indicator light " GREEN " 250 Volt

800202 Indicator light " RED " 250 Volt

800203 Indicator light " GREEN " 400 Volt

800204 Remains warmth lamp with cable

800205 Remains warmth lamp without cable

800400 energy regulator 74512

800401 energy regulator for 2 circle heating elements

800403 thermostat

800404 Main switch 4 - polig

800405 Main switch 2 - polig

800500 Electronics for pan detection (Type 230 Volt)

800501 Electronics for pan detection (Type 400 Volt)

800800 Beam radiator 230 Volt / 2300 Watt round

800801 Beam radiator 230 Volt / 2500 Watt round

800802 Beam radiator 230 Volt / 2300 Watt round with pan detection

800803 Beam radiator 230V / 1200 Watt

800810 Beam radiator 230 Volt / 3000 Watt 6 corner

800820 Beam radiator 230 Volt / 2500 Watt square

800821 Beam radiator 230 Volt / 3000 Watt square

800822

800823 Beam radiator 400 Volt / 4000 Watt square with pan detection

800830 2 Beam radiators 230 Volt / 5000 Watt with pan detection

800831 2 Beam radiators 400 Volt / 8000 Watt with pan detection

800840 2 circle Beam radiator 230V / 2200W / 750W round

800841 2 circle Beam radiator 230V / 2500W 6 corner

800842 2 circle Beam radiator 230V / 3400W 6 corner

801101 knob behind "1-10D" for Heating with energy regulator

801103 knob left "1-10D" for Heating with energy regulator

801110 knob 0 - 10 black/silver ( New ) only BMS

Beam radiator 400 Volt / 4000 Watt square without pan detection

Page 14 of 15

Ver.1.0 Bartscher 2008 ©

Page 15

15 Technical documentation

Page 15 of 15

Ver.1.0 Bartscher 2008 ©

Loading...

Loading...