Page 1

ICE MAKERS

EISWÜRFELBEREITER

Q-SERIE (Kegelform)

FABBRICATORE DI

GHIACCIO A CUBETTI

MACHINE À GLACE

EN CUBES

104204 Q25

104206 Q45

104218 Q75

104216 Q150

INSTRUCTION MANUAL

BETRIEBSHANDBUCH

LIBRETTO ISTRUZIONE

MANUEL DE ISTRUCTION

71503928_Bartscher-service Ice makers

ALL

-

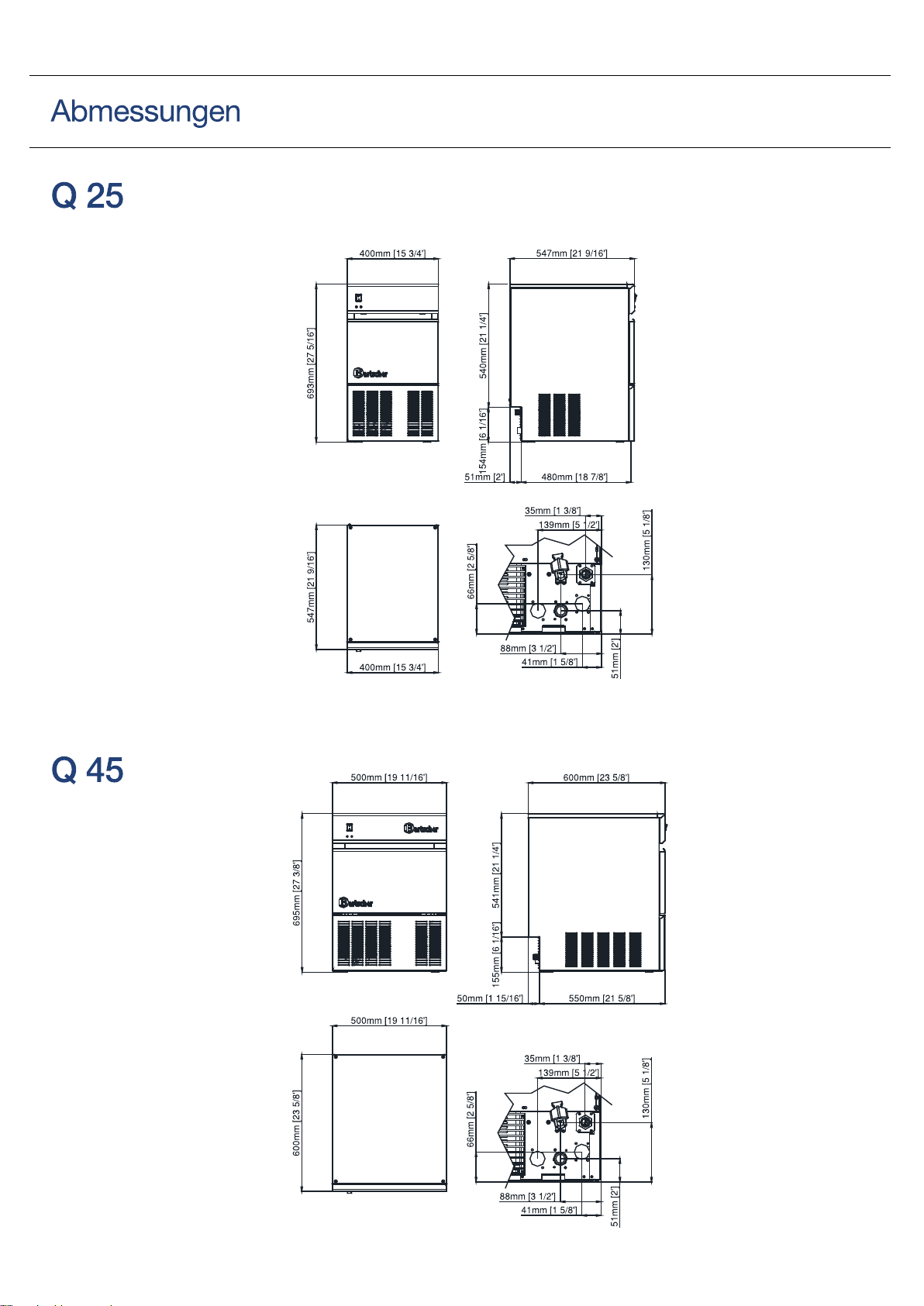

Page 2

Page 3

e

q

t

max 0,5 MPa (5 bar)

min 0,1 MPa (1 bar)

i

w

o

t

a

y

m

50 m

r

max 32°C

min 10°C

u

in

m

s

d

j

f

g

h

k

2!

;

2)

Page 4

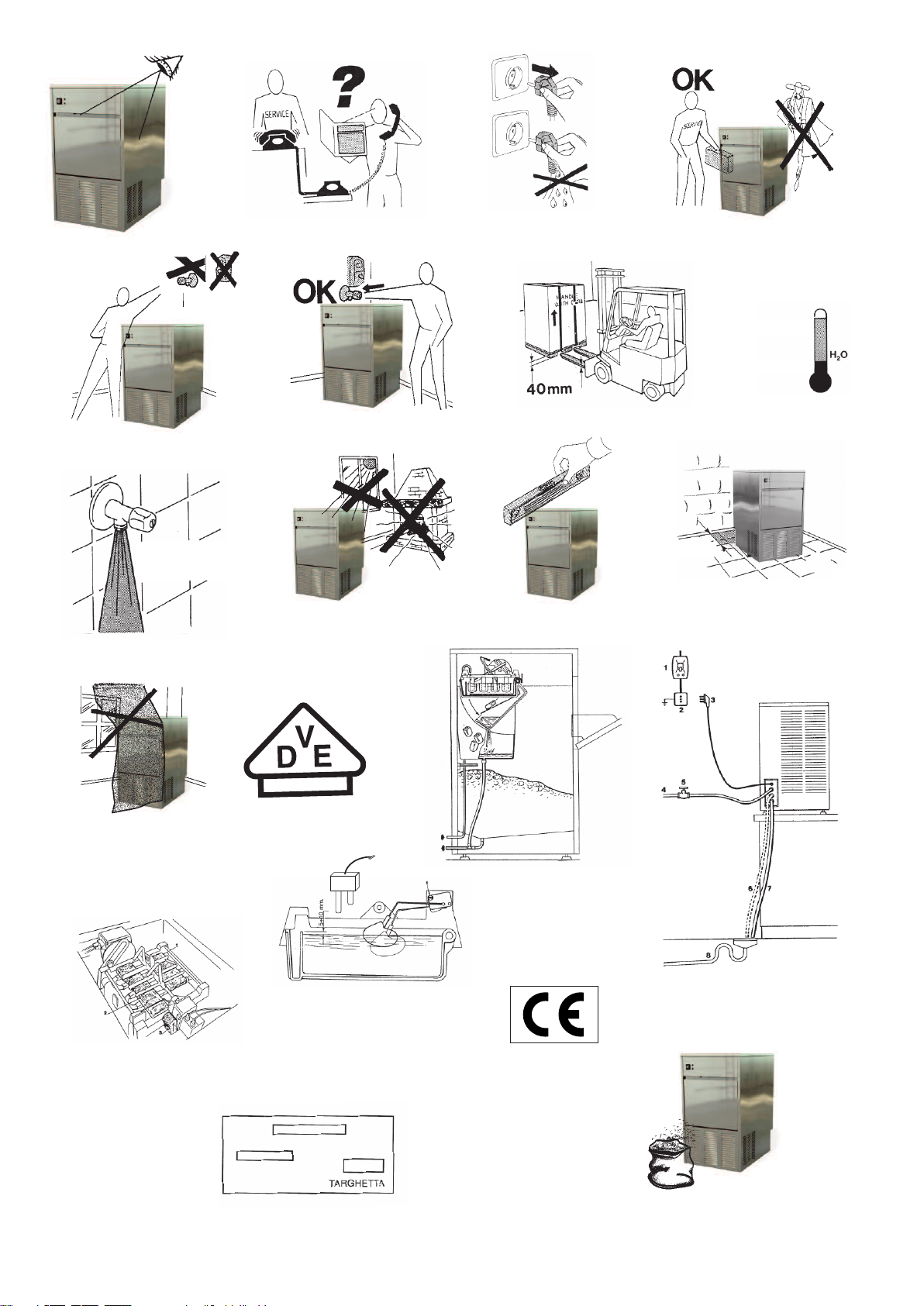

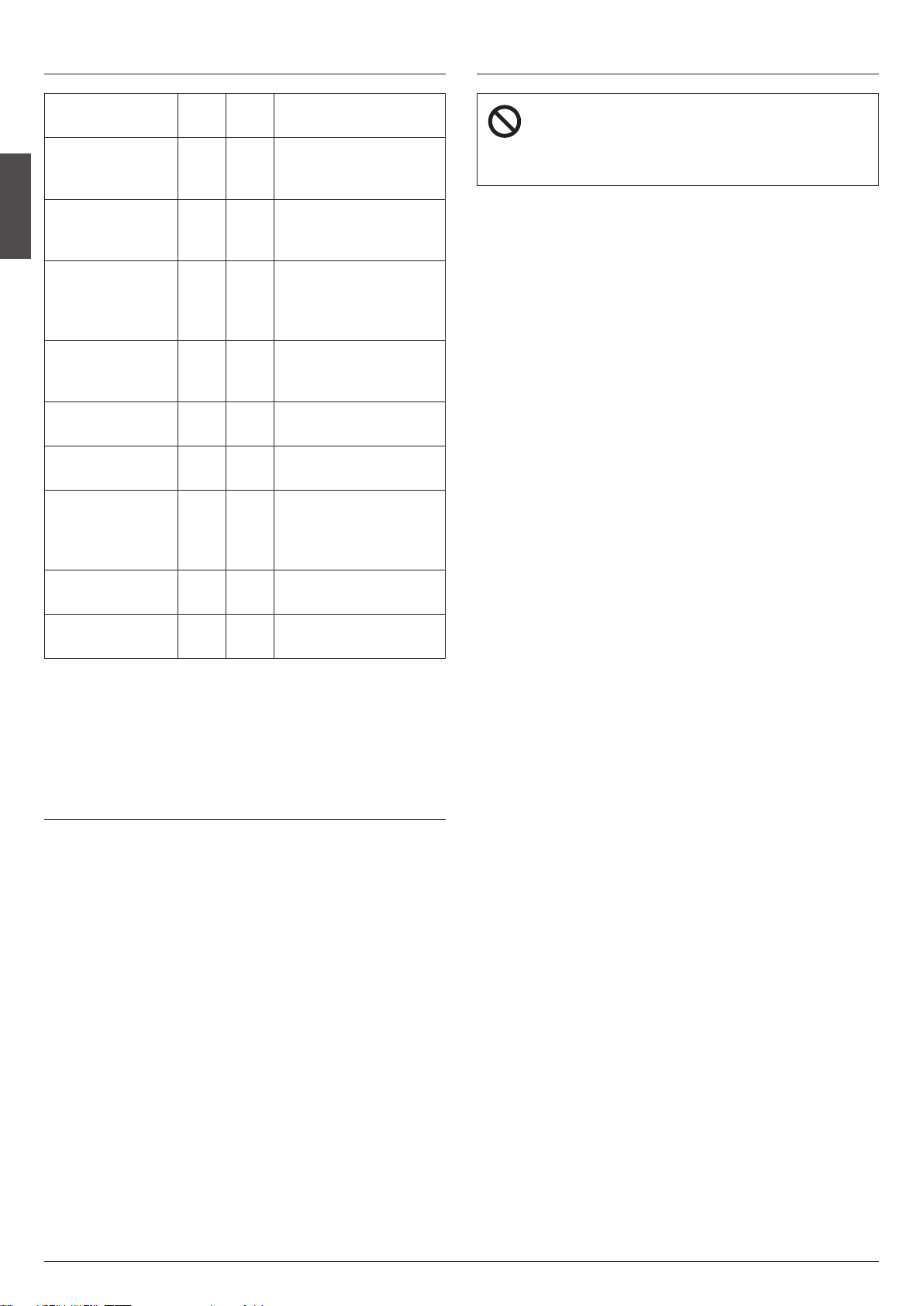

Q Series - Kegeleis

Eisproduktion (10°C / 10°C)

Eisproduktion (21°C / 15°C)

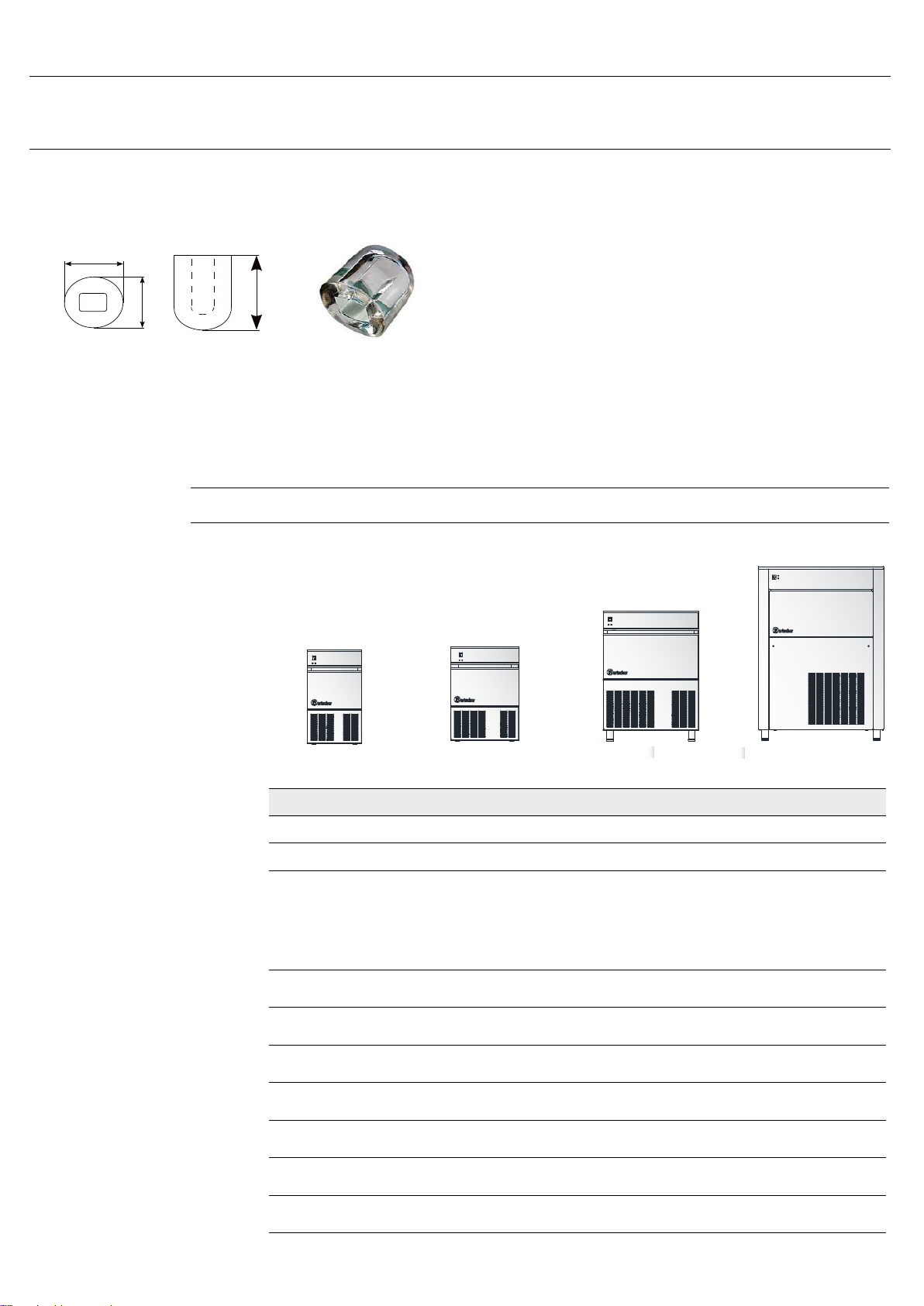

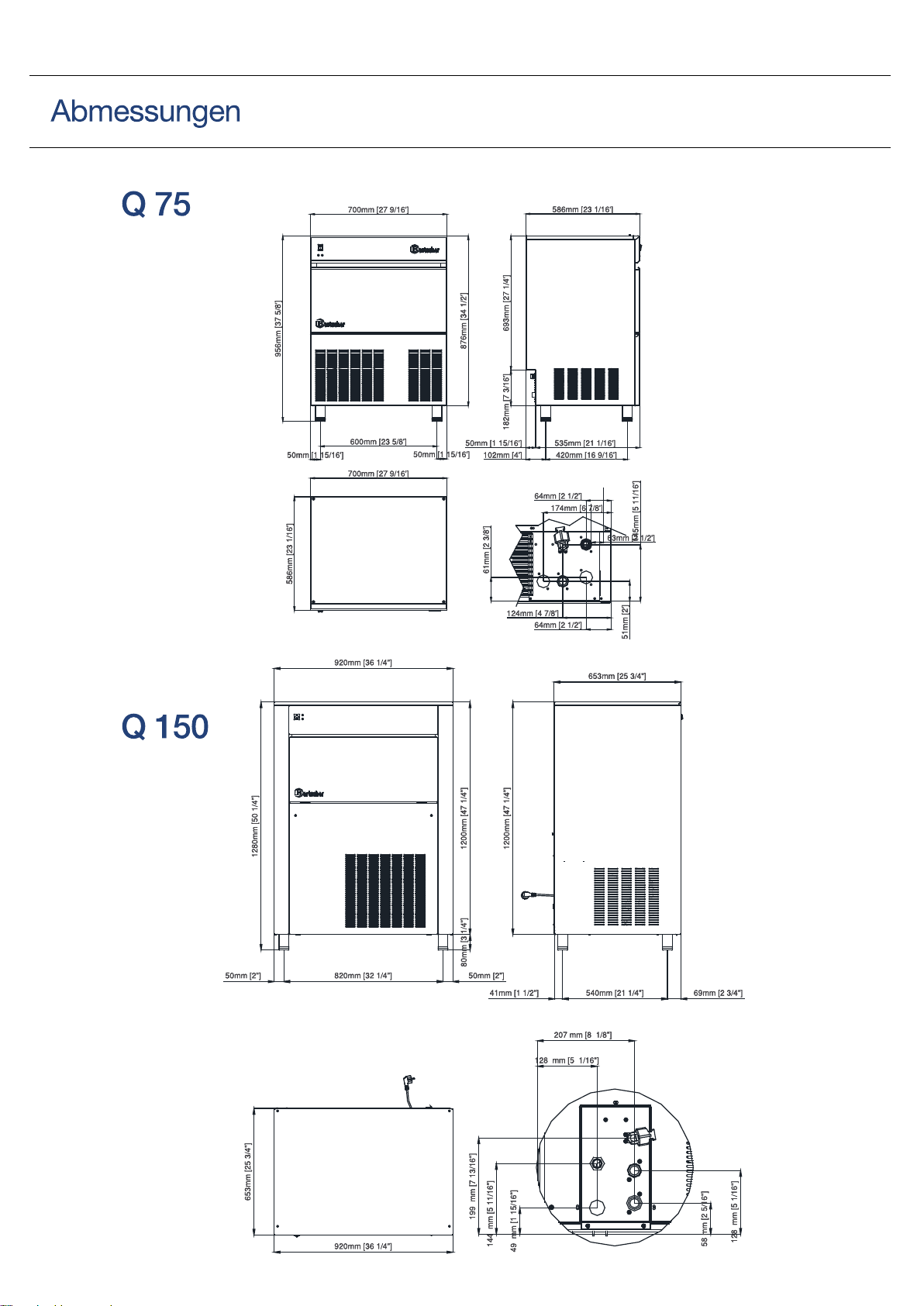

Abmessungen

Externe Breite

Externe Höhe mit Füße(ohne Füße)

Tiefe

Vorratsbehälter

Netto Gewicht / Brutto

W Anschlusswert

Eiswürfel Programm

Kältemittel

Q 25

MODELL

25 kg

20 kg

400 mm

(690) mm

545 mm

10 kg

33 kg / 39 kg

265 W

15

051 Q54 Q Q 75

R134a

500 mm

(693) mm

600 mm

16 kg

45 kg

38 kg

35

41 kg / 48 kg

370 W

R134a

700 mm

585 mm

36 kg

956 mm

75 kg

66 kg

60

55 kg / 63 kg

R134a

620 W

920 mm

650 mm

67 kg

1279 mm

150 kg

135 kg

100 kg / 116 kg

R134a

990 W

90

40 mm

26 mm

30 mm

17 g

Page 5

Page 6

Page 7

WARNING

i

INDICE

Description Pag.

THE FOLLOWING OPERATIONS AND THOSE

HIGHLIGHTED BY THE SYMBOL AT THE SIDE

ARE STRICTLY FORBIDDEN FOR WHOEVER USES

HE MACHINE SUCH OPERATIONS MUST BE

T

PERFORMED EXCLUSIVELY BY QUALIFIED PERSONNEL

specially:

E

• electrical connections

• water connections

• machine installation

• machine testing

• repairing machine components and parts

• disassembling the machine and/or its

components

• adjustments and settings

• machine cleaning and maintenance relative to

the following parts and components:

- electrical

- electronic

- mechanical

- cooling

1. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1

CONNECTING THE APPLIANCE TO THE MAINS

. ACTIVATING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2

3. OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 ALARM SIGNALS FOR AIR / WATER MODELS . . . . . . 9

4. CONTROL PANEL SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5. OPERATING PROBLEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6. SERVICE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7. CLEANING AND MAINTENANCE

7.1 CLEANING THE AIR CONDENSER . . . . . . . . . . . . . . . . . 11

7.2 CLEANING THE WATER INLET FILTER . . . . . . . . . . . . . . 11

7.3 CLEANING THE CONTAINER . . . . . . . . . . . . . . . . . . . . . . 11

8. TECHNICAL SERVICE DATA

8.1 ELECTRONIC BOARD FUNCTIONS . . . . . . . . . . . . . . . . 12

8.2 ELECTRONIC BOARD INPUTS AND OUTPUTS . . . . . 12

8.3 OPERATION CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . 12

8.4 FEATURES OF THE GAS REFRIGERATOR

PLANT FREON R404a . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.5 PROGRAMMED MAINTENANCE WARNING . . . . . . . . . 13

8.6 CONNECTION OF ELECTRICAL CABLES AND

COMPONENTS TO THE PC BOARD . . . . . . . . . . . . . . . . . 14

9. MAINTENANCE

9.1 PERIODICAL MAINTENANCE AND CLEANING . . . . .15

9.2 ICEMAKER CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

9.3 PARTS REPLACEMENT PROCEDURES . . . . . . . . . . . . . .15

. . . . . . . 8

English

THE TEXT WITH THIS SYMBOL

IS OF MORE IMPORTANTE

OR POTENTIAL DANGER SIGNALS

NOTE claries the ongoing operations

10. WEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11. WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

GENERAL INFORMATION

• The ice making machines approved by VDE bear the symbol

shown in fig. fon the packing, the serial number plate and

the machine structure.

CE

Our products comply with directives 2006/95/ec

2004/108/ec therefore they also bear the marking on the manual cover.

• This appliance is not intended to be used by persons - including children - with reduced physical, sensory or mental

capabilities, or with no experience and knowledge, unless

they have been instructed on how to use the appliance and

are supervised by a person who is responsible for their safety.

Children should be supervised to ensure that they do not

play with the appliance

Do not start the appliance before the technician intervenes

(fig.

).

r

71503928/0 - REV.0001/2013

7

Page 8

1. INSTALLATION

i

i

Implement the following operations before activating the

ce maker:

i

1. Verify that the ice maker has not been damaged during

transport (fig.

2. Remove all the material provided from the container: supply

English

ipe, drain pipe, documentation and any accessories.

p

3. Clean inside the container with a sponge dampened with

warm water and a little sodium bicarbonate; rinse with clean

water and dry carefully.

4. Place the ice maker in its definite location and ensure that it

is perfectly level (fig.

Note: When choosing where to install the appliance, make sure

that:

• the room temperature never drops below 10°C (50°F) and does

not exceed 43°C (110° F).

• the water temperature must be no less than 10°C (50°F) and no

more than 32°C (90°F) (fig. u).

• the supply water pressure must be no less than 0,1 MPa (1 bar)

and no more than 0,5 MPa (5 bar).

Should the pressure exceed 0,5 MPa, install a pressure reducer on

the machine water supply (fig. i).

• d) the machine is away from heat sources and in a well-ventilated area (fig. o).

q

).

).

a

Note: Install the machine in a position that the ventilation of the

ooling unit is not obstructed in any way (only for air-cooled ma-

c

chines) (fig.

• Do not install the machine in a dusty room as the condenser of

the cooling unit can be easily clogged (only for air-cooled machines) (fig. 2)).

If the machine is installed in an area where the drinking water

•

has a high content of salt solutions, follow the manufacturer's

instructions in order to minimise the problem.

• To prevent the ice from absorbing bad smells and tastes, never

store food, bottles, etc. in the container.

• Do not leave the ice container door open during normal operation.

There must be a differential switch (cut-out) in the electrical system.

1.1. CONNECTING THE APPLIANCE TO THE MAINS

• If the power supply cable is damaged, it must be replaced

by qualified personnel to prevent any hazards to persons

s

).

Connect only to the drinking water mains

5. Use the new set of mobile junctions (water pipe) supplied

with the appliance. The old set of junctions must not be

reused.

6. Install the water connections before the electrical connections.

7. Connect the 3/4’’ supply pipe (supplied) to the machine and

to the cold drinking water supply line.

For practical and safety purposes, it is advisable to install a

shut-off valve (not supplied by us) (fig. h: 1. switch; 2. socket;

3. electrical plug; 4. water supply; 5. valve; 6. water drain from

the condenser: water-cooled version; 7. water drain from the

container; 8. water drain with open siphon).

8. Apply the flexible pipe (supplied) with a 20 mm inner diameter and of adequate length (not more than 1 metre from

the machine) to the water drain fitting of the machine in

order to reach the drain well (fig. h).

8

71503928/0 - REV.00 01/2013

Page 9

2. ACTIVATING THE MACHINE 3. OPERATION

iii

Implement the following operations before activating the

ice maker.

. look at the pictures:

1

• remove the cover by loosening the relative fastening screws.

• release the gear motor, the blades and the float (where applicable) by removing the factory-set stops 1, 2 and 3, which

have been fixed to prevent damage during transport (fig.

. For the water-cooled models connect also the second

)

j

fitting to the water outlet, which conveys the water coming

from the condenser.

Note: Implement a minimum inclination of 3% to the pipes for

perfect water flow from the appliance, ensuring that these have

no narrowing sections and are not siphoned. It is advisable that

the pipes drain into an open siphon (fig.

2. Connect the machine to the power supply after having verified that the mains voltage corresponds to that on the serial

number plate on the rear panel of the appliance.

The maximum voltage variation tolerance allowed is ±

10% of the rated value.

• Provide a power supply circuit to the machine, with its own

bipolar main switch and a minimum of 3 mm contact opening. The machine should also have its own fuse or automatic

protection and an earthed plug.

• All must be sized according to the amperage indicated on

the serial number plate (fig. ;). The socket must be easily

accessible.

h

).

Simply press the ON/OFF button to start and stop the

machine.

• The ice cube makers can be easily adapted to the furnishing

of every room.

• The ice cubes are formed around the fingers of the evaporator, inside a tray filled with water and continuously moved

y revolving blades.

b

• The level of the water in the tray is kept constant by a float

connected to a microswitch that controls the opening and

closing of a water inlet electrovalve of the water supply.

• When the ice cubes reach the required dimensions, they

come in contact with the revolving blades that cause the relative gear motor to swing, which stresses a micro switch and

simultaneously causes the following through a relay:

- the delivery of hot gas to the evaporator by an electrovalve

opening, which leads to the cubes gradually dropping off

the fingers of the evaporator.

- the tilting of the water tray connected by means of a lever

to a gear motor.

• The cubes drop and slide on a slanting grid inside the tray

and are conveyed into the container beneath.

• The remaining water in the tray is collected into the relative

pan on one side of the container and conveyed towards the

drain. The tray automatically returns to its horizontal position

after about a minute and fills with water till the pre-set level.

In the meantime, the hot gas valve closes and the ice forming cycle proceeds smoothly; a complete cycle can vary from

about 15’ to about 25’ depending on the water and room

temperatures.

• The quantity of ice inside the container is controlled by the

electronic sensor fixed on one side of the container itself;

when the ice cubes reach the level of the bulb, the machine

stops completely. After removing enough ice from the container for no cubes to be in contact with the bulb, the appliance will resume its normal production.

English

Note: After removing the ice cubes, remove any remaining ice

on the control bulb for production to resume quicker.

3.1 ALARM SIGNALS FOR AIR / WATER MODELS

• Overheating condenser: the machine restarts automatically

once the alarm has been resolved. The cause may be due to:

clogged air filter, faulty fan, room temperature too high, no

water (only in the water version).

• Water error: if there is no water, the machine restarts automatically 60 minutes after the alarm is triggered.

Note: You can exit from the alarm status after having disconnected / connected the power supply (ON/OFF button).

• The machine stops when the container is full: the sensor

of the container is controlled by the control board and stops

the machine when the ice comes in contact with it. The machine stops at the end of the defrosting cycle.

71503928/0 - REV.0001/2013

9

Page 10

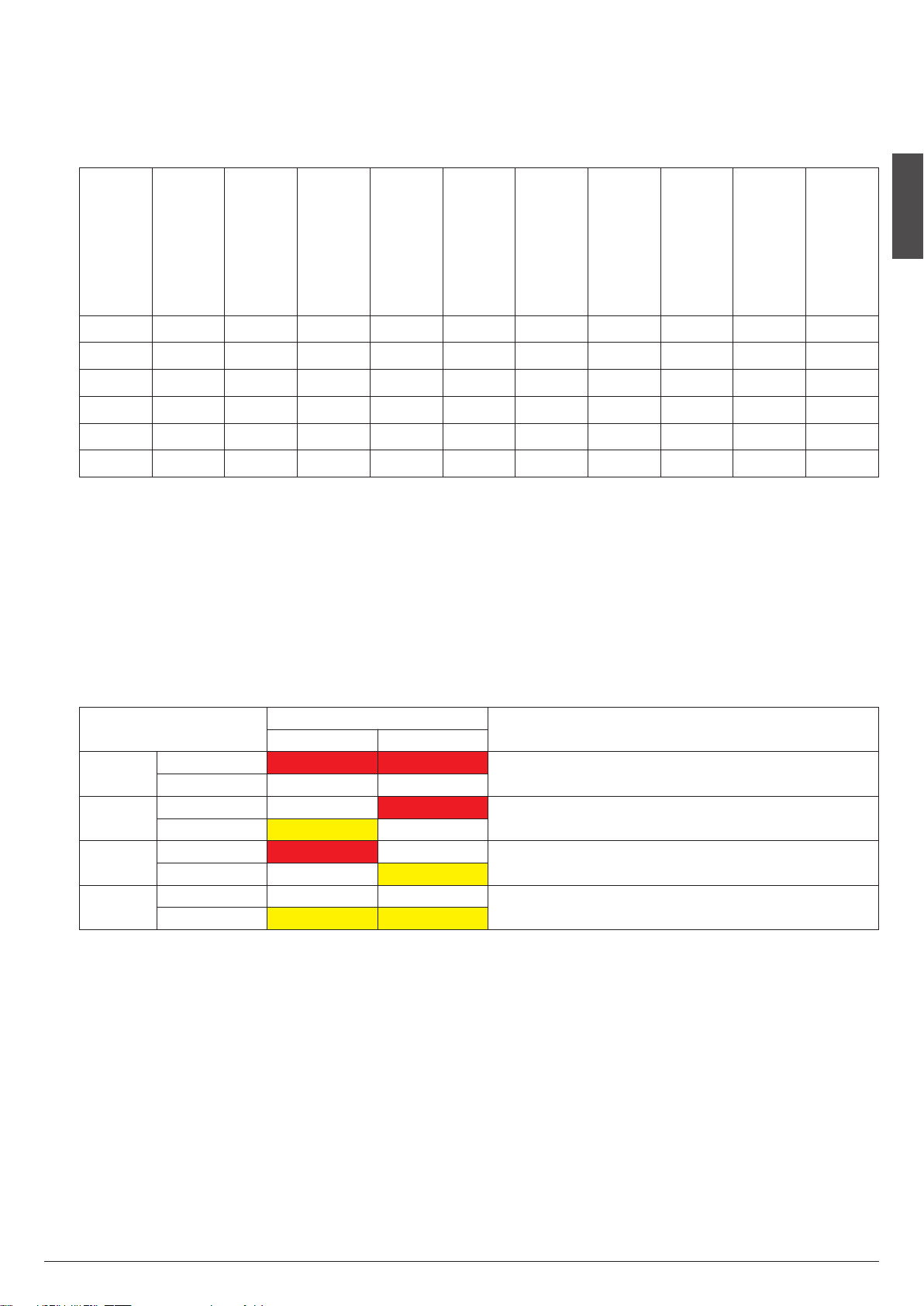

4. SIGNALS

6. SERVICE INFORMATION

Function Status

Machine ON ON OFF

Bin temperature

English

sensor error

Condenser

emperature

t

sensor error

Error cold cycle too

long or defrosting

too long

Condenser

overheating error

No water error LL ON

Maintenance

warning

Wash / clean LV LV

Start stand-by LV OFF

Led 1

reen

G

OFF LL

FF

O

ON ON Machine OFF

OFF ON Machine OFF

LA LA

Led 2

Notes

ed

R

pplicable to all

A

conditions that are

ot in alarm/error

n

Temperature sensor

out of range.

Machine OFF

Temperature sensor

out of range.

L

L

The machine

continuous to run

The signal is triggered

after attempting to restart

The pre-set number of

operating hours has been

reached. The machines

continous to run

Signalled during the wash

routine

Waits to start after

switch-o

THE FOLLOWING OPERATIONS MUST BE

IMPLEMENTED SOLELY BY OUR

QUALIFIED PERSONNEL

1. Verify that the water supply valve is open, then plug in the

achine and switch on the main switch; the appliance starts-

m

up in automatic mode (fig.

ON/OFF start button (fig. 2@).

2. Verify that the water reaches the tray, the float stops the

water before the overflow and that there are no leaks in the

system and in the water channels. The normal level of water

inside the tray is about 5/10 mm from the upper edge (fig.

).

k

The level of water can be adjusted by rotating the microfloat

or the water sensor on the slot on the relative support after

having loosened fastening screw 1 (fig. k). This adjustment

must be implemented after having disconnected the power

supply.

3. Verify that there is no abnormal vibration due to loose screws.

4.

Always stop the appliance before implementing any operations

to resolve water leaks, tighten screws, etc.

5. Verify an ice production cycle ensuring that the cubes are

conveyed into the container.

6. Verify that the container sensor functions properly: place an

ice cube on the bulb inside the container; the appliance

should stop within 1 minute and restart automatically shortly

after removing it.

7. Replace the cover previously removed.

) after having pressed the

g

LL= flashing slowly

LV= flashing quickly

LA= alternate flashing

ON = steady light

5.

OPERATING PROBLEMS

• If the condenser overheats

The machine stops and only the air/water condensation remains in operation. The machine automatically restarts when the temperature returns to below the limits set. Only after three consecutive alarms within a period of 5 hours, the machine turns off and

stays off.

• Freezing cycle too long

In the case of three consecutive alarms within 5 hours, the machine stops.

Calculation of the maximum time of the freezing cycle:

1stcycle = 50'

2ndcycle = duration of 1 cycle x 1.5.

If the 1st cycle lasted less than 7' the maximum time of the next cycle will be 50'.

• Defrosting too long

If the defrosting time is greater than 2 minutes and there are 2 consecutive failures within 5 hours, the machine stops.

• Freezing cycle less than 7 minutes

The electronics calculate the cycle time as too long at 50 minutes.

• Water loading too long

If the load time for the water is greater than 5' the machine stops in alarm. After a break of 120' the machine restarts automatically.

If water shortage is ongoing, the machine will attempt to restart every 120'.

10

71503928/0 - REV.00 01/2013

Page 11

7. CLEANING AND MAINTENANCE

i

THE FOLLOWING OPERATIONS MUST BE

IMPLEMENTED SOLELY BY OUR

QUALIFIED PERSONNEL

• Use a cloth dampened with a specific chlorine-free product

for stainless steel to clean the structure.

Note: Disconnect the electrical power supply from the appliance

to perform maintenance and cleaning operations.

7.1 CLEANING THE AIR CONDENSER

• To make the most of your appliance in terms of efficiency

and durability, the air filter at the front of the machine must

be cleaned every week (fig. 2#).

• The filter is removed by simply extracting it. Simply wash the

filter with a water jet of warm water and dry it before setting

it back in place.

Do not use brushes or blunt objects to clean the filter.

It is absolutely forbidden to operate the producer without

the air filter to prevent malfunctioning.

For all extraordinary maintenance and/or repairs (me-

hanical, cooling and electrical parts) that require adjust-

c

ments and/or components to be replaced, always refer to

an authorised service centre.

If the appliance should not be used for long periods of

ime:

t

- disable the machine

- remove all the ice from the container

- drain all the water

- thoroughly clean the machine

- leave the door of the container ajar

English

7.2 CLEANING THE WATER INLET FILTER

• Close the water shut-off valve of the appliance, disconnect

the water inlet pipe and remove the filter screen that is on

the water inlet electrovalve with a pair of pliers.

• Clean the screen with a water jet and reassemble it into its

place.

7.3 CLEANING THE CONTAINER

• Remove the ice from the container. Clean inside the container with a sponge dampened with warm water and a little sodium bicarbonate;

• rinse with clean water and dry carefully.

71503928/0 - REV.0001/2013

11

Page 12

8. TECHNICAL SERVICE DATA

THE FOLLOWING OPERATIONS MUST BE

IMPLEMENTED SOLELY BY OUR

QUALIFIED PERSONNEL

8.1 ELECTRONIC BOARD FUNCTIONS

English

Ice level check with probe

•

• Condensing temperature check with probe (machine stop

with temperature > 70°C water version; > of 80°C air).

• Maintenance check. The maintenance alert can be programmed after a certain number of hours of functioning.

8.2 ELECTRONIC BOARD INPUTS AND OUTPUTS

Low voltage

inputs

Condenser probe

Container Probe

Water level sensor

Defrosting start micro

Defrosting end micro

Electronic board

High voltage

inputs 230V/50HZ

Compressor

Tilting Motor

Hot gas electrovalve

Water electrovalve

Blades gear motor

Electric fan

8.3 OPERATION CHARACTERISTICS

• On the starting the machine goes into defrosting and disharge the water pan.

c

• The production cycle start with two minutes of delay that

allow a correct balancing of the refrigeration system and

therefore a good output and a best production.

• During the machine operation, at the end of every defrost-

ng, the water load happens with 80 seconds of delay, this to

i

allow the evaporator subcooling.

• When the bin is full of ice, the probe comes in contact with

the ice and the electronic card stop the machine only on the

end of defrosting time. This to always have the cubes completely formed and at the same dimensions.

• Signalling of alarms for the models air and water version:

- condenser overheating : the machine goes to alarm and it

restart again automatically once that the cause has been removed and / or the temperature has re-entered in the range

of established operation;

- error of not water feeding: in case of lack of water the machine automatically start again after 60 minutes from the

alarm reset.

• Condenser probe: with condenser temperature < 24°C, the

board makes the fan turn guaranteeing optimal condition of

condensation and machine yield.

• Resistance values of the temperature probes (deposit probe

and condenser probe) with reference to the room temperature:

Temperature °C Sensor resistance Ohm

20 2762,034556

25 2200,000000

•

PCB MICROPROCESSOR RESET

Pressing the ON/OFF button.

30 1765,531939

12

71503928/0 - REV.00 01/2013

Page 13

.4 FEATURES OF THE GAS REFRIGERATOR PLANT

8

FREON R134a

• Medium and maximum series “E” blade machines absorption

at room temperature of 32°C.

• Condensing pressure and evaporator temperature cycle start

nd end at room temperature of 32°C.

a

English

cycle (bar)

Machine

Gas

Max. ampere

Medium ampere

pressure strarting

Condensing

21 134 A 2 A 1,8 A 11,5 -3,3 9 -17 7,5 15/17 GR 6

25 134 A 1,6 A 1,4 A 11 -2 9 -13 5,8 15/17 GR 2,8

35 134 A 2,7 A 2,1 A 14 -2 10 -15 8,6 20/17 GR 4,7

60 R134a 4,2 A 3,4 A 14,7 -2 11,3 -15 12,7 35/17 GR 7,5

75 R134a 4,6 A 3,8 A 14,6 -2 11,4 -13 13,3 60/17 GR 9,4

90 R134a 4,7 A 4,2 A 14,9 -2 10,8 -15 14,4 60/17 GR 12,5

* Expressed in water litres per hour at water temperature of

15°C and room temperature of 21°C

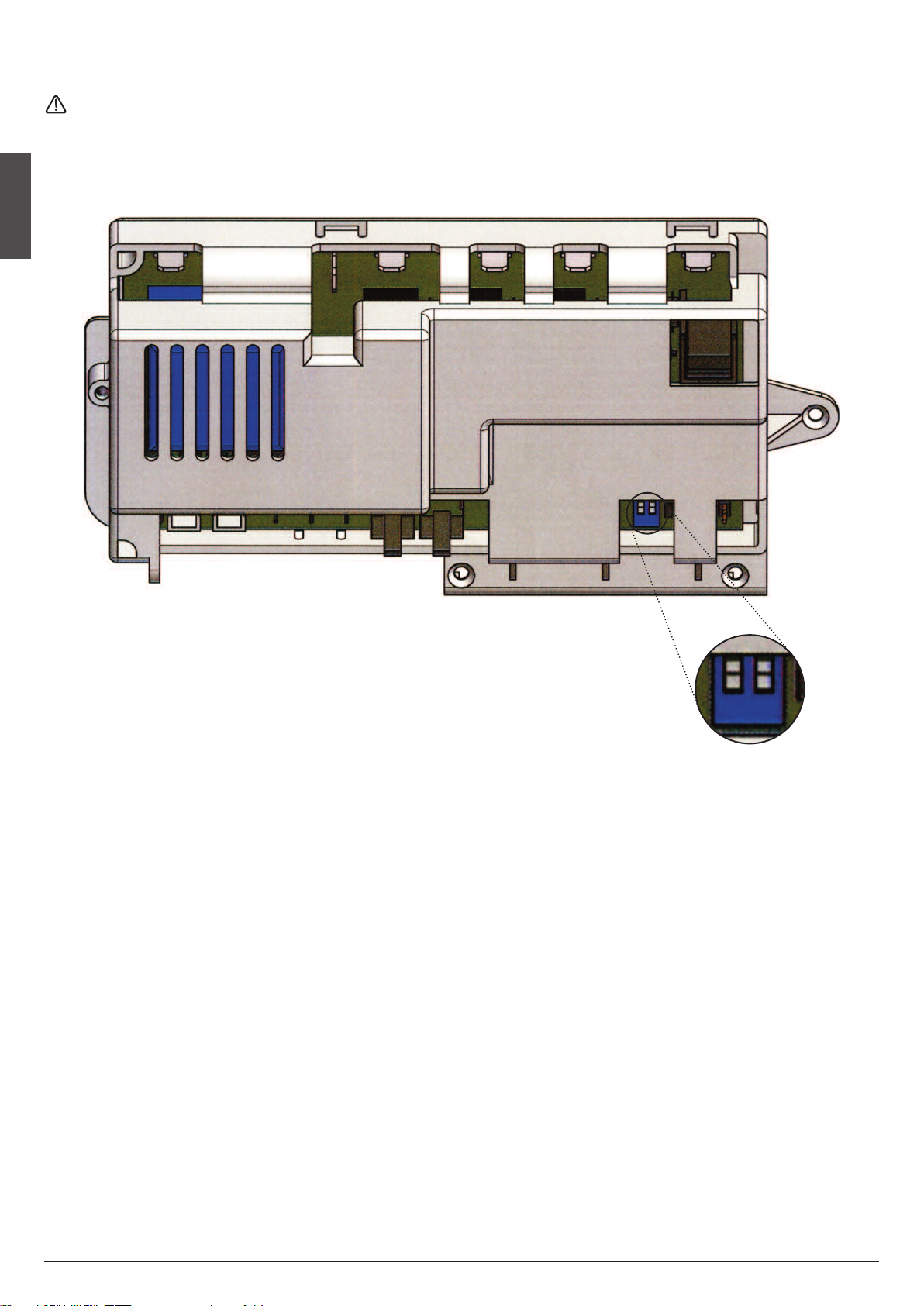

8.5 PROGRAMMED MAINTENANCE WARNING

• The programmed maintenance time is set at 0 hour by the

manufacturer.

• In order to modify this time and/or reset the maintenance

recall function; proceed with dipswitch setup, as shown in

the attached table.

DIP

1 2

1

2

3

4

OFF

ON

OFF

ON

OFF

ON

OFF

ON

(bar)

starting cycle (°c)

Evaporation

temperature

pressure end cycle

Condensing

Interval of maintenance to 0 hour

Interval of maintenance to 2000 hours

Interval of maintenance to 6000 hours

Interval of maintenance to 3500 hours

cycle (bar)

Evaporation

temperature end

NOTE

on 24 hrs/kw

Electrical

consumption

in gr

weight singel cube

Cubes for cycles and

Water consumption

l/h*

* In case of programmed maintenance, to reset and to restore

the programming to the initial value it's necessary to press

the RESET button for at least 5 seconds.

71503928/0 - REV.0001/2013

13

Page 14

.6 CONNECTION OF ELECTRICAL CABLES AND COMPONENTS

8

TO THE PC BOARD

bserve the connection with the colors of electric cables.

O

Blue

English

Brown

Orange

Black

White

Red

Micro tip

Micro defrost

Cumun micro

Float level sensor

Probe deposit ice

Dip. Switch

to set the

Condenser probe

maintenance hours

14

71503928/0 - REV.00 01/2013

Page 15

9. MAINTENANCE

9.1 PERIODICAL MAINTENANCE AND CLEANING

leaning and maintenance especially will vary, depending

C

upon ambient and use conditions.

In particular affect: hard water, ice volume produced and

location requirements.

The following maintenance procedures should be sched-

led once per year al least from the local service Agency.

u

Be sure the electrical power supply of the machine is OFF,

before starting any maintenance and cleaning procedure.

a) Close the water supply, shut-o valve, disconect the water

inlet pipe and remove the strainer from its seat in the water

inlet elettrovalve withdrawing it bay means of pilers. Clean

the strainer under running water and reassemble.

b) Check that the ice maker cabinet is levelled in side-to-side

and front-to-rear directions.

c) Check paddle shaft motor and harvest motor operation.

d) If you think it opportune, check by means of a gauges the

delivery pressure and the evaporator temperature.

e) Clean the air-cooled condenser using a nonmetal brush or a

vacuum cleaner.

f) Check that fan blades move freely and are not touching any

sourfaces.

g) Check for refrigerant leaks.

h) Check for water leaks. Pour water down bin drain to be sure

that drain line is open and clear.

i) Check operation of the bin thermostat.

9.2 ICEMAKER CLEANING

a) Remove the top panel.

b) Remove all ice from the storage bin.

c) Close the water supply shut-o valve.

d) Fill tilting pan with a solution of water and citric acid (200-

400 grs. of citric acid in one litre of water) and by means of

a brush clean the inside of the tilting pan and the evaporator ngers. Start the icemaker to tilt the pan, rinse with clean

water in abudance and repeat cleaning three times.e)

Add hot water to the ice storage bin and thoroughly wash

and rinse all surfaces within the bin.

f) Clean and sanitize the ice storage bin frequently.

9.3 PARTS REPLACEMENT PROCEDURES

a) ADJUSTABLE LEGS FOR N55S÷N90L MODELS

• Using the couplings and adjustable feet supplied and screwing them on the base nipples the icemaker can be placed at

9,5 cm. abt. from ground level.

• Extended feet are available on request to adjust the icemaker at 16 cm. about from ground level.

• The adjustment should be performed during initial installation of the cabinet and any time the cabinet is moved from

the original location to another site.

b) COMPRESSOR REPLACEMENT

• Remove the front panel grid and the right side panels.

On N45S÷N140 models remove the rear panel grid and the

•

side panels.

• Remove the cover and disconnect the electrical leads from

the compressor junction box.

• Bleed o or blow the refrigerant charge through the valve.

Unsolder and disconnect both the suction line and the dis-

•

charge line (from the compressor).

• Remove compressor mounting bolts and the compressor

from the unit base.

• Always install a replacement drier, anytime the sealed refrigeration system is open. Do not replace the drier until all other

repairs or replacements have been completed.

• To install the replacement compressor follow previous steps

in reverse.

• Thoroughly evacuate the system to remove moisture and

non-condensables after compressor replacement.

• Before proceeding with the refrigerant charge check nameplate for specic refrigeration charge for individual cuber.

c) AIR COOLED CONDENSER REPLACEMENT

• Remove the front panel grid and the right side panels.

• Remove the screws which attach the condenser to the unit

base.

• Bleed o or blow the refrigerant from the system.

• Unsolder the refrigerant lines from condenser and remove it

from the unit.

• Install the replacement condenser following previous steps

in reverse.

• Thoroughly evacuate the system to remove moisture and

non condensables; then proceed with the charge of FREON

R134a.

d) DRIER REPLACEMENT

• Remove the front panel grid and the right side panels.

• Bleed o or blow the refrigerant charge through the Henry-

type valve.

• Unsolder the capillary tube from one end of the drier and

the refrigerant line from the other end.

• To install a replacement drier remove factory seals.

• Thoroughly evacuate the refrigerant system.

• Charge the system with refrigerant by weight (see name-

plate) and check for leaks.

e) FAN MOTOR REPLACEMENT

• Remove the front panel grid and the right side panels.

• Trace the electric wire leads of fan motor and disconnect the

same.

• Remove the bolts securing the fan motor assembly to the

cabinet base and the remove the assembly.

• Install the replacement fan motor following previous steps

in reverse anc check that the fan blade do not touch any

sourface and move freely.

English

Be sure the electrical power supply and the water supply

are OFF, before starting any removal and replacement procedures, as a precaution to prevent possible personal injury or damage to equipment.

71503928/0 - REV.0001/2013

15

Page 16

) EVAPORATOR ASSEMBLY REPLACEMENT

f

• Remove the top cover.

• Remove six screws securing the paddle shaft supports (two)

and the paddle motor support; then remove the paddle

motor/paddle shaft/supports assembly.

Remove the bolts securing the evaporator supports (two) to

•

the cabinet.

• Sideways remove the evaporator supports.

• Unsolder the capillary tube, the hot gas solenoid valve tube

English

and the suction line.

To install the replacement evaporator assembly follow pre-

•

vious steps in reverse.

• Install the replacement drier; thoroughly evacuate the system and proceed with the refrigerant charge.

g) WATER RESERVOIR/TILTING LEVER/SUPPORT ASSEMBLY

REPLACEMENT

• Remove screws and top cover.

• Remove the gear motor/paddle shaft/support assembly.

• Remove the screws securing the evaporator supports (two).

• Sideways remove one evaporator support support as well as

one reservoir gudgeon support.

• Slightly lift the evaporator and remove the water reservoir

assembly.

• To install the replacement water reservoir assembly follow

previous steps in reserve.

) HARVEST MOTOR REPLACEMENT

l

• Remove the top cover.

• Remove the screws securing the harvest motor to the cabi-

net base.

• Remove the seeger from the cam pin.

Trace the electric wire leads of harvest motor and disconnect

•

the same; then remove the harvest motor/cam/support assembly.

• Remove the lock pin securing the cam to the motor shaft

and the screws joining the harvest notor to the relative sup-

ort.

p

• Install the replacement harvest motor on the support and

apply the cam; make a Ø 3 mm hole on the motor shaft and

to do it take as a guide the hole already existing on the cam.

• To install the replacement harvest motor assy follow previous steps in reverse.

h) WATER INLET ELECTROVALVE REPLACEMENT

• Remove the rear panel.

• Check that water supply is closed.

• Disconnect the water supply connection pipe from the valve

and that of the electrovalve from the reservoir.

• Break contact from the electrovalve and remove the screws

(two) securing the electrovalve to the relevant frame.

• To install the replacement electrovalve follow previous steps

in reverse; before installing the water supply pipe check that

the gasket is not defective.

i) PADDLE MOTOR REPLACEMENT

• Remove the top cover.

• Remove six screws securing the paddle shaft supports (two)

and the paddle motor support.

• Trace the electric wire leads of paddle motor and disconnect

the same; then remove the paddle shaft motor assy.

• Remove the paddle shaft assy from the paddle motor gudgeon (or guide pin).

• To install the replacement paddle motor follow previous

steps in reverse.

16

71503928/0 - REV.00 01/2013

Page 17

ACHTUNG

i

INDEX

Beschreibung Pag.

DIE MIT DIESEM SYMBOL GEKENNZEICHNETEN

OPERATIONEN DÜRFEN NUR VON EINEM

AUTORISIERTEN KUNDENDIENSTTECHNIKER

DURCHGEFÜHRT WERDEN.

Im Einzelnen:

• Elektrischer Anschluss

• Wasseranschluss

• Installation

• Maschinentest

• Reparatur aller Teile und Werkteile des

Gerätes

• Demontage des Gerätes bzw. seiner Bauteile

• Regulierung und Eichung des Gerätes

• Wartung und Reinigung des Gerätes

Entsprechend Ihrer Teile und Komponenten:

- Elektrische,

- Elektronische,

- Mechanische,

- Gefrier-.

DER TEXT MIT DIESEM SYMBOL IST VON

BESONDERER BEDEUTUNG UND WEIST AUF

POTENZIELLE GEFAHR HIN

1. INSTALLIEREN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.1 ANSCHLUSS DES GERÄTES

AN DIE STROMVERSORGUNG . . . . . . . . . . . . . . . . . . . . 18

2. INBETRIEBNAHME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3. ARBEITSWEISE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 ALARMMELDUNGEN FÜR DIE MODELLE

AUSFÜHRUNG WASSER / LUFT . . . . . . . . . . . . . . . . . . .19

4. MELDUNGEN AUF DER SCHALTFLÄCHE . . . . . . . . . . . . . 20

5. FUNKTIONSSTÖRUNGEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6. HINWEISE FÜR DEN “SERVICE” . . . . . . . . . . . . . . . . . . . . . . . 20

7. REINIGUNG UND WARTUNG

7.1 KONDENSATOR REINIGEN . . . . . . . . . . . . . . . . . . . . . . . . 21

7.2 REINIGEN DES ZUFLUSSWASSERFILTERS . . . . . . . . . 21

7.3 REINIGEN DES VORRATSBEHÄLTERS . . . . . . . . . . . . . . 21

8. TECHNISCHE DATEN FÜR DEN SERVICE

8.1 FUNKTIONEN DER ELEKTRONISCHEN

LEITERPLATTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.2 EINGÄNGE UND AUSGÄNGE

DER ELEKTRONISCHEN LEITERPLATTE . . . . . . . . . . . . 22

8.3 BETRIEBSEIGENSCHAFTEN . . . . . . . . . . . . . . . . . . . . . . . 22

8.4 EIGENSCHAFTEN DER KÜHLANLAGE . . . . . . . . . . . . 23

8.5 PROGRAMMIERTER WARTUNGSHINWEIS . . . . . . . . . 23

8.6 ZUSAMMENSTECKEN DER ELEKTRISCHEN

LEITUNGEN UND KOMP. FÜR DIE PC BOARD . . . . . 24

9. WARTUNG

9.1 WARTUNG UND REGELMÄSSIGE REINIGUNG . . . . .25

9.2 REINIGEN DER EISMASCHINE . . . . . . . . . . . . . . . . . . . . .25

9.3 VORGANGSWEISE ZUM AUSTAUSCHEN

VON TEILEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

10. RAEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11. SCHALTPLÄNE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Deutsch

ALLGEMEINE INFORMATIONEN

WICHTIG klärt den laufenden Betrieb

71503928/0 - REV.0001/2013

• Die Eismaschinen sind durch VDE zugelassen und tragen das

in Abb. fdargestellte Symbole auf der Verpackung, auf

dem Typenschild und auf der Karosserie.

CE

unsere produkte entsprechen den bestimmungen

2006/95/ce - 2004/108/ce und tragen daher das zeichen

auf dem umschlag der bedienungsanleitung.

• Dieses Gerät ist nicht dafür bestimmt, von Personen (einschließlich Kindern) benutzt zu werden, die aufgrund ihrer

physischen, sensorischen oder geistigen Fähigkeiten oder

ihrer Unerfahrenheit und Unkenntnis nicht in der Lage sind,

das Gerät sicher zu bedienen, es sei denn sie werden durch

eine für ihre Sicherheit zuständige Person beaufsichtigt und

erhielten von ihr Anweisungen, wie das Gerät zu benutzen

ist. Kinder sollten beaufsichtigt werden, um sicherzustellen,

dass sie nicht mit dem Gerät spielen.

Das Gerät nicht vor dem Eingriff des technischen Personals

in Betrieb nehmen (Abb. r)

17

Page 18

1. INSTALLIEREN

i

i

Vor der Inbetriebnahme folgende Hinweise für die Aufstel-

ung des Gerätes beachten:

l

1. Gerät auf Transportschäden untersuchen (Abb.

2. Zubehör aus dem Vorratsbehälter entnehmen: Versorgungsund Abflussschläuche, Unterlagen und eventuelles Zubehör.

. Vorratsbehälter mit einem Schwamm, warmem Wasser und

3

einem Sodabikarbonat auswaschen. Mit klarem Wasser nachspülen und gut austrocknen.

4. Gerät an dem vorgesehenen Platz aufstellen und waagerecht

ausrichten (Abb.

Wichtig: Bei der Auswahl des Installationsraums des Gerätes

muss sichergestellt werden, dass:

• die Raumtemperatur sinkt nicht unter 10°C (50°F) und steigt

nicht über 32°C (90°F).

• die Wassertemperatur sollte nicht unter 10°C (50°F) und nicht

Deutsch

über 32°C (90°F) sein (Abb. u).

• der Wasserversorgungsdruck darf nicht unter 0,1 MPa (1 bar)

liegen und 0,5 MPa (5 bar) nicht überschreiten.

Sollte der Druck 0,5 MPa überschreiten muss ein Druckminderer

an die hydraulische Versorgung der Maschine angebracht werden (Abb. i).

• in der Nähe der Maschine dürfen keine Wärmequellen vorhanden und Luftzirkulation muss gegeben sein (Abb. o).

a

).

q

Wichtig: Die Maschine an einem Ort aufstellen, wo die Ventila-

ion der Kühleinheit nicht verdeckt wird (nur für luftgekühlte Ma-

t

schinen) (Abb.

).

• Die Maschine nicht an staubigen Orten aufstellen, da sich hier

der Kondensator der Kühleinheit schnell verstopfen kann (nur bei

luftgekühlten Maschinen ) (Abb. 2))

Sollte die Maschine an einem Ort aufgestellt sein, wo das Trink-

•

wasser einen hohen Salzgehalt hat, sollten die Anweisungen der

Herstellerfirma abgewartet werden, damit Störungen minimal

gehalten werden können.

• In dem Nahrungsmittelbehälter keine Flaschen oder ähnliches

aufbewahren, damit das Eis keinen schlechten Geruch oder Geschmack annehmen kann.

• Während des normalen Betriebes die Klappe des Eisbehälters

nicht offen stehen lassen

Die elektrische Anlage muss mit einem Differenzialschalter

ausgestattet sein (Sicherung).

1.1 ANSCHLUSS DES GERÄTES AN DIE STROMVERSORGUNG

• Bei einer eventuellen Beschädigung des elektrischen Stromkabels muss es durch Fachpersonal ersetzt werden, um jegliche Gefahr für Personen auszuschließen.

s

).

Anschluss nur an das Trinkwassernetz

4. Benutzen Sie den neuen Bausatz der mobilen Verbindungen

(Wasserleitung), der mit dem Gerät mitgeliefert wird. Der alte

Bausatz darf nicht wiederverwendet werden.

4. Die hydraulischen Anschlüsse vor den elektrischen ausführen.

4. Den beiliegenden Anschlussschlauch 3/4” am Gerät und am

Trinkwasseranschluss anschließen.

Aus praktischer Sicht und für die Sicherheit empfiehlt es sich,

ein Absperrventil vorzusehen (gehört nicht zum Lieferumfang) (Abb. h: 1. Schalter; 2. Steckdose; 3. Stecker; 4. Wassereinlass; 5. Absperrventil; 6. Wasserabfluss vom

Kondensator: wasserkühlende Ausführung; 7. Wasserabfluss

vom Behälter; 8. offener Wasserabfluss).

4. Abflussstutzen über einen Plastikschlauch (nicht länger als 1

Meter von der Maschine entfernt) von 20 mm lichtem Durchmesser zu einem Ablauf (Abb. h) führen.

18

71503928/0 - REV.00 01/2013

Page 19

2. INBETRIEBNAHME 3. ARBEITSWEISE

iii

Vor der Inbetriebnahme folgende Hinweise für die Aufstellung des Gerätes beachten:

. Zeichnungen nachschauen.

1

• Deckel nach Lösen der beiden Schrauben abnehmen.

• Transportblockierungen 1, 2, 3, von Paddelmotor, Paddeln

und Schwimmer entfernen (Abb.

Wasserkühlung muss an den Abfluss auch einen zweiten An-

chluss haben, der das Wasser aus dem Kondensator ableitet

s

Wichtig: Für einen richtigen Wasserabfluss muss eine Neigung

der Leitungen von min. 3% vorgesehen werden, wobei darauf geachtet werden muss, dass diese keine Knicke oder Verschlüsse

aufweisen. Es ist angemessen, dass die Leitungen durch einen offenen Siphon ableiten (Abb.

2. Vor dem Netzanschluss der Maschine ist zu überprüfen, dass

die vorhandene Spannung mit den Angaben des Typenschildes auf der Rückseite des Gerätes übereinstimmt.

Die maximale zugelassene Toleranz der Spannungsabweichung beträgt ± 10% vom Nennwert.

• Für das Gerät muss ein elektrischer Versorgungskreislauf mit

einem doppelpoligen Hauptschalter, einer Unterbrechung

der Kontakte von min. 3mm sowie einer Sicherung oder automatischen Schutz und einer geerdeten Steckdose vorhanden sein.

• Alles muss für die Stromstärke geeignet sein, die auf dem

Schild der Fabrikationsnummer verzeichnet ist (Abb. ;). Die

Steckdose sollte einfach zu erreichen sein.

h

) Bei Ausführungen mit

j

).

Zum Ein- und Ausschalten der Maschine ist lediglich der

ON/OFF-Schalter zu drücken .

Die Eiswürfelerbereiter sind besonders kompakt. Sie lassen sich

•

daher leicht in jede Einrichtung einfügen.

• Die Eiswürfel entstehen an den Fingern eines Verdampfer, die

in eine mit Wasser gefüllte Wanne hineinragen, welches durch

drehende Paddel ständig in Bewegung gehalten wird.

Der Wasserstand wird durch einen Schwimmer konstant gehalten,

•

der über einen Mikroschalter das Wasser-Magnetventil steuert.

• Wenn die Eiswürfel die vorgesehene Größe erreicht haben und

die Paddel berühren, bewegt sich der Paddelmotor und schaltet über einen Mikroschalter das Relais ein.Dadurch geschieht

Folgendes:

- heißes Gas strömt durch das geöffnete Magnetventil in den

Verdampfer. Er wird erwärmt und die Eiswürfel lösen sich.

- der Wannenmotor läuft an und schwenkt die Wanne abwärts.

• Die Eiswürfel werden durch das Ablenkgitter in den Vorratsbehälter gelenkt.

• Das in der Wanne verbliebene Wasser gelangt in den Wasserbehälter an der Seite des Vorratsbehälters und von dort in den

Abfluss. Die Wanne bewegt sich nun automatisch nach etwa

einer Minute in die Horizontale zurück und füllt sich bis zu dem

eingestellten Wasserhöchststand. Inzwischen ist das Heißgasventil geschlossen und der neue Gefriervorgang beginnt.Die

Zeit für einen kompletten Programmablauf liegt zwischen 15’

und 25’ Minuten in Abhängigkeit von der Wasser- und der Umgebungstemperatur.

• Die Füllung des Vorratsbehälters wird durch einen Thermostatfühler überwacht, der an einer Seitenwand angebracht ist. Sobald der Fühler von Eis berührt wird, wird die Eisproduktion

unterbrochen. Erst wenn soviel Eis entnommen wurde, dass der

Fühler wieder frei ist, arbeitet das Gerät automatisch weiter.

Deutsch

Wichtig: Für eine schnelle Wiederaufnahme der Produktion, nach

der Entnahme den Kontrollfühler von eventuellen Eisrückständen

befreien.

3.1 ALARMMELDUNGEN FÜR DIE MODELLE AUSFÜHRUNG

WASSER / LUFT

• Temperaturüberschreitung Kondensator: das Gerät schaltet

sich automatisch wieder ein sobald der Grund der Alarmmeldung beseitigt wurde. Auslöser können sein: Luftfilter verstopft,

Ventilator defekt, Raumtemperatur zu hoch, Wasser fehlt (nur

bei der Ausführung mit Wasser).

• Fehler Wasser: sollte Leitungswasser fehlen, schaltet sich das

Gerät 60min nach der Alarmmeldung automatisch wieder ein.

Wichtig: Es ist möglich die Alarmbedingungen abzuwenden ohne

die Stromversorgen ab- und wieder einzuschalten (Taste ON/OFF).

Ausschalten des Gerätes aufgrund eines vollen Behälters. Die

•

Sonde des Behälters steuert von der elektronischen Leiterplatte aus

die Abschaltung des Gerätes, sobald Eis mit ihr in Berührung kommt.

Das Gerät schaltet sich am Ende des Entfrostungszyklus ab.

71503928/0 - REV.0001/2013

19

Page 20

4. MELDUNGEN

6. HINWEISE “SERVICE”

Statusfunktion

Gerät eingeschaltet ON OFF

Fühler Vorratsbehälter defekt

Kondensatorsfühler

defekt

Fehler: Kühlzyklus zu

lang oder Abtauvorgang zu lang

Fehler

Temperaturüberschreitung

Kondensator

Deutsch

Fehler kein Wasser LL ON

Wartungsanzeige LA LA

Waschen / Reinigung

Warten Start LV OFF

LL= langsames Aufleuchten

LV= schnelles Aufleuchten

LA= unterschiedliches Aufleuchten

ON= Dauerlicht

LED 1

Grün

OFF LL

OFF LL

ON ON Maschine zu

OFF ON Maschine zu

LV LV

LED 2

Anmerkungen

Rot

Gilt für alle Zustände, die

nicht Alarme oder Fehlermeldungen sind

Fühler außerhalb des

Richtwertes

ühler außerhalb des

F

Richtwertes Die Maschine

unktioniert auf jeden Fall

f

Die Meldung wird angezeigt nach Versuch Gerät

wieder einschalten

Betriebstundenlimit erreicht

Die Maschine funktioniert

auf jeden Fall

Es wird angezeigt wenn

das Gerät sich in Routinereinigung bendet

Warten auf Neustart nach

dem Ausschalten

DIE FOLGENDEN EINGRIFFE DÜRFEN NUR

VON EINEM AUTORISIERTEN KUNDEN

DIENSTTECHNIKER DURCHGEFÜHRT WERDEN

1. Wasserabsperrventil öffnen und Netzstecker einstecken. Das

erät nimmt automatisch seinen Betrieb auf (Abb.

G

dem die Betriebstaste ON/OFF gedrückt wurde (Abb.

2. Sicherstellen, dass das Wasser an der Wanne angelangt, dass

der Sensor bzw. der Schwimmer den Eintritt vor dem Überlaufen stoppt und das keine Leckagen an der Anlage und an

den Wasserleitungen vorliegen. Das normale Wasserniveau

in der Wanne beträgt circa 5 / 10 mm an den oberen Rändern (Abb. k)

Der Wasserstand kann nach dem Lösen der Schrauben 1

(Abb. k) durch Schwenken des Schwimmschalters verändert werden. Diese Einstellung nur mit abgeschalteter Stromzufuhr vornehmen.

3. Prüfen, ob Nebengeräusche auftreten. Diese werden meist

durch gelockerte Schrauben verursacht.

4. Keine Arbeiten am Gerät durchführen während dieses unter

Spannung steht.

5. Arbeitsablauf des Gerätes kontrollieren. Prüfen, ob alle Eiswürfel in den Vorratsbehälter gelangen.

6. Die Funktion der Sonde im Behälter prüfen: einen Eiswürfel

an das Thermostat im Inneren des Behälters halten. Das Gerät

sollte sich innerhalb von 1min abschalten und automatisch

wieder einschalten, nachdem das Eis entfernt wurde, nach

nicht mehr als einer weiteren Minute.

7. Deckel wieder aufsetzen.

g

, nach-

)

2@

).

5. FUNKTIONSSTÖRUNGEN

• Im Falle einer erhöhten Kondensatortemperatur

Die Maschine stoppt, nur der Luft-Wasserkondensator bleibt in Betrieb. Die Maschine startet automatisch erneut, wenn die Temperatur wieder unter den gesetzten Grenzwert fällt. Erfolgt innerhalb von 5 Stunden der dritte Alarm in Folge, dann stoppt die Maschine

komplett.

• Einfrier-Zyklus zu lang

Wenn der dritte Alarm in Folge innerhalb von 5 Stunden erfolgt, stoppt die Maschine komplett.

Berechnung der maximalen Zeit des Einfrier-Zyklus:

1. Zyklus = 50 Minuten

2. Zyklus = Dauer des 1. Zyklus x 1,5.

Wenn der 1. Zyklus weniger als 7 Minuten dauerte, dann liegt die maximale Zeit des folgenden Zyklus bei 50 Minuten.

• Abtau-Zyklus zu lang

Wenn das Abtauen länger als 2 Minuten dauert und innerhalb von 5 Stunden 2 Fehler auftreten, dann stoppt die Maschine.

• Einfrier-Zyklus liegt unter 7 Minuten

Die Elektronik berechnet die Zykluszeit auf 50 Minuten oder länger.

• Wasserbeladezeit zu lang

Wenn die Wasserbeladezeit 5 Minuten übersteigt, dann erfolgt ein Not-Stopp der Maschine. Nach einer Zeit von 120 Minuten startet

die Maschine automatisch erneut. Wenn das Wasser weiterhin fehlt, dann versucht die Maschine alle 120 Minuten neu zu starten.

20

71503928/0 - REV.00 01/2013

Page 21

7. REINIGUNG UND WARTUNG

i

DIE FOLGENDEN EINGRIFFE DÜRFEN NUR

VON EINEM AUTORISIERTEN KUNDEN

DIENSTTECHNIKER DURCHGEFÜHRT WERDEN

• Für die Reinigung des Aufbaus ist ein mit einem spezifischem

Reinigungsmittel für rostfreien Stahl (ohne Chlor) befeuch-

etes Tuch ausreichend.

t

Wichtig: Vor der Durchführung von Wartungs- und Reinigungsoperationen muss die elektrische Versorgung abgetrennt

werden.

7.1 KONDENSATOR REINIGEN

• Für eine längere Lebensdauer und höhere Effizienz des Gerätes ist es notwendig eine wöchentliche Reinigung der Luftfilter durchzuführen, die an der Vorderseite angebracht sind

2#

).

(Abb.

• Um den Filter zu entfernen ist es ausreichend, ihn herauszuziehen und mit einem lauwarmen Wasserstrahl zu reinigen

und ihn vor dem Wiedermontieren abzutrocknen.

Für die Reinigung des Filters keine Bürsten oder stumpfe

Gegenstände benutzen.

Für alle außerordentlichen Wartungs- oder/und Reparaturar-

eiten (mechanisch und elektrische Teile sowie Gefrierkom-

b

ponenten), die zum Austausch oder/und der Einstellung von

Bestandteilen führen, sollte sich immer an ein autorisiertes

Servicecenter gewandt werden.

ollte das Gerät längere Zeit ausgeschaltet sein:

S

- das Gerät abschalten

- Eis aus dem Behälter entfernen

- Wasser ablassen

- ein gründliche Reinigung vornehmen

- die Klappe des Behälters einen spaltbreit geöffnet lassen

Deutsch

Um Funktionsstörungen zu vermeiden, ist es absolut verboten, den Eiswürfelbereiter ohne Luftfilter zu betreiben.

7.2 REINIGEN DES ZUFLUSSWASSERFILTERS

• Wasserabsperrventil schließen. Anschlussschlauch am Gerät

abschrauben und Filter mit einer Zange aus seinem Sitz am

Eingang des Wassermagnetventil nehmen.

• Unter fließendem Wasser reinigen und wieder einsetzen.

7.3 REINIGEN DES VORRATSBEHÄLTERS

• Eis entnehmen. Behälter mit einem Schwamm auswaschen.

Hierzu warmes Wasser und ein mildes Reinigungsmittel verwenden.

• Mit klarem Wasser nachspülen und austrocknen.

71503928/0 - REV.0001/2013

21

Page 22

8. TECHNISCHE DATEN FÜR DEN SERVICE

DIE FOLGENDEN EINGRIFFE DÜRFEN NUR

VON EINEM AUTORISIERTEN KUNDEN

DIENSTTECHNIKER DURCHGEFÜHRT WERDEN

8.1 FUNKTIONEN DER ELEKTRONISCHEN LEITERPLATTE

Kontrolle der Eismenge durch Sonde

•

• Kontrolle der Kondensationstemperatur durch Sonde (bei

Temperaturen > 70°C Ausführung Wasser; > 80°C Ausführung Luft Abschaltung des Geräts).

• Kontrolle der Wartung. Es ist möglich Wartungshinweise zu

programmieren, die nach einer bestimmten Anzahl von Betriebsstunden erscheinen.

8.2 EINGÄNGE UND AUSGÄNGE DER ELEKTRONISCHEN

LEITERPLATTE

Deutsch

Eingänge mit

Niedrigspannung

Kondensatorsonde

Behältersonde

Wasserstandssonde

Mikroschalter

Abtauungsstart

Mikroschalter

Abtauungsstopp

Eingänge mit

Hochspannung

230V/ 50HZ

Verdichter

Schwenkungsmotor

Magnetventil Heißgas

Leiterplatte

Elektronische

Magnetventil Wasser

Getriebemotor Paddel

Elektroventilator

8.3 BETRIEBSEIGENSCHAFTEN

• Nach dem Start der Maschine durchläuft diese einen Abtauyklus und entleert die Wasserwanne. "Abtauungszyklus mit

z

Ablauf des Wanneswassers"

• Der Eiswürfelproduktionszyklus beginnt mit einer Verzöge-

rung von 2 Minuten, in welcher er den Kühlkreis vorkühl

• Während des Betyriebszyklus, nach jeder Abtauung, wird die

asserwanne mit einer Verzögerung von 80 Sek. gekühlt, in

W

welcher der Verdampfer vorgekühlt wird.

• Wenn der Vorratsbehälter voll ist, schaltet das Gerät nach

dem Abtauzyklus ab.

• Alarmliste für die Luft/Wassergekühlte Versionen:

- Wenn der Kondensator überhitzt, schaltet das Gerät ab und

es erscheint eine Fehlermeldung. Nach der Abkühlung des

Kondensators nimmt das Gerät den Betrieb wieder auf.

- bei Wassermangel schaltet das Gerät ab und es erscheint

eine Fehlermeldung. Nach 60 Minuten nimmt das Gerät den

Betrieb automatisch wieder auf.

• Kondensatorsonde: mit Kondensatortemperatur < 24°C ar-

beitet der Ventilator so, dass optimale Konditionen gegeben

sind für Kondensation und die Leistungsfähigkeit des Geräts.

• Widerstandswerte der Temperatursonden (die Ablagerungssonde und die Kondensersonde) in Bezug auf die Raumtemperatur:

Temperatur °C Sensorwiderstand Ohm

20 2762,034556

25 2200,000000

30 1765,531939

• Reset der Mikroprozessorplatine

Den Schalter ON/OFF betätigen.

22

71503928/0 - REV.00 01/2013

Page 23

.4 EIGENSCHAFTEN DER KÜHLANLAGE MIT KÜHLMITTEL

8

R134A

• Durchschnittliche und maximale Aufnahme der Geräte mit

Paddeln der Serie “E” bei einer Raumtemperatur von 32°C.

• Kondensationsdruck und Temperatur des Verdampfers Zy-

lusbeginn und -Qnde bei einer Raumtemperatur vom 32°C.

k

Geräte

Gas

Max. Amper

Amper

Durchschnitt

Zyklusstart (Bar)

Kondensationsdruck

21 R134a 2 A 1,8 A 11,5 -3,3 9 -17 7,5 15/17 GR 6

25 R134a 1,6 A 1,4 A 11,0 -2 9 -13 5,8 15/17 GR 2,8

35 R134a 2,7 A 2,1 A 14,0 -2 10 -15 8,6 20/17 GR 4,7

60 R134a 4,2 A 3,4 A 14,7 -2 11,3 -15 12,7 35/17 GR 7,5

75 R134a 4,6 A 3,8 A 14,6 -2 11,4 -13 13,3 60/17 GR 9,4

90 R134a 4,7 A 4,2 A 14,9 -2 10,8 -15 14,4 60/17 GR 12,5

* In Litern pro Stunde bei einer Wassertemperatur von 15°C

und einer Raumtemperatur von 21°C

8.5 PROGRAMMIERTER WARTUNGSHINWEIS

• Die programmierte Wartungszeit wird in der Fabrik auf 0

Stunden eingestellt.

• Um diese Zeitspanne zu verändern und/oder die Wartungs

hinweisfunktion auszuschießen, muss das Setup der Dip

Switch nach der beigelegten Tabelle durchgeführt werden.

DIP

1 2

1

2

3

4

OFF

ON

OFF

ON

OFF

ON

OFF

ON

(°c)

peratur Zyklusstart

Verdampfungstem-

Druck Zyklusende

(Bar)

Kondensations

Zyklusende (Bar)

Temperatur

Verdampfungs

Stromverbrauch

Würfel Für Zyklus

Bei 24 H/Kw *

In G

Einzelnen Würfels

Und Gewicht Eines

l/h*

Wasserverbrauch

Deutsch

NOTE

Wartungsintervall 0 Stunden

Wartungsintervall von 2000 Stunden

Wartungsintervall von 6000 Stunden

Wartungsintervall von 3500 Stunden

* Im Fall von Vorprogrammierte Wartung, um den Wert zu lö

schen, die RESET Taste für 5 Sekunden drücken.

71503928/0 - REV.0001/2013

23

Page 24

.6 ZUSAMMENSTECKEN DER ELEKTRISCHEN LEITUNGEN

8

UND KOMPONENTEN FÜR DIE PC BOARD

Die Verbindung mit dem COLORS von elektrischen Kabeln.

Blau

Deutsch

Braun

Orange

Schwarz

Weiß

Rot

Dip. Switch

Wasserniveau-Sensor

Steuerleitung Abtauung

zur Einstellung der

Wartungsstunden

Füllstandsensor Eisbehälter

Mikroschalter Ende Abtauung

Mikroschalter Beginn Abtauung

Temperatursensor Kondensator

24

71503928/0 - REV.00 01/2013

Page 25

9. WARTUNG

9.1 WARTUNG UND REGELMÄSSIGE REINIGUNG

ie Häufigkeit von Reinigung und speziell der Wartung

D

wird je nach Umgebung und Betriebsbedingungen variieren. Insbesondere hat folgendes Auswirkungen: hartes

Wasser, produziertes Eisvolumen und Anforderungen des

Standortes.

ie nachstehenden Wartungsarbeiten sollten mindestens

D

einmal jährlich von Ihrem Kundendienst vor Ort festgesetzt werden.

Achten Sie darauf, dass die Stromversorgung der Maschine

abgeschaltet ist, bevor mit Wartungsarbeiten oder mit der

Reinigung begonnnen wird.

a) Schließen Sie die Wasservorsorgung mit dem Sperrventil,

schrauben Sie das Wasserzuussrohr ab und entfernen Sie

das Sieb aus seinem Sitz am Wasserzuuss-des Magnetventil, indem Sie es am Stapler herausziehen. Reinigen Sie das

Sieb unter ießendem Wasser und bauen Sie es dann wieder ein.

b) Überprüfen Sie, ob der Eismaschinenkorpus seitlich und von

vorne nach hinten ausnivelliert ist.

c) Überprüfen Sie den Betrieb des Schaufelwellen- und des Ent-

nahmemotors.

d) Wenn Sie es für angebracht halten, prüfen Sie mit Messge-

räten den Abgabedruck und die Temperatur des Verdampfers

e) Reinigen Sie den luftgekühlten Kondensator mit einer Bür-

ste (keine Drahtbürste) oder mit einem Staubsauger.

f) Überprüfen Sie, ob sich die Ventilatorblätter frei bewegen

und an keinen Flächen anstreifen.

g) Prüfen Sie das Gerät auf Kühlmittellecks.

h) Prüfen Sie das Gerät auf Wasserlecks. Gießen Sie Wasser durch

den Abuss des Beckens, um sicherzustellen, dass die Abussleitung frei von Verstopfungen ist.

i) Prüfen Sie den Betrieb des Lagergefäß-Thermostats.

9.2 REINIGEN DER EISMASCHINE

a) Entfernen Sie die obere Deckplatte

b) Nehmen Sie alles Eis aus dem Lagergefäß heraus.

c) Schließen Sie das Wasserzufuhr-Sperrventil.

d) Füllen Sie das Neigebecken mit einer Lösung aus Wasser und

Zitronensäure (200-400 g Zitronnensäure auf einen Liter Wasser) und reinigen Sie die Neigepfanne und die Verdampfernger mit einer Bürste. Lassen Sie die Eismaschine das

Becken neigen und spülen Sie es mit reichlich Wasser ab.

Wiederholen Sie diese Reinigung drei Mal.

e) Geben Sie heißes Wasser in das Eislagergefäß und waschen

und spülen Sie alle Flächen im Gefäß gründlich.

f) Reinigen und desinzieren Sie das Eislagergefäß häug.

9.3 VORGANGSWEISEN ZUM AUSTAUSCHEN VON TEILEN

a) STELLFÜSSE

• Benutzen Sie gelieferten Kopplungen und Stellfüße und

schrauben Sie diese in die Bodenlaschen ein. Die Eismaschine kann bis auf 9,5 cm vom Boden hochgestellt werden.

• Auf Anfrage sind verlängerte Füße erhältlich, um die Eismaschine auf 16 cm vom Boden hochstellen zu können.

• Das Einstellen sollte bei der anfänglichen Installation der Eismaschine und jedes Mal, wenn diese vom ursprünglichen

tandort anders wohin verschoben wurde, vorgenommen

S

werden.

Achten Sie darauf, dass die Strom- und die Wasserversorgung abgeschaltet sind, bevor Sie Teile entfernen und aus-

auschen, um durch diese Vorsichtsmaßnahme

t

Körperverletzungen und Schäden am Gerät zu verhüten.

b) AUSTAUSCHEN DES KOMPRESSORS

• Entfernen Sie das vordere Gitter und die rechte Seite

• Entfernen Sie die Abdeckung und klemmen Sie die Strom-

drähte von der Verteilerdose des Kompressors ab.

• Entleeren Sie die Kühlmittelleitung über das Ventil.

• Löten Sie die Ansaugleitung und die Ablassleitung ab und

trennen Sie diese (vom Kompressor9 ab).

• Entfernen Sie die Befestigungsschrauben des Kompressors

und heben Sie ihn vom Boden des Gerätes heraus.

• Installieren Sie jedes Mal, wenn das versiegelte Kühlsystem

oen ist, einen Ersatztrockner. Tauschen Sie den Trockner

aber erst aus, wenn alle anderen Reparaturen bzw. Austauscharbeiten abgeschlossen sind.

• Zum Installieren befolgen Sie die oben angegebenen

Schritte in der umgekehrten Reihenfolge.

• Entleeren Sie nach dem Austauschen des Kompressors das

System gründlich, um Feuchtigkeit und nicht kondensierbare

Stoe zu entfernen.

• Vor dem Nachfüllen von Kühlmittel muss auf der Gerätplakette nachgesehen werden, welches Kühlmittel für das Gerät

nachzufüllen ist.

c) AUSTAUSCHEN EINES LUFTGEKÜHLTEN KONDENSATORS

• Entfernen Sie das vordere Gitter und die rechte Seite

• Entfernen Sie die Schrauben, mit denen der Kondensator am

Gerätboden befestigt ist.

• Entleeren Sie das Kühlmittel aus dem System.

• Löten Sie die Kühlmittelleitungen vom Kondensator ab und

nehmen Sie ihn aus dem Gerät heraus.

• Zum Installieren des Ersatzkondensators befolgen Sie die

oben angegebenen Schritte in der umgekehrten Reihenfolge.

• Entleeren Sie das System gründlich, um Feuchtigkeit und

nicht kondensierbare Stoe zu entfernen, dann befüllen Sie

es mit FREON R134a.

d) AUSTAUSCHEN DES TROCKNERS

• Entfernen Sie das vordere Gitter und die rechte Seite

• Entleeren Sie die Kühlmittelleitung über das Ventil vom Typ

Henry.

• Löten Sie das Kapillarrohr vom einen Ende des Trockners und

die Kühlmittelleitung vom anderen Ende ab.

• Zum Installieren eines Ersatztrockners müssen die werkseitigen Dichtungen entfernt werden.

• Das Kühlmittelsystem gründlich entleeren.

• Befüllen Sie das System mit Kühlmittel nach Gewicht (siehe

Gerätplakette) und überprüfen Sie es auf Leckstellen.

Deutsch

71503928/0 - REV.0001/2013

25

Page 26

) AUSTAUSCHEN DES VENTILATORMOTORS

e

• Entfernen Sie das vordere Gitter und die rechte Seite

• Verfolgen Sie die Stromdrähte des Ventilatormotors und

klemmen Sie diese ab.

• Enfernen Sie die Bolzen, mit denen die Baugruppe Ventilaor-Motor am Gerätboden befestigt ist und entfernen Sie

t

diese aus dem Gerät.

• Installieren Sie den Ersatzmotor, indem Sie die obigen

Schritte in der umgekehrten Reihenfolge befolgen und überprüfen Sie, ob das Ventilatorblatt nicht irgendeine Fläche be-

ührt und ob es sich frei bewegt.

r

f) AUSTAUSCHEN DER VERDAMPER-BAUGRUPPE

• Entfernen Sie die obere Deckplatte.

• Entfernen Sie die sechs Schrauben, mit denen die Schaufel-

wellenhalterungen (zwei) und die Schaufelmotorhalterung

befestigt sind, und entfernen Sie dann die Baugruppe aus

Schaufelmotor,Schaufelwelle und Halterungen.

• Entfernen Sie die Schrauben, mit denen die Verdampferhal-

terungen (zwei) am Gerät befestigt sind.

• Nehmen Sie die Verdampferhalterungen seitlich heraus.

• Löten Sie das Kapillarrohr, das Rohr des Heißgas-Magnet-

Deutsch

ventils und die Ansaugleitung ab.

• Zum Installieren des Ersatzverdampfers befolgen Sie die

oben angegebenen Schritte in der umgekehrten Reihenfolge.

• Installieren Sie den Ersatztrockner, entleeren Sie das System

gründlich und befüllen Sie es dann mit Kühlmittel.

g) AUSTAUSCHEN DER BAUGRUPPE WASSERTANK/NEIGEHE-

BEL/HALTERUNG

• Entfernen Sie die Schrauben und obere Deckplatte.

• Entfernen Sie die Baugruppe Getriebemotor/Schaufel/Hal-

terung.

• Entfernen Sie die Schrauben, mit denen die Halterungen des

Verdampfers (zwei).

• Entfernen Sie eine Verdampferhalterung nach der anderen

seitlich sowie eine Stifthalterung des Tanks.

• Heben Sie den Verdampfer leicht an und entfernen Sie die

Baugruppe des Wassertanks.

• Zum Installieren des Wassertanks befolgen Sie die oben

angegebenen Schritte in der umgekehrten Reihenfolge.

) AUSTAUSCHEN DES SCHAUFELMOTORS

i

• Entfernen Sie die obere Deckplatte.

• Entfernen Sie die sechs Schrauben, mit denen die Schaufel-

wellenhalterungen (zwei) und die Halterung des Schaufelmotors befestigt sidn.

Verfolgen Sie die Stromdrähte des Schaufelmotors nach und

•

klemmen Sie diese ab. Nehmen Sie dann die Baugruppe des

Schaufelwellenmotors heraus.

• Entfernen Sie die Schaufelwellengruppe vom Stift (bzw.

Führungszapfen) des Schaufelmotors.

Zum Installieren des Ersatz-Schaufelmotors befolgen Sie die

•

oben angegebenen Schritte in der umgekehrten Reihenfolge.

l) ERSETZEN DES ENTNAHMEMOTORS

• Entfernen Sie die obere Deckplatte.

• Entfernen Sie die Schrauben, mit denen der Entnahmemotor

am Gerätboden befestigt ist.

• Entfernen Sie den Schließring vom Nockenzapfen.

• Verfolgen Sie die Stromdrähte des Entnahmemotors nach

und klemmen Sie diese ab. Nehmen Sie dann die Baugruppe

des Entnahmemotors heraus.

• Entfernen Sie den Sperrstift mit dem die Nocke an der Motorwelle befestigt ist und die Schrauben, mit denen der Entnahmemotor mit seiner Halterung verbunden ist.

• Installieren Sie den Ersatz-Entnahmemotor an der Halterung

und bringen Sie die Nocke an. Bohren Sie ein Loch mit Ø 3

mm in die Motorwelle, wobei Sie als Führung das Loch benutzen, das an der Nocke bereits vorhanden ist.

• Zum Installieren des Ersatz-Entnahmemotors befolgen Sie

die oben angegebenen Schritte in der umgekehrten Reihenfolge.

h) AUSTAUSCHEN DES WASSERZULAUF-MAGNETVENTILS

• Entfernen Sie die Rückwand.

• Überprüfen Sie, ob die Wasserzufuhr abgesperrt ist.

• Trennen Sie das Wasserzufuhr-Anschlussrohr vom Ventil und

das Rohr des Magnetventils vom Tank ab.

• Unterbrechen Sie den Kontakt vom Magnetventil und entfernen Sie die Schrauben (zwei), mit denen das Magnetventil am zugehörigen Rahmen befestigt ist.

• Zum Ersetzen des Ersatz-Magnetventil befolgen Sie die obigen Schritte in umgekehrter Reihenfolge. Überprüfen Sie vor

dem Installieren des Wasserzufuhrrohrs, ob die Dichtung

nicht beschädigt ist.

26

71503928/0 - REV.00 01/2013

Page 27

ATTENZIONE

i

INDICE

LE OPERAZIONI EVIDENZIATE CON

QUESTO SIMBOLO

SONO STRETTAMENTE RISERVATE

AL TECNICO PATENTATO.

In particolare:

• Allacciamenti elettrici

• Allacciamenti idrici

• Installazione della macchina

• Collaudo della macchina

• Interventi di riparazione su tutti i componenti

e organi della macchina

• Smontaggio della macchina

e/o suoi componenti

• Interventi di regolazione e taratura

• Manutenzione e pulizia della macchina

relativa a parti e componenti

- Elettrici

- Elettronici

- Meccanici

- Frigoriferi

Descrizione Pag.

1. INSTALLAZIONE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.1

COLLEGAMENTO DELL’APPARECCHIATURA

ALLA RETE ELETTRICA

2. MESSA IN FUNZIONE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3. FUNZIONAMENTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

.1 SEGNALI DI ALLARME PER I MOD. ARIA/ACQUA . . 29

3

4. SEGNALAZIONE ELETTRONICA . . . . . . . . . . . . . . . . . . . . . . . 30

5. ANOMALIE DI FUNZIONAMENTO . . . . . . . . . . . . . . . . . . . . . 30

6. INFORMAZIONE PER IL SERVICE . . . . . . . . . . . . . . . . . . . . . . 30

7. PULIZIA E MANUTENZIONE

7.1 PULIZIA DEL CONDENSATORE AD ARIA . . . . . . . . . . 31

7.2 PULIZIA DEL FILTRO ENTRATA ACQUA . . . . . . . . . . . . 31

7.3 PULIZIA DEL CONTENITORE . . . . . . . . . . . . . . . . . . . . . . 31

8. DATI TECNICI PER IL SERVICE

8.1 FUNZIONE SCHEDA ELET TRONICA . . . . . . . . . . . . . . . 32

8.2 INGRESSI E USCITE SCHEDA ELETTRONICA . . . . . . . 32

8.3 CARATTERISTICHE DI FUNZIONAMENTO . . . . . . . . . . 32

8.4 CARATTERISTICHE DELL’IMPIANTO FRIGORIFERO . . 33

8.5 AVVISO DI MANUTENZIONE PROGRAMMATA . . . . . .33

8.6 CONNESSIONE DEI CAVI ELETTRICI E DEI

COMPONENTI ALLA SCHEDA ELETTRONICA . . . . . . . 34

9. MANUTENZIONE

9.1 MANUTENZIONE E PULIZIA PERIODICA . . . . . . . . . . .35

9.2 PULIZIA DEL FABBRICATORE DI GHIACCIO . . . . . . . .35

9.3 SOSTITUZIONE DEI COMPONENTI . . . . . . . . . . . . . . . .35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Italiano

IL TESTO EVIDENZIATO CON QUESTO SIMBOLO

È DI PARTICOLARE IMPORTANZA

O SEGNALA POTENZIALE PERICOLO

NOTA chiarisce le operazioni in corso

9. RAEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10. SCHEMI ELETTRICI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

INFORMAZIONI GENERALI

• I produttori di ghiaccio con approvazione VDE portano sull’imballaggio, sulla targhetta di immatricolazione e sulla carrozzeria il simbolo in fig. f.

CE

I nostri prodotti rientrano nelle direttive 2006/95/ec 2004/108/ec pertanto riportano anche la marcatura sulla

copertina del libretto.

• Questo apparecchio non è inteso per uso di persone -inclusi

bambini- con ridotte capacità fisiche, sensoriali o mentali, o

senza esperienza e conoscenza, a meno che abbiano ricevuto istruzioni relativamente all’uso dell’apparecchio e siano

controllati da una persona responsabile per la loro sicurezza.

I bambini dovrebbero essere controllati in modo da assicurare che non giochino con l’apparecchio

Non mettere in funzione l’apparecchio prima dell’intervento del tecnico (fig. r).

71503928/0 - REV.0001/2013

27

Page 28

1. INSTALLAZIONE

i

i

Italiano

Prima di mettere in funzione il produttore di ghiaccio ese-

uire le seguenti operazioni:

g

1. Controllare che l’apparecchio non abbia subito danni durante il trasporto (fig.

2. Estrarre dal deposito tutto il materiale in dotazione: tubo ali-

entazione, tubo scarico, documentazione ed eventuali ac-

m

cessori.

3. Pulire l’interno del deposito con una spugna inumidita in

acqua tiepida unita ad un poco di bicarbonato di soda; sciacquare con acqua pura ed asciugare accuratamente.

4. Posizionare il produttore nella sede definitiva assicurandosi

che sia perfettamente in piano (fig.

Nota: nella scelta dell’ambiente in cui installare la macchina è

necessario assicurarsi che:

• la temperatura ambiente non scenda al di sotto dei 10°C (50°F)

e non superi i 43°C (110° F).

• la temperatura dell’acqua non sia inferiore a 10°C (50°F) e non

superi i 32°C (90°F) (fig. u).

• la pressione dell’acqua di alimentazione non sia inferiore a 0,1

MPa (1 bar) e non superi i 0,5 MPa (5 bar). Qualora la pressione superi i 0,5 MPa prevedere l’applicazione di un riduttore di

pressione sull’alimentazione idrica alla macchina (fig. i).

• la macchina sia lontana da fonti di calore ed in posizione ben

aerata (fig. o).

q

).

).

a

Nota:Installare la macchina in posizione tale che la ventilazione

el gruppo frigorifero non sia in alcun modo ostacolata ( solo

d

per macchine raffreddate ad aria). (fig.

• Non installare la macchina in locali polverosi poiché si può verificare un rapido intasamento del condensatore del gruppo frigorifero (solo per macchine raffreddate ad aria) (fig. 2))

Nel caso in cui la macchina sia installata in zone dove l’acqua

•

potabile abbia un alto tenore di sali in soluzione, attenersi alle

istruzioni del costruttore onde limitare al minimo l’inconveniente.

Onde evitare che il ghiaccio assorba cattivi odori e sapori, non con-

•

servare mai nel contenitore alimenti, bottiglie ed altro.

• Durante il normale funzionamento non lasciare aperto lo sportello del contenitore del ghiaccio

Nell’impianto elettrico deve essere presente un interruttore

differenziale (salvavita).

1.1 COLLEGAMENTO DELL’APPARECCHIATURA

ALLA RETE ELETTRICA

• Nei casi in cui il cavo di alimentazione elettrica dell’apparecchio risultasse danneggiato, esso dovrà essere sostituito da

personale qualificato in modo da prevenire qualsiasi rischio

alle persone

s

).

Collegare solo alla rete d’acqua potabile.

5. Utilizzare il nuovo set di giunzioni mobili (tubo acqua) fornito con l’apparecchio. Il vecchio set di giunzioni non deve

essere riutilizzato.

6. Eseguire gli allacciamenti idrici prima di quelli elettrici.

7. Allacciare il tubo di alimentazione da 3/4” in dotazione, alla

macchina e alla linea idrica di alimentazione acqua fredda

potabile.

È consigliabile applicare per motivi di praticità e sicurezza un

rubinetto d’intercettazione, non di nostra fornitura (fig. h:

1. interruttore; 2. presa; 3. spina; 4. alimentazione idrica; 5. rubinetto; 6. scarico acqua dal condensatore: versione raffreddamento ad acqua; 7. scarico acqua dal deposito; 8. scarico

acqua con sifone aperto).

8.

Applicare sul raccordo di scarico acqua della macchina il tubo

flessibile in dotazione del diametro interno di 20 mm. e di una

lunghezza adeguata (non superiore ad un metro dalla macchina) a raggiungere il pozzetto di scarico (fig. h).

28

71503928/0 - REV.00 01/2013

Page 29

2. MESSA IN FUNZIONE 3. FUNZIONAMENTO

iii

1. prendere visione delle figure illustrative:

• togliere il coperchio previa rimozione delle viti di fissaggio

elative.

r

• sbloccare il motoriduttore, le palette ed il galleggiante (dove

presente) togliendo gli arresti 1, 2, 3, applicati in fabbrica per

evitare danni durante il trasporto (fig.

raffreddamento ad acqua collegare allo scarico anche il se-

ondo raccordo che convoglia l’acqua proveniente dal con-

c

densatore.

Nota: Per un perfetto deflusso dell’acqua dall’apparecchio prevedere una pendenza minima del 3% della tubazione controllando cha la stessa non subisca strozzature o sifonamenti. È

opportuno che la tubazione scarichi in un sifone aperto (fig.

2. Prima di collegare la macchina elettricamente, accertarsi che

il voltaggio di rete corrisponda a quello indicato sulla targhetta d’immatricolazione posta sullo schianale dell’apparecchio.

La massima tolleranza consentita sulla variazione di tensione è di ± 10% del valore nominale.

• Prevedere un circuito di alimentazione elettrica alla macchina, con un proprio interruttore generale bipolare ed apertura dei contatti di almeno 3 mm. e con un proprio fusibile o

protezione automatica ed una presa elettrica dotata di collegamento a terra.

• Il tutto dimensionato secondo l’amperaggio indicato sulla

targhetta d’immatricolazione (fig. ;). La presa elettrica

dovrà essere facilmente accessibile.

). Nelle versioni con

j

h

Per avviare e spegnere la macchina basta premere il pulsante

ON/OFF .

I fabbricatori di ghiaccio in cubetti Icematic possono essere fa-

•

cilmente adattabili all’arredamento di ogni locale.

• La formazione del ghiaccio in cubetti avviene attorno ai peduncoli dell’evaporatore, immersi in una vaschetta, riempita di

acqua agitata in continuazione da palette rotanti.

l livello dell’acqua nella vaschetta è mantenuto costante da un gal-

I

•

leggiante collegato ad un micro che comanda l’apertura o meno di

una elettrovalvola di entrata acqua dell’alimentazione idrica.

• Quando i cubetti hanno raggiunto la dimensione prevista, essi

vengono a contatto con le palette agitatrici facendo oscillare il

motoriduttore relativo, il quale sollecita un micro che tramite un

).

relé provoca contemporaneamente:

- l’invio di gas caldo all’evaporatore mediante l’apertura di una

elettrovalvola, con conseguente graduale distacco dei cubetti

dai peduncoli dell’evaporatore.

- il ribaltamento della vaschetta acqua collegata mediante una

leva ad un motoriduttore.

• I cubetti una volta staccatisi scivolano su una griglia inclinata

posta all’interno della vaschetta e vengono convogliati nel sottostante deposito.

• L’acqua residua della vaschetta viene raccolta nell’apposito recipiente situato su un lato del deposito e convogliata verso lo

scarico. La vaschetta ritorna automaticamente dopo circa un minuto in posizione orizzontale e si riempie d’acqua fino al livello

prestabilito. Nel frattempo la valvola del gas caldo ritorna a chiudersi ed il ciclo di formazione ghiaccio procede regolarmente; il

tempo per un ciclo completo può variare da circa 15’ a circa 25’

a seconda della temperatura dell’acqua e dell’ambiente.

• La quantità di ghiaccio nel deposito è controllata dalla sonda

elettronica fissata su una parete del deposito stesso; quando i

cubetti raggiungono il livello del bulbo la macchina si arresta

completamente. Dopo prelievi di ghiaccio che permettono di

liberare il bulbo dal contatto con i cubetti, il produttore riprenderà la sua normale produzione.

Italiano

Nota: Dopo i prelievi liberare il bulbo di controllo da eventuali residui di ghiaccio per una più celere ripresa della produzione.

3.1 SEGNALI DI ALLARME PER I MODELLI ARIA/ACQUA

•

Sovratemperatura condensatore: la macchina riparte automaticamente una volta ripristinate le cause di allarme. Le cause possono essere: filtro aria intasato, ventilatore difettoso, temperatura ambiente

troppo elevata, mancanza acqua (solo per versione ad acqua).

• Errore acqua: in caso di mancanza acqua di rete la macchina riparte automaticamente dopo 60 minuti dall’allarme.

Nota: È possibile uscire dalla condizione di allarme previo disinserimento/ inserimento dell’energia elettrica (Pulsante ON/OFF).

• Arresto macchina per deposito pieno: la sonda del deposito,

comandata dalla scheda elettronica, ferma la macchina quando

il ghiaccio viene a contatto. La macchina si arresta alla fine del

ciclo di sbrinamento.

71503928/0 - REV.0001/2013

29

Page 30

4. SEGNALAZIONI

6. INFORMAZIONI SERVICE

Italiano

Funzione Stato

Macchina accesa ON OFF

rrore sonda

E

temperatura

eposito

d

Errore sonda

temperatura

condensatore

Errore ciclo freddo