BARTLETT V6-CF Operation Manual

Operation Manual

Model V6-CF

Series 700

Controller

BARTLETT

INSTRUMENT COMPANY

1404 Avenue M

Fort Madison, IA 52627

319-372-8366

www.bartinst.com

Table of Contents |

|

INTRODUCTION ................................................................................................................................ |

2 |

PRECAUTIONS................................................................................................................................... |

2 |

CONTROLLER FRONT PANEL ....................................................................................................... |

3 |

QUICK START.................................................................................................................................... |

4 |

FIRST FIRING OF THE KILN........................................................................................................... |

5 |

PROGRAM THE CONTROLLER. ............................................................................................................... |

5 |

REVIEW THE SAMPLE PROGRAM BEFORE FIRING. .................................................................................... |

6 |

START THE FIRING............................................................................................................................... |

7 |

REVIEW THE RESULTS.......................................................................................................................... |

7 |

CONE FIRE PROGRAMMING.......................................................................................................... |

8 |

VARY-FIRE ......................................................................................................................................... |

9 |

VARY-FIRE PROGRAMMING STEPS......................................................................................................... |

9 |

CALCULATING RAMP RATES FOR VARY FIRE:..................................................................................... |

10 |

WRITE YOUR OWN CONE FIRE PROGRAM ............................................................................. |

11 |

START THE FIRING ........................................................................................................................ |

11 |

OPERATION OF THE CONTROLLER DURING A FIRING ....................................................... |

12 |

END OF FIRING - CPLT .................................................................................................................. |

14 |

REVIEW THE RESULTS........................................................................................................................ |

14 |

VIEW (INFORMATION) SECTION................................................................................................ |

15 |

CONE TABLE ..................................................................................................................................... |

15 |

REVIEW PROGRAM............................................................................................................................. |

15 |

VIEW SEGMENT ................................................................................................................................. |

16 |

ONE-TOUCH INFORMATION (HOT) KEYS ................................................................................ |

16 |

OPTIONS SECTION ......................................................................................................................... |

17 |

DELAY - THIS KEY IS USED TO DELAY THE START OF A FIRING............................................................... |

17 |

ALARM ............................................................................................................................................. |

17 |

MENU ............................................................................................................................................... |

18 |

ZONE CONTROL ............................................................................................................................. |

22 |

1. FEATURES AND ENHANCEMENTS ....................................................................................... |

22 |

2. GENERAL DESCRIPTION ........................................................................................................ |

22 |

3. AUTOMATIC LAG FUNCTION ................................................................................................ |

22 |

4. THERMOCOUPLE OFFSETS .................................................................................................... |

22 |

5. THREE THERMOCOUPLES...................................................................................................... |

23 |

APPENDIX A - CONE FIRE TEMPERATURE PROFILES......................................................... |

24 |

APPENDIX B - ERROR CODES .................................................................................................... |

25 |

FULL POWER TEST............................................................................................................................. |

26 |

APPENDIX C - COMMON QUESTIONS AND SITUATIONS ..................................................... |

28 |

APPENDIX D - FIRING PROGRAM BLANK.............................................................................. |

29 |

APPENDIX E - CONNECTION DIAGRAM ................................................................................... |

30 |

1

Introduction

This manual covers the operation of the V6-CF series 700 kiln controller. The V6-CF is a versatile controller that regulates the temperature in your kiln so you can fire a variety of products like ceramics, glass, or jewelry. The experienced operator can go straight to the quick start guide. The novice can learn more about different types of firing by reading the programming sections of the manual and the ceramics and glass introductions on our web site www.bartinst.com .

In the following pages:

First Firing steps you through the initial firing for new kilns to “season” the elements. Controller Front Panel is a visual table-of-contents for the function of each key on the face-plate. Cone Fire is the quick, easy method of programming for ceramics.

Vary Fire (also known as ramp-hold) is the versatile programming method for writing your own profiles for glass, jewelry and ceramics.

The other sections of the manual will answer questions about what to expect during a firing.

Precautions

The controller is used to control temperature; it is not a safety device.

Do not operate the controller in temperatures above 125oF.

Always supervise your kiln during a firing.

The controller contains electronic components which are sensitive to static electricity. Before handling the controller dissipate any static charge you may have by touching metal or a screw on the controller panel, the electrical box, the kiln lid, or some other grounded object.

Always check the position of the thermocouple probe before starting a firing. The current temperature displayed on the controller is measured at the end of the thermocouple which must be in the firing chamber about 1” to 1-1/2”. Seal the opening around the thermocouple with kaowool or similar material if necessary.

Always review the current program (by pressing Review Program) before firing to ensure the correct profile is programmed.

Ensure the kiln and the areas around the kiln are clear of combustible material. See kiln manufacture’s recommendation on required clearances.

2

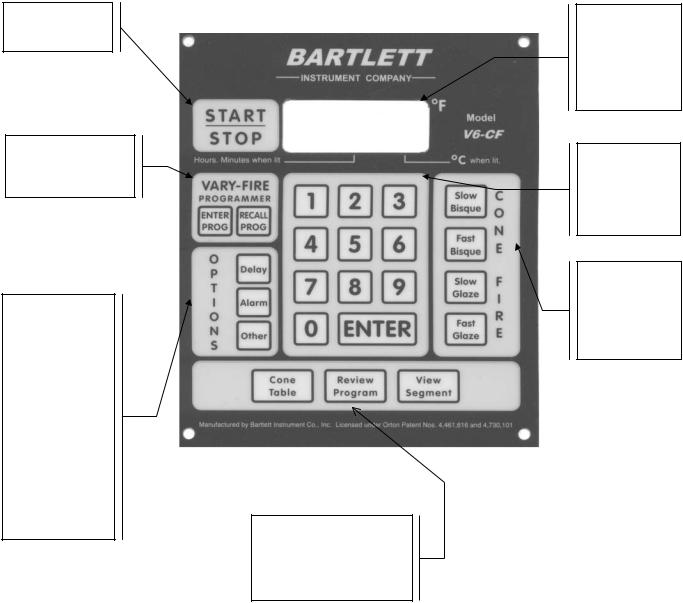

START-STOP p. 11

VARY-FIRE

ENTER PROG p. 9 RECALL PROG p. 11

OPTIONS

Delay p. 17 Alarm p. 17 Menu p. 18 In Menu RSET p. 18

PRHT p. 18 & 19 Id p. 18

16-S p. 18 & 19 CNOS p. 18 & 20 CHGo p. 18 ERCd p. 18 & 21

TCOS p. 18, 20, 21 bd T p. 18

Controller Front Panel

LED DISPLAY

Decimal in lower right indicates temperature in oC. Decimal in middle indicates a time.

NUMBER

KEYS for entering

temperatures and times.

Hot Keys p 16

CONE FIRE p. 8

Create your own custom cone fire program p. 11

VIEW p. 15

Cone Table p. 15

Review Program p. 15

View Segment p. 16

Hot Keys p. 16

3

QUICK START

1.Read all precautions before using your controller.

2.Apply power to the kiln/controller

3.Clear the display and get to the idle mode by pressing ENTER.

4.Program the controller.

5.Review the program before firing to ensure the correct program is ready to fire.

6.Press Start. -On- will be displayed and then the kiln temperature. The relays and elements will be cycled on and off to regulate the temperature according to the program.

7.At the end of the firing the controller will flash the current temperature, firing time, and CPLt. Press ENTER to return to the IdLE state.

•IMPORTANT PROGRAMMING NOTE: Before initiating a firing profile or performing any other function, the controller must be at IdLE. Pressing the ENTER key will clear the display of errors (E-) or FAIL.

•In most cases when programming, you will choose an option, then press ENTER to accept the option.

•With the display flashing IdLE alternating with the current temperature, you are ready to proceed with programming.

•The CONE FIRE mode uses a patented method to achieve correct heat-work so it is ideal for firing ceramics. The advantage of using the CONE FIRE method is that a very complicated firing profile may be chosen with just a few key strokes. The CONE FIRE method helps protect against over and under firing by carefully tracking and controlling the temperature at the end of the firing as the cone temperature is approached. The final temperature is adjusted according to the final firing rate. For example, as the heating elements age and the heating rate slows, the final temperature will be adjusted downward to ensure the correct amount of heat-work.

•The VARY-FIRE mode can be used for ceramics, glass, jewelry, glazes, decals, etc. It allows you to create your own firing profiles which can be saved and used over and over.

•If there is a kiln sitter on the kiln it must be set according to the manufacturer’s directions. Insert a cone in the sitter that is one or two cones hotter than the controller setting.

4

First Firing of the Kiln

The purpose of the first firing is to put a protective oxide layer on the elements and thermocouple. The first firing is done without ware in the kiln that might give off fumes that contaminate the elements. This first firing should have shelves and witness cones. The witness cones should be on the middle of the shelf nearest the center of the kiln. The programmed cone number should match the cones provided with the kiln. Our example calls for a cone 04 firing but if your kiln is supplied with different cones, substitute that cone number in the programming.

The first firing should be done according to the kiln manufacture’s specifications if they are different from these instructions.

1.Apply power to the kiln/controller. The display will show WAIT, and then go to IdLE.

2.If the display shows PF press ENTER to proceed to the IdLE state.

Program the controller.

This example is for a Fast Glaze to cone 04 with no hold time at the end of firing.

Press |

Fast Glaze |

Display will show F-GL |

|

|

|

Press |

ENTER |

Display will show CONE/xxx |

|

|

|

Press |

0 |

0 |

|

|

|

Press |

4 |

04 |

|

|

|

Press |

ENTER |

Display will show HOLd/ 0.00 |

|

|

|

Press |

ENTER |

Display returns to IdLE/temp |

|

|

|

5

Review the sample program before firing.

Press Review Program key, the display will cycle through the following information.

Display shows |

Description |

|

|

|

|

F-GL |

Firing speed, fast glaze |

|

|

|

|

PRHT/0.00 |

Shows zero preheat time |

|

|

|

|

CONE/ 04 |

Programmed for cone 04 |

|

|

|

|

°F /1945 |

Top temperature for cone 04 |

|

|

|

|

CNOS/0 |

Shows 0°F cone adjustment |

|

|

|

|

HOLD/0.00 |

Indicates zero hold at the top |

|

temperature |

||

|

||

|

|

|

dELA/00.00 |

Indicates delay start of 0 |

|

|

|

|

ALRM/9999 |

Alarm is disabled |

|

|

|

|

ERCD/ on |

Error detection is enabled |

|

|

|

|

FIRE/xxxx |

Shows the number of firings done |

|

with this controller |

||

|

||

|

|

6

Start the Firing.

Press start to begin the firing |

The display will show –ON- then the current temperature. You will hear |

|

clicking when the relays cycle power to the elements to regulate the |

|

temperature. This firing will take around 6 to 7 hours. |

|

|

|

|

End of firing |

At the end of the firing, the display will flash between |

CPLT |

CPLT / Firing time / kiln temperature |

|

|

|

|

Press ENTER to return to |

|

IdLE |

The display will now flash IdLE / kiln temperature. You may open the |

|

kiln when the temperature has cooled to 150°F. |

|

|

Review the Results

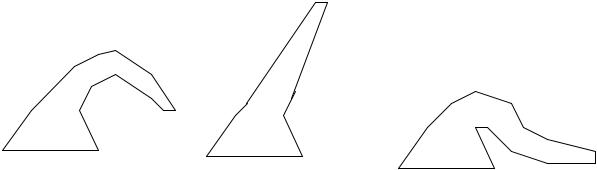

A properly bent cone indicates that the kiln is functioning properly and accurately. The tip of the cone will be level with the top of the cone’s base when fired properly. The diagrams below will give you an idea of a properly fired, under fired and over fired cone. Some variation from a proper bend is expected and can be compensated for with the cone offset adjustment for each particular cone number based on test firings.

Proper bend |

|

Under fired |

|

Over fired |

|

|

|

|

|

7

CONE FIRE Programming

This is the quickest and easiest method to program the controller to fire ceramics. Programming consists of choosing the firing speed and entering the clay or glaze’s cone number. The firing speed is chosen by the type of firing and thickness of the clay. The bisque firings include water smoking and carbon burn-out stages. The glaze speeds allow for faster firings. All 4 speeds will calculate the firing rate at the end of a firing and adjust the final temperature for correct heat-work. Follow these few steps to enter a cone fire program.

Press |

Slow Bisque |

Display shows |

The slow bisque speed is used for thicker hand thrown ware. The |

|

|

S-bC |

slow speed gives extra time for release of water and carbon burn-out. |

|

|

|

Typical firing times range from 13-17 hours depending on the cone |

|

|

|

#. Hand built pieces may need a preheat stage. |

|

|

|

|

|

OR |

Display shows |

The fast bisque speed is for thinner ware that requires less time for |

|

Fast Bisque |

F-bC |

water smoking and carbon burn-out. Firing time is 9 – 11 hours, |

|

|

|

typically, and depends on the cone number. |

|

|

|

|

|

OR |

Display shows |

Slow glaze is used for firing glaze on thicker ware or for bisquing |

|

Slow Glaze |

S-GL |

very thin ware. Typical firing time is 6-8 hours depending on the |

|

|

|

cone number. |

|

|

|

|

|

OR |

Display shows |

Fast glaze is the fastest speed and is used for glaze firing on thin |

|

Fast Glaze |

F-GL |

ware, china paint firings, and decal firings. Firing times range from |

|

|

|

4 to 5 hours |

|

|

|

|

Press |

ENTER |

Display shows |

The displayed firing speed was accepted and now the controller is |

|

|

CONE/xxx |

waiting for the cone number to be entered. The x’s represent the |

|

|

|

cone number last selected. |

|

|

|

|

Press |

Number keys for |

Display shows |

Use the number keys to display a new cone number. Remember, |

|

cone number |

xxx |

cone numbers starting with a 0 are lower temperature than cone |

|

|

|

numbers not starting with a 0. For example, don’t mistake a cone 6 |

|

|

|

for a cone 06! |

Press |

ENTER |

Display shows |

The displayed cone number was accepted and now the controller is |

|

|

HOLd/0.00 |

waiting for the hold time at the top temperature to be entered. |

|

|

|

Usually this value is left at 0. If a time is entered the hours are to the |

|

|

|

left of the decimal and the minutes to the right. |

|

|

|

|

Press |

ENTER |

Programming complete |

Zero hold was accepted and programming is complete. |

|

|

Display is back to Idle |

|

|

|

|

|

NOTE - A preheat segment for drying (candling) ware can be added to any cone fire program. See options section for PREHEAT instructions.

TEMPERTURE REACHED at the end of a cone fire program:

When the display is at IdLE, pressing Review Program, will show the heat-work adjusted temperature that was reached. The temperature is displayed after oF in review program. This temperature will remain until the controller is reprogrammed. Record this temperature in your log after each cone firing.

8

VARY-FIRE

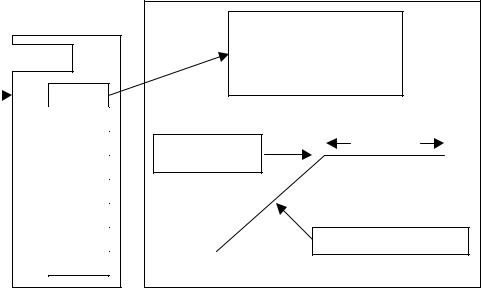

The V6-CF has 6 vary-fire user programs to store and reuse. Each program has from 1 to 8 segments (2 to 16 segments if 16-S option is on). Each segment has a firing rate, a soak temperature, and a hold time.

|

|

|

|

|

Each |

|

|

|

|

|

program |

|

Controller |

|

|

|

|

|

|

|

|

has 8 |

|

|

has 6 |

|

|

|

segments |

|

programs |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Each Segment has: |

|

Ramp rate ( in degrees / hr ) |

User 1 |

Hold temperature |

|

Hold time |

Segment 1 |

|

Segment 2 |

|

Segment 3 |

Hold time |

Segment 4 |

Hold temperature |

|

|

Segment 5 |

|

Segment 6 |

|

Segment 7 |

Ramp rate (in degrees / hr) |

|

|

Segment 8 |

|

Vary-Fire programming steps

1.Press “Enter Prog” to start Vary-Fire programming – the display will show USER/#

2.Select User number – Press a number key 1-6 then ENTER.

3.Enter number of segments – Press a number key 1-8 then ENTER

4.Enter the ramp rate for segment 1 – Type ramp rate then press ENTER. Rates of 1 thru 9999°F/hr are valid. See note for calculating ramp rate.

5.Enter the hold temperature for segment 1 – Type hold temperature then press ENTER. Valid temperatures range from 1°F thru MAX kiln temperature.

6.Enter the hold time for segment 1 - Type hold time then press ENTER. Displayed time is in the format hr.min. Left of decimal are hours, to the right of decimal are minutes.

7.Repeat steps 4 – 6 for each segment.

8.Enter an alarm temperature – Type an alarm temperature then press ENTER. See

OPTIONS section for more information on alarm temperature. The alarm set at 9999 is

turned off.

The following are notes to help with programming a Vary-Fire program. APPENDIX A CONE FIRE PROFILES can be used as a starting point for a Vary-Fire program for ceramics.

9

Loading...

Loading...