Bartlett Genesis LT3140, Genesis Mini LT1120 Operation Manual

Operation Manual

Genesis

Model LT3140

&

Genesis Mini

Model LT1120

BARTLETT

INSTRUMENT COMPANY

1032 Avenue H

Fort Madison, IA 52627

319-372-8366

www.bartinst.com

1

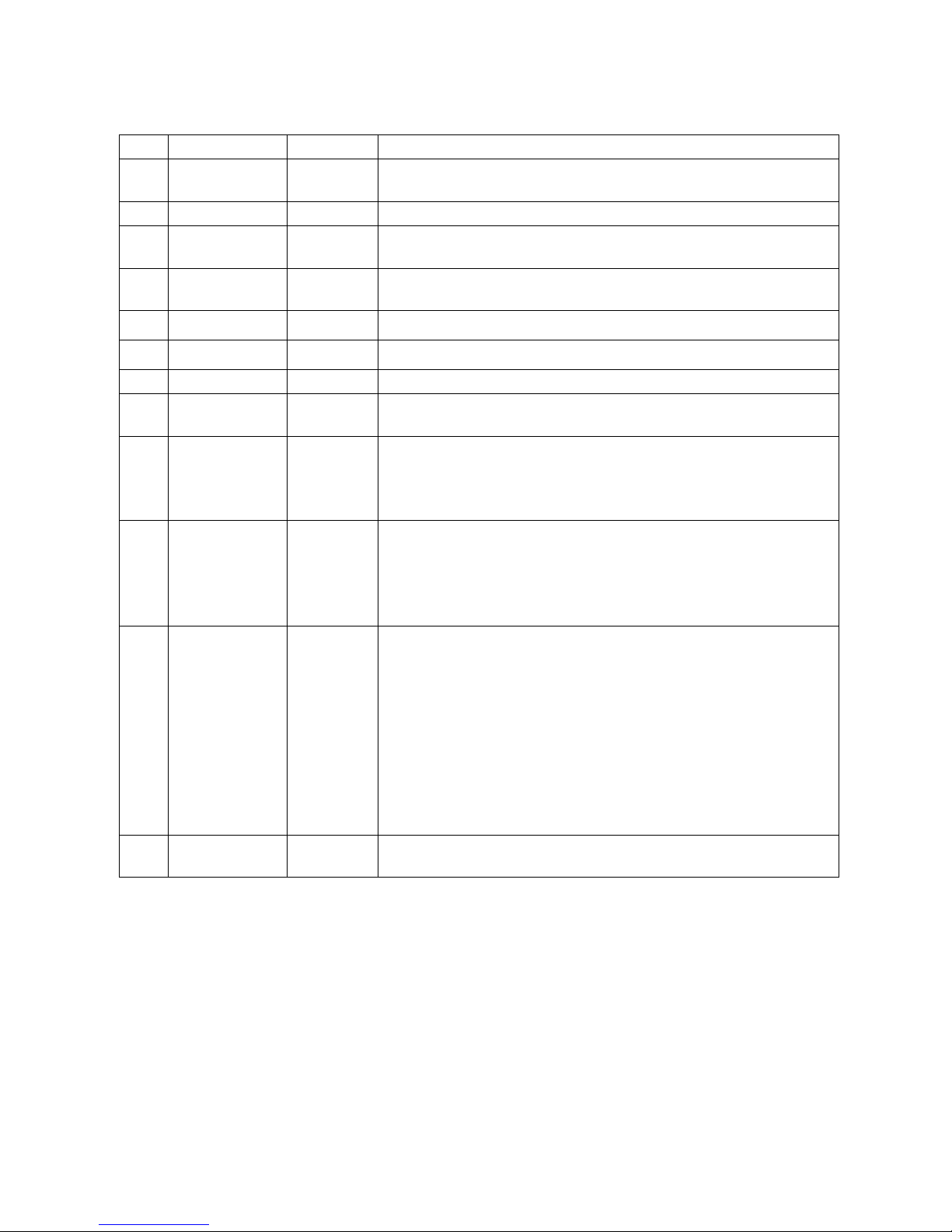

Table of Contents

Introduction .................................................................................................................................................. 2

Precautions ................................................................................................................................................... 2

Home Screen Overview ................................................................................................................................. 3

Quick Start ..................................................................................................................................................... 4

First Firing of the Kiln .................................................................................................................................... 5

Program the Controller ............................................................................................................................. 5

Review Program Before the Firing ............................................................................................................ 5

Start The First Test Firing .......................................................................................................................... 6

Review the Results .................................................................................................................................... 6

Ceramics Programming (Bisc or Glaze) ......................................................................................................... 7

Glass Programming ....................................................................................................................................... 9

Custom Programming ................................................................................................................................. 10

Calculating Ramp Rates for Custom Firing .............................................................................................. 12

Custom Ceramics Program ...................................................................................................................... 13

Start A Firing................................................................................................................................................ 13

Operation of the Controller During A Firing ........................................................................................... 13

Adjustments During a Firing .................................................................................................................... 15

End of Firing – COMPLETE ....................................................................................................................... 16

Care of Thermocouple ............................................................................................................................ 17

Menu Screen ............................................................................................................................................... 17

Data Menu .............................................................................................................................................. 17

Diagnostics .............................................................................................................................................. 18

Adjustments ............................................................................................................................................ 18

Configuration .......................................................................................................................................... 19

Restore Presets ....................................................................................................................................... 22

Customization ......................................................................................................................................... 22

Factory Configuration ............................................................................................................................. 22

Appendix A: Error Codes ............................................................................................................................. 23

Full Power Test ........................................................................................................................................ 24

Appendix B: Cone Fire Temperature Profiles.............................................................................................. 25

Appendix C: Custom Firing Default Programs ............................................................................................. 26

Appendix D: Blank Firing Program .............................................................................................................. 29

Appendix E: Common Questions and Situations ........................................................................................ 30

Appendix F: Zone Control ........................................................................................................................... 31

1. Features and Enhancements........................................................................................................... 31

2. General Description ........................................................................................................................ 31

3. Automatic Lag Function .................................................................................................................. 31

4. Thermocouple Offsets..................................................................................................................... 31

5. Three Thermocouples ..................................................................................................................... 32

Appendix G: Genesis Connection Diagram ................................................................................................. 33

Appendix H: Genesis Mini Connection Diagram ......................................................................................... 34

2

Introduction

This manual covers the operation of the Genesis 3140 & Genesis 1120 kiln controllers. The Genesis

is a versatile touch screen controller that regulates the temperature in your kiln so you can fire a variety

of products like ceramics, glass, jewelry, and more. The Genesis has preset ceramic programs with cone

fire programming, preset glass firing profiles, and 30 custom programs, along with Wi-Fi capabilities for

software updating, built in diagnostics, and maintenance logging among other new features.

Precautions

The controller is used to control temperature; it is not a safety device.

Do not operate the controller in temperatures above 160ᴼ F.

Always supervise your kiln during a firing.

The controller contains electronic components which are sensitive to static electricity.

Before handling the controller dissipate any static charge you may have by touching metal or

a screw on the controller panel, the electrical box, the kiln lid, or some other grounded

object.

Always check the position of the thermocouple probe before starting a firing. The current

temperature displayed on the controller is measured at the end of the thermocouple which

must be in the firing chamber about 1” to 1-1/2”. Seal the opening around the thermocouple

with kaowool or similar material if necessary.

Always review the current program before firing to ensure the correct profile is

programmed.

Ensure the kiln and the areas around the kiln are clear of combustible material. See kiln

manufacturer’s recommendation on required clearances.

3

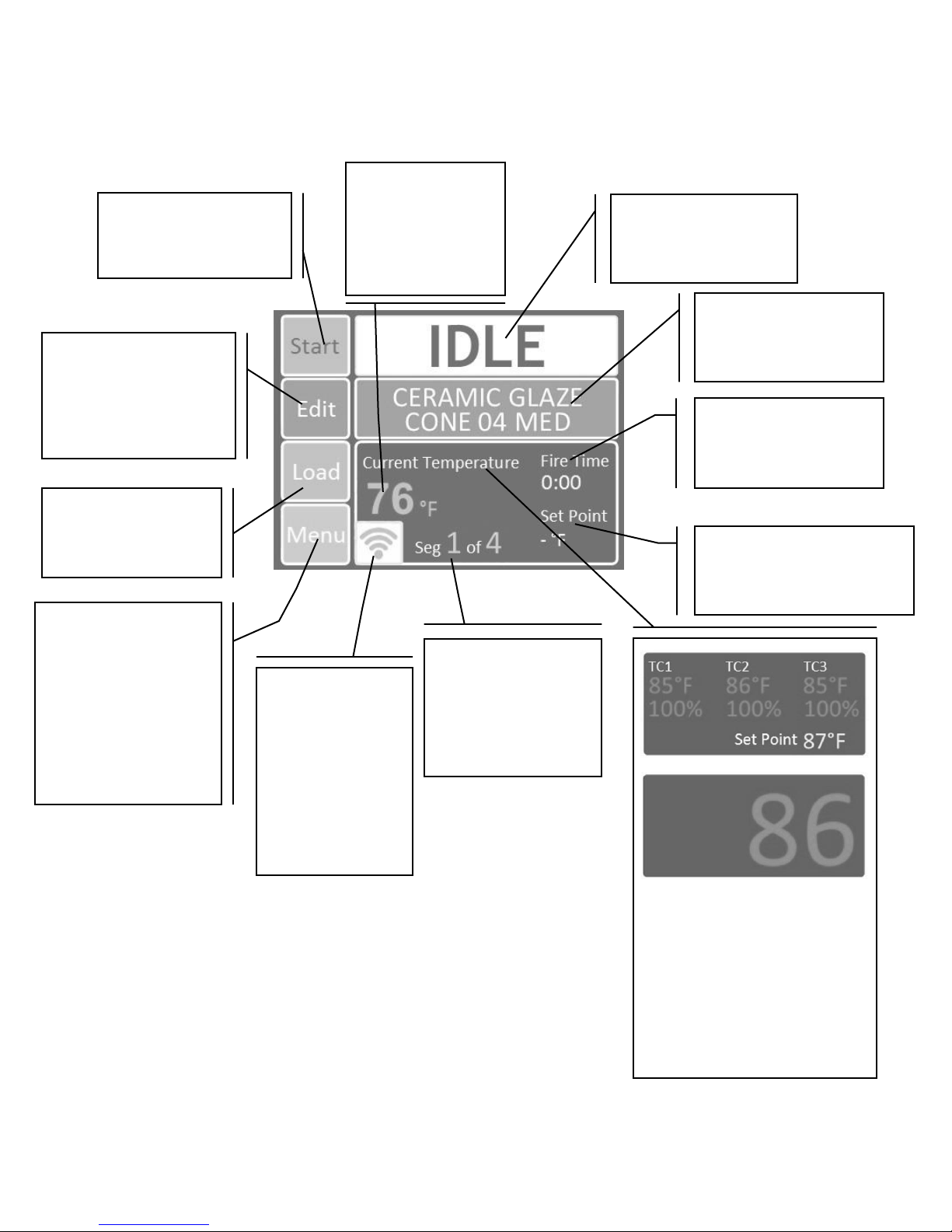

Home Screen Overview

Figure 1: Home Screen Overview

Status

Displays the current

status of the kiln.

Current Program

Displays the program

currently loaded

Start

Press to begin firing

process.

Edit or View Menu

Press to edit or view

(novice mode) the

currently loaded

program

Load

Press to load a new or

saved program

Menu Options

Data Menu

Diagnostics

Adjustments

Configuration

Restore Presets

Customization

Factory Config

Current

Temperature

Displays the current

temperature of the

kiln.

Segment

Displays the segment

the firing currently is in

and the total number

of segments

Fire Time

The firing time in

hours:minutes

Wi-Fi

Indicates the Wi-Fi

signal strength. An

Exclamation mark

by the Wi-Fi symbol

indicates connected

to Wi-Fi but not to

the internet

Set Point

Displays the temperature

the kiln is trying to fire to

Toggle Status

Press anywhere in the square to

toggle status to see each

thermocouples temperature,

percentage of power to each

element, and the set point. The

single temperature is TC2’s

reading

4

Quick Start

Step 1: Load A Program (See Pages 7-13)

Press the Load button.

Select the type of program.

o Ceramic (Bisc or Glaze)

o Glass

o Custom

Step 2: Review or Edit the Program (See Pages 7-13 )

Press the Edit or View button.

Review and confirm the program selection.

Step 3: Start the Firing (See Page 13)

Press the Start button.

Enter the start code.

Press Start.

5

First Firing of the Kiln

The purpose of the first firing is to put a protective oxide layer on the elements and thermocouple.

The first firing is done without ware in the kiln that might give off fumes that contaminate the elements.

This first firing should have shelves and witness cones. The witness cones should be on the middle of the

shelf nearest the center of the kiln. If your kiln is supplied with cones, the programmed cone number

should match the cones provided, or you may use a cone of your own choice for the first firing. The

example below is for a cone 04 firing, but if you use a cone other than 04, substitute that cone number

in the programming. Note: The first firing should be done according to the kiln manufacturer’s

specifications if they are different from these instructions.

Program the Controller

This example is for a Fast Glaze to cone 04 with no hold time at the end of the firing. The example below

is for programming in Novice Mode (See page 19 for more info).

Step

Display Shows

Key Press

What This Selection Means

1

Home Screen

Load

You’re ready to load the Ceramics program

into the controller

2

What Are You

Firing?

Ceramics

Choose from Ceramics, Glass, or Other.

Choose Ceramics for the first firing of the kiln.

3

Cone Number

04

Temperature

1945

Next

Use the scroll bar on the right until Cone 04 is

displayed.

4

What Speed?

Fast - Glaze thin pieces

The firing time for a Fast Glaze firing generally

ranges between 4 to 5 hours.

5

Preheat time?

None - Thin, bone dry

bisc or glaze

No preheat time is needed.

6

Program loaded:

CERAMIC GLAZE

CONE 04 FAST

OK

Returns to Home Screen at IDLE.

Review Program Before the Firing

Press the View key to review the loaded program. Check that the settings are correct. If you’d

like to change the alarm, go to Adjustments under Menu (See page 18 for instruction). When ready to

fire, press BACK to return to the Home Screen.

Figure 2: First firing program example. Use the green scroll bar on the right to see more options.

6

Start The First Test Firing

Step

Display Shows

Key Press

What This Selection Means

1

Home Screen

Start

The kiln is ready to be fired.

2

Start Firing

CERAMIC BISC

CONE 04 FAST

1-Start

Now

This kiln is ready to be fired and the start code must be

entered.

3

Enter Start Code

1

The controllers default start code is 1. To change the Start

Code, see page 21 for more details.

4

Enter Start Code

Start

Upon pushing Start, the firing will begin. You will hear clicking

when the relays cycle power to the elements to regulate the

temperature. This firing will take around 6 to 7 hours.

5

COMPLETE – Clear

returns to idle.

Clear

The firing has gone to complete. The current temperature, fire

time, segment, and set point is displayed.

6

Home Screen

Pressing clear returns the controller to IDLE. You may open the

kiln when the temperature has cooled to 150°F.

Review the Results

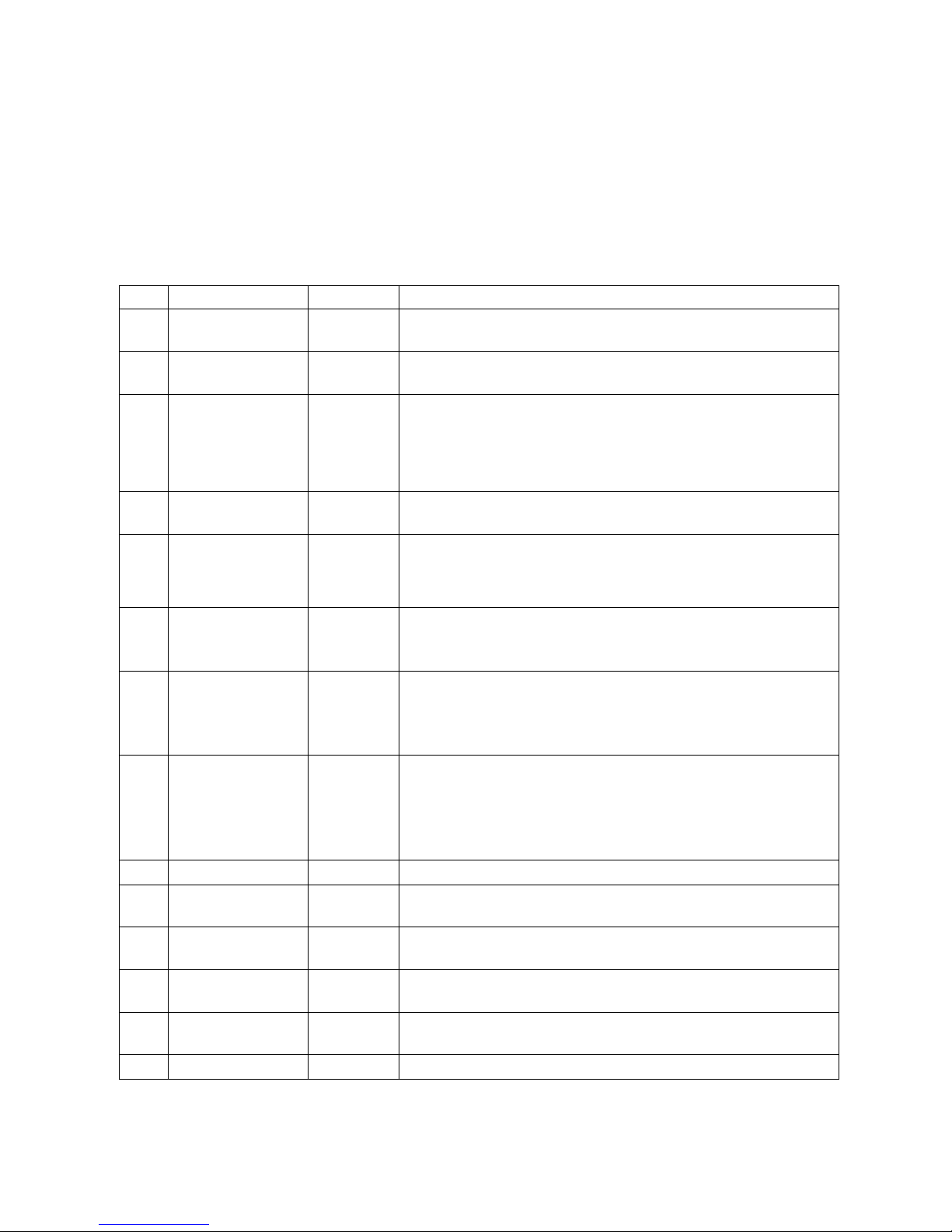

A properly bent cone indicates that the kiln is functioning properly and accurately. The tip of the

cone will be level with the top of the cone’s base when fired properly. The diagram below will give you

an idea of a properly fired, under fired, and over fired cone. Some variations from a proper bend is

expected and can be compensated for with the cone offset adjustment for each particular cone number

based on test firings.

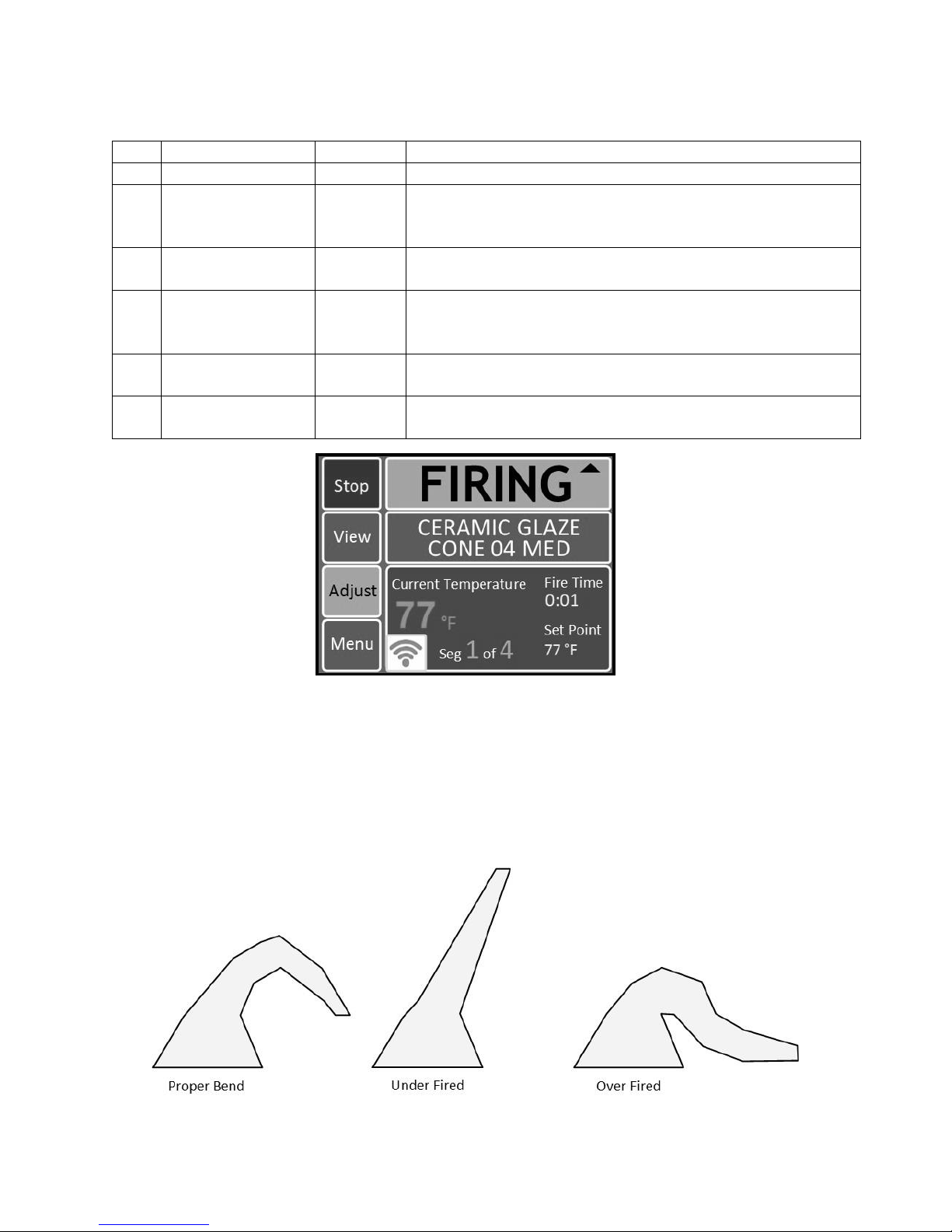

Figure 3: Sample firing screen. For more information about a firing in progress, see Adjustments During A Firing

on Page 15.

Figure 4: Samples of a properly fired, under fired, and over fired cone.

7

Ceramics Programming (Bisc or Glaze)

Programming in Novice mode is the easiest method to program the controller to fire ceramics.

Programming consists of choosing a cone number, firing speed, and a preheat time. The firing speed is

chosen by the type of firing and thickness of the clay used. All 4 speeds below will calculate the firing

rate at the end of a firing and adjust the final temperature for correct heat-work.

Ceramics Programming – Novice Mode ON:

Step

Display Shows

Key Press

What This Selection Means

1

Home Screen

Load

You’re ready to load a different program into the controller

memory.

2

What are you

firing?

Ceramics

Choose from Ceramics, Glass, and Other. Choose Ceramics

for a bisc or glaze firing.

3

Cone Number

XX

Temperature

XXXX

Next

Use the scroll bar to choose the desired cone number for the

firing. Remember, cone numbers starting with a 0 are a

lower temperature than cone numbers not starting with a 0.

For example, don’t mistake a cone 6 for a cone 06!

4

What speed?

Choose the firing speed either Fast, Medium, MedSlo, or

Slow.

Fast

Fast is the fastest firing speed and is used for glaze firings on

thin ware, china paint firings, and decal firings. Firing times

range from 4 to 5 hours.

Or

Medium

Medium is used for firing glaze on thicker ware or for bisque

firing very thin ware. Typical firing time is 6-8 hours

depending on the cone number.

Or

MedSlo

MedSlo is used to bisque medium pieces or thinner ware

that requires less time for water smoking and carbon burn-

out. Typical firing time is 9-11 hours, depending on cone

number.

Or

Slow

Slow is used to bisc thicker, hand thrown ware. The slow

speed gives extra time for release of water and carbon burn-

out. Typical firing times range from 13-17 hours depending

on the cone number. Hand built pieces may need a preheat

stage.

5

Preheat Time?

Choose the preheat time, either None, 4 Hr, 8 Hr, or 12 Hr.

None

No preheat time is needed when the pieces are a thin, bone

dry bisc or glaze.

Or

4 Hr

Use a 4 hour preheat time for thicker, slightly wet pieces.

Or

8 Hr

Use an 8 hour preheat time for thick, wet pieces.

Or

12 Hr

Use a 12 hour preheat time for hand built, kids pieces.

6

Program Loaded:

OK

Return to Home Screen at IDLE.

8

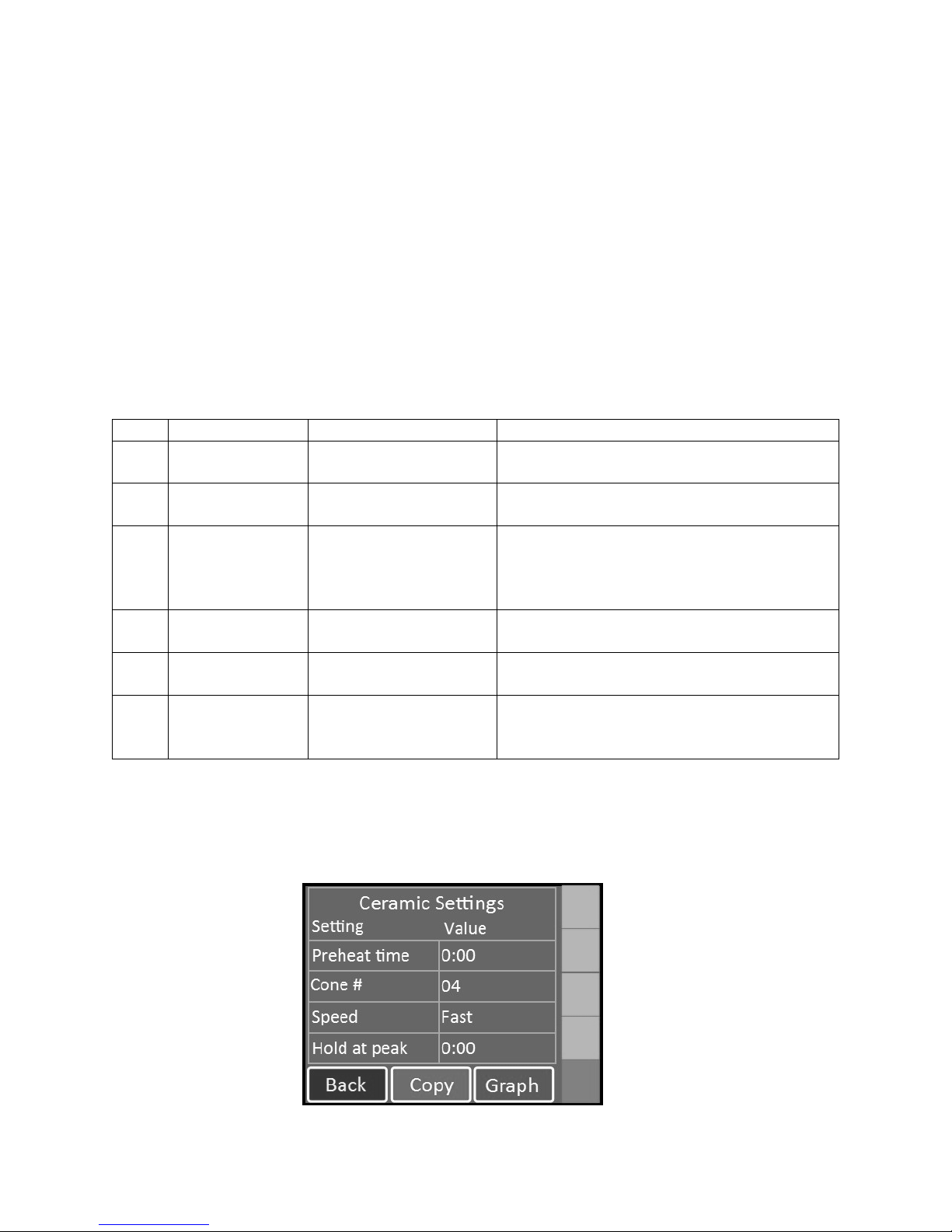

Ceramics Programming - Novice Mode Off:

Step

Display Shows

Key Press

What This Selection Means

1

Home Screen

Load

You’re ready to load a different program into the controller

memory.

2

Load Program

Choose between 1-Bisc, 2-Glaze, 3-Glass, or 4-Custom

1-Bisc

The default bisc program will be loaded to the controller.

Any saved changes made to the bisc program will overwrite

the default program.

Or

2-Glaze

The default glaze program will be loaded to the controller.

Any saved changes made to the glaze program will overwrite

the default program.

3

Program Loaded:

OK

Returns to Home Screen. To make changes to the loaded

program, go into the edit menu.

4

Home Screen

Edit

Displays the current settings for the firing. To change the

settings, press the setting to be changed and select the new

setting. For example: To change the preheat time, press

Preheat Time, type in the new preheat time, and press str.

5

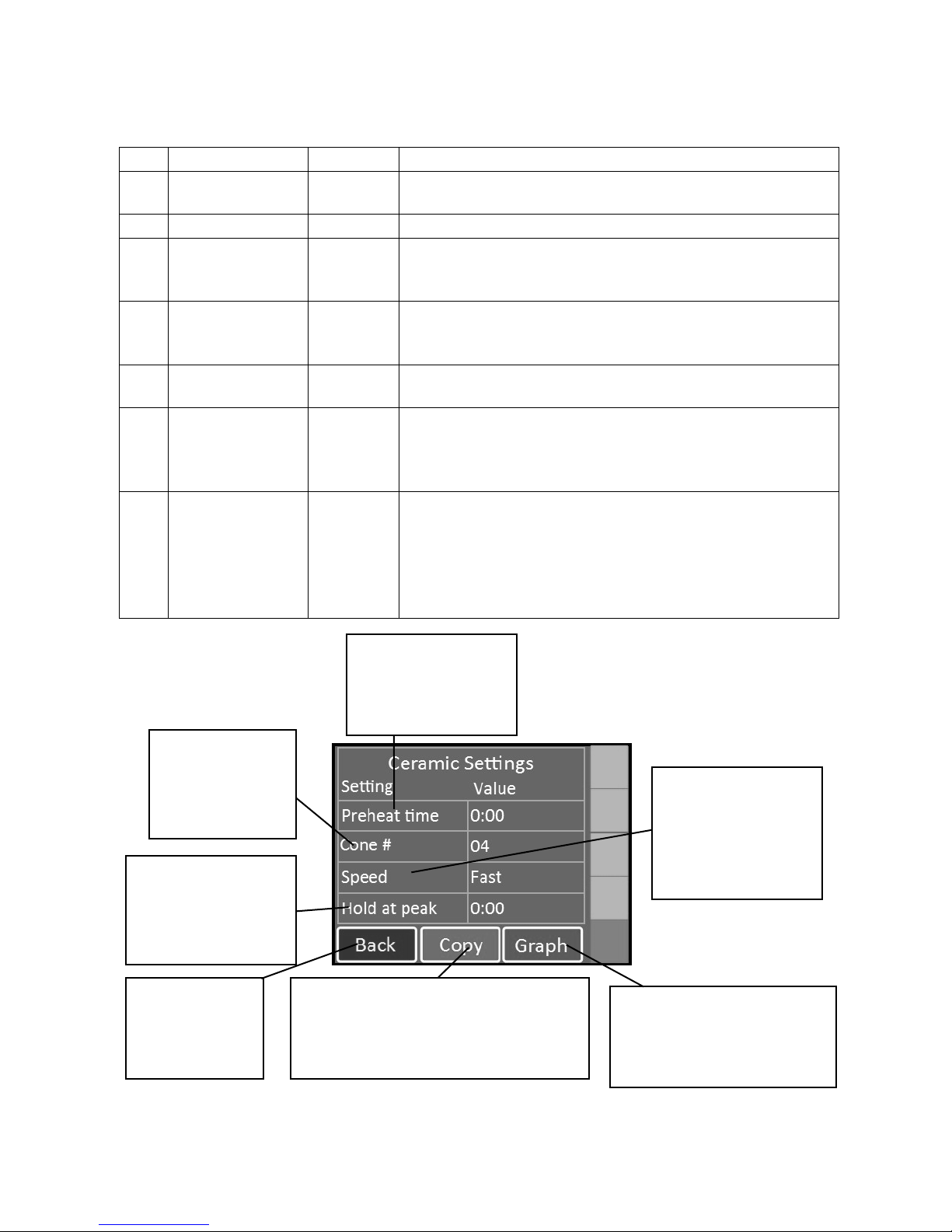

Ceramics Settings

Preheat Time

Cone #

Speed

Hold at Peak

Cooling

Back

Returns to Home Screen at IDLE.

Press Preheat time

to change value.

Min: 0:00

Max: 24:00

Press Cone # to

change the value.

Min: Cone 022

Max: Cone 12

Press Speed to

change the value.

Options: Fast,

Medium, MedSlo,

and Slow

Press Hold at Peak

to change value.

Min: 0:00

Max: 24:00

Press to graph and see a

table of the loaded program.

Includes time, temperature,

and segments.

Press BACK to

return to the

Home Screen

Press Copy to copy the loaded program

to one of the custom user programs.

The list of user programs will appear

when Copy is pressed.

Figure 5: Ceramics programming sample.

9

Note: When a preheat is selected, the temperature ramps up at 60°F/hour (33°C/hr) to 200°F (93°C) for

the amount of time programmed.

When the copy function is used and Copy is selected, the controller will return to the IDLE screen. The

loaded program will become the copied program in its new user location.

Notes for Cooling (Not Pictured): Scroll down to select Cooling. Cooling is set to Off unless changed by

the user. With cooling turned on, it adds 2 segments on to the end of the firing. The first segment cools

the kiln from the top temperature down to 1900°F at a rate of 9999 (As fast as possible). The 2nd and

final segment cools the kiln from 1900°F down to 1500°F at a rate of 150°F per hour.

Glass Programming

Programming in Novice mode is the easiest method to program the controller for glass firings.

Programming consists of choosing the type of firing, firing speed, and COE (Coefficient of Expansion).

The firing speed is chosen by the size of the glass being fired.

Glass Programming – Novice Mode ON:

Step

Display Shows

Key Press

What This Selection Means

1

Home Screen

Load

You’re ready to load a different program into the controller

memory.

2

What are you

firing?

Glass

Choose from Ceramics, Glass, and Other. Choose Glass for

slumping, fusing, or casting glass.

3

What type of

firing?

Choose the type of firing, either Slump, Tac Fuse, Full Fuse, or

Cast.

Slump

Slump is used for firing glass pieces that you want to conform

to a mold.

Tac Fuse

Tac Fuse is used for fusing glass that result in softened edges

Full Fuse

Full Fuse is used for fusing glass that result in soft, round edges

Cast

Cast is used for melting glass pieces together.

4

What speed?

Choose the firing speed, either Fast, Medium, MedSlo, or Slow.

Fast

Fast is the fastest firing speed and is used for glass pieces that

are either under 2in. x 2in. or very thin

Medium

Medium is used for glass pieces that are under 4in. x 4in. or

very thick.

MedSlo

MedSlo is used for glass pieces that are under 8in. x 8 in. or 2 to

3 layers thick.

Slow

Slow is the slowest firing speed and is used for glass pieces that

are over 8in. x 8in. or multiple sheets thick.

5

Program

Loaded:

OK

Return to Home Screen at IDLE.

10

Glass Programming – Novice Mode OFF:

Step

Display Shows

Key Press

What This Selection Means

1

Home Screen

Load

You’re ready to load a different program into the controller

memory.

2

Load Program

3-Glass

Choose between 1-Bisc, 2-Glaze, 3-Glass, or 4-Custom

3

Glass

Choose the type of glass firing, either Slump, Tac Fuse, Full

Fuse, or Cast.

Slump

Slump is used for firing glass pieces that you want to conform

to a mold.

Tac Fuse

Tac Fuse is used for fusing glass that result in softened edges

Full Fuse

Full Fuse is used for fusing glass that result in soft, round edges

Cast

Cast is used for melting glass pieces together.

4

Program

Loaded:

OK

Returns to Home Screen. To make changes to the loaded

program, go into the edit menu.

5

Home Screen

Edit

Displays the current settings for the firing. To change the

settings, press the setting to be changed and select the new

setting. For example: To change the speed, press Speed, select

the desired speed, and press Save.

6

Glass Settings

Temperature

Hold Time

Speed

Glass COE

Graph

Press to graph the currently loaded program.

7

Graph

Table

Press TABLE to view and edit each individual segment of the

firing. Use the scroll bar at the right side of the screen to view

each segment in the loaded program. Displays the current

settings for each segment of the firing (rate, temperature, and

hold time for each segment). To change the settings, press the

setting to be changed and select the new setting. For example:

To change the rate for Segment 1, press the temperature listed

under Segment 1’s rate, type in the new temperature, and

press Save. Any saved changes made to the Custom user

program will overwrite the default program.

8 Back

Returns to Home Screen at IDLE.

Custom Programming

The default custom programs are listed in Appendix C: Custom Firing Default Programs. The

Genesis has 30 Custom user programs to store and reuse. User programs 1-12 have 32 segments each,

while 13-30 have 8 segments each. Each segment has a firing rate, a soak temperature and a hold time.

Custom programs can only be edited with Novice Mode set to OFF. See page 19 for more information.

Loading...

Loading...