Barksdale UAS3 User Manual

3. Operating elements

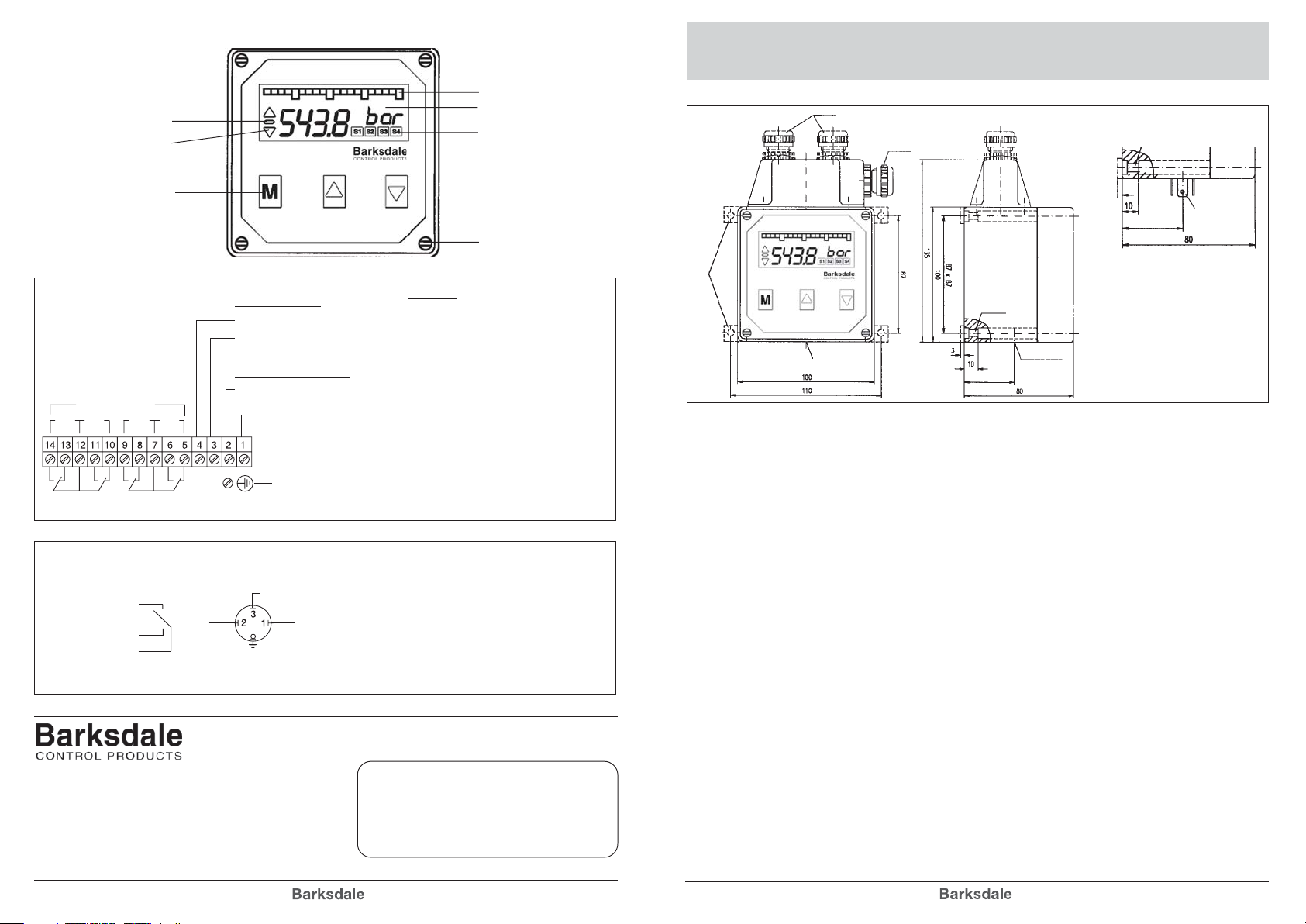

Operating Instructions Pressure Switch UDS 3 with 4 Relay Outputs

and Trip Amplifier UAS 3

Sign

Trend arrows

Menu buttons

Electrical

connection

Switch contacts

S2S3S4

S1

S2S3S4

S1

Analog output

Analog-GND (0 V)

4...20 mA (0...10 V)

Current supply

0 V

+18 V DC...+30V DC

M4

Sensor connection UAS 3

acc. DIN 43650

gn

1 = +Ub

2 = –Ub (*)

3 = Signal

(*) in combination with 2-wire circuit pin 2 is not required.

1

bn

2

ws

3

–Ub

Barksdale GmbH

Dorn-Assenheimer Strasse 27

D-61203 Reichelsheim / Germany

Tel.: +49 - 60 35 - 9 49-0

Fax: +49 - 60 35 - 9 49-111 and 9 49-113

e-mail: info@barksdale.de

www.barksdale.de

Signal

Protective

load

+Ub

20-part bargraph

8-digit 14-segment display

Switchpoint display SP1...SP4

Cover screws

max. RL =

(max. 10 mA)

Contact rating : max. 120 V DC / 250 V AC

Switching power : max. 120 W / 1250 V AC

Switching capacitiy : 220 V AC / 3 A VDE 0660 T.2

Constant current : max. 5 A

Switching rate : max. 20/s

Analog measuring input

By choice:

Current input : 4...20 mA

Voltage input : 0...10 V DC

Resistance input : Poti (500 Ohm...100 kOhm)

UB –12 V

20 mA

Item-Nr.: 923-1196

Software version: V1. or higher

Index C, 08. 06. 2004

Specifications are subject to

changes without notice.

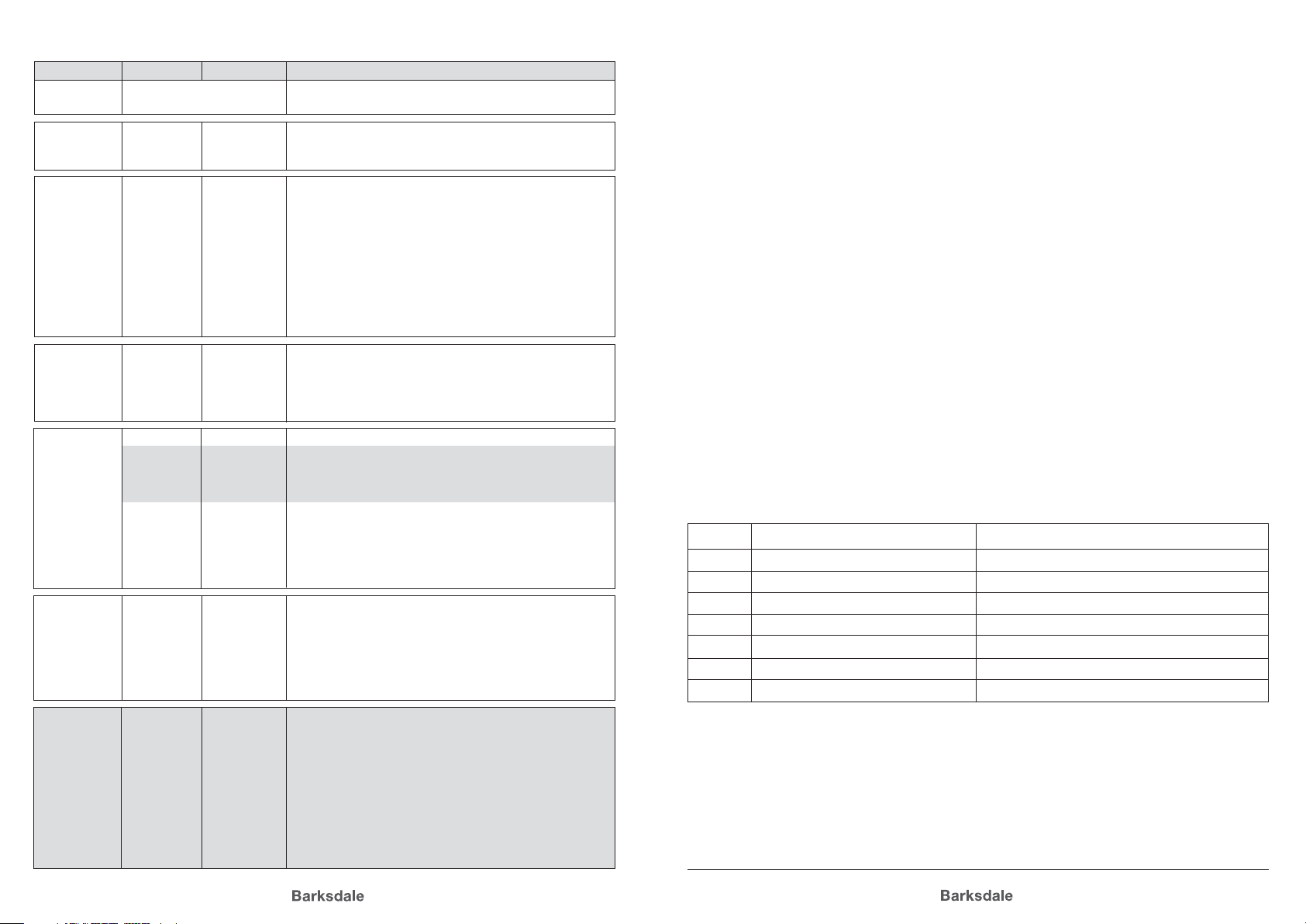

Dimensions (in mm)

UDS 3

Fixing lugs (for M4 screws)

optional Pg 13,5

Pressure conn.

Pg 13,5

4 x ø4,5

38,5

Pressure conn.

Connection UAS 3

Plug 3-pin

38,5

DIN 43650

1. Product description

Intended applications

- The pressure switch / trip amplifier is a device to monitor system pressure, temperature, flow, level,

etc. and has four switching outputs and one analog output.

- The pressure switch is only to be installed in systems where the maximum pressure Pmax is not

exceeded (according to the values on the type label).

- The trip amplifier is only to be connected to input signals according to the values on the type label at

the bottom side of the device.

- Attention: This device is not designed to be used as the only safety relevant element in pressurized

systems according PED 97/23/EC.

2. Starting operations

Only assemble or disassemble the device when depressurized!

- The pressure switch should be installed and operated only by authorized personel.

- Front cover and device bottom form a function unit. Exchanging the parts can result in measuring errors

or malfunctioning. See serial number inside the front cover. For wall mounting remove the four front cover

screws and the front cover. Then fasten the device with four screws to the wall and finally remount the

front cover. To damp strong vibrations shock mounts must be used.

- Mount the pressure connection (G 1/4 female) of the UDS 3 to the pressure system with a flexible pipe

and tighten with a 45 Nm torque. For pressure peaks damping screws must be used.

- UAS 3: Connect the sensor to the 3-pin cube plug at the bottom side of the device.

- The electrical connection (supply, analog output switching contacts) must be carried out according to

the connection tables depicted on the top of the device by removing the cover cap and insert the cable

through the cable gland PG 13,5. If required, additional cable glands can be installed in the cover cap

by breaking out the perforated cavities.

- The electrical connection must be carried out in accordance with the VDE 0100 regulations. In order to

ensure trouble-free operation it is essential to connect the protective lead.

When operating from 230 V AC loads at the switch contacts independent cables must be installed for

supply and switches (cover cap with two cable screw connections).

- If inductive loads (magnets, contactors, etc.) are connected to the switch relays, suitable protective

devices (varistors etc.) must be provided.

12

List of functions

4. Operation

Main Menu Sub Menu Value Description

Measuring .... Display of the actually measured value

mode and the measuring unit

MENU Display keylock

UNLK No keylock, all parameters can be adjusted

LOCK Keylock active, all parameters visibal but can not be changed

SP.1 ... SP.4 Switchpoint menu SP1..SP4

MODE STND Standard evaluation (rising/falling)

WIND Window technology

ERRO Error output

ON .... Switch-on value for SP1..SP4; if the ON-value is smaller

than the OFF-value, the switch evaluatiuon is falling

OFF .... Switch-off value SP1..SP4

LEV Inversion of the switching output SP1...SP4

HLFS High-level-fail-safe (Normally Open function)

LLFS Low-level-fail-save (Normally Closed function)

DEL 0,0s..9,9 s Switch-on / switch-off delay for SP1...SP2 in seconds

ANOP Analog output menu

ANOP ON Analog output in operation

OFF Analog output switched off

AOZS .... Scale the analog output - start value (e.g. 0 bar=4mA)

AOFS Scale the analog output - end value (e.g. 400bar=20mA)

DISP Display menu

UNIT bar Adjustment of the measuring unit, the recalculation to the new

(only PSI unit value is done automatically

UDS3) MPa

:

DAMP 0,0s..9,9 s Damping of the displayed measuring value in seconds

OFFS .... Measuring value -Offset, means shifting the display range

CUT .... Cut-Off, means signal-surpression within the cut-off range

BGZS .... Scale the bargraph - start value

BGFS .... Scale the bargraph - end value

PEAK Peakholding menu

MIN .... Display the peak value „Min“

CLRM NO no deletion

YES delete „Min“-value

MAX .... Display the peak value „Max“

CLRX NO no deletion

YES delete „Max“-value

After the unit is switched on, the unit starts an automatic self-test.

The device is menu operated and configured by the three keys on the front.

With the „M“ key (= mode) you change between the operation / indicating level to the dialog values and the

adjusted / actual values. With the keys („⇑“ = up) and („⇓“= down) you change between the dialog values

in the menu or change the values / functions in the menus.

A change of any configuration starts always with the M-Mode and indicated by the flashing cursor. After a

change has been made the M-mode key must be pressed to confirm each configuration; to set numbers,

each digit has to be confirmed with the M-Mode before adjusting the next one. By confirming the last digit

the new configuration will be stored in the memory.

Pushing the down key at the end of the sub-menu the software will switch automatically to the main-menu.

For a quick termination of programming you can change into the measuring mode from any level in the

menu by pressing the M-key for 5 seconds.

If the dialog is not continued within two minutes the device automatically returns to the measuring mode

without accepting the new values (see also: „List of functions“).

5. Key lock

Activating the („⇑“ = up) and („⇓“ = down) keys together for more than 5 seconds will block any changings

in all menues; shown by „LOCK“ in the display.

In this mode, all configuration values can be checked only, but not changed.

Repeating this action will unlock the configuration menu and shown by „UNLK“ in the display.

6. Error handling

The internal self-check software will monitor the proper functioning of the unit. When any of the following

failures will occur, the flashing display will indicate the following text:

Display Error Cause

max Positive excess of the measuring range The measured value exceeds the max. of the range

min Negative excess of the measuring range The measured value is lower than the min. of the range

anao Failure of the analog output Output loop is not closed or short circuited

sens Sensor failure (internal) Sensor bridge not in balance, might be been overloade

data Stored data failure (EEProm) (internal) Memory failure

prog Processor failure (internal) Microcontroller failure

cal Calibration failure (internal) Calibration values are wrong

CAL Calibration menu

(only UAS3) DECP 0000..0,000 Declaration of the decimal-point for the measuring value

ZSCL .... Scale the measuring-value indication - start value

FSCL .... Scale the measuring-value indication - end value

UNIT bar Declaration of the measuring unit

PSI

:

TEXT Enables the indication of the measuring-unit whitch is defined

in the UTXT menu

UTXT ABCD Programm a free configurable text for the measuring unit

CODE Calibration menu for the manufacturer

43

Loading...

Loading...