Barksdale 9000, 9020 User Manual

Valves

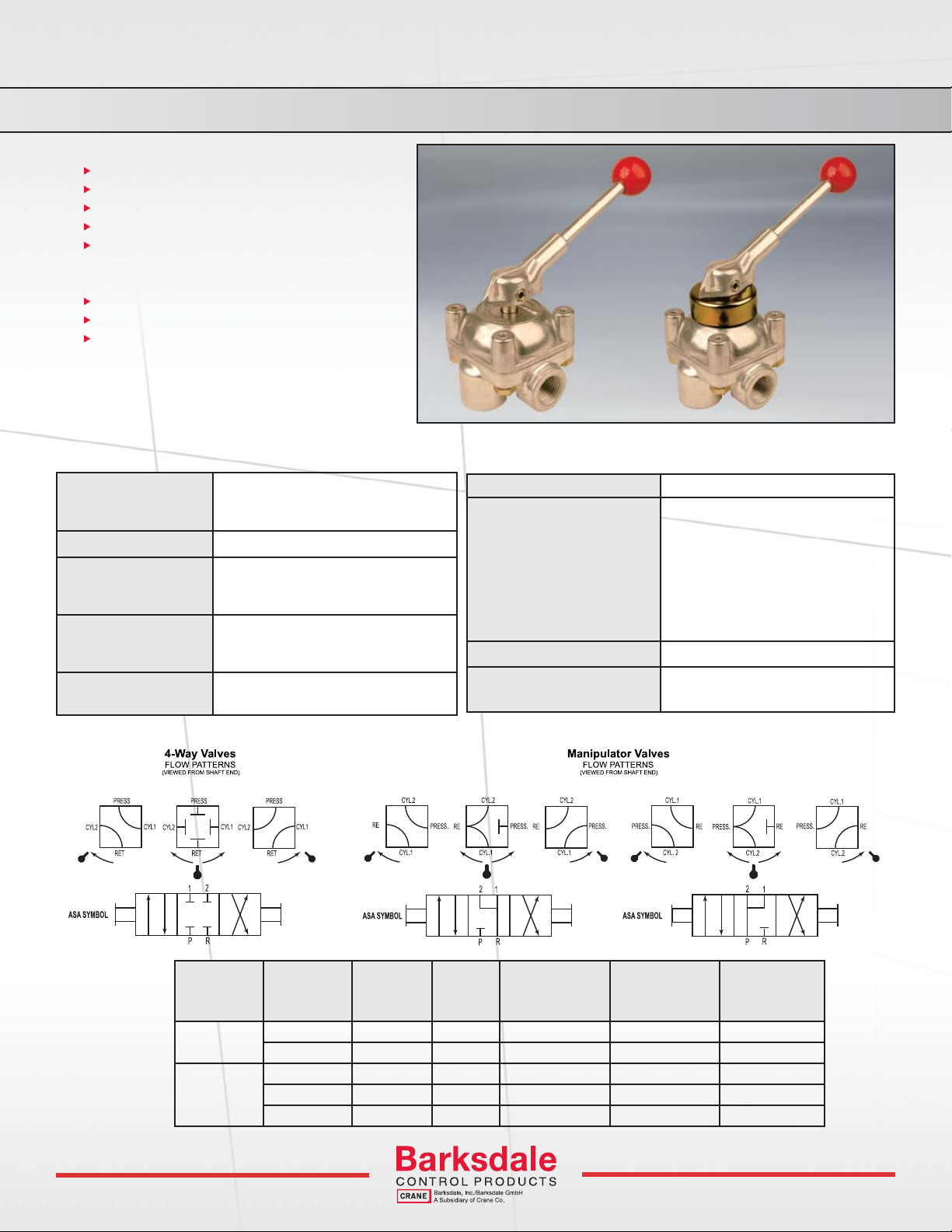

Shear-Seal® Directional Control Valve Series 9000, 9020

Features

Original Shear-Seal® technology

Interflow/non interflow

Easy panel mounting

Tolerates contaminates

Spring return option

Applications

Pilot valve for pneumatic valve actuators

Gas manifold controls

Manual control of 2-position cylinder

Shown with option “D” red ball type handle

General Specifications*

Working Pressure:

Cv, Minimum Orifice:

Back Pressure:

Proof Pressure:

Burst Pressure:

* See product confi gurator for additional options.

Pneumatic or hydraulic from 150

psi to 350 psi (10.3 to 24.1 bar); see

table

See table

Must not exceed 250 psi (17.2

bar) at return port for satisfactory

operation

1-1/2 times working pressure except

at return port (without damage to

valve)

2-1/2 times working pressure except

at return port (300 psi, 20.7 bar)

Media Temperature Range:

Wetted Material:

Body:

Standard O-Rings:

Pressure Seals:

Rotor:

Handle Rotation:

Detent:

-40° to +250°F (-40° to +121°C)

Anodized aluminum

Buna N

Brass

Hard anodized aluminum

90°; 45° each side of center

3-position detent (except -MC,

-MR options)

CLOSED CENTER (Float Center) OPEN CENTER CLOSED CENTER

T

Port

Size

NPT

9000 Series

Non Interfl ow

9020 Series

Interfl ow

1

1/4” 3/16” 0.52 150 (10.3) 150 (10.3) 2 (0.9)

3/8” 3/16” 0.52 150 (10.3) 150 (10.3) 2 (0.9)

1/4” 3/8” 2.3 350 (24.1) 250 (17.2) 2 (0.9)

3/8” 3/8” 2.3 350 (24.1) 250 (17.2) 2 (0.9)

1/2” 3/8” 2.3 350 (24.1) 250 (17.2) 2 (0.9)

Min.

Flow

Passage

Dia.

T T T T T

Cv

Factor

Air and Oil

Rated

Pressure

psi (bar)

Manipulator

Rated

Pressure

psi (bar)

Approx.

Shipping

Weight

lbs. (kg)

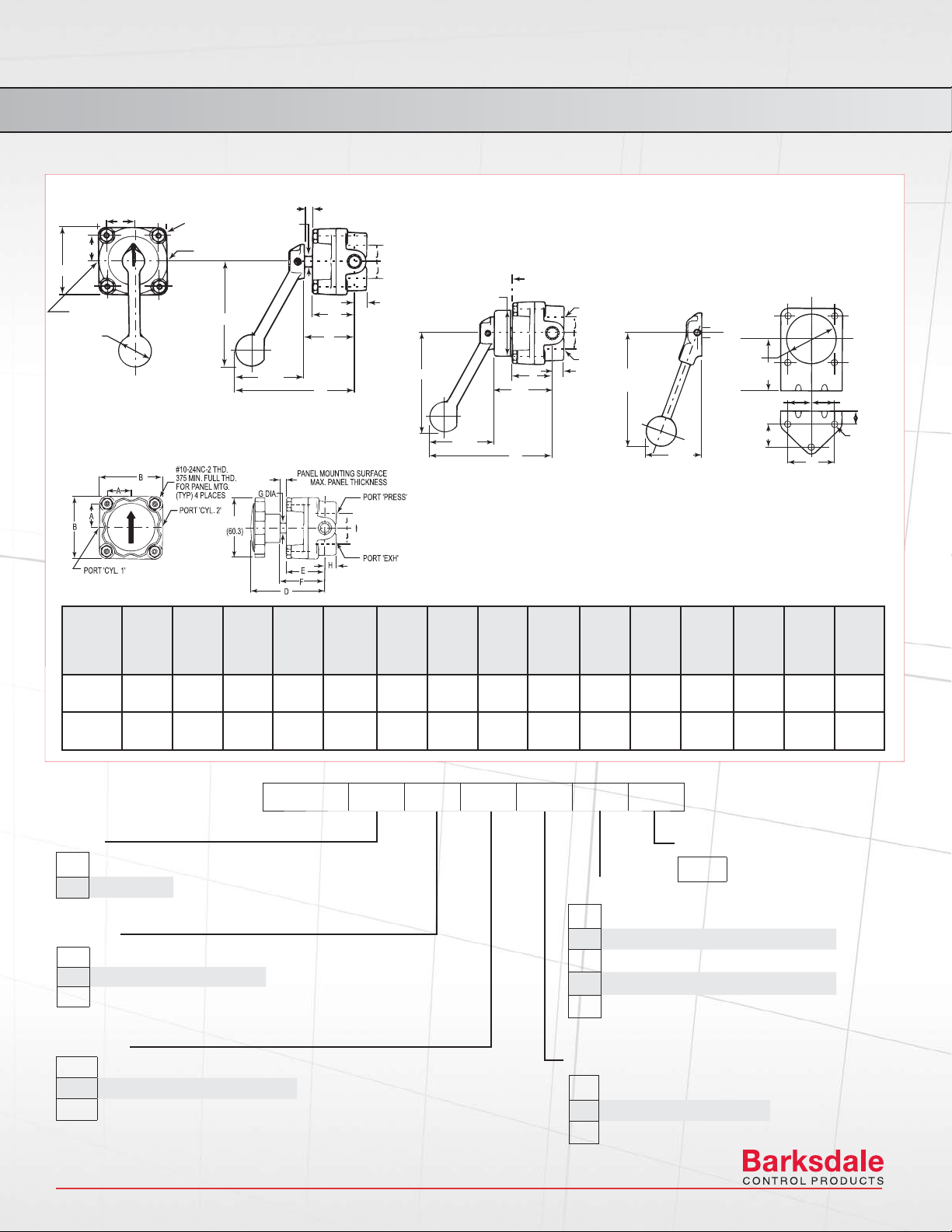

Shear-Seal® Directional Control Valve Series 9000, 9020

(

Technical Drawings

REGULAR

PANEL MOUNTING

SURFACE .250 MAX.

PANEL THICKNESS

E

F

1

D

1

.625

“-D” option “-C” option

SPRING CENTER/REVERSE

PANEL MOUNTING

SURFACE

PORT*

PORT*

H

E

F

2

D

2

2.781

(70.6)

G2 DIA.

H

C

RED BALL

TYPE HANDLE

5.437

(138.1)

3.125

(79.4)

MOUNTING BRACKET

and 4 SCREWS

2.125

(54.0)

2.375

(60.3)

1.0 (25.4)

1.0 (25.4)

2.0

50.8)

1.0 (25.4)

.281 DIA.

3 PLACES

B

PORT*

1.250

(31.8 )

#10-24NC-2 THD.

A

A

.375 MIN. FULL THD.

FOR PANEL MTG.

(TYP) 4 PLACES

PORT*

C

“-E” option

BLACK KNOB

(not available with spring return)

2.375

2.781

(70.6)

G1 DIA.

.562 (14.3)

PORT

SIZE

NPT

ABC

1/4 & 3/8 1.000

(25.4)

1/2 1.000

(25.4

2.625

(66.7)

3.125

(79.4)

(104.8)

(104.8)

Product Configurator

Series

900 Non interfl ow

902 Interfl ow

Port Size

1 1/4” pressure port

2 3/8” pressure port

3 1/2” pressure port (interfl ow only)

Black

Knob

Regular

Spring

Center/

Rever

D-1

4.781

(121.4)

4.843

(123.0)

D-2 E

5.188

(133.8)

5.250

(133.4)

4.125

4.125

D

3.656

(92.9)

3.718

(94.4)

Example: 902 2 -M

1.688

(42.9)

1.750

(44.5)

Black

Knob

F

2.062

(52.4)

2.125

(54.0)

Regular

Spring

Center/

Black

Knob

Rever

F-1

2.000

(50.8)

2.062

(52.4)

F-2

2.406

(61.1)

2.468

(62.7)

G

0.437

(11.1)

0.437

(11.1)

Options

2-position 90° rotation (no center position)

-B

-C Mounting bracket w/ 4 screws

Red ball type handle

-D

Mounting bracket & red ball type handle

-CD

Black knob (not available for spring return)

-E

Dimensions in inches (mm)

Regular

Spring

Center/

Rever

G-1

0.437

(11.1)

0.437

(11.1)

G-2 H J

1.906

(48.4)

1.906

(48.4)

0.531

(13.5)

0.625

(15.9)

Optional O-ring Material

-Zxx See supplemental guide

0.656

(16.7)

0.937

(23.8)

Operation

-M Manual operation

-MC Manual (spring return to center)

-MR Manual (spring return to reverse)

Flow Pattern

Blank if closed center selector

-A Closed center manipulator

-G Open center manipulator

3211 Fruitland Avenue • Los Angeles, CA 90058 • 800-835-1060 • Fax: 323-589-3463 • www.barksdale.com

See Barksdale’s Standard Conditions of Sale • Specifications are subject to modification at any time • Bulletin #B0040-H • 12/08 • ©2008 • Printed in the U.S.A.

2

Loading...

Loading...