Page 1

THE WALL-MOUNT™ STEP CAPACITY GAS/ELECTRIC - WG*S SERIES

Integrated Part Load Value (IPLV) Efficiency Up to 15.5 BTU/WATT

WG3S1, WG4S1, WG5S1 60HZ

GREEN REFRIGERANT

23,000 to 56,500 BTUH Cooling Capacity

36,000 to 99,000 BTUH Heating Capacity

The Bard Wall-Mount Electric Air Conditioner with gas fired heating is a self contained energy efficient system

which is designed to offer maximum indoor comfort at a minimal cost without using valuable indoor floor space

or outside ground space. This unit is the ideal product for versatile applications such as: new construction,

modular offices, school modernization, portable structures, correctional facilities, retail stores or other

commercial applications. Factory or field installed accessories are available to meet specific job requirements.

Engineered Features

Multi-Capacity Two-Stage:

Simple thermostatic control seamlessly

stages the compressor and indoor airflow

rate between high and low capacity

operations without cycling the compressor.

This helps to maximize comfort, humidity

control, energy efficiency and overall

reduction in compressor cycling for

improved system life.

Step Capacity Compressor:

Copeland step-capacity (2-stage) scroll

compressors are designed for increased

efficiency, quieter operation and improved

reliability for longer life.

R-410A Refrigerant:

Designed with R-410A (HFC) non-ozone

depleting refrigerant in compliance with

the Montreal protocol and 2010 EPA

requirements.

Thermal Expansion Valves:

All models use TXV.

Liquid Line Filter Drier:

Protects system against moisture.

Aluminum Finned Copper Coils:

Grooved tubing and enhanced louvered

fin for maximum heat transfer and energy

efficiency.

High & Low Pressure Switches are

Auto-Reset

Built-in lockout circuit resets from the

room thermostat. Provides commercial

quality protection to the compressor.

Compressor Control Module:

Standard on all units. Built-in off-delay

timer adjustable from 30 seconds to 5

minutes. 2-minute on-delay if power

interrupt. 120-second bypass for low

pressure control, and both soft and

manual lockouts for high and low pressure

controls. Alarm output for alarm relay.

Crankcase Heaters:

Factory installed crankcase heaters are

standard on all models. This helps to

insure ease of start at low temperatures

and improves compressor life.

• Complies with efficiency requirements of ANSI/ASHRAE/IESNA 90.1-2007.

• Certified to ANSI/ARI Standard 390-2003 for SPVU (Single Package Vertical Units).

• Intertek ETL Listed to Standard for Safety Heating and Cooling Equipment ANSI/UL

1995/CSA 22.2 No. 236-05, Third Edition.

• Intertek ETL Listed to Standard for Gas-Fired Central Furnaces ANSI Z21.47-2006, CSA

2.3-2006 Fifth Edition, Addenda A dated 10-01-2007, Addenda B dated 06-01-2008.

• Commercial Product - Not intended for Residential application.

Phase Rotation Monitor:

Standard on all 3 phase scroll

compressors. Protects against reverse

rotation if power supply is not properly

connected.

Twin Blowers:

Move air quietly. All models feature

variable speed blower motors providing

automatic airflow adjustment for high

static or free blow (non-ducted) operation

at a very low sound level. Motor overload

protection is standard on all models.

ECM Indoor Blower Motor:

Features a variable speed motor

providing super-high efficiency, low

sound levels and soft-start capabilities.

The motor is self-adjusting to provide the

proper airflow rate for the staged

capacity, and for higher static pressure in

ducted installations without user

adjustment or wiring changes.

Ventilation Controller:

Automatically adjusts damper position to

maintain the desired ventilation airflow rate

up to 480 cfm of fresh air during any

operation mode. Fully closes during

unoccupied modes. Factory set for 480

cfm. Also, CO2 sensor ready - just add

CO2 sensor for demand ventilation based

on CO2 level in the space.

Electrical Components:

Are easily accessible for routine inspection

and maintenance through a right side,

service panel opening. Features a

lockable, hinged access cover to the circuit

breaker or rotary disconnect switch.

PTCR Start Assist:

Standard on 1-phase models.

Heat Exchanger:

Heavy duty 18-gauge stainless steel

tubular heat exchanger. Mechanically

joined construction. Ten-year warranty.

In-Shot Burners:

Advanced burner design, quiet operation.

Low NOx models available. Low NOx

models can be converted to LP gas. High

altitude kits available.

R-410A

MEA # (Heating): 73-03-E

MEA # (Cooling): 179-03-E

Integrated DSI Control:

Direct spark ignition control and

remote sensor delivers smooth,

proven ignition sequence.

Timed blower control and

diagnostics are also features of

integrated control.

Gas Controls:

Honeywell gas valve and

burner orifices are factory

standard for natural gas. Field

convertible to LP gas with

certified conversion kit.

Hinged Service Door:

Hinged door with compression latches (one lockable) for filter

service access, heat exchanger inspection, and indoor blower/

motor service.

Pre-Painted 20 Gauge Zinc Coated Steel Cabinet:

Cleaned, rinsed, sealed and dried before the polyurethane

primer is applied. The cabinet is handsomely finished with a

baked on textured enamel, which allows it to withstand 1000

hours of salt spray tests per ASTM B117-03.

16 Gauge Zinc Coated Unit Base

Two-Inch, Pleated Disposable Air Filters:

Are standard equipment.

Condenser Fan and Motor

Shroud Assembly:

Slides out for easy access.

Circuit Breakers/Rotary Disconnect:

Standard on all versions of single (230/208 volt) and three

phase (230/208 volt) equipment. Rotary disconnects are

standard on all versions of three phase (460 volt) equipment.

Slope Top:

Standard feature for water run-off.

Full Length Mounting Brackets:

Built into cabinet for improved appearance and easy installation.

Top Rain Flashing:

Standard feature on all models.

Ventilation Options:

Several patented ventilation options are available and can be

factory or field installed.

• High Efficiency

• Low Sound Level

Form No. S3396-1112

Supersedes S3396-212

Page 1 of 12

Page 2

M

E

O

M

G

C

C

V

R

B

L

F

F

F

F

M

B

B

C

C

F

C

S

C

M

C

E

R

C

E

R

I

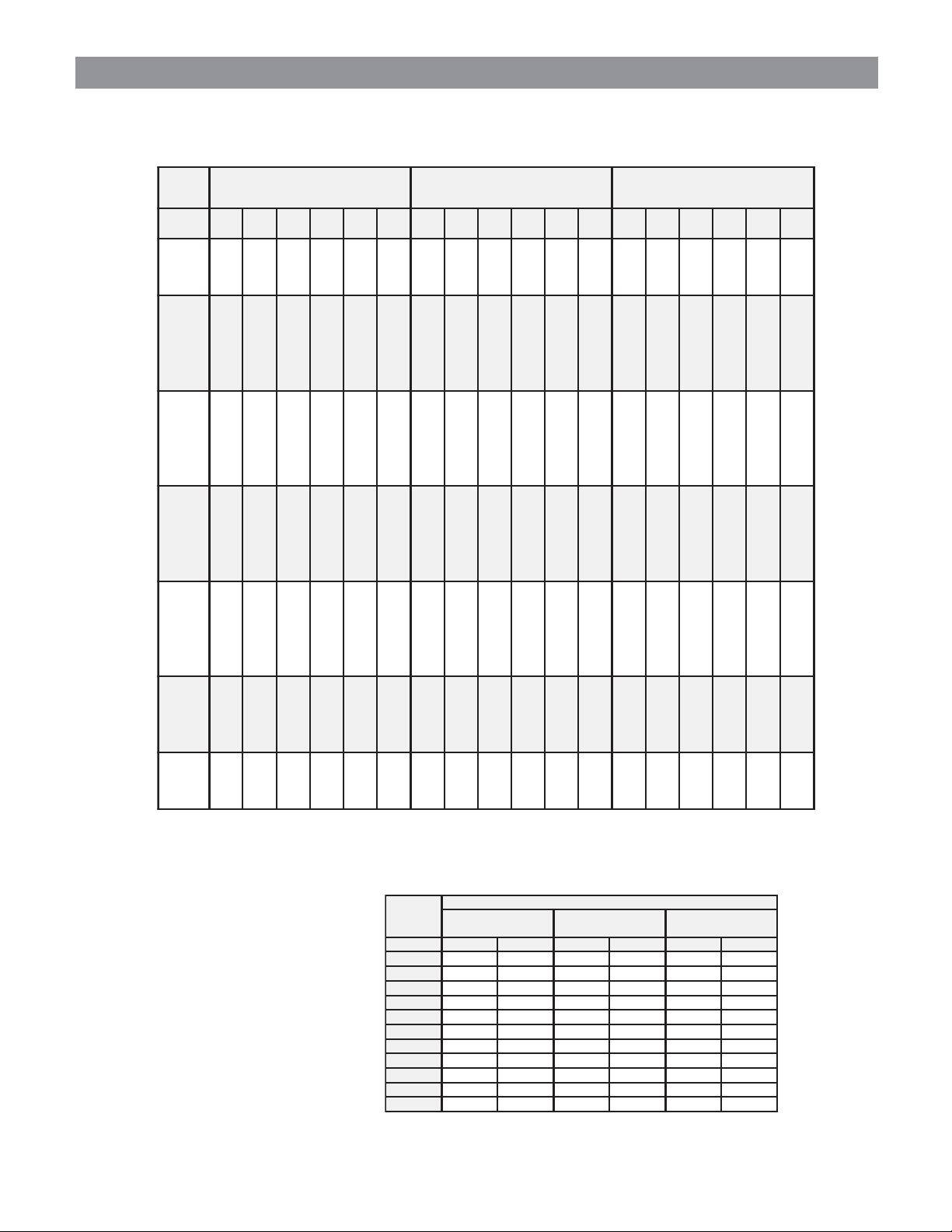

Specifications

H

F

M

I

O

A

T

C

1

M

I

O

A

T

C

ledo

zH06-gnitaRcirtcel

egnaRegatloVgnitarep

yticapmAtiucriCmumini

eziSeriWdleiF*80141801218801

eziSeriWdnuor

.xaM-esuFyaleD**540351540402060552

rosserpmo

epyTrosserpmo

stlo

spmAdaoLdeta

tnerruCnoitceleStiucriChcnar

spmArotoRdekco

resnednoC&rotoMna

DPS/MPR/PH-rotoMna

spmArotoMna

MFC/.AIDna

rotaropavE&roto

DPS/MPR/PH-rotoMrewol

spmA-rotoMrewol

egatSts1-gnilooCMF

egatSdn2-gnilooCMF

eziSretli

)A014-R(egrah

).sbl(thgieWgnippih

1

* Based on 75°C copper wire. All wiring must conform to the National Electrical Code and all local codes.

** Maximum time delay fuse or HACR type circuit breaker.

1 Add 45 lbs. for factory installed WGSCRVMP-5 Commercial Room Ventilator or WGSEIFM-5 Economizer, and 90 lbs. for WGSERV-5 Energy Recovery Ventilator.

A-1S3GW B-1S3GW C-1S3GW A-1S4GW B-1S4GW C-1S4GW A-1S5GW B-1S5GW C-1S5GW

1-06-802/0323-06-802/0323-06-0641-06-802/0323-06-802/0323-06-0641-06-802/0323-06-802/0323-06-064

352-791352-781605-414352-791352-781605-414352-791352-781605-414

133211838241444371

010141010121010101

llorcSllorcSllorcSllorcSllorcSllorcSllorcSllorcSllorcS

802/032802/032064802/032802/032064802/032802/032064

3.31/4.112.8/5.63.34.71/0.511.11/4.95.41.32/8.910.51/4.317.6

7.612.115.42.125.315.67.526.815.9

28859269881481132126

2-058-3/12-058-3/11-058-3/12-058-3/12-058-3/11-058-3/12-058-3/12-058-3/11-058-3/1

5.25.23.15.25.23.15.25.23.1

0072-"420072-"420072-"420072-"420072-"420072-"420072-"420072-"420072-"42

elbairaV2/1elbairaV2/1elbairaV2/1elbairaV4/3elbairaV4/3elbairaV4/3elbairaV4/3elbairaV4/3elbairaV4/3

6.36.36.37.47.47.40.60.60.6

008008008001100110011003100310031

001100110011005100510051007100710071

2x03x022x03x022x03x022x03x022x03x022x03x022x03x022x03x022x03x02

651651651042042042642642642

585 585 036 586 586 037 017 017 557

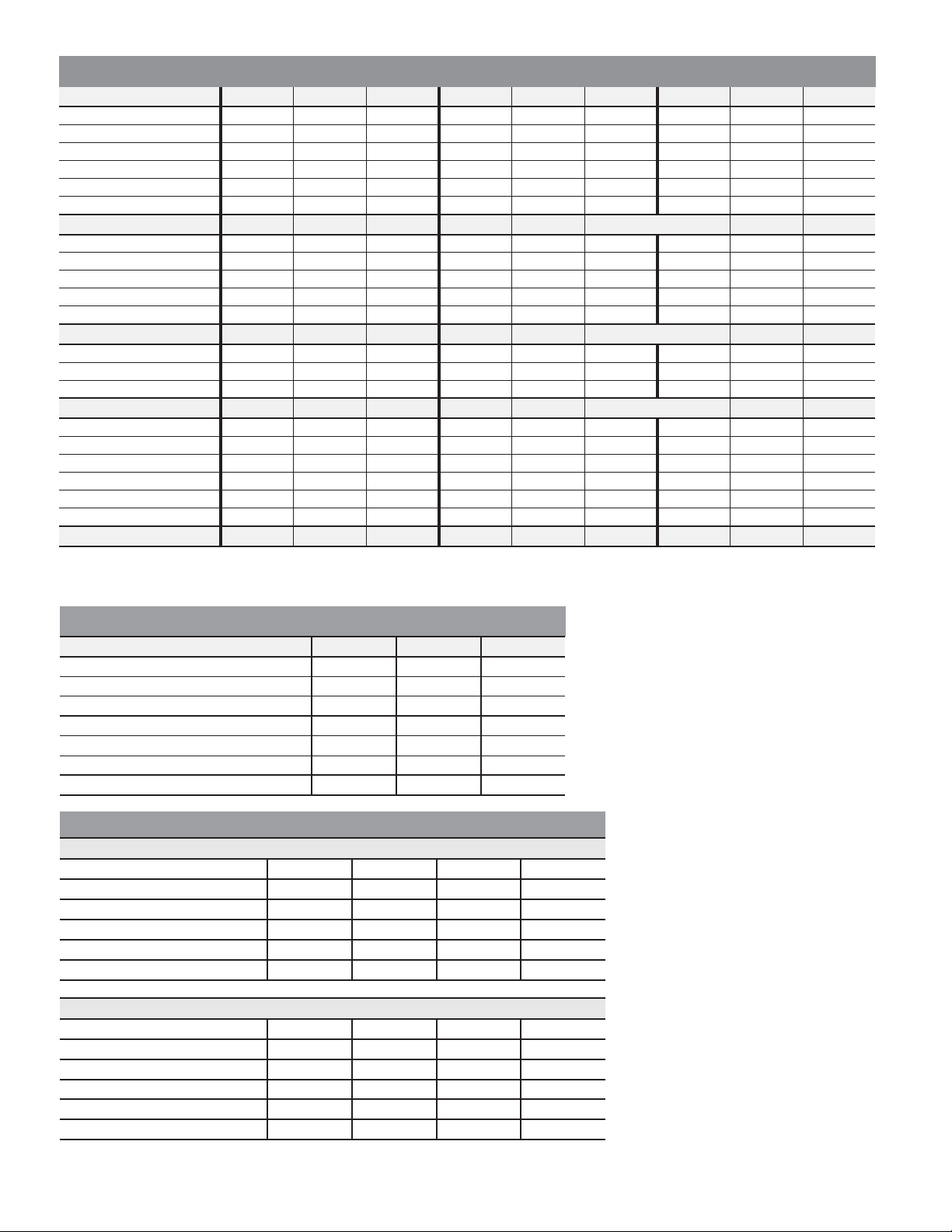

ledo

noitarepOegatSdn2,HUTByticapaCgniloo

1 006,43005,64005,65

1 8.015.117.01

noitarepOegatSdn2RE

lioCteW,MFCdeta

noitarepOegatSts1,HUTByticapaCgniloo

noitarepOegatSts1RE

lioCteW,MFCdeta

)3002-093dradnatSIRAotdeifitreC(VLP

edoCtupnIgnitaeHledo

HUTBtupn

2 005,04 000,16 000,18 000,99

)yticapaCgnitaeH(HUTBtuptu

2 0.18 0.18 0.18 0.18

EUF

)F(egnaResiRerutarepme

)F(esiRtnatsnoC/MFCgnitaeHtnatsno

edoCtupnIgnitaeHledo

HUTBtupn

2 000,63 005,45 000,27 005,78

)yticapaCgnitaeH(HUTBtuptu

2 0.18 0.18 0.18 0.18

EUF

)F(egnaResiRerutarepme

)F(esiRtnatsnoC/MFCgnitaeHtnatsno

1 .ledomhcaerofdetcelesebnactupniynA

2 .margorPnoitacifitreCycneiciffEAMAGhtiwecnadroccanideifitrecsgnitargnitaeH

Form No. S3396-1112

Supersedes S3396-212

Page 2 of 12

A B C D

000,05 000,57 000,001 000,521

55-52 06-03 07-04 08-05

53/069 05/0011 05/5631 07/0441

A B C D

000,54 005,76 000,09 005,211

55-52 06-03 07-04 08-05

03/069 54/0011 54/5631 56/0441

1S3GW 1S4GW 1S5GW

001100410061

000,32006,33005,04

8.012.210.11

00800110031

0.415.513.41

etoNeeS—ecnamrofreP&snoitpOyticapaCgnitaeHetareDdleiF%0

etoNeeS—ecnamrofreP&snoitpOyticapaCgnitaeHdradnatSyrotca

11

11 woleB

1

11

11 woleB

1

sgnitaRwolfriA&ycneiciffE,yticapaCmetsySgniloo

sgnitaRwolfriA&ycneiciffE,yticapaCmetsySgnitae

Page 3

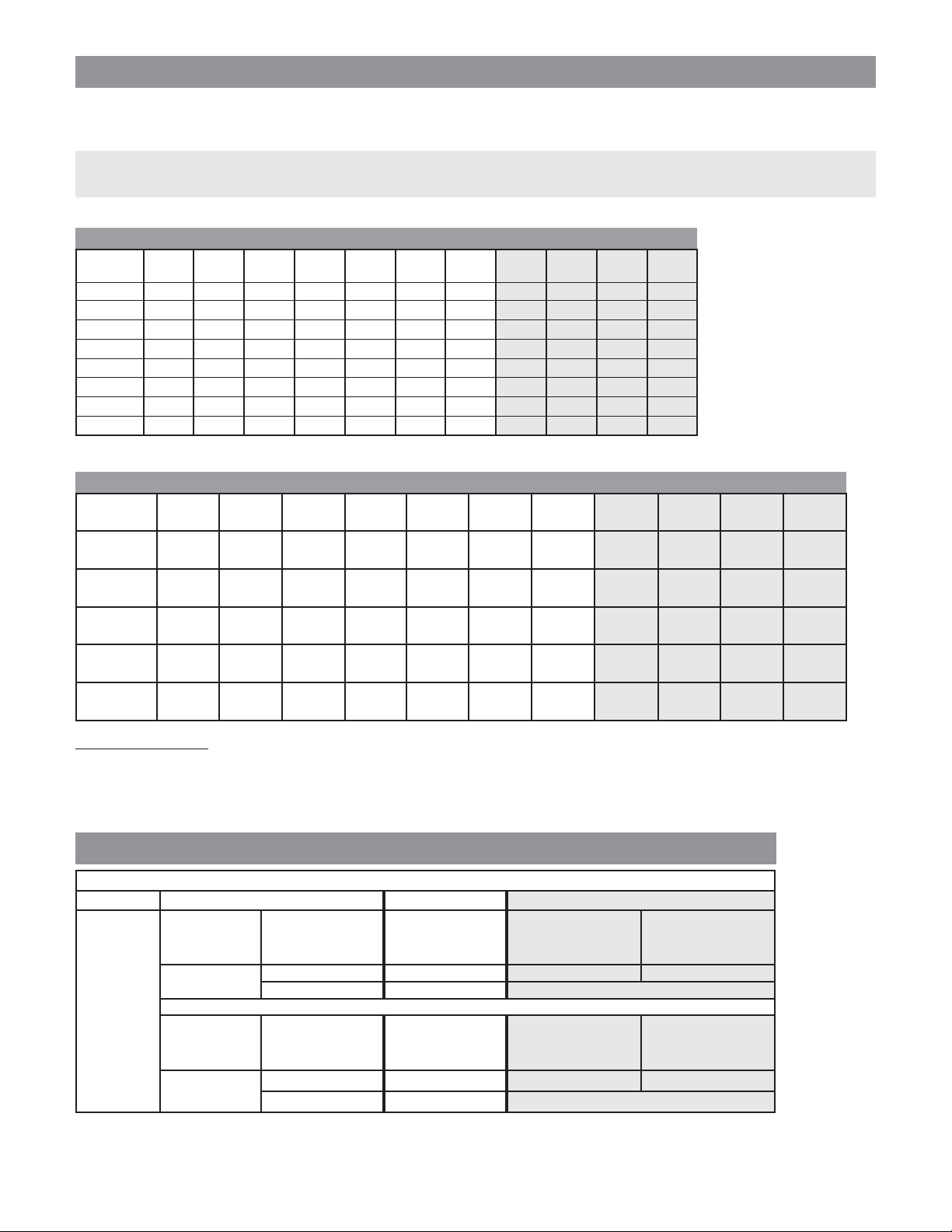

Indoor Blower Performance 1

detaR

LEDOM

PSE

xaM

PSE

suounitnoC

MFC

1S3GW51.005.00080080011069001156310441

1S4GW02.005.052800110041069001156310441

1S5GW02.005.005800310061069001156310441

2

3

detaR

egatSts1

MFCgnilooC

4

detaR

egatSdn2

MFCgnilooC

000,05

UTB

tupnI

1 Motor will deliver consistent CFM through voltage supply range with no deterioration (197-253V for 230/208V models, 414-506V for 460V models).

2 Continuous CFM is the total air being circulated during continuous (manual) fan mode.

3 Will occur automatically with a call for “Y1” signal from thermostat.

4 Will occur automatically with a call for “Y2” signal from thermostat.

5 Will occur automatically with a call for “W” signal from thermostat.

6 Constant CFM of Variable Speed Motor should maintain mid-rise temperature differential through range of allowable static.

MFCgnitaeH 65

000,57

UTB

tupnI

000,001

UTB

tupnI

000,521

UTB

tupnI

Ventilation System Packages

Bard Wall-Mounts are designed to provide optional ventilation packages to meet all of your ventilation and indoor air quality requirements.

All units are equipped with a barometric fresh air damper as the standard ventilation package. All ventilation packages can be built-in at the

factory, or field-installed at a later date.

BLANK OFF PLATE - WGSBOP STANDARD

A blank off plate is installed on the inside of the service door. It covers the air inlet openings which restricts any outside

air from entering the unit. The blank off plate should be utilized in applications where outside air is not required to be

mixed with the conditioned air.

COMMERCIAL ROOM VENTILATOR - WGSCRVMP-5 OPTIONAL

The built-in commercial room ventilator is internally mounted behind the service door and allows outside ventilation air,

up to 50% of the total airflow rating of the unit, to be introduced through the air inlet openings. It includes a built-in

exhaust air damper with integral bug screen. Automatic control is integrated to maintain desired ventilation air at the

various supply airflows while on Stage 1, Stage 2 or ventilation modes of operation.

The commercial room ventilator (CRV) is a simple and innovative approach to improving the indoor air quality by

providing fresh air intake and exhaust capability through the CRV. The damper can be easily adjusted to control the

COMMERCIAL ROOM VENTILATOR

amount of fresh air supplied into the building. The CRV can be controlled by indoor blower operation or field controlled

based on room occupancy. The CRV is power open - spring return on power loss. Complies with ANSI/ASHRAE

Standard 62.1 “Ventilation for Acceptable Indoor Air Quality”.

CO

Sensor Ready: • WGSCRVMP-5 is designed for CO2 based on ventilation control

2

by simply wiring in a field installed CO2 sensor if desired.

ECONOMIZER - WGSEIFM-5 OPTIONAL

The built-in economizer system is internally mounted behind the service door and allows outdoor air to be introduced

through the air inlet openings. The amount of outdoor air varies in response to the system controls and settings defined

by the end user. It includes a built-in exhaust air damper. The economizer is designed to provide “free cooling” when

outside air conditions are cool and dry enough to satisfy cooling requirements without running the compressor. This in

turn provides lower operating costs, while extending the life of the compressor.

Standard Features:

• One Piece Construction - Easy to install with no mechanical linkage adjustment required.

ECONOMIZER

• Exhaust Air Damper - Built in with positive closed position. Provides exhaust air capability to prevent

pressurization of tight buildings.

• Actuator Motor - 24 volt, power open, spring return with built in torque limiting switch.

• Proportioning Type Control - for maximum “free cooling” economy and comfort.

• Moisture Eliminator & Prefilter - permanent, washable aluminum construction.

• Enthalpy Control - adjustable to monitor outdoor temperature and humidity.

• Minimum Position Potentiometer - adjustable to control minimum damper blade position for ventilation purposes.

• Mixed Air Sensor - to monitor outside and return air to automatically modulate damper position.

WALL-MOUNT ENERGY RECOVERY VENTILATOR - WGSERV-5 OPTIONAL

The wall-mount energy recovery ventilator (WGSERV-5) is a highly innovative approach to address indoor air quality ventilation

requirements as established by ANSI/ASHRAE Standard 62.1. The WGSERV-5 allows up to 450 CFM (depending upon

speed setting) of fresh air and exhaust through the unit while maintaining superior indoor comfort and humidity levels. In most

cases this can be accomplished without increasing equipment sizing or operating costs. Heat transfer efficiency is up to 74%

during summer and 80% during winter conditions.

The WGSERV-5 consists of a unique “rotary energy recovery cassette” that provides effective sensible and latent heat

transfer capabilities during summer and winter conditions. Various control schemes are addressed including limiting ventilation

ENERGY RECOVERY VENTILATOR

during building occupancy only.

The WGSERV-5 is designed to be internally mounted behind the service door in the WGS Gas/Electric units. It can be builtin at the factory or field installed as an option. WGSERV-5 can be independently adjusted for intake and exhaust rates.

Manufactured under U.S. Patent Nos. 5,301,744; 5,485,878

NOTE: See Page 4 for WGSCRV Performance Data &

Page 5 & 6 for WGSERV Performance Data

Form No. S3396-1112

Supersedes S3396-212

Page 3 of 12

Page 4

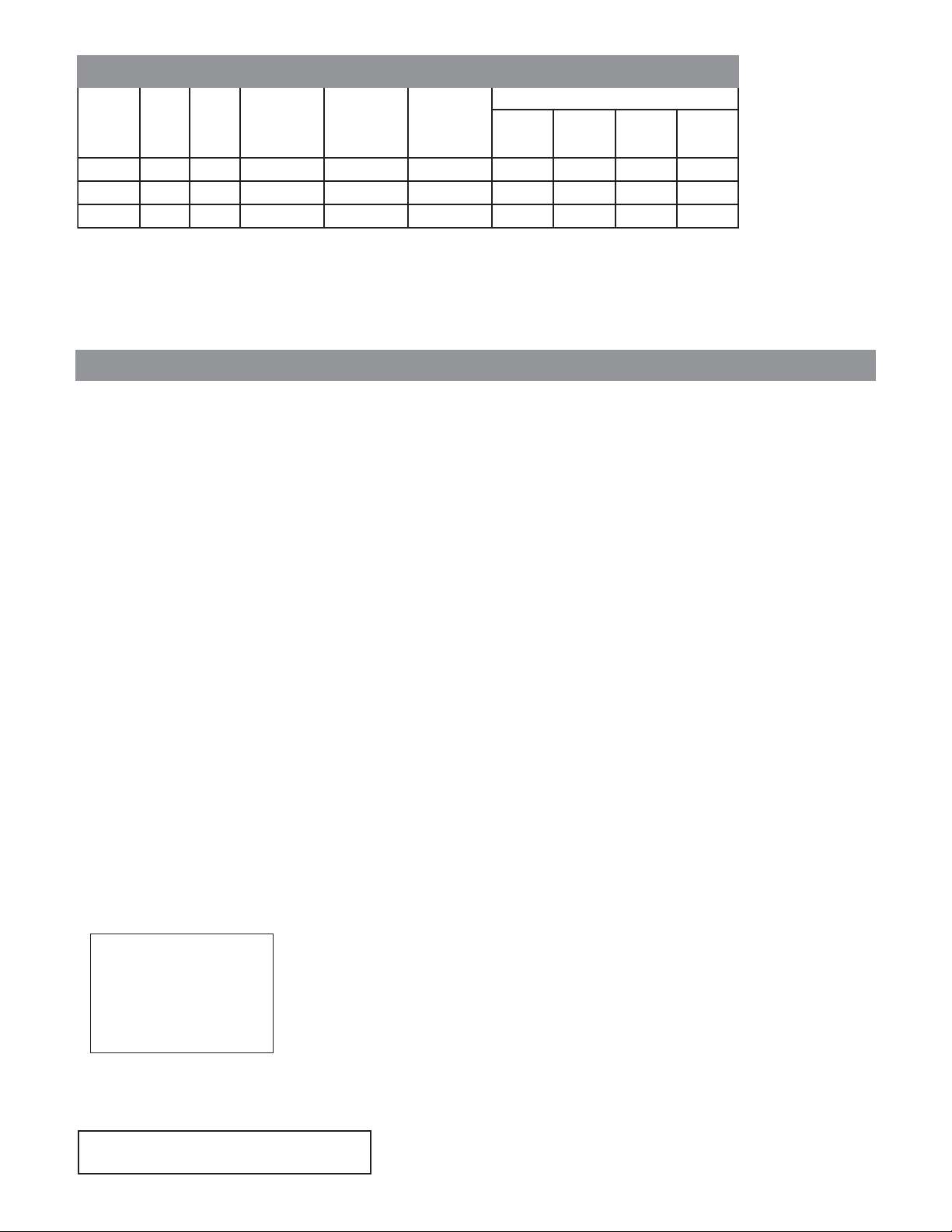

WGSEIFM-5 Economizer and WGSCRVMP-5 Commercial Ventilator Airflow

700

600

500

400

300

Ventilation Airflow (CFM)

200

100

0

0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 25 27.5 30

Vent Position

WG4S Ventilation Airflow

900

800

700

WG3S Ventilation Airflow

Stage #2

Operation

Blower Only

& Stage #1

Operation

600

500

400

Ventilation Airflow (CFM)

300

200

100

0

0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 25 27.5 30

Vent Position

WG5S Ventilation Airflow

1000

900

800

700

600

500

400

Ventilation Airflow (CFM)

300

200

Stage #2

Operation

Stage #1

Operation

Blower Only

Stage #2

Operation

Stage #1

Operation

Blower Only

Form No. S3396-1112

Supersedes S3396-212

Page 4 of 12

100

0

0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 25 27.5 30

Vent Position

Page 5

Energy Recovery Ventilator Performance Data — WGSERV-A5 (230V) & WGSERV-C5 (460V)

A5C-,A5A-VRESGW—ATADNOITACILPPA

ECNAMROFREPGNILOOCREMMUS

)BW°26/BD°57SNOITIDNOCNGISEDROODNI(

tneibmA

.D.O

/BD

F TLV SLV LLV TRH SRH LRH TLV SLV LLV TRH SRH LRH TLV SLV LLV TRH SRH LRH

BW

575641208541488697821847813149467188911166524901334701536533127094824845860852472

501

0708541085410847884780 88911889110334733470270927090608560850

5608541085410

08 00513 05121 04491 00981 0927 01611 00952 0999 01951 85061 4916 4689 00691 0657 04021 44521 8384 6077

57 56412 05121 4139 97821 0927 9855 94671 0999 9567 24901 4916 9474 65331 0657 6975 8458 8384 9073

001

07 25321 05121 202 1147 0927 121 65101 0999 661 7926 4916 301 6867 0657 621 9194 8384 08

56 05121 05121 0 0927 0927 0 0999 0999 0 4916 4916 0 0657 0657 0 8384 8384 0

06 05121 05121 0 0927 0927 0 0999 0999 0 4916 4916 0 0657 0657 0 8384 8384 0

0809513027907812459812385221314795229972897140161559494111656918406806310852117839078

57564120279447119782123857407946712997756924901559478956533184068037845817837764

59

0725321027923621147238597516510129974612792655942431686784068361919417838401

56027902790238523850299729970

06027902790238523850299729970559455940840684060178317830

08 09513 0927 00342 45981 4734 08541 47952 4995 08991 40161 6173 88321 65691 6354 02151 08521 3092 7769

57 56412 0927 57141 97821 4734 5058 94671 4995 55611 24901 6173 6227 65331 6354 0288 8458 3092 5465

07 25321 0927 2605 1147 4734 7303 65101 4995 2614 7926 6173 0852 6867 6354 0513 9194 3092 6102

09

56 0927 0927 0 4734 4734 0 4995 4995 0 6173 6173 0 6354 6354 0 3092 3092 0

06 0927 0927 0 4734 4734 0 4995 4995 0 6173 6173 0 6354 6354 0 3092 3092 0

08095130684037624598161928306147952699387912401618742626316569142032366108521539144601

5756412068450661978216192369994671699335631249018742564865331420323301845853912166

58

0725321068429471147619259446510169930616792687429183686742032664919453913892

56068406840

06068406840619261920699369930874287420420342030 539153910

57 56412 0342 53091 97821 8541 12411 94671 8991 15651 24901 9321 4079 65331 2151 44811 8458 869 0857

07 25321 0342 2299 1147 8541 3595 65101 8991 8518 7926 9321 8505 6867 2151 4716 9194 869 1593

08

56 2524 0342 2281 1552 8541 3901 6943 8991 8941 8612 9321 929 6462 2151 4311 3961 869 627

06 0342 0342 0 8541 8541 0 8991 8991 0 9321 9321 0 2151 2151 0 869 869 0

07253210 2532111470 114765101065101792607926686706867919409194

57

5625240252415520 1552694306943861208612646206462396103961

06000000000000000000

MFC054--ETARNOITALITNEV

)kcalB(deepShgiH

YCNEICIFFE%06

847884780 88911889110334733470270927090608560850

619261920699369930874287420420342030

MFC073--ETARNOITALITNEV

)eulB(deepSmuideM

YCNEICIFFE%26

559455940840684060178317830

)deR(deepSwoL

YCNEICIFFE%46

539153910

MFC082--ETARNOITALITNEV

LEGEND:

VLT = Ventilation Load - Total

VLS = Ventilation Load - Sensible

VLL = Ventilation Load - Latent

HRT = Heat Recovery - Total

HRS = Heat Recovery - Sensible

HRL = Heat Recovery - Latent

WVL = Winter Ventilation Load

WHR = Winter Heat Recovery

ECNAMROFREPGNITAEHRETNIWA5C-,A5A-VRESGW

)BDF°07SNOITIDNOCNGISEDROODNI(

ETARNOITALITNEV

tneibmA

.D.O

MFC054

.FFE%77

MFC073

.FFE%87

F°/BD LVW RHW LVW RHW LVW RHW

56034207810002065101510911

06068404730004021302030932

55092701650995086404540853

05027908470008032605060874

540512106390999097706570795

04085410321109911053907090717

5301071001910993101901085010638

0304491079410895107421001210659

52078120486108971030410163105701

02003420178108991085510215105911

51037620850208912041710366104131

MFC082

.FFE%97

.noitacilpparetniwrofnwohssiylnoecnamrofrepelbisneS:ETON

Form No. S3396-1112

Supersedes S3396-212

Page 5 of 12

Page 6

This page intentionally left blank.

Form No. S3396-1112

Supersedes S3396-212

Page 6 of 12

Page 7

4

0

6

0

0

8

0

0

0

0

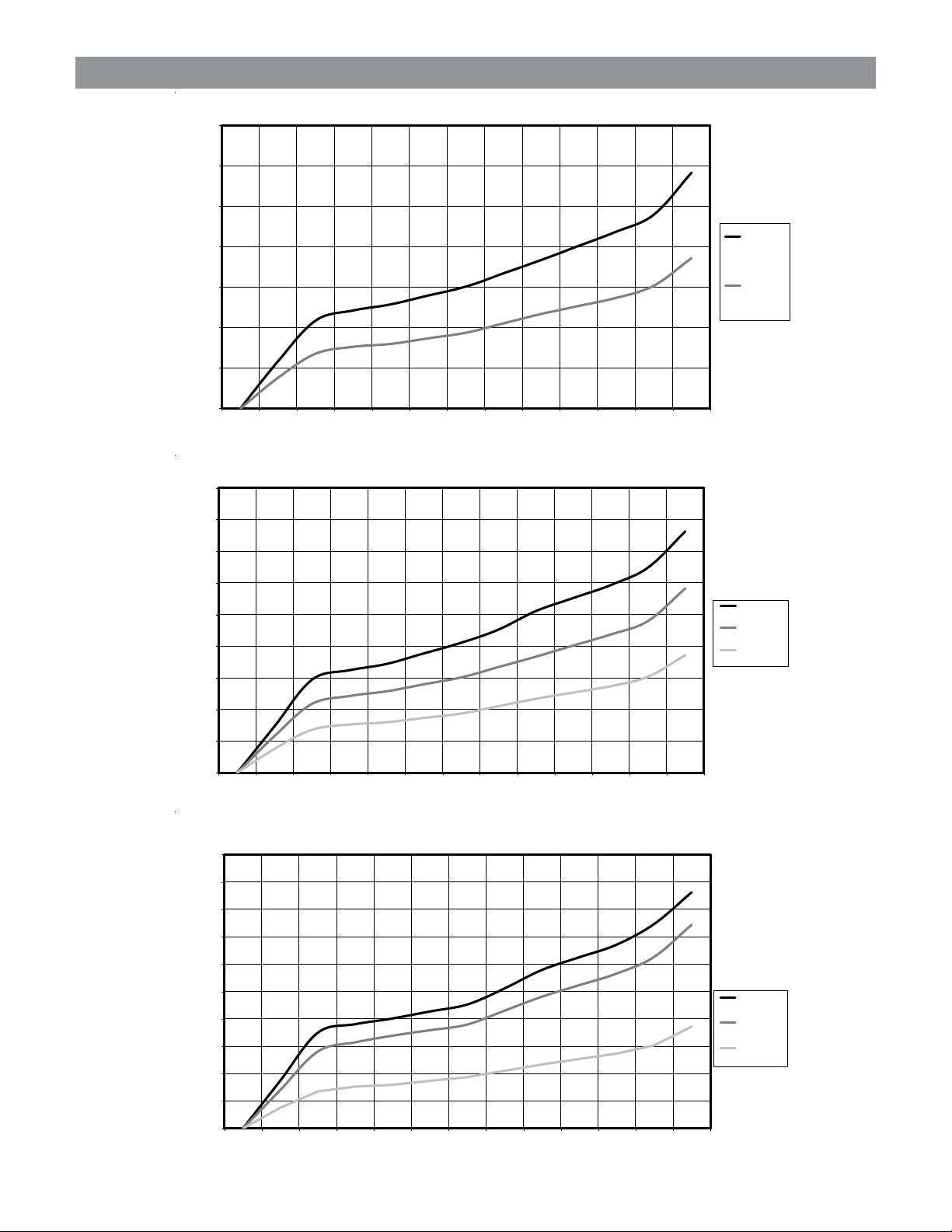

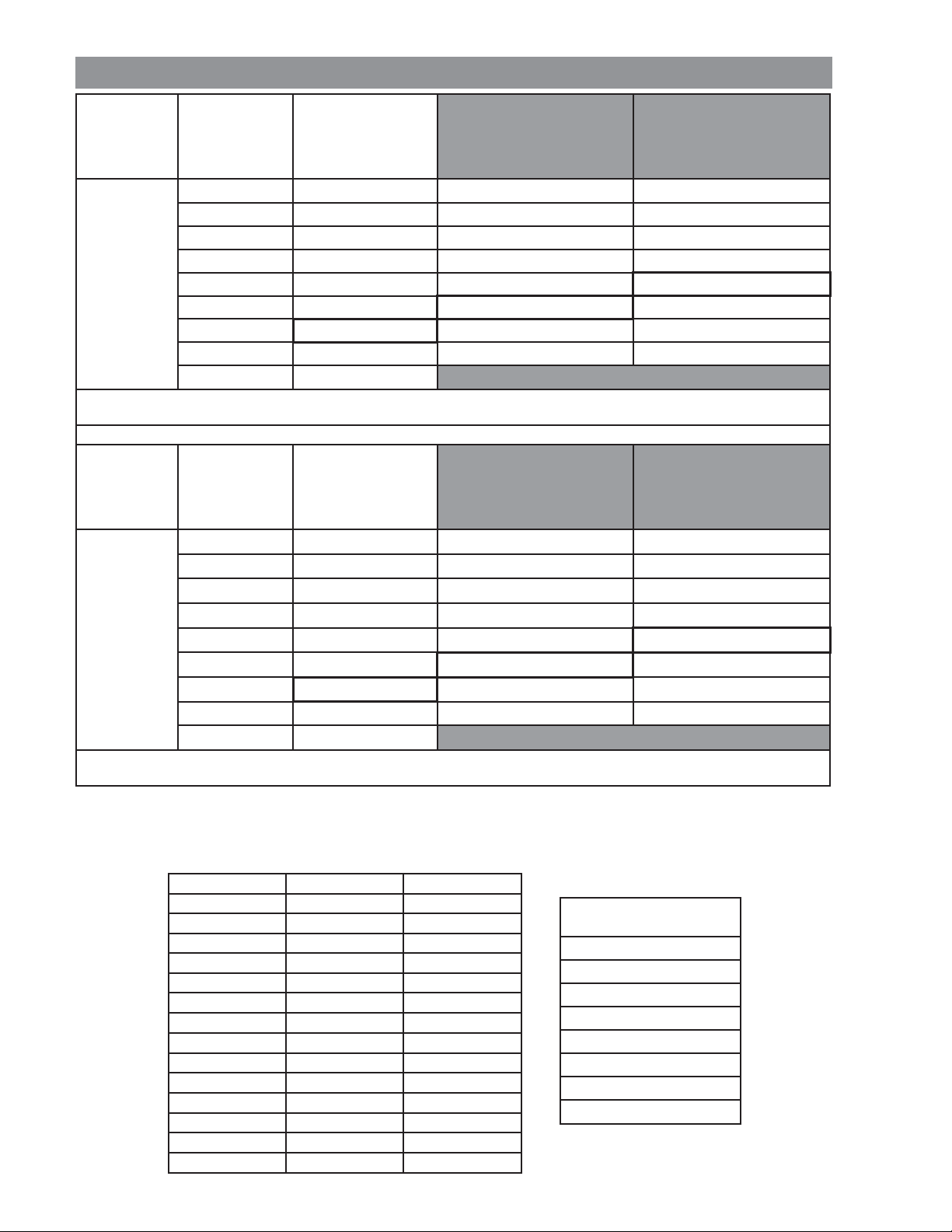

Important Information Concerning Altitude Impact on Heating Input Ratings

Heating input, and thus heating output, decreases with altitude. No orifice change is required up to 6,000 feet elevation and derate occurs naturally due

to altitude impact. Natural gas models may require orifice change based on BTU content of gas. See Natural Gas Orifice and Altitude Tables on

next page for details. For Propane Gas see the Propane Gas Conversion Table below.

Above 6,000 feet elevation orifice changes are required, and capacity reductions are a function of altitude impact and orifice change. Pressure switch

change is required above 6,000 feet elevation. For Natural Gas see the Orifice and Altitude Tables on next page. For Propane Gas see the Propane

Gas Conversion Table below.

SEITICAPACETAREDSAGLARUTAN

detaRGW

tupnI

000,54

000,05

005,76

000,57

000,09

000,001

005,211

000,521

aeS

leveL000100020003000400050006 0007 0008 0009 000,01

000,54065,34021,24086,04006,93088,83089,73

000,05004,84008,64002,54000,44002,34002,24

005,76043,56081,36020,16004,95023,85079,65

000,57006,27002,07008,76000,66008,46003,36

000,09021,78042,48063,18002,97067,77069,57

000,001008,69006,39004,09000,88004,68004,48

005,211009,801003,501007,101000,99002,79059,49

000,521000,121000,711000,311000,011000,801005,501

044,73 027,63 072,63 046,53

006,14 008,04 003,04 006,93

061,65 080,55 504,45 064,35

004,26 002,16 054,06 004,95

088,47 044,37 045,27 082,17

002,38 006,18 006,08 002,97

006,39 008,19 576,09 001,98

000,401 000,201 057,001 000,99

SEITICAPACETARED)PL(ENAPORP

detaRGW

tupnI

005,04

000,54

057,06

005,76

000,57

000,18

000,09

000,001

005,211

000,521

aeS

leveL000100020003000400050006

005,04

000,54

057,06

005,76

000,57

000,18

000,09

000,001

005,211

000,521

258,93

082,44

877,95

024,66

008,37

407,97

065,88

004,89

007,011

000,321

825,93

029,34

292,95

088,56

002,37

650,97

048,78

006,79

008,901

000,221

402,93

065,34

608,85

043,56

006,27

804,87

021,78

008,69

009,801

000,121

655,83

048,24

438,75

062,46

004,17

211,77

086,58

002,59

001,701

000,911

232,83

084,24

843,75

027,36

008,07

464,67

069,48

004,49

002,601

000,811

0007 0008 0009 000,01

485,73

067,14

673,65

046,26

006,96

861,57

025,38

008,29

004,401

000,611

216,63

086,04

819,45

020,16

008,76

422,37

063,18

004,09

007,101

000,311

046,53

006,93

064,35

004,95

000,66

082,17

002,97

000,88

000,99

000,011

443,43

061,83

615,15

042,75

006,36

886,86

023,67

008,48

004,59

000,601

27,23

63,63

80,94

45,45

06,06

44,56

27,27

08,08

09,09

00,101

Gas Pressure Inches W.C.

Minimum permissible gas supply pressure for purpose of input adjustment: Natural 4.5 LP 11.0

Maximum permissible gas supply pressure for purpose of input adjustment: Natural 11.0 LP 13.0

Manifold Pressure: Natural 3.5 LP 10.0

Propane Gas Conversion Kits -- Fits All WG-Series Models

detacidnIsAstiKnoisrevnoCsaGesU--SAG)PL(ENAPORP

SLEDOMtiKnoisrevnoCsaGenaporP1-KCGWesU 2-KCGWesU

yrotcaF

dradnatS

tupnI

S3GW

S4GW

S5GW

All orifice sizes shown are millimeters (mm).

UTB000,52

renruBreP

lanoitpO

dleiF%01

detrevnoC

etareD

056,22-005,22

UTB

renruBreP

saG

taeH

eulaV

.tF.uC/UTB

0052

hctiwSerusserP)55.(dradnatS

saG

taeH

eulaV

.tF.uC/UTB

0052

hctiwSerusserP)55.(dradnatS

teeF0006otpU

ecifirOllatsnI

05.1

teeF0006otpU

ecifirOllatsnI

54.1

05.1 54.1

54.1 04.1

teeF0008ot1006

erusserPseriuqeR

dnaegnahChctiwS

nwohSsaecifirO

teeF0008ot1006

erusserPseriuqeR

dnaegnahChctiwS

nwohSsaecifirO

teeF000,01ot1008

erusserPseriuqeR

dnaegnahChctiwS

nwohSsaecifirO

tiKnoisrevnoCnidedulcnI)24.(hctiwSerusserP

teeF000,01ot1008

erusserPseriuqeR

dnaegnahChctiwS

nwohSsaecifirO

tiKnoisrevnoCnidedulcnI)24.(hctiwSerusserP

Form No. S3396-1112

Supersedes S3396-212

Page 7 of 12

Page 8

deriuqeRsecifirOfo.oN

gnitaRtupnItinUnodesaB

000,54)2(

000,05)2(

000,86)3(

000,57)3(

000,09)4(

000,001)4(

000,311)5(

000,521)5(

Natural Gas Orifice and Altitude Tables

teeF000,8ot100,6

hctiwSerusserPseriuqeR

yrotcaF

dradnatS

tupnI

UTB00052

renruBreP

*taeHsaG

eulaV

.tF.uC/UTB

oNteeF000,6otpU

tpecxEsegnahC

tnetnoCUTBrof

947-00709.208.207.2

997-05708.207.206.2

ecifirOdnaegnahC

egnahC

tnetnoCUTBnodesaB

teeF000,01ot100,8

hctiwSerusserPseriuqeR

ecifirOdnaegnahC

egnahC

tnetnoCUTBnodesaB

948-00807.206.205.2

998-05806.205.254.2

949-00905.254.2

999-05954.2

**9401-0001

0011-0501

)04.2(

]03.2[

)04.2(

53.2

52.202.2

hctiwSerusserP)55.(dradnatS

ezisecifirodellatsniyrotcafdradnatsehtsi)04.2( dellatsnidleifroftinuehthtiwdeppihserasecifiro]03.2[

etared%01lanoitpo

teeF000,8ot100,6

lanoitpO

dleiF%01

detrevnoC

etareD

UTB00522

renruBreP

*taeHsaG

eulaV

.tF.uC/UTB

oNteeF000,6otpU

tpecxEsegnahC

egnahC

tnetnoCUTBrof

947-00757.207.206.2

997-05707.206.205.2

hctiwSerusserPseriuqeR

ecifirOdnaegnahC

tnetnoCUTBnodesaB

)04.2(

53.2

]03.2[

)24.(tiKhctiwSerusserPedutitlAhgiH981-0268redrO

teeF000,01ot100,8

hctiwSerusserPseriuqeR

ecifirOdnaegnahC

egnahC

tnetnoCUTBnodesaB

948-00806.205.2

998-05805.254.2

949-009

)04.2(

999-05953.2

**9401-0001

]03.2[

53.2

]03.2[

52.202.2

)04.2(

]03.2[

52.2

0011-050152.252.202.2

hctiwSerusserP)55.(dradnatS

.etartupni%01lanoitpodellatsni

*

**

snoitidnoclevel

dleifroftinuehthtiwdeppihserasecifiro]03.2[

.ytivargcificeps06.,detarutas,F06,yrucreMsehcni00.03:snoitidnocdradnatstA

)24.(tiKhctiwSerusserPedutitlAhgiH981-0268redrO

tupnidetarllufrofezisecifirodellatsniyrotcafehtsi)04.2(

aesdnasagtfuc/UTB5201lanimonnodesabsgnitartupnidradnatsdnagnizisecifiroyrotcafsaGlarutaNllA

All other orifice sizes shown are available as individual items. See Orifice charts below for part numbers and number required.

.oNtraPdraB)mm(eziSecifirOretemaiDecifirO

290-010901.26280.0

880-010951.26480.0

780-010902.26680.0

680-010952.25880.0

280-010903.25090.0

Form No. S3396-1112

Supersedes S3396-212

Page 8 of 12

580-010953.25290.0

970-010904.25490.0

480-010954.24690.0

390-010905.24890.0

490-010906.24201.0

590-010907.23601.0

690-010957.22801.0

790-010908.22011.0

890-010909.22411.0

Page 9

2

0

0

0

0

0

0

0

0

0

1

0

04,71003,61

0

0

0

0

0

0

0

0

06,91006,61

55,22059,61

07,52006,22

05,82056,22

07,23057,22

07,13005,92

01,53002,03

05,72000,52

57,03003,52

00,43002,52

03,53000,13

09,93008,13

09,44008,13

06,54003,93

03,05005,93

58,45008,83

522,81

007,61

054,02

528,61

054,32

522,71

529,62

002,32

577,92

571,32

578,33

051,32

526,82

005,52

527,13

006,52

529,53

006,52

521,73

570,23

055,14

054,23

527,64

575,23

053,74

521,04

058,15

528,93

051,75

525,93

050,91

570,71

003,12

570,71

053,42

525,71

521,82

577,32

527,92

000,62

576,23

009,52

058,73

000,62

059,83

051,33

002,34

001,33

055,84

573,33

570,94

529,04

004,35

051,04

574,95

058,03

574,62

526,33

571,62

577,93

004,62

577,04

002,43

579,13

579,62

006,43

574,62

527,14

577,62

006,24

572,53

524,33

056,72

573,63

522,72

057,24

574,72

050,44

577,53

578,43

053,82

051,83

000,82

008,34

051,82

005,54

003,63

053,63

520,92

529,93

057,82

058,44

528,82

059,64

008,63

058,44

527,33

573,05

571,43

008,05

527,14

005,64

573,43

002,25

579,43

525,25

525,24

572,84

571,53

521,45

527,53

574,45

523,34

050,05

000,63

050,65

054,63

004,65

051,44

528,15

008,63

579,75

571,73

523,85

579,44

002,04

578,91

054,71

051,22

523,71

059,45

574,04

008,16

578,04

005,65

008,04

521,46

055,14

006,85

007,14

527,56

001,24

576,06

006,24

054,76

056,24

577,26

005,34

521,96

002,34

007,02

578,12

050,32

522,42

052,52

528,71

000,32

575,71

051,62

054,81

004,42

523,81

056,72

001,91

008,52

050,91

001,92

057,91

002,72

577,91

055,03

050,13

528,71

523,92

053,42

523,23

521,81

525,03

529,42

006,33

576,81

007,13

524,52

059,43

052,91

009,23

059,52

003,63

528,91

001,43

574,62

056,73

056,33

056,32

050,53

055,32

575,53

521,42

052,63

059,32

005,73

006,42

054,73

053,42

524,93

522,52

001,93

051,52

525,04

058,52

007,04

009,52

006,14

574,62

003,24

056,62

576,24

59,93008,92

053,03

054,63

004,03

577,14

005,03

522,13

008,73

526,03

526,34

571,13

001,23

051,93

058,03

574,54

058,13

059,23

005,04

570,13

523,74

055,23

523,33

006,24

578,13

529,84

058,23

007,33

007,44

007,23

055,05

002,33

570,43

577,64

525,33

571,25

055,33

1

erutarepmeTroodtuO—ataDnoitacilppAgnilooCegatSdn

004,52

004,02

006,82

005,02

000,23

004,02

003,53

000,72

000,93

001,72

009,34

004,72

057,34

054,43

058,84

053,43

008,35

008,73

007,92

007,14

005,92

009,54

005,92

004,84

003,73

006,35

006,73

009,95

009,73

052,06

008,54

058,46

004,44

008,07

057,34

009,33

1

erutarepmeTroodtuO—ataDnoitacilppAgnilooCegatSts

525,62

059,02

058,92

571,12

053,33

578,02

574,63

055,72

053,04

576,72

524,54

050,82

000,54

009,43

057,05

050,53

524,55

002,93

053,03

523,34

571,03

521,74

521,03

529,94

529,73

053,55

573,83

528,16

526,83

001,26

575,64

058,66

522,54

006,27

053,44

526,72

055,12

051,13

008,12

007,43

004,12

576,73

570,82

007,14

572,82

059,64

057,82

052,64

575,04

579,03

529,44

528,03

053,84

057,03

054,15

525,83

001,75

051,93

527,36

573,93

000,46

004,74

528,86

000,64

004,47

529,44

527,82

051,22

054,23

524,22

050,63

529,12

578,83

006,82

520,34

579,14

526,13

055,64

005,13

575,94

053,13

579,25

051,93

058,85

529,93

526,56

031,04

009,56

522,84

008,07

577,64

002,67

005,54

528,92

057,22

057,33

050,32

004,73

053,34

572,23

051,84

051,23

008,05

000,23

005,45

577,93

006,06

007,04

525,76

578,04

008,76

050,94

577,27

055,74

000,87

570,64

529,03

057,44

009,23

577,94

528,23

520,25

006,23

520,65

004,04

053,26

574,14

524,96

526,14

007,96

578,94

057,47

523,84

008,97

056,64

F°05F°55F°06F°56F°07F°57 F°08 F°58 F°09 F°59 F°001 F°501 F°011 F°511

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

yticapaC

gnilooC

gnilooClatoT

gnilooCelbisneS

gnilooClatoT

gnilooClatoT

053,32

F°05F°55F°06F°56F°07F°57 F°08 F°58 F°09 F°59 F°001 F°501 F°011 F°511

gnilooCelbisneS

gnilooClatoT

yticapaC

gnilooC

054,22

050,53

576,32

057,83

579,22

gnilooCelbisneS

gnilooCelbisneS

gnilooClatoT

gnilooClatoT

578,82

570,04

521,92

053,44

574,92

572,14

056,92

576,54

570,03

gnilooCelbisneS

gnilooCelbisneS

gnilooClatoT

gnilooClatoT

573,53

574,84

054,92

005,74

058,53

000,05

051,03

057,84

523,63

525,15

058,03

000,05

008,63

gnilooCelbisneS

gnilooCelbisneS

gnilooClatoT

gnilooClatoT

053,43

007,25

057,53

001,75

057,43

056,45

054,63

577,85

051,53

006,65

051,73

054,06

055,53

055,85

058,73

521,26

059,53

gnilooCelbisneS

gnilooCelbisneS

gnilooClatoT

gnilooClatoT

.B.W/.B.D

26/57

76/08

27/58

26/57

76/08

27/58

26/57

76/08

ledoM

1S3GW

1S4GW

27/58

1S5GW

.B.W/.B.D

26/57

76/08

27/58

26/57

76/08

27/58

26/57

76/08

ledoM

1S3GW

1S4GW

27/58

1S5GW

Form No. S3396-1112

Supersedes S3396-212

Page 9 of 12

1 Below 50°F requires a factory of field installed low ambient control.

2 Return air temperature °F

Page 10

This page intentionally left blank.

Form No. S3396-1112

Supersedes S3396-212

Page 10 of 12

Page 11

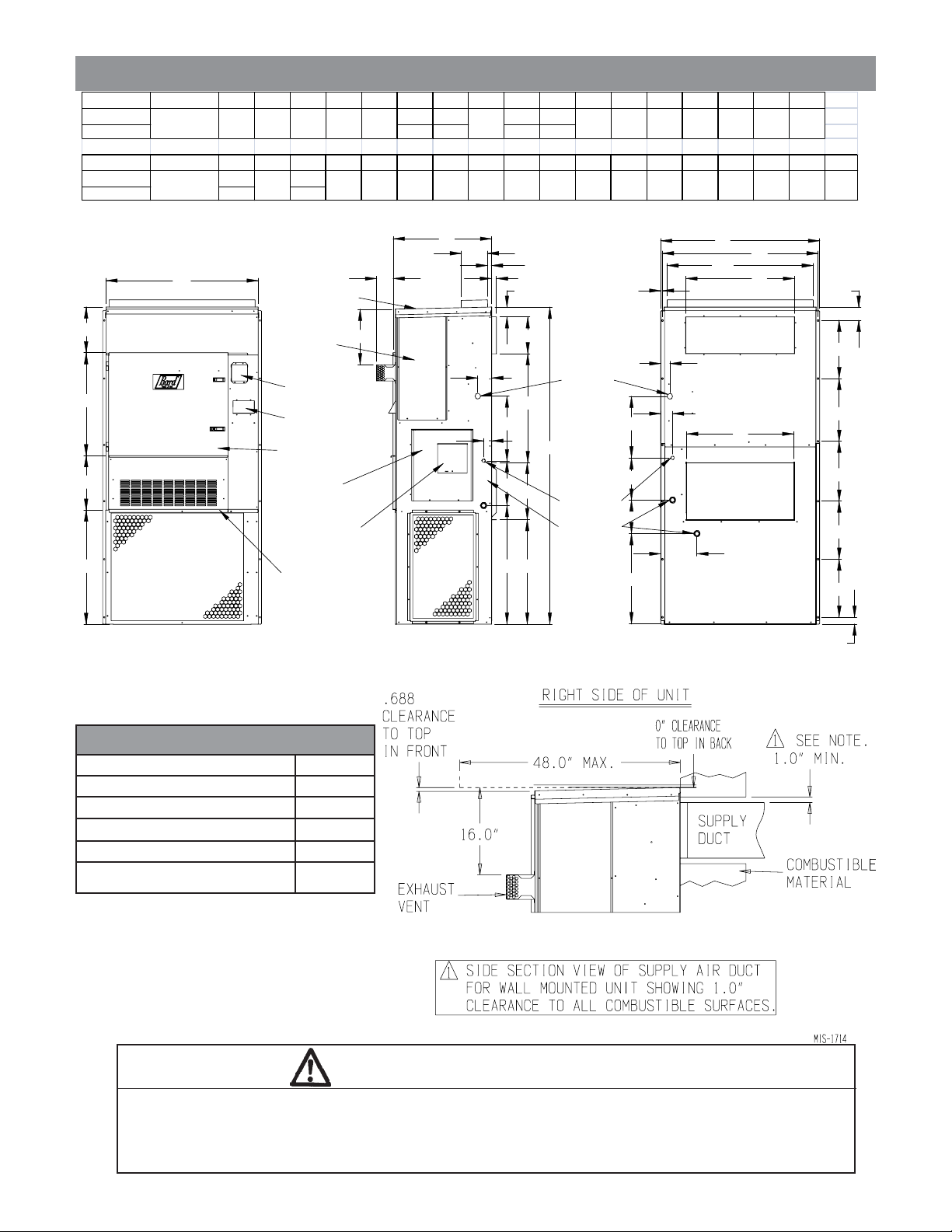

43.38

S1

34.9

M

DIMENSIONS OF BASIC UNIT

UNIT A B C D E F G H I J K L M N O P Q R

WG3S1 31.63 87.5 33.38 28.75

G4S1/WG5S1 41.63 97.5

UNIT S T U V W X Y Z AA BB CC DD EE FF GG HH II JJ KK

WG3S1 3.75 24.9

9.88 29.88 15.88 27.25

16 - 6 HOLES

5

13.75

43.81

38.75

12.19 10 40.25

3.25

4.5

2.514.88 30 14.12 15.44 42.8815.31

1.257.25 1.132.253.88 42 17.34 8.44

0.44

2.75 12.75 28.25

3.75

JJ

KK

D

DD

W

4 DEG. PITCH IN TOP

VESTIBULE

DOOR

COMBUSTION

AIR EXHAUST

COMBUSTION

AIR INTAKE

SERVICE/FILTER

HINGED DOOR

F

G

CONDENSER

AIR OUTLET

FRONT

CONTROL

PANEL DOOR

CIRCUIT BREAKER/

DISCONNECT ACCESS

PANEL (LOCKABLE)

VENT OPTION

PANEL

P

N

CONDENSER

AIR INLET

RIGHT SIDE

FF

GG

HH

A

I

C

K

GAS

ENTRANCES

H

LOW VOLTAGE

ENTRANCES

HIGH VOLTAGE

ENTRANCES

U

M

Z

L

J

II

Q

X

AA

Y

V

FIGURE 1

COMBUSTIBLE CLEARANCE

SUPPLY OPENING

BB

RETURN OPENING

CC

EE

E

B

BACK

O

B

R

S

S

S

S

S

T

MIS-2328 D

teltuOresnednoC"02

poT1erugiFeeS

ecivreSrenruB"02

)lairetamgnirevocfoor

A minimum of one (1) inch clearance must be maintained between the supply air duct and combustible materials. This is

required for the first three (3) feet of ducting.

It is important to insure that the one (1) inch minimum spacing is maintained at all points.

Failure to do this could result in overheating the combustible material and may result in a fire causing damage, injury or death.

secnaraelCmumini

)slairetamelbitsubmocmorf(tcuDteltuO'3tsrif"1

)slairetamelbitsubmocmorf(lanimreTtneV"71

CroB,AssalCrodooW(esaBelbitsubmoC

"0

WARNING

Form No. S3396-1112

Supersedes S3396-212

Page 11 of 12

Page 12

A

Air Conditioning Wall-Mount Model Nomenclature

WG 3 S 1 A X B B X X X X X

MODEL

NUMBER

COOLING

CAPACITY

3 - 3 Ton

4 - 4 Ton

5 - 5 Ton

STEP CAPACITY

SPECIALTY

PRODUCTS

(Non-Standard)

C= Canadian Approval

*125,000 BTU input model is not NOx certified.

REVISION

CODE

VOLTS & PHASE

A - 230/208-60-1

B - 230/208-60-3

C - 460-60-3

EMISSIONS

X - Standard

N - NOx Certified*

HEATING INPUT

A = 50,000

B = 75,000

C = 100,000

D = 125,000*

FILTER OPTIONS

X - 2-inch Pleated

W - 1-inch Washable

VENT OPTIONS

(See Table)

COLOR OPTIONS

X - Beige (Standard)

4 - Buckeye Gray

8 - Dark Bronze

COIL OPTIONS

X - Standard

1 - Phenolic Coated Evap.

2 - Phenolic Coated Cond.

3 - Phenolic Coating on

OUTLET OPTIONS

X - Front (Standard)

T - Top

snoitpOnoitalitneV

sledoM S5GW,S4GW,S3GW

1 .noitareporosserpmocerutarepmetwolrofrezimonocehtiwderiuqersilortnoctneibmawoL

2 .noitceleskcolblanimrethtiw)etar(sdeepstsuahxednaekatnifonoitcelestnednepednI

)eznorBkraD="8";yarGeyekcuB="4";egieB="X"(tinuhctamotdeificepsebtsumnoitporoloC

noitpircseD

)dradnatS(etalPffO-knalB B5-POBSGW

tsuahxE/wnruteRgnirpSgnitaludoM-rotalitneVlaicremmoC V5-PMVRCSGW

tsuahxE/wgnitaludoMylluF)lanretnI(rezimonocE 1 E5-MFIESGW

tsuahxE/wtloV032-rotalitneVyrevoceRygrenE 2 R-A5A-VRESGW

tsuahxE/wtloV064-rotalitneVyrevoceRygrenE 2 R-A5C-VRESGW

dellatsnIyrotcaF

.oNedoC

dellatsnIdleiF

.oNtraP

CONTROL

MODULES

(See Table)

both coils

dellatsnIdleiF-stiKnoisrevnoCteltuOylppuSpoT

SLEDOMHTIWDESU EGIEB-XROLOCTINU YARGEYEKCUB-4ROLOCTINU EZNORBKRAD-8ROLOCTINU

S5GW,S4GW,S3GWX-5GW-OST4-5GW-OST8-5GW-OST

seludoMlortnoCgninoitidnoCri

CPH 1 CPL 2 MCC 3 CAL 4 KS 5 edoCdellatsnIyrotcaF traPdellatsnIdleiF

DTSDTSDTSXA/N

DTSDTSDTS

DTSDTSDTS

DTSDTSDTS

DTSDTSDTS

STD = Standard equipment for these specified models.

1 HPC. High pressure control is auto reset. Always used with compressor control module (CCM) which is included. See note 3.

2 LPC. Low pressure control is auto reset. Always used with compressor control module (CCM) which is included. See note 3.

3 CCM. Compressor control module has adjustable 30-second to 5-minute delay-on-break timer. On initial power-up, or any time the power is interrupted, the delay-on-make will be

2-minutes plus 10% of the delay-on-break setting. There is no delay-on-make during routine operation of the unit. The module also provides the lockout feature (with 1

retry) for high and/or low-pressure controls, and a 2-minute timed bypass for low-pressure control.

4 LAC. Low ambient control permits cooling operation down to 0°F.

5 SK. Start capacitor and potential relay start kit can be used with all -A single phase models. Increases starting torque 9x. Not used for -B or -C three phase models.

)detoNsatpecxEsledoMllA(

H82-AMC

ylnOdellatsnIdleiF A-1S3GWrof411KS

ylnOdellatsnIdleiF A-1S4GWrof111KS

ylnOdellatsnIdleiF A-1S5GWrof511KS

seirosseccAdellatsnIdleiFlanoitpO

NOITPIRCSED REBMUNTRAP

)teeF000,01-0006(tiKhctiwSerusserPedutitlAhgiHsaGlarutaN 981-0268

.selbaTedutitlAdnaecifirOeeS.tnetnocUTBsaGdnaedutitlAnopUgnidnepeDderiuqeReByaMegnahCecifirOsaGlarutaN:etoN

)edutitlAteeF0006-0(tiKnoisrevnoCsaGenaporP 1-KCGW

)edutitlAteeF000,01-0006(tiKnoisrevnoCsaGenaporP 2-KCGW

)tnevlacitrevtoof5rofstrapllasedulcnI(tiKtneVlacitreV A5-KVV

A5-KVVrofnoitcesepiptnevlacitrevtoof1lanoitiddA 102-0268

A5-KVVrofnoitcesepiptnevlacitrevtoof2lanoitiddA 071-0268

A5-KVVrofnoitcesepiptnevlacitrevtoof3lanoitiddA 002-0268

A5-KVVrofnoitcesepiptnevlacitrevtoof5lanoitiddA 171-0268

Form No. S3396-1112

Supersedes S3396-212

Page 12 of 12

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Due to our continuous product improvement policy,

all specifications subject to change without notice.

Before purchasing this appliance, read important energy cost

and efficiency information available from your retailer.

Form No.

S3396

November, 2012

Supersedes S3396-212

Loading...

Loading...