Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead, just as planned.

Manual: 2100-502

Supersedes: NEW

File: Vol. I, Tab 20

Date: 01-11-08

USER'S INFORMATION MANUAL

WG3S, 4S & 5S - Series Combination Gas/Electric Wall-Mount™

We're pleased you've chosen our air conditioner/gas furnace to supply your cooling/heating needs. Please

keep this manual in a safe, yet readily available place. It contains important and useful information.

ATTENTION, INSTALLER: After installing air conditioner/gas furnace, give the user:

• User's Information Manual • Parts List

• Installation Instructions • Warranty Information

ATTENTION, USER! Your installer should give you the above four important documents relating to your

air conditioner/gas furnace. Keep these as long as you do your equipment. Pass these documents on to later

purchasers or furnace users. If any of the four documents are missing or damaged, contact your installer or

manufacturer for replacement. For efficient service, please give your unit model and serial number, from

Section 1 or from your serial rating plate.

WARNING

If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

•

Installation and service must be performed by a qualified installer or the gas supplier.

WARNING

Read and follow all safety information in this manual, operating instructions and furnace safety

labels. Failure to follow safety precautions could result in damage, injury or death.

IMPORTANT SAFETY NOTE: You must know how to turn off gas and electricity to air conditioner/gas furnace.

Your qualified installer, service agency or gas supplier can teach you to use controls and switches.

WARNING

Do not use this air conditioner/gas furnace if any part has been under water. Immediately call a

qualified service technician to inspect the unit and to replace any part of the control system

and any gas control which has been underwater.

Thank you for reading these safety statements.

Please read on so you will know how to maintain your air conditioner/gas furnace for years of dependable service.

Manual 2100-502

Page 1 of 15

CONTENTS

Section 1

Rating Plate Information .............................................. 3

Section 2

Important Safety Precautions ................................ 3 & 4

Section 3

Understanding How Your Furnace and

Air Conditioner Works ........................................... 5 & 6

Section 4

Turning Off Furnace in an Emergency ............... 6, 7 & 9

Section 5

Operating Your Furnace ............................................. 10

Section 6

Proper Maintenance of Your Furnace

and Air Conditioner ...................................... 10, 12 & 14

Section 7

Air Conditioning Start Up Procedure

Crankcase Heater ...................................................... 14

Section 8

Ventilation Options..................................................... 15

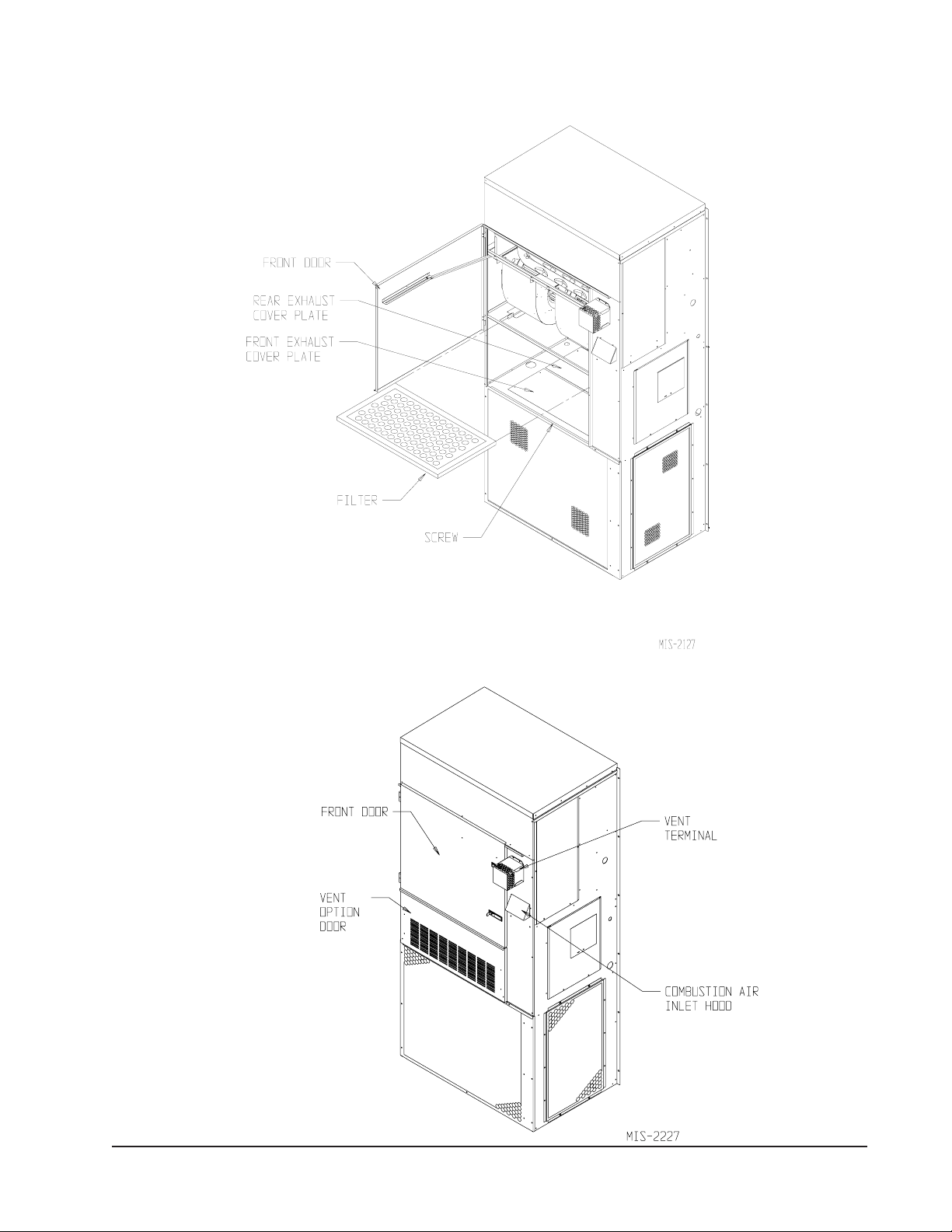

Figures

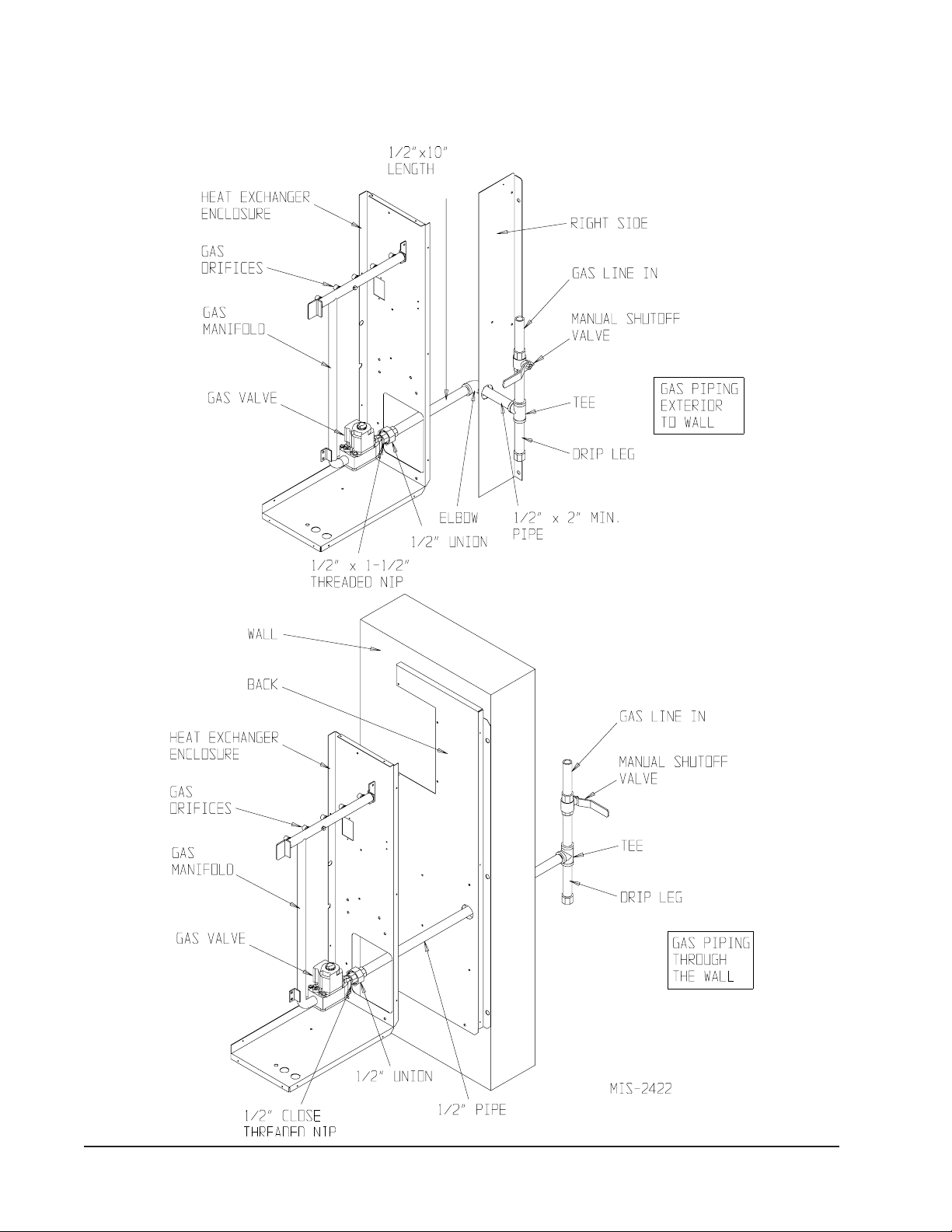

Figure 1 Typical Gas Piping ..................................... 8

Figure 2 Step-by-Step Instructions

on Lighting Burners .................................. 11

Figure 3 Filter Locations ....................................... 13

Figure 4 Periodic Inspections ............................... 13

Location of Access Panels

Figure 5 Start Up Procedures ................................ 14

Section 9

Replacement Parts .................................................... 15

Section 10

Outdoor Coil .............................................................. 15

Manufactured under the following U.S. Patent Numbers:

5,485,878; 5,022,116; 4,924,934;

4,875,520; 4,825,936

COPYRIGHT DECEMBER 2007

BARD MANUFACTURING COMPANY, INC.

BRYAN, OHIO USA 43506

Manual 2100-502

Page 2 of 15

SECTION 1 • RATING PLATE INFORMATION

Record the manufacturer’s name, unit model number and serial number below. These are your furnace

rating plate. Record installation date which is important for warranty purposes.

YOUR FURNACE INFORMATION

Furnace Type ________________________________________________________________

Manufacturer’s Name__________________________________________________________

Model Number _______________________________________________________________

Serial Number _______________________________________________________________

Date Installed ________________________________________________________________

Installer/Servicer _____________________________________________________________

Address _____________________________________________________________________

City/State/Zip Code ___________________________________________________________

Telephone Number _____________________________________________________

SECTION 2 • IMPORTANT SAFETY

PRECAUTIONS

2.A HAZARD ALERT SYMBOL

An explanation point surrounded by a triangle.

2.B SIGNAL WORDS

Years of safe, dependable service are assured

when you understand and follow all safety

precautions.

Signal words “WARNING” and “CAUTION”

alert you to potential hazards.

“WARNING” indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

“CAUTION” indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury. It may also be used to

alert against unsafe practices. It can also be used

to signal property damage only potential.

2.C. SAFETY PRECAUTIONS

These are some of our most important safety

precautions; others are throughout this manual.

Please read and follow them.

THIS PRODUCT MUST BE GAS PIPED BY

A LICENSED PLUMBER OR GAS FITTER

IN THE COMMONWEALTH OF

MASSACHUSETTS.

2.1 GAS AND COMBUSTION PRODUCTS

WARNING

Any condition that will allow gas or

combustion products to enter furnace area

can cause nausea, asphyxiation or fire

resulting in damage, injury or death.

Natural gas and propane (LP) gas have

characteristic odors. When your furnace is

operating correctly, you should not smell any

unfamiliar odor. Normally, burning gas with air

produces combustion products which contain

carbon dioxide, oxygen and water vapor. Under

abnormal conditions, combustion products can

contain aldehydes and carbon monoxide.

Manual 2100-502

Page 3 of 15

• Aldehydes have a strong pungent, acrid smell

that can cause nausea.

• Carbon monoxide is tasteless, colorless and

odorless. It can cause headaches, flu-like

symptoms or nausea. We refer to all these

symptoms as nausea in this manual. It can also

cause death by asphyxiation.

WARNING

Front door must be in place during furnace

operation. Hot surfaces behind front door.

WARNING

Any unfamiliar smell can alert you to

presence of gas or aldehydes. If you

detect any unfamiliar odor follow instruction

in Section 4.B.1. Otherwise, nausea,

asphyxiation or fire could occur resulting in

damage, injury or death.

WARNING

Do not block or cover combustion openings

in the furnace. Blocking or covering these

openings could cause nausea,

asphyxiation or fire resulting in damage,

injury or death.

WARNING

A loud noise may mean faulty burner

ignition. If your furnace makes a loud

noise, turn it off. Follow instructions in

Section 4.B.2. If you don’t turn off your

furnace, it could cause fire or an explosion

resulting in damage, injury or death.

2.2 STORAGE AND USE OF FLAMMABLE,

CORROSIVE AND COMBUSTIBLE

PRODUCTS NEAR YOUR FURNACE

WARNING

Never store or use flammable liquids or

vapors near or on your furnace. These

include gasoline, kerosene, cigarette

lighter fluid, cleaning fluids, solvents, paint

thinners or painting compounds.

Flammable vapors can travel great

distances before igniting.

WARNING

Never store or use anything near or on

your furnace that can produce vapors that

are corrosive to gas-fired furnaces. Vapors

from products containing chlorines,

fluorines, bromines and iodines can cause

vent system or heat exchanger failure.

Examples of such products are spray or

aerosol containers, detergents, bleaches,

cat litter, waxes, adhesives, solvents and

other cleaning compounds. Vent system

or heat exchanger failure could cause

nausea, asphyxiation or fire resulting in

damage, injury or death.

WARNING

Do not operate furnace with blower door

open or removed. Do not alter furnace to

allow operation with blower door removed.

Doing either could allow combustion

products to circulate throughout the

furnace area causing nausea, asphyxiation

or fire resulting in damage, injury or death.

Manual 2100-502

Page 4 of 15

WARNING

Never store anything combustible near or

on your unit. A fire could occur resulting in

damage, injury or death.

2.3 ALTERATION OF FURNACE CONTROLS

WARNING

The ignition system consists of a direct spark igniter

(DSI) and remote sensor. When the thermostat calls for

heat the DSI sparks to light main burner gas. Once

ignited the remote sensor confirms flame carry over to

all burners.

Do not alter any gas or electrical controls

(gas control or safety controls) in any

manner. Altering them could cause

furnace to operate unsafely resulting in

damage, injury or death.

SECTION 3 • UNDERSTANDING HOW

YOUR FURNACE WORKS

Your installer should have given you a detailed

explanation of how the furnace operates. Shown below

are the basic operation characteristics and sequence of

operation. If you have any questions consult your

installer and/or service agency.

* * IMPORTANT * *

There are many types of thermostats

compatible with this furnace. Make sure

you understand the specific type installed.

Ask installer for detailed explanation, and

retain thermostat instruction manual for

reference.

There is a 60-second delay after main burner is on until

the comfort air blower starts on heating speed. After the

thermostat is satisfied, the burners will go off as gas

valve closes. The inducer will continue to run for 30

seconds, and the comfort air blower will continue to run

for 2-1/2 minutes.

3.2 BASIC OPERATION – COOLING CYCLE

On a call for cool the compressor and condenser fan will

start immediately, and the comfort air blower will start 7

seconds later on cooling speed. Note: Some models

may be equipped with optional Low Ambient Control

that will cycle the condenser fan motor to maintain

proper refrigerant pressures under lower outdoor

temperature conditions. When the thermostat is

satisfied the compressor and condenser fan will stop and

the comfort air blower will continue to operate for 60

seconds.

3.2.1 COMPRESSOR CONTROL MODULE

(CCM)

All models are equipped with a compressor control

module. This control is an anti-short cycle/lockout

timer with high and low pressure switch monitoring and

alarm relay output.

This furnace is equipped with a vent shut-off system

which monitors the combustion air into the burners by

means of a pressure sensing device. When the vent

becomes blocked, this device turns off the gas valve

circuit to prevent flue products from entering the

structure. In the event that this occurs, shut off furnace

and contact a qualified service agency.

3.1 BASIC OPERATION – HEATING CYCLE

This furnace is operated by an Integrated Furnace

Control (IFC) and a gas control system which controls

all functions of the furnace.

On a call for heat from the thermostat, the IFC first turns

on the inducer motor. The pressure switch then closes

signaling the ignition control to proceed with ignition

function.

Delay on Make Timer and Break Time Delay

• On initial power up, or any time the power is

interrupted to the unit, the delay on make period

begins. This delay will be 2 minutes plus 10% of

the delay on break setting. This feature assures

that pressures will be equalized for normal start

up if there are brief power interruptions, and can

accommodate staggered starts for dual unit

installations as long as the off delay periods are

set differently for the two units.

• During routine operation of the unit with no

power interruptions the compressor will operate

on demand with no delay as long as off delay

time has been met.

• Adjustable 30-second to 5-minute delay on break

timer assures that pressures can equalize if units

are short cycled by the operating controls or

personnel. Recommended settings would be 2

minutes for unit 1 and 3 minutes for Unit 2.

Manual 2100-502

Page 5 of 15

High Pressure Switch and Lockout Sequence

PHASE MONITOR

• If the high pressure switch opens, the compressor

contactor will de-energize immediately. The

lockout time in the CCM will go into a soft

lockout and stay locked out until the high

pressure switch closes and the delay on break has

expired.

• If the high pressure switch opens again during

the same operating cycle the CCM will go into a

manual lockout condition.

• Recycling the wall thermostat resets the manual

lockout.

Low Pressure Switch, Bypass and Lockout

Sequence (Optional)

• If the low pressure switch opens for more than

120 seconds the compressor contactor will deenergize and the CCM will go into soft lockout.

• Regardless of the state of the low pressure switch

the compressor contactor will reenergize after

the delay on break time has expired.

• If the low pressure switch remains open, or opens

again for longer than 120 seconds, the CCM will

go into a manual lockout and the alarm relay

circuit will energize.

• Recycling the wall thermostat resets the manual

lockout.

All units with three phase scroll compressors are

equipped with a three phase line monitor to prevent

compressor damage due to phase reversal.

The phase monitor in this unit is equipped with two

LEDs. If the “&” signal is present at the phase monitor

and phases are correct, the green LED will light.

If phases are reversed, the red fault LED will be lit and

compressor operation is inhibited.

3.3 MANUAL FAN (CONTINUOUS AIRFLOW)

OPERATION

If wall thermostat is set to MANUAL (ON) position to

operate comfort air blower continuously to provide air

circulation throughout the building, the blower will

operate at a level that is lower than cooling or heating

airflows on the heating speed rather than the cooling –

as is typical with most systems. This permits the air to

circulate as desired but helps keep the operating noise

level down as well a conserving energy.

During a call for cooling, the blower automatically

shifts up to cooling speed, and remains there until 60

seconds after thermostat is satisfied then drops back to

heating speed.

SECTION 4 • TURNING OFF FURNACE IN

AN EMERGENCY

NOTE: Both high and low pressure switch controls

are inherently automatic reset devices. The

high pressure switch opens at 425 and closes

at 325 psig, and the low pressure switch opens

at 14 and closes at 30 psig. The lockout

features, both soft and manual, are a function

of the Compressor Control Module.

Alarm Relay Output

• Alarm terminal on Compressor Control Module

is 24V AC output connection for applications

where signal is desired. This terminal is

powered whenever compressor is in manual

lockout due to high pressure or low pressure

sequences as described.

WARNING

Have a qualified installer, service agency

or gas supplier teach you location and

operation of gas and electrical shut-off

devices. Ask them any questions you have

about this section. If you don’t turn off your

furnace in an emergency damage, injury or

death could result.

Manual 2100-502

Page 6 of 15

In an emergency you

and electricity. Find out how

must

know how to turn off gas

before

the emergency.

WARNING

2. ELECTRICAL SHUT-OFF DEVICES

In an emergency, you may not be able to reach

both of your electrical shut-off devices.

Therefore, you must know how to turn off

electricity using either one of them. Here are

two types of electrical shut-off devices:

Should overheating occur or the gas

supply fail to shut off, shut off the manual

gas valve to the furnace before shutting off

the electrical supply. Failure to do so can

cause a fire or explosion which could result

in damage, injury or death.

4.A GAS AND ELECTRICAL SHUT-OFF

DEVICES

1. GAS SHUT-OFF DEVICES

In an emergency, you may not be able to reach

all the gas shut-off devices. You must know

how to turn off gas using any one of the three

manual types:

a. Manual Shut-off Switch on Gas Control

Gas control location is behind the access

panel on the right side. See Lighting and

Shutdown Instructions in Section 5 for

more information.

To turn gas control furnace knob OFF, turn

it to “OFF” position. Use this same

procedure when you leave a vacation home

vacant and do not want the furnace to

operate.

a. There should be an electrical shut-off

device located on or immediately adjacent

to the furnace.

b. There should be a separate circuit breaker

or fuse serving only the furnace located in

the main circuit breaker or fuse panel.

Know its location and make sure this device

is clearly identified.

b. Manual In-Line Shut-off Valve in Gas

Supply Line.

This valve could be next to furnace.

Figure 1 shows a typical installation.

Normally, gas is ON when you turn the

shut-off valve handle parallel to gas pipe.

Gas is OFF when you turn handle 90° from

gas pipe.

c. Manual Shut-off Valve at Natural Gas

Meter or Propane (LP) Gas Tank.

Normally, natural gas is ON when you turn

shut-off parallel to gas pipe. Gas is OFF

when you turn shut-off 90° from gas pipe.

Some valves require a wrench or other

tools.

Manual 2100-502

Page 7 of 15

FIGURE 1

TYPICAL GAS PIPING

Manual 2100-502

Page 8 of 15

4.B POSSIBLE EMERGENCIES AND

RECOMMENDED ACTIONS

WARNING

3.

Possible Emergency

above room temperature. The blower is on but

the air coming from your room registers is hot,

then cold, then hot, then cold in a continuing

cycle. This condition indicates lack of airflow

through furnace.

: Your thermostat is set

If gas or electricity is off due to an

emergency, only a qualified installer,

service agency or gas supplier should turn

it back on. Doing it yourself could result in

damage, injury or death.

1.

Possible Emergency

unfamiliar smell; or not knowing what may be

wrong or what to do about it.

ACTION: For your safety –

a. Leave your house or building immediately.

b. Go to a neighbor’s or another building.

c. Use their telephone.

d. Call your gas supplier. Tell them you smell

gas and give them your name and address.

e. If you cannot reach gas supplier, call fire

department.

: Smelling gas or other

WARNING

ACTION:

a. Make sure air filter is clean and installed

correctly.

b. Check that registers and return air grilles are

open and unobstructed.

c. If condition continues, call your local

qualified service technician or gas supplier.

4.

Possible Emergency

you smell unfamiliar odors that go away when

furnace is off.

: While furnace is operating,

WARNING

Unfamiliar odors may mean gas or

aldehydes are present which could result in

damage, injury or death.

Three important

1. Don’t try to light any gas appliances.

2. Don’t touch any electrical switches

3. Don’t use the telephone in your house or

building.

Any of the above may cause a spark, which

could cause a fire or explosion resulting in

damage, personal injury or death.

2.

Possible Emergency

below room temperature; yet even though the

blower is on, the air coming from your room

registers continually gets hotter.

ACTION:

a. Turn room thermostat to its lowest or OFF

setting.

b. If you can do so safely, turn gas off. Use

manual shut-off valve at gas meter or on

propane (LP) gas tank. You may need a

wrench or tools. If you can safely turn off

electricity at the main circuit panel, do so.

If you cannot do these things safely, leave

your home or building immediately. Call

your gas supplier or fire department from a

neighbor’s phone for help.

things not to do

: Your thermostat is set

–

ACTION:

a. Turn thermostat to its lowest or OFF setting.

b. Move gas valve control knob to OFF position.

c. If blower is not operating, immediately turn

off electricity to furnace using shut-off

device near furnace or at main circuit panel.

d. If blower is operating, wait five minutes for

furnace to cool down and then turn off

electricity to furnace using shut-off device

near furnace or at main circuit panel.

e. Call your local qualified service technician

or gas supplier.

Manual 2100-502

Page 9 of 15

Possible Emergency

5.

breaker for furnace cannot be reset without

tripping again or new fuses continue to blow.

ACTION:

a. Move gas valve control knob to OFF.

b. Call your local qualified service technician

or gas supplier.

: Main electrical circuit

SECTION 6 • PROPER MAINTENANCE

OF YOUR FURNACE

You need special abilities, mechanical skills and tools to

maintain your furnace properly. If you are uncertain

about your abilities or if you lack proper skills or tools,

do not try to maintain or repair your furnace yourself.

Instead, contact a qualified installer, service agency or

gas supplier.

SECTION 5 • OPERATING YOUR

FURNACE

After reading the Safety Information and Precautions

follow Operating Instructions on front door of furnace

and instructions repeated on Page 11.

WARNING

If you do not follow these instructions

exactly a fire or explosion could occur

resulting in damage, injury or death.

WARNING

Never use tools to move gas control knob.

Only use your hand. If gas control knob

will not move by hand, do not force it or try

to repair it. Call a qualified installer,

service agency or gas supplier. Forcing

knob can cause gas to leak which could

result in fire or explosion resulting in

damage, injury or death.

6.A IF YOU SMELL GAS OR ANY UNFAMILIAR

SMELL WHILE WORKING ON YOUR

FURNACE:

1. Do not try to light main burners.

2. Do not touch or turn on any electrical

switch.

3. Do not use any phone in your building.

4. Immediately call your gas supplier from a

neighbor’s phone. Follow gas supplier’s

instructions.

5. If you cannot reach your gas supplier, call

fire department.

6.B LUBRICATION REQUIREMENTS

The main blower motor, outdoor fan motor,

and the induced draft blower motor are

permanently lubricated, and no maintenance is

required.

6.C MAKE SURE AIR FILTER(S) IS IN PLACE

Ask your installer, local qualified service

technician or gas supplier to make sure your

filter(s) is in place properly. Become familiar

with its location and procedures for removing,

cleaning and replacing it.

Recommended filter sizes are shown below.

Properly operating your furnace requires certain

abilities, mechanical skills and tools. If you are

uncertain about your abilities or if you lack proper skills

or tools, do not proceed. Instead, contact a qualified

installer, service agency or gas supplier.

An automatic ignition device lights the burners. Do not

try to light manually. See Figure 2 on Page 11 for step

by step instructions.

Manual 2100-502

Page 10 of 15

Main System Filter: 20x30x2 throwaway for

WG3S, WG4S & WG5S models.

See Figure 3 on Page 13 for filter locations.

WARNING

Operating furnace without clean air filter(s)

can damage blower motor, heat exchanger

or air conditioning system components.

This can cause system failure which could

result in damage or injury.

FIGURE 2

START UP PROCEDURE

Manual 2100-502

Page 11 of 15

6.D KEEP AIR FILTER(S) CLEAN

As a user, your personal responsibility is to

keep air filter(s) clean.

2. Make sure the vent terminal is in place and

is physically sound.

3. Reviewing that the return air duct

connection(s) is physically sound, is sealed

to the furnace casing.

CAUTION

A dirty air filter(s) reduces system

efficiency and can cause erratic control

performance. These could result in

damage to blower motor or heat

exchanger.

1. During the first four weeks after your

furnace is installed, inspect your air filter(s)

for dirt every week. Then check the filters

monthly and replace as necessary.

2. If the filter(s) is of a washable type, clean

filter(s) according to the manufacturer’s

specifications.

WARNING

After cleaning or changing filter(s), filter

access must be closed and latched.

Failure to do so could cause nausea,

asphyxiation, or fire resulting in damage,

injury or death.

6.E DO NOT OBSTRUCT DUCT WORK

For proper operation, keep registers and return

air grilles open. Do not cover or block them

with rugs, carpets, drapes or furniture.

6.F HAVE YOUR FURNACE CHECKED

ANNUALLY

The furnace, vent terminal, and the combustion

air intake hood should be inspected yearly by a

qualified service agency, generally prior to the

heating season. Detailed procedures for this

inspection are contained in the instructions

booklet and should be handled by the qualified

service agency only.

A general inspection of the furnace, the furnace

area and the vent terminal should be conducted

on a regular basis by the owner/occupant. This

review should include:

4. The physical support of the furnace is

sound without sagging, cracks, gaps, etc.

around the unit so as to provide a seal

between the unit and the structure.

5. Inspect for any obvious signs of

deterioration of the furnace.

6. Periodic examinations of the vent terminal

should also be conducted by the owner on a

regular basis, preferably every month but

at least every two months during the heating

season.

7. Check the entire vent terminal for any

blockage. If any debris is present remove it.

8. If unit is vertically vented, inspect vent

system annually including drain tube.

Clean or replace if necessary.

6.G THE FOLLOWING PROCEDURE SHOULD

BE FOLLOWED FOR THE PERIODIC

INSPECTION AS CONDUCTED BY THE

OWNER/OCCUPANT.

1. Set the wall thermostat to the OFF position

or lower the set point lever to a temperature

well below the existing room temperature.

Shut off electric power to the furnace. A

circuit breaker is located behind the lower,

small access panel on the right side.

2. Remove the burner access door. See

Figure 4.

3. Use flashlight or trouble light to observe the

burner compartment and burners. There

should be very minimal scaling or sooting

in this area. Any loose debris may be

vacuumed out. Also observe the sides of

the heat exchanger tubes for “hot spots” due

to improper burner alignment or overfiring

and give particular attention to any area

where it looks like there may be any

deterioration from corrosion or rusting.

Observe for any corrosion on the burners

themselves. Should anything appear

questionable, contact your service agency.

1. Make sure the furnace always has the

minimum clearance as detailed on the

furnace rating plate. Special attention must

be given to these items if any remodeling is

done.

Manual 2100-502

Page 12 of 15

FIGURE 3

FILTER LOCATIONS

FIGURE 4

PERIODIC INSPECTIONS

Manual 2100-502

Page 13 of 15

4. Inspect the vent terminal, or vent system

observing for any debris from weather,

birds, and the like. Clean if necessary.

Also check the combustion air inlet hood to

make sure it is clear. See Figure 4.

WARNING

Leakage of products of combustion into the

living area may result in asphyxiation

resulting in injury or death

5. Restore the electrical power to the furnace

by turning the switch back on. Adjust the

thermostat to call for heating operation.

6. Observe the main burners flames. The main

burners should be mostly “blue” with

possibly a little orange (not yellow) at the

tips of the flames. The flames should be in

the center of the heat exchanger

compartments and not impinging on the

heat exchanger surfaces.

7. Observe the flames until the blower starts

(there is a normal delay 30 second period

until the heat exchanger warms up). There

should be no change in the size or shape of

the flame. If there is any wavering or

blowing of the flame on the blower start-up,

it is an indication of a possible leak in the

heat exchanger. Turn off the gas valve in

the gas line leading to the furnace, and then

the main electrical switch to the furnace and

call your service agency.

8. Replace the burner access door.

SECTION 7 • AIR CONDITIONING START

UP PROCEDURE CRANKCASE HEATERS

FOR NON-SCROLL COMPRESSOR UNITS

All models covered by this user guide utilize a

compressor crankcase heater. It is secured on the

exterior of the compressor at its base, and is controlled

internally within the control panel to be energized

anytime the compressor is off.

Some form of crankcase heat is essential to prevent

liquid refrigerant from migrating to the compressor,

causing oil pump out on compressor start-up and

possible valve failure due to compressing a liquid.

The decal in Figure 5 is affixed to all outdoor units with

crankcase heaters detailing start-up procedures.

very important. Please read carefully

FIGURE 5

START-UP PROCEDURES DECAL

This is

.

IMPORTANT

These procedures must be followed at initial start-up and at any time power has

been removed for 12 hours or longer.

To prevent compressor damage which

may result from the presence of liquid

refrigerant in the compressor crankcase.

1. Make certain the room thermostat is in

the “off” position (the compressor is not to

operate).

2. Apply power by closing the system

disconnect switch. This energizes the

compressor heater which evaporates the

liquid refrigerant in the crankcase.

3. Allow 4 hours or 60 minutes per pound

of refrigerant in the system as noted on

the unit rating plate, whichever is greater.

Manual 2100-502

Page 14 of 15

4. After properly elapsed time, the

thermostat may be set to operate the

compressor.

5. Except as required for safety while

servicing—Do not open system

disconnect switch.

7961-061

SECTION 8 • VENTILATION OPTION

ASSEMBLIES

The standard Blank Off Plate (BOP) is installed on the

inside of the vent option door to cover the air inlet

openings which eliminates outside air from entering the

unit.

The optional Commercial Room Ventilator (CRV)

allows up to 50% outside fresh air to be introduced to

the building and includes a built-in exhaust damper.

The CRV complies with ASHRAE Standard 62.1

“Ventilation for Acceptable Indoor Air Quality”

.

SECTION 9 • REPLACEMENT PARTS

Replacement parts for the gas/electric units are available

through local distributors.

A replacement parts list manual is supplied with each

unit. When ordering parts or making inquiries

pertaining to any of the units covered by these

instructions, it is very important to always supply the

complete model number and serial number of the unit.

This is necessary to assure that the correct parts (or an

approved alternate part) are issued to the service agency.

The optional EIFM-Series Economizer allows for nonmechanical cooling when the outdoor temperature and

humidity conditions allow. It has automatic controls

that are set to lock out the mechanical cooling and

draw air from outside to cool the structure when the

outside air is below the control set point. This device

can also allow some continuous fresh air to be drawn

into the structure depending on its minimum position

setting.

The optional ERV-Series Energy (Heat) Recovery

Ventilator allows for a continuous change of outside

and inside air. It recovers up to 65% of the energy to

minimize the economic impact of conditioning the

space with fresh air when applying ASHRAE Standard

62.1 fresh air requirements.

SECTION 10 • OUTDOOR COIL

Period cleaning of the outdoor coil to permit full and

unrestricted airflow circulation is essential. Reduced

airflow through the outdoor coil can shorten equipment

service life as well as increase operating costs.

Manual 2100-502

Page 15 of 15

Loading...

Loading...