Bard WERVPA5, WERVPC5 Installation Instructions Manual

INSTALLATION INSTRUCTIONS

WALL MOUNT ENERGY RECOVERY

VENTILATOR WITH EXHAUST

AND OUTDOOR AIR SHUT-OFF DAMPER

Models:

WERVPA5 WERVPC5

For Use With Bard 3.5 – 6 Ton

Wall Mount Air Conditioners and Heat Pumps

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 2100-635A

Supersedes: 2100-635

Date: 3-21-18

Page 1 of 18

CONTENTS

Model Nomenclature .............................................. 3

Electrical Specifications ......................................... 3

General Description .............................................. 3

General Information .............................................. 3

Unpacking ............................................................ 3

Performance and Application Data – WERVP*5 ........ 4

Basic Field Installation ........................................... 5

Basic Installation (Factory-Installed Versions) ......... 12

Control Wiring ..................................................... 12

Ventilation Airflow ................................................ 13

Energy Recovery Ventilator Maintenance ................ 16

Figures

Figure 1 Remove Blower Assembly and

Discard Shipping Plate ........................ 5

Figure 2 Remove Access Panels ........................ 6

Figure 3 Remove Air Filter and

Exhaust Cover Plate ............................ 7

Figure 4 Install Exhaust Blower Assembly ........... 8

Figure 5

Figure 6 Connect Leads to Terminals ............... 10

Figure 7

Figure 8 Speed Tap Label ............................... 13

Figure 9 Airflow Diagram ................................ 13

Figure 10 Heat Pump Wiring ............................. 14

Figure 11 Heat Pump Wiring w/CO

and CompleteStat ............................. 15

Figure 12 Belt Replacement Instructions ........... 17

Figure 13 Hub Assembly with Ball Bearings ....... 18

Table

Table 1 Ventilation Air ................................... 12

Plug Exhaust Blower Into Control Panel

Attach Hood and Replace Access Panel

Controller

2

.. 9

. 11

Manual 2100-635A

Page 2 of 18

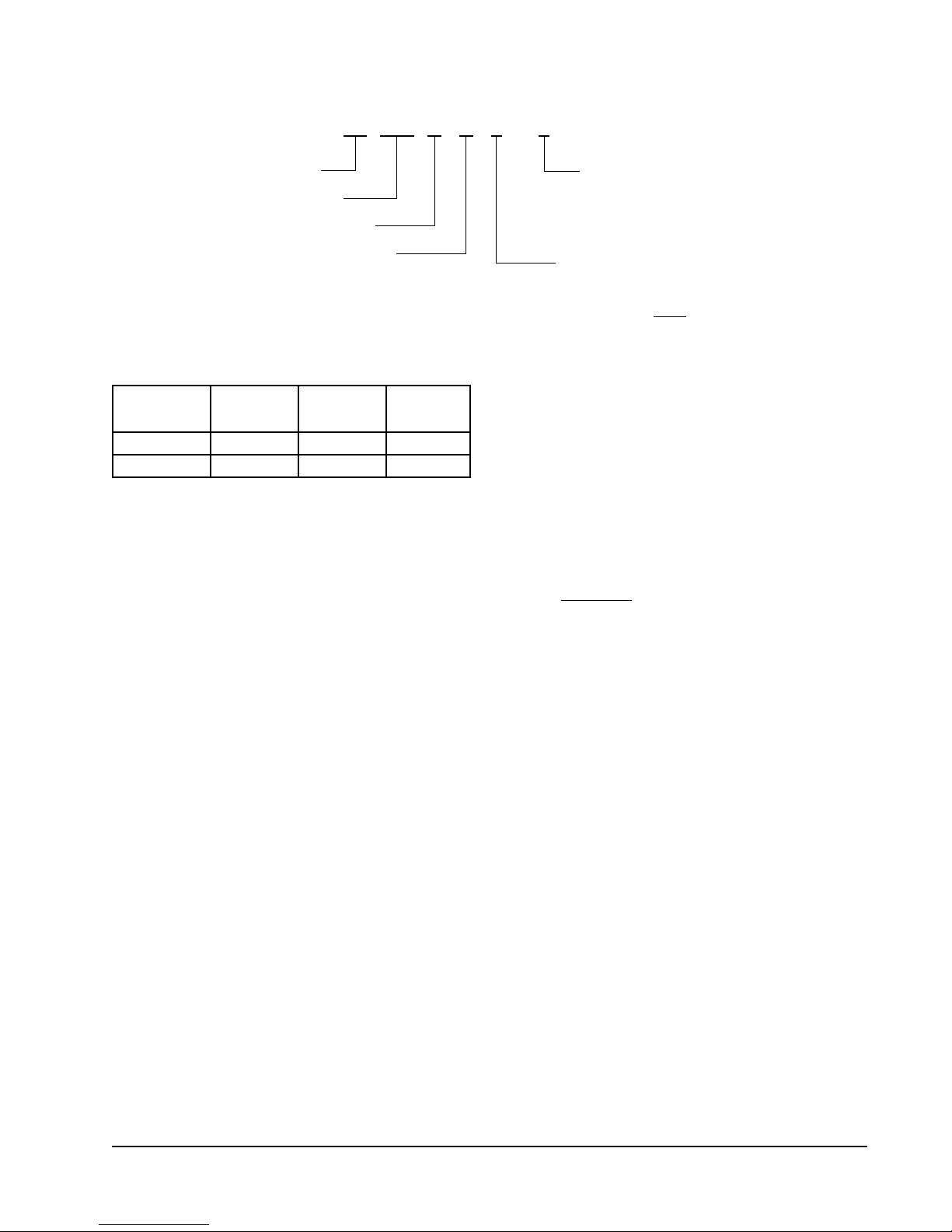

WALL MOUNT ENERGY RECOVERY VENTILATOR MODEL NOMENCLATURE

W ERV P A 5 – X

W – Wall Mount Color

Energy Recovery Ventilator

Plug-In Vent Connection

Electrical

A – 230/208 volt

C – 460 volt

X – Beige

1 – White

4 – Gray

5 – Desert Brown

Wall Mount – Cabinet Size

5 – W42A* thru W72A*

W42H* thru W60H*

(* revision letter)

8 – Dark Bronze

A – Aluminum

S – Stainless

ELECTRICAL SPECIFICATIONS

Model Voltage Amps

WERVPA5 230/208 2.2 24V

WERVPC5 460 1.2 24V

Control

Voltage

GENERAL DESCRIPTION

The Wall Mount Energy Recovery Ventilator was

designed to provide energy efficient, cost effective

ventilation to meet IAQ (Indoor Air Quality)

requirements while still maintaining good indoor

comfort and humidity control for a variety of

applications such as schools, classrooms, lounges,

conference rooms, beauty salons and others. It

provides a constant supply of fresh air for control

of airborne pollutants including CO

formaldehyde, excess moisture, virus and bacteria.

The ventilator incorporates patented rotary heat

exchanger technology to remove both heat and moisture.

It is designed as a single package which can be easily

factory or field installed for new installations or retrofit

to the new Bard W series wall-mounted units. The

package consists of a unique rotary Energy Recovery

Cassette that can be easily removed for cleaning or

maintenance. The WERVP*5 has two 15" diameter

heat transfer wheels for efficient heat transfer. The

heat transfer wheels use a permanently bonded dry

desiccant coating for total heat recovery. An outdoor

air shutoff damper is an integral feature of the WERVP

and prevents infiltration when the ERV is turned off.

, smoke, radon,

2

effectively during both summer and winter conditions.

Provides required ventilation to meet the requirements

of ASHRAE 62.1 standard.

NOTE: During operation below 5°F outdoor

temperature, freezing of moisture in the heat

transfer wheel can occur. Consult the factory if

this possibility exists.

GENERAL INFORMATION

NOTE: This manual covers both factory- and field-

installed WERVP assemblies. For factoryinstalled WERVP, skip information pertaining to

installation of the WERVP system.

The ventilator should only be installed by a trained

heating and air conditioning technician. These

instructions serve as a guide to the technician installing

the ventilator package. They are not intended as a stepby-step procedure with which the mechanically inclined

owner can install the package. The ventilator housing is

shipped in one carton which contains the following:

• Energy recovery ventilator

• Service door

• Rain hood and mist eliminator

• Installation instructions

UNPACKING

Upon receipt of the equipment, be sure to compare the

model number found on the shipping label with the

accessory identification information on the ordering and

shipping document to verify that the correct accessory

has been shipped.

Ventilation is accomplished with two blower/motor

assemblies each consisting of a drive motor and dual

blowers for maximum ventilation at low sound levels.

The intake and exhaust blowers can be operated at the

same speed (airflow rate) or different speeds to allow

flexibility in maintaining desired building pressurization

conditions. Factory shipped on medium intake and low

exhaust. See Figure 8 on page 13 to change speeds.

The rotating energy wheels provide the heat transfer

Inspect the carton housing of each ventilator as it is

received and before signing the freight bill, verify that

all items have been received and that there is no visible

damage. Note any shortages or damage on all copies

of the freight bill. The receiving party must contact

the last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent. Concealed

damage not discovered until after loading must be

reported to the carrier within 15 days of its receipt.

Manual 2100-635A

Page 3 of 18

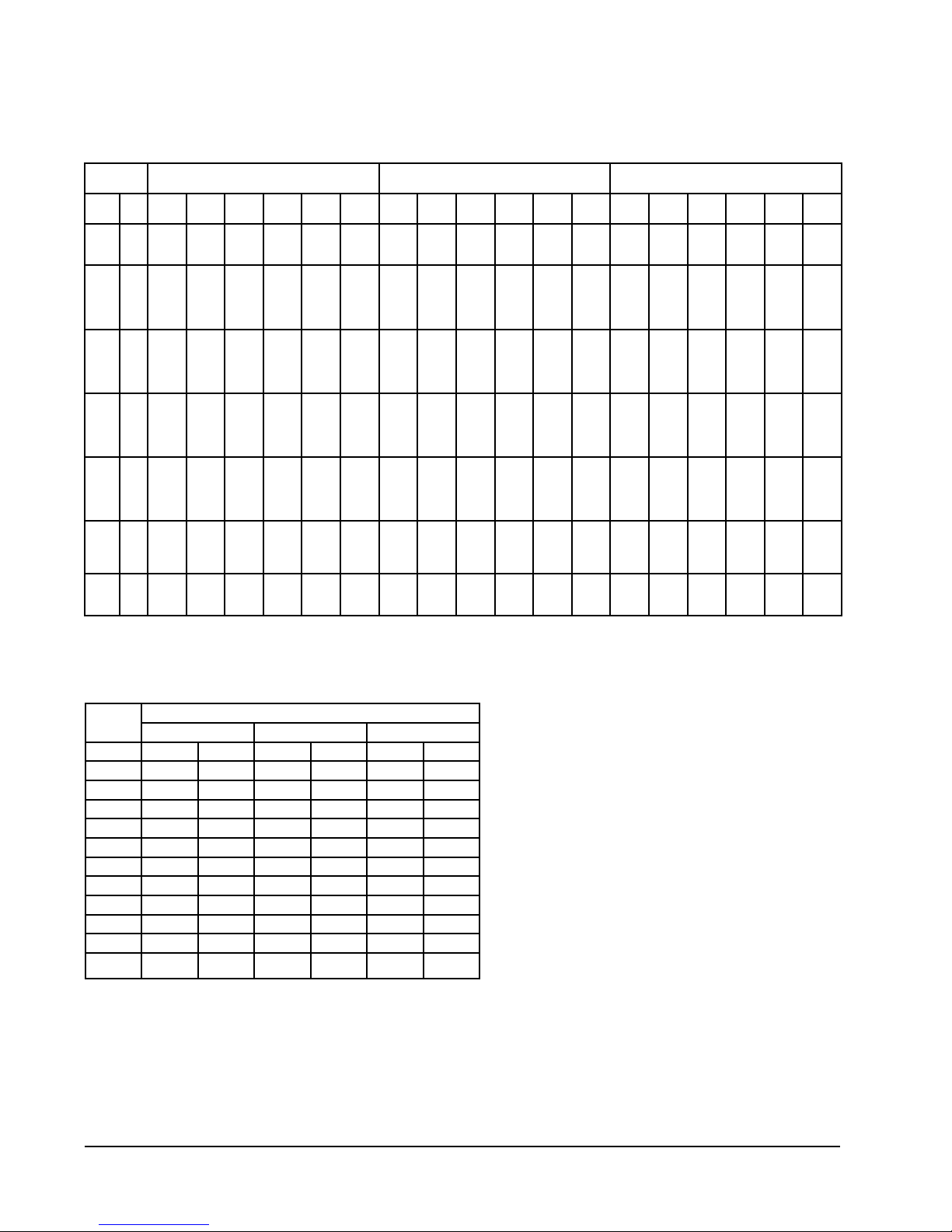

PERFORMANCE AND APPLICATION DATA – WERVP*5

Summer Cooling Performance

(Indoor Design Conditions 75°DB/62°WB)

Ambient

OD

DB/

F VLT VLS VLL HRT HRS HRL V LT VLS VLL HRT HRS HRL V LT VLS VLL HRT HRS HRL

WB

1057570

100

95

90

85

80

757065

21465

14580

65

14580

80

31590

75

21465

70

12352

65

12150

60

12150

80

31590

75

21465

70

12352

65

9720

60

9720

80

31590

75

21465

70

12352

65

7290

60

7290

80

31590

75

21465

70

12352

65

4860

60

4860

75

21465

70

12352

65

4252

60

2430

12352

4252

60

Ventilation Rate 450 CFM Ventilation Rate 375 CFM Ventilation Rate 300 CFM

3786

14310

4475

17887

12150

5737

11805

14580

6884

13952

14580

14580

12150

12150

12150

12150

12150

9720

9720

9720

9720

9720

7290

7290

7290

7290

7290

4860

4860

4860

4860

4860

2430

2430

2430

2430

0

0

0

19440

9314

202

0

0

21870

11744

2632

0

0

24300

14175

5062

0

0

26730

16605

7492

0

0

19035

9922

1822

0

0

12352

0

4252

0

0

9477

9477

20533

13952

8029

7897

7897

20553

13952

8029

6318

6318

20533

13952

8029

4738

4738

20533

13952

8029

3159

3159

13952

8029

2764

1579

8029

2764

0

9477

9477

9477

7897

7897

7897

7897

7897

6318

6318

6318

6318

6318

4738

4738

4738

4738

4738

3159

3159

3159

3159

3159

1579

1579

1579

1579

0

12150

12150

26325

17887

10293

10125

10125

26325

17887

10293

8100

8100

26325

17887

10293

6075

6075

26325

17887

10293

4050

4050

17887

10293

3543

2025

10293

3543

0

12150

12150

10125

10125

10125

10125

10125

0

12635

6054

131

0

0

14215

7634

1711

0

0

15794

9213

3290

0

0

17374

10793

4870

0

0

12372

6449

1184

0

8029

0

2764

0

0

0

8100

8100

8100

8100

8100

6075

6075

6075

6075

6075

4050

4050

4050

4050

4050

2025

2025

2025

2025

0

0

0

0

0

16200

7762

168

0

0

18225

9787

2193

0

0

20250

11812

4218

0

0

22275

13837

6243

0

0

15862

8268

1518

0

10293

3543

0

8018

8018

17374

11805

6793

6682

6682

17374

11805

6793

5345

5345

17374

11805

6793

4009

4009

17374

11805

6793

2672

2672

11805

6793

2338

1336

6793

2338

0

8018

8018

8018

6682

6682

6682

6682

6682

5345

5345

5345

5345

5345

4009

4009

4009

4009

4009

2672

2672

2672

2672

2672

1336

1336

1336

1336

0

0

0

0

0

10692

5123

111

0

0

12028

6459

1447

0

0

13365

7796

2784

0

0

14701

9132

4120

0

0

10469

5457

1002

0

6793

2338

0

9720

9720

21060

14310

8235

8100

8100

21060

14310

8235

6480

6480

21060

14310

8235

4860

4860

21060

14310

8235

3240

3240

14310

8235

2835

1620

8235

2835

0

9720

9720

9720

8100

8100

8100

8100

8100

6480

6480

6480

6480

6480

4860

4860

4860

4860

4860

3240

3240

3240

3240

3240

1620

1620

1620

1620

0

0

0

4590

0

0

12960

6210

135

0

0

14580

7830

1755

0

0

16200

9450

3375

0

0

17820

11070

4995

0

0

12690

6615

1215

0

8235

2835

0

9587

6512

6512

14110

9587

5517

5427

5427

14110

9587

5517

4341

4341

14110

9587

5517

3256

3256

14110

9587

5517

2170

2170

9587

5517

1899

1085

5517

1899

0

6512

6512

6512

5427

5427

5427

5427

5427

4341

4341

4341

4341

4341

3256

3256

3256

3256

3256

2170

2170

2170

2170

2170

1085

1085

1085

1085

0

0

0

3075

0

0

8683

4160

90

0

0

9768

5246

1175

0

0

10854

6331

2261

0

0

11939

7416

3346

0

0

8502

4432

814

0

5517

1899

0

Winter Heating Performance

(Indoor Design Conditions 70°F DB)

Ambient

OD

DB/°F WVL WHR WVL WHR WVL WHR

65 2430 1944 2025 1640 1620 1328

60 4860 3888 4050 3280 3240 2656

55 7290 5832 6075 4920 4860 3985

50 9720 7776 8100 6561 6480 5313

45 12150 9720 10125 8201 8100 6642

40 14580 11664 12150 9841 9720 7970

35 17010 13608 14175 11481 11340 9298

30 19440 15552 16200 13122 12960 10627

25 21870 17496 18225 14762 14580 11955

20 24300 19440 20250 16402 16200 13284

15 26730 21384 22275 18042 17820 14612

450 CFM 375 CFM 300 CFM

NOTE: Sensible performance only is shown for winter

application.

Ventilation Rate

LEGEND:

VLT = Ventilation Load – Total

VLS = Ventilation Load – Sensible

VLL = Ventilation Load – Latent

HRT = Heat Recovery – Total

HRS = Heat Recovery – Sensible

HRL = Heat Recovery – Latent

WVL = Winter Ventilation Load

WHR = Winter Heat Recovery

NOTE: All performance data is based on

operating intake and exhaust blower on

the same speed.

Manual 2100-635A

Page 4 of 18

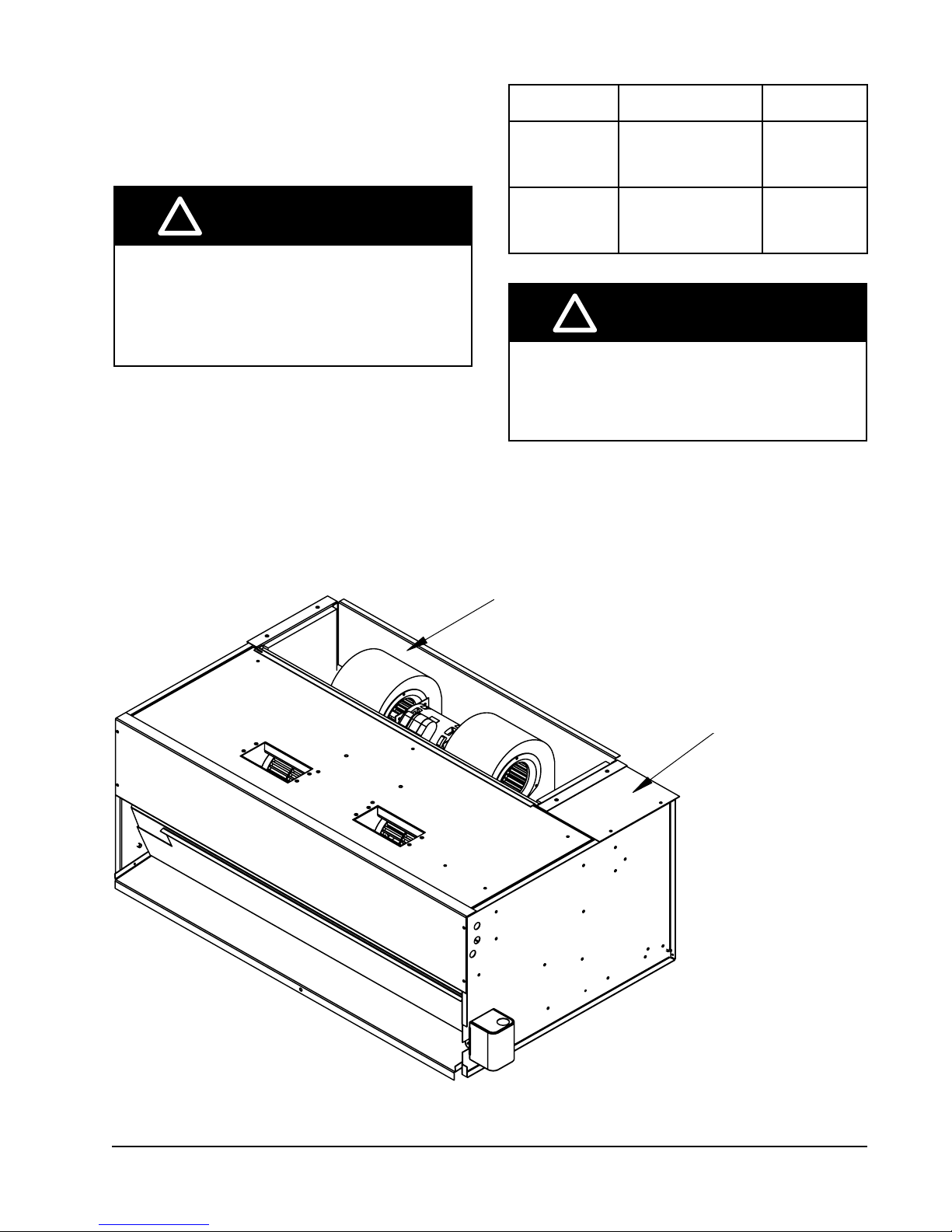

BASIC FIELD INSTALLATION

MIS-2233

Discard Shipping

plate

Remove Exhaust

Blower Assembly

1. Unpack the ventilator assembly which includes the

integral ventilator with attached electrical harness

and miscellaneous hardware.

!

WARNING

Open and lock unit disconnect switch

before installing this accessory to prevent

injury or death due to electrical shock or

contact with moving parts. Turn thermostat

to OFF.

2.

Remove exhaust blower assembly from back of

ventilator and discard shipping plate (see Figure 1).

FIGURE 1

Remove Blower Assembly and Discard Shipping Plate

Model

WERVPA5

WERVPC5

!

Be sure the correct model and voltage

energy recovery ventilator is used with

the correct air conditioner or heat pump to

ensure correct voltage compatibility.

For Use With the

Following Units

W42AA/W42HA-A, -B

W48AA/W48HA-A, -B

W60AA/W60HA-A, -B

W72AB-A, -B

W42AA/W42HA-C

W48AA/W48HA-C

W60AA/W60HA-C

W72AB-C

Electrical

230/208 -

1 or 3 phase

460 - 3 phase

CAUTION

REMOVE EXHAUST

BLOWER ASSEMBLY

DISCARD SHIPPING

PLATE

Manual 2100-635A

Page 5 of 18

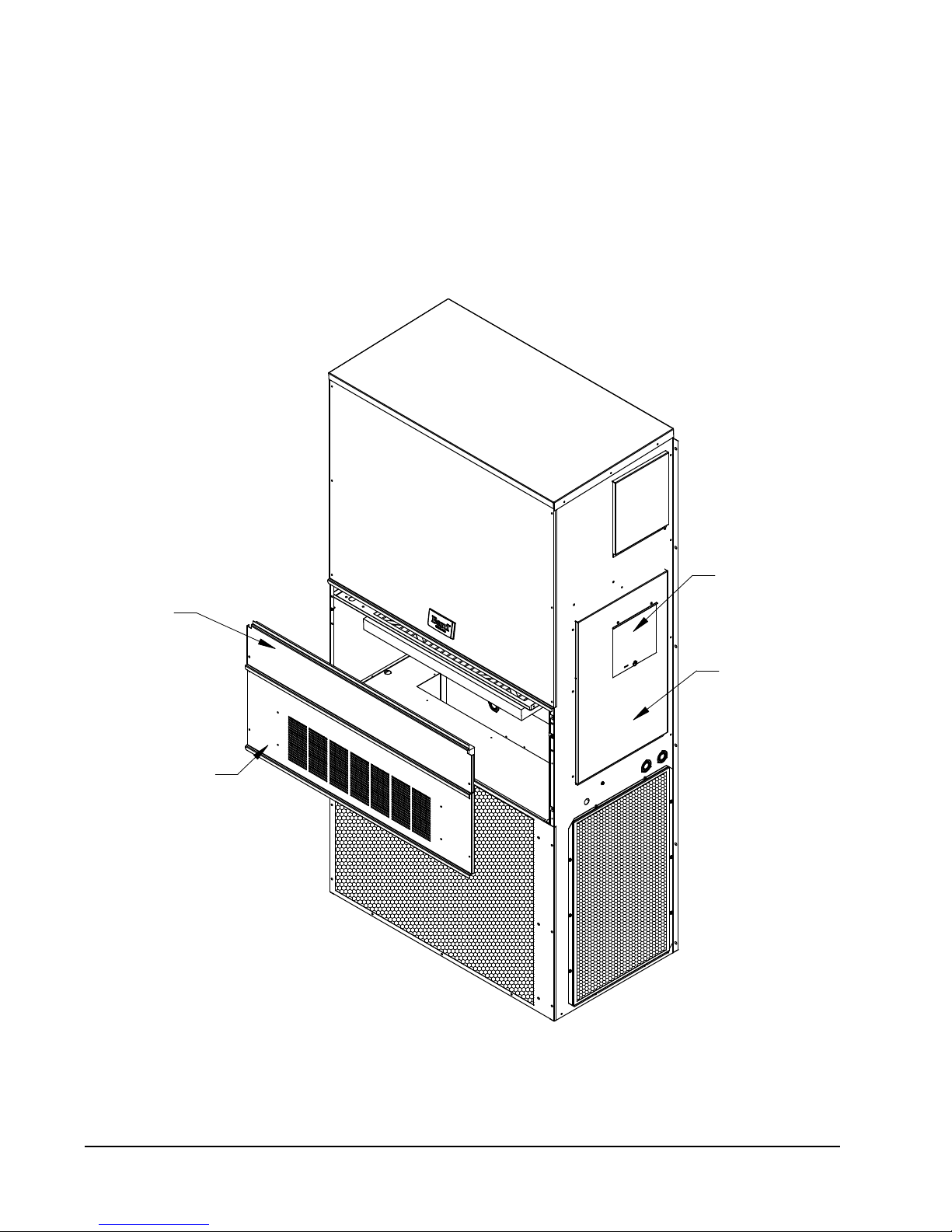

3. Disconnect unit power.

4. Remove the existing exterior filter access and

service access panels on the Bard wall mount unit

(see Figure 2). Save the filter access panel and

discard service access panel.

Remove Access Panels

FIGURE 2

REMOVE & SAVE

FILTER DOOR

REMOVE & DISCARD

SERVICE ACCESS DOOR

CIRCUIT BREAKER

DOOR

CONTROL PANEL

DOOR

Manual 2100-635A

Page 6 of 18

MIS-3744

Loading...

Loading...