Bard WE252, WE301, WE371, WE421, WE482 Installation Instructions Manual

...

WALL MOUNTED PACKAGED

AIR CONDITIONER

INSTALLATION

INSTRUCTIONS

Models:

WE252 WE301

WE371 WE421

WE482 WE602

WE701

THESE MODELS ALL USE REFRIGERANT R-407C

and ARE FOR 50HZ OPERATION.

Bard Manufacturing Company

Bryan, Ohio 43506

Since 1914...Moving ahead, just as

planned.

MIS-383

Manual No.: 2100-385B

Supersedes: 2100-385A

File: Volume III, Tab 16

Date: 04-25-05

©

Copyright 2002

CONTENTS

Getting Other Information

...................................1

Wall Mount General Information

Model Nomenclature ............................................ 2

Shipping Damage ................................................ 5

General ................................................................ 5

Duct Work ............................................................ 5

Filters ................................................................... 6

Fresh Air Intake .................................................... 6

Condensate Drain ................................................ 6

Installation Instructions

Wall Mounting Information ................................... 7

Proper Unit Placement ......................................... 7

Mounting the Unit ................................................. 7

Wiring – Main Power .......................................... 12

Wiring – Low Voltage ......................................... 12

Start Up

Important Installer Note...................................... 14

High Pressure Switch ........................................ 14

Service Hints ...................................................... 14

Sequence of Operations .................................... 14

Compressor Control Module .............................. 14

Adjustments ....................................................... 15

Phase Monitor .................................................... 15

Pressure Service Ports ...................................... 15

Troubleshooting

Fan Blade Setting Dimensions .......................... 16

Removal of Fan Shroud ..................................... 16

Refrigerant Charge ............................................ 16

Cooling Pressures ............................................. 18

Optional Accessories ......................................... 19

R-407C Refrigerant

Service Procedures & Considerations ............... 20

Charging ............................................................ 20

Leaks ................................................................. 20

Figures

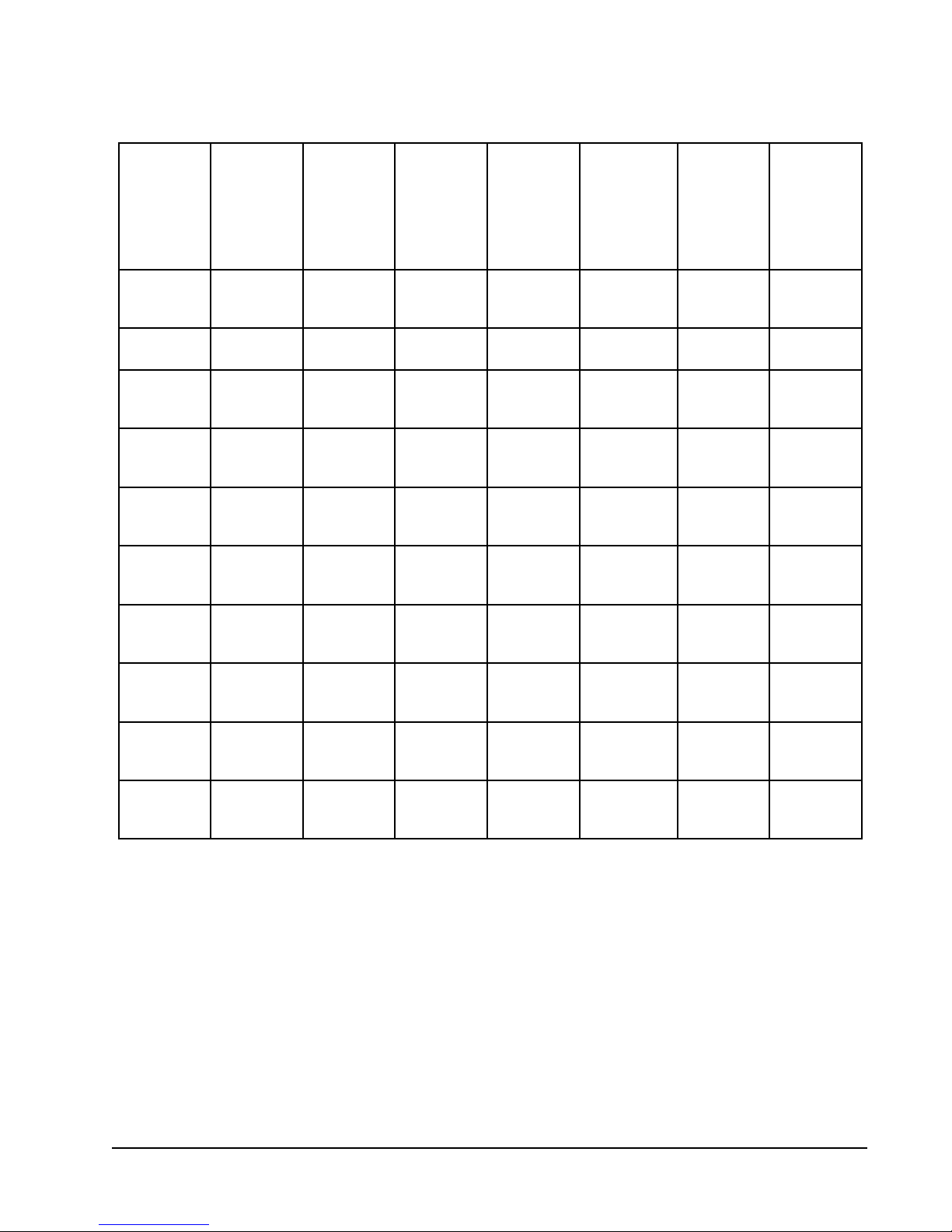

Figure 1 Unit Dimensions................................... 4

Figure 2 Fresh Air Damper Assembly ................ 6

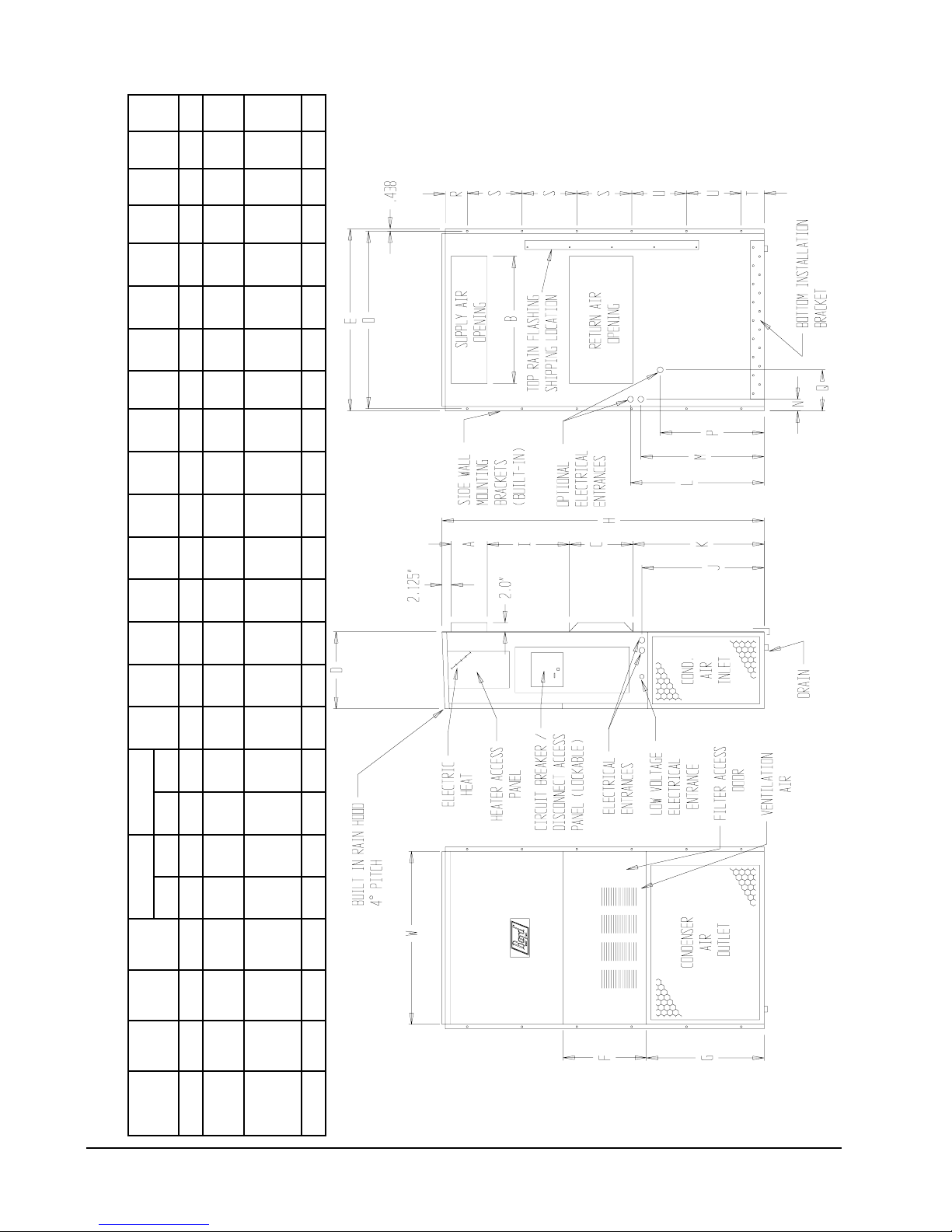

Figure 3 Mounting Instructions........................... 8

Figure 4 Electric Heat Clearance ....................... 9

Figure 5 Wall-Mounting Instructions ................. 10

Figure 6 Wall-Mounting Instructions ................. 10

Figure 7 Common Wall-Mounting Instructions . 11

Figure 8 Low Voltage Wiring Diagram ............. 13

Figure 9 Fan Blade Setting .............................. 16

Tables

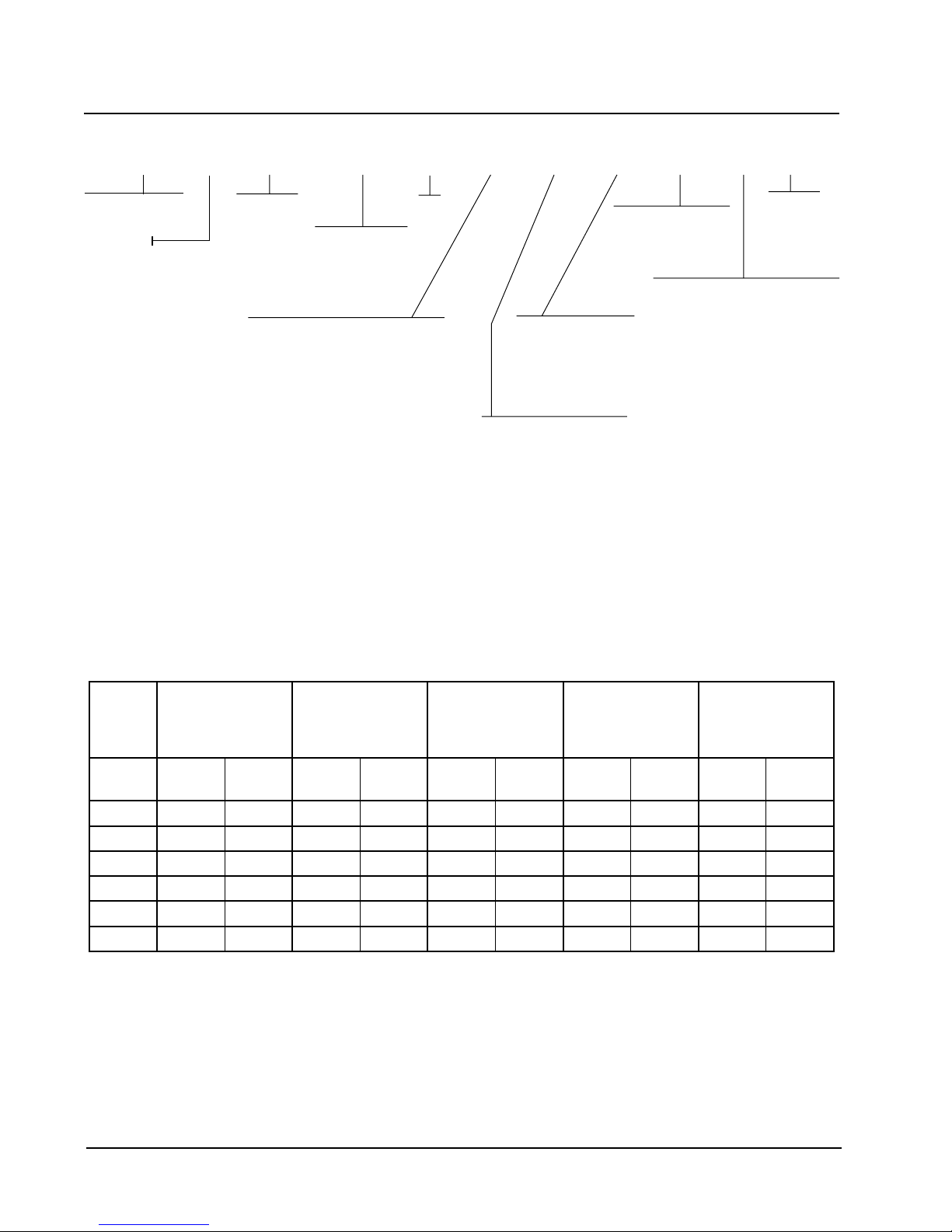

Table 1 Electric Heat Table ............................... 2

Table 2 Electrical Specifications ....................... 3

Table 3 Thermostat Wire Size ........................ 12

Table 4 Wall Thermostat and

Subbase Combinations...................... 12

Table 5 Fan Blade Setting Dimension ............ 16

Table 6 Suction Line Temperatures ................ 16

Table 7 Rated CFM and ESP ......................... 16

Table 8 Indoor Blower Performance ............... 17

Table 9 Maximum ESP of Operation –

Electric Heat Only .............................. 17

Table 10 Cooling Pressures ............................. 18

Table 11 Optional Accessories ......................... 19

Table 12 R-407C Temperature/Pressure Chart 20

GETTING OTHER INFORMATION AND PUBLICATIONS

These publications can help you install the air

conditioner or heat pump. You can usually find these at

your local library or purchase them directly from the

publisher. Be sure to consult current edition of each

standard.

National Electrical Code ........................ ANSI/NFPA 70

Standard for the Installation ................ ANSI/NFPA 90A

of Air Conditioning and

Ventilating Systems

Standard for Warm Air ........................ ANSI/NFPA 90B

Heating and Air

Conditioning Systems

Load Calculation for ............................. ACCA Manual J

Residential Winter and

Summer Air Conditioning

Duct Design for Residential ................ ACCA Manual D

Winter and Summer Air

Conditioning and Equipment

Selection

FOR MORE INFORMATION, CONTACT

THESE PUBLISHERS:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Avenue NW

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating Refrigerating,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Manufactured under the following U.S. patent numbers:

5,485,878; 5,301,744; 5,002,116;

4,924,934; 4,875,520; 4,825,936

Manual 2100-385B

Page 1

WALL MOUNT GENERAL INFORMATION

AIR CONDITIONER WALL MOUNT MODEL NOMENCLATURE

WE 42 1 — F 07 X X X X X J

MODEL NUMBER

CAPACITY

25 - 2 TON

30 - 2-1/2 TON

37 - 3 TON

42 - 3-1/2 TON

48 - 4 TON

60 - 5 TON

70 - 6 TON

REVISIONS

VOLTS & PHASE

D - 240/220-50-1

F - 415/380-50-3

VENTILATION OPTIONS

X - BAROMETRIC FRESH AIR DAMPER

B - BLANK-OFF PLATE

M - MOTORIZED FRESH AIR DAMPER

V - COMMERCIAL VENTILATOR

MOTORIZED WITH EXHAUST

E - ECONOMIZER (INTERNAL) - FULLY

MODULATING WITH EXHAUST

R - ENERGY RECOVERY VENTILATOR -

MOTORIZED WITH EXHAUST

KW

COLOR OPTIONS

X-

BEIGE (STANDARD)

1 - WHITE

2 - MESA TAN

4 - BUCKEYE GRAY

5 - DESERT BROWN

FILTER OPTIONS

X - ONE INCH THROWAWAY

W - ONE INCH WASHABLE

P - TWO INCH PLEATED

OUTLET OPTIONS

X - FRONT (STANDARD)

COIL OPTIONS

X - STANDARD

1 - PHENOLIC COATED EVAPORATOR

2 - PHENOLIC COATED CONDENSER

3 - PHENOLIC COATED EVAPORATOR

AND CONDENSER

CONTROL

MODULES

TABLE 1

ELECTRIC HEAT TABLE

D-103EW

sledoMD-252EWF-252EW

WK

1-V042

STTAW

1-V022

STTAW

3-V514

STTAW

3-V083

STTAW

D-173EW

1-V042

STTAW

1-V022

STTAW

0.5110502244844157311050224

0.7 0476656504760665

0.811081276

0.0149991148

0.21 871118049

0.41 0543108211

F-103EW

F-173EW

3-V514

STTAW

3-V083

STTAW

3-V514

STTAW

F-124EW

F-284EW

F-206EW

F-107EW

3-V083

STTAW

Manual 2100-385B

Page 2

TABLE 2

ELECTRICAL SPECIFICATIONS

1

3

gnitarepO

stloVdetaR

ledoM

Z0D-252EW

50D

80D

Z0F-252EW

50F

Z0D-103EW

50D

01D

Z0F-103EW

70F

21F

Z0D-173EW

50D

01D

Z0F-173EW

70F

21F

Z0F-124EW

70F

41F

Z0F-284EW

70F

41F

Z0F-206EW

70F

41F

Z0F-107EW

70F

41F

1

Maximum size of the time delay fuse or HACR type circuit breaker for protection of field wiring conductors.

2

Based on 75°C copper wire. All wiring must conform to NEC and all local codes.

3

These “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the

National Electric Code (latest revision), Article 310 for power conductor sizing.

Caution: When more than one field power conductor circuit is run through one conduit, the conductors must be

derated. Pay special attention to Note 8 of Table 310 regarding Ampacity Adjustment Factors when more than

three (3) conductors are in a raceway.

IMPORTANT: While this electrical data is presented as a guide, it is important to electrically connect properly sized

fuses and conductor wires in accordance with all existing local codes.

esahPdna

1-022/042452-891

3-083/514654-243

1-022/042452-891

3-083/514654-243

1-022/042452-891

3-083/514654-243

3-083/514654-243

3-083/514654-243

3-083/514654-243

3-083/514654-243

egatloV

egnaR

rebmuN

rewoPdleiF

stiucriC

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

muminiM

tiucriC

yticapmA

51

72

34

7

01

22

92

55

9

51

32

42

92

55

11

61

52

11

61

03

31

61

03

51

61

03

91

91

23

mumixaM

lanretxE

esuF

tiucriCro

rekaerB

02

03

54

51

51

53

53

06

51

51

52

53

53

06

51

02

52

51

02

03

02

02

03

02

02

03

52

52

53

2

rewoPdleiF

eziSeriW

21

01

8

41

41

8

8

6

41

41

01

8

8

6

41

21

01

41

21

01

21

21

01

21

21

01

01

01

01

2

dnuorG

eziSeriW

21

01

01

41

41

01

01

01

41

41

01

01

01

01

41

21

01

41

21

01

21

21

01

21

21

01

01

01

01

Manual 2100-385B

Page 3

MIS-1665

BACK VIEW

FIGURE 1

UNIT DIMENSIONS (IN INCHES)

EFGI JKLMNOPQRSTUABCB

ylppuSnruteR

thgieH

)H(

htpeD

)D(

htdiW

)W(

ledoM

2.83572.71365.0788.788.7288.3188.720.045.8157.5239.7157.6257.8252.920.7257.291.9357.2241.991.40.210.50.21

103EW

252EW3.33521.71365.0788.788.9188.1188.910.535.8157.5265.0257.6260.8252.920.7236.231.4360.2255.0191.40.210.50.21

173EW

124EW

570.24234.22578.4888.988.9288.5188.9288.3401.9166.130.0386.2349.6296.4334.2373.388.2488.320.0144.10.6188.10.61

284EW

206EW

SIDE VIEW

FRONT VIEW

107EW570.2434.22578.4988.988.9288.5188.9288.3401.9166.140.0386.240.7357.445.2473.388.2488.330.010.20.6188.10.12

Manual 2100-385B

Page 4

SHIPPING DAMAGE

DUCT WORK

Upon receipt of equipment, the carton should be

checked for external signs of shipping damage. If

damage is found, the receiving party must contact the

last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent.

GENERAL

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct work.

Flanges are provided for attaching the supply and return

ducts.

These instructions explain the recommended method to

install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

air conditioning system should be carefully read before

beginning the installation. Note particularly “Starting

Procedure” and any tags and/or labels attached to the

equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made. See Page 1 for information on codes and

standards.

Size of unit for a proposed installation should be based

on heat loss calculation made according to methods of

Air Conditioning Contractors of America (ACCA). The

air duct should be installed in accordance with the

Standards of the National Fire Protection Association for

the Installation of Air Conditioning and Ventilating

Systems of Other Than Residence Type, NFPA No.

90A, and Residence Type Warm Air Heating and Air

Conditioning Systems, NFPA No. 90B. Where local

regulations are at a variance with instructions, installer

should adhere to local codes.

All duct work, supply and return, must be properly sized

for the design air flow requirement of the equipment.

Air Conditioning Contractors of America (ACCA) is an

excellent guide to proper sizing. All duct work or

portions thereof not in the conditioned space should be

properly insulated in order to both conserve energy and

prevent condensation or moisture damage.

Refer to Table 9 for maximum static pressure available

for duct design.

Design the duct work according to methods given by the

Air Conditioning Contractors of America (ACCA).

When duct runs through unheated spaces, it should be

insulated with a minimum of one inch of insulation. Use

insulation with a vapor barrier on the outside of the

insulation. Flexible joints should be used to connect the

duct work to the equipment in order to keep the noise

transmission to a minimum.

A 1/4 inch clearance to combustible material for the first

3 feet of duct attached to the outlet air frame is required.

See Wall Mounting Instructions and Figures 3 and 4 for

further details.

Ducts through the walls must be insulated and all joints

taped or sealed to prevent air or moisture entering the

wall cavity.

Some installations may not require any return air duct.

A metallic return air grille is required with installations

not requiring a return air duct. The spacing between

louvers on the grille shall not be larger than 5/8 inches.

Any grille that meets the 5/8 inch louver criteria may be

used. It is recommended that Bard Return Air Grille Kit

RG-2 thru RG-5 or RFG-2 thru RFG-5 be installed when

no return duct is used. Contact distributor or factory for

ordering information. If using a return air filter grille,

filters must be of sufficient size to allow a maximum

velocity of 400 fpm.

NOTE: If no return air duct is used, applicable

installation codes may limit this cabinet to

installation only in a single story structure.

Manual 2100-385B

Page 5

Loading...

Loading...