WALL MOUNTED P ACKAGED

AIR CONDITIONER

INSTALLATION

INSTRUCTIONS

Models:

WA611

WA701-B

WA701-C

WA702-A

WA721

Bard Manufacturing Company

Bryan, Ohio 43506

Since 1914...Moving ahead, just as planned.

MIS-801

Manual No.: 2100-425

Supersedes:

File: Volume III, Tab 16

Date: 01-01-03

© Copyright 2003

CONTENTS

Getting Other Information and Publications

For more information, contact these publishers: ..... 1

Wall Mount General Information

Air Conditioner Wall Mount Model Nomenclature.... 2

Shipping Damage .................................................... 5

General ............................................................... 5

Duct Work ............................................................... 5

Filters ............................................................... 6

Fresh Air Intake ....................................................... 6

Condensate Drain.................................................... 6

Installation Instructions

Wall Mounting Information....................................... 7

Mounting the Unit .................................................... 7

Typical Installations ................................................. 7

Wiring – Main Power ............................................. 7

Wiring – Low Voltage Wiring ................................. 9

Figures

Start Up

Important Installer Note ......................................... 14

Crankcase Heaters................................................ 14

High Pressure Switch ............................................ 14

Three Phase Scroll Compressor Start Up

Information............................................................. 14

Service Hints ......................................................... 15

Sequence of Operation.......................................... 15

Compressor Control Module.................................. 15

Adjustments........................................................... 16

Phase Monitor ....................................................... 16

Pressure Service Ports .......................................... 16

Troubleshooting

Fan Blade Setting Dimensions .............................. 17

Removal of Fan Shroud......................................... 17

Refrigerant Charge ................................................ 17

Pressure Chart ...................................................... 18

Optional Accessories............................................. 19

Tables

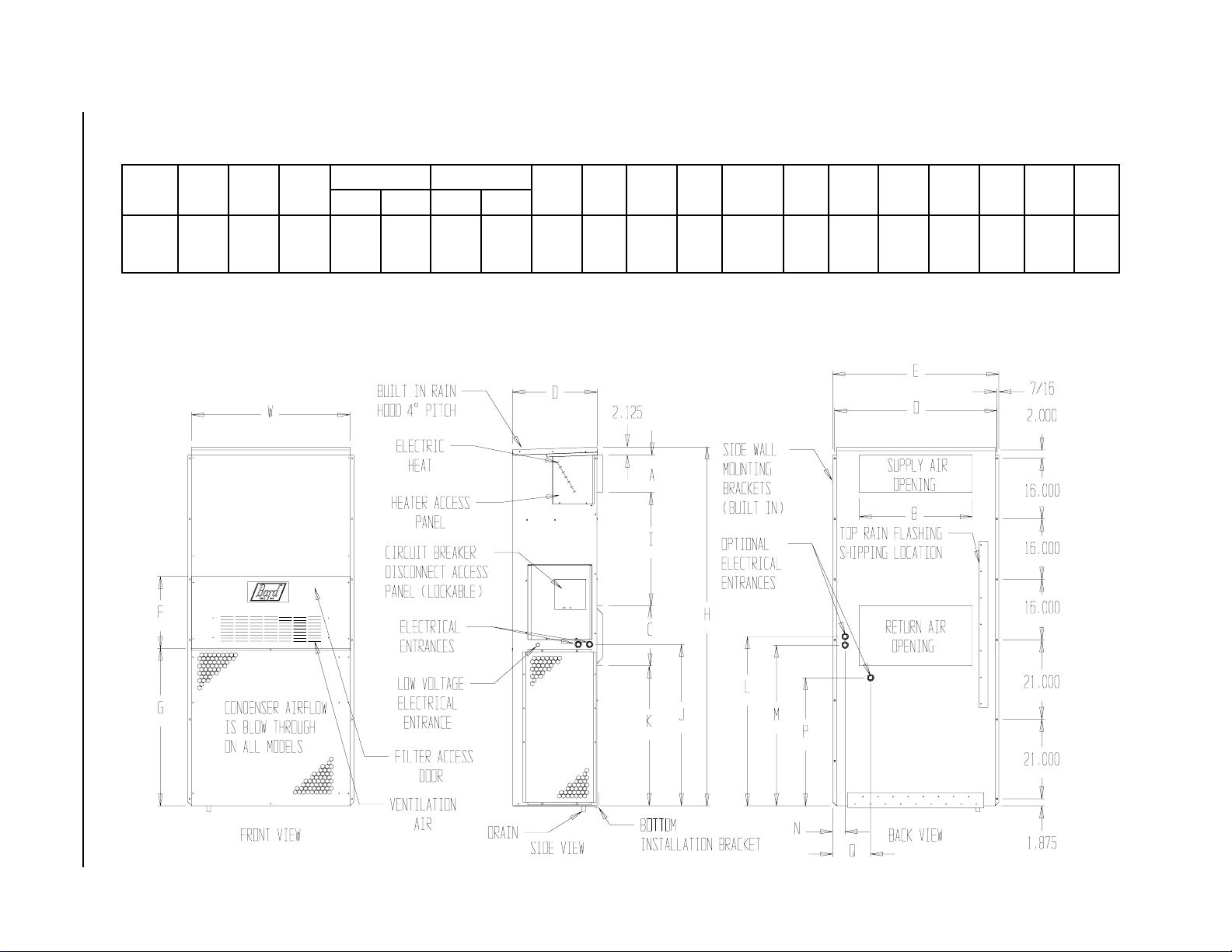

Figure 1 Unit Dimensions..................................... 3

Figure 2 Blower Damper Assembly...................... 6

Figure 3 Mounting Instructions............................. 8

Figure 4 Wall-Mounting Instructions .................. 10

Figure 5 Wall-Mounting Instructions .................. 10

Figure 6 Common Wall-Mounting Instructions ....11

Figure 7 Electric Heat Clearances ..................... 12

Figure 8 Low Voltage Wiring.............................. 13

Figure 9 Start-Up Label...................................... 14

Figure 10 Fan Blade Setting ................................ 17

Table 1 Electric Heat Table................................. 2

T able 2 Dimensions of Basic Unit ....................... 3

Table 3 Electrical Specifications ......................... 4

Table 4 Operating Voltage Range ...................... 9

Table 5 Thermostat Wire Size ............................ 9

Table 6 Wall Thermostat and

Subbase Combinations.......................... 9

Table 7 Fan Blade Dimensions......................... 17

Table 8 Suction Line Temperatures .................. 17

Table 9 CFM and ESP ...................................... 17

Table 10 Indoor Blower Performance ................. 17

Table 11 Maximum ESP of Operation

Electric Heat Only ................................ 18

Table 12 Cooling Pressure ................................. 18

Table 13 Optional Accessories ........................... 19

i

Getting Other Information and Publications

These publications can help you install the air

conditioner or heat pump. You can usually find these at

your local library or purchase them directly from the

publisher. Be sure to consult current edition of each

standard.

National Electrical Code .......................ANSI/NFPA 70

Standard for the Installation ............... ANSI/NFPA 90A

of Air Conditioning and

Ventilating Systems

Standard for Warm Air....................... ANSI/NFPA 90B

Heating and Air

Conditioning Systems

Load Calculation for ....................... ACCA Manual J or

Residential Winter and Manual N

Summer Air Conditioning

Low Pressure, Low Velocity .......... ACCA Manual D or

Duct System Design for Winter Manual Q

and Summer Air Conditioning

FOR MORE INFORMATION, CONTACT

THESE PUBLISHERS:

ACC A Air Conditioning Contractors of America

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating Refrigerating,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Manufactured under the following U.S. patent numbers:

5,485,878; 5,301,744; 5,002,116; 4,924,934;

4,875,520; 4,825,936

Manual 2100-425

Page 1

WALL MOUNT GENERAL INFORMA TION

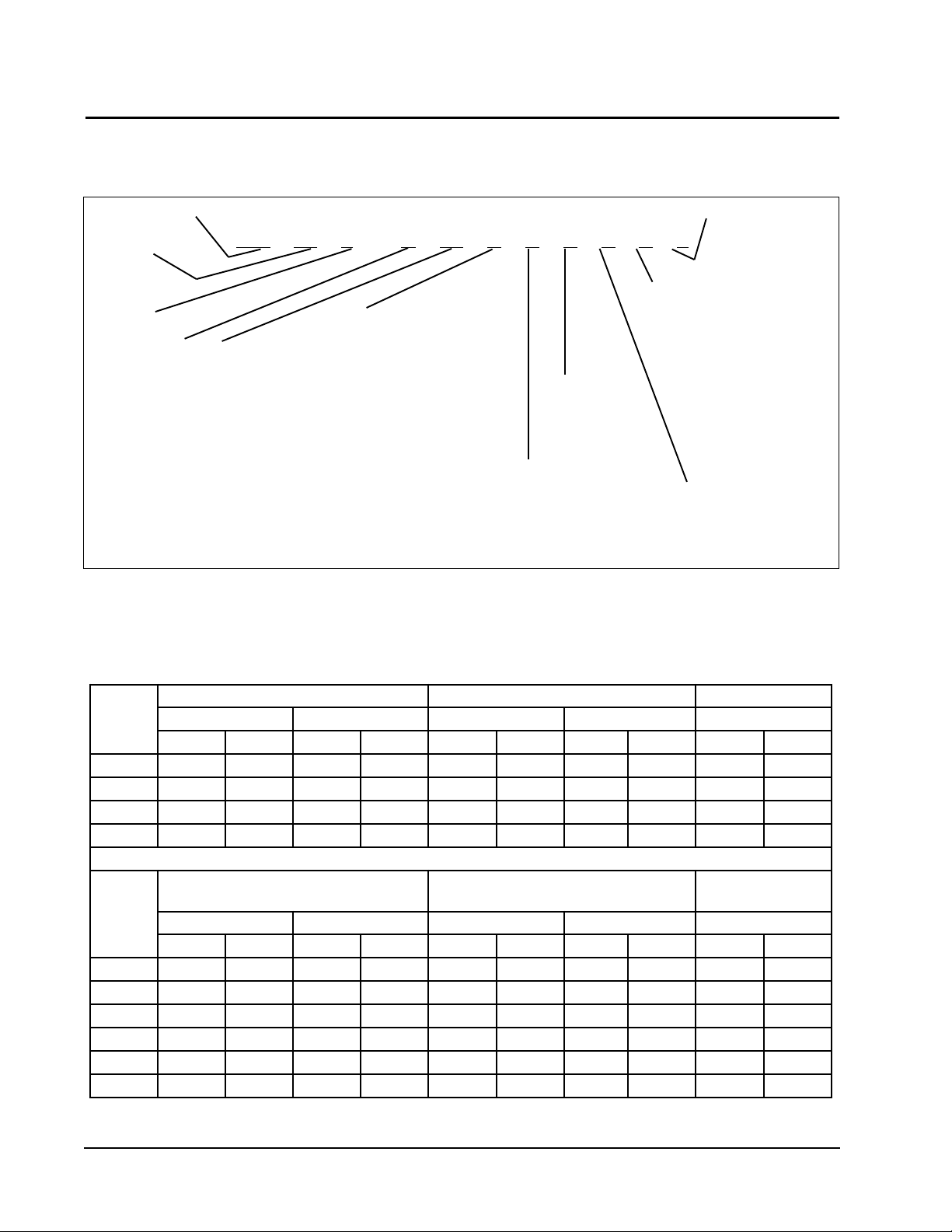

AIR CONDITIONER WALL MOUNT MODEL NOMENCLATURE

MODEL NUMBER

CAPACITY

61 – 5 Ton

70 – 6 Ton

72 – 6 To n

REVISION

VOL TS & PHASE

A – 230/208-1

B – 230/208/60-3

C – 460/60-3

NOTE: For 0KW and circuit breakers (230/208 V) or pull disconnects (460 V) applications, insert 0Z in the KW field of model number.

WA 70 1 – B 09 X X X X X J

VENTILATION OPTIONS

X – Barometric Fresh Air Damper

KW

00 – No KW

0Z – No KW

w/Circuit

Breaker

or Pull

Disconnect

05 – 5 KW

09 – 9 KW

10 – 10 KW

15 – 15 KW

18 – 18 KW

(Standard)

B – Blank-off Plate

M – Motorized Fresh Air Damper

V – Commercial Room V entilator -

Motorized with Exhaust

E – Economizer (Internal) - Fully

Modulating with Exhaust

R – Energy Recovery V entilator -

with Exhaust

FILTER OPTIONS

X – One Inch Throwaway

W – One Inch Washable

P – Two Inch Pleated

COLOR OPTIONS

X – Beige

(Standard)

1 – White

(Standard)

COIL OPTIONS

X – Standard

1 – Phenolic Coated Evaporator

2 – Phenolic Coated Condenser

3 – Phenolic Coated Evaporator

CONTROL MODULES

J – Standard on all

Models

and Condenser

OUTLET OPTIONS

X – Front (Standard)

TABLE 1

ELECTRIC HEAT TABLE

sledoM

1-V0421-V8023-V0423-V8023-V064

WKSPMAHUTBSPMAHUTBSPMAHUTBSPMAHUTBSPMAHUTB

0.5

0.8

0.9

0.01

8.02004,811.81001,41------------------

3.33006,828.82008,12------------------

------------7.12009,137.81053,428.01000,23

6.14054,532.63009,62------------------

A-116AWB-116AWC-116AW

sledoM

1-V0421-V8023-V0423-V8023-V064

WKSPMAHUTBSPMAHUTBSPMAHUTBSPMAHUTBSPMAHUTB

0.5

0.9

0.01

0.51

0.81

0.02

8.02050,711.81008,21------------------

------------7.12006,037.81030,328.01007,03

6.14031,432.63006,52------------------

5.26002,151.45004,832.63002,152.13004,833.71000,74

------------3.34034,165.73001,64------

2.38062,861.27002,15------------------

A-207AW

B-107AW

B-127AW

Manual 2100-425

Page 2

C-107AW

C-127AW

TABLE 2

DIMENSIONS OF BASIC UNIT FOR ARCHITECTURAL AND INSTALLATION REQUIREMENTS (Nominal)

htdiW

tinU

W

116AW

07AW

244/1-228/7-498/7-98/7-928/7-518/7-928/7-34918/5-140361/11-24734/3-442/1-244/1-3348/7-3301

127AW

All dimensions in inches.

htpeD

D

thgieH

H

ylppuSnruteR

EFGI J KL MNOPQABCB

FIGURE 1

UNIT DIMENSIONS

Manual 2100-425

Page 3

MIS-764

Manual 2100-425

Page 4

SLEDOMdetaR

Z0A,00A-116AW

50A80A01A-

Z0B,00B-116AW

90B-

Z0C,00C-116AW

90C-

Z0A,00A-207AW

50A01A51A02A-

Z0B,00B-107AW

90B51B81B-

Z0C,00C-107AW

90C51C-

Z0B,00B-127AW

90B51B81B-

Z0C,00C-127AW

90C51C-

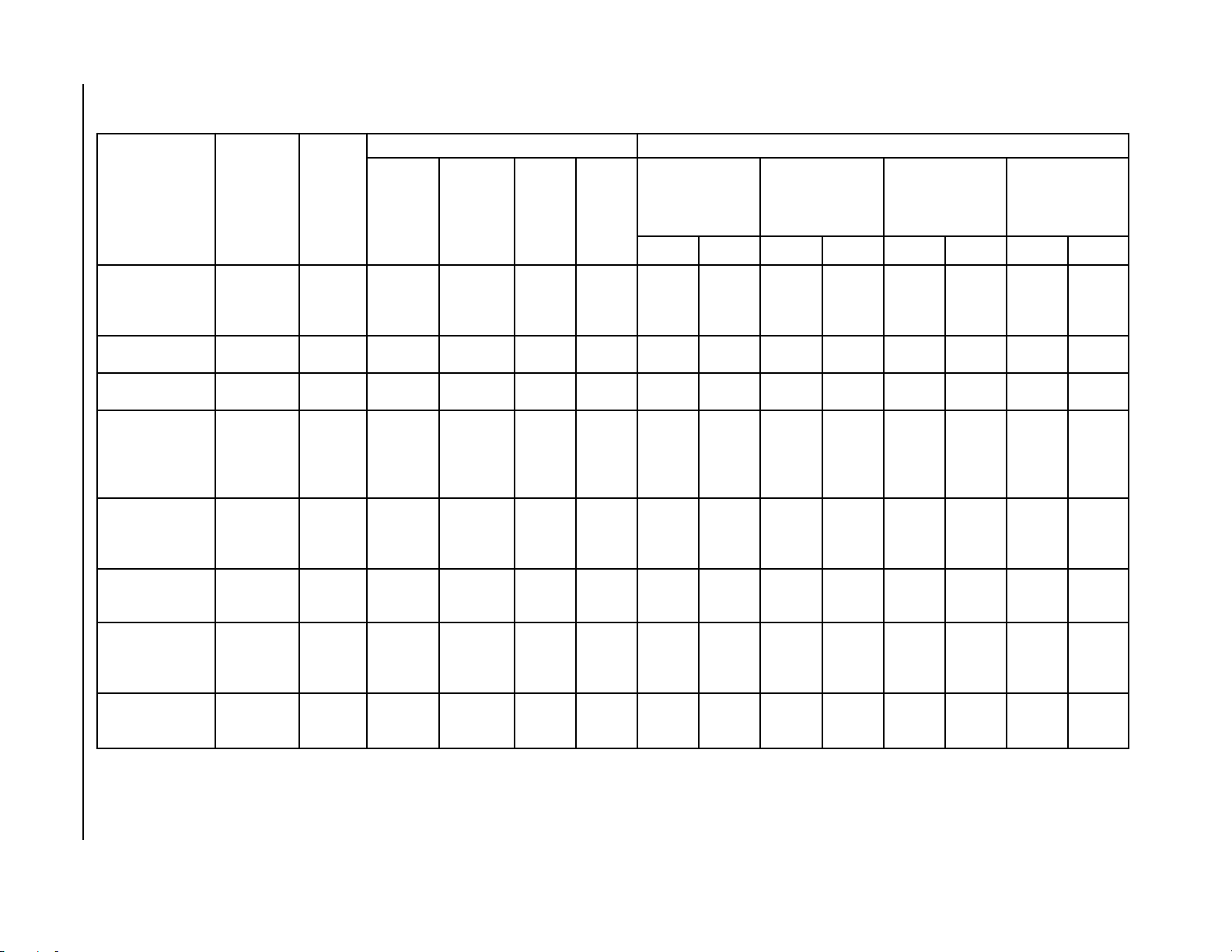

TABLE 3

ELECTRICAL SPECIFICATIONS

TIUCRICELGNIS TIUCRICLAUD

3

fo.oN

rewoP

stiucriC

1

1-802/302

3-802/032

3-064

1-802/302

3-802/032

3-064

3-802/032

3-064

1

1

1

1

1

1

1

1

1

1

2ro1

2ro1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

muminiM

tiucriC

34

34

74

85

92

33

51

71

84

84

95

58

011

63

63

25

06

71

71

62

63

63

25

06

71

71

62

1

revO

yticapmA

05

05

06

06

54

54

02

02

06

06

06

09

011

05

05

06

06

52

52

03

05

05

06

06

52

52

03

2

mumixaM

dleiF

tnerruC

noitcetorP

eriW

eziS

8

8

8

6

8

8

21

21

8

8

6

4

2

8

8

6

6

21

21

01

8

8

6

6

21

21

01

2

3

tiucriCmuminiM

dnuorG

eriW

eziS

01

01

01

01

01

01

21

21

01

01

01

8

6

01

01

01

01

21

21

01

01

01

01

01

21

21

01

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

95

95

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

yticapmA

ATKCBTKCATKCBTKCATKCBTKCATKCBTKC

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

62

25

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

1

revOmumixaM

tnerruC

noitcetorP

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

06

06

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

03

06

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

2

eziSeriWdleiF

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

6

6

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

01

6

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

2

eziSeriWdnuorG

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

01

01

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

01

01

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

AN

j

Maximum size of the time delay fuse or HACR type circuit breaker for protection of field wiring conductors.

k

Based on 75°C copper wire. All wiring must conform to the National Electric Code (NEC) and all local codes.

These "Minimum Circuit Ampacity" values are to be used for sizing the field power conductors. Refer to the National Electric Code (latest

l

version), Article 310 for power conductor sizing.

conduit, the conductors must be derated. Pay special attention to Note * of Table 310 regarding Ampacity Adjustment Factors when

more than 3 conductors are in a raceway.

CAUTION: When more than one filed power conductor circuit is run through one

SHIPPING DAMAGE

DUCT WORK

Upon receipt of equipment, the carton should be

checked for external signs of shipping damage. If

damage is found, the receiving party must contact the

last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent.

GENERAL

The equipment covered in this manual is to be

installed by trained, experienced service and

installation technicians.

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct

work. Flanges are provided for attaching the supply

and return ducts.

These instructions explain the recommended method

to install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

air conditioning system should be carefully read

before beginning the installation. Note particularly

“Starting Procedure” and any tags and/or labels

attached to the equipment.

All duct work, supply and return, must be properly

sized for the design air flow requirement of the

equipment. Air Conditioning Contractors of America

(ACCA) is an excellent guide to proper sizing. All

duct work or portions thereof not in the conditioned

space should be properly insulated in order to both

conserve energy and prevent condensation or moisture

damage.

Refer to Table 9 for maximum static pressure available

for duct design.

Design the duct work according to methods given by

the Air Conditioning Contractors of America (ACCA).

When duct runs through unheated spaces, it should be

insulated with a minimum of 1 inch of insulation. Use

insulation with a vapor barrier on the outside of the

insulation. Flexible joints should be used to connect

the duct work to the equipment in order to keep the

noise transmission to a minimum.

A 1/4 inch clearance to combustible material for the

first three feet of duct attached to the outlet air frame is

required. See Wall Mounting Instructions and Figures

4 and 5 for further details.

Ducts through the walls must be insulated and all

joints taped or sealed to prevent air or moisture

entering the wall cavity.

While these instructions are intended as a general

recommended guide, they do not supersede any

national and/or local codes in any way. Authorities

having jurisdiction should be consulted before the

installation is made. See Page 1 for information on

codes and standards.

Size of unit for a proposed installation should be based

on heat loss calculation made according to methods of

Air Conditioning Contractors of America (ACCA).

The air duct should be installed in accordance with the

Standards of the National Fire Protection Association

for the Installation of Air Conditioning and

Ventilating Systems of Other Than Residence Type,

NFPA No. 90A, and Residence Type Warm Air

Heating and Air Conditioning Systems, NFPA No.

90B. Where local regulations are at a variance with

instructions, installer should adhere to local codes.

CAUTION

Some installations may not require any return

air duct. A metallic return air grille is required

with installations not requiring a return air

duct. The spacing between louvers on the

grille shall not be larger than 5/8 inches.

Any grille that meets the 5/8 inch louver criteria, may

be used. It is recommended that Bard Return Air Grille

Kit RG-2 thru RG-5 or RFG-2 thru RFG-5 be installed

when no return duct is used. Contact distributor or

factory for ordering information. If using a return air

filter grille, filters must be of sufficient size to allow a

maximum velocity of 400 fpm.

NOTE: If no return air duct is used, applicable

installation codes may limit this cabinet to

installation only in a single story structure.

Manual 2100-425

Page 5

FILTERS

A 1 inch throwaway filter is supplied with each unit.

The filter slides into position making it easy to service.

This filter can be serviced from the outside by

removing the service door. A 1 inch washable filter

and 2 inch pleated filter are also available as optional

accessories. The internal filter brackets are adjustable

to accommodate the 2 inch filter by bending down the

tabs to allow spacing for the 2 inch filters.

FRESH AIR INTAKE

All units are built with fresh air inlet slots punched in

the service panel.

If the unit is equipped with the fresh air damper

assembly, the assembly is shipped already attached to

the unit. The damper blade is locked in the closed

position to allow the damper to operate, the maximum

and minium blade position stops must be installed.

See Figure 2.

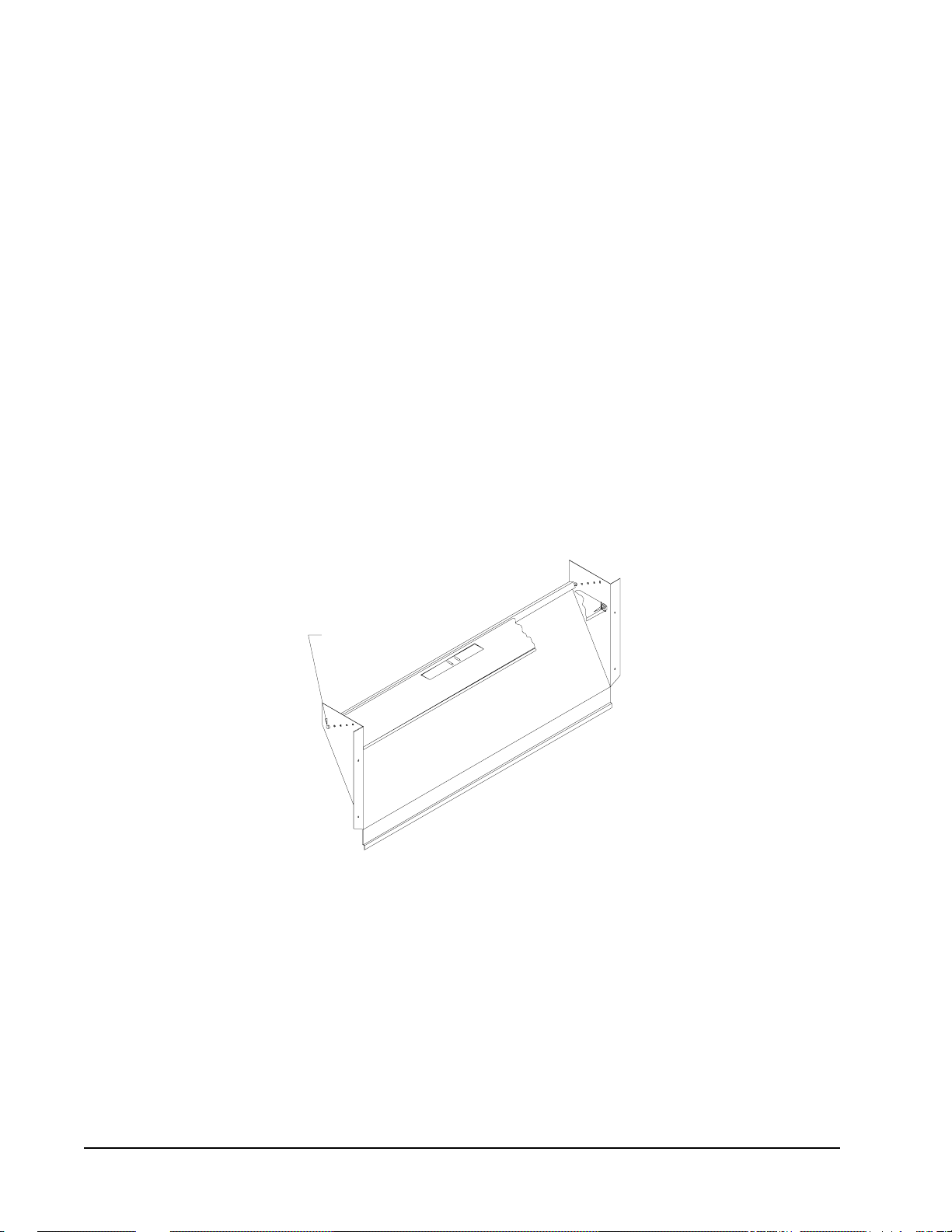

BLOWER DAMPER ASSEMBLY

All capacity, efficiency and cost of operation

information as required for Department of Energy

“Energyguide” Fact Sheets is based upon the fresh air

blank-off plate in place and is recommended for

maximum energy efficiency.

The blank-off plate is available upon request from the

factory and is installed in place of the fresh air damper

shipped with each unit.

CONDENSATE DRAIN

A plastic drain hose extends from the drain pan at the

top of the unit down to the unit base. There are

openings in the unit base for the drain hose to pass

through. In the event the drain hose is connected to a

drain system of some type, it must be an open or

vented type system to assure proper drainage.

FIGURE 2

BLADE IS LOCKED

CLOSED FOR

SHIPPING

MIS-938

Manual 2100-425

Page 6

INST ALLA TION INSTRUCTIONS

WALL MOUNTING INFORMATION

1. Two holes, for the supply and return air openings,

must be cut through the wall as shown in Figure 3.

2. On wood-frame walls, the wall construction must

be strong and rigid enough to carry the weight of

the unit without transmitting any unit vibration.

See Figures 4 and 5.

WARNING

Fire hazard can result if 1/4 inch clearance to

combustible materials for supply air duct is

not maintained. See Figure 3.

3. Concrete block walls must be thoroughly inspected

to insure that they are capable of carrying the

weight of the installing unit. See Figure 4.

MOUNTING THE UNIT

1. These units are secured by wall mounting brackets

which secure the unit to the outside wall surface at

both sides. A bottom mounting bracket is provided

for ease of installation.

2. The unit itself is suitable for “0” inch clearance,

but the supply air duct flange and the first 3 feet of

supply air duct require a minimum of 1/4 inch

clearance to combustible material. If a combustible

wall, use a minimum of 30-1/2" x 10-1/2"

dimensions for sizing. However, it is generally

recommended that a 1 inch clearance is used for

ease of installation and maintaining the required

clearance to combustible material. The supply air

opening would then be 32" x 12". See

Figures 3, 4 and 7 for details.

WARNING

Failure to provide the 1/4 inch clearance

between the supply duct and a combustible

surface for the first 3 feet of duct can result in

fire.

3. Locate and mark lag bolt locations and bottom

mounting bracket location. See Figure 4.

4. Mount bottom mounting bracket.

5. Hook top rain flashing under back bend of top.

Top rain flashing is shipped secured to the right

side of the back.

6. Position unit in opening and secure with 5/16 lag

bolts; use 7/8 inch diameter flat washers on the lag

bolts.

7. Secure rain flashing to wall and caulk across entire

length of top. See Figure 3.

8. For additional mounting rigidity, the return air and

supply air frames or collars can be drilled and

screwed or welded to the structural wall itself

(depending upon wall construction). Be sure to

observe required clearance if combustible wall.

9. On side by side installations, maintain a minimum

of 20 inches clearance on right side to allow access

to heat strips and control panel and to allow proper

airflow to the outdoor coil. Additional clearance

may be required to meet local or national codes.

TYPICAL INSTALLATIONS

See Figure 6 for common ways to install the wallmount unit.

WIRING — MAIN POWER

Refer to the unit rating plate for wire sizing

information and maximum fuse or “HACR" type

circuit breaker size. Each outdoor unit is marked with

a “Minimum Circuit Ampacity”. This means that the

field wiring used must be sized to carry that amount of

current. Depending on the installed KW of electric

heat, there may be two field power circuits required. If

this is the case, the unit serial plate will so indicate. All

models are suitable only for connection with copper

wire. Each unit and/or wiring diagram will be marked

“Use Copper Conductors Only”. These instructions

must be adhered to. Refer to the National Electrical

Code (NEC) for complete current carrying capacity

data on the various insulation grades of wiring

material. All wiring must conform to NEC and all

local codes.

The electrical data lists fuse and wire sizes (75ºC

copper) for all models, including the most commonly

used heater sizes. Also shown are the number of field

power circuits required for the various models with

heaters.

Manual 2100-425

Page 7

The unit rating plate lists a “Maximum Time Delay

Relay Fuse” or “HACR" type circuit breaker that is to

be used with the equipment. The correct size must be

used for proper circuit protection and also to assure

that there will be no nuisance tripping due to the

momentary high starting current of the compressor

motor.

The disconnect access door on this unit may be locked

to prevent unauthorized access to the disconnect. To

MOUNTING INSTRUCTIONS

convert for the locking capability, bend the tab located

in the bottom left hand corner of the disconnect

opening under the disconnect access panel straight

out. This tab will now line up with the slot in the door.

When shut, a padlock may be placed through the hole

in the tab preventing entry.

See Start-up section for information on three phase

scroll compressor start-ups.

FIGURE 3

NOTE: It is recommended that a bead of silicone

caulking be placed behind the side mounting

flanges and under the top flashing at the

time of installation.

Manual 2100-425

Page 8

MIS-796

WIRING — LOW VOLTAGE WIRING

230/208V, 1 phase and 3 phase equipment dual

primary voltage transformers. All equipment leaves

the factory wired on 240V tap. For 208V operation,

reconnect from 240V to 208V tap. The acceptable

operating voltage range for the 240 and 208V taps are

shown in Table 4 below.

TABLE 4

OPERATING VOLTAGE RANGE

PATEGNAR

V042612-352

V802781-022

THERMOSTAT WIRE SIZE

remrofsnarT

AVALFeguaGeriW

553.2

NOTE: The voltage should be measured at the field

Five (5) wires should be run from thermostat subbase

to the 24V terminal board in the unit. A five

conductor, 18 gauge copper, color-coded thermostat

cable is recommended. The connection points are

shown in Figure 8.

TABLE 5

power connection point in the unit and while

the unit is operating at full load (maximum

amperage operating condition).

mumixaM

ecnatsiD

teeFnI

eguag02

eguag81

eguag61

eguag41

eguag21

54

06

001

061

052

TABLE 6

WALL THERMOSTAT AND SUBBASE COMBINATIONS

tatsomrehTesabbuSserutaeFetanimoderP

200-3048

1113F78T

140-3048

C4308T

910-3048

0671C478T

120-3048

4391D478T

940-3048

083-39F1

340-3048

002-MC

300-4048

0221A935Q

---loocegats1,taehegats1

210-4048

1001A476Q

210-4048

1001A476Q

---taehegats2,loocegats2

---

loocegats1,taehegats1

no-otua:naFlooc-ffo-taeh:metsyS

no-otua:naFlooc-ffo-taeh:metsyS

taehegats2,loocegats1

taehegats2,loocegats2

gnimmargorpyad7cinortcelE

loocegats1,taehegats1

no-otua:naFlooc-otua-taeh:metsyS

no-otua:naFlooc-otua-taeh:metsyS

no-otua:naFlooc-ffo-taeh:metsyS

Manual 2100-425

Page 9

FIGURE 4

WALL-MOUNTING INSTRUCTIONS

SEE FIGURE 3 —MOUNTING INSTRUCTIONS

FIGURE 5

WALL-MOUNTING INSTRUCTIONS

SEE UNIT DIMENSIONS, FIGURE 1,

FOR ACTUAL DIMENSIONS

MIS-548

SEE FIGURE 1 FOR

DUCT DIMENSIONS

Manual 2100-425

Page 10

MIS-549

FIGURE 6

COMMON WALL-MOUNTING INSTALLATIONS

MIS-550

Manual 2100-425

Page 11

MIS-277

FIGURE 7

ELECTRIC HEAT CLEARANCE

Side section view of supply air duct for

wall mounted unit showing 1/4 inch

clearance to combustible surfaces.

WARNING

• A minimum of 1/4 inch clearance must be maintained between

the supply air duct and combustible materials. This is required

for the first 3 feet of ducting.

• It is important to insure that the 1/4 inch minimum spacing is

maintained at all points.

• Failure to do this could result in overheating the combustible

material and may result in fire.

Manual 2100-425

Page 12

FIGURE 8

LOW VOLTAGE WIRING

Manual 2100-425

Page 13

START UP

IMPORTANT INSTALLER NOTE

For improved start-up performance, wash the indoor

coil with a dishwasher detergent.

CRANKCASE HEATERS

WA611, WA70 and WA721 units are provided with

compressor crankcase heat.

The WA611, WA70 and WA721 models have a band

type heater located around the bottom of the

compressor. This heater is controlled by the crankcase

heater relay. The heater is only energized when the

compressor is not running.

Some form of crankcase heat is essential to prevent

liquid refrigerant from migrating to the compressor,

casing oil pump out on compressor start-up and

possible valve failure due to compressing a liquid.

The decal in Figure 9 is affixed to all WA611, WA70

and WA721 units detailing start-up procedure. This is

very important. Please read carefully.

FIGURE 9

START-UP LABEL

IMPORTANT

These procedures must be followed at

initial start-up and at any time power

has been removed for 12 hours or

longer.

To prevent compressor damage which may

result from the presence of liquid

refrigerant in the compressor crankcase.

1. Make certain the room thermostat is in

the "off" position (the compressor is

not to operate).

2. Apply power by closing the system

disconnect switch. This energizes the

compressor heater which evaporates

the liquid refrigerant in the crankcase.

3. Allow 4 hours or 60 minutes per pound

of refrigerant in the system as noted

on the unit rating plate, whichever is

greater.

4. After properly elapsed time, the

thermostat may be set to operate the

compressor.

5. Except as required for safety while

servicing – Do not open system

disconnect switch.

7961-061

HIGH PRESSURE SWITCH

The WA611, WA70 and WA721 models are supplied

with a remote reset high pressure switch. If tripped,

this pressure switch may be reset by turning the

thermostat off then back on again.

THREE PHASE SCROLL COMPRESSOR

START UP INFORMATION

Scroll compressors, like several other types of

compressors, will only compress in one rotational

direction. Direction of rotation is not an issue with

single phase compressors since they will always start

and run in the proper direction.

However, three phase compressors will rotate in either

direction depending upon phasing of the power. Since

there is a 50-50 chance of connecting power in such a

way as to cause rotation in the reverse direction,

verification of proper rotation must be made. All three

phase units incorporate a phase monitor to ensure

proper field wiring. See the Phase Monitor" section

later in this manual.

Verification of proper rotation must be made any time

a compressor is change or rewired. If improper

rotation is corrected at this time there will be no

negative impact on the durability of the compressor.

However, reverse operation for over one hour may

have a negative impact on the bearing due to oil pump

out.

NOTE: If compressor is allowed to run in reverse

rotation for several minutes, the

compressor's internal protector will trip.

All three phase ZR3 compressors are wired identically

internally. As a result, once the correct phasing is

determined for a specific system or installation,

connecting properly phased power leads to the same

Fusite terminal should maintain proper rotation

direction.

Verification of proper rotation direction is made by

observing that suction pressure drops and discharge

pressure rises when the compressor is energized.

Reverse rotation also results in an elevated sound level

over that with correct rotations, as well as,

substantially reduced current draw compared to

tabulated values.

The direction of rotation of the compressor may be

changed by reversing any two line connections to the

unit.

Manual 2100-425

Page 14

SERVICE HINTS

1. Caution homeowner to maintain clean air filters at

all times. Also, not to needlessly close off supply

and return air registers. This reduces air flow

through the system, which shortens equipment

service life as well as increasing operating costs.

2. Check all power fuses or circuit breakers to be sure

they are the correct rating.

3. Periodic cleaning of the outdoor coil to permit full

and unrestricted airflow circulation is essential.

SEQUENCE OF OPERATION

During routine operation of the unit with no power

interruptions the compressor will operate on demand

with no delay.

High Pressure Switch and Lockout Sequence

If the high pressure switch opens, the compressor

contactor will de-energize immediately. The lockout

timer will go into a soft lockout and stay in soft

lockout until the high pressure switch closes and the

delay on break time has expired. If the high pressure

switch opens again in this same operating cycle the

unit will go into manual lockout condition and the

alarm relay circuit will energize. Recycling the wall

thermostat resets the manual lockout.

COOLING – Circuit R-Y makes at thermostat pulling

in compressor contactor, starting the compressor and

outdoor motor. The G (indoor motor) circuit is

automatically completed on any call for cooling

operation or can be energized by manual fan switch on

subbase for constant air circulation. On all 208/230

volt models, when G circuit is de-energized the indoor

blower motor will continue to run for one minute. On

a call for heating, circuit R-W1 make at the thermostat

pulling in heat contact for the strip heat and blower

operation. On a call for second stage heat, R-W2

makes bringing on second heat contactor, if so

equipped.

COMPRESSOR CONTROL MODULE

The compressor control module is standard on the

models covered by this manual. The compressor

control is an anti-short cycle/lockout timer with high

and low pressure switch monitoring and alarm relay

output.

Adjustable Delay On Make And Break Timer

On initial power up or any time power is interrupted to

the unit the delay on make period begins which will

be 2 minutes plus 10% of the delay on break setting.

When the delay on make is complete and the high

pressure switch (and low pressure switch if employed)

is closed, the compressor contactor is energized.

Upon shutdown the delay or break timer starts and

prevents restart until the delay on break and delay on

make periods have expired.

Low Pressure Switch, Bypass, and Lockout

Sequence

If the low pressure switch opens for more than 120

seconds, the compressor contactor will de-energize

and go into a soft lockout. Regardless the state of the

low pressure switch, the contactor will reenergize after

the delay on make time delay has expired. If the low

pressure switch remains open, or opens again for

longer than 120 seconds the unit will go into manual

lockout condition and the alarm relay circuit will

energize. Recycling the wall thermostat resets the

manual lockout.

Alarm Relay Output

Alarm terminal is output connection for applications

where alarm relay is employed. This terminal is

powered whenever compressor is locked out due to

HPC or LPC sequences as described.

NOTE: Both high and low pressure switch controls

are inherently automatic reset devices. The

high pressure switch and low pressure

switch cut out and cut in settings are fixed by

specific air conditioner or heat pump unit

model. The lockout features, both soft and

manual, are a function of the Compressor

Control Module.

Manual 2100-425

Page 15

ADJUSTMENTS

PHASE MONITOR

Adjustable Delay on Make and Delay on Break

Timer

The potentiometer is used to select Delay on Break

time from 30 seconds to 5 minutes. Delay on Make

(DOM) timing on power-up and after power

interruptions is equal to 2 minutes plus 10% of Delay

on Break (DOB) setting:

0.5 minute (30 seconds) DO B =123 second DOM

1.0 minute (60 seconds) DO B =126 second DOM

2.0 minute (120 seconds)DOB =132 second DOM

3.0 minute (180 seconds)DOB =138 second DOM

4.0 minute (240 seconds)DOB =144 second DOM

5.0 minute (300 seconds)DOB =150 second DOM

During routine operation of the unit with no power

interruptions the compressor will operate on demand

with no delay.

Typical Settings for Dual Unit Installation:

Unit 1: DOB set at 2 minutes, and DOM is 132 seconds

Unit 2: DOB set at 4 minutes, and DOM is 144 seconds

All units with three phase scroll compressors are

equipped with a 3 phase line monitor to prevent

compressor damage due to phase reversal.

The phase monitor in this unit is equipped with two

LEDs. If the Y signal is present at the phase monitor

and phases are correct the green LED will light.

If phases are reversed, the red fault LED will be lit and

compressor operation is inhibited.

If a fault condition occurs, reverse two of the supply

leads to the unit. Do not reverse any of the unit

factory wires as damage may occur.

PRESSURE SERVICE PORTS

High and low pressure service ports are installed on all

units so that the system operating pressures can be

observed. Pressure tables can be found later in the

manual covering all models. It is imperative to match

the correct pressure table to the unit by model number.

Manual 2100-425

Page 16

TROUBLESHOOTING

FAN BLADE SETTING DIMENSIONS

Shown in the drawing below are the correct fan blade

setting dimensions for proper air delivery across the

outdoor coil.

Any service work requiring removal or adjustment in

the fan and/or motor area will require that the

dimensions below be checked and blade adjusted in or

out on the motor shaft accordingly.

FIGURE 10

FAN BLADE SETTING

TABLE 7

FAN BLADE DIMENSIONS

ledoMAnoisnemiD

116AW

07AW

127AW

52.1

57.

REMOVAL OF FAN SHROUD

1. Disconnect all power to unit.

2. Remove the screws holding both grills – one on

each side of unit – and remove grills.

3. Remove screws holding fan shroud to condenser

and bottom – (9) screws.

4. Unwire condenser fan motor.

5. Slide complete motor, fan blade, and shroud

assembly out the left side of the unit.

6. Service motor/fan as needed.

7. Reverse steps to reinstall.

REFRIGERANT CHARGE

The correct system R-22 charge is shown on the unit

rating plate. Optimum unit performance will occur

with a refrigerant charge resulting in a suction line

temperature (6 inches from compressor) as shown in

Table 8:

TABLE 8

SUCTION LINE TEMPERATURES

sledoM

116AW

07AW

127AW

detaR

wolfriA

053,145-2506-75

008,106-8585-65

008,116-9595-75

The suction line temperatures in Table 8 are based

upon 80ºF dry bulb / 67ºF wet bulb (50 percent R.H.)

temperature and rated airflow across the evaporator

during cooling cycle.

TABLE 9

CFM and ESP

1

detaR

ledoM

116AW053,102.001,1--574,1

07AW008,102.573,1--000,2

127AW008,102.574,1--000,2

detaR

MFC

1

F°59

.pmeTDO

detaR

PSE

F°28

wolFriA

egnaR

.pmeTDO

dednemmoceR

Rated CFM and ESP on high speed tap.

Q

TABLE 10

INDOOR BLOWER PERFORMANCE – CFM AT 230 VOLTS

116AW

.P.S.E

HnI2O

0.007,1575,1524,1573,1002,2000,2006,1054,1

1.055,1574,1573,1052,1001,2009,1525,1573,1

2.004,1053,1052,1001,1000,2008,1------

3.052,1051,1001,1---578,1007,1------

4.------------577,1006,1------

5.------------056,1574,1------

deepShgiHdeepSmuideM

lioCyrDlioCteWlioCyrDlioCteWlioCyrDlioCteWlioCyrDlioCteW

1

deepShgiHdeepSwoL

07AW

127AW

j This model has 3-speed motor, but low speed cannot be used.

Manual 2100-425

Page 17

TABLE 11

MAXIMUM ESP OF OPERATION

ELECTRIC HEAT ONLY

ledoM116AW07AW127AW

deepS

WK

50A80A01A02A-

90B51B81B-

90C51C-

muideM

deepS

03.

03.

03.

03.

03.

---

---

03.

---

hgiH

deepS

03.

03.

03.

03.

03.

---

---

03.

---

woL

deepS

05.

---

05.

04.

05.

05.

05.

05.

05.

hgiH

deepS

05.

---

05.

05.

05.

05.

05.

05.

05.

woL

deepS

---

---

---

---

05.

05.

05.

---

---

hgiH

deepS

---

---

---

---

05.

05.

05.

---

---

TABLE 12

COOLING PRESSURE – (All temperatures °F)

nruteR

riA

ledoM

C-,B-.A-116AW

A-207AW

C-,B-107AW

127AW

.pmeTerusserP5708580959001501011511

BD57

BW26

BD08

BW76

BD58

BW27

BD57

BW26

BD08

BW76

BD58

BW27

BD57

BW26

BD08

BW76

BD58

BW27

BD57

BW26

BD08

BW76

BD58

BW27

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

27

732

77

342

08

252

86

512

37

022

67

822

26

412

76

022

27

522

36

502

86

112

37

612

27

732

77

342

08

252

86

822

37

432

67

242

36

032

86

632

37

342

46

222

96

722

47

432

37

042

87

642

18

552

96

242

47

842

77

752

46

742

96

452

47

162

56

732

07

442

57

152

47

742

97

352

28

262

07

652

57

362

87

272

56

562

07

172

57

972

66

452

17

162

67

862

57

652

08

362

38

272

17

272

67

972

97

982

66

082

17

782

67

792

76

862

27

572

77

582

67

962

18

672

48

682

27

982

77

692

08

603

76

992

27

603

77

613

86

682

37

492

87

303

77

682

28

392

58

303

37

503

87

313

18

423

86

613

37

423

87

533

96

203

47

013

97

123

97

403

48

213

78

323

47

423

97

233

28

443

96

333

47

243

97

353

07

813

57

723

08

933

97

723

58

533

88

743

57

343

08

253

38

463

07

153

57

063

08

273

17

633

67

543

18

753

Low side pressure ± 2 psig

High side pressure ± 5 psig

Tables are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct operating

charge being in the system, the charge should be removed, system evacuated and recharged to serial plate instruction.

Manual 2100-425

Page 18

TABLE 13

OPTIONAL ACCESSORIES

WA611-A

WA611-B

WA611-C

WA702-A

WA701-B

WA701-C, WA721-C

LEDOMNOITPIRCSED

50A-50AWHEegakcaPretaeHX

01A-01AWHEegakcaPretaeHX

51A-51AWHEegakcaPretaeHX

02A-02AWHEegakcaPretaeHX

90B-06AWHEegakcaPretaeHXX

51B-50AWHEegakcaPretaeHXX

81B-50AWHEegakcaPretaeHXX

90C-A50AWHEegakcaPretaeHXX

51C-A50AWHEegakcaPretaeH X

50A-16AWHEegakcaPretaeHX

01A-16AWHEegakcaPretaeHX

80A-16AWHEegakcaPretaeHX

90B-16AWHEegakcaPretaeHX

5-POBetalPffOknalB XXXXXXX

5-DAFBrepmaDriAhserFcirtemoraB XXXXXXX

5-DAFMrepmaDriAhserFdezirotoM XXXXXXX

5-VRCtsuahxEhtiwrotalitneVmoorssalC XXXXXXX

5-MFIEtsuahxEhtiwrezimonocE XX XXXX

A5A-VREWrotalitneVyrevoceRygrenEXXX

A5C-VREWrotalitneVyrevoceRygrenEXX

C10-DPMWtiKtcennocsiDlluPXX

WA721-B

Manual 2100-425

Page 19

Loading...

Loading...