Page 1

PA13-SERIES PACKAGED AIR CONDITIONERS

Cooling Capacities: 23,000 to 56,000

SEER: 13.0

GREEN REFRIGERANT R-410A

BACK (OUTDOOR AIRFLOW) END OF UNIT

FRONT (INDOOR AIRFLOW) END OF UNIT

Standard Engineered Features

Air Conditioner Compressor:

Reciprocating compressors with

crankcase heaters are standard on 2,

2½ and 3-ton models. Scroll

compressors are used on all other

models and no crankcase heaters

are required.

R-410A Refrigerant:

Designed with R-410A (HFC) nonozone depleting refrigerant in

compliance with the Montreal protocol

and 2010 EPA requirements.

ECM Indoor Blower Motor:

Features an electronically commutated

motor providing super-high efficiency,

low sound levels and soft-start

capabilities. The motor is selfadjusting to provide the proper airflow

rate for a broad range of static

pressure in ducted installations without

user adjustment or wiring changes.

Aluminum Finned Copper Coils:

Grooved tubing and enhanced

louvered fin for maximum heat

transfer and energy efficiency.

Outdoor coil is constructed with

special corrosion resistant

hydrophilic fin stock with 2-layer

coating. (1st layer - blue acrylic

primer; 2nd layer - clear topcoat.)

Thermal Expansion Valves:

Models with reciprocating

compressors have bleed TXV,

models with scroll compressor have

non-bleed TXV.

Discharge Muffler:

Standard on 2½ and 3-ton models.

Liquid Line Filter Drier:

Protects system against moisture.

Compressor Control Module:

Built-in off-delay timer adjustable from

30 seconds to 5 minutes. 2-minute

on-delay if power interrupt. 120second bypass for low pressure

control, and both soft and manual

lockouts for high and low pressure

controls. Alarm output for alarm relay.

Phase Rotation Monitor:

Standard on all 3-phase models.

Protects against reverse rotation if

power supply is not properly

connected.

High & Low Pressure Switches are

Auto-Reset

Built-in lockout circuit resets from the

room thermostat. Provides commercial

quality protection to the compressor.

Pre-Painted 20 Gauge Zinc Coated

Steel Cabinet:

Cleaned, rinsed, sealed and dried

before the polyurethane primer is

applied. The cabinet is handsomely

finished with a baked on textured

enamel, which allows it to withstand

1000 hours of salt spray tests per

ASTM B117-03.

Pre-Painted 16 Gauge Zinc Coated

Unit Base:

The unit base is treated with the

same paint coatings as the cabinet

above, insuring years of service.

Top Discharge Outdoor Fan:

Efficiently moves air quietly for

effective heat exchange.

Electrical Components & Controls:

Readily accessible for easier service.

Field Installed Accessories

Optional Field Installed Electric Heat

Strips:

With automatic limit and thermal cutoff.

• Field installed heater package for all

models.

• Features slide-in field assembly with

various BTUH outputs.

• Permits stocking of only one unit.

Optional Field Installed Low Ambient

Control:

Cycles outdoor fan motor below 55°F

outdoor temperature to maintain acceptable

condensing pressure.

• Intertek ETL Listed to Standard for Safety Heating

and Cooling Equipment ANSI/UL 1995/CSA 22.2

No. 236-05, Third Edition.

Form No. S3383-1112

Supersedes S3383-510

Page 1 of 8

Page 2

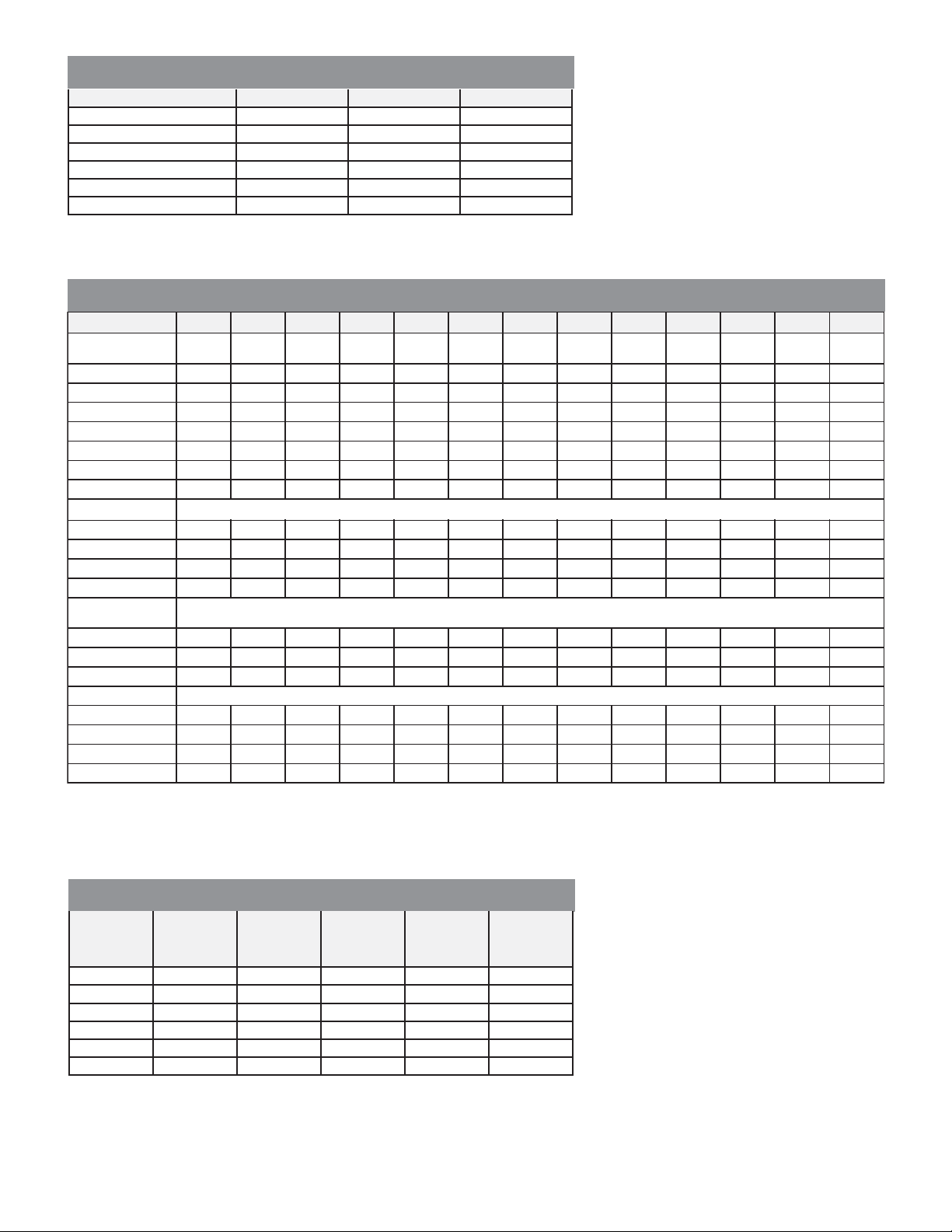

Cooling Capacities and Efficiency Ratings

SLEDOM esahP HUTB REES

A-24231AP1000,3200.31

A-20331AP1000,9200.31

B-,A-26331AP3dna1000,4300.31

C-,B-,A-22431AP3dna1000,3405.31

C-,B-,A-28431AP3dna1005,6400.31

C-,B-,A-20631AP3dna1000,6500.31

Tested and Certified in accordance with ARI Standard 210/240-2003.

General Specifications

ledoM A-24231AP A-20331AP A-26331AP B-26331AP A-22431AP B-22431AP C-22431AP A-28431AP B-28431AP C-28431AP A-20631AP B-20631AP C-20631AP

–gnitaRcirtcelE

AtiucriC–zH06

egnaRegatloVgnitarepO352-791352-791352-791352-781352-791352-781605-414352-791352-781605-414352-791352-781605-414

yticapmAtiucriCmuminiM 4 51814261333221339241936271

CSCB9

eziSeriWdleiF 3 21018210101418012180101

eziSeriWdnuorG21018

.xaM–esuFyaleD 2 02525302055351050402060452

802/032–spmAtinulatoT8.11/8.018.41/3.314.81/4.613.31/0.711.81/2.614.51/1.414.017.42/0.320.81/9.617.019.82/3.529.91/7.719.11

AtiucriC–rosserpmoC

epyTrosserpmoC.piceR.piceR.piceR.piceRllorcSllorcSllorcSllorcSllorcSllorcSllorcSllorcSllorcS

stloV802/032802/032802/032802/032802/032802/032064802/032802/032064802/032802/032064

spmAdaoLdetaR5.8/5.711/5.941/219.8/6.77.31/8.116.9/3.87.77.81/7121/9.017.79.22/3.919.31/7.116.8

spmArotoRkcoL84/8475/7547/4757/57511/511511/51105711/7111.38/1.3805431/431011/01125

dnarotoMnaF

resnednoC

PH–rotoMnaF528-6/1528-6/1528-6/1528-6/1528-4/1528-4/1528-4/1528-4/1528-4/1528-4/1528-4/1528-4/1528-4/1

spmArotoMnaF1.11.11.11.15.15.15.15.15.15.15.15.15.1

MFC/.aiD–naF0072/"420062/"420062/"420062/"420043/"420043/"420043/"420043/"420043/"420043/"420043/"420043/"420043/"42

rotaropavEdnarotoM

PH–rotoMrewolB 1 MCE-3/1MCE-2/1MCE-2/1MCE-2/1MCE-2/1MCE-2/1MCE-2/1MCE-4/3MCE-4/3MCE-4/3MCE-4/3MCE-4/3MCE-4/3

spmA–rotoMrewolB2.27.23.33.39.39.39.35.45.45.40.50.50.5

).zo014-R(egrahC5758021021061061061061061061061061061

)sdnuop(thgieWgnippihS063014014014044044094044044094054054005

1 ECM = Electronically Commutated Motor

2 Maximum time delay fuse or HACR type circuit breaker for protection of field wiring devices.

3 Based on

75°C

copper wire. All wiring must conform to the National Electrical Code and all local codes.

4 These “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to National Electric Code (latest revision), Article 310 for power

conductor sizing.

1-06-802/0321-06-802/0321-06-802/0323-06-802/0321-06-802/0323-06-802/0323-06-0641-06-802/0323-06-802/0323-06-0641-06-802/0323-06-802/0323-06-064

115101125182241862619

210101418014180121

Indoor Blower Performance 1

2

LEDOM

detaR

PSE

XAM

PSE

suounitnoC

wolfriA

4231AP01.005.00060080001

0331AP51.005.005700010001

6331AP51.005.052800110011

2431AP02.005.052900410041

8431AP02.005.0520105510571

0631AP02.005.0051105710571

1 Motor will deliver consistent CFM through voltage supply range with no deterioration (197-253V for all 230/208V models).

2 Continuous CFM is the total air being circulated during continuous (manual fan) mode.

3 Will occur automatically with a call for “Y” for cooling mode operation.

4 Will occur automatically with a call for “W1” for heating mode operation.

Form No. S3383-1112

Supersedes S3383-510

Page 2 of 8

3

detaR

gnilooC

MFC

4

detaR

taeHcirtcelE

MFC

Page 3

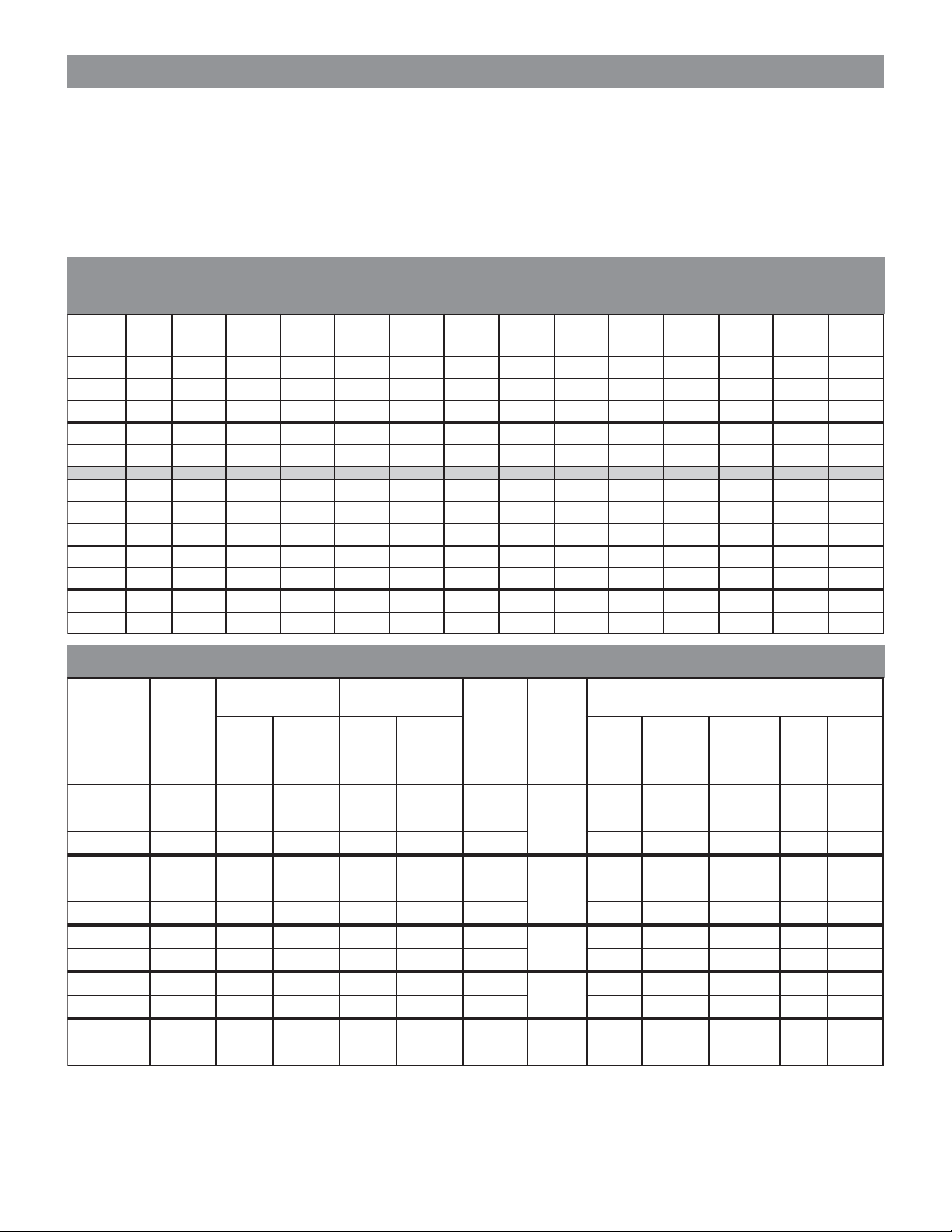

Optional Field Installed Electric Heater Packages

Optional field-installed electric heater packages are available for 5 through 15Kw

capacities. The heater packages are UL listed to be field-installed into the basic unit.

They feature prewired control circuit wiring with plug-in connector. Simply slide the

heater into the unit, plug in the pretested control circuit and connect the separate high

voltage circuit wiring.

IMPORTANT: While this electrical data is presented as a guide, it is important to

electrically connect properly sized fuses and conductor wires in accordance with the

National Electrical Code and all existing local codes.

Optional Field Installed Heater Packages Are Only To Be Used With The Models

As Indicated Below

retaeH

egakcaP

ledoM

&stloV

esahP

50A-323PHE1-802/042 XXX

01A-323PHE1-802/042 XXX

51A-323PHE1-802/042XX

90B-323PHE3-802/042X

51B-323PHE3-802/042X

50A-315PHE1-802/042 XXX

01A-315PHE1-802/042 XXX

51A-315PHE1-802/042 XXX

90B-315PHE3-802/042 XXX

51B-315PHE3-802/042 XXX

90C-315PHE3-064 XXX

51C-315PHE3-064 XXX

A-24231APA-20331APA-26331APB-26331APA-22431APB-22431APC-22431APA-28431APB-28431APC-28431APA-20631APB-20631APC-20631AP

Optional Field Installed Electric Heater Table — 2 through 5 Ton

yticapaC&WK.rtH

retaeH

egakcaP

.oNledoM

tinU

stloV

sesahP

WKHUTBWKHUTB

50A-323PHE1-802/0425

)084(stloV042@

001,7157.3008,211.81/8.02

01A-323PHE1-802/04201001,4305.7000,622.63/6.141

51A-323PHE1-802/04251002,1552.11004,831.45/5.26186/9707/084/48

50A-315PHE1-802/0425

001,7157.3008,211.81/8.02

01A-315PHE1-802/04201001,4305.7000,622.63/6.141

51A-315PHE1-802/04251002,1552.11004,831.45/5.26186/9707/084/48

90B-323PHE3-802/0429007,0357.6000,327.81/7.12

51B-323PHE3-802/04251002,1552.11004,832.13/2.631

90B-315PHE3-802/0429007,0357.6000,327.81/7.12

51B-315PHE3-802/04251002,1552.11004,832.13/2.631

90C-315PHE3-0849 007,038.01

51C-315PHE3-08451002,15811

1 Maximum size of the time delay fuse or HACR circuit breaker for protection of field wiring devices.

2 Based on wire suitable for 75°C. Other wiring materials must be rated for marked “Minimum Circuit Ampacity” or greater. Based on 75°C copper wire. All wiring

must conform to the National Electric Code and all local codes.

3 These “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the National Electric Code (latest revision), Article 310 for

power conductor sizing.

IMPORTANT: While this electrical data is presented as a guide, it is important to electrically connect properly sized fuses and conductor

wires in accordance with the National Electrical Code and all existing local codes.

yticapaC&WK.rtH

stloV802@

V802/042

.rtH

spmA

)084(

retaeH

lanretnI

tiucriC

rekaerB

.oN

dleiF

3

.niM

stiucriC

tiucriC

yticapmA

BtiucriC

1

2

revO.xaM

tnerruC

noitcetorP

2

dleiF

rewoP

gniriW

132/6252/0301/0101

06/03

64/3505/068/601

132/6252/0301/0101

06/03

enoN

enoN

enoN

142/8252/0301/0101

142/8252/0301/0101

141514141

64/3505/068/601

93/6404/058/801

93/6404/058/801

82030121

Form No. S3383-1112

Supersedes S3383-510

Page 3 of 8

dnuorG

eriW

eziS

Page 4

002,51

008,41

000,71

000,51

008,81

052,51

007,91

007,81

009,81

002,91

000,22

003,42

054,61

052,51

002,81

053,51

006,51

004,91

052,02

001,12

056,71

057,51

004,91

007,51

059,51

057,12

055,22

058,81

002,61

000,51

006,02

056,61

001,02

008,12

001,71

003,12

000,32

003,61

002,32

000,42

053,61

006,61

056,42

054,52

007,61

059,61

051,62

058,62

005,91

004,32

050,62

051,02

008,42

050,02

057,72

058,02

002,62

056,02

005,92

006,12

002,12

006,72

002,13

003,22

008,12

000,92

059,23

058,91

001,22

008,91

059,32

004,02

058,52

059,02

057,72

055,12

006,92

051,22

005,13

001,02

007,42

003,72

004,02

004,13

051,82

001,53

005,82

008,83

059,82

002,33

059,92

001,73

003,03

000,14

008,03

007,93

000,23

004,44

004,23

001,94

009,23

009,02

000,12

055,62

059,12

004,82

000,32

003,03

050,42

051,23

050,52

000,43

003,12

055,92

001,33

052,92

007,63

053,92

008,04

008,92

051,53

059,03

001,13

000,93

058,12

058,13

002,22

057,43

003,03

052,83

002,03

058,24

007,03

051,73

000,23

058,04

001,43

001,32

057,22

006,32

053,63

005,42

006,83

004,13

054,63

000,42

051,83

009,42

058,93

001,13

058,93

005,23

004,14

055,33

000,34

055,13

058,44

001,93

050,33

057,24

059,13

058,64

054,23

001,14

050,43

006,44

008,23

058,84

003,33

001,34

001,53

005,64

006,13

004,34

052,24

002,43

008,64

003,43

001,25

058,43

009,13

057,54

004,23

057,44

053,63

052,94

002,63

051,55

008,63

007,23

001,84

002,33

003,74

055,83

056,15

051,83

051,85

007,83

005,33

054,05

620,43

008,94

057,04

001,45

050,04

002,16

056,04

003,43

008,25

058,43

053,25

009,24

059,14

000,65

002,46

006,24

F°erutarepmeTroodtuO

005,71

052,71

004,22

001,42

059,71

005,32

002,52

004,81

055,42

003,62

005,71

003,72

003,82

009,22

054,03

005,22

054,43

008,22

051,82

009,23

054,53

057,72

001,04

001,82

056,14

052,43

058,44

007,33

051,43

057,05

058,44

059,53

003,84

053,53

056,45

058,53

000,45

052,34

051,85

005,24

001,34

008,56

057,71

000,81

054,82

007,92

054,32

058,13

002,32

059,53

005,32

052,13

053,43

058,63

059,03

055,14

053,13

054,34

059,43

056,64

006,43

056,25

050,53

056,64

058,63

001,05

054,63

005,65

009,63

007,55

055,34

008,95

050,34

054,76

006,34

003,81

005,81

006,92

001,13

050,42

003,33

009,32

004,73

002,42

057,53

053,43

003,83

002,43

050,34

006,43

003,54

056,53

005,84

054,53

005,45

009,53

254,84

007,73

058,15

005,73

053,85

059,73

053,75

058,34

004,16

006,34

001,44

050,96

008,81

008,81

056,52

004,72

052,91

057,62

005,82

007,91

009,72

056,92

001,02

000,92

057,03

001,03

006,02

F°55 F°06 F°56 F°07 F°57 F°08 F°58 F°09 F°59 F°001 F°501 F°011 F°511 F°021

yticapaC

gnilooC

2

22

009,13

gnilooCelbisneS

gnilooClatoT

gnilooClatoT

26/57

000,91

057,03

005,23

006,42

007,43

006,42

009,83

058,42

051,73

054,73

007,93

004,73

005,44

008,73

001,74

004,63

003,05

053,63

004,65

057,63

052,05

006,83

056,35

055,83

051,06

059,83

050,95

002,44

051,44

050,36

007,07

056,44

003,91

005,91

059,13

009,33

052,52

001,63

003,52

054,04

055,52

001,04

007,83

002,14

051,04

051,64

055,04

051,73

009,84

001,25

052,73

003,85

006,73

050,25

005,93

054,55

055,93

001,26

059,93

009,06

058,44

058,46

059,44

006,27

054,54

008,91

059,91

051,33

003,53

058,52

055,73

059,52

000,24

002,62

002,04

008,24

007,24

009,24

008,74

053,34

056,05

059,73

001,83

058,35

052,06

054,83

009,35

004,04

052,75

055,04

050,46

059,04

007,26

055,54

056,66

008,54

005,47

002,64

052,02

053,43

054,02

007,63

054,62

059,83

056,62

055,34

058,62

007,14

054,54

052,44

056,54

001,64

004,94

054,25

007,83

056,55

000,93

051,26

053,93

003,14

007,55

057,02

gnilooCelbisneS

76/08

051,83

006,53

009,02

050,72

004,04

003,72

050,54

005,72

051,84

002,34

057,54

004,84

050,15

058,84

052,45

005,93

004,75

009,93

050,46

002,04

055,75

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

27/58

26/57

76/08

27/58

26/57

76/08

27/58

26/57

gnilooCelbisneS

gnilooClatoT

gnilooClatoT

76/08

27/58

006,14

050,95

002,24

058,06

gnilooCelbisneS

gnilooClatoT

26/57

059,14

000,66

055,46

052,64

054,86

006,64

054,67

000,74

006,24

009,76

059,24

004,66

059,64

052,07

054,74

053,87

008,74

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooClatoT

gnilooClatoT

gnilooClatoT

76/08

27/58

26/57

gnilooCelbisneS

gnilooClatoT

76/08

27/58

ledoM .B.W/.B.D 22

Cooling Application Data — Outdoor Temperature 1

Form No. S3383-1112

Supersedes S3383-510

Page 4 of 8

4231AP

0331AP

6331AP

2431AP

8431AP

0631AP

1 Below 55°F, unit requires a field installed low ambient control model CMA-28.

2 Return air temperature °F.

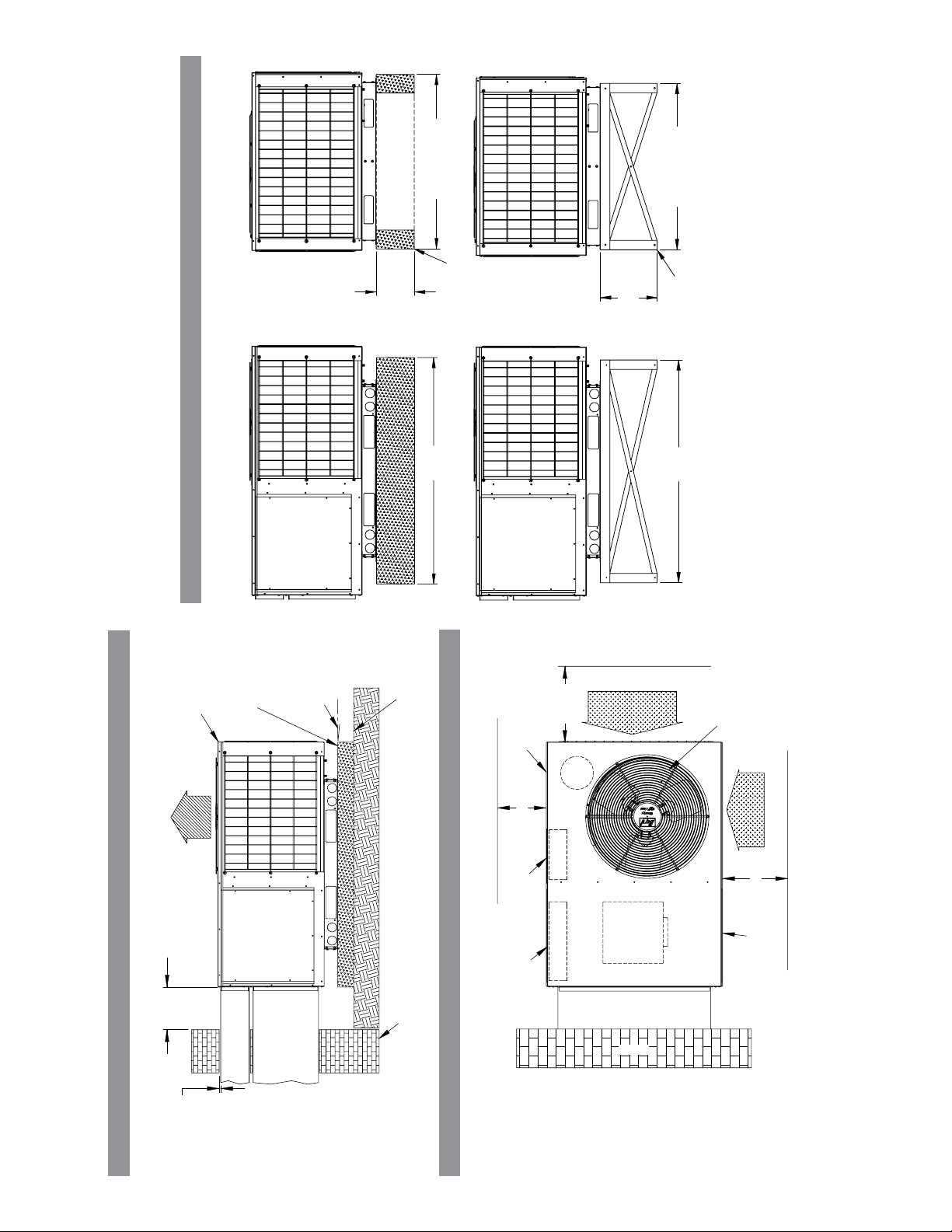

Page 5

Side

Both legs must rest

on surface of platform

32°F or lower climate

12" min. if in

48" min.

48" min.

32°F or lower climate

12" min. if in

on surface of platform

Both legs must rest

Platform can be as

shown or solid

Poured concrete,

brick, or block

Metal frame

MIS-2144 A

Elevated Mounting Platforms (Field Constructed)

View

Package Unit

Air Outlet

1/4 inch per foot

Mounting Slab

slope away

Nearest Structure

Air Inlet

from building

Ground Level

Top

Compressor

View

Access

36" min.

24" min.

ressor

Comp-

Condenser fan

from top.

and motor access

MIS-2143 A

above fan.

Leave 60" min.

Air Inlet

The distance between

requirements.

outside wall and unit

varies with installation

Supply Duct

Return Duct

units only).

material if distance

on electric heat

between outside

wall and unit is less

than 3 feet (needed

any combustible

1 inch clearance

Slab Mounting at Ground Level

between duct and

Nearest Structure

Access

Control Panel

Control Panel

and

Access

Heater Package

Blower

Blower Motor

Nearest Structure

24" min.

Access

Blower Service

Heater Package

Supply and Return Ducts

Building

Building

Airflow & Service Access Clearances

Form No. S3383-1112

Supersedes S3383-510

Page 5 of 8

Page 6

Unit Dimensions

Unit General Dimensions

Compressor

access door

Control panel door

High voltage knockout

D

Low voltage knockout

Heater package knockout

Heater package access panel

W

L

A

E

B

Supply opening

Drain access

C

Return opening

F

Condenser fan

H

Blower motor

access door

47 11/16"

Condenser air

intake grille

Unit Dimension Chart

Unit

PA/PH1324,1330,1336 5.875 32.875 13.875 32.875 26.25 53.25 38.125 23.25 1.125 1.375 35.625

PA/PH1342,1348,1360 9.875 37.875 15.875 37.875 33.25 55.25 42.375 30.25 1.5 2.375 38.125

Supply Size Return Size Unit Overall Dimensions

A C B C H (heigh t) L (lengt h ) W (widt h ) D E F G

Optional Control Modules — Field Installed

traPdellatsnIdleiF oTelbacilppA noitpircseD

82-AMCsledoMllAlortnoCtneibmAwoL

51-CMCsledoMA-llAtiKtratSrosserpmoC

Condenser air

intake grille

G

MIS-2142 A

Form No. S3383-1112

Supersedes S3383-510

Page 6 of 8

Page 7

Optional Equipment — Roof Hood

M

R

R

0

0

M

9

9

• Shipped knocked down

• Polyester baked enamel galvanneal cabinet

• Heavy insulation - 1/2 inch

.oNledo

A-313PH

A-315PH

gnippihS-stinutnelaviuqE†

oTelbacilppAthgieWgnippihS

sledomnot3dna2/1-2,2011

sledomnot5dna4,2/1-3021

• Built-in filter

• Fresh air damper assembly provides up to 15% outside air.

• Requires prefabricated roof curb 9042-003 or 9042-004.

Order separately.

Performance and Application Data — RHP

RHP313-A Ventilation Air

riAylppuS

citatS)MFC(riAnoitalitneV

00.0A/NA/N331381622062382092403023073

02.0A/NA/N331381622062382092403A/NA/N

04.0A/NA/N33138162.2062382092A/NA/NA/N

citatSnruteR00.050.001.051.002.052.003.053.004.054.0

AIR CONDITIONING UNIT

MIS-2254

D

38 1/4

X A WIDTH

ROOF HOOD

FILTER

FRESH AIR

OPENING

RETURN AIR SUPPLY AIR

1 1/2"

JH

12 1/2"

Heavy gauge galvanized with wood nailing strip, welded/leakproof one piece

construction - ready to install.

5.0

C

RHP513-A BFAD Ventilation Air

riAylppuS

citatS

00.0A/NA/N08561512052082013043073004

02.0A/NA/N08561512052082013043073004

04.0A/NA/N08561512052082013043073004

citatSnruteR00.050.001.051.002.052.003.053.004.054.0

)MFC(riAnoitalitneV

Unit Dimensions

dooHfooR

ledoM

ledoM

4231HP/4231AP

A-313PHR

0331HP/0331AP

6331HP/6331AP

2431HP/2431AP

A-315PHR

8431HP/8431AP

0631HP/0631AP

lanimoN

egannoT

noT2

noT½2

noT3

noT½3

noT4

noT5

A C D

8/1-83624/1-35

24334/1-5502x61)2(

"1

retliF

dna

Optional Equipment — Pre-Fabricated Roof Curb

• Heavy gauge galvanized with wood nailing strip.

• Prefabricated roof curb requires roof hood RHP313-A & RHP513-A.

Order separately.

.oNledo

300-240

400-240

oTelbacilppA†.U.EthgieWgnippihS

sledomnot3dna2/1-2,208.441

sledomnot5dna4,2/1-308.061

gnippihS-stinutnelaviuqE†

5.0

61x61)1(

02x61)1(

htiWdesU

ledoM

300-2409

)bruC63P(

400-2409

)bruC06P(

ledoM A B C 1 D E F J 1 H 1

A-313PHR8/3-084/1-044/1-738/3-838/3-53244/3-418/1-91sledoMnoT3&,2/1-2,2llA

A-315PHR8/3-288/1-448/1-148/3-838/3-53444/3-418/1-91sledoMnoT5&4,2/1-3llA

dooHfooR

dnapmuPtaeH

stinUgninoitidnoCriA

1 Duct Sizing Information:

Return air dimension “C” is length / Supply air dimension “C” is length.

Return air dimension “H” is width / Supply air dimension “J” is width.

Form No. S3383-1112

Supersedes S3383-510

Page 7 of 8

Page 8

Optional Equipment — Energy Recovery Ventilator

t

D

1

1

9

9

8

8

7

y

ROOF HOOD

SUPPLY DUCTRETURN DUCT

ROOF

PACKAGE UNIT

ROOF CURB

MIS-2253

• Assures continuous supply of fresh air and reduction of all indoor air pollutants. IAQ ASHRAE 62.1

• Provides 250 to 400 CFM (adjustable) of outside air and exhaust. Efficiencies up to 77% heating and 65% cooling.

• Designed for easy installation on roof hoods RHP313-A and RHP513-A.

.oNledoM

)V802/032(X-D3A-RVRE.sbl521

)064(X-D3C-RVRE.sbl521

C3A-RVRE-ATADNOITACILPPADNAECNAMROFREP

ecnamrofrePgnilooCremmuS

tneibmA

.D.O

F°BW/B

TLV SLV LLV TRH SRH LRH TLV SLV LLV TRH SRH LRH TLV SLV LLV TRH SRH LRH

57080,91069,21021,6020,21461,8558,3205,51035,01279,4129,9937,6281,3529,11001,8528,3157,7562,5684,2

07069,21069,210461,8461,80 035,01035,010

50

56069,21069,210461,8461,80 035,01035,010937,6937,60001,8001,80562,5562,50

08080,82008,01082,71096,71408,6688,01518,22577,8040,41106,41616,5589,8055,71057,6008,01704,11783,4910,7

57080,91008,01082,8020,21408,6612,5205,51577,8727,6129,9616,5503,4529,11057,6571,5157,7783,4363,3

00

07089,01008,01081719,6408,6311129,8577,8641907,5616,539268,6057,6211064,4783,437

56008,01008,010

06008,01008,010408,6408,60 577,8577,80

08080,82046,8044,91096,71344,5742,21518,22020,7597,51106,41294,4801,01055,71004,5051,21704,11015,3798,7

57080,91046,8044,01020,21344,5775,6205,51020,7284,8129,9294,4824,5529,11004,5525,6157,7015,3142,4

5

07089,01046,8043,2719,6344,5474,1129,8020,7109,1907,5294,4612,1268,6004,5264,1064,4015,3059

56046,8046,80

06046,8046,80 344,5344,50

08080,82084,6006,12096,71280,4806,31518,22562,5055,71106,41963,3232,11055,71050,4005,31704,11236,2477,8

57080,91084,6006,21020,21280,4839,7205,51562,5732,01129,9963,3255,6529,11050,4578,7157,7236,2811,5

0

07089,01084,6005,4719,6280,4538,2129,8562,5656,3907,5963,3043,2268,6050,4218,2064,4236,2828,1

56084,6084,60

06084,6084,60 280,4280,40

08080,82023,4067,32096,71127,2869,41518,22015,3503,91106,41642,2553,21055,71007,2058,41704,11557,1256,9

57080,91023,4067,41020,21127,2892,9205,51015,3299,11129,9642,2576,7529,11007,2522,9157,7557,1699,5

5

07089,01023,4066,6719,6127,2591,4129,8015,3114,5907,5642,2364,3268,6007,2261,4064,4557,1507,2

56023,4023,40

06023,4023,40 127,2127,20

57080,91061,2029,61020,21063,1956,01205,51557,1747,31129,9321,1897,8529,11053,1575,01157,7778378,6

07089,01061,2028,8719,6063,1655,5129,8557,1661,7907,5321,1685,4268,6053,1215,5064,4778385,3

0

56087,3061,2026,1183,2063,1020,1170,3557,1613,1569,1321,1248263,2053,1210,1535,1778856

06061,2061,20

07089,010089,01719,60 719,6129,80 129,8907,50907,5268,60 268,6064,40064,4

5

56087,30 087,3183,20 183,2170,30 170,3569,10569,1263,20 263,2535,10535,1

06

000000000000000000

MFC004-ETARNOITALITNEV

ycneiciffE%36

408,6408,60 577,8577,80 616,5616,50 057,6057,60 783,4783,40

344,5344,50 020,7020,70 294,4294,40 004,5004,50 015,3015,30

280,4280,40 562,5562,50 963,3963,30 050,4050,40 236,2236,20

127,2127,20 015,3015,30 642,2642,20 007,2007,20 557,1557,10

063,1063,10 557,1557,10321,1321,10 053,1053,107787780

020,7020,70 294,4294,40 004,5004,50 015,3015,30

562,5562,50 963,3963,30 050,4050,40 236,2236,20

015,3015,30 642,2642,20 007,2007,20 557,1557,10

ecnamrofrePgnitaeHretniW

)BDF°07snoitidnoCngiseDroodnI(

tneibmA

.D.O

F°BD

56061,2026,1557,1333,1053,1930,1

06023,4042,3015,3766,2007,2970,2

55084,6068,4562,5100,4050,4811,3

05046,8084,6020,7533,5004,5851,4

LVW RHW LVW RHW LVW RHW

ycneiciffE%57MFC004 ycneiciffE%67MFC523

ETARNOITALITNEV

54008,01001,8577,8966,6057,6791,5

04069,21027,9035,01200,8001,8732,6

53021,51043,11582,21633,9054,9672,7

03082,71069,21040,41076,01008,01613,8

52044,91085,41597,51400,21051,21553,9

02006,12002,61055,71833,31005,31593,01

51067,32028,71503,91176,41058,41434,11

)BW°26/BD°57snoitidnoCngiseDroodnI(

MFC523-ETARNOITALITNEV

ycneiciffE%46

937,6937,60001,8001,80562,5562,50

616,5616,50 057,6057,60 783,4783,40

Legend:

VLT = Ventilation Load - Total

VLS = Ventilation Load - Sensible

VLL = Ventilation Load - Latent

HRT = Heat Recovery - Total

cneiciffE%77MFC052

HRS = Heat Recovery - Sensible

HRL = Heat Recovery - Latent

WVL = Winter Ventilation Load

WHR = Winter Heat Recovery

MFC052-ETARNOITALITNEV

ycneiciffE%56

hgieWgnippihS

SNOISNEMIDTINU

ledoM htdiW htpeD thgieH thgieWgnippihS

RVRE4/3-23*4/3-814/3-81.sbl521

* Does not include 1" mounting brackets on each side of ERVR.

Form No. S3383-1112

Supersedes S3383-510

Page 8 of 8

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Due to our continuous product improvement

policy, all specifications subject to change

without notice.

Before purchasing this appliance, read important energy

cost and efficiency information available from your retailer.

Form No.

S3383

November, 2012

Supersedes: S3383-510

Loading...

Loading...