QC SERIES

INSTALLATION

INSTRUCTIONS

CHILLED WATER UNIT

Model:

QC501

Bard Manufacturing Company

Bryan, Ohio 43506

Since 1914...Moving ahead, just as planned.

MIS-1554

Manual No.: 2100-416C

Supersedes: 2100416B

File: Vol II Tab 14

Date: 12-22-03

© Copyright 2003

CONTENTS

Getting Other Information and Publications

For more information, contact these publishers: ..... 1

QC General Information

QC Model Nomenclature ......................................... 2

Shipping Damage .................................................... 5

Unit Removal From Skid.......................................... 5

Handling Unit After Removal From Skid .................. 5

Removal of Wall Bracket from Shipping Location ... 6

General.................................................................... 6

Minimum Installation Height .................................... 6

Duct Work................................................................ 9

Filters....................................................................... 9

Condensate Drain.................................................. 10

Mist Eleminator Service ..........................................11

Figures

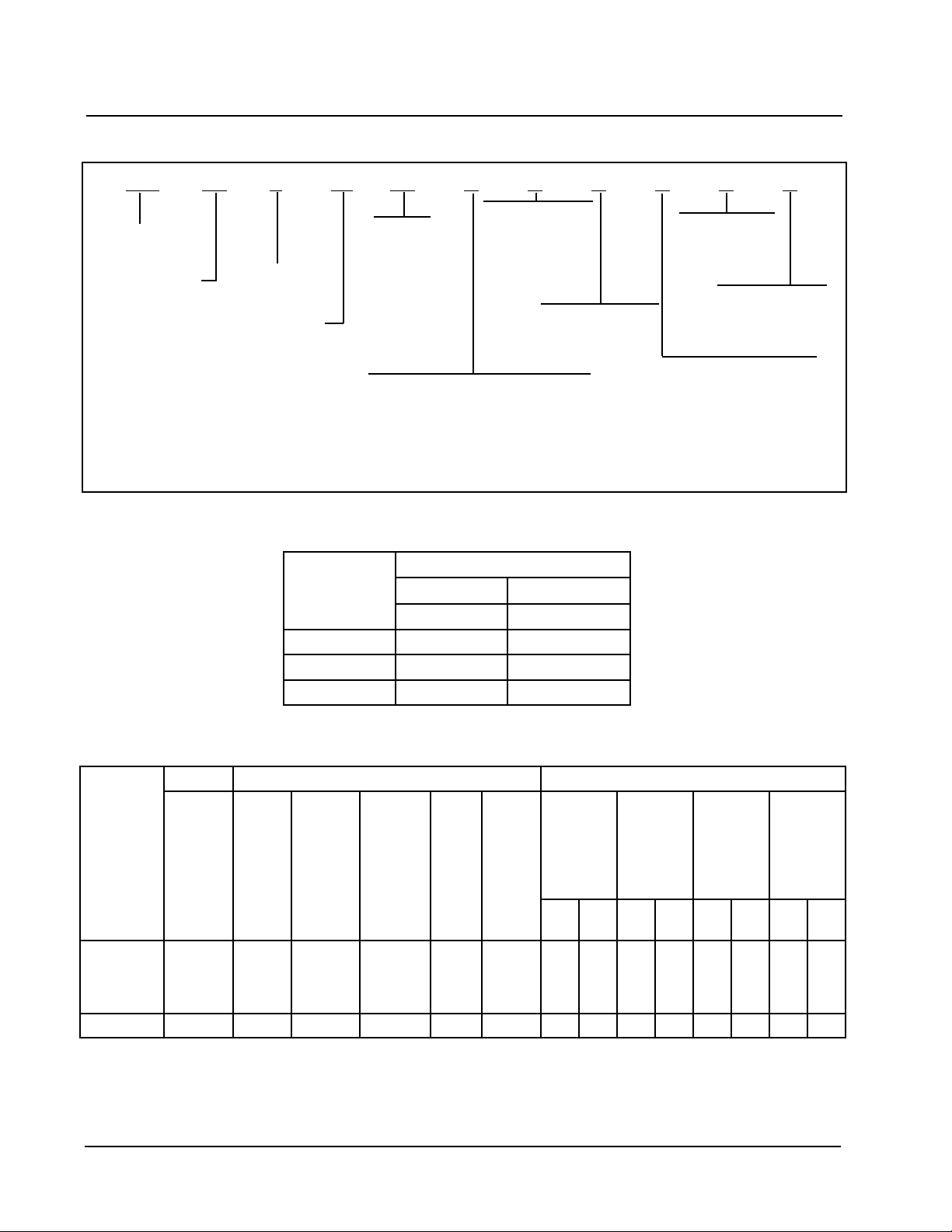

Figure 1 Unit Dimensions..................................... 4

Figure 2 Removal of Unit From Skid .................... 5

Figure 3 Proper Handling of Unit After Removal

from Skid................................................ 6

Figure 4 Installation of Unit w/Wall Sleeve .......... 7

Figure 5 Installation With Free Blow Plenum....... 8

Figure 6 Ducted Application................................. 8

Figure 7 Supply Duct Connections ...................... 9

Figure 8 Filter Location ........................................ 9

Figure 9A Side Drain (Side View)......................... 10

Figure 9B Optional Rear Drain ............................. 10

Figure 9C Rear Drain (Top View).......................... 10

Figure 10 Fresh Air Damper Removal ................. 12

Figure 11 Removal of QT

Figure 12 Remove Locking Screws from Wheels 14

Figure 13 Unit Mounting Without Wall Sleeve ..... 15

Figure 14 Component Location............................ 16

Figure 15 Low Voltage Wire Harness Plug .......... 18

Figure 16 Remote Thermostat Wiring "X" Option 19

Figure 17 Remote Thermostat Wiring "D" Option 20

Figure 18 Internal 2-Way Valve Piping................. 24

Figure 19 Internal 3-Way Valve Piping................. 25

EC ERV......................... 13

Installation Instructions

Mounting the Unit .................................................. 14

Wiring – Main Power ............................................. 17

Wiring – Low Voltage Wiring ................................. 17

General Information ............................................... 17

Fluid Connections.................................................. 17

Low Voltage Connections...................................... 18

Start Up

Optional CFM ........................................................ 21

Important Installer Note ......................................... 21

Service Hints ......................................................... 21

Sequence of Operation.......................................... 21

Troubleshooting ECM Blower Motors ............. 22-23

Tables

Table 1 Factory Built-In Electric Heat ................... 2

Table 2 Electrical Specifications ........................... 2

Table 2A Cooling Performance Chart...................... 3

Table 3 Operating Voltage Range....................... 17

Table 4 Wall Thermostats and Subbase

Combinations ......................................... 17

Table 5 Indoor Blower Performance ................... 21

i

GETTING OTHER INFORMATION AND PUBLICATIONS

These publications can help you install the air

conditioner or heat pump. You can usually find these at

your local library or purchase them directly from the

publisher. Be sure to consult current edition of each

standard.

National Electrical Code ......................ANSI/NFPA 70

Standard for the Installation ..............ANSI/NFPA 90A

of Air Conditioning and

Ventilating Systems

Standard for Warm Air...................... ANSI/NFPA 90B

Heating and Air

Conditioning Systems

Load Calculation for Residential ...... ACCA Manual J

Winter and Summer

Air Conditioning

Duct Design for Residential ............. ACCA Manual D

Winter and Summer Air Conditioning

and Equipment Selection

Closed-Loop/Ground Source Heat Pump........ IGSHPA

Systems Installation Guide

Grouting Procedures for Ground-Source ........ IGSHPA

Heat Pump Systems

Soil and Rock Classification for the Design ...IGSHPA

of Ground-Coupled Heat Pump Systems

Ground Source Installation Standards.............IGSHPA

Closed-Loop Geothermal Systems – Slinky ... IGSHPA

Installation Guide

FOR MORE INFORMATION, CONTACT

THESE PUBLISHERS:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Avenue

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating Refrigerating,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

IGSHPA International Ground Source

Heat Pump Association

490 Cordell South

Stillwater, OK 74078-8018

Manual 2100-416

Page 1

QC SERIES WATER SOURCE GENERAL INFORMATION

QC MODEL NOMENCLATURE

QC 50 1 – A 10 X X X X X X

Model Number

QC - QTec™ Model

Capacity

50 - 4 ton

NOTE 1: Electric heat available

for -A models only

Revision

Volts & Phase

A - 230/208-60-1

K - 115-60-1

FACTORY BUILT-IN ELECTRIC HEAT TABLE

Filter Options

KW

0Z - 0KW

05 - 5 KW

10 - 10KW

15 - 15KW

(Note 1)

Ventilation Option

B - Blank Off Plate (no ventilation)

X - Barometric Fresh Air Damper (no exhaust)

V - Commercial Ventilator (w/Exhaust)

P - Commercial Ventilator (w/Exhaust)

Motorized, Power Return

R - Energy Recovery Ventilator (w/Exhaust) - 230/208-60-1 versions only

X - 1 Inch Fiberglass

(Standard)

F - 2 Inch Fiberglass

P - 2 Inch pleated

Color

V - Platinum w/Slate

Front (vinyl)

4 - Gray Paint

TABLE 1

Valve Options

4 - 2-way valve

5 - 3-way valve

Internal Controls

X - None

Climate Control

X - None

D - Electronic/prog/man/auto

sledoMA-105CQ

1-V0421-V802

WKHUTBHUTB

0.5083,61092,21

0.01076,23075,42

0.51051,94068,63

TABLE 2

ELECTRICAL SPECIFICATIONS

tiucriCelgniStiucriClauD

3

.oN

detaR

&stloV

sledoM

Z0A-105CQ

50A01A51A-

Z0K-105CQ1-511101514141 ––––––––

sesahP

1-802/032

dleiF

rewoP

stiucriC

1

1

1

2ro1

muminiM

tiucriC

7

33

85

38

1

yticapmA

51

53

06

09

2

mumixaM

lanretxE

roesuF

tiucriC

rekaerB

41

8

6

4

2

dleiF

rewoP

eriW

eziS

eriW

eziS

41

01

01

8

3

muminiM

tiucriC

dnuorG

yticapmA

TKC

A

B

–

–

–

–

–

–

33

05

1

mumixaM

lanretxE

roesuF

tiucriC

rekaerB

TKC

TKC

A

B

–

–

–

–

–

–

04

05

2

dleiF

rewoP

eziSeriW

TKC

TKC

A

B

–

–

–

–

–

–

8

8

2

TKC

TKC

A

–

–

–

01

dnuorG

eziSeriW

TKC

B

–

–

–

01

Q

R

S

Manual 2100-416

Page 2

Maximum size of the time delay fuse or HACR type circuit breaker for protection of field wiring conductors.

Based on 75° C copper wire. All wiring must conform to the National Electrical Code and all local codes.

These “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the National

Electric Code (latest revision), article 310 for power conductor sizing. CAUTION: When more than one field

power conductor circuit is run through one conduit, the conductors must be derated. Pay special attention to Note 8

of Table 310 regarding Ampacity Adjustment Factors when more than three conductors are in a raceway.

TABLE 2A

COOLING PERFORMANCE CHART

)0001(yticapaCHUTB)0001(yticapaCHUTB

MPGTWEMFC

6

84.611.113.55.148.627.413.35.7

014.717.117.52.344.728.519.43.11

6

81.516.015.44.834.520.313.35.7

010.611.119.40.040.620.419.43.11

6

89.311.018.33.530.423.113.35.7

017.416.011.49.636.423.219.43.11

6

86.216.90.32.236.226.93.35.7

016.640.013.37.332.325.019.43.11

6

84.712.212.50.646.034.513.35.7

018.818.210.63.949.134.719.43.11

6

82.617.115.47.242.925.313.35.7

014.713.211.56.544.032.519.43.11

6

89.413.116.35.939.726.113.35.7

011.617.111.10.240.920.319.43.11

6

87.318.019.22.635.627.93.35.7

017.412.115.33.835.728.019.43.11

240001

440001

640001

840001

240021

440021

640021

840021

latoTelbisneStnetaLlatoTelbisneStnetaLGISP.dH.tF

1.515.016.45.833.522.319.14.4

9.310.019.38.532.426.119.14.4

8.216.92.30.330.320.019.14.4

6.111.95.23.039.124.89.14.4

9.515.114.41.240.921.319.14.4

8.411.117.33.937.726.119.14.4

6.317.019.24.635.629.99.14.4

5.213.012.26.332.524.89.14.4

lioCretaW

porDerusserP1egatS2dna1egatS

Manual 2100-416

Page 3

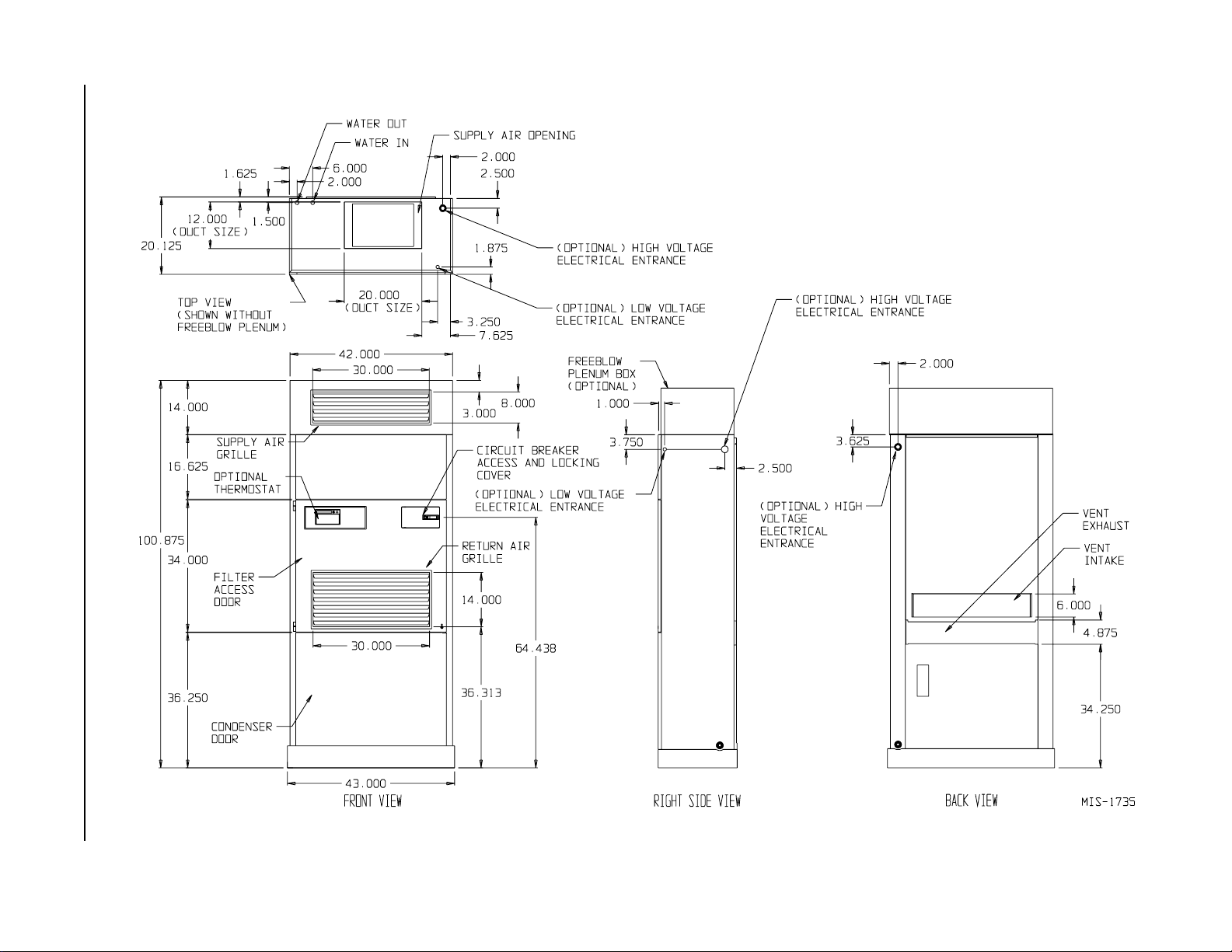

Manual 2100-416

Page 4

FIGURE 1

UNIT DIMENSIONS

SHIPPING DAMAGE

Upon receipt of equipment, the carton should be

checked for external signs of shipping damage. The

skid must remain attached to the unit until the unit is

ready for installation. If damage is found, the receiving

party must contact the last carrier immediately,

preferably in writing, requesting inspection by the

carrier’s agent.

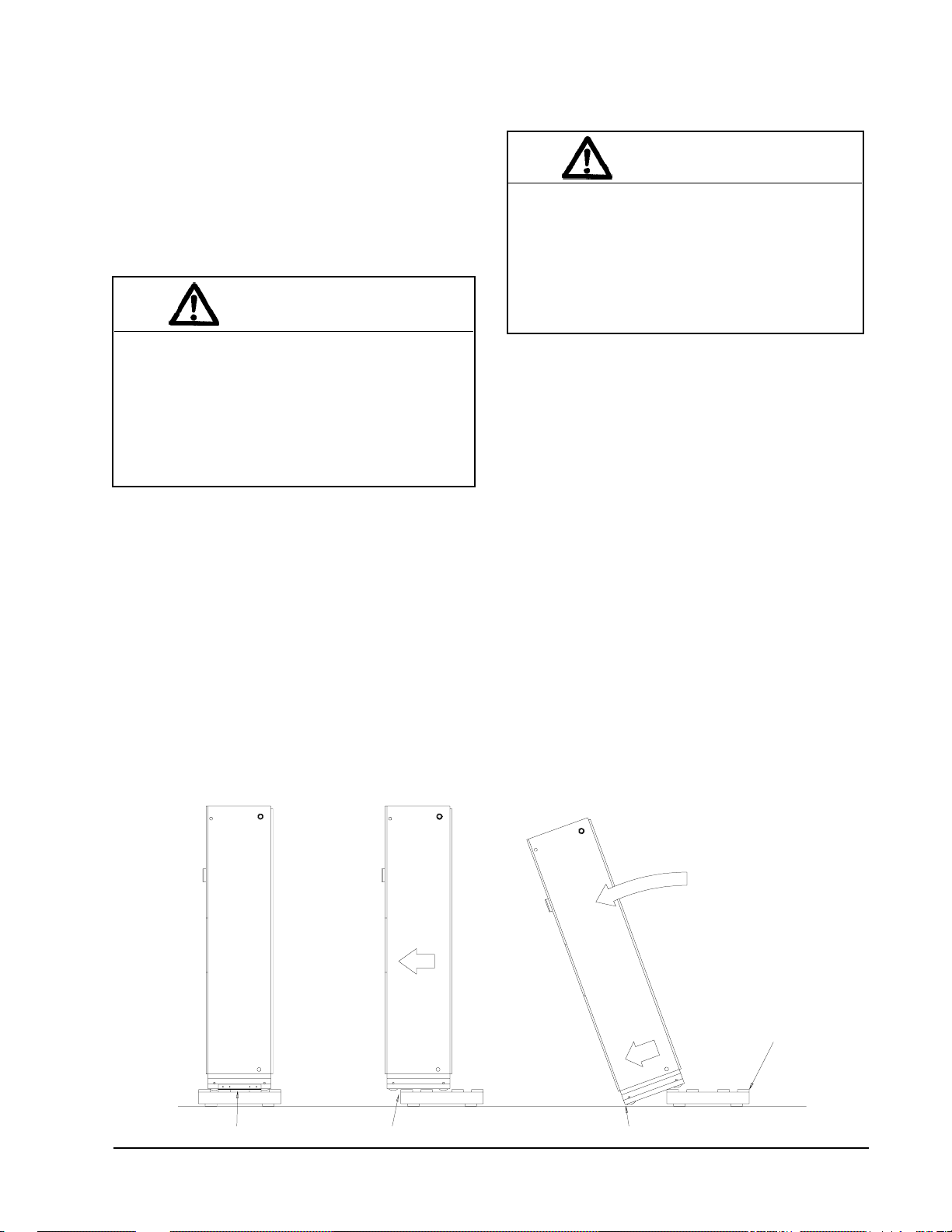

UNIT REMOVAL FROM SKID

WARNING

HANDLING UNIT AFTER REMOVAL FROM

SKID

W ARNING

Exercise extreme caution when pushing the

unit on the rollers. Handle and push from the

lower 1/3 of the unit. Insure that debris is not

on the floor where the unit is to be moved on

the rollers. Failure to do so could result in the

unit tipping over and causing bodily injury

and/or damage to the unit.

This unit is heavy and requires more than one

person to handle and remove from the skid.

Check unit wheels to ensure that wheels are

locked before removing from skid. Extreme

caution must be taken to prevent injury to

personnel and damage to the unit.

It is recommended that the unit not be removed from

the skid with a fork lift.

The shipping brackets on each side of the unit must be

removed and discarded. See Figure 2-A on Page 5.

The return air grille panel can be removed to provide a

place to hold the unit. The unit can be slid forward on

the skid until the front wheels hang over the edge of the

skid. See Figure 2-B. The unit can be tipped forward

and slid down the edge of the skid until the front

wheels touch the ground. See Figure 2-C. The wheels

will not roll. They are shipped from the factory locked

so they will not roll. The back of the skid will have to

be held down to keep it from tipping up. The skid can

be slid out from under the unit. The unit can then be

set upright.

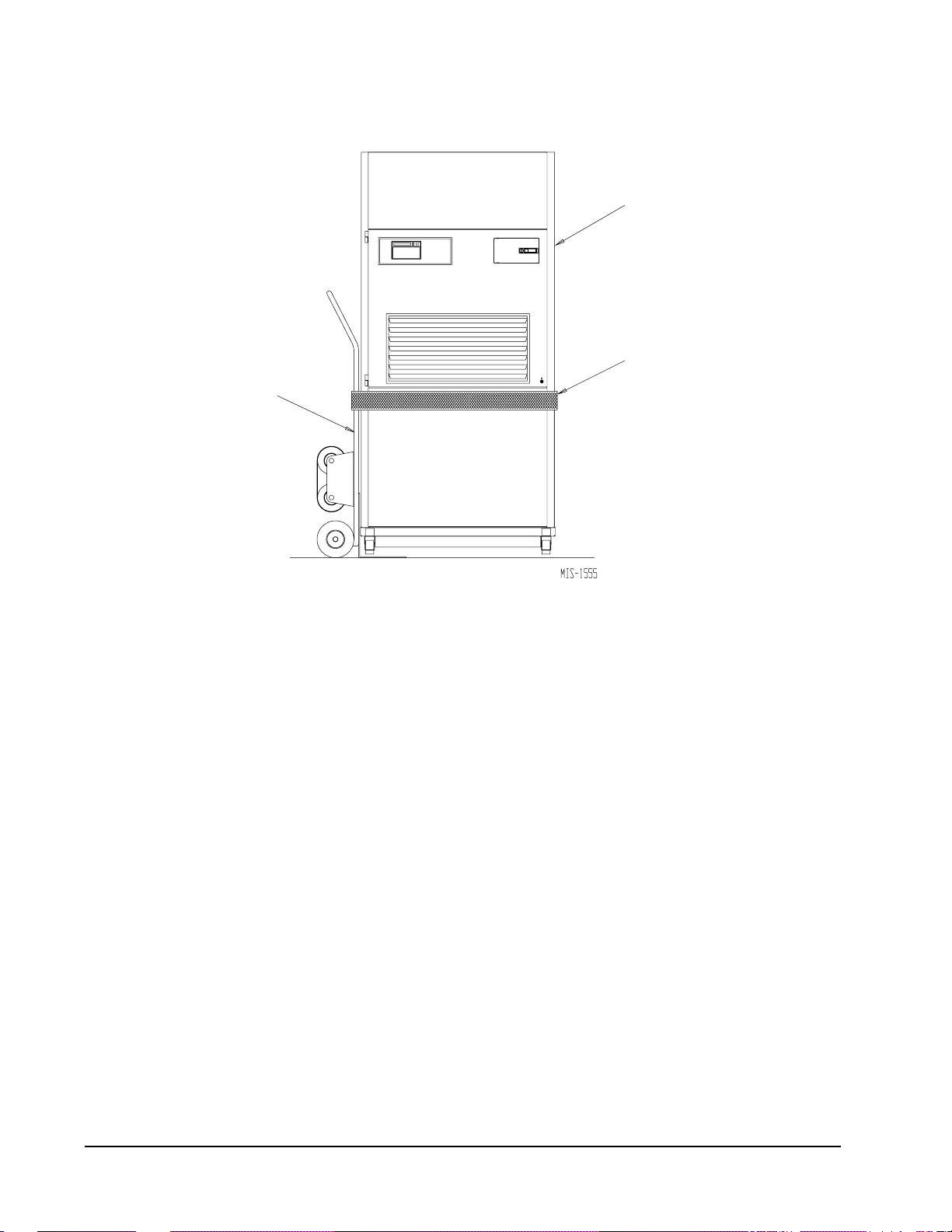

REMOVAL OF UNIT FROM SKID

The unit will have to be turned sideways and removed

from the skid to fit through a 36” doorway. If the door

height allows, the unit can be slid sideways through the

door.

If the unit can not be slid through the door, then the unit

will have to be put on a cart and tipped down to roll

through the door. It is recommended that an appliance

cart by used with a strap to hold the unit on the cart.

The wheels of the unit must be locked. If the wheels

were allowed to roll, the unit could roll off the cart.

The blade of the appliance cart should be slid under the

wheels of the unit. See Figure 3. The strap of the

appliance cart should be placed around the unit and

strapped tightly. Help will be required to tip the unit

back onto the cart. The unit can be leaned far enough

back to be rolled through the door. Be careful when

setting the unit back up to keep from damaging the unit.

FIGURE 2

MIS-1603

A SHIPPING BRACKETS B FRONT WHEELS OVER EDGE C FRONT WHEELS ON FLOOR

HOLD SKID DOWN

Manual 2100-416

Page 5

APPLIANCE

CART

FIGURE 3

PROPER HANDLING OF UNIT

AFTER REMOVAL FROM SKID

QTEC UNIT

(RIGHT SIDE)

STRAP

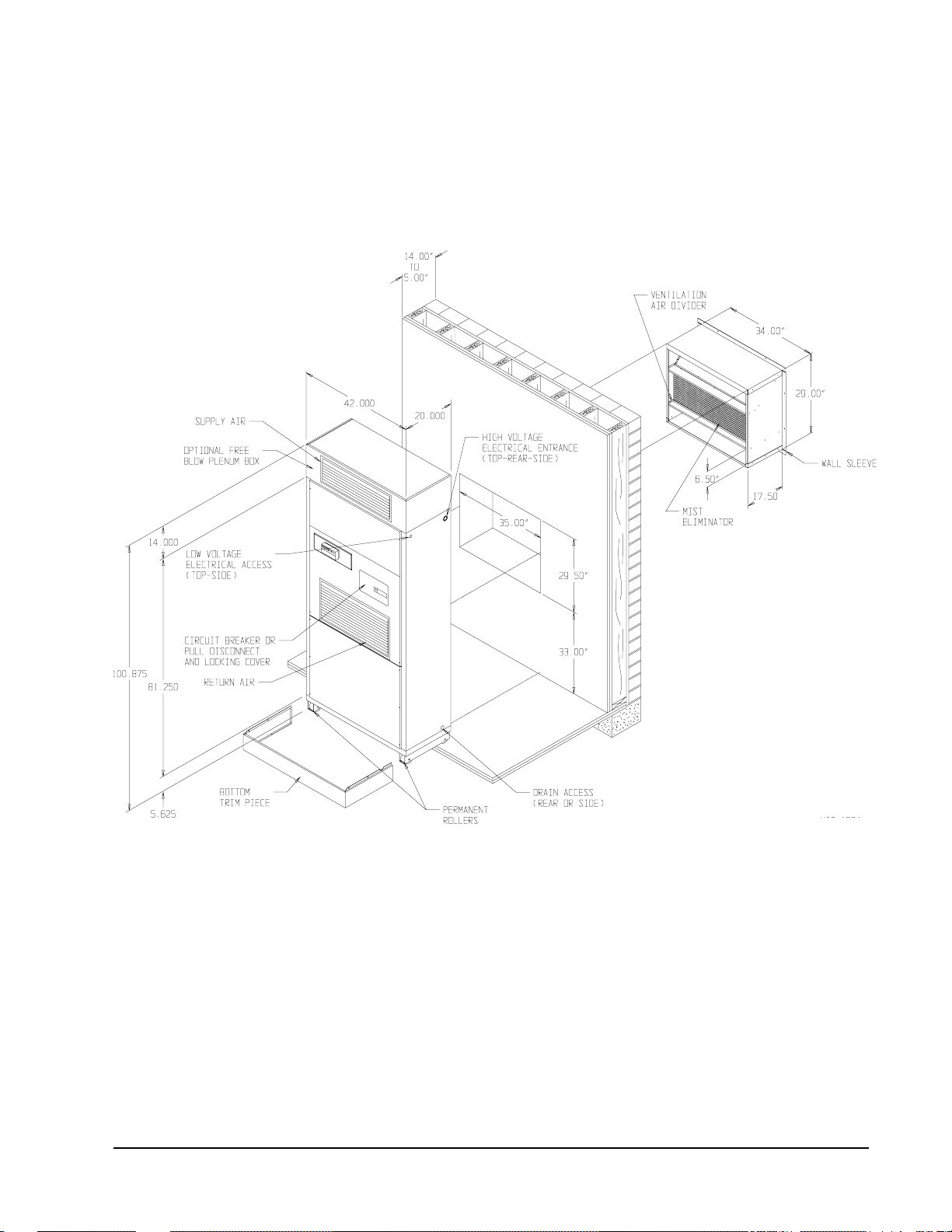

REMOVAL OF WALL BRACKET FROM

SHIPPING LOCATION

The wall brackets are attached to the back of the unit.

Remove and retain the wall brackets for use when

attaching the unit to the wall. In those installations

where a wall sleeve is required these two wall brackets

are to be discarded. A different style bracket is supplied

with the sleeve assembly.

GENERAL

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The unit is designed for use with or without duct work.

For use without duct work, Plenum Box QPB** is

recommended.

These instructions explain the recommended method to

install the water source self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

air conditioning system should be carefully read before

beginning the installation. Note particularly “Start

Procedure” and any tags and/or labels attached to the

equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation

is made. See Page 1 for information on codes and

standards.

Size of unit for a proposed installation should be based

on heat loss calculation made according to methods of

Air Conditioning Contractors of America (ACCA). The

air duct should be installed in accordance with the

Standards of the National Fire Protection Systems of

Other Than Residence Type, NFPA No. 90A, and

Residence Type Warm Air Heating and Air

Conditioning Systems, NFPA No. 90B. Where local

regulations are at a variance with instructions, installer

should adhere to local codes.

MINIMUM INSTALLATION HEIGHT

The minimum installation height of the unit with a Free

Blow Plenum is 8 ft. 6 in. This provides enough

clearance for the plenum to be removed. See Figure 5.

The minimum installation height for ducted

applications is 8 ft. 4-1/2 in. This provides enough

clearance to install the duct work. See Figure 6.

Manual 2100-416

Page 6

FIGURE 4

INSTALLATION OF UNIT THRU WALL WITH WALL SLEEVE

MIS-1564

Manual 2100-416

Page 7

FIGURE 5

INSTALLATION WITH FREE BLOW PLENUM

CEILING

20 IN.

MINIMUM

FIGURE 6

DUCTED APPLICATION

FIXED CEILINGSUSPENDED

CEILING

MIS-1558

FLOOR

DUCT

DUCT FLANGE

Manual 2100-416

Page 8

FLOOR

MIS-1559

DUCT WORK

Any heat pump is more critical of proper operating

charge and an adequate duct system than a straight air

conditioning unit. All duct work must be properly

sized for the design air flow requirement of the

equipment. Air Conditioning Contractors of America

(ACCA) is an excellent guide to proper sizing. All duct

work or portions thereof not in the conditioned space

should be properly insulated in order to both conserve

energy and prevent condensation or moisture damage.

When duct runs through unheated spaces, it should be

insulated with a minimum of one inch of insulation.

Use insulation with a vapor barrier on the outside of the

insulation. Flexible joints should be used to connect

the duct work to the equipment in order to keep the

noise transmission to a minimum.

EC

The QT

air duct to the top of the unit. Duct connection size is

12 inches x 20 inches. The duct work is field supplied

and must be attached in a manner to allow for ease of

removal when it becomes necessary to slide the unit out

from the wall for service. See Figure 7 for suggested

attachment method.

NOTE: Unit cabinet, supply air duct and free blow

series unit has provision to attach a supply

plenum are approved for “0” clearance to

combustible material.

When used with a ducted supply, a QCX Cabinet

Extension can be used to conceal the duct work above

the unit to the ceiling. This extends 20” above the unit

for a total height above the floor of 10’-7/8”. See

Optional Accessories, Page 18 for the correct Cabinet

Extension model number. The unit is equipped with a

variable speed indoor blower motor which increases in

speed with an increase in duct static pressure. The unit

will therefore deliver proper rated air flow up to the

Maximum ESP shown in Table 5. However, for quiet

operation of the air system, the duct static should be

kept as low as practical, within the guidelines of good

duct design.

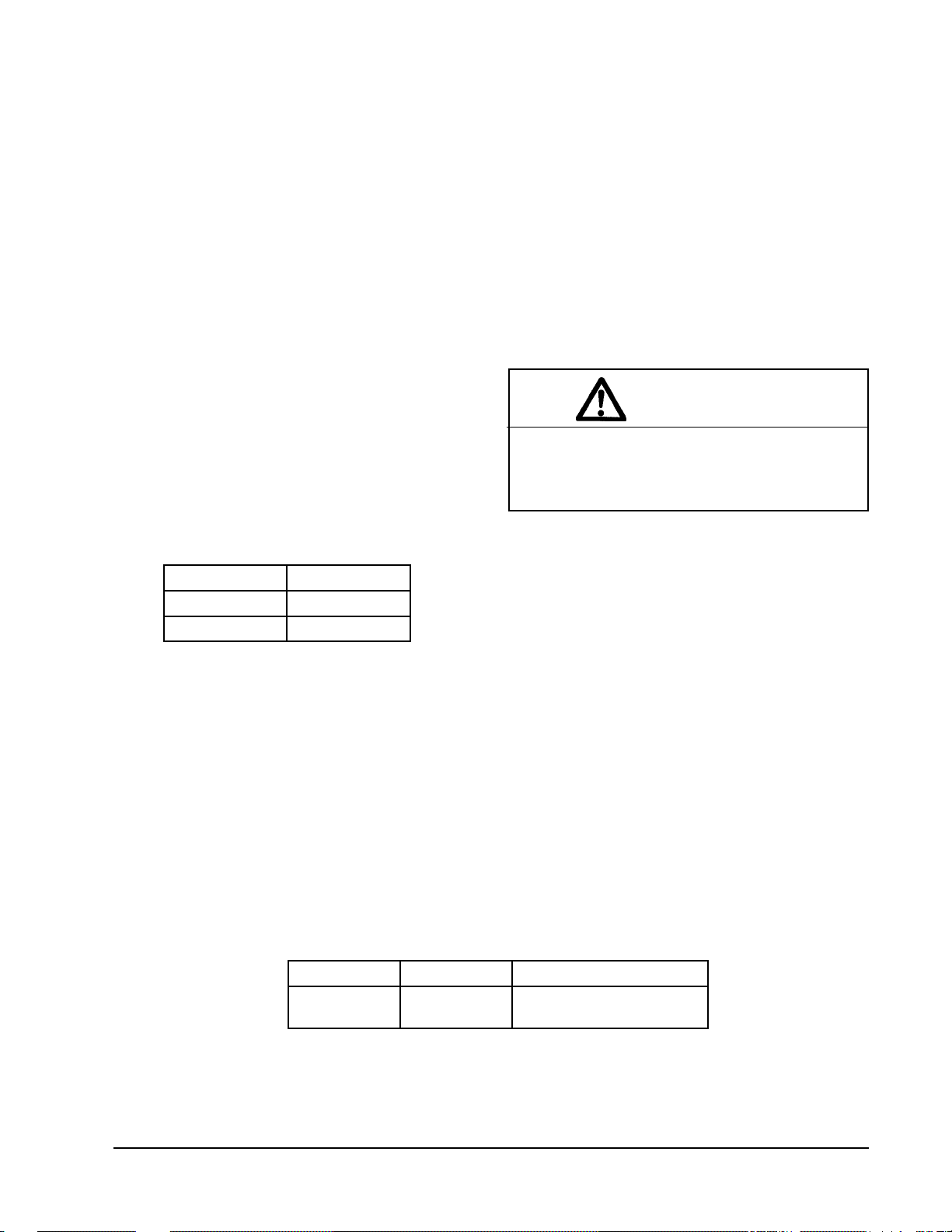

FILTERS

Two 1 inch throw away filters are supplied with each

unit. The filters fit into a fixed rack.

The filters are serviced from the inside of the building .

To gain access to the filters release the latch on the

circuit breaker door and one 1/4 turn fastener near the

bottom of the door. This door is hinged on the left so it

will swing open.

The internal filter brackets are adjustable to

accommodate 2 inch filters. The tabs for the 1 inch

filters must be bent down to allow the 2 inch filters to

slide in place.

FIGURE 7

SUPPLY DUCT CONNECTIONS

SUPPLY DUCT

TO BE FIELD

SUPPLIED

ATTACHMENT

SCREWS TO BE

FIELD SUPPLIED

ROOM SIDE

OF QC UNIT

MIS-978

DUCT FLANGE

PROVIDED WITH UNIT

The QTEC series units are designed for use with free

return (non-ducted) and either free blow with the use of

QPB Plenum Box or a duct supply air system.

The QPB Plenum Box mounts on top of the unit and

has both vertically and horizontally adjustable louvers

on the front discharge grille. See Optional Accessories,

Page 18, for the correct Plenum Box model number.

FIGURE 8

FILTER LOCATION

FILTERS

RETURN AIR

GRILLE

Manual 2100-416

Page 9

CONDENSATE DRAIN

The condensate drain hose is routed down from the

evaporator drain pan on the right side of the unit into

the compressor compartment. There are three

locations that the drain can exit the cabinet. For a

stand pipe type of drain, the drain hose can exit the

rear of the cabinet. There is adequate hose length to

reach the floor on the right hand side of the unit.

If the drain is to be hard plumbed, there is a 3/4 inch

pipe connection located on the right hand cabinet

side near the rear and one on the cabinet rear panel.

In these installations the drain tube is to be slipped

over the pipe connection inside of the cabinet.

FIGURE 9A

SIDE DRAIN (SIDE VIEW)

QTEC UNIT

See Figures 9A, 9B and 9C.

NOTE: Whichever type of drain connection is used a

“P” trap must be formed.

The side drain requires a water trap for proper drainage.

See Figure 8A. The drain can be routed through the floor

or through the wall.

If the drain is to be routed through

an unconditioned space, it must be protected from

freezing

. The drain line must be able to be removed from

the unit if it is necessary to remove the unit from the wall.

FIGURE 9C

REAR DRAIN (TOP VIEW)

DRAIN LINE

SLEEVE

WALL

(MAXIMUM 10”

FOR REAR

DRAIN)

COUPLINGS NOT

SHOWN BUT

RECOMMENDED

FOR EASE OF

REMOVABILITY

FOR SERVICE

MIS-976

OPTIONAL REAR DRAIN

MIS-974

Manual 2100-416

Page 10

FIGURE 9B

WATER

TRAP

MIS-977

WALL

BRACKET

UNIT

The rear drain can be used with wall thickness of up to

10 inches where a water trap can be installed between

the unit and the interior wall. See Figure 8B. The trap

cannot extend beyond the edge of the unit or it will

interfere with the wall mounting bracket. The drain can

be routed through the floor or through the wall. If the

drain is routed through the wall, the drain line must be

positioned such that it will not interfere with the sleeve

flange or the grille. See Figure 9C on Page 10. If the

drain is to be routed through an unconditioned space,

it must be protected from freezing.

BAROMETRIC FRESH AIR DAMPER (Optional)

Before start to remove make sure the power has been

turned off. The hinged return air grille panel must be

opened. The fresh air damper assembly can be seen on

the back of the unit. Refer to Figure 10.

1. The fresh air damper is attached to the back of the

unit with one screw on either side of the assembly.

Both of the screws must be removed.

2. Once the mounting screws are removed, tilt the

assembly down and lift it out.

MIST ELIMINATOR SERVICE (Optional –

only used with one of the vent options)

A mist eliminator is supplied with the wall sleeve. The

mist eliminator is constructed of aluminum frame and

mesh. The mist eliminator is located in the top section

of the wall sleeve and can be removed from the inside

of the building without removing the unit from the wall.

This requires that the ventilation package must be

removed.

The steps necessary to remove each of the vent options

are listed following.

It is recommended that the mist eliminator be inspected

annually and serviced as required. The mist eliminator

can be inspected from the outside of the building by

looking through the outdoor grille. The mist eliminator

can be serviced from the outside. The outdoor grille

must be removed to do so.

The mist eliminator can be cleaned by washing with

soap and water. The excess water should be shaken off

the mist eliminator before it is reinstalled.

The mist eliminator can be seen through the opening.

The mist eliminator must be raised up and the bottom

can be pulled toward the front of the unit.

COMMERCIAL ROOM VENTILATOR OPTION

Before stating the removal make sure the power has

been turned off. The hinged return air grille must be

opened. The commercial room ventilator (CRV) can

be seen after the panel has been removed. The CRV

must be removed to gain access to the mist eliminator.

1. The two mounting screws in the front of the CRV

must be removed.

2. The power connectors for the CRV (located on the

right side of the unit) must be disconnected.

Squeeze the tabs on the sides of the connector and

pull straight out. Unplug both of the connectors.

3. Slide the CRV straight out of the unit.

The mist eliminator can be seen through the opening in

the back of the unit. The mist eliminator must be

raised up and the bottom can be pulled toward the front

of the unit and removed.

Manual 2100-416

Page 11

FIGURE 10

FRESH AIR DAMPER REMOVAL

MOUNTING SCREW

Manual 2100-416

Page 12

MIS-1627

QTEC ENERGY RECOVERY VENTILATOR

OPTION

Before starting the removal make sure that the power

has been turned off. The hinged return air grille panel

must be opened. The energy recovery ventilator

(QERV) can be seen after the panel is opened. To gain

access to the mist eliminator, the QERV must be

removed. Refer to Figure 11

1. The front fill plate of the QERV must be removed.

There is one screw on either side of the plate.

Remove these screws and remove the plate.

2. On either side of the QERV there are mounting

screws that hold the QERV in place. Remove both

of these screws.

REMOVAL OF THE QTEC ENERGY RECOVERY VENTILATOR

3. Underneath the heat recovery cassette there is a

power connector for the lower blower assembly. To

disconnect this plug, the tabs on both sides of the

plug must be squeezed to release the plug. While

squeezing the tabs, pull the plug out of the socket.

4. The QERV is plugged into the unit on the right side

of the unit. Both of these plugs must be

disconnected to remove the QERV. Squeeze the

tabs on the sides of the connector and pull straight

out.

5. Slide the QERV assembly straight out of the unit

being careful not to let the cassette slide out of the

QERV.

The mist eliminator can be seen through the opening in

the back of the unit. The mist eliminator must be raised

up and the bottom can be pulled toward the front of the

unit and removed.

FIGURE 11

MOUNTING

SCREWS

POWER

CONNECTORS

LOWER BLOWER

ASSEMBLY POWER

CONNECTOR

FRONT FILL

MIS-1605

Manual 2100-416

Page 13

INSTALLATION INSTRUCTIONS

MOUNTING THE UNIT

When installing a QC unit near an interior wall on the

left side, a minimum of 8 inches is required; 12 inches

is preferred.

When installing a QC unit near an interior wall on the

right side, a minimum of 12 inches is required as

additional space is required to connect the drain.

This clearance is required to allow for the attachment of

the unit to the wall mounting brackets and the side trim

pieces to the wall.

This unit is to be secured to the wall with the wall

mounting brackets provided. The unit itself, the supply

duct, and the free blow plenum are suitable for “0”

clearance to combustible material.

NOTE: When a wall sleeve is to be used discard the

brackets shipped with the heat pump and

attache the unit to the sleeve with bracket

supplied with the wall sleeve.

Following are the steps for mounting the QC units for

reference see Figure 13.

1. Attach wall mounting bracket to the structure wall

with field supplied lag bolts. The fluid piping

connections are to be within the confines of this

bracket. See Figure 1 for cabinet openings and

location of fluid coil connection points.

7. Position side trim pieces to the wall and attach with

field supplied screws. There are two long and two

short pieces supplied. The long pieces are to

enclose the gap behind the unit. The short pieces

are to fill the gap behind the cabinet extension or the

free blow plenum box. They may be cut to suit the

ceiling height or overlap the unit side trim. There is

sufficient length to trim up to a 10’2” ceiling.

FIGURE 12

REMOVING LOCKING SCREWS FROM WHEELS

2. Position the unit in front of the wall mounting

bracket.

3. Remove the locking screws from the wheels. Refer

to Figure 11.

4. Roll the unit up to the wall mounting bracket. The

unit must be level from side to side. If any

adjustments are necessary, shim up under the rollers

with sheets of steel or any substance that is not

affected by moisture.

5. Secure the unit to the wall bracket with provided

#10 hex head sheet metal screws. There are

prepunched holes in the cabinet sides, and the

bracket has slotted holes to allow for some

misalignment.

6. Position the bottom trim piece to the unit and attach

with provided screws (dark colored).

Manual 2100-416

Page 14

REMOVE SCREWS

FROM WHEELS

BEFORE ROLLING

INTO PLACE

MIS-1523

FIGURE 13

UNIT MOUNTING WITHOUT VENTILATION WALL SLEEVE

(REFER TO MOUNTING INSTRUCTIONS ON PAGE 13)

SIDE TRIM

(2 PIECES)

SIDE TRIM (2

PIECES)

BOTTOM TRIM PIECE

WALL MOUNTING

BRACKET

MIS-1557

BOTTOM TRIM

EXTENSION

Manual 2100-416

Page 15

FIGURE 14

COMPONENT LOCATION

SIDE FIELD

WIRE ENTRANCE

REMOTE THERMOSTAT

TERMINAL BLOCK

INDOOR BLOWER

CONTROL BOX/ CIRCUIT

BREAKER PANEL

WIRING – MAIN POWER

Refer to the unit rating plate and/or Table 2 for wire

sizing information and maximum fuse or “HACR

Type” circuit breaker size. Each unit is marked with a

“Minimum Circuit Ampacity”. This means that the

field wiring used must be sized to carry that amount of

current. Depending on the installed KW of electric

heat, there may be two field power circuits required. If

this is the case, the unit serial plate will so indicate. All

models are suitable only for connection with copper

wire. Each unit and/or wiring diagram will be marked

Manual 2100-416

Page 16

MIS-1736

“Use Copper Conductors Only”. These instructions

must be

adhered to. Refer to the National Electrical

Code (NEC) for complete current carrying capacity data

on the various insulation grades of wiring material. All

wiring must conform to NEC and all local codes.

The electrical data lists fuse and wire sizes (75° C

copper) for all models, including the most commonly

used heater sizes. Also shown are the number of field

power circuits required for the various models with

heaters.

The unit rating plate lists a “Maximum Time Delay

Relay Fuse” or “HACR Type” circuit breaker that is to

be used with the equipment. The correct size must be

used for proper circuit protection, and also to assure that

there will be no nuisance tripping due to the momentary

high starting current of the compressor motor.

The disconnect access door on this unit may be locked

to prevent unauthorized access to the disconnect.

The field wiring connections are located behind the top

panel in the circuit breaker panel. The return air panel

must be removed first. This panel is equipped with a

door switch which shuts the unit down when it is

removed. The filter rack must be removed next.

WIRING – LOW VOLTAGE WIRING

The Climate Control Option D is an electronic,

programmable thermostat. The subbase of the

thermostat is factory wired to the front panel of the unit.

Compatible for use with Energy Recovery Ventilator or

Economizer.

GENERAL

This unit is equipped with a variable speed ECM motor.

The motor is designed to maintain rated airflow up to

the maximum static allowed. It is important that the

blower motor plugs are not plugged in or unplugged

while the power is on. Failure to remove power prior

to unplugging or plugging in the motor could result in

motor failure.

230/208V, 1 PHASE AND 3 PHASE EQUIPMENT

DUAL PRIMARY VOLTAGE TRANSFORMERS

All equipment leaves the factory wired on 240V tap.

For 208V operation, reconnect from 240V to 208V tap.

The acceptable operating voltage range for the 240 and

208V taps are as noted in Table 3.

TABLE 3

OPERATING VOLTAGE RANGE

PATEGNAR

V042612-352

V802781-022

NOTE: The voltage should be measured at the field

power connection point in the unit and while

the unit is operating at full load (maximum

amperage operating condition).

The standard Climate Control Option X is a remote

thermostat connection terminal block. See Figure 17

for wiring diagram. Compatible thermostats are listed

in Table 4.

CAUTION

Do not plug in or unplug blower motor connectors while the power is on. Failure to do so

may result in motor failure.

FLUID CONNECTIONS

See Figure 1 for location of fluid connection.

Connection size is 1” FPT.

If the free blow plenum box is to be used, there are

knock outs in the top of the box that can be removed to

allow passage of the fluid piping.

All plumbing to and from the unit is to be installed in

accordance with local plumbing codes. The use of

plastic pipe where permissible is recommended to

prevent electrolytic corrosion of the fluid pipes.

It is strongly recommended that the fluid piping to the

unit be insulated to prevent water droplets from

condensing on the pipe surface.

TABLE 4

WALL THERMOSTATS AND SUBBASE COMBINATIONS

tatsomrehTesabbuSserutaeFtnanimoderP

940-3048

)083-39FI(

A/N

looC/taeH/otuA/launaM

cinortcelEelbammargorP

Manual 2100-416

Page 17

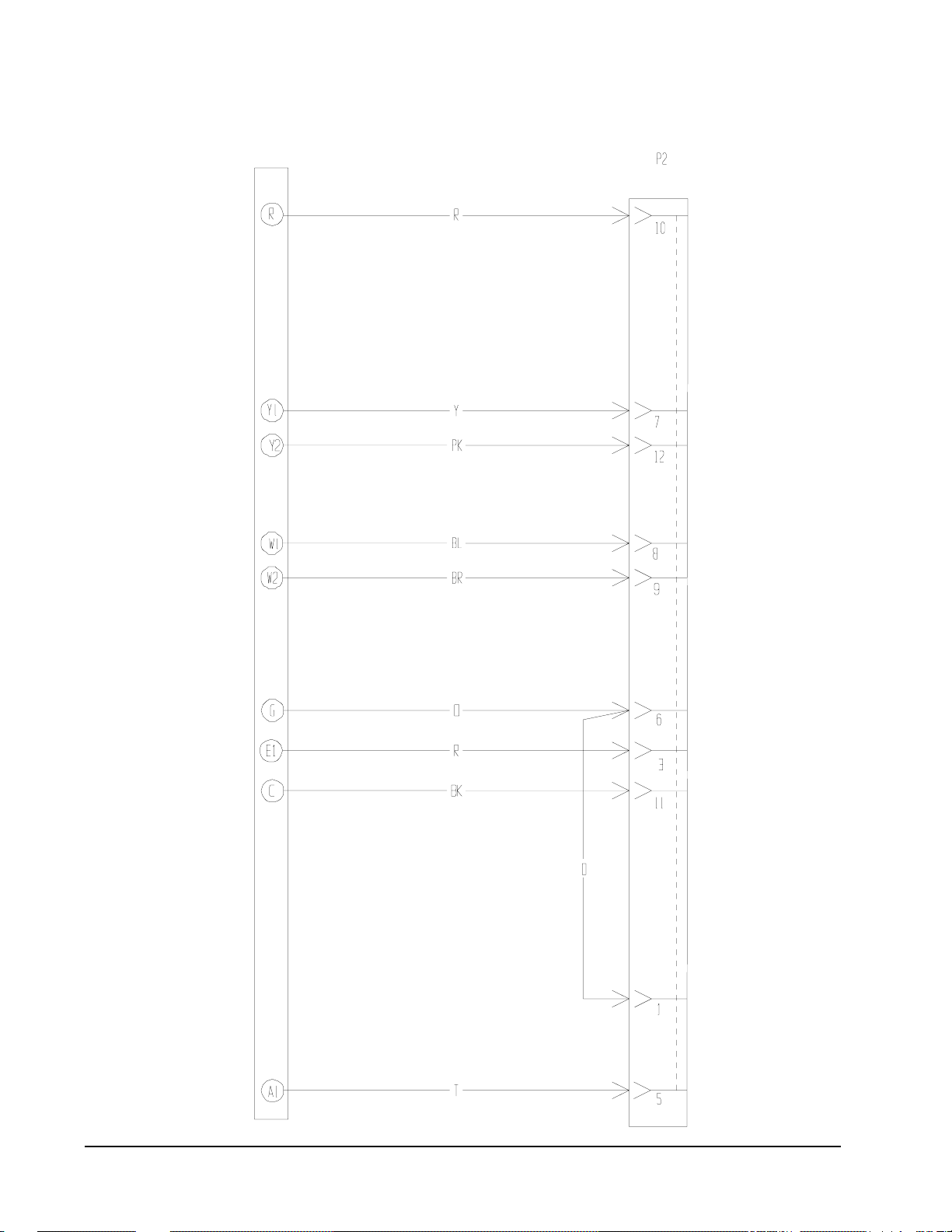

LOW VOLTAGE CONNECTIONS

These units use a grounded 24 volt AC low voltage

circuit.

The “R” terminal is the hot terminal and the “C”

terminal is grounded.

“G” terminal or pins 6 and 1 of P2 are the fan inputs.

Both must be energized for proper fan operation. This

is done automatically in the factory installed climate

control options. If the climate control option is

abandoned and connections are made directly to P2

both pins 6 and 1 of P2 must be energized for proper

operation.

“Y” terminal or pin 7 of P2 is the first stage cooling

input.

“B” terminal or pin 8 of P2 is the first stage heating

input.

“R” terminal or pin 10 of P2 is 24 VAC hot.

“C” terminal or pin 11 of P2 is 24 VAC grounded.

“L” terminal or pin 12 of P2 is the second stage

cooling input.

“W2” terminal or pin 9 of P2 is second stage heating

output.

“O1” terminal of pin 5 of P2 is the ventilation input.

This terminal energizes any factory installed ventilation

option.

LOW VOLTAGE CONNECTIONS FOR

DDC CONTROL

Fan Only Energize G

1st Cooling Mode Energize Y, G

2nd Cooling Mode Energize Y, L, G

1st Stage Heating Energize G, B

2nd Stage Heating Energize G, B, W2

Ventilation Energize G, O1

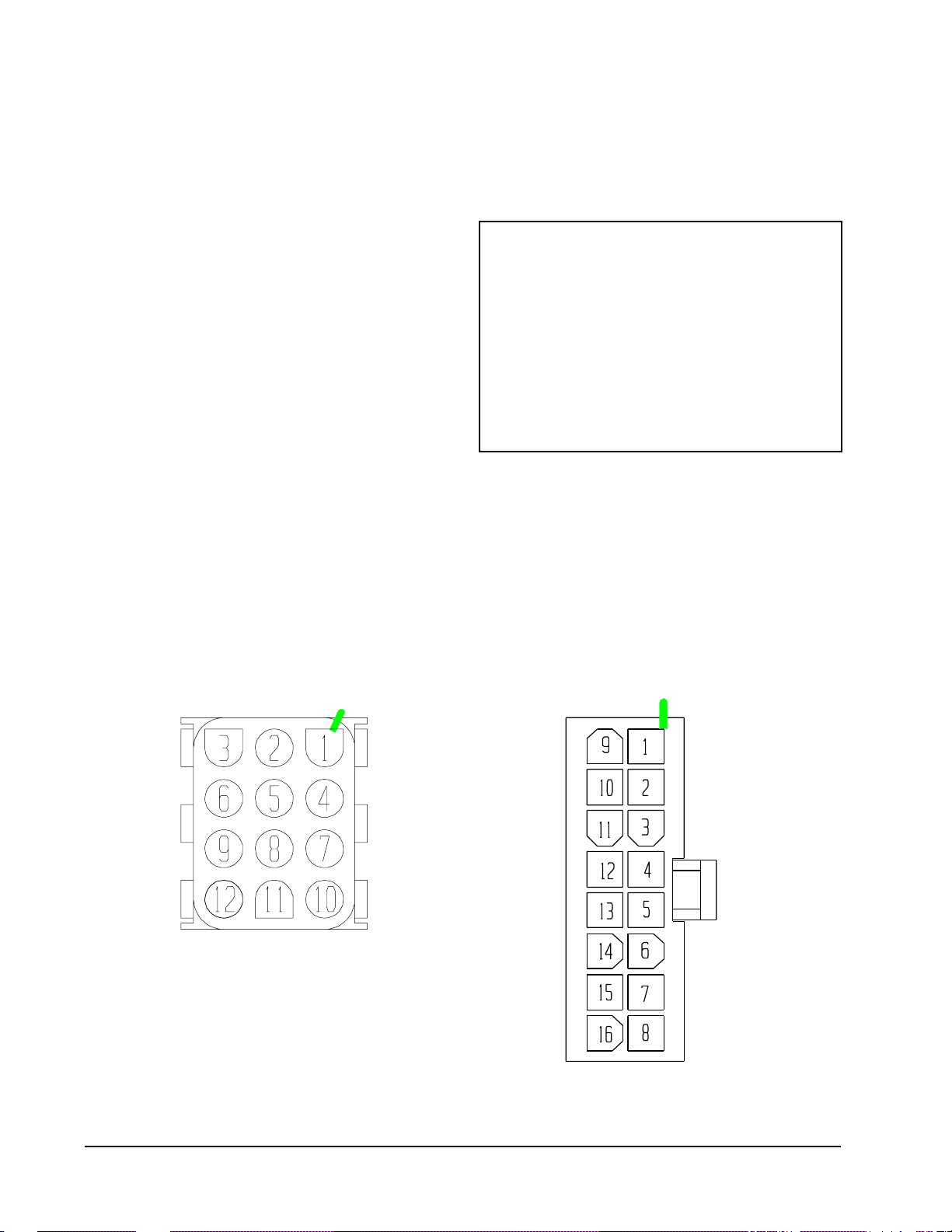

BLOWER MOTOR LOW VOLTAGE

VIEWED FROM PIN END

FIGURE 15

WIRE HARNESS PLUG

VIEWED FROM PIN END

MIS-1285

Manual 2100-416

Page 18

IF93-380

FIGURE 16

REMOTE THERMOSTAT WIRING DIAGRAM

“X” OPTION

MIS-1734

Manual 2100-416

Page 19

IF93-380

FIGURE 17

REMOTE THERMOSTAT WIRING DIAGRAM

“D” THERMOSTAT OPTION

Manual 2100-416

Page 20

4102-028

START UP

OPTIONAL CFM

These units are shipped from the factory set to operate

at the optional CFM level shown in Table 4. This

provides lower operating sound levels for non-ducted,

free discharge applications. This CFM level will reduce

the system capacity performance by approximately 2%

at the same energy efficiency.

Rated CFM is required for ducted applications for

maximum performance rating. To obtain full CFM on

these models, connect jumper wire as follows:

1. Disconnect all power to the unit. Failure to do so

may result in damage to the motor.

2. Open hinged return air grille panel

3. Open control panel cover.

4. Add pink jumper wire (provided) to terminal

5 and 6 on the terminal board.

5. Reverse steps to reassemble.

IMPORTANT INSTALLER NOTE

For improved start up performance, wash the indoor

coil with dishwashing detergent.

SERVICE HINTS

1. Caution user to maintain clean air filters at all times.

Also, not to needlessly close off supply air registers.

This may reduce air flow through the system which

shortens equipment service life as well as increasing

operating costs and noise levels.

2. The wall thermostat perform multiple functions. Be

sure that all function switches are correctly set for

the desired operating mode before trying to

diagnose any reported service problems.

SEQUENCE OF OPERATION

FIRST STAGE COOLING – Circuit R-Y makes the

thermostat open the first stage cooling water valve.

SECOND STAGE COOLING – Circuit R-Y2 make

the thermostat open the second stage cooling water

valve. The G (indoor motor) circuit is automatically

completed on any call for cooling operation, or can be

energized by manual fan switch on subbase for constant

air circulation.

Caution: Second stage cooling must always be

energized in conjunction with first stage. If

the second state were energized alone, the

condensate from the upper part of the coil

could be blow off or re-evaporated as it

passes down over the dry portion of the

coil.

HEATING – A thermostat demand for heating makes

R-W1 circuit as well as R-G circuit. This starts the

indoor blower as well as turns on the electric heater.

SECOND STAGE HEATING (15 KW only) – Circuit

R-W2 energizes the second contactor and brings on the

last 5 KW of heat.

TABLE 5

INDOOR BLOWER PERFORMANCE

1

DETAR

LEDOM

105CQ0.08.00021000100015711

NOTE: These units are equipped with a variable speed (ECM) indoor motor that automatically

j Maximum ESP (inches WC) shown is with 1” thick disposable filter (reduced by .2 for 2” filter).

k Rated CFM for ducted applications – required for maximum performance rating. To obtain full CFM locate low

voltage terminal strip in the circuit breaker box.There is a pink jumper wire with both ends attached to terminal

marked “G2”. Move one end of the jumper to terminal “Y”.

l Optional CFM – the unit is shipped from the factory set to operate at the optional CFM level shown.

This provides lower operating sound levels for non-ducted, free discharge applications. This reduces

system capacity performance by approximately 2% at the same energy efficiency.

m Continuous fan CFM is the total air being circulated during continuous fan mode.

PSE

adjusts itself to maintain approximately the same rate of indoor air flow in both heating

and cooling, dry and wet coil conditions, and at both 230/208 or 460 volts.

PSE.XAM

2

3

LANOITPO

MFCDETAR

MFC

4

@

MFC

SUOUNITNOC

MFC

Manual 2100-416

Page 21

PSE

.XAM

y

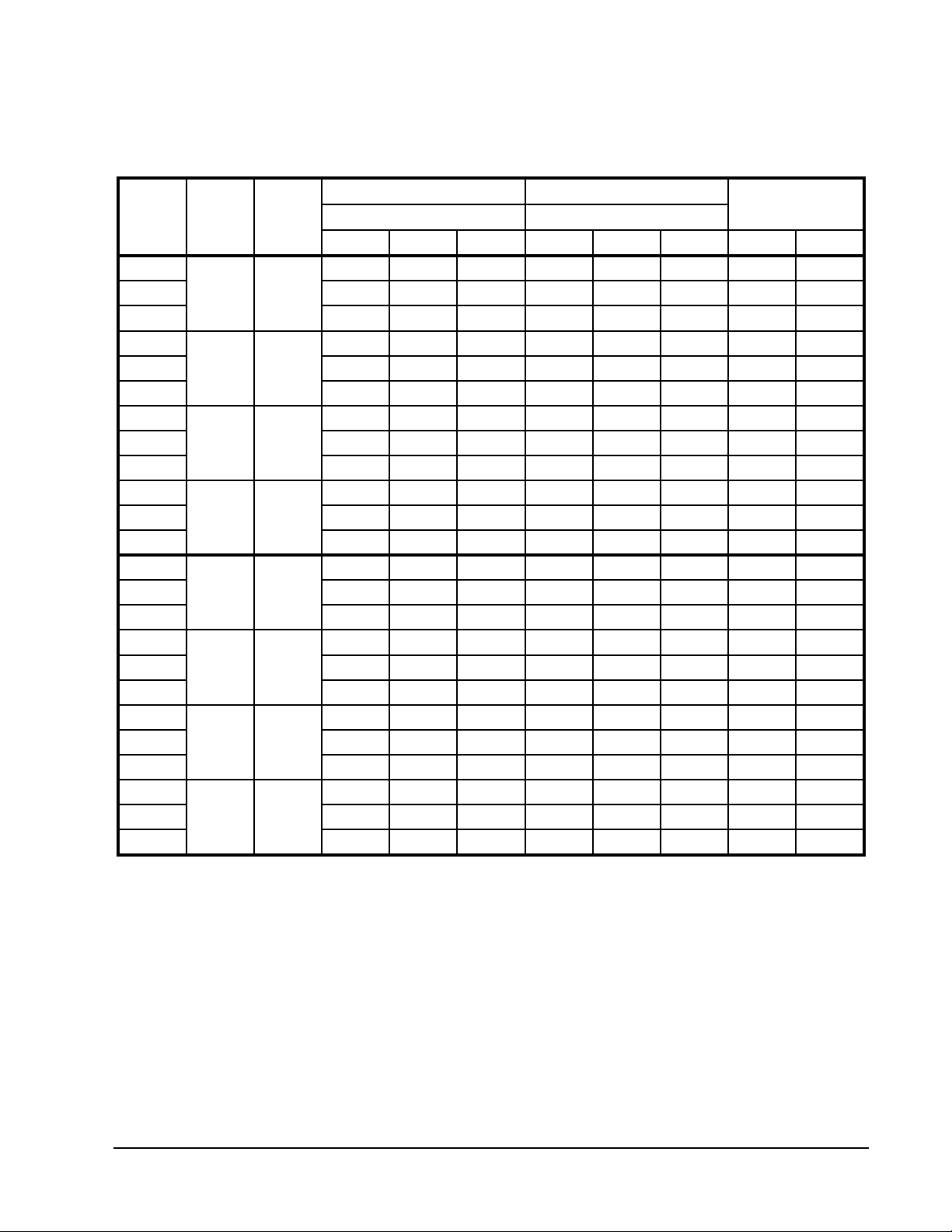

TROUBLESHOOTING ECM BLOWER MOTORS

CAUTION

Disconnect power from unit before removing or replacing connectors, or servicing motor.

Wait at least 5 minutes after disconnection power before opening motor.

MOTPMYS ERUDECORP/ESUAC

.gnitratsnehwylthgilsskcorrotoM

tratst'nowrotoM

%

tnemevomoN

%

%

%

%

%

%

%

%

nuR kcehCerutisoM

MCIrofpu-tratslamronsisihT

rotomtarewopkcehC

tfahsthgitrofrotomkcehC

rotomta)CotRCAV42(egatlovwolkcehC

rotomta)C,R,W,Y,G(snoitcennocegatlovwolkcehC

ssenrahrotomnosrotcennocnisnipdetaesnurofkcehC

G-RneewtebrepmujyraropmetahtiwtseT

%

rewolbfoffodetset

%

%

%

%

ODT'NOD

%

%

"spoolpird"llatsni

%

tnemecalperrof

%

– sretlifcitatswol,ycneiciffehgihdnemmoceR

– naelcsretlifgnipeekdnemmoceR

– ,citatsmuminimrofkrowtcudngiseD

– krowtcuddnemmocerdnarofkooL

tratst'nowtub,skcorrotoM

gniebelihwnwoddnapusetallicsorotoM

tenibacforewolbysioN

)deeps(MFChgihta"sffup"ro"stnuH"

erutsioMfoecnedivE

dnaderuccosahnoitcnuflamfoeruliafrotoM

tneserpsierutsiom

revomriaedisnitneserperutsiomfoecnedivE

snoitcennocdnagniriw,slortnoc,rotomtuokcehC

rotomgnicalpererofebylhguoroht

;nitegt'nacretawosnwodsrotcennoctneirO

srebmunledomlortnocdnarotomdezirohtuaesU

:muminimaoterusserpcitatspeeK

trofmocmumixam

rassecenerehw,tnemevorpmi

.tnemecalperni,

%

%

%

%

%

– ,stcudnismaeshguorhtgniltsihwriarofkcehC

.slenaprostenibac

– noitamrofedtcud/tenibacrofkcehC

%

– noitcitserecudeR

– wolfriamumixamecudeR

%

%

%

%

%

%

%

mrofrepdnarotomecalpeR kcehCerutsioM

kcehCerutsioMmrofreP

snruterdetcirtseresU

tnuomrotomtnailpmocroesoolrofkcehC

tfahsnothgitsileehwrewolberusekaM

.tfahsnodaolonhtiwetallicsootrotomroflamronsitI

.cte,slenap,gnisuohrewolbesoolrofkcehC

?deepsrewolbhgihgnitaerccitatshgiH

?"gniffup"ecuderretlifrolenapgnivomerseoD

dabsirotomehtemussayllacitamotuA

snoitsopksolc'o4dna7evobasrotcennocetacoL

rehtonahtiwrebmunledomlortnocforotomenoecalpeR

)tnemecalperdezirohtuanasselnu(

H"2/1evahemoS.sretlifporderusserphgihesU

2

!pordO

Manual 2100-416

Page 22

MOTPMYS ERUDECORP/ESUAC

yllacitarresnurtubstratsrotoM

%

%

%

MFCtaeh

tnettimretnironwoddnapuseiraV

)deeps(MFChgihta"sffupro"stnuH"

%

%

%

snoitacilppa

%

%

%

%

roloocrofllacmetssysetipsedMFCwoltasyatS

%

%

mrofreP kcehCerutsioM

–noitcirtserecudeR

–wolfriamumixamecudeR

etelpmoc

"gas"ronoitairavrofegatlovenilkcehC

;rotomta)C,R,W,Y,G(snoitcennocegatlovwolkcehC

srotcennocssenrahrotomnisnipdetaesnu

deepselbairavni(dnammocMFCcitarrerof"kB"kcehC

?tatsomreht-slortnocmetsystuokcehC

?"gniffup"ecuderretlifrolenapgnivomerseoD

snoitcennocdnaseriw)tatsomreht(egatlovwolkcehC

siyaledlitnutiaw-edomyaladnitonsinafyfireV

rotomtadetcennocton/gnissim"R"

kcehctnemecalperlortnoc/rotommrofreP

%

%

NOTPMYS ERUDECORP/ESUAC

%

ODT'NOD

%

%

esioNriA

MFChgihtasyatS

ffotuhst'nowrewolB

esionevissecxE

ylesiwtnempuqeehteziS

rotomgnitresnierofebnoitatneirokcehC

srotcennoc

%

%

%

–etatsdilosrotatsomrehtdehctiwscairTrofkcehC

yaler

%

%

–?ylreporpteswolfriasI

–?nwodwolsotrewolbesuacretlifgnivomerseoD

retlifecalper/kcehC

–retlifporderusserpwolesU

–snoitcritsertcudtcerroc/kcehC

%

%

%

sgulpecroF

rotomtadetcennocton/gnissim"R"

etelpmocemityaledlitnutiaw-?edomyaladninafsI

?WroY,GotnislortnocmorfegakaeltnerruC

.esionrotomrotcud,tenibac,esionriasitifienimreteD

.yrssecenfiremotsucweivretnI

?deepsrewolbhgihgnitaerccitatshgiH

wolfriawolhtiwetasnepmocnehtmetsysezisrevO

sdrawkcabrotcennocrewopnigulP

ERUDECORPKCEHCERUTSIOM ERUDECORPKCEHCTROFMOC

%

%

%

%

%

%

"nwod"detneiroerasrotcennoC

rotomrednu"poolpird"htiwsessenrahegnarrA

?deggulpniardetsnednoC

)yticapactnetalhcumoot(wolfriawolrofkcehC

noitidnocdegrahcrednurofkcehC

%

%

%

%

%

%

tenibacdnastcudnrtuerniskaelgulpdnakcehC

sgnitteswolfriareporpkcehC

esiontsewolroferusserpcitatswoL

MFCnafsuounitnocwolteS

stinugniloocdeeps-2dnatatsidimuhesU

MFCetalugertahtMCIrofdengisedslortnocgninozesU

?noitacoldabnitatsomrehT

Manual 2100-416

Page 23

Valve Location

FIGURE 18

INTERNAL 2-WAY VALVE PIPING

Water Valves

Valve Detail

"NC" side of valve

Manual 2100-416

Page 24

"COM" side of valve

"NO" side of valve

MIS-1899

Valve Location

FIGURE 19

INTERNAL 3-WAY VALVE PIPING

Water Valves

Valve Detail

"NC" side of valve

"COM" side of valve

"NO" side of valve

MIS-1900

Manual 2100-416

Page 25

Loading...

Loading...