QT

EC

Wall Sleeve

INSTALLATION

INSTRUCTIONS

Models

: QWS48A

QWS48A-16

QWS48A-19

QWS48A-23

QWS48A-30

© Copyright 2003

Bard Manufacturing Company

Bryan, Ohio 43506

Since 1914 . . . Moving ahead just as

planned.

Manual No.: 2100-319F

Supersedes: 21 10-319E

File: Vol. II Tab 14

Date: 11-07-05

Manual 2100-319F

Page 1 of 10

CONTENTS

Getting Other Information and Publications 3

EC Wall Sleeve General Information

QT

Shipping Damage .................................................. 4

General .................................................................. 4

Installation Instructions

Installation Wood Framed Walls......................4 & 6

Installation Masonry Construction Walls..........6 & 7

Accessory Item – QCDS48

Installation with 16" Thick Walls ............................ 8

Installation with 19" Thick Walls ............................ 8

Installation with 23" Thick Walls ............................ 8

Installation with 30" Thick Walls ............................ 8

Accessory Item - QCDS48

Condensate Disposal System................................ 9

Attachment of Wall Sleeve to Unit ....................... 10

Figures

Figure 1 Wood Framed Installation..................... 4

Figure 2 Application of Sealant to 2 x 6 Plate..... 5

Figure 3 Application of Sealant to Flanges ......... 5

Figure 4 Masonry Construction Installation......... 6

Figure 5 Typical Installation With 14"

Maximum Wall Thickness..................... 7

Figure 6 Condenser Fill Plate Application........... 8

Figure 7 QCDS48 Condensate Disposal

System.................................................. 9

Figure 8 Attaching Base Assembly to Sleeve

Showing Caulking ............................... 10

Manual 2100-319F

Page 2 of 10

Getting Other Information and Publications

These publications can help you install the air

conditioner or heat pump. You can usually find these at

your local library or purchase them directly from the

publisher. Be sure to consult current edition of each

standard.

Standard for the Installation of ...........ANSI/NFPA 90A

Air Conditioning and

Ventilating Systems

Standard for Warm Air Heating ......... ANSI/NFPA 90B

Air Conditioning Systems

QT

EC

Installation Instruction Manual..... Bard/2100-288

FOR MORE INFORMATION, CONTACT THESE

PUBLISHERS:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Avenue, NW

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating, Refrigerating

& Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

BARD Bard Manufacturing Company

1914 Randolph Drive

Bryan, OH 43506

Telephone: (419) 636-1194

Fax: (419) 636-2640

Manual 2100-319F

Page 3 of 10

SHIPPING DAMAGE

Upon receipt of equipment, the carton should be checked

for external signs of shipping damage. If damage is

found, the receiving party must contact the last carrier

immediately, preferably in writing requesting inspection

by the carrier’s agent.

GENERAL

The QWS48A series is designed for use with the QT

Series Air Conditioners and Air Source Heat Pumps.

The QWS48A is for use with wall thickness of 5 to 14

inches. One QWS48A series wall sleeve is required for

each QTEC Model to be installed.

The equipment covered in this manual is to be installed

by trained service and installation technicians.

These instructions explain the recommended method to

install the wall sleeve.

These instructions and any instructions packaged with

any separate equipment required to make the entire air

conditioning system should be carefully read before

beginning the installation.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made.

FIGURE 1

WOOD FRAMED INSTALLATION

EC

INSTALLATION – WOOD FRAMED

WALLS

For wood frame construction walls, the dimensions of

the opening must be 48 inches tall by 43 inches wide. A

2 x 6 header will be required for the opening. The sides

of the opening must have trimmer studs to support the

header, and to provide a structural member on which to

fasten the sleeve. (See Figure 1.) All of the dimensions

are referenced from the finished floor height.

After the opening is framed in, a treated 2 x 6 bottom

support and seal plate must be cut to fit in the bottom of

the opening. Construction adhesive should be applied to

the 2 x 6 before it is put in place. (See Figure 2.) This

will help hold the plate in place and provide an

additional seal for the bottom of the opening. The

treated 2 x 6 must be fastened to the bottom of the

opening flush to the finished surface of the outside wall.

The 2 x 6 must be sealed to the outside wall with

construction adhesive. Any gaps between the sides of

the 2 x 6 plate and the opening must also be sealed. See

Figure 2. NOTE: The actual thickness of 2 x 6 must be

1-1/2".

Once the opening is framed, the sheeting can be

installed, the sheeting material must not extend into the

opening.

The sleeve should be test fit into the opening to make

sure of the dimensions. The sleeve must be inserted into

the opening from the outside of the building. The

bottom of the sleeve must be level from side to side, and

the sleeve must be square in the opening. A slope is

built into the bottom of the sleeve from the inside to the

outside. This will allow any water that gets into the

sleeve to drain out. Once the test fit is completed, the

sleeve must be removed from the opening, and two 1/4

inch beads of sealant must be applied to the mounting

flanges of the sleeve. (See Figure 3.)

Manual 2100-319F

Page 4 of 10

FIGURE 2

APPLICATION OF SEALANT TO 2 X 6 PLATE

APPLY CONSTRUCTION

ADHESIVE TO SEAL.

APPLY CONSTRUCTION ADHESIVE TO SEAL.

SLEEVE OPENING

TREATED 2 X 6 BOTT OM SUPPORT AND SEAL PLA TE

FRONT VIEW

FIGURE 3

APPLICATION OF SEALANT TO FLANGES

OUTSIDE

WALL

APPLY CONSTRUCTION

ADHESIVE TO SEAL.

Manual 2100-319F

Page 5 of 10

The sleeve is then reinserted into the prepared opening

from the outside of the building. All of the mounting

flanges must contact the exterior wall. Check to see

that there is enough sealant to make this joint

watertight. Additional sealant must be applied as

necessary. The sleeve must be centered in the opening,

and the bottom of the sleeve must be checked to make

certain that it is level from side to side. The bottom

flange should be secured to the wall by using two

screws through the holes in the bottom mounting flange

of the sleeve. The sleeve must be checked to make sure

that it is square in the opening. Once the sleeve is

square, the side and top mounting flanges of the sleeve

must be secured to the wall with screws through the

holes in the flanges. The gaps between the side flanges,

and the top and bottom flanges must be filled with

additional sealant.

On the inside of the building, the gaps between the

sleeve and the opening must be filled with insulation.

This will help insulate the sleeve and prevent any

unwanted outdoor air. See Figure 5.

If the QT

EC

unit will be drained through the wall, the

drain line must be installed through the wall.

Information for the drain installation is contained in the

QTEC Installation Instructions.

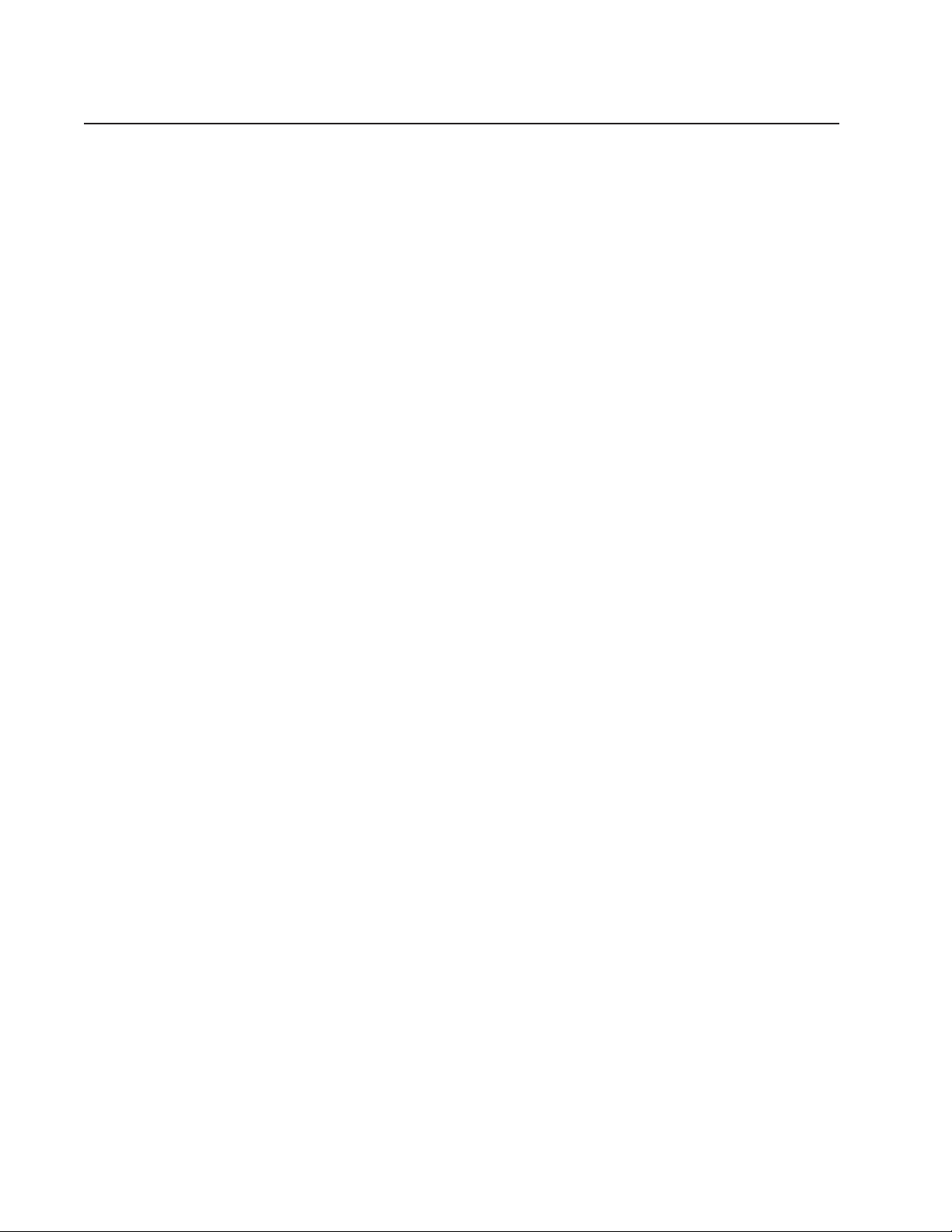

INSTALLATION – MASONRY

CONSTRUCTION WALLS

For masonry construction walls, the dimensions for the

opening will be 48-1/4 inches tall by 43-1/4 inches wide.

These dimensions are plus or minus 1/4 inch and are

measured from the finished floor height. See Figure 4.

These will be the finish dimensions of the opening.

A 1-1/2 inch spacer needs to be installed in the bottom

of the opening to raise the sleeve off the floor. Masonry

blocks 1 inch thick, minimum of 6 inches wide, with 1/2

inch mortar between the block and floor will provide the

required spacing. These blocks are to be laid flush with

the outside wall, and must provide a water tight seal to

the floor and to the opening sides. See Figure 2.

The sleeve should be test fit in the opening before final

preparations are made. The sleeve will be installed into

the opening from the outside of the building in. The

sleeve must be centered in the opening from side to side.

The mounting flanges of the sleeve must contact the

outside wall all around the opening. The side and top

mounting flanges must have the mounting holes drilled

into the outside wall for the concrete anchors which will

hold the sleeve in the wall. The holes should be drilled

through the holes in the sleeve with the sleeve level and

FIGURE 4

MASONRY CONSTRUCTION INSTALLATION

Manual 2100-319F

Page 6 of 10

square in the opening. A slope is built into the bottom of

the sleeve from the inside to the outside. This will allow

any water that gets into the sleeve to drain out. Once the

test fitting has been checked out, the sleeve should be

removed from the wall.

sealant must be applied as required. The sleeve must be

anchored to the wall. All four mounting flanges must be

fastened with two fasteners each to the outside wall.

The gaps between the side flanges, and the top and

bottom flanges must be sealed to the wall.

With the sleeve removed, two 1/4 inch beads of sealant

must be applied to the flanges that contact the outside

wall. See Figure 3

The sleeve must be installed back in the wall making

sure that the predrilled holes in the wall line up with the

holes in the mounting flanges of the sleeve. Check to

make sure that there is enough sealant between the wall

and the flanges to make the joint watertight. Additional

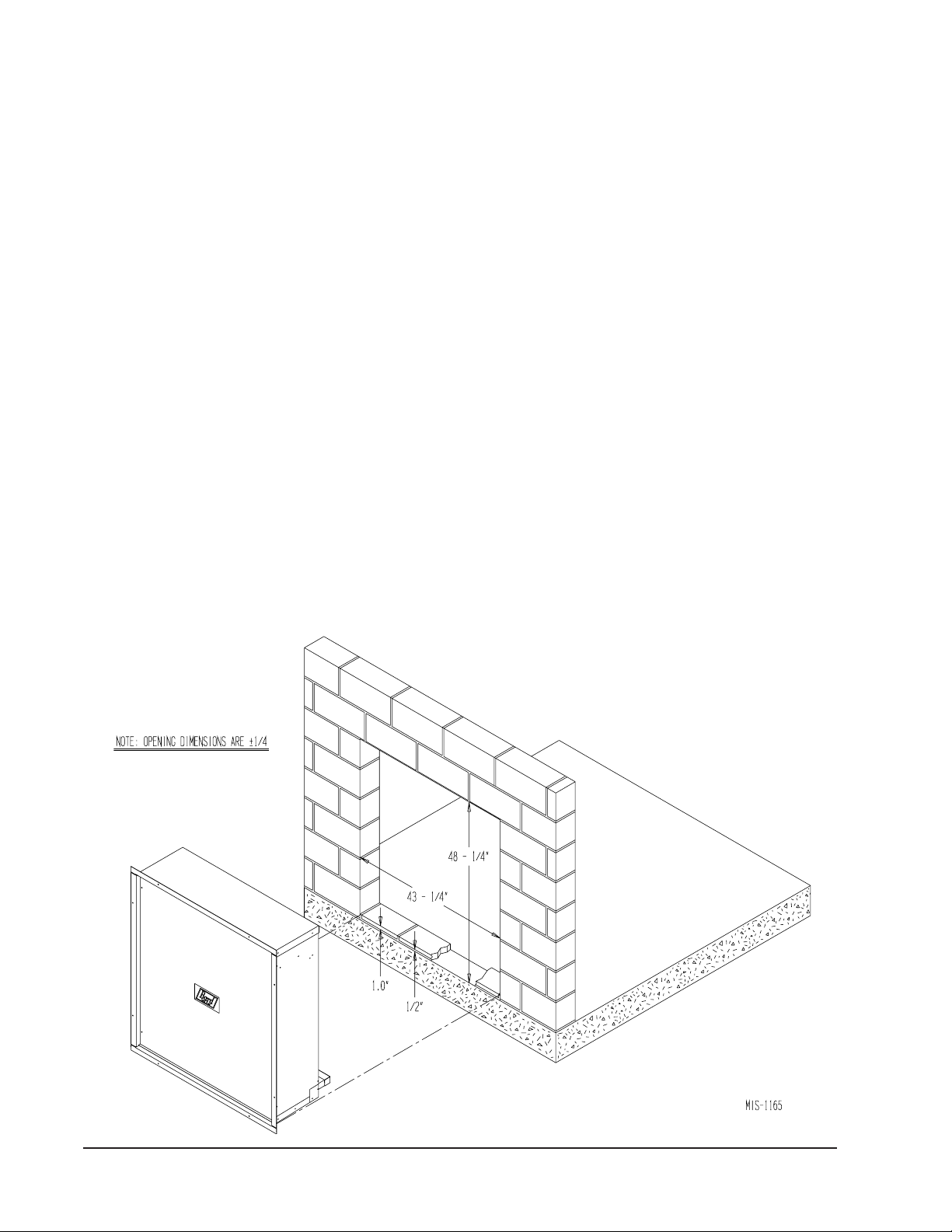

TYPICAL INSTALLATION WITH 14" MAX. WALL THICKNESS

INSIDE

WALL

WALL BRACKET

On the inside of the building, the gaps between the

sleeve and the opening must be filled with insulation.

This will help insulate the sleeve and prevent infiltration

of any unwanted outdoor air. See Figure 5.

If the QTEC unit will be drained through the wall, the

drain line must be installed through the wall.

Information for the drain installation is contained in the

QTEC Installation Instructions.

FIGURE 5

OUTSIDE WALL

INSULATION

OUTDOOR GRILLE

QTEC UNIT

WALL BRACKET

CONDENSER COIL AND F AN

INSERTED INTO SLEEVE

INSULATION

TOP SECTION VIEW

Manual 2100-319F

Page 7 of 10

INSTALLATION WITH 16" THICK WALLS

When an application is required on a building with 16" wall,

a Wall Sleeve model number QWS48A-16 is required.

INSTALLATION WITH 23" THICK WALLS

When an application is required on a building with 23" wall,

a Wall Sleeve model number QWS48A-23 is required.

The installation of the QWS48A-16 is similar to the

QWS48A with one exception. A condenser fill plate is

supplied with QWS48A-16, and is to be attached to the top

of the outdoor coil housing on the QT

EC

unit. See Figure 6.

To attach fill plate, remove the three screws on top of coil

section, place condenser fill plate and secure with the three

screws.

INSTALLATION WITH 19" THICK WALLS

When an application is required on a building with 19" wall,

a Wall Sleeve model number QWS48A-19 is required.

The installation of the QWS48A-19 is similar to the

QWS48A with one exception. A condenser fill plate is

supplied with QWS48A-19, and is to be attached to the top

EC

of the outdoor coil housing on the QT

To attach fill plate, remove the three screws on top of coil

section, place condenser fill plate and secure with the three

screws.

unit. See Figure 6.

The installation of the QWS48A-23 is similar to the

QWS48A with one exception. A condenser fill plate is

supplied with QWS48A-23, and is to be attached to the top

EC

of the outdoor coil housing on the QT

unit. See Figure 6.

To attach fill plate, remove the three screws on top of coil

section, place condenser fill plate and secure with the three

screws.

INSTALLATION WITH 30" THICK WALLS

When an application is required on a building with 30" wall,

a Wall Sleeve model number QWS48A-30 is required.

The installation of the QWS48A-30 is similar to the

QWS48A with one exception. A condenser fill plate is

supplied with QWS48A-30, and is to be attached to the top

EC

of the outdoor coil housing on the QT

To attach fill plate, remove the three screws on top of coil

section, place condenser fill plate and secure with the three

screws.

unit. See Figure 6.

FIGURE 6

INSTALLATION OF CONDENSER FILL PLATE IN QWS48A-16, QWS48A-19, QWS48-23, QWS48-30 APPLICATION

CONDENSER

FILL PLA TE

SCREW

CONDENSER

FILL PLA TE

SEAL

Manual 2100-319F

Page 8 of 10

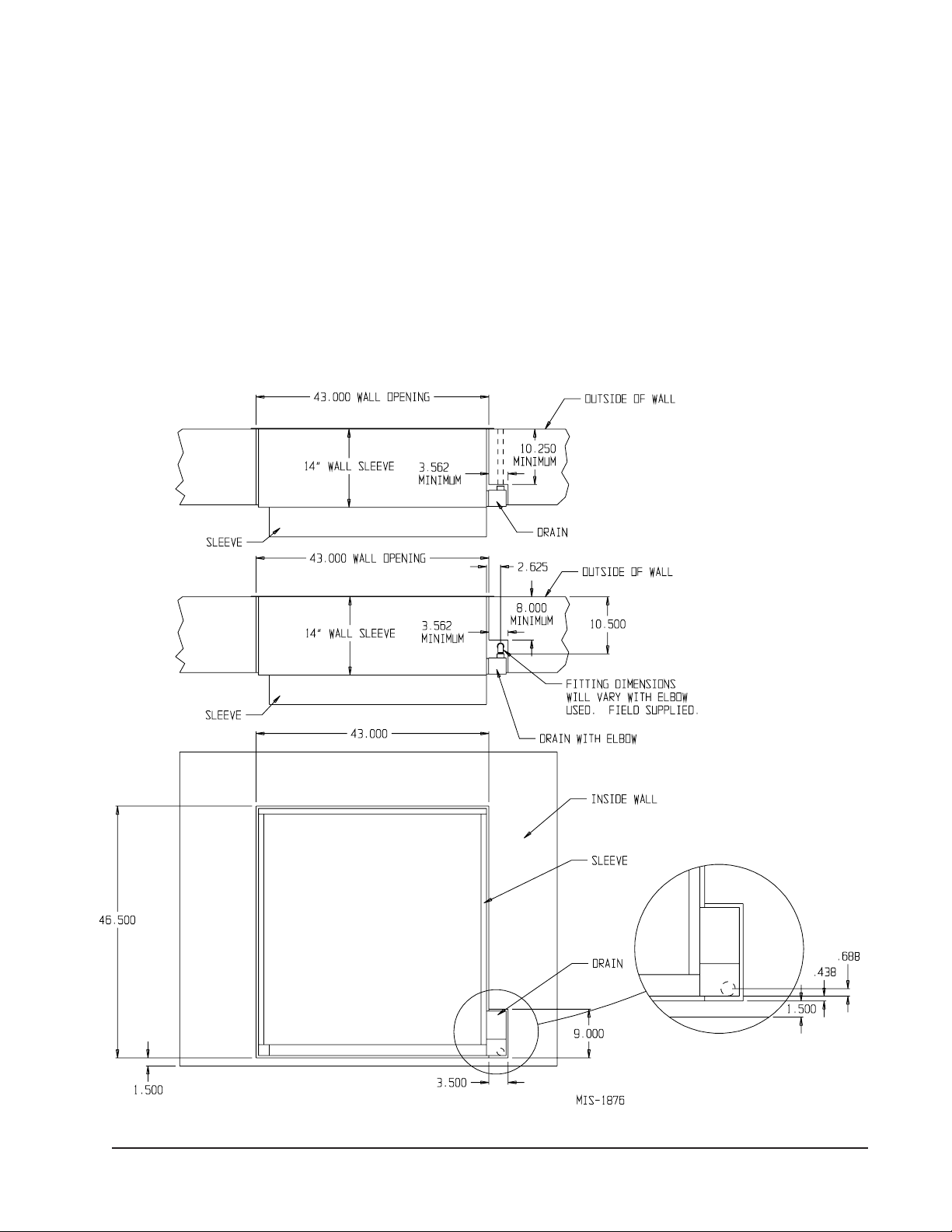

ACCESSORY ITEM

The QCDS48 is a condensate disposal system for use on

all QTEC models. The system consists of a drain box

and a rear drain assembly. The drain attaches to the side

of the sleeve. The drain box has a rear drain and an

overflow. The rear drain assembly installs in the rear

QCDS48 CONDENSATE DISPOSAL SYSTEM

drain of the QTEC. This system allows the QTEC unit to

be installed or removed from the sleeve without

connecting or disconnecting the drain line.

The installation of the QCDS48 requires that a recessed

area next to the sleeve opening be built. See Figure 7 for

dimensions of the recess for the drain box.

FIGURE 7

Manual 2100-319F

Page 9 of 10

ATTACHMENT OF WALL SLEEVE TO

EC

UNIT

QT

All Wall Sleeve Models covered in this manual are

equipped with two different methods to attach the QT

Model being applied.

The first method is with brackets supplied with the QT

unit. These brackets are screwed to the sleeve side with

six screws per side. This method can be used if adequate

clearance is available on each side of the unit to drive

the screws. If this method is used, the studs attached to

the wall sleeve must me removed and discarded.

The second method is for installation where there is not

adequate clearance to drive the screws into the cabinet

sides. The attachment can be made from inside the unit.

There are two threaded studs extending from the room

side of the sleeve to matching holes in the unit rear

panel, and are secured with a 5/16" nut on each side.

See Figure 3.

FIGURE 8

ATTACHING BASE ASSEMBLY TO SLEEVE

SHOWING CAULKING

EC

EC

To use this method, discard the two side mounting

brackets. Remove the nuts and washers from the

threaded studs and retain for use later. Remove the

lower cabinet door and locate the mating holes in the

rear of the cabinet. It may be necessary to clear the

holes of gasket material.

Roll unit into place making sure the unit is aligned from

side to side and that studs have entered the holes in the

cabinet back. Push unit back until the rubber seal on the

rear of the cabinet touches the flange on the wall sleeve.

Replace the washers and nuts previously removed from

the studs. Tighten nuts until there is some compression

of the gasket. Replace the lower cabinet panel.

Manual 2100-319F

Page 10 of 10

ATTATCH BASE

ASSEMBLY TO SLEEVE

SEAL BETWEEN SLEEVE &

BRACKET WITH SEALANT

AS SHOWN

SEAL CORNER OF

BRACKET WITH SEALANT

AS SHOWN

MIS-1848

Loading...

Loading...